Patents

Literature

44results about How to "Uniform densification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

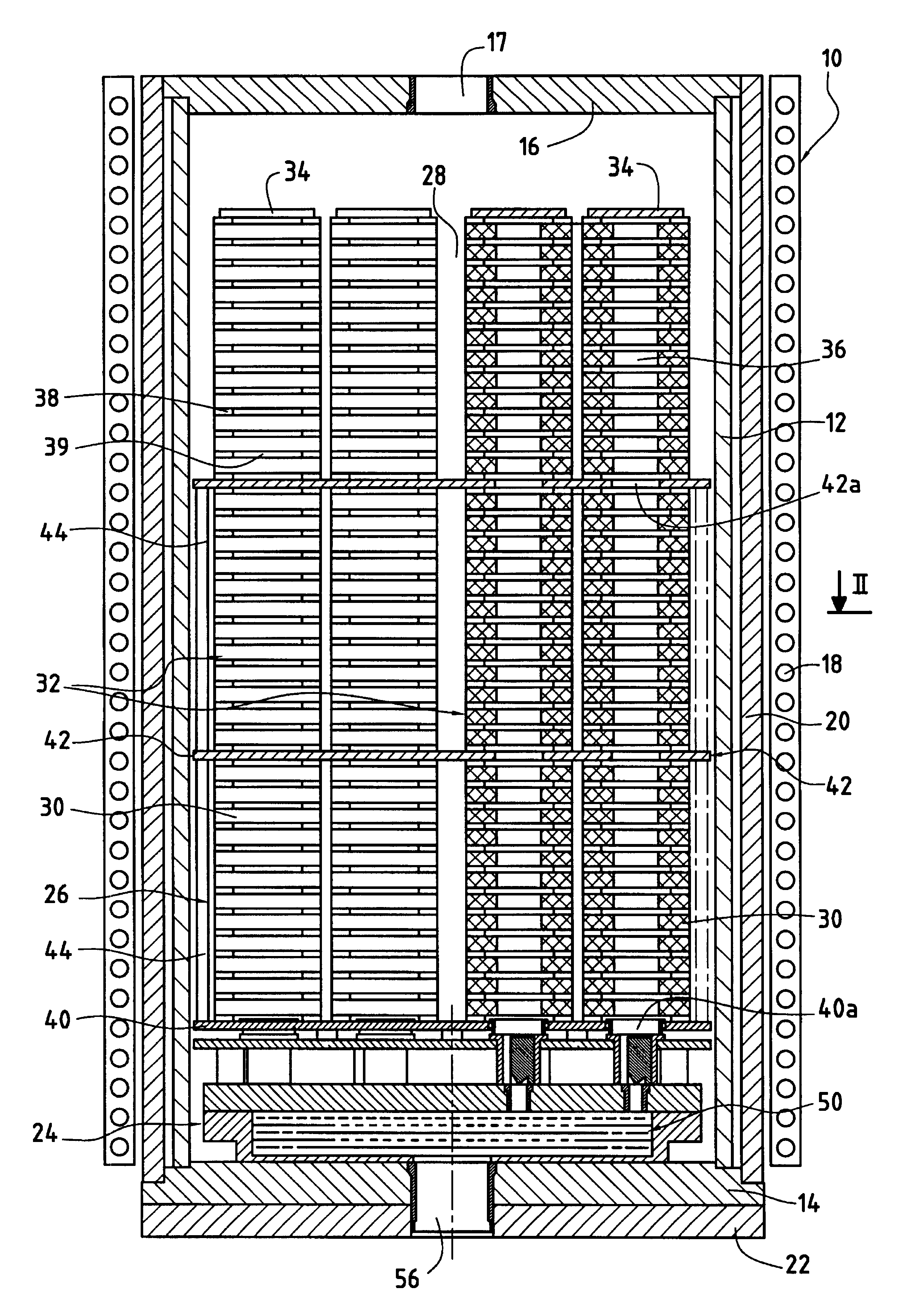

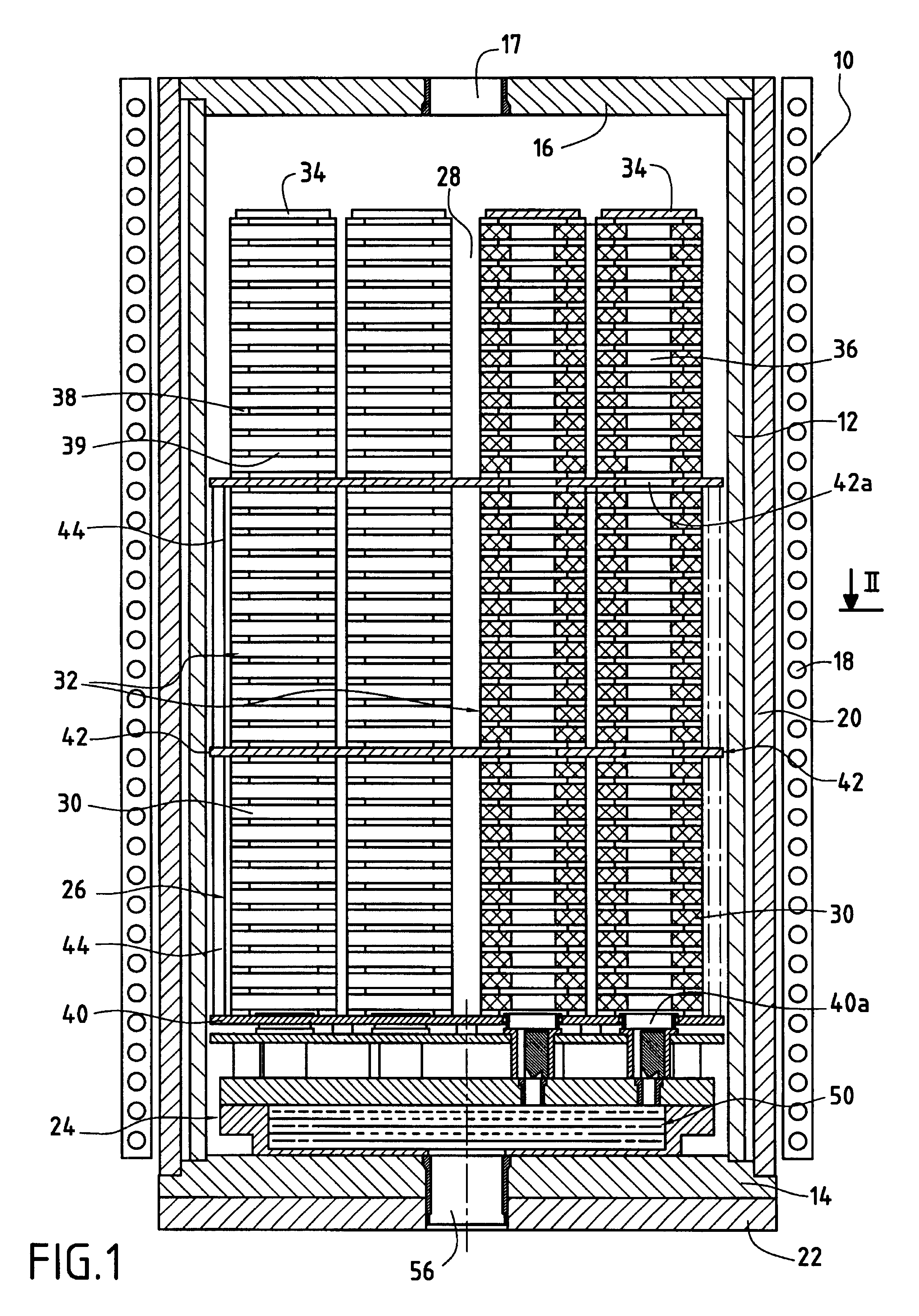

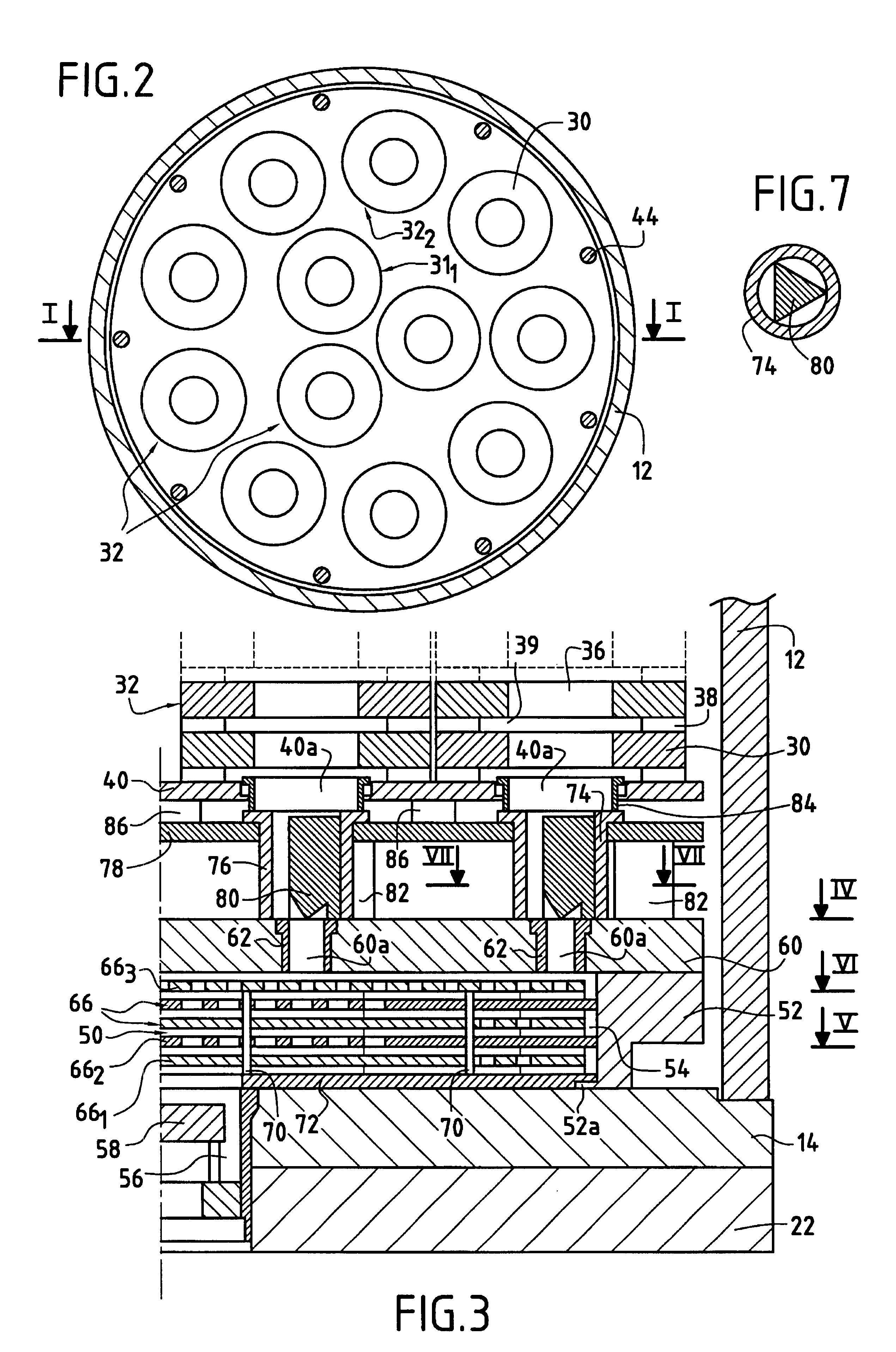

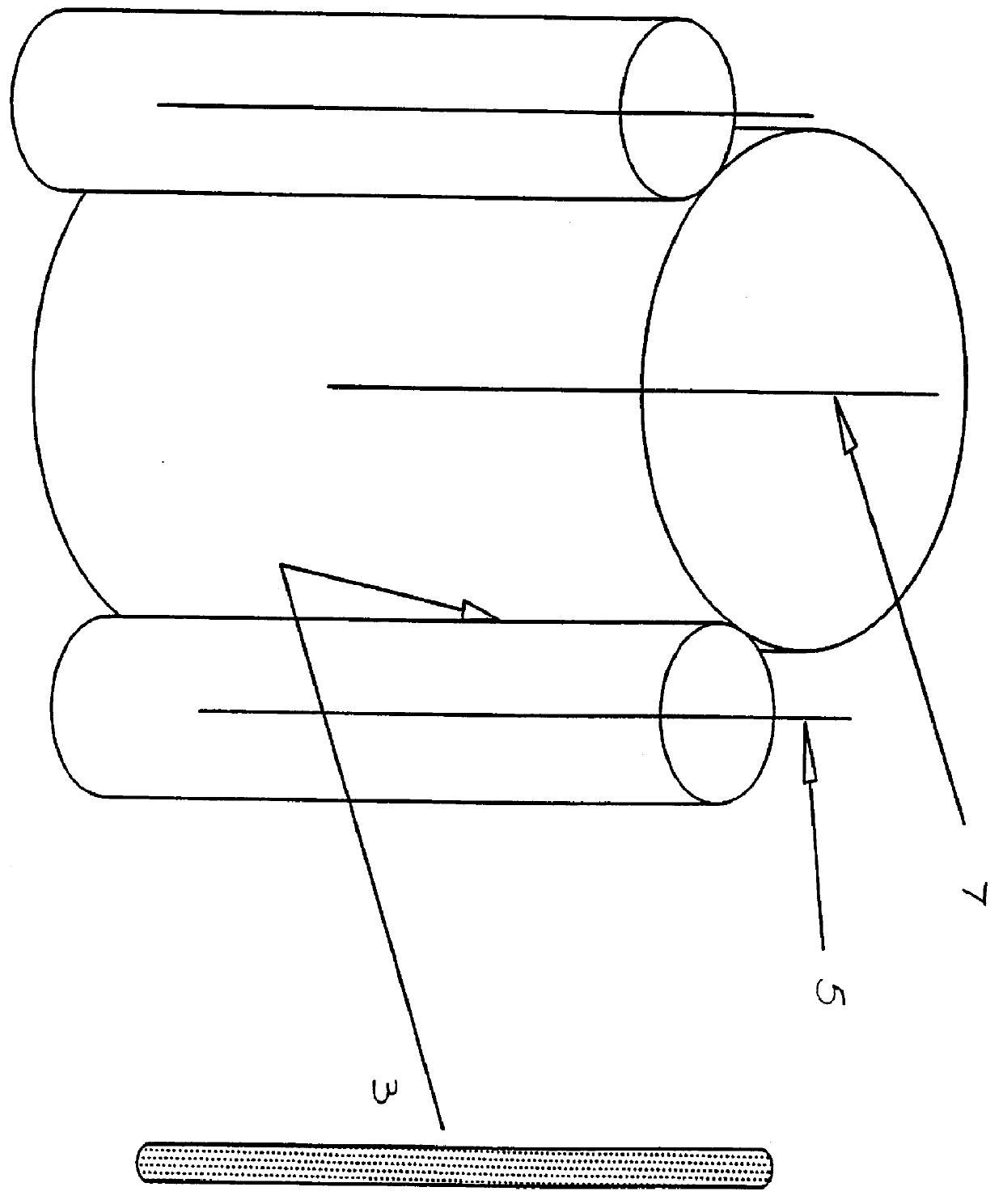

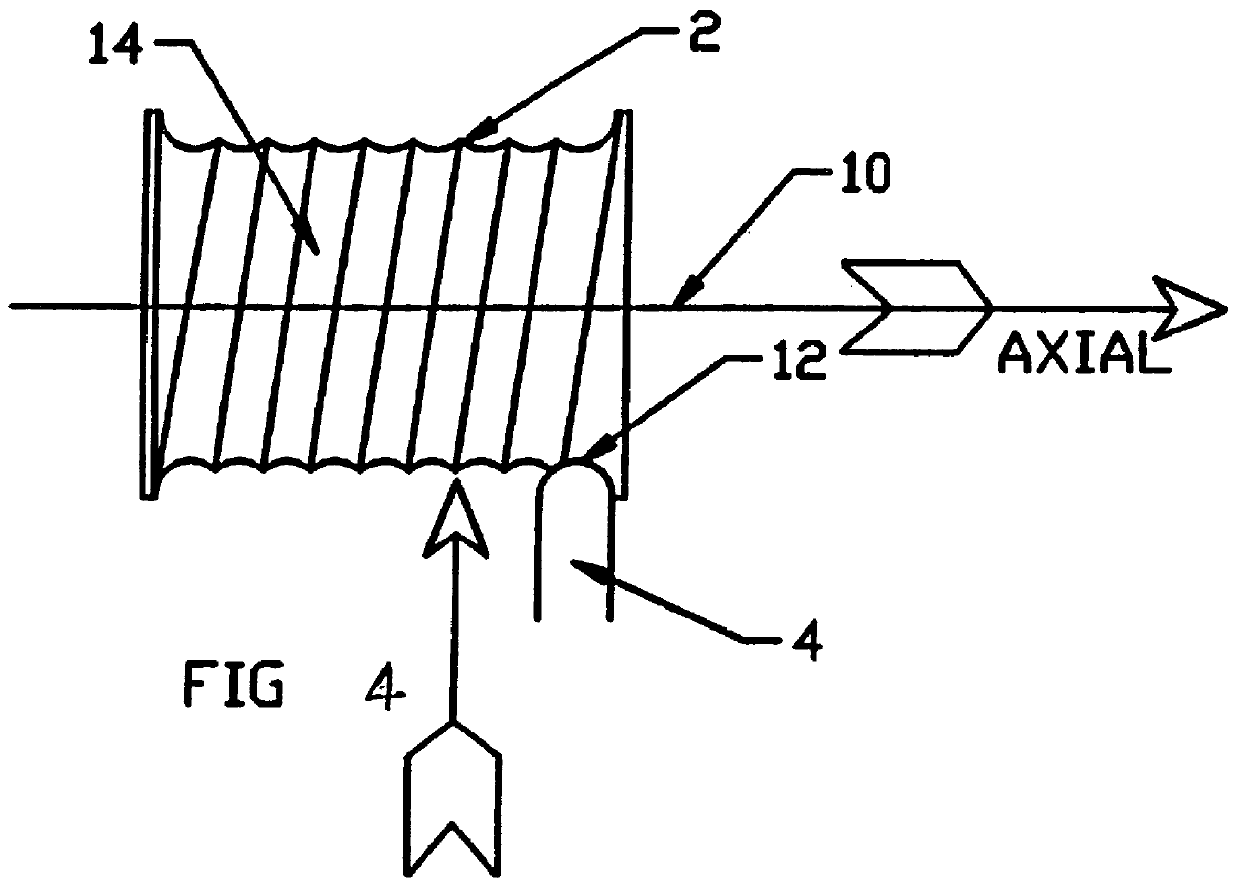

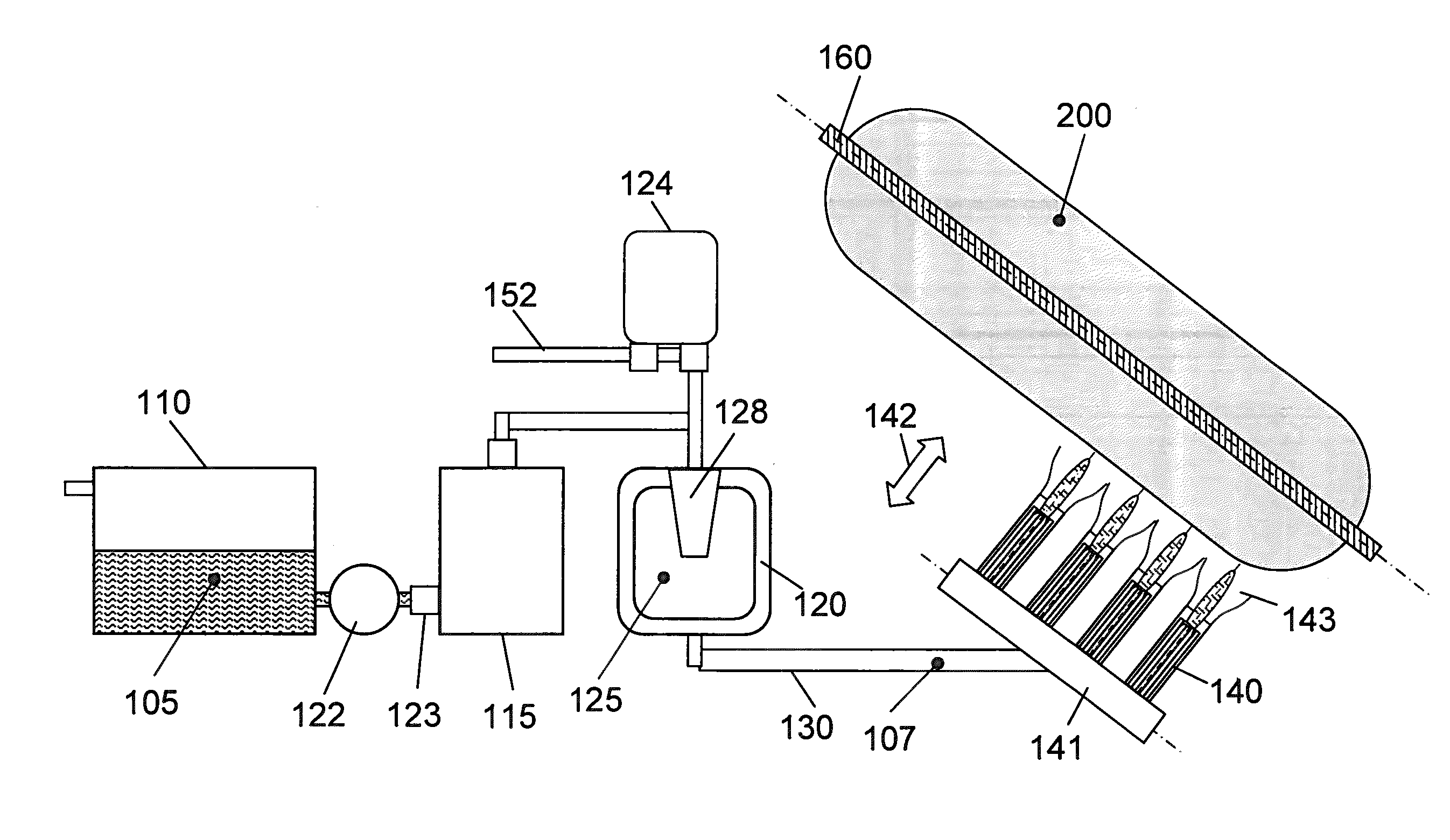

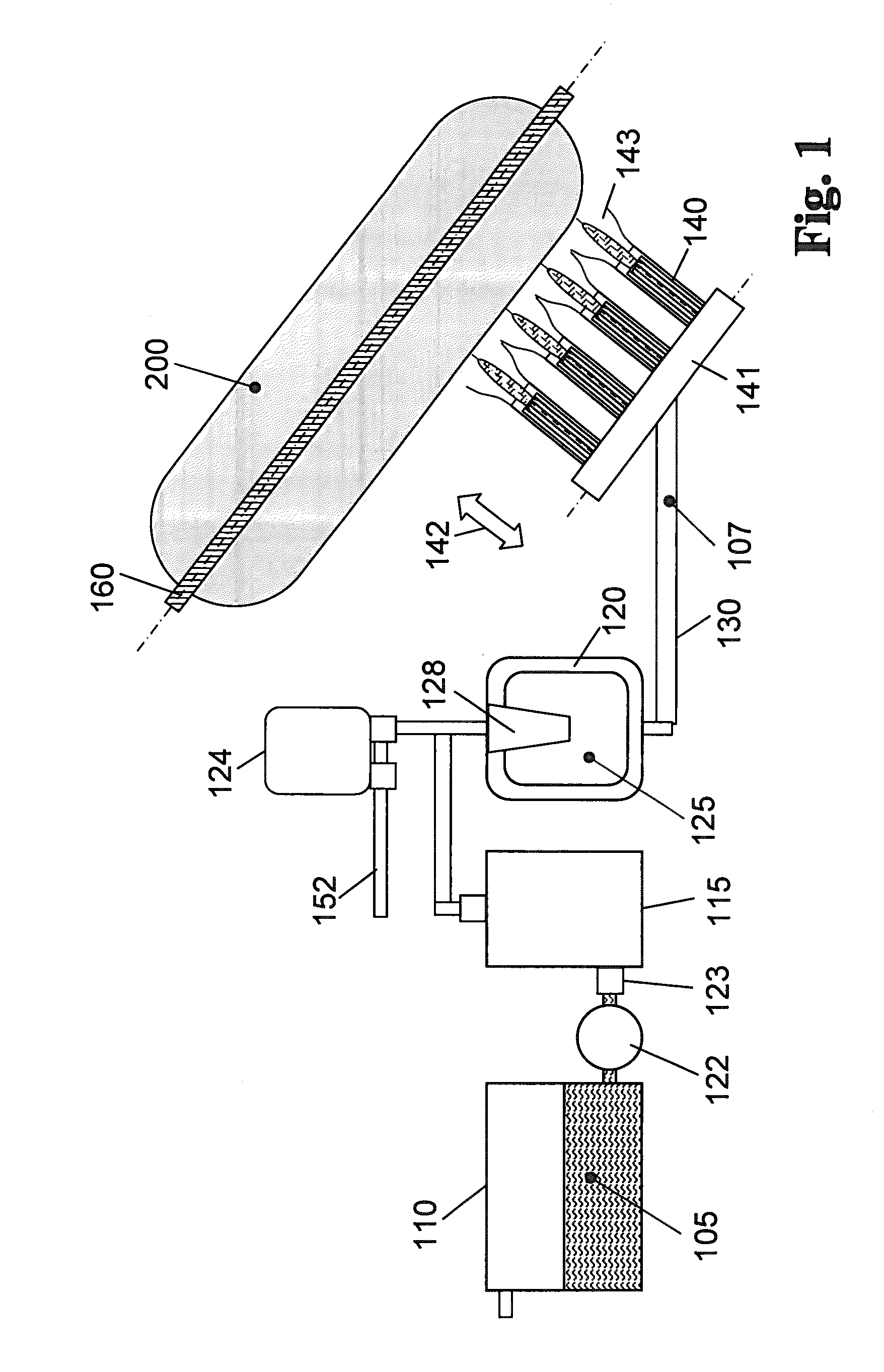

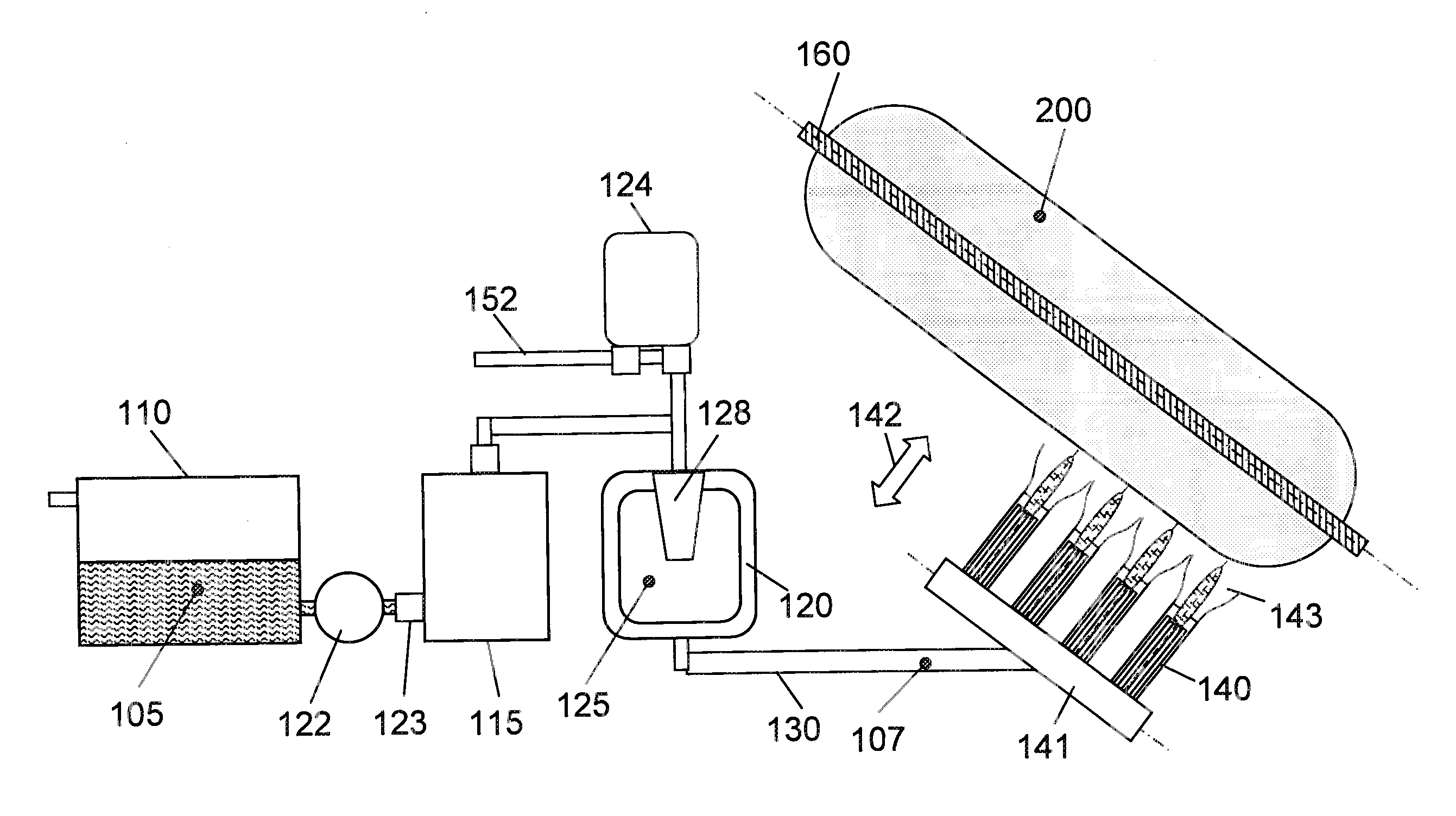

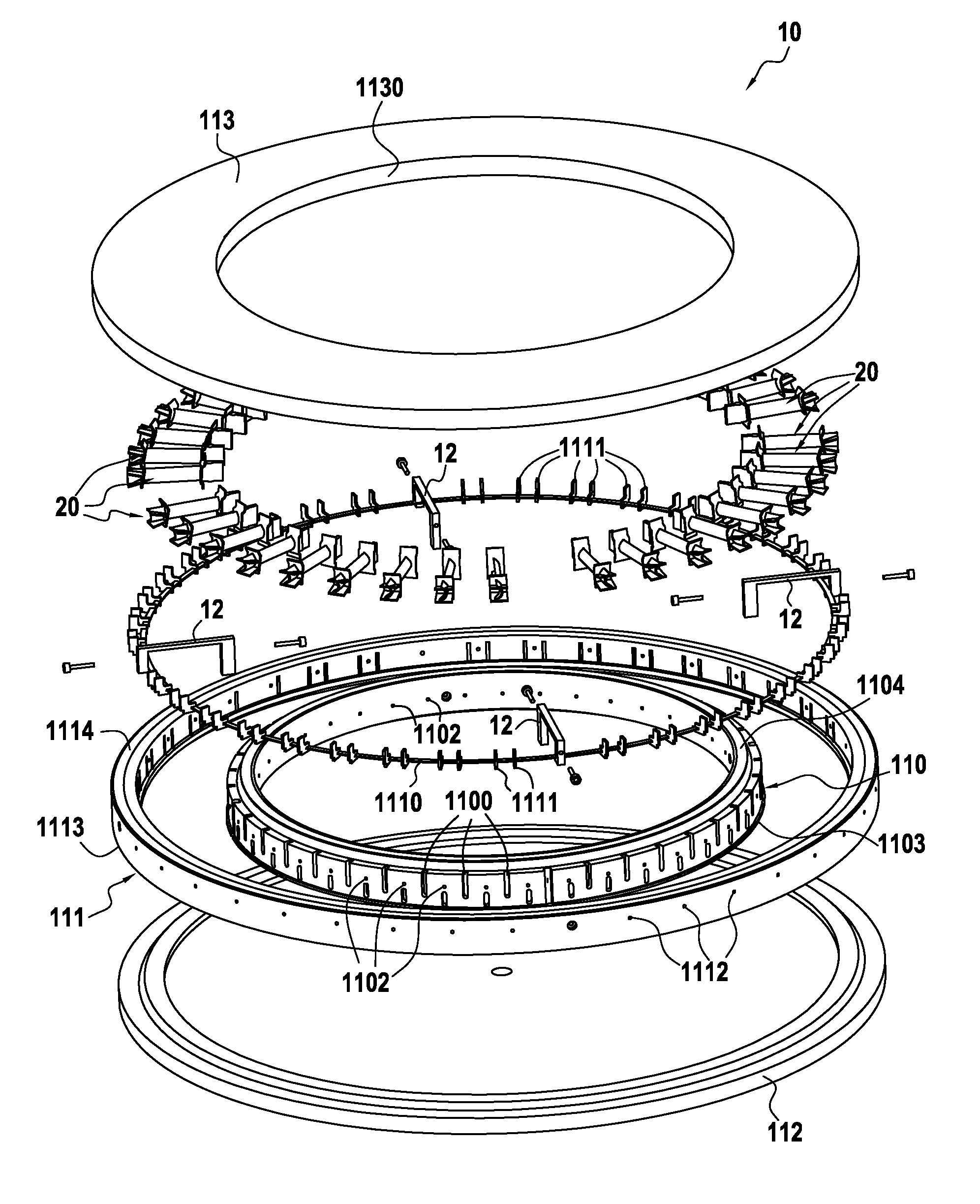

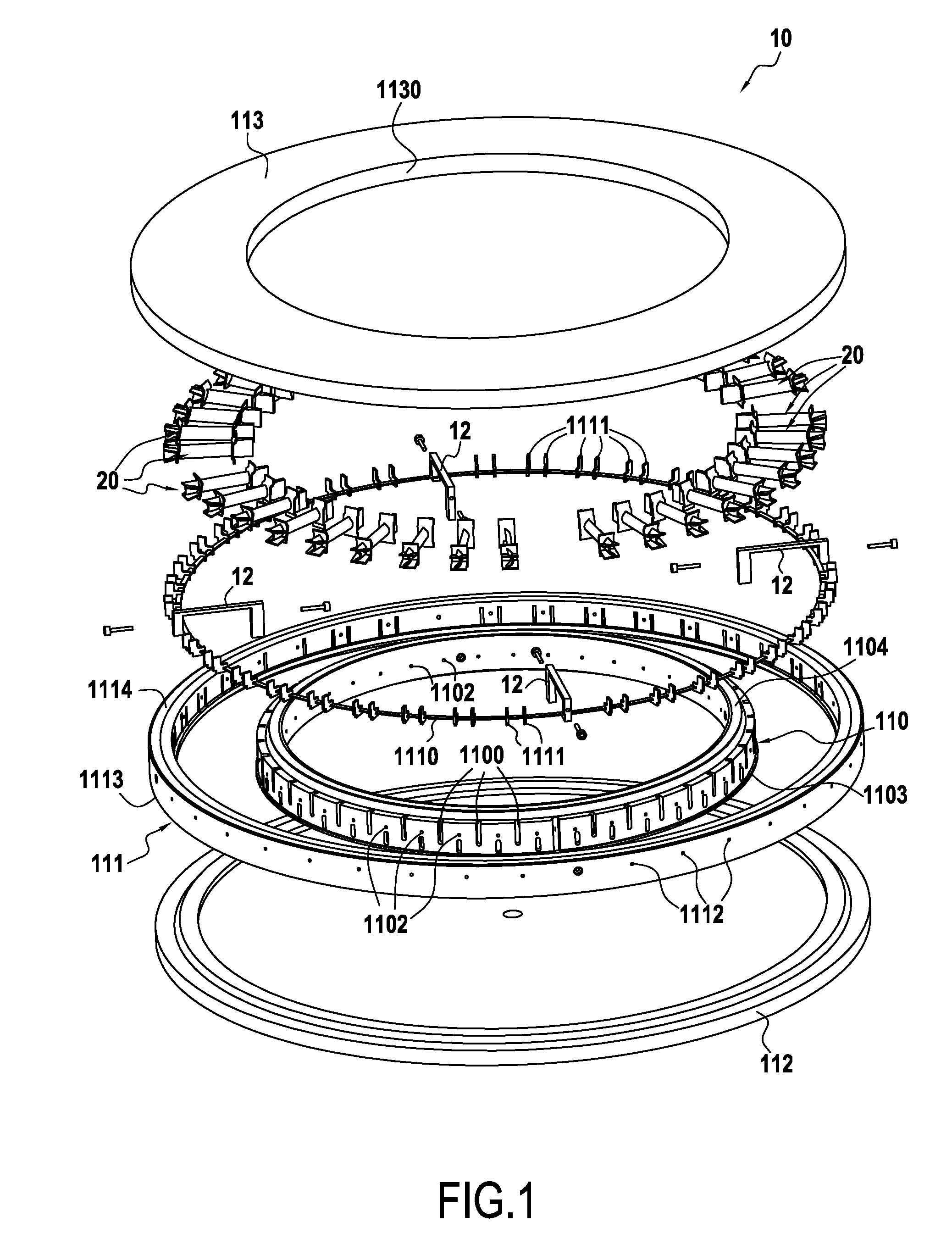

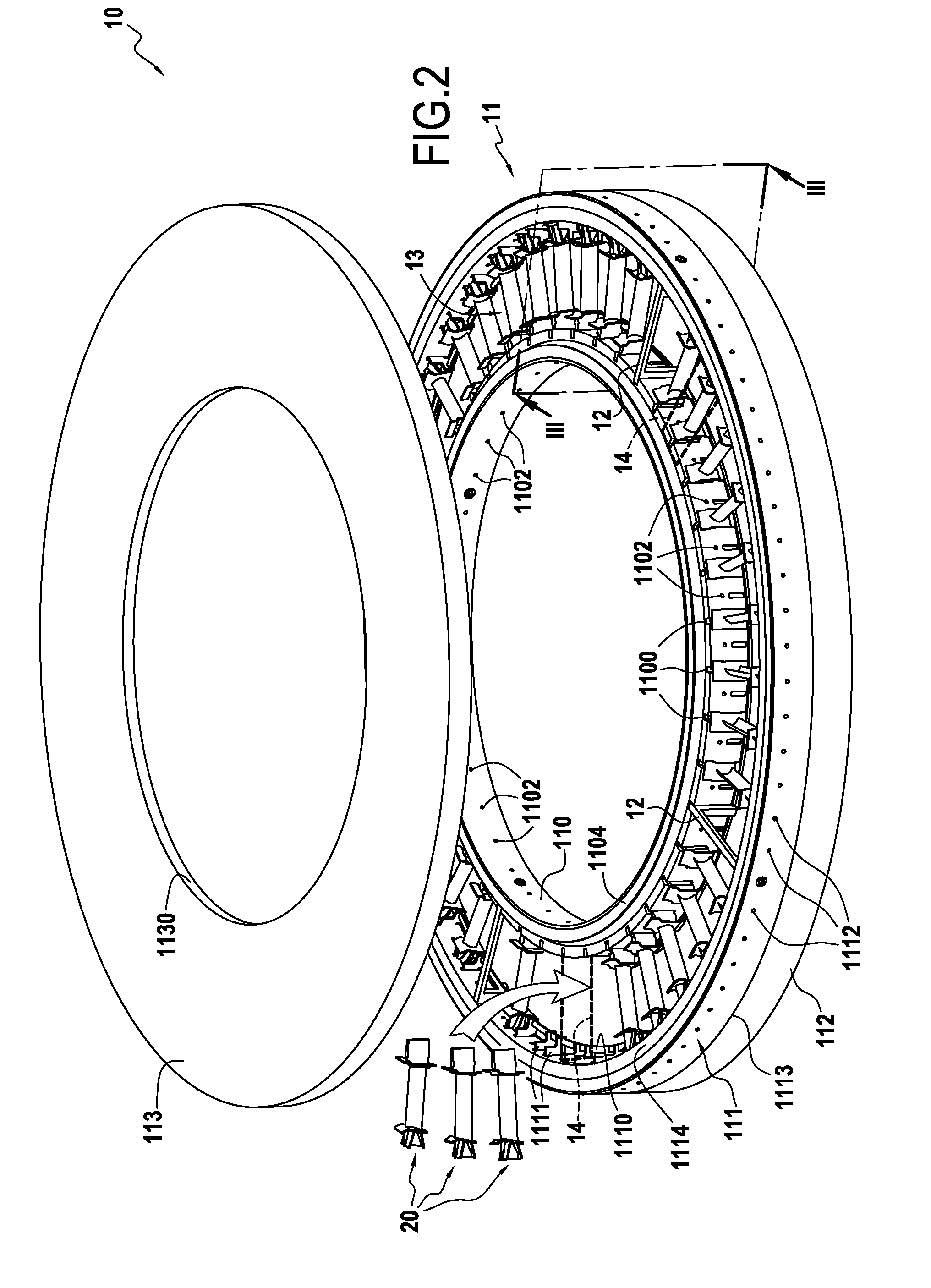

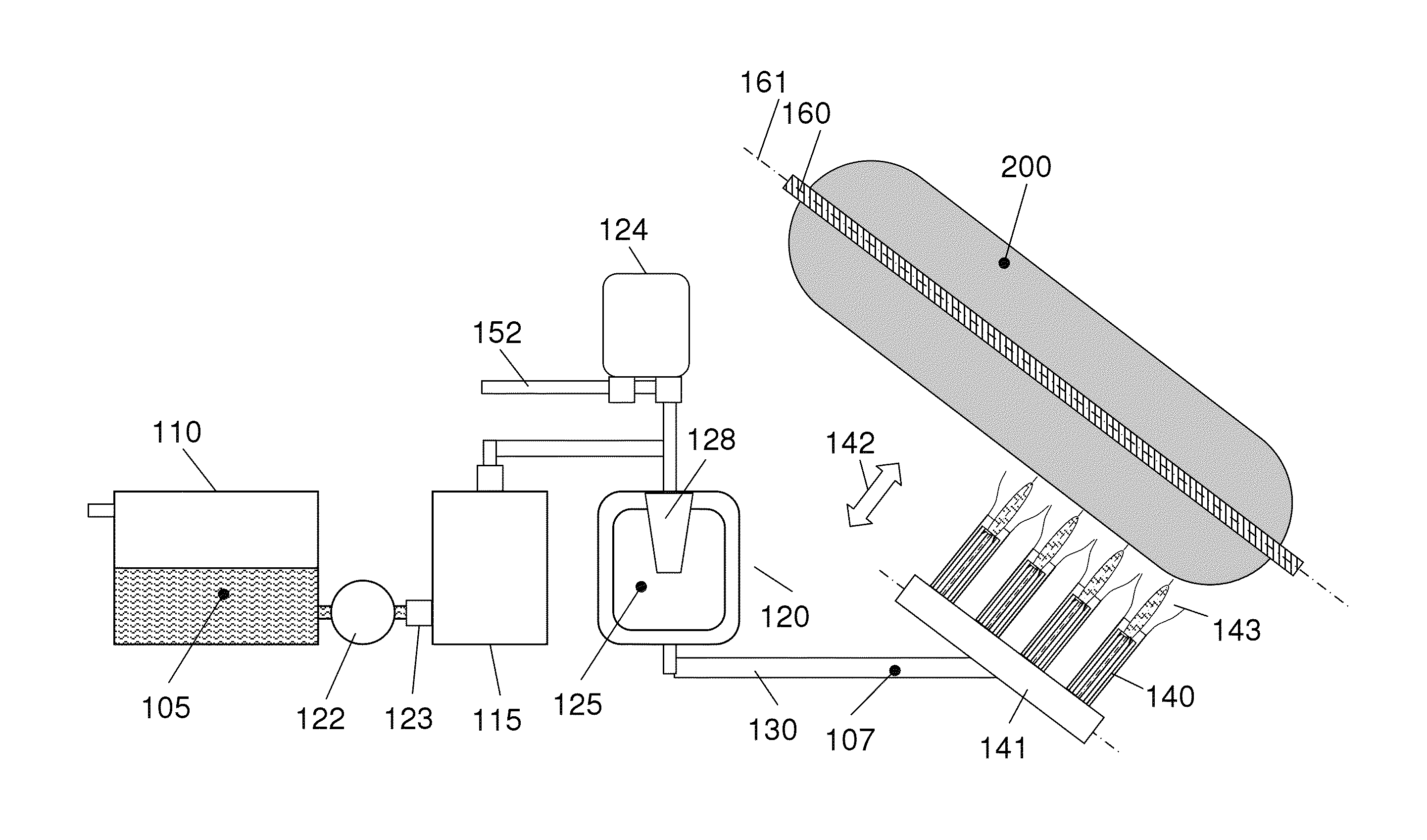

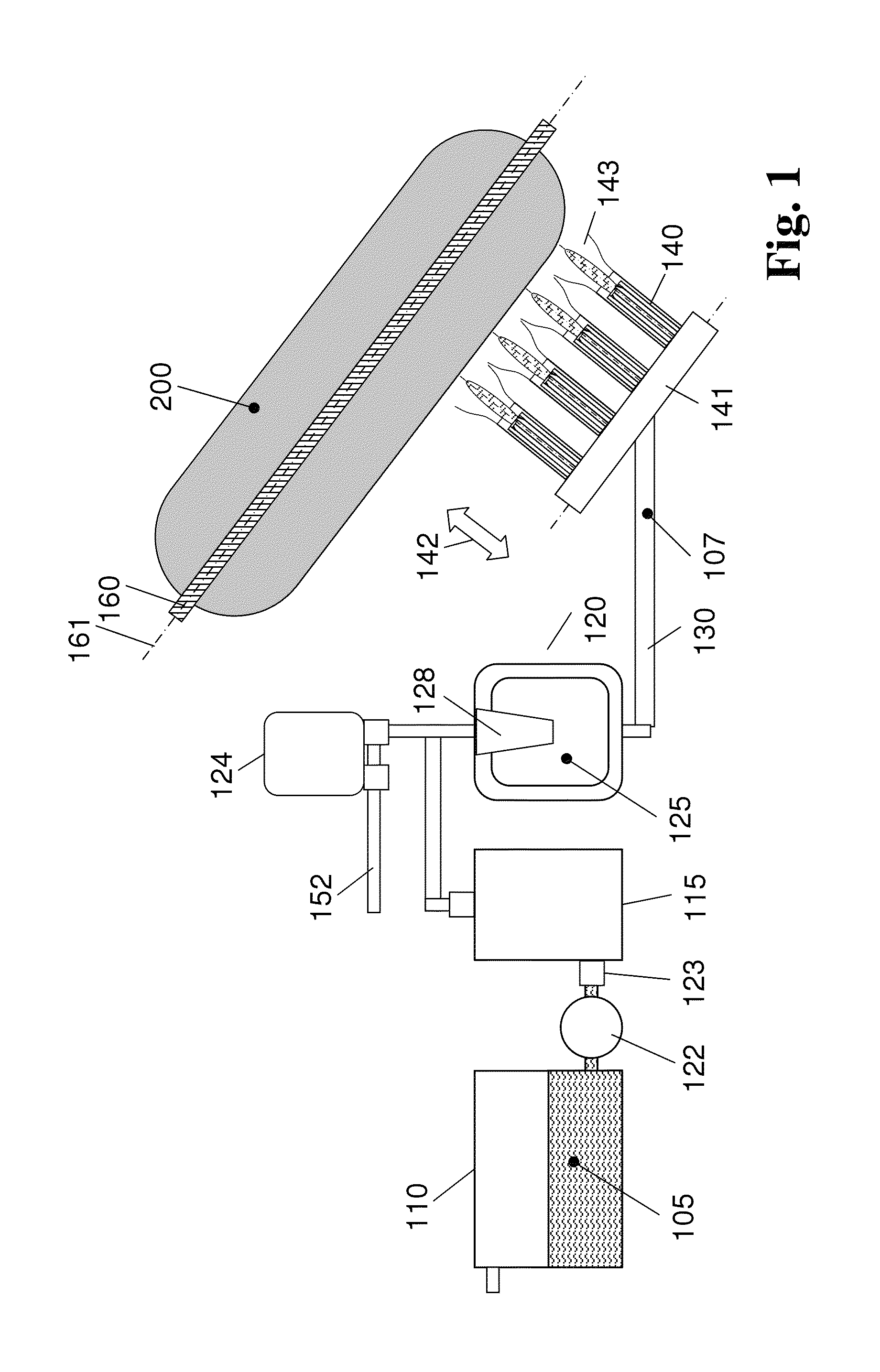

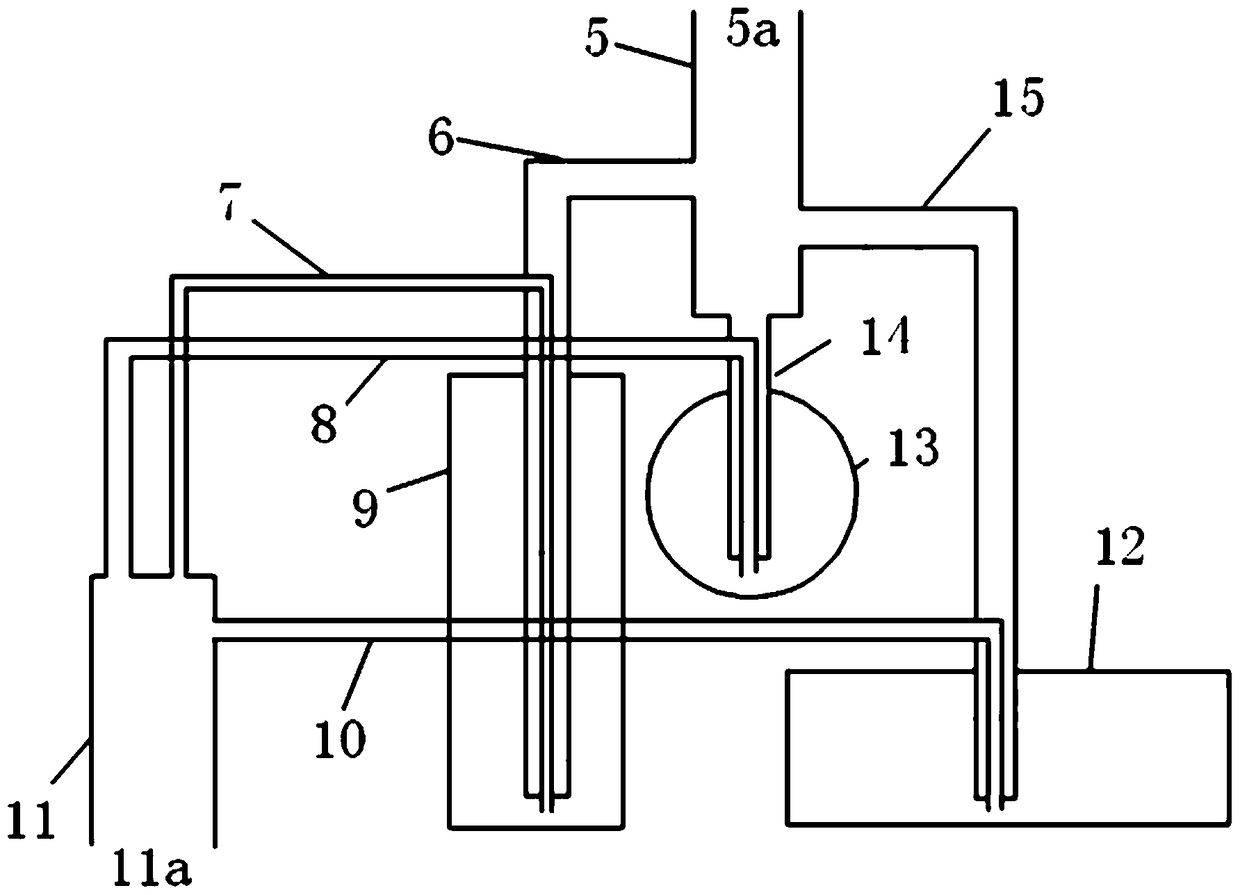

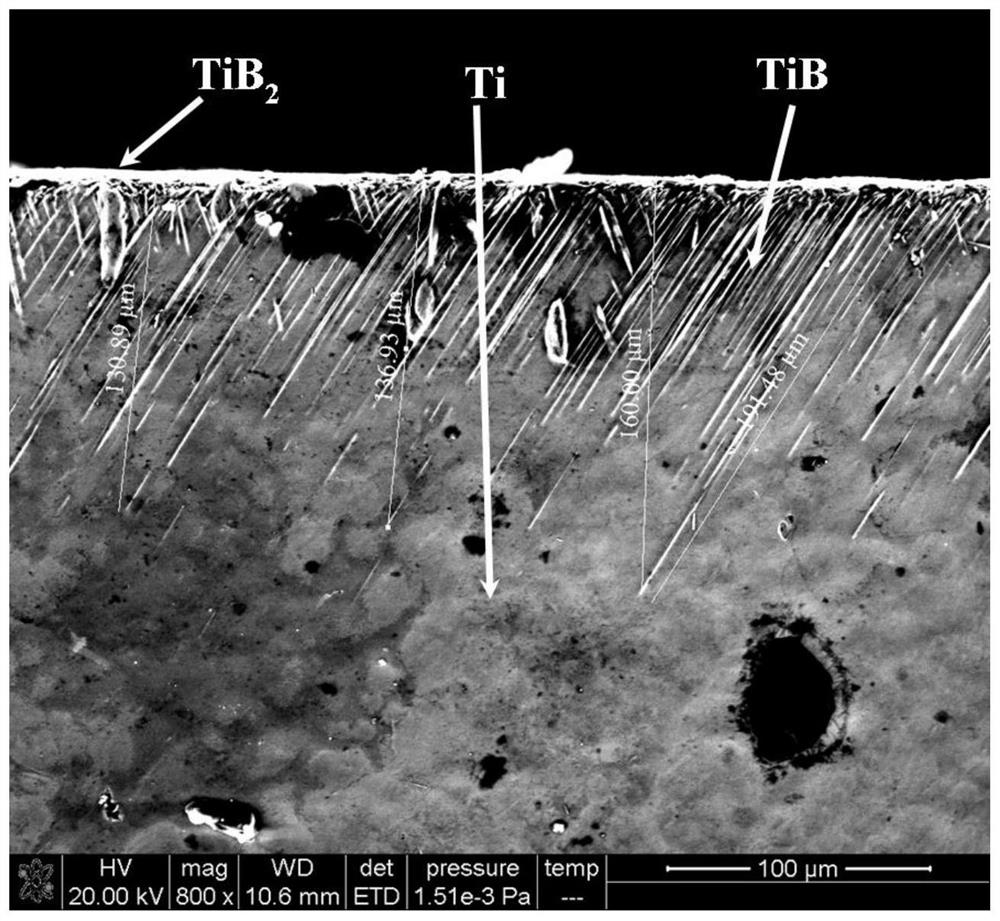

Gas preheater and process for controlling distribution of preheated reactive gas in a CVI furnace for densification of porous annular substrates

InactiveUS6572371B1Efficient heatingEfficiency of gasCharge manipulationChemical vapor deposition coatingPorous substrateSusceptor

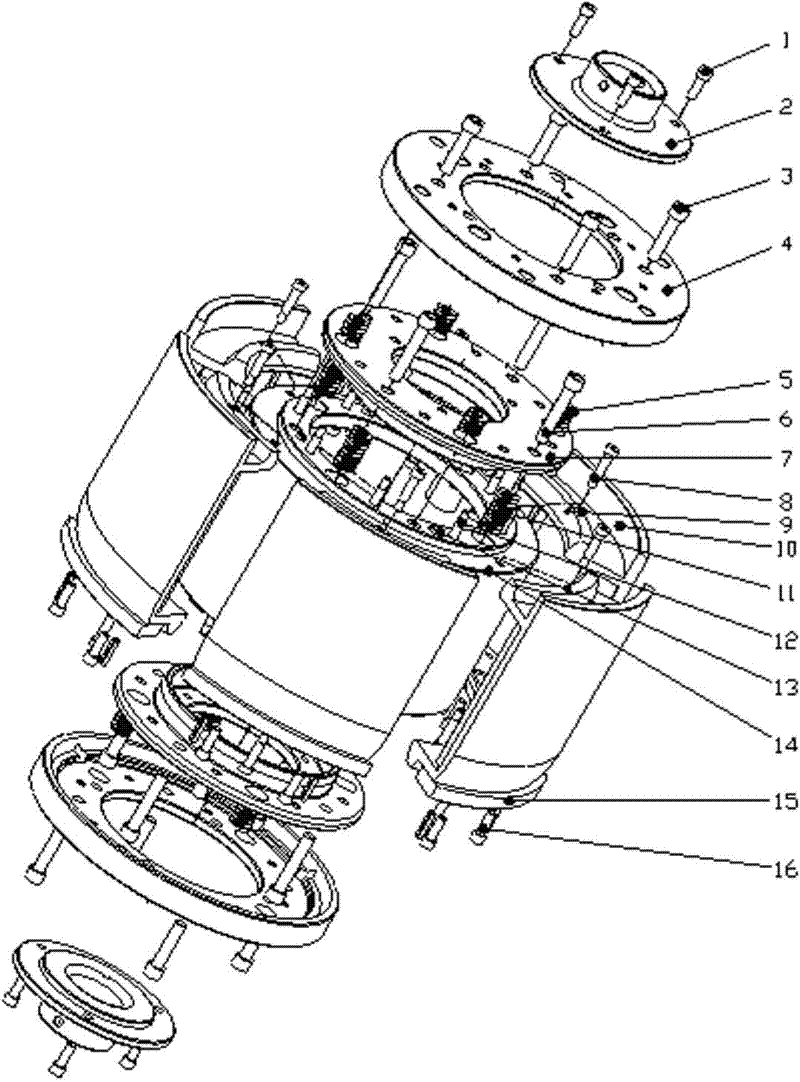

A gas preheater for a CVI furnace designed for the densification of annular porous substrates arranged in a plurality of vertical annular stacks of substrates, comprising: a sleeve made of heat conductive material resting upon the bottom wall of a susceptor and delimiting a gas preheating chamber, with a gas inlet opening in the gas preheating chamber; a heat exchange assembly located in the gas preheating chamber; a gas distribution plate resting upon the sleeve, covering the gas preheating chamber and provided with a plurality of passages for preheated gas; a load supporting plate for supporting stacks of annular substrates and provided with a plurality of passages in communication with respective passages of the gas distribution plate and registration with internal volumes of respective stacks of annular substrates; and nozzles inserted in passages communicating the gas preheating zone with the internal volumes of respective stacks of annular substrates for adjusting the flows of preheated gas respectively admitted in said internal volumes.

Owner:SAFRAN LANDING SYSTEMS

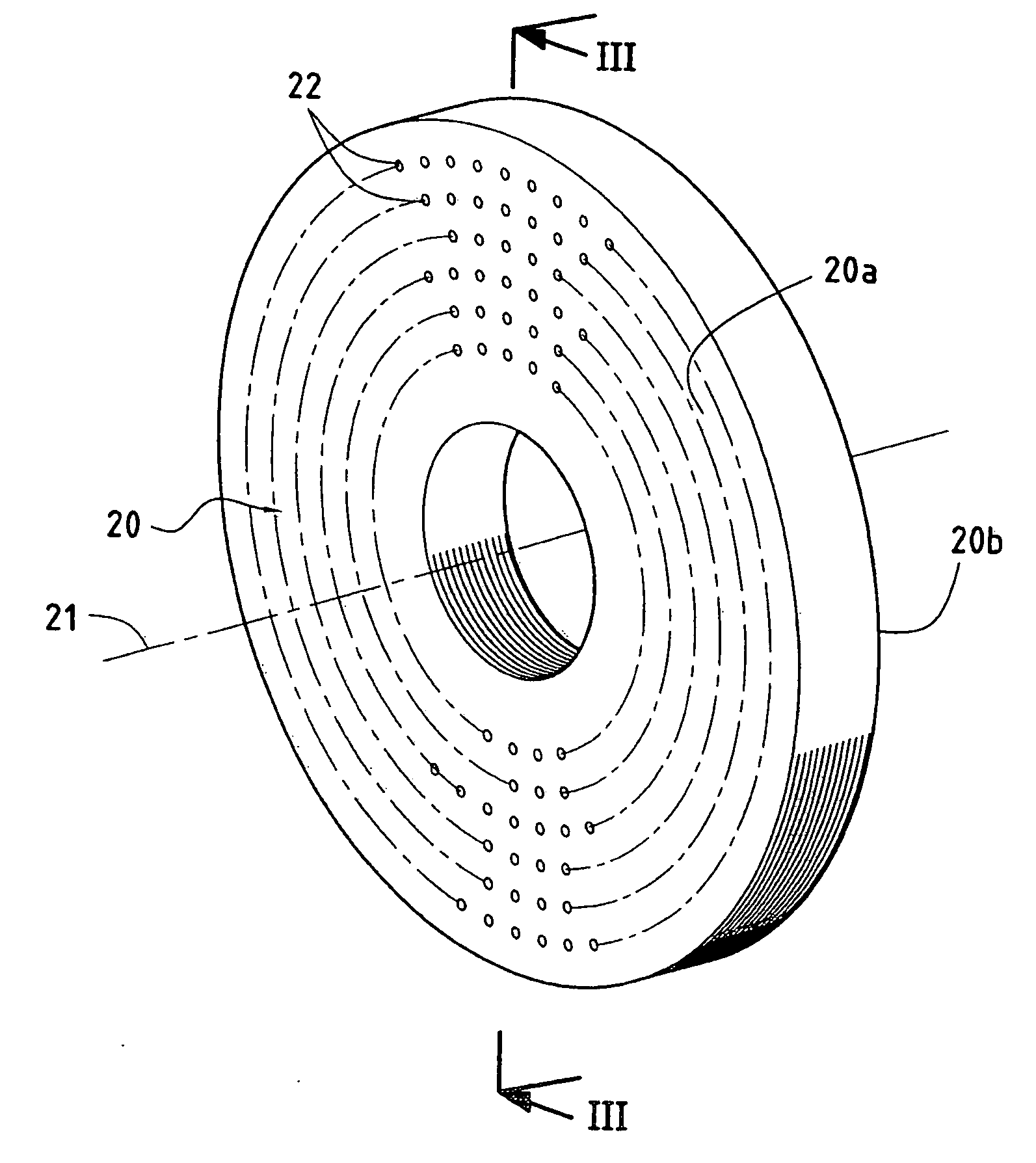

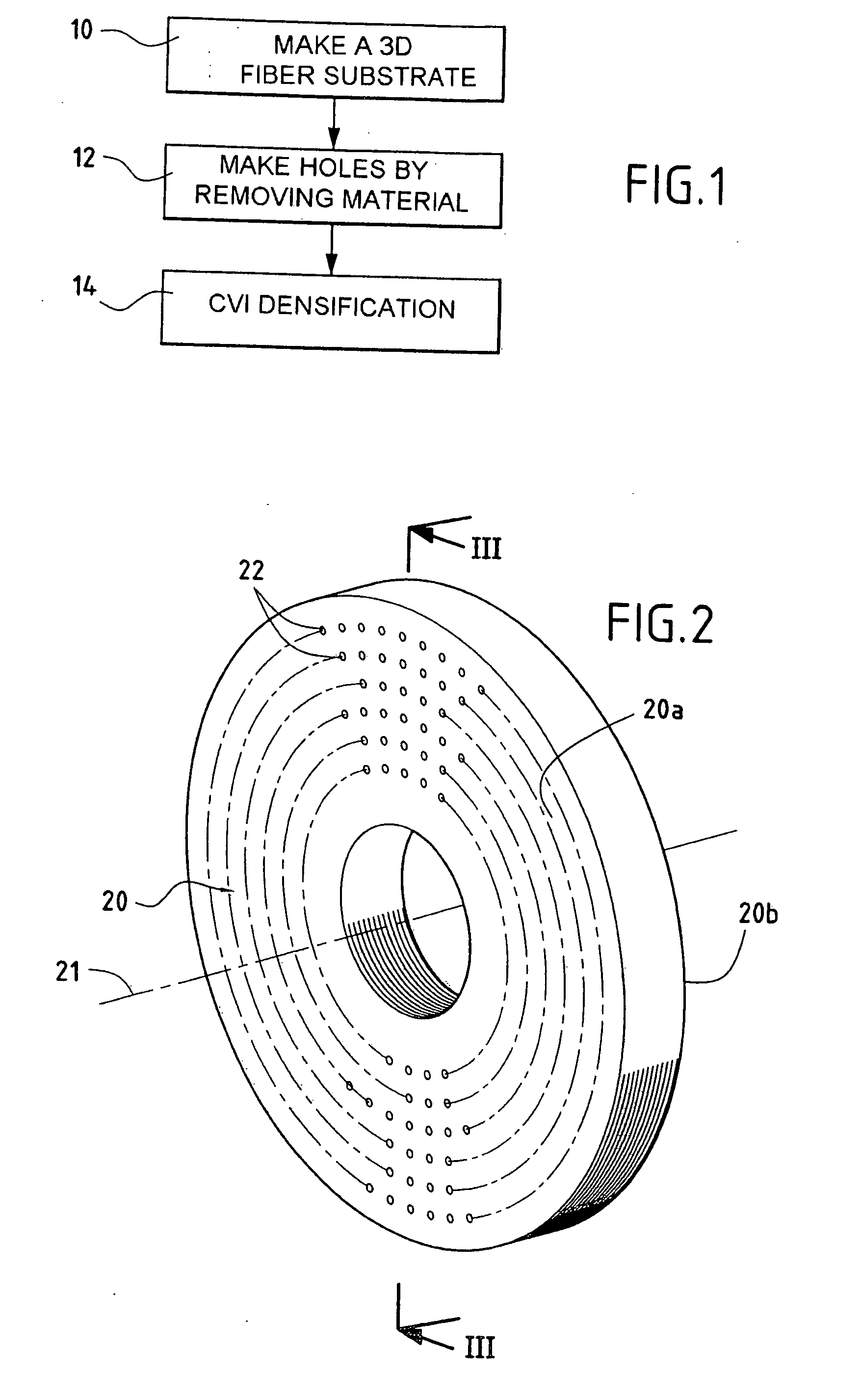

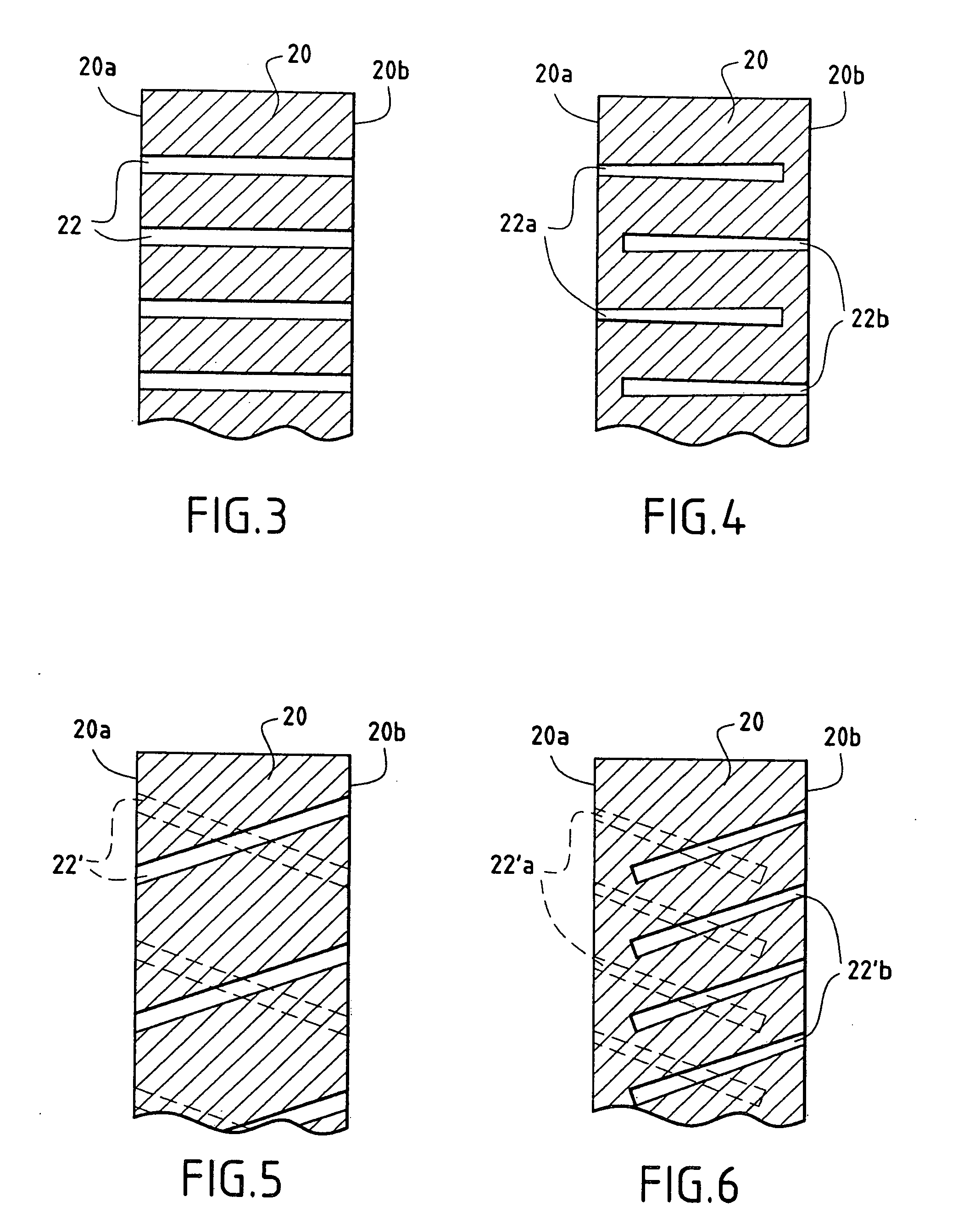

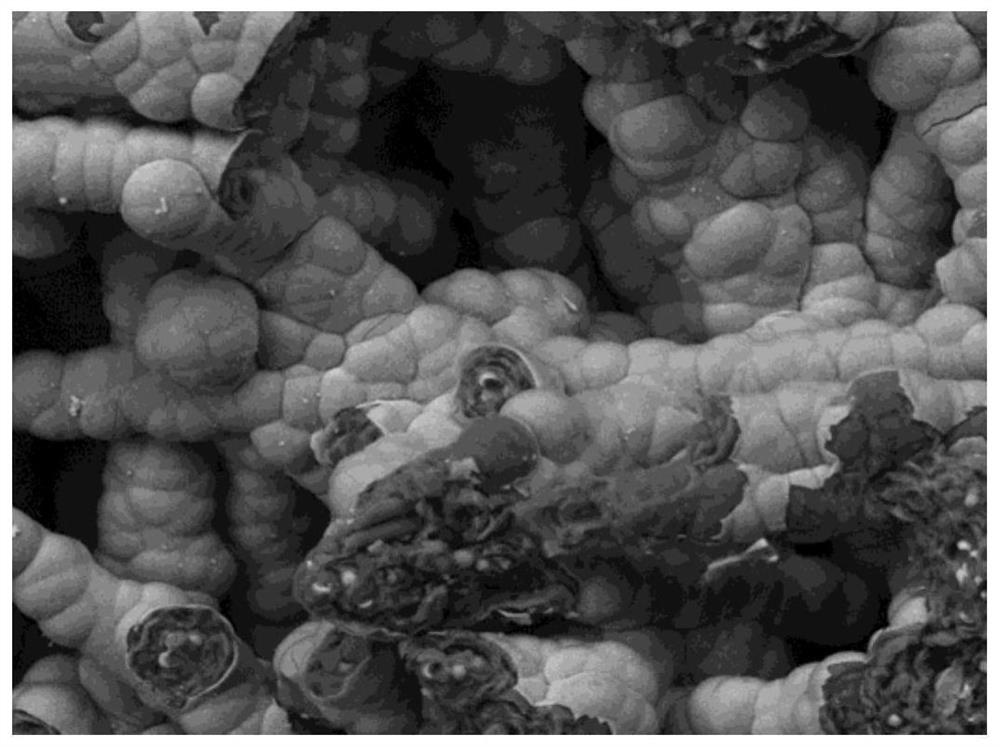

Method and substrate for making composite material parts by chemical vapour infiltration densification and resulting parts

InactiveUS20090110877A1Facilitated DiffusionUniform densificationRadiation applicationsPretreated surfacesGas phaseVolumetric Mass Density

A composite material part is made by forming a fiber preform (20), forming holes (22) extending within the preform from at least one face thereof, and densifying the preform with a matrix formed at least in part by a chemical vapor infiltration (CVI) type process. The holes (22) are formed by removing material from the preform with fibers being ruptured, for example by machining using a jet of water under pressure, the arrangement of the fibers in the preform with the holes being substantially unchanged compared with the initial arrangement before the holes were formed. This enables the densification gradient to be greatly reduced, and it is possible in a single densification cycle to obtain a density that, in the prior art, required a plurality of cycles separated by intermediate scalping.

Owner:SNECMA PROPULSION SOLIDE

Point contact densification

InactiveUS6110419AUniform densificationLess `` damage ''Bearing componentsGear wheelsPoint contactMetal

Owner:STACKPOLE INT POWDER METAL LTD

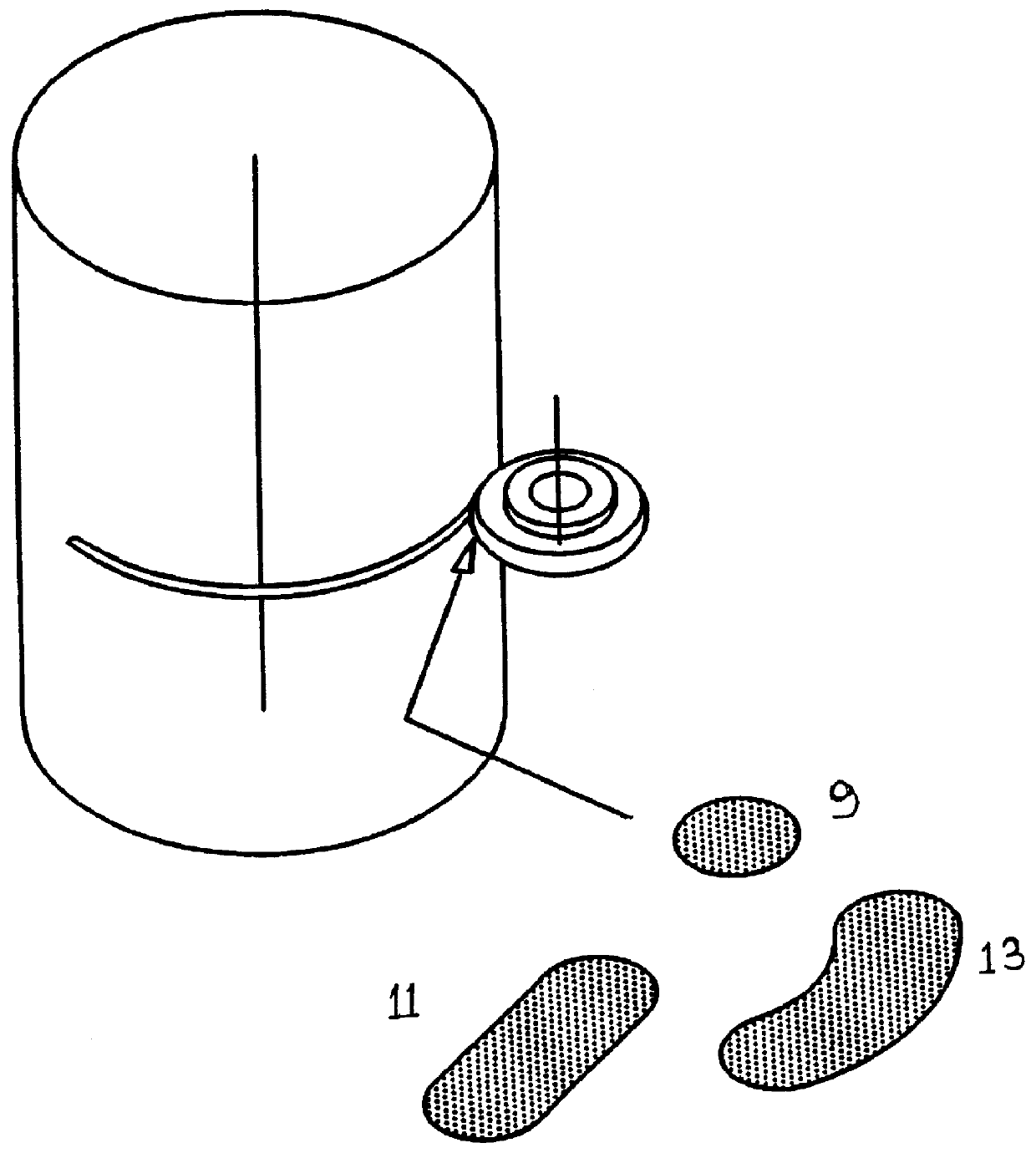

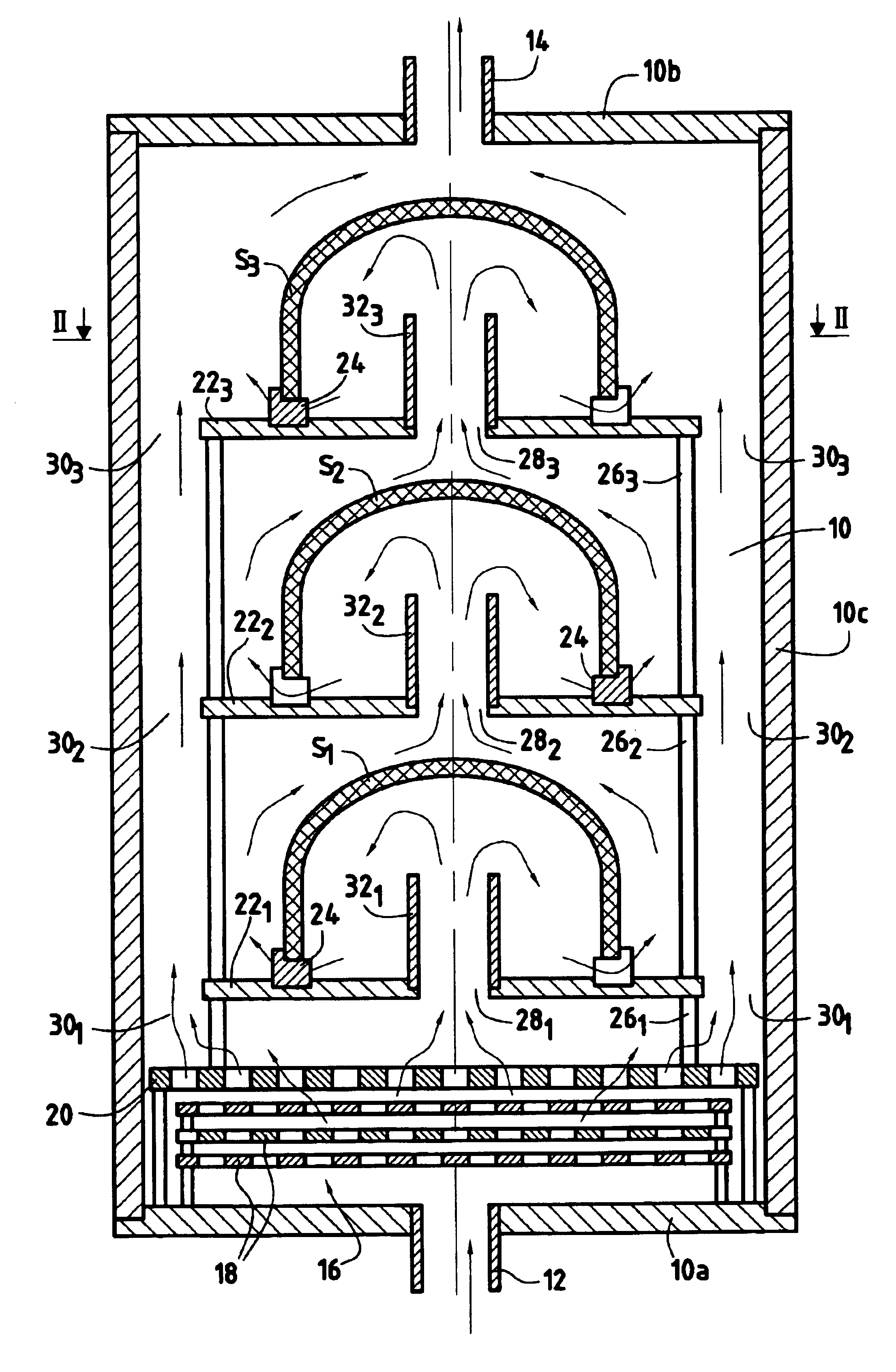

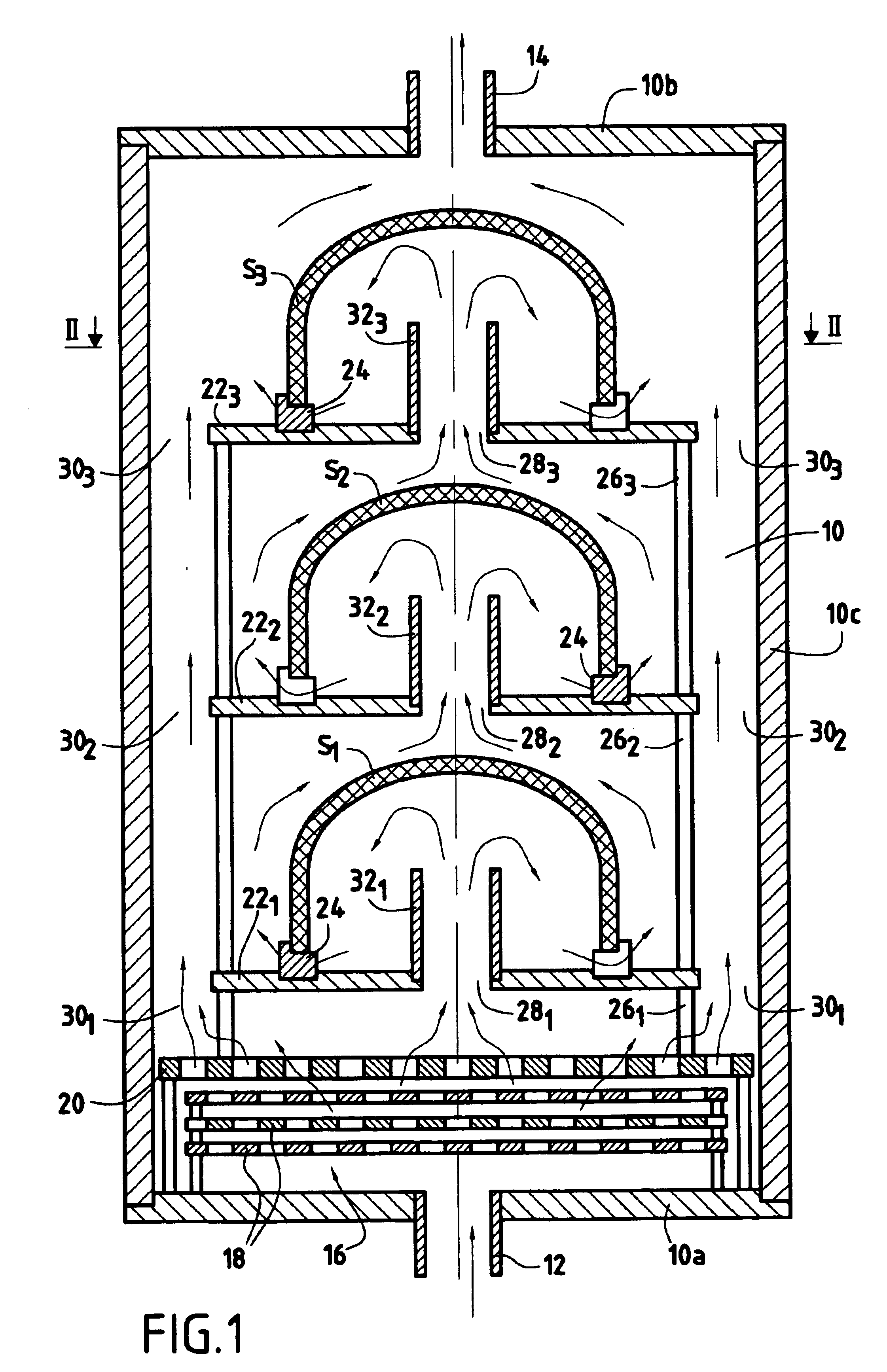

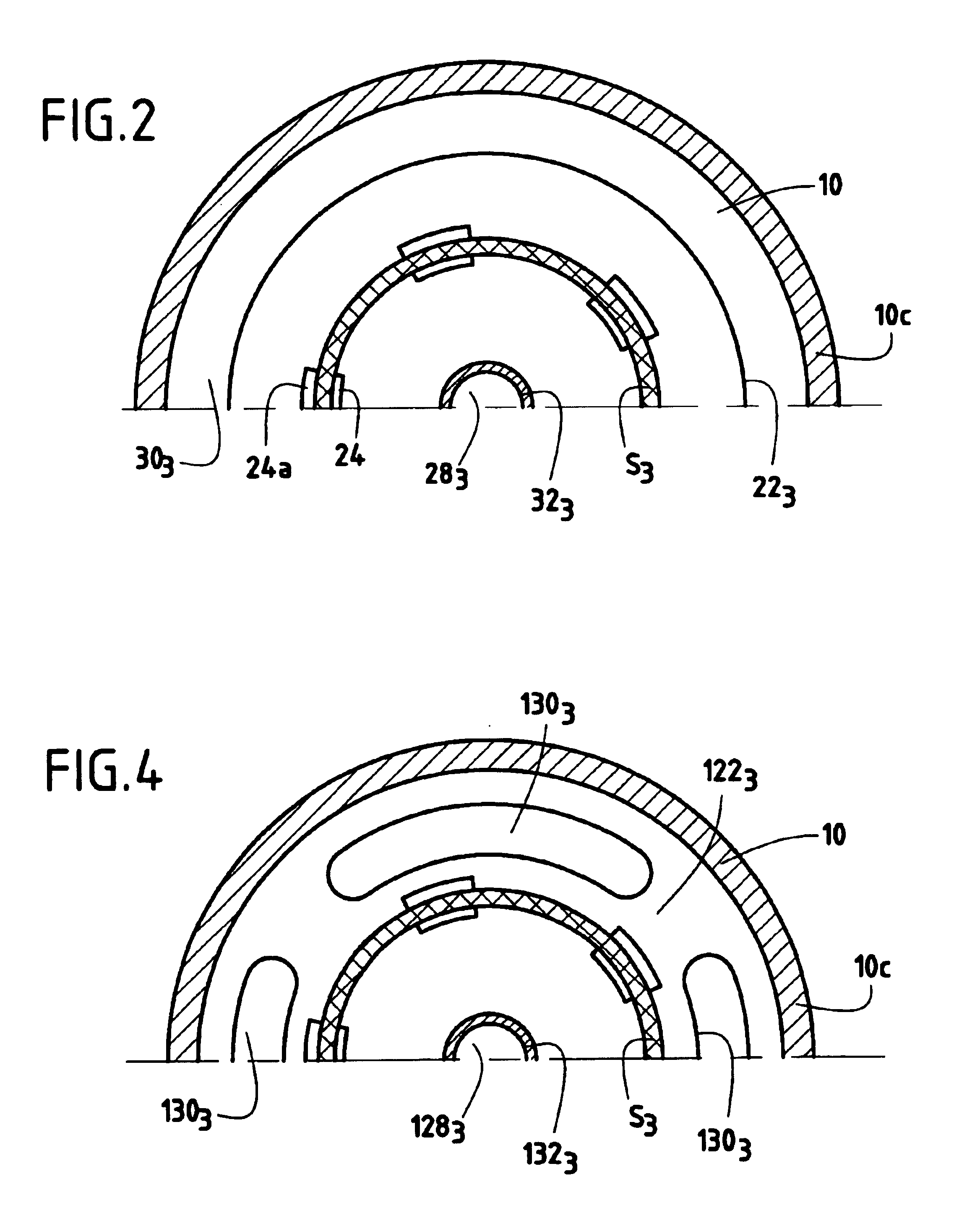

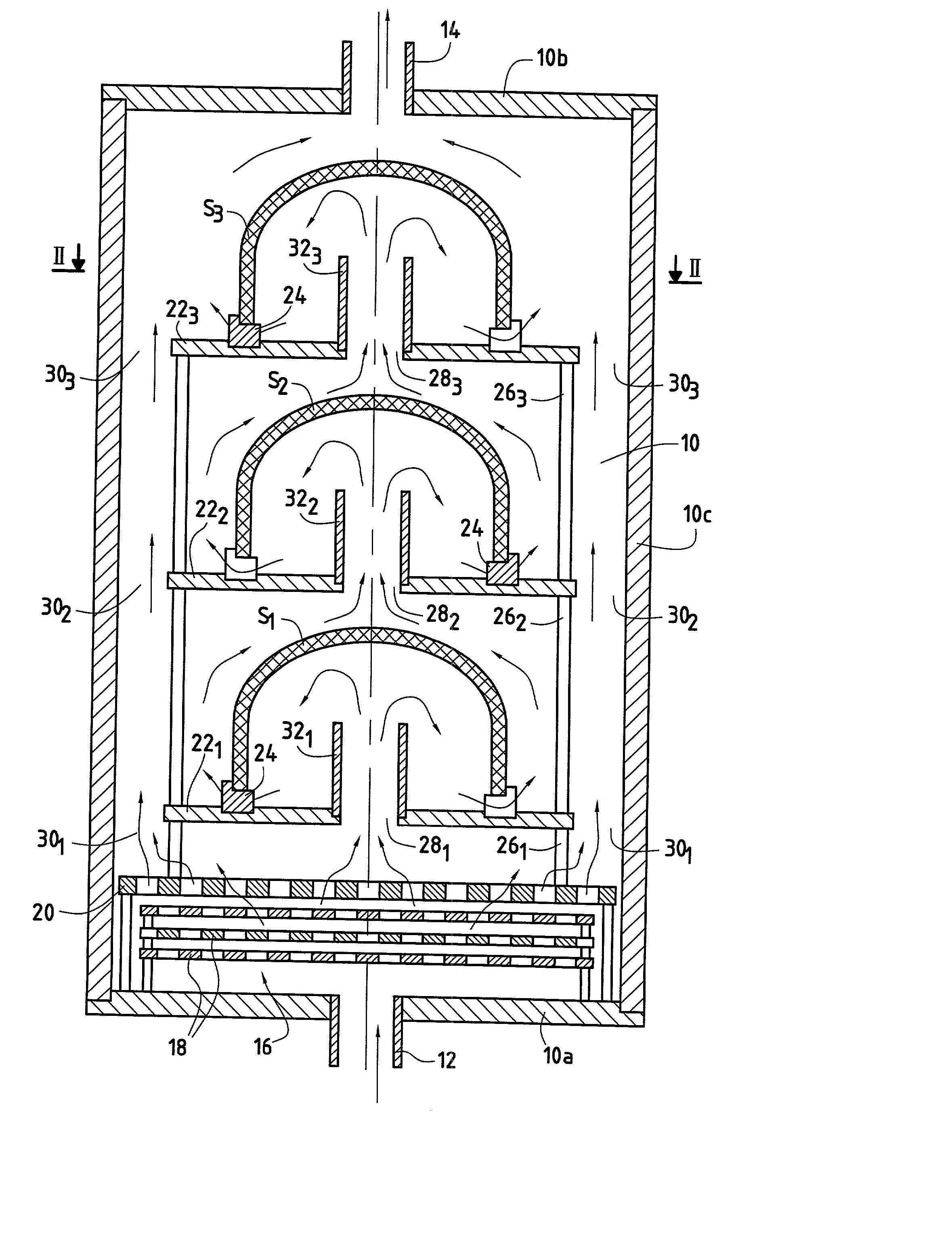

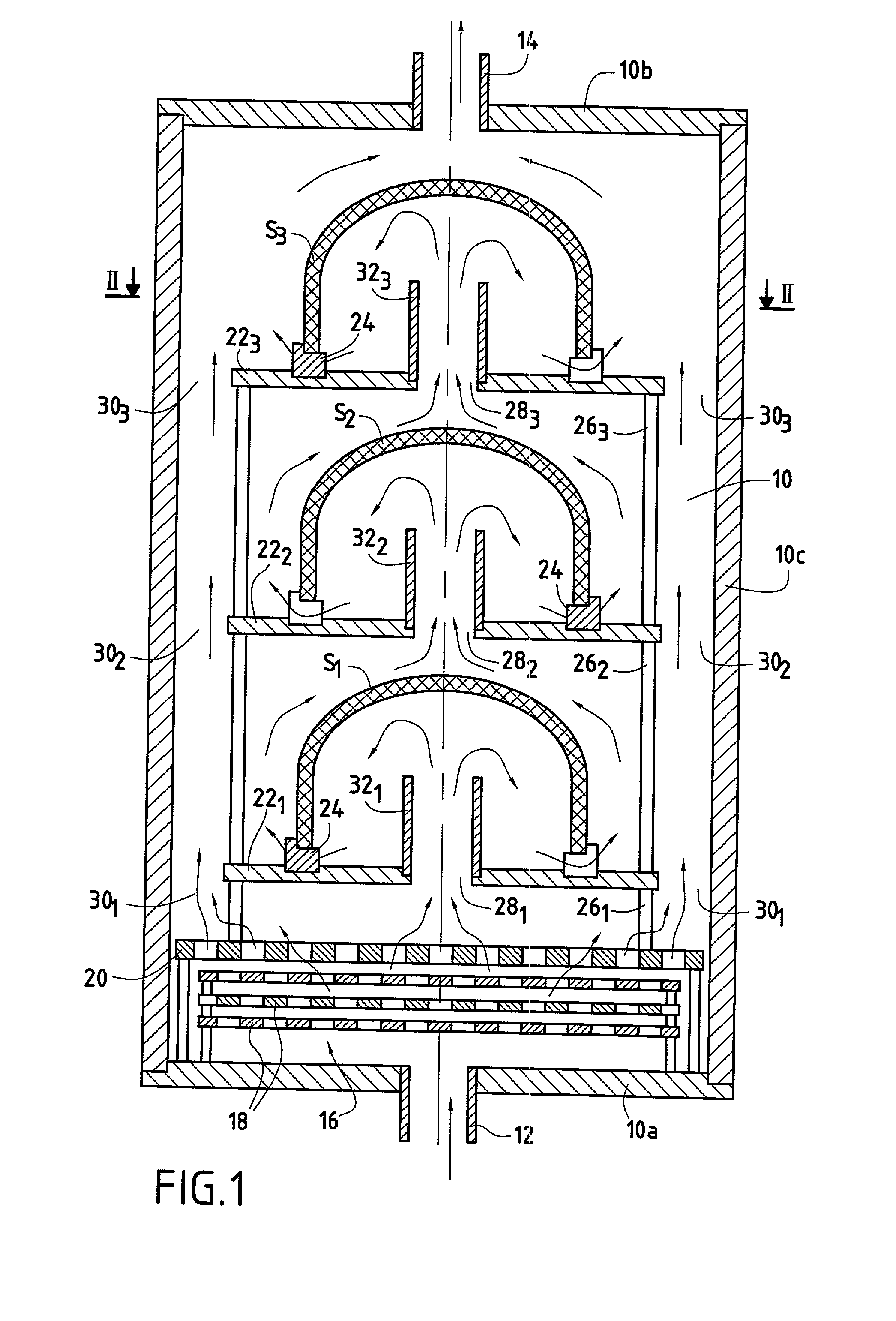

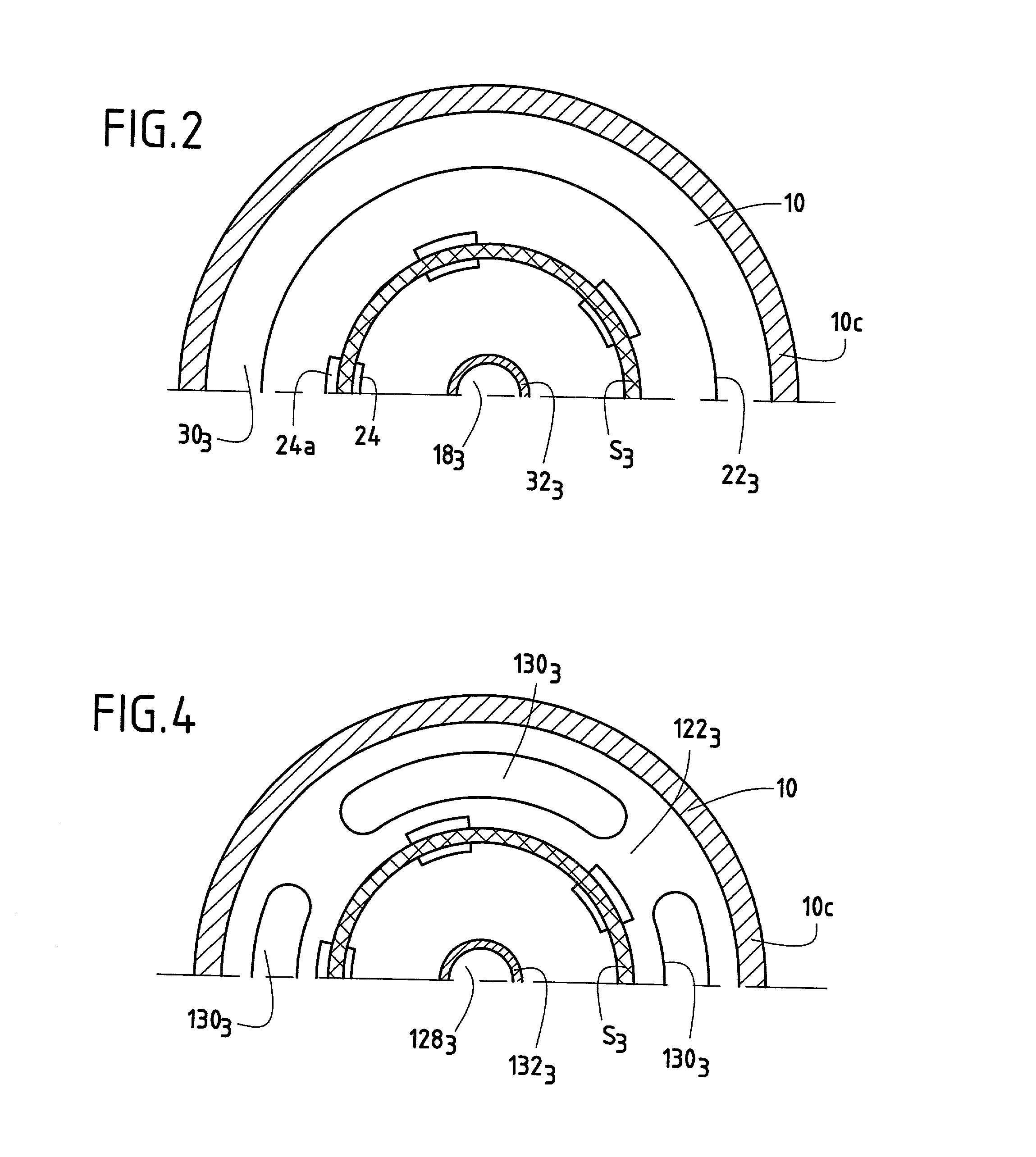

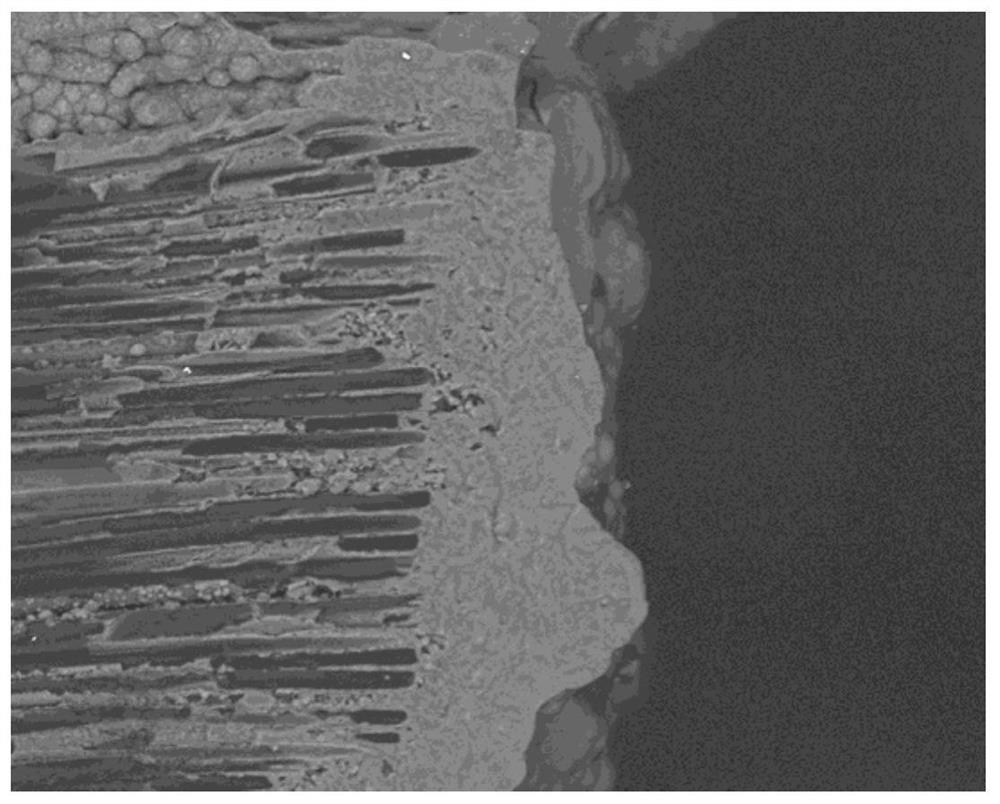

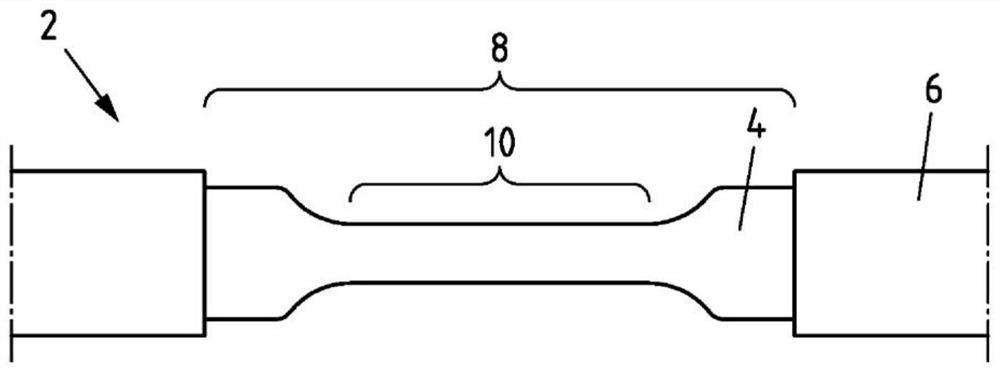

Densifying hollow porous substrates by chemical vapor infiltration

InactiveUS6942893B2Free from defectUniform densificationLiquid surface applicatorsChemical vapor deposition coatingPorous substrateReactive gas

A porous substrate having a concave inside face and an outside face is disposed in an enclosure, and reactive gas is introduced into the enclosure to densify the substrate. At least a portion of the gas is divided into two non-zero fractions. The first fraction of the gas is fed to the inside face of the substrate. The second fraction of the gas is fed to only the outside face of the substrate. Alternatively, the first fraction of the gas is fed via a tooling extending into an inside volume defined by the concave inside face of the substrate.

Owner:GERAKL

Densifying hollow porous substrates by chemical vapor infiltration

InactiveUS20020076491A1Free from defectPromotes uniform densificationLiquid surface applicatorsChemical vapor deposition coatingPorous substrateGas phase

Part of the flow of reactive gas admitted into the enclosure (10) is guided to the inside of the volume defined by a concave inside face of the or each hollow-shaped substrate (S1, S2, S3) so that said concave inside face is swept in full by a fraction of the total admitted gas flow.

Owner:GERAKL

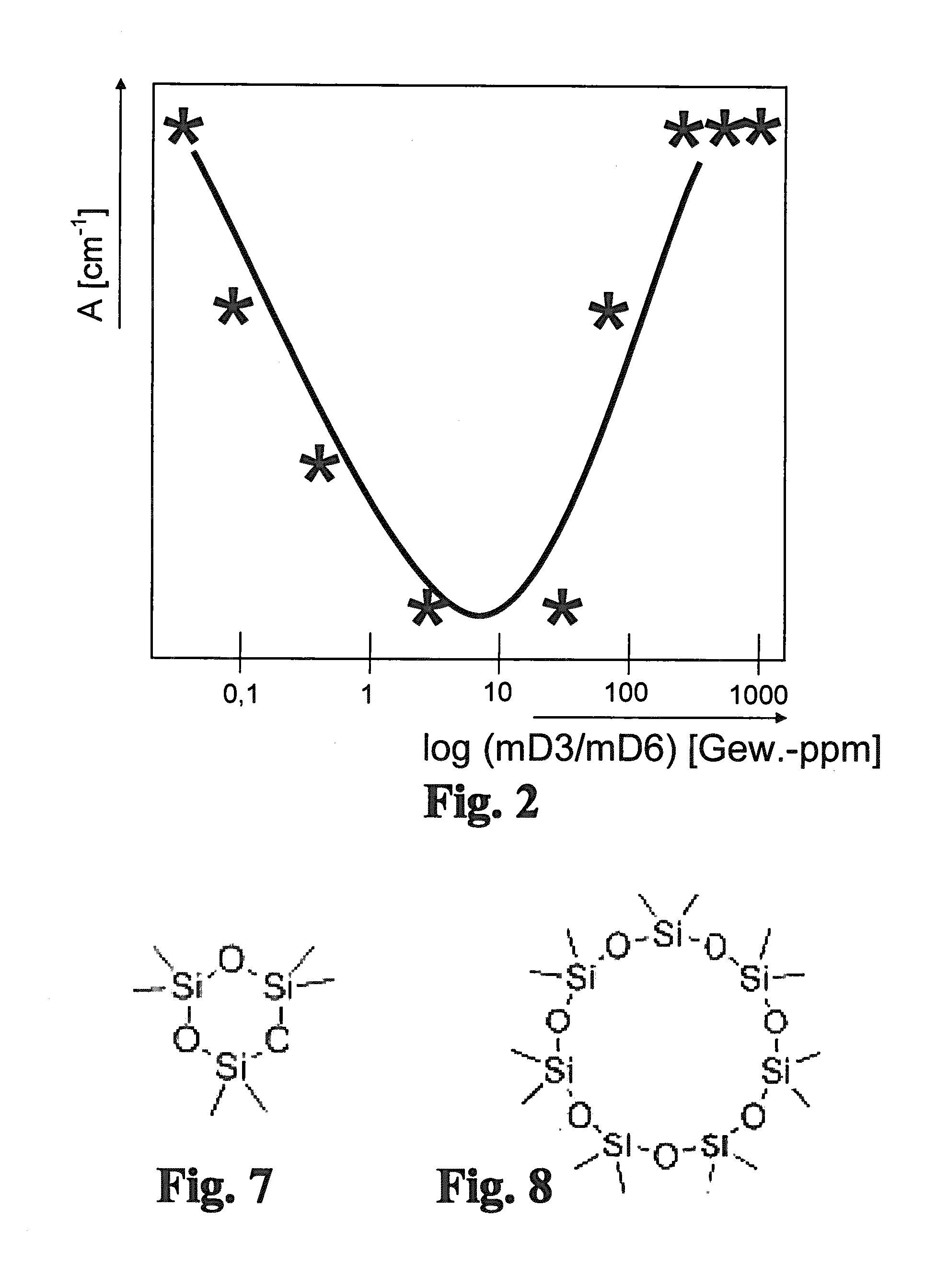

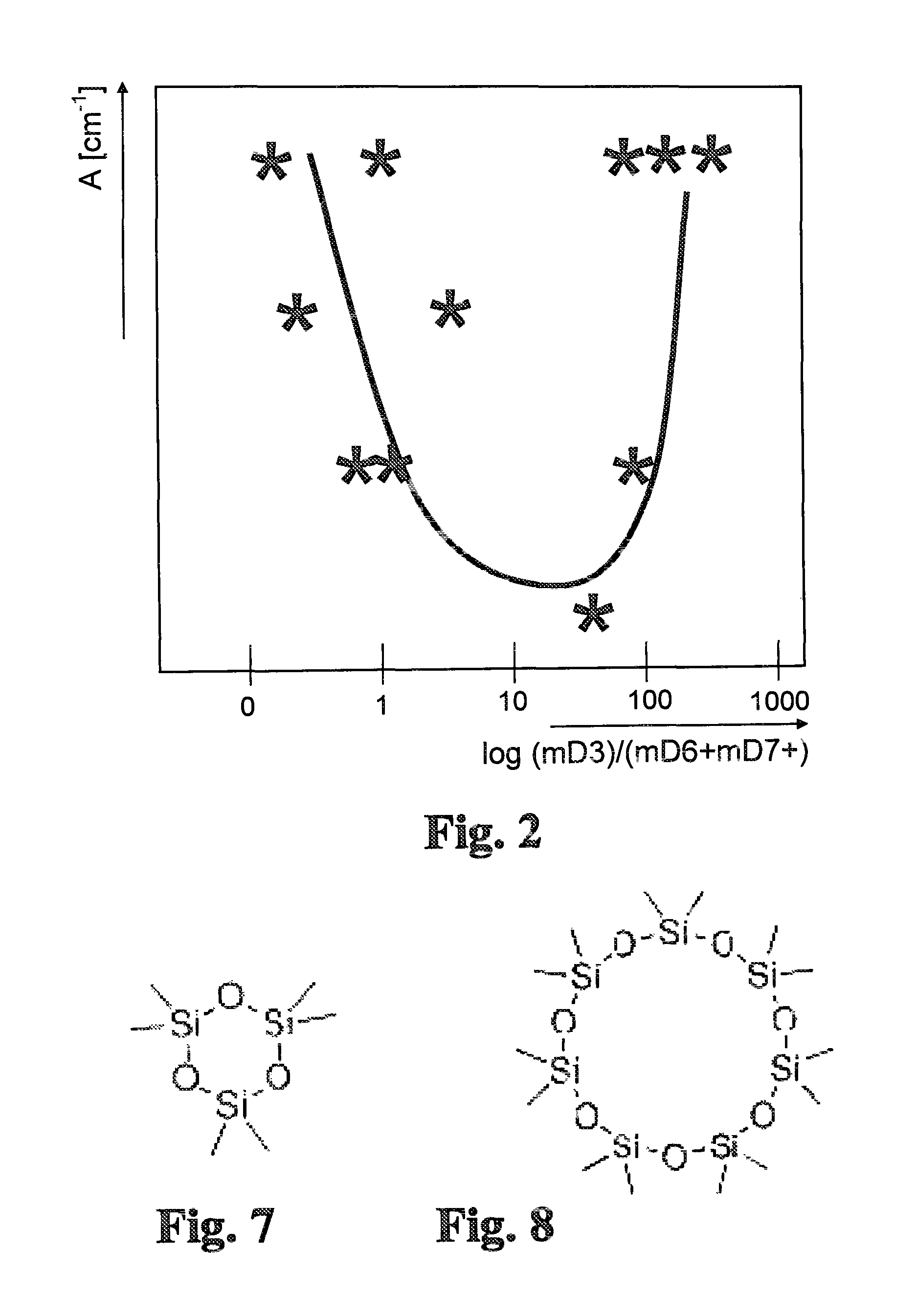

Method for producing synthetic quartz glass

InactiveUS20130133378A1Uniform densificationEasy to produceGlass shaping apparatusGlass deposition burnersOctamethylcyclotetrasiloxaneQuartz

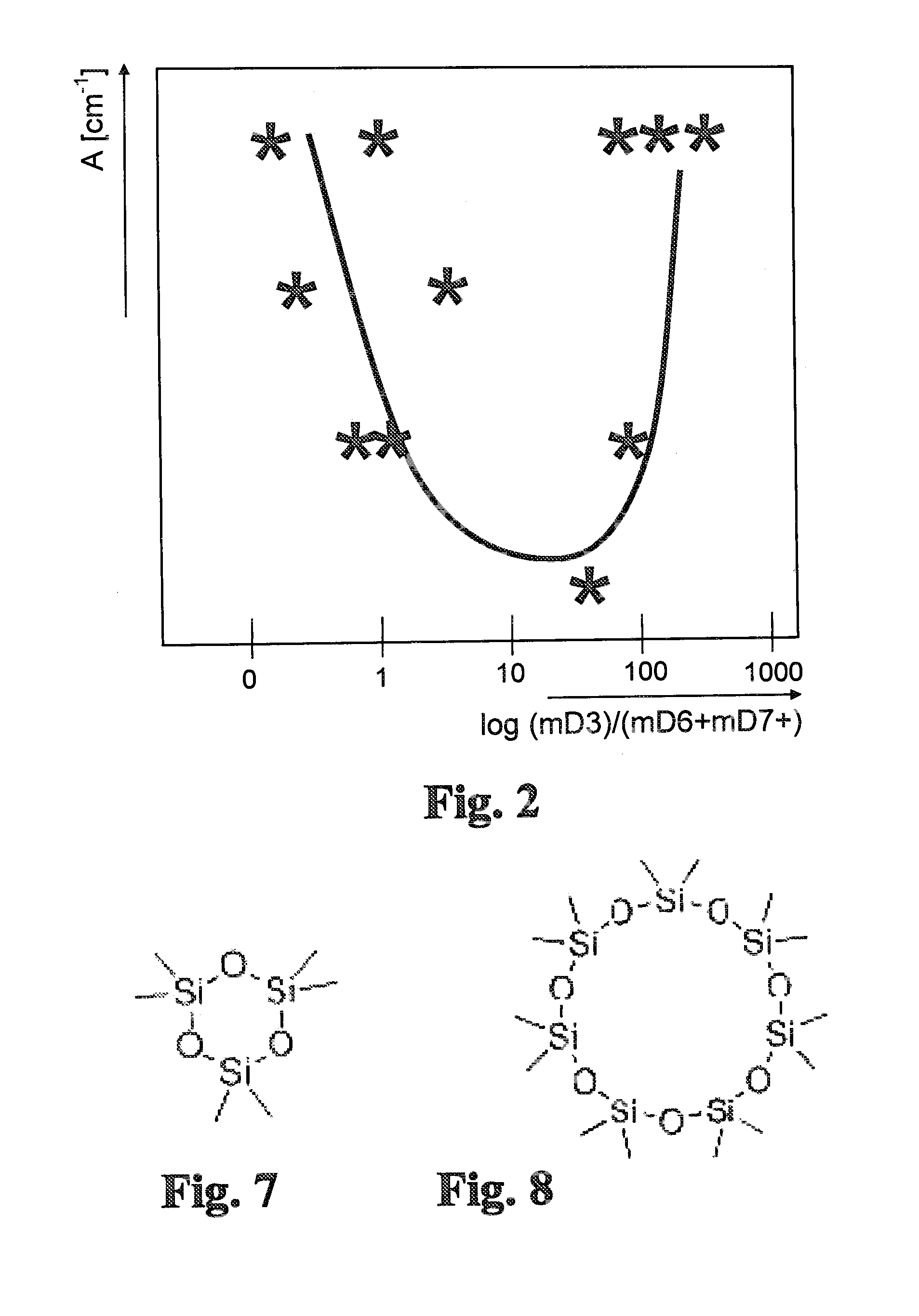

A known method for producing synthetic quartz glass comprises the method steps: providing a liquid SiO2 feedstock material, which contains octamethylcyclotetrasiloxane D4 as the main component, vaporizing the SiO2 feedstock material into a feedstock material vapor, converting the feedstock material vapor into SiO2 particles, depositing the SiO2 particles on a deposition surface while forming a porous SiO2 soot body, and vitrifying the SiO2 soot body while forming the synthetic quartz glass. Starting therefrom, to produce large-volume cylindrical soot bodies with outer diameters of more than 300 mm of improved material homogeneity, it is suggested according to the invention that the liquid feedstock material contains additional components comprising hexamethylcyclotrisiloxane D3 and the linear homolog thereof with a weight fraction mD3, decamethylcyclohexasiloxane D6 and the linear homolog thereof with a weight fraction mD6, and tetradecamethylcycloheptasiloxane D7 and / or hexadecamethylcyclooctasiloxane D8 and the linear homologs thereof with a weight fraction mD7+, wherein the weight ratio mD3 / mD6 is in a range between 0.05 and 90 and the weight fraction mD7+ is at least 20 wt. ppm.

Owner:HERAEUS QUARZGLAS

Method for producing synthetic quartz glass

ActiveUS20130133375A1Uniform densificationEasy to produceMaterial analysis by optical meansGlass shaping apparatusOctamethylcyclotetrasiloxaneSoot

A method for producing synthetic quartz glass comprises providing a liquid SiO2 feedstock material containing octamethylcyclotetrasiloxane D4, vaporizing the SiO2 feedstock material into vapor, converting the vapor into SiO2 particles, depositing the particles to form a porous SiO2 soot body, and vitrifying the soot body, forming the synthetic quartz glass. To produce cylindrical soot bodies with outer diameters above 300 mm and improved material homogeneity, the liquid feedstock material contains additional components comprising hexamethylcyclotrisiloxane D3 and the linear homolog thereof with a weight fraction mD3, decamethylcyclohexasiloxane D6 and the linear homolog thereof with a weight fraction mD6, and tetradecamethylcycloheptasiloxane D7 and / or hexadecamethylcyclooctasiloxane D8 and the linear homologs thereof with a weight fraction mD7+, wherein the weight ratio mD3 / mD6 is between 0.5 and 500 and the weight fraction mD7+ is at least 20 wt. ppm.

Owner:HERAEUS QUARZGLAS

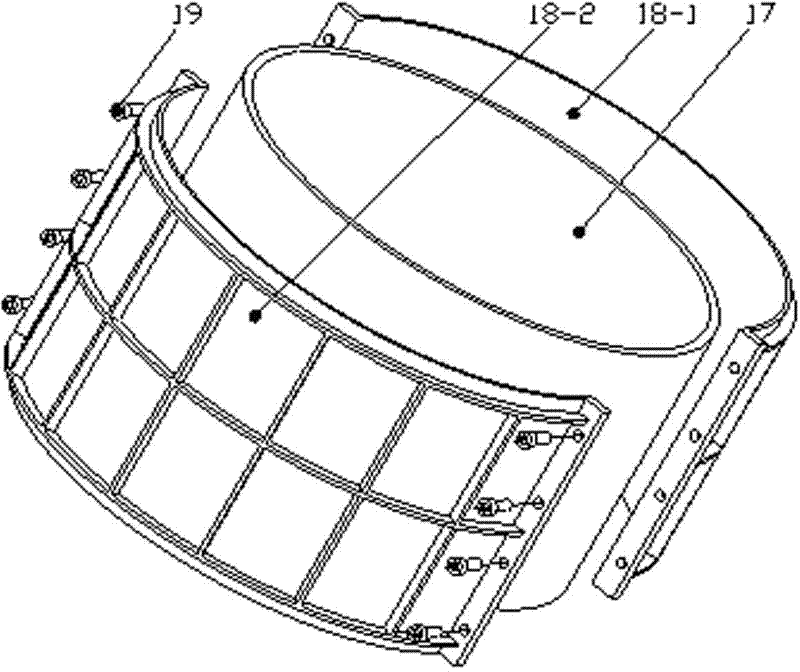

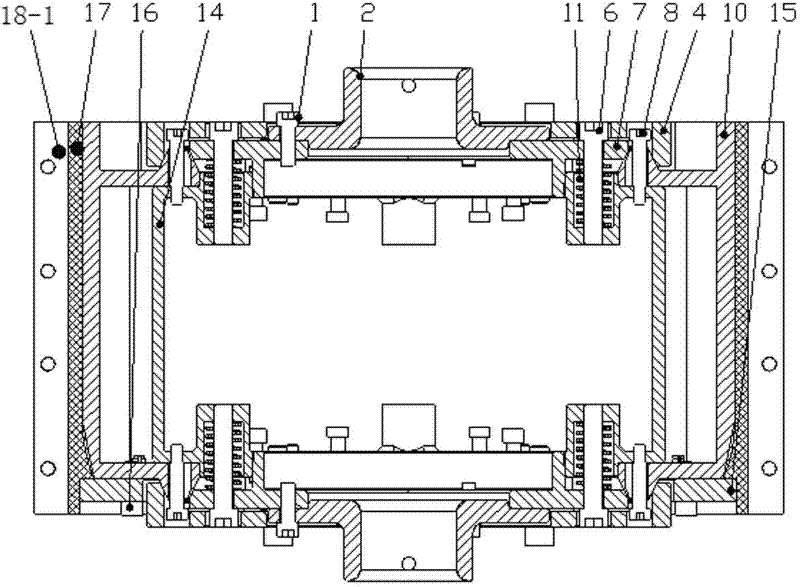

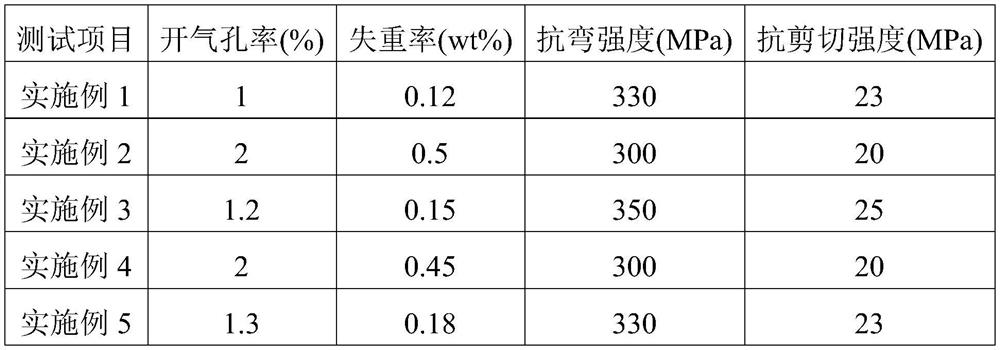

Mould for using two-dimensional fiber fabric to produce blanks of carbon-carbon composite barrel products

A mould for using two-dimensional fiber fabric to produce blanks of carbon-carbon composite barrel products comprises an inner mould and an outer mould. The inner mould comprises a slider, an inner supporting barrel, an inner pressure block, an outer pressure block and a mould mounting flange. The mould mounting flange is connected with the outer pressure block through a screw I, the outer pressure block is connected with the inner pressure block through a screw II and a spring I, the inner pressure block is connected with the inner supporting barrel through a screw III and a spring II, and the slider is connected with the inner supporting barrel through a screw IV. The outer mould comprises a flap mould I, a flap mold II and connecting bolts. The mould is simple in structure and convenient in operation, using the mould to produce the blanks of carbon-carbon composite barrel products can realize uniformity and densification of the blanks, blank demoulding is convenient, machining of seam allowances is not needed, production efficiency is high, and quality of finished products is stable.

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

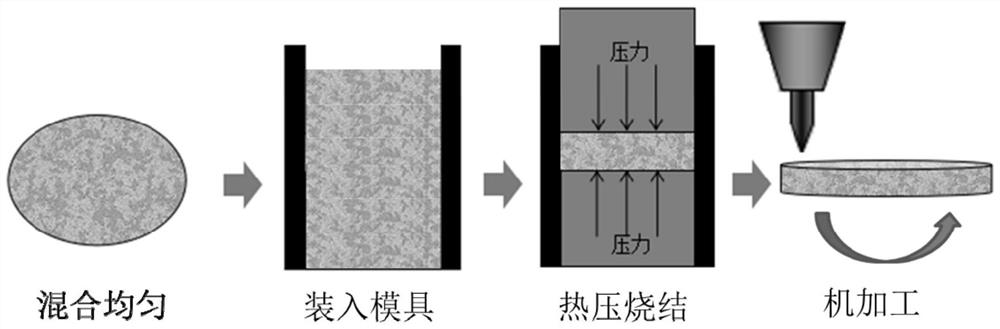

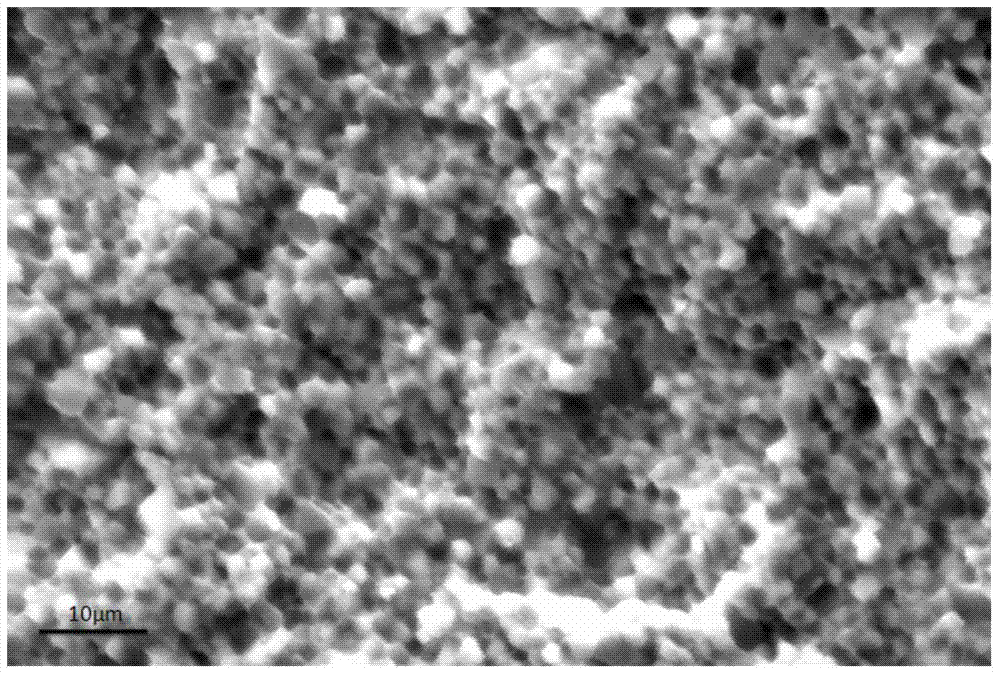

Preparation method of tantalum-silicon alloy sputtering target material

InactiveCN112030120AHigh densityUniform structureVacuum evaporation coatingSputtering coatingSilicon alloyTantalum

The invention relates to a preparation method of a tantalum-silicon alloy sputtering target material. The preparation method comprises the following steps of (1) uniformly mixing tantalum powder and silicon powder; (2) loading into a mold and sealing; (3) carrying out hot pressed sintering treatment on the sealed mold at 1130-1170 DEG C so as to obtain a tantalum-silicon alloy sputtering target crude product; and (4) machining to obtain the tantalum-silicon alloy sputtering target material. According to the preparation method, the tantalum-silicon alloy sputtering target material with the purity and density meeting the requirements can be prepared, the density reaches 99 percent or above, energy consumption and cost can be reduced, and the preparation method is suitable for large-scale popularization.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

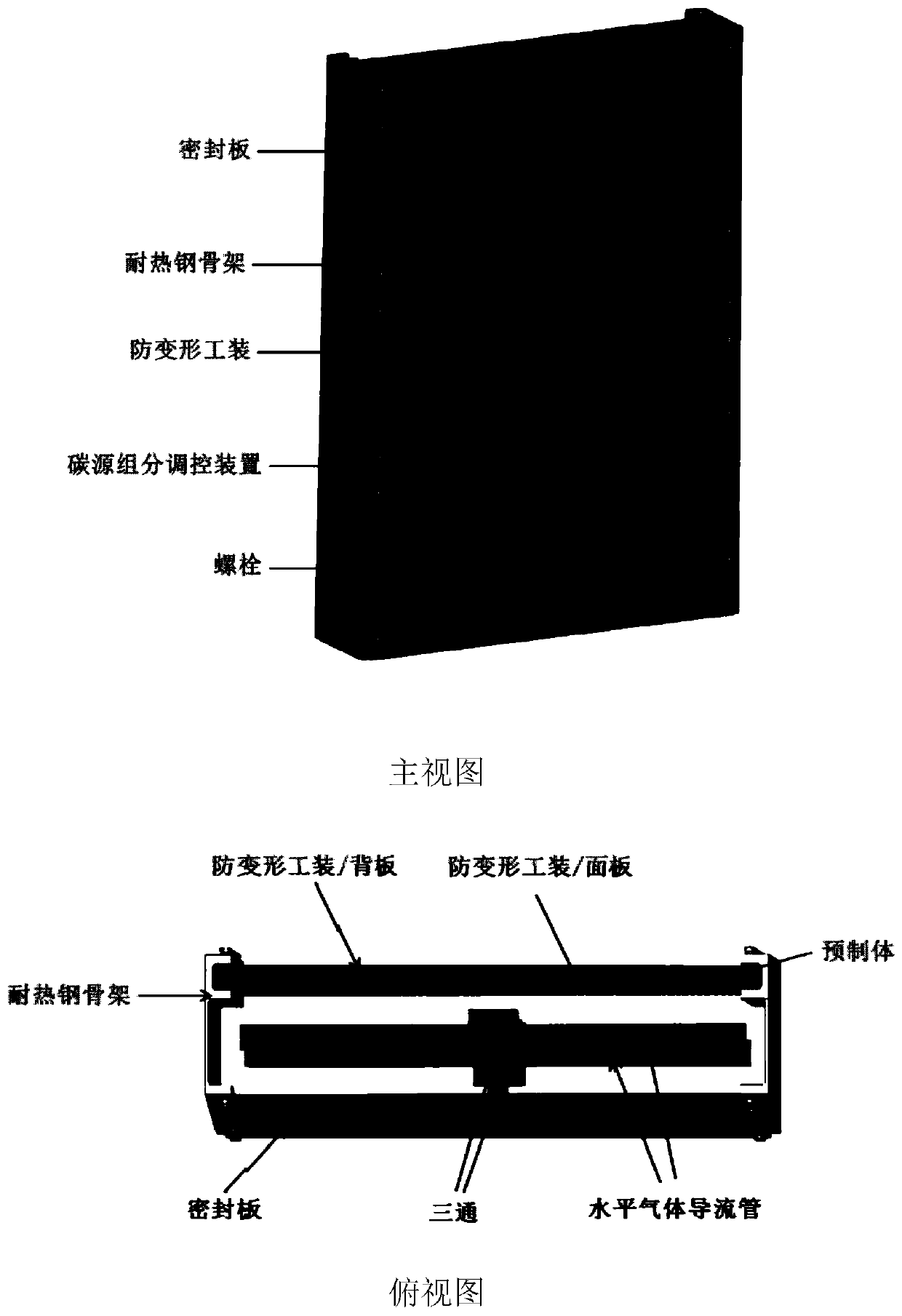

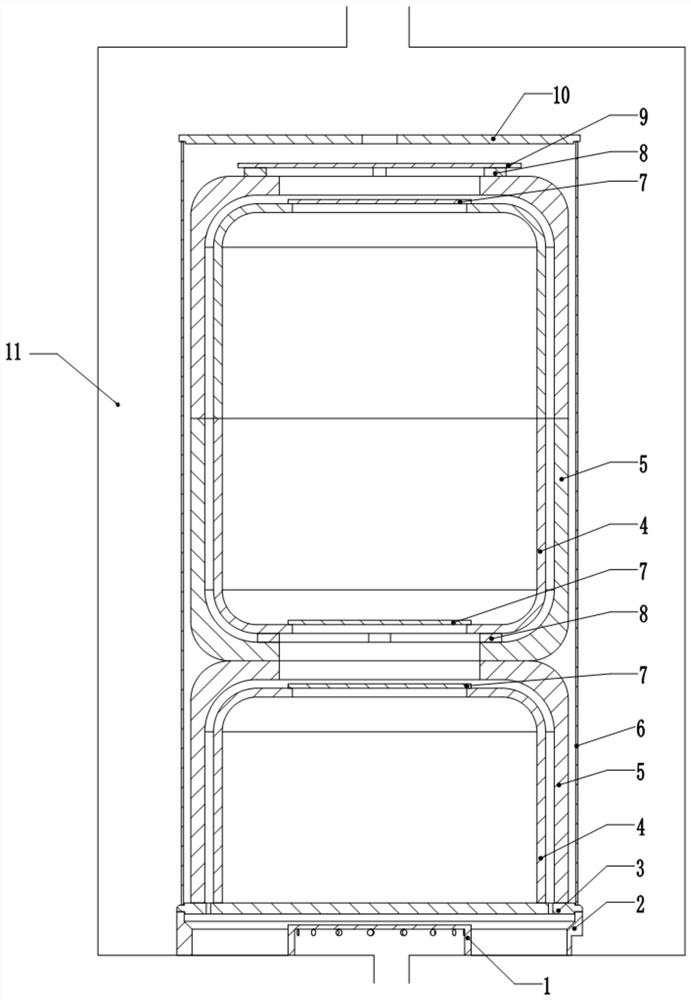

Ultra-large-size carbon/carbon composite material sheet and equipment for preparing the same

PendingCN111574237AReduce distortionAchieve near net shapeChemical vapor deposition coatingCarbon compositesCarbon fibers

The invention discloses a super-large-size carbon / carbon composite material sheet and equipment for preparing the same. The invention discloses a super-large-size carbon / carbon composite material sheet. A preparation method of the super-large-size carbon / carbon composite material sheet comprises the following steps: (1) designing and constructing a reactor; (2) clamping and loading a carbon fiberpreform; (3) performing carbon source component regulation and flow field control setting; (4) performing chemical vapor deposition densification; and (5) discharging and dismounting the tool. The invention further designs equipment matched with the process, the super-large-size carbon / carbon composite sheet with high straightness, uniform densification and small deformation can be obtained through cooperation of the equipment and the process, and a feasible method is provided for near-net forming preparation of the super-large-size carbon / carbon composite sheet.

Owner:CENT SOUTH UNIV

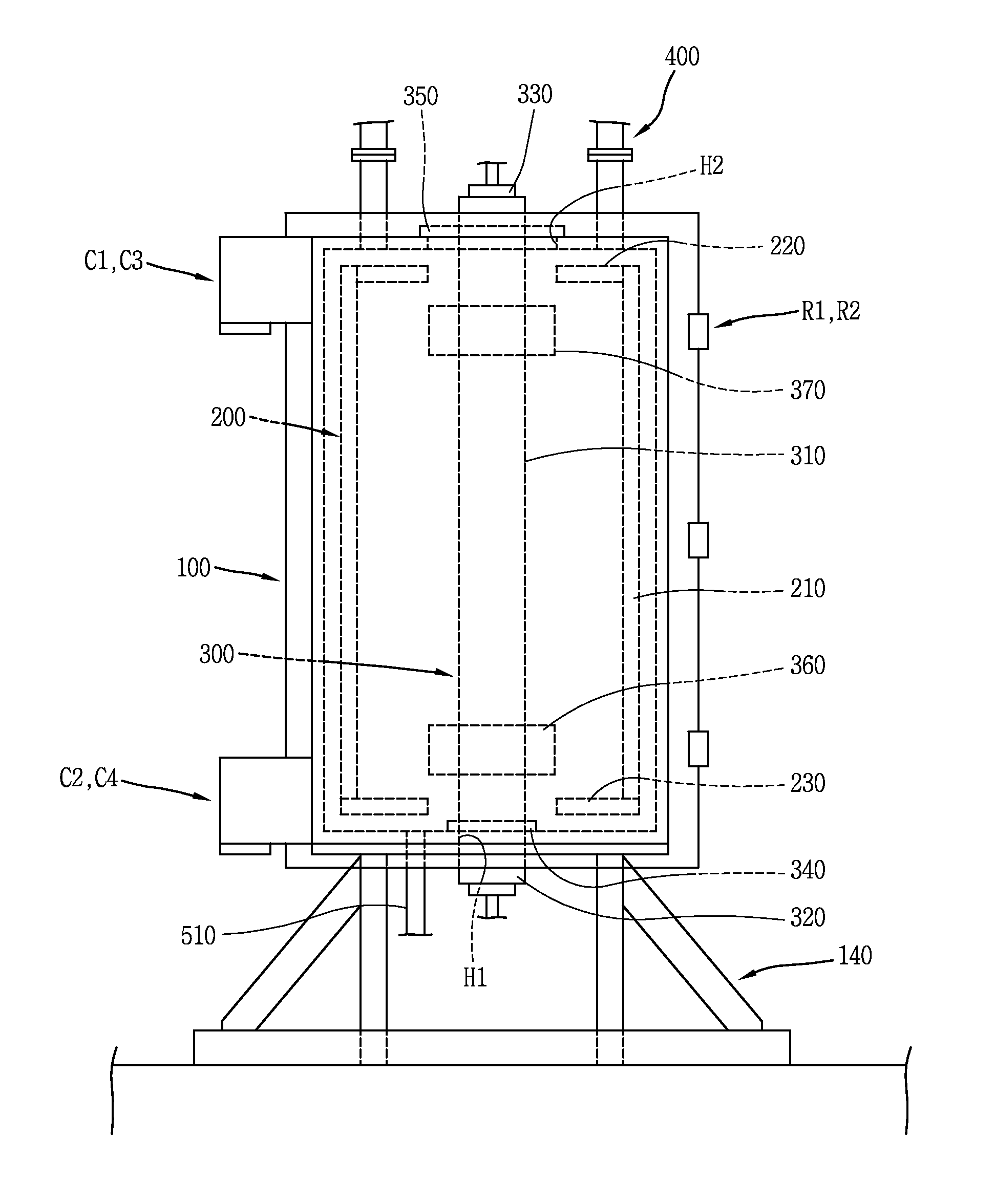

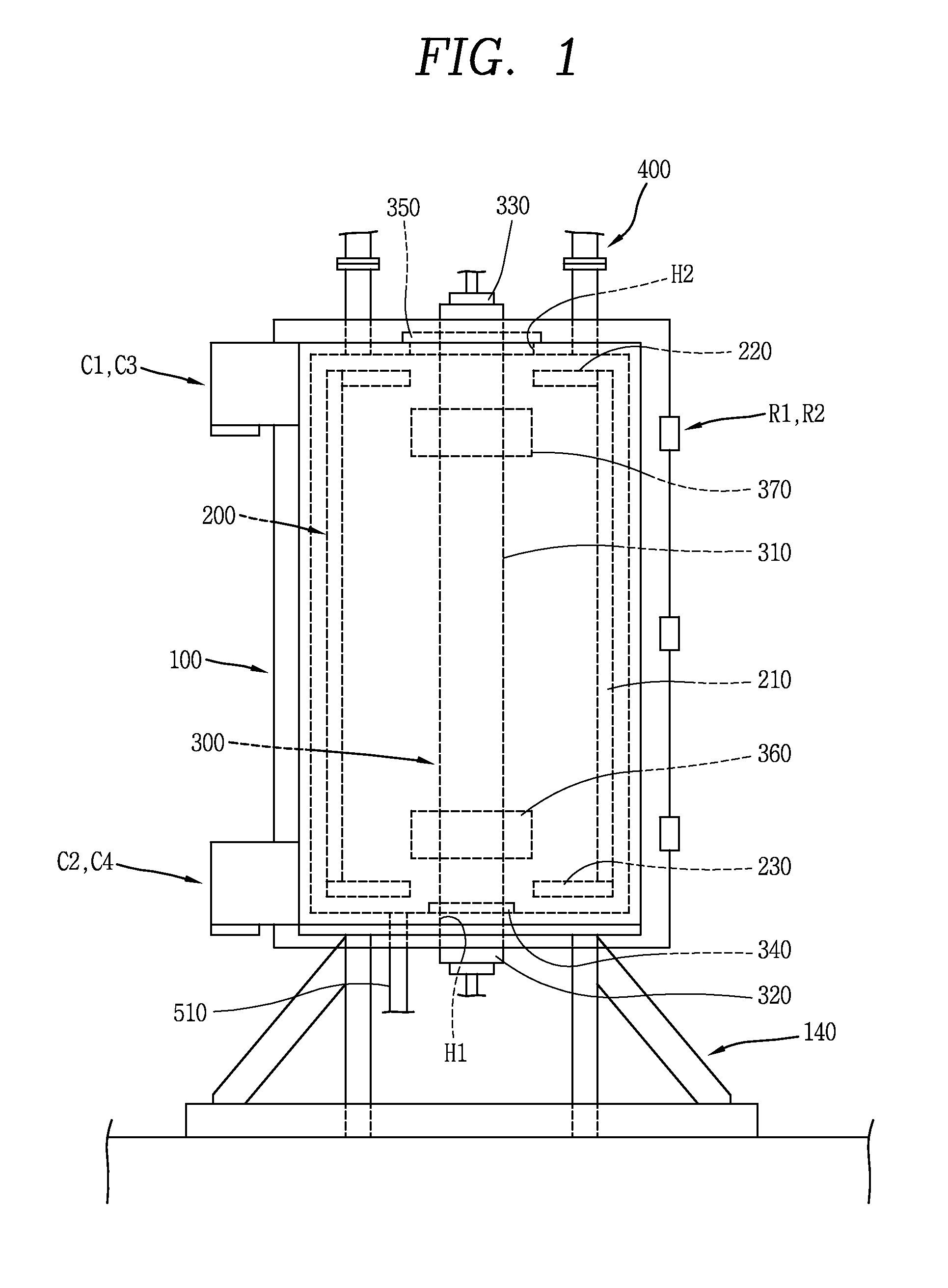

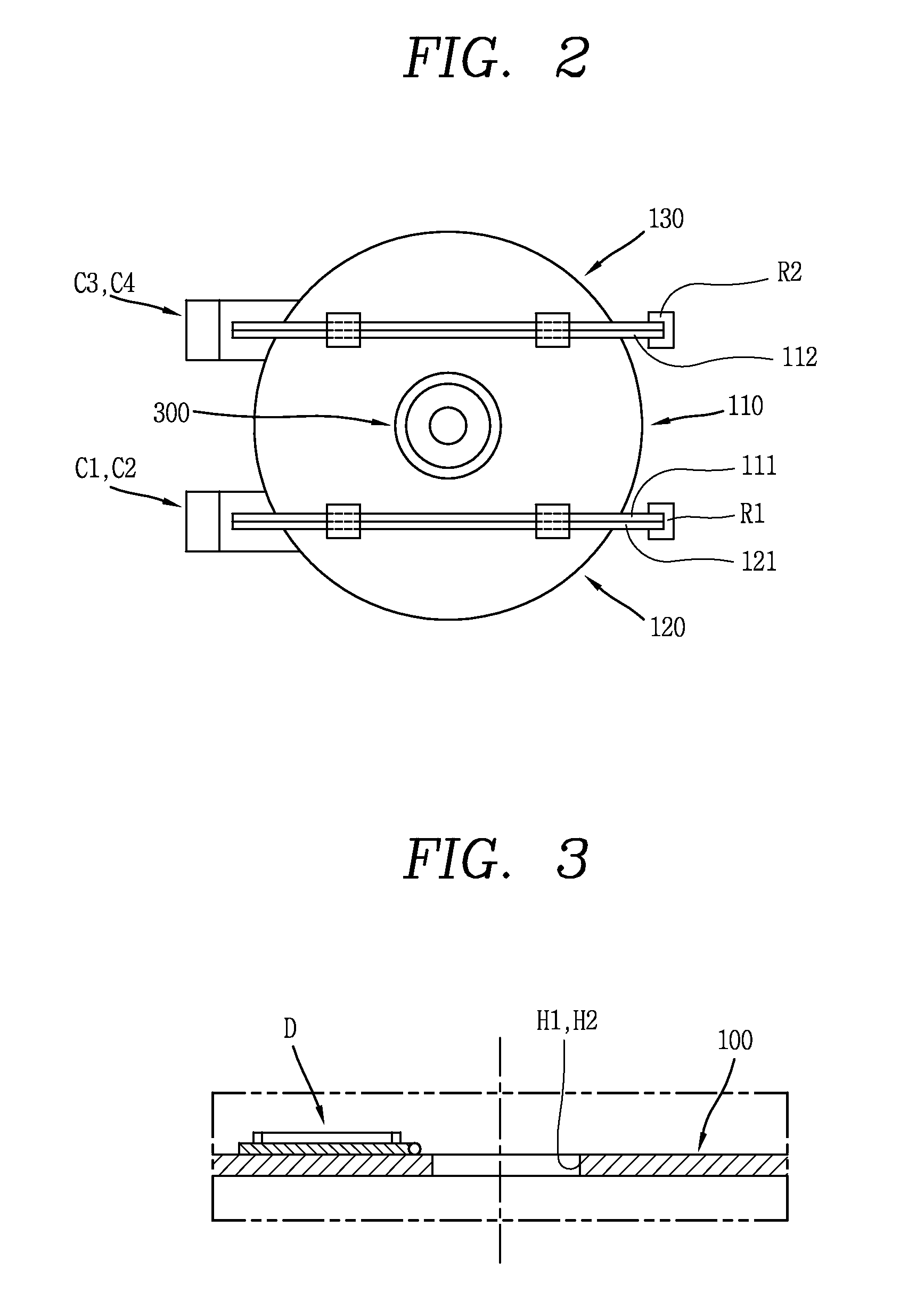

Apparatus for densifying carbon/carbon composite material

InactiveUS20150240362A1Minimize energy consumptionShorten the timeChemical vapor deposition coatingCarbon compositesEngineering

A densifying apparatus including: a reaction chamber; a fixed heater is disposed close to the inner wall of the reaction chamber and generating heat; a detachable heater detachably coupled to the reaction chamber and generating heat; and a gas supply unit supplying a gas into the reaction chamber. It is possible to minimize energy consumption when densifying a small amount of preforms or a large amount of preforms and uniformly densify disc preforms having the shape of a thick ring. Further, it is possible to reduce time to density those preforms.

Owner:DACC CARBON

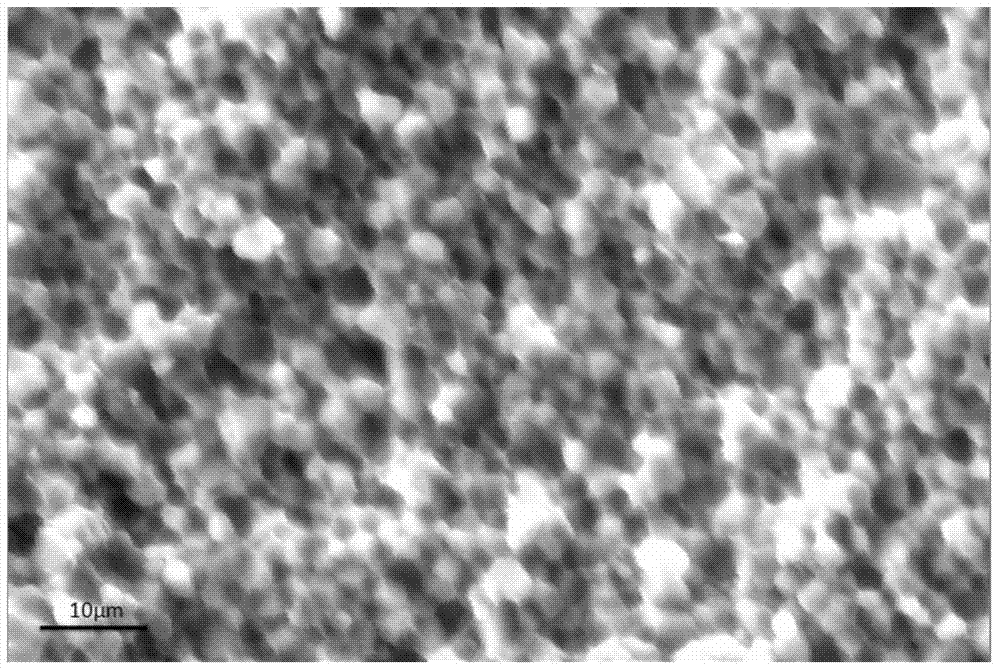

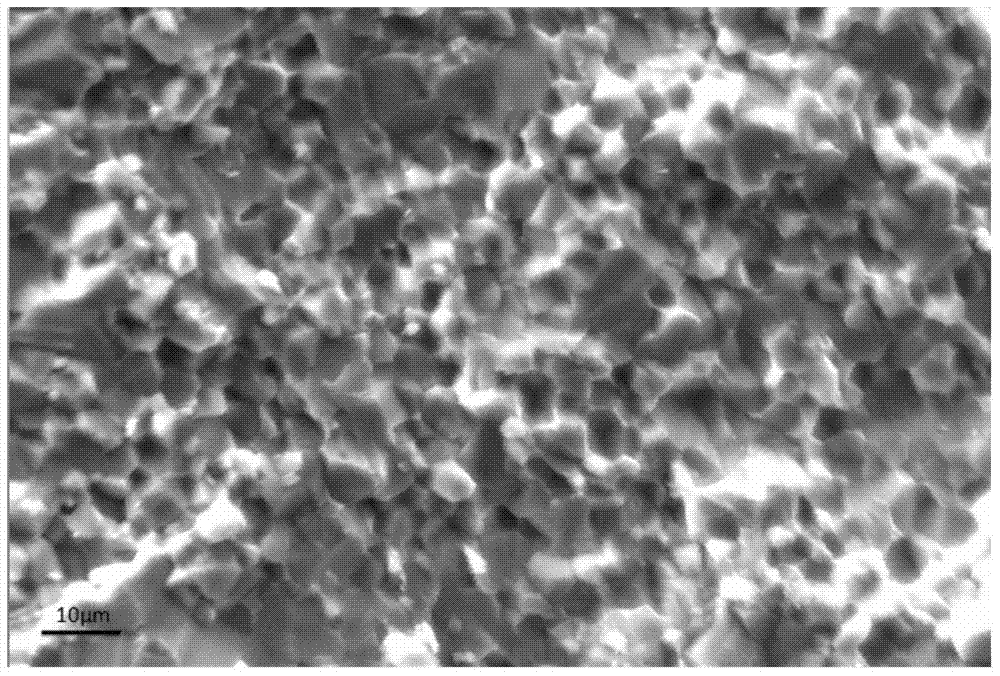

Semiconductor molybdenum target material and preparation method and application thereof

ActiveCN111850495AUniform densificationReduced pre-sintering processFinal product manufactureVacuum evaporation coatingSemiconductorIntegrated circuit

The invention relates to a semiconductor molybdenum target material and a preparation method and application thereof. The preparation method comprises the steps of high-purity molybdenum powder screening and die filling, cold isostatic pressing, sintering, hot-rolling and annealing which are performed sequentially, and then the semiconductor target material is prepared and obtained, wherein a stage temperature rise sintering method is adopted for sintering, the temperature rise rate is gradually decreased at the temperature rise stage of 20-1,500 DEG C, and the temperature rise rate is gradually increased at the temperature rise stage of 1,500-1,900 DEG C. According to the preparation method, a pre-sintering process is omitted; by adopting the stage temperature rise sintering mode and controlling the changing trend of the temperature rise rate, a molybdenum target blank is more uniform and compact, the total impurity content is further reduced, and therefore the molybdenum target material with grain <=40 microns, purity >=99.97% and a uniform internal structure without internal defects is obtained and can be applied to a semiconductor integrated circuit.

Owner:宁波江丰钨钼材料有限公司

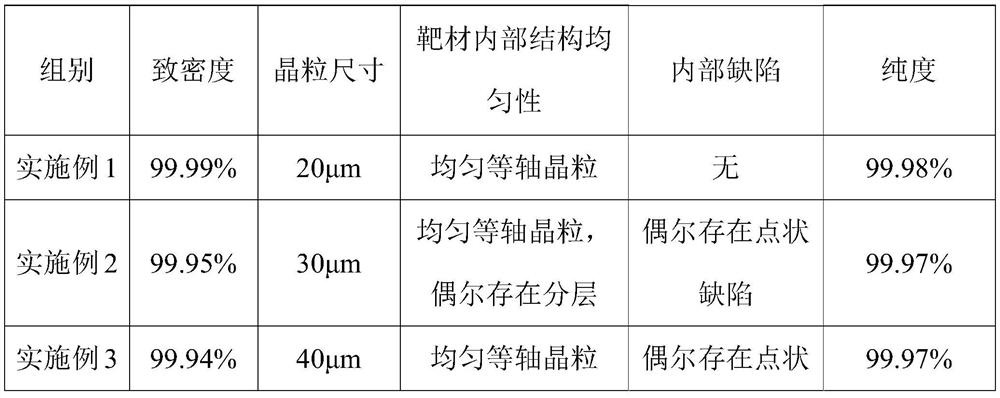

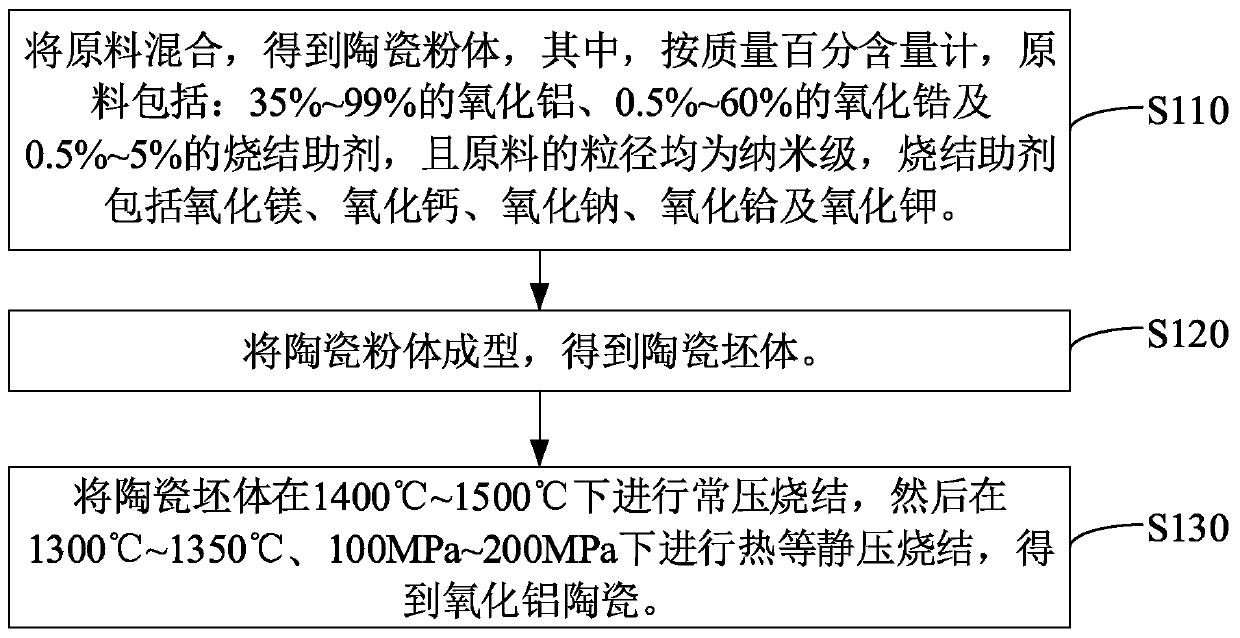

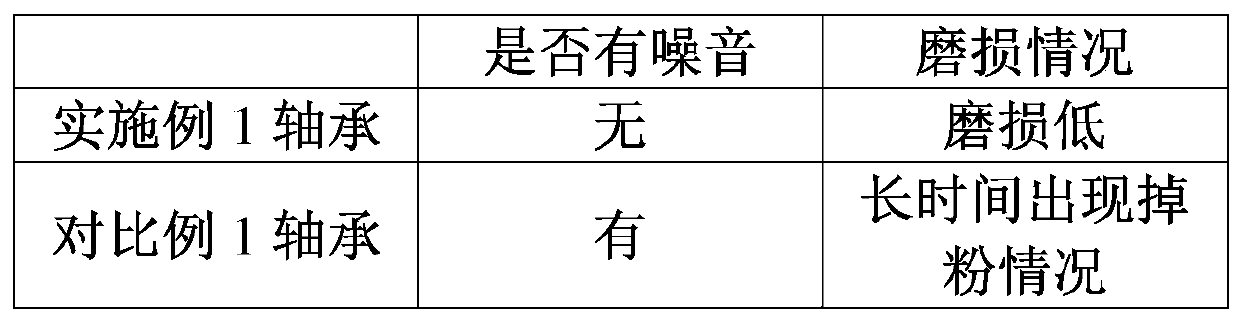

Alumina ceramic, preparation method thereof and ceramic bearing

InactiveCN111302777AImprove mechanical propertiesImprove fracture toughnessRolling contact bearingsSliding contact bearingsOxide ceramicAluminium oxides

The invention relates to aluminum oxide ceramic, a preparation method thereof and a ceramic bearing. The preparation method of the aluminum oxide ceramic comprises the following steps: mixing the following raw materials in percentage by mass: 35%-99% of aluminum oxide, 0.5%-60% of zirconium oxide and 0.5%-5.0% of a sintering aid to obtain ceramic powder, wherein the particle sizes of the raw materials are nanoscale, and the sintering aid comprises magnesium oxide, calcium oxide, sodium oxide, hafnium oxide and potassium oxide, molding the ceramic powder to obtain a ceramic green body, carryingout normal pressure sintering on the ceramic green body at 1400-1500 DEG C, and then carrying out hot isostatic pressing sintering at 1300-1350 DEG C under 100-200 MPa to obtain the aluminum oxide ceramic. The preparation method of the aluminum oxide ceramic can be used for breaking the aluminum oxide ceramic with relatively high toughness.

Owner:SHENZHEN SUNTECH ADVANCED CERAMICS

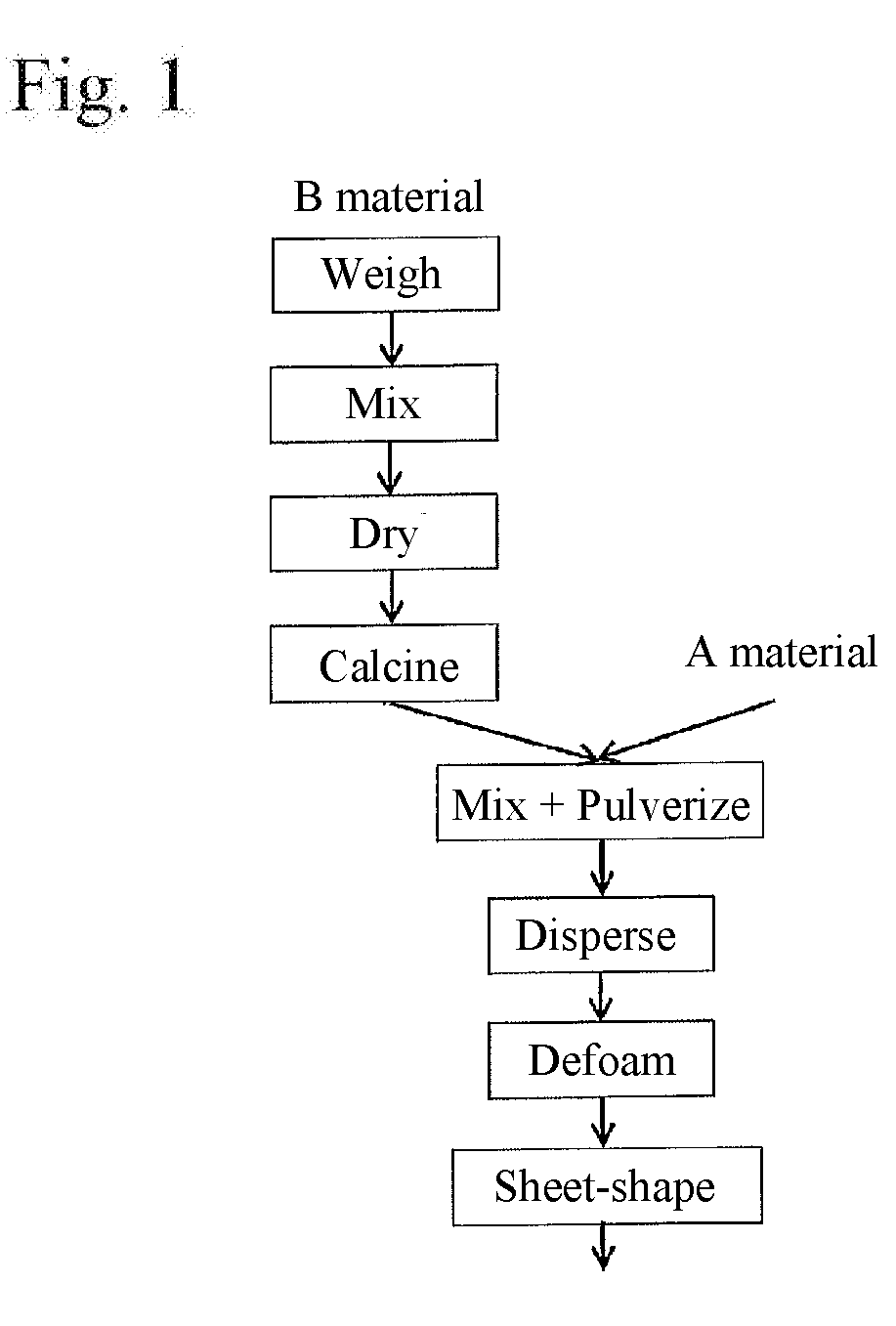

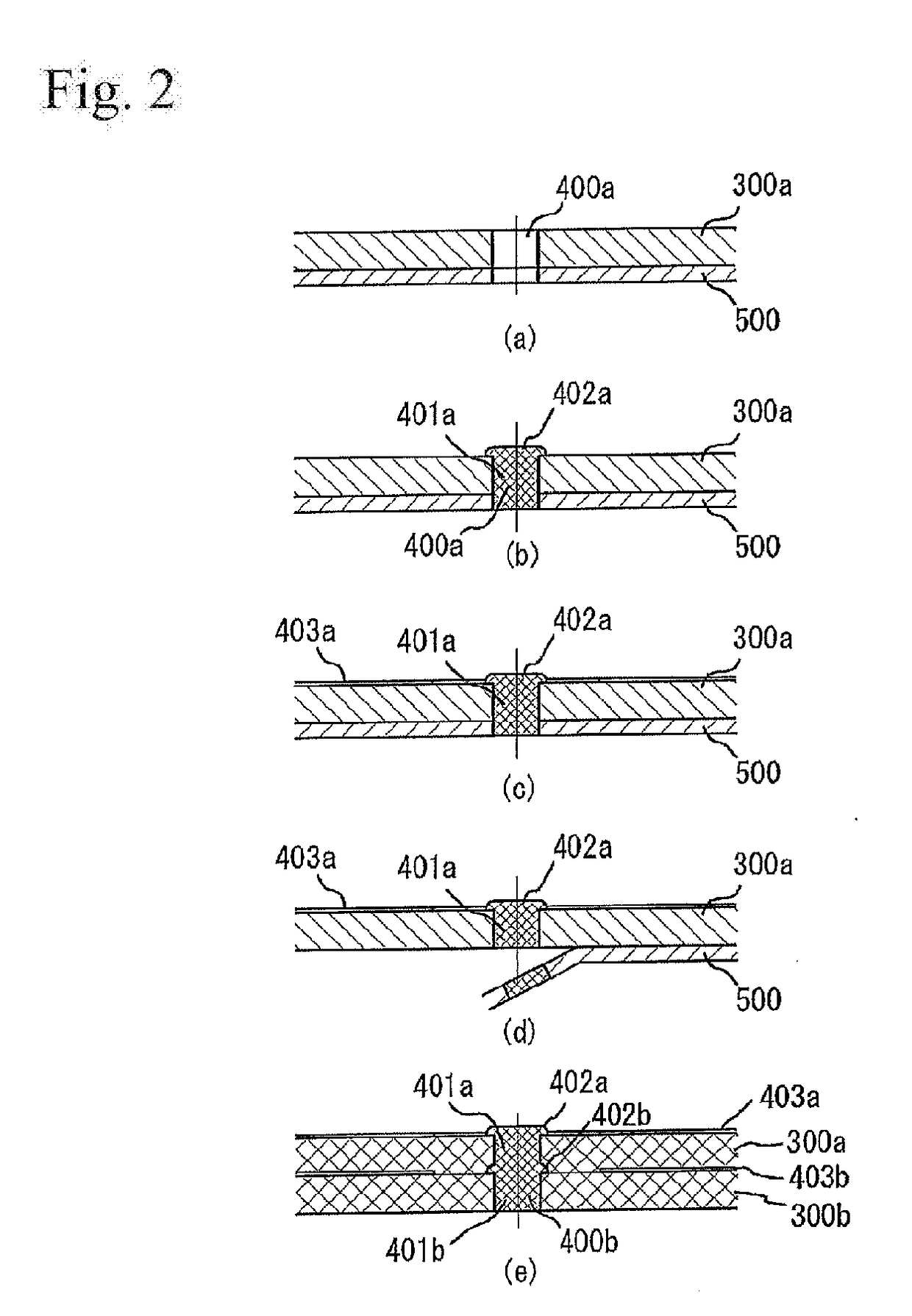

Method for producing dielectric ceramic, and dielectric ceramic

ActiveUS20180222800A1Densification of the microstructure is uniformly attainedVariationCeramicsCeramic layered productsDielectricVitrification

A method for producing a dielectric ceramic includes: shaping mixed powdery particles including a cordierite material (2MgO.2Al2O3.5SiO2) and a low-temperature-sintering material including Al, Si and Sr, the Si being partially vitrified; and firing the resultant shaped body. The method includes the step of wet-pulverizing the low-temperature-sintering material together with at least the cordierite material to prepare mixed powder particles having a median diameter D50 less than 1 μm; and, in a process until a time of the preparation of the mixed powder particles, the low-temperature-sintering material undergoes no step of wet-pulverizing only the low-temperature-sintering material, and drying the resultant pulverized material.

Owner:HITACHI METALS LTD

Preparation method of AlN ceramic base plate for microelectronic packaging

InactiveCN103539457AGuaranteed compositional uniformityGuaranteed uniformityCeramic sinteringCompression molding

Owner:HEFEI UNIV OF TECH +1

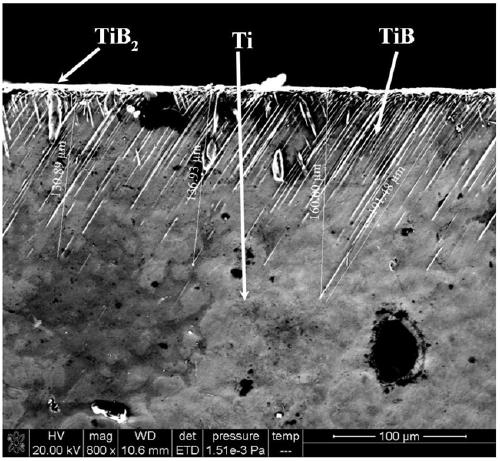

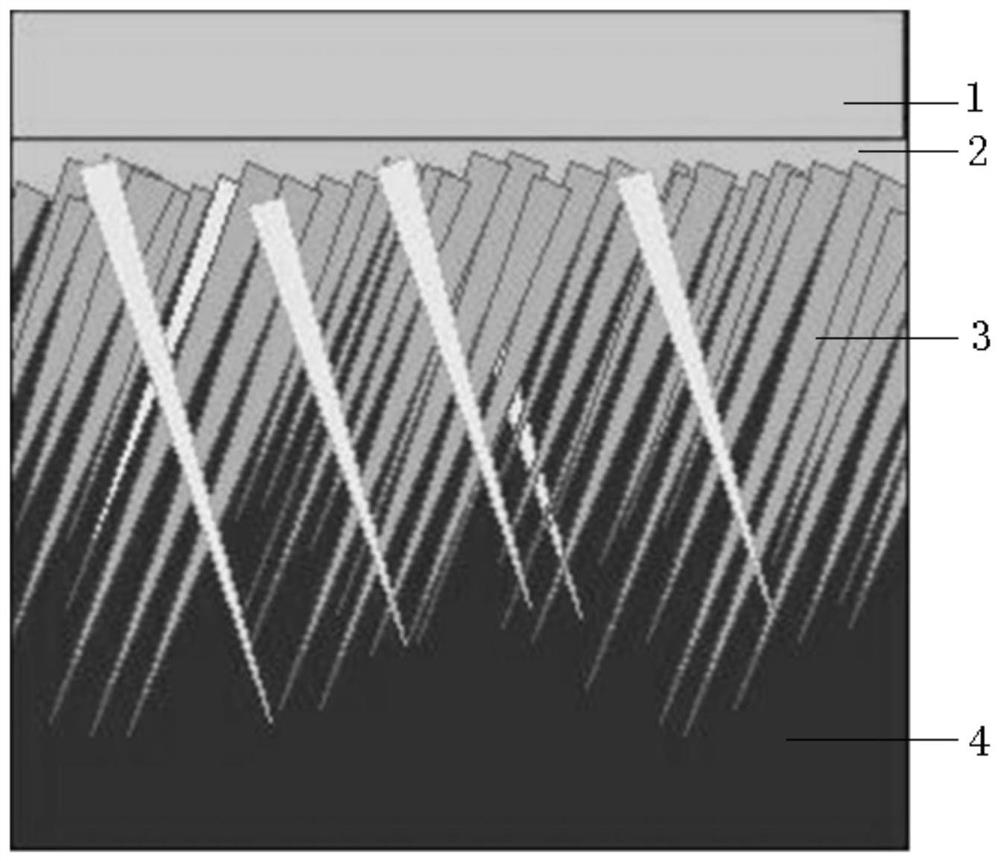

Titanium based cathode material with uniform and dense TiB2 layer and preparation method of titanium based cathode material

ActiveCN109695044AImprove the bonding force between layersPrevent corrosionSurface reaction electrolytic coatingAluminum electrolysisTitanium

The invention provides a titanium based cathode material with a uniform and dense TiB2 layer and a preparation method of titanium based cathode material, and belongs to the technical field of cathodematerial preparation. The preparation method comprises the following steps that (1) a titanium substrate with the surface being completely treated is subjected to boronizing treatment, a boronizing agent is prepared from anhydrous borax, anhydrous potassium carbonate and B4C, a graphite crucible serves as an anode, a metal titanium plate serves as a cathode, and thus a TiB2-TiB / Ti gradient composite material is obtained; (2) the surface of the TiB2-TiB / Ti gradient composite material is completely cleaned; and (3) the completely treated composite material is subjected to TiB2 molten salt electrode position, and the TiB2-TiB / Ti gradient composite material with the surface electrodeposited with a TiB2 cladding material is obtained. According to the preparation method, the cathode TiB2-TiB / Tigradient composite material for aluminum electrolysis with the uniform and dense TiB2 outermost layer can be obtained, the TiB2 layer is thickened at the same time, and the service life of the cathodematerial is prolonged.

Owner:GUANGXI NORMAL UNIV

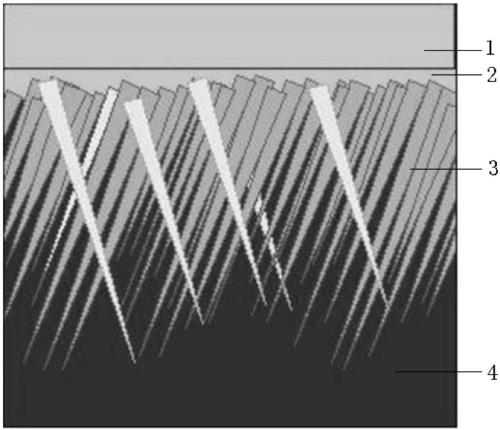

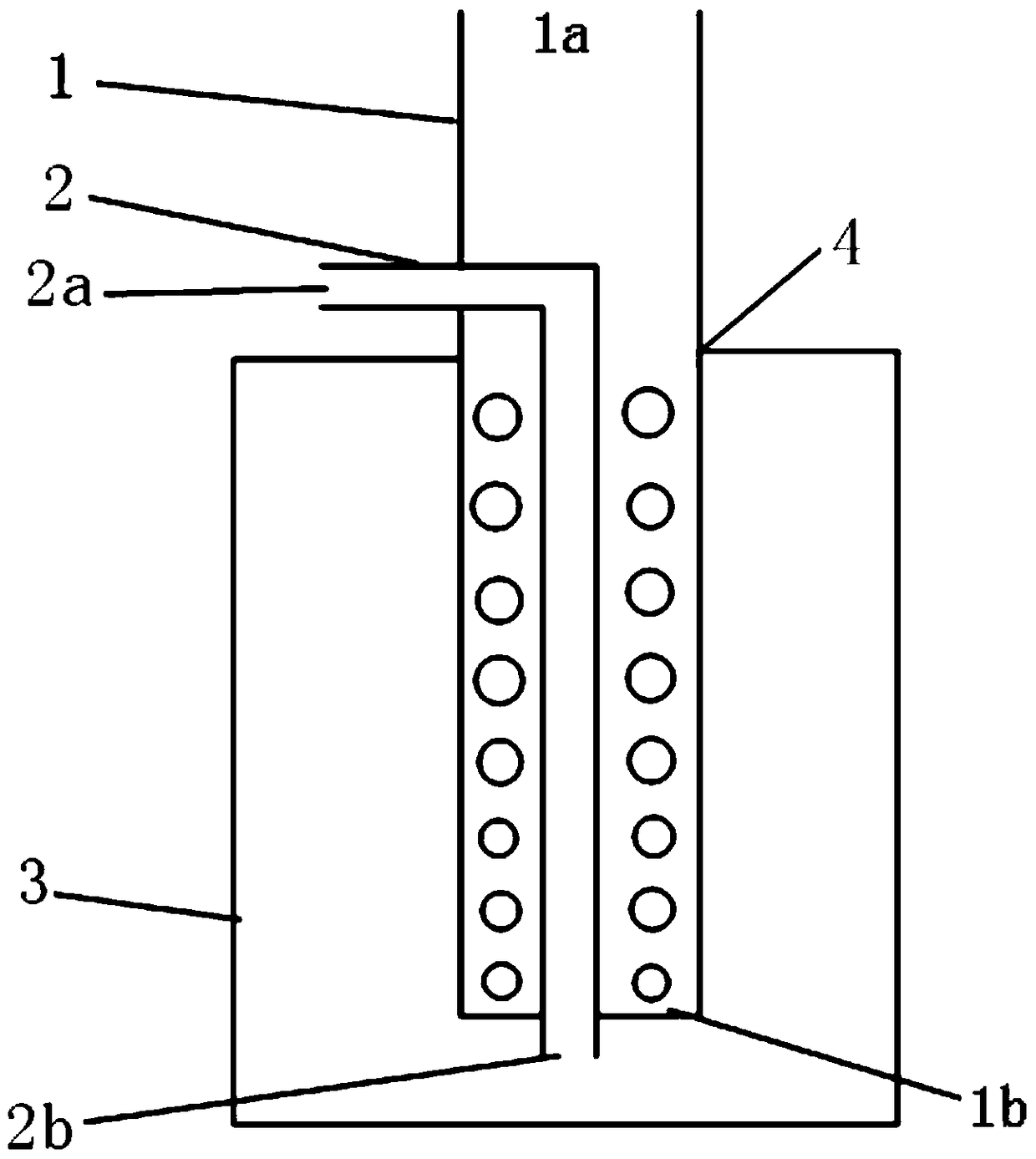

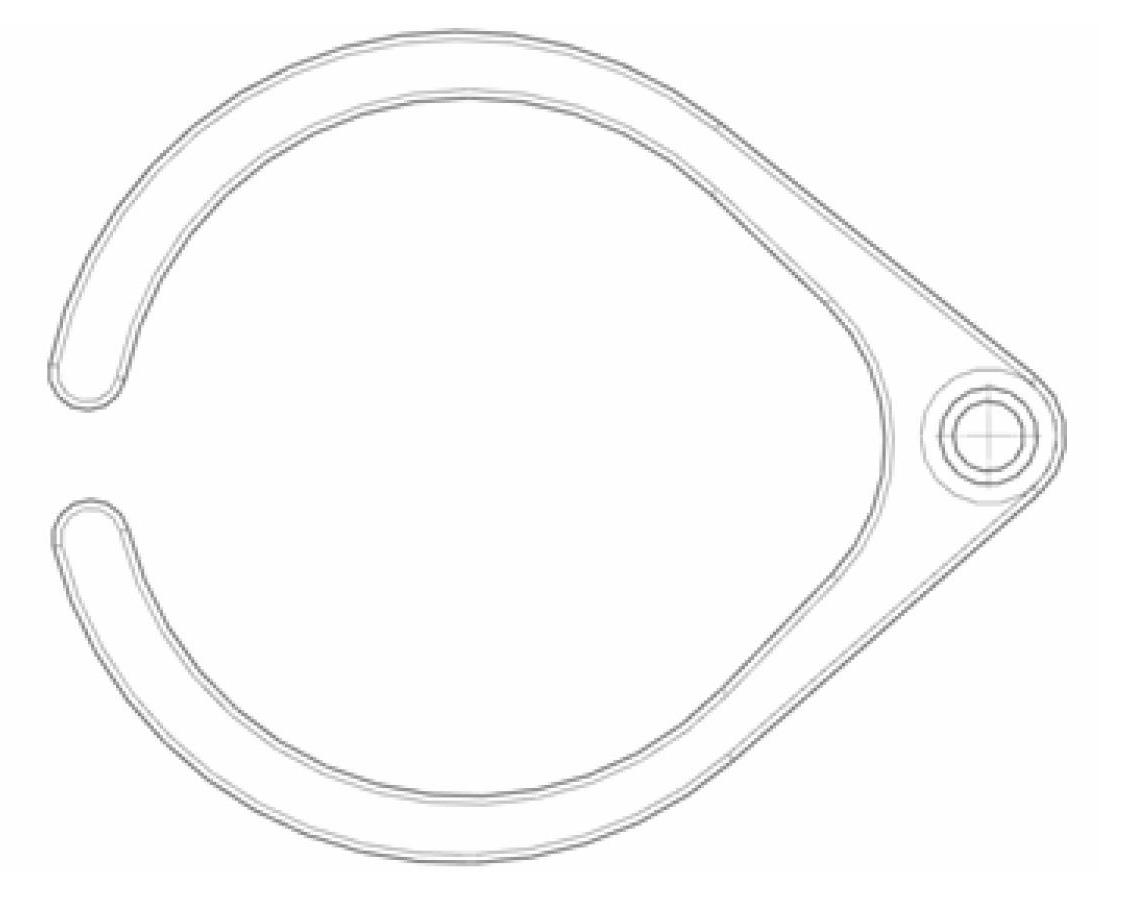

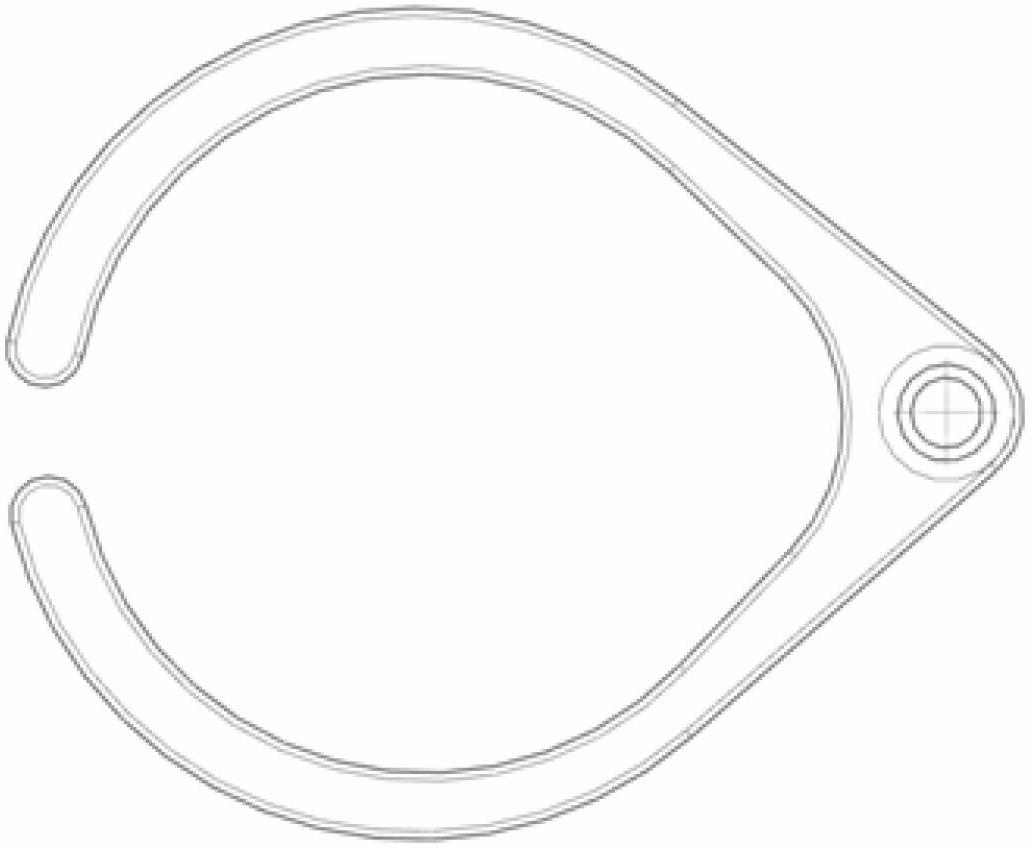

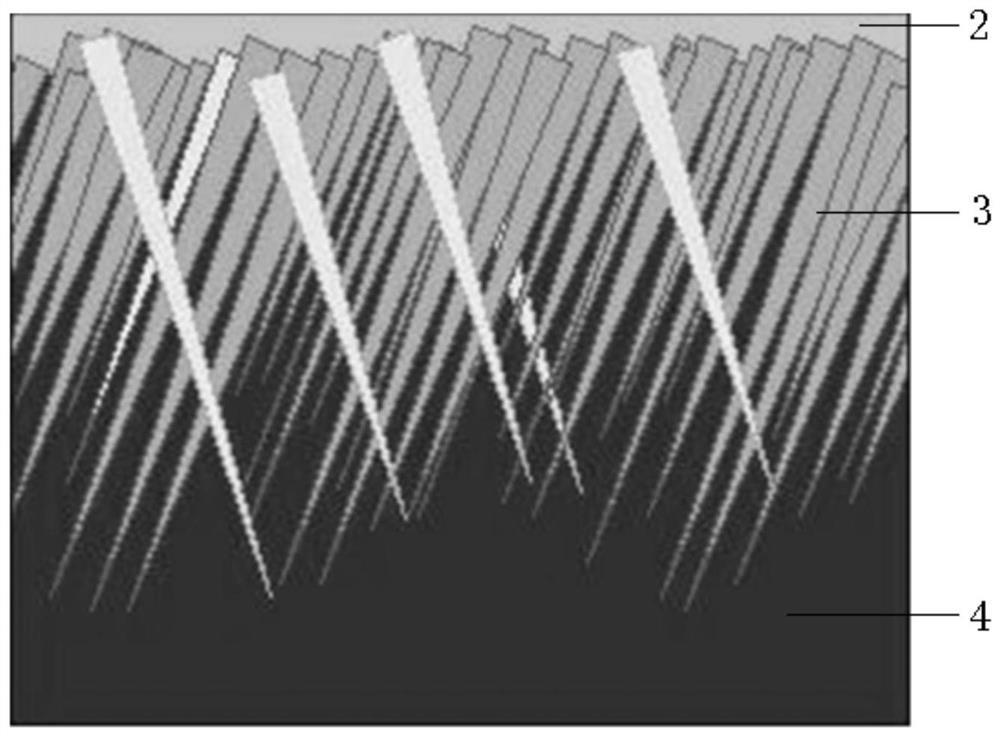

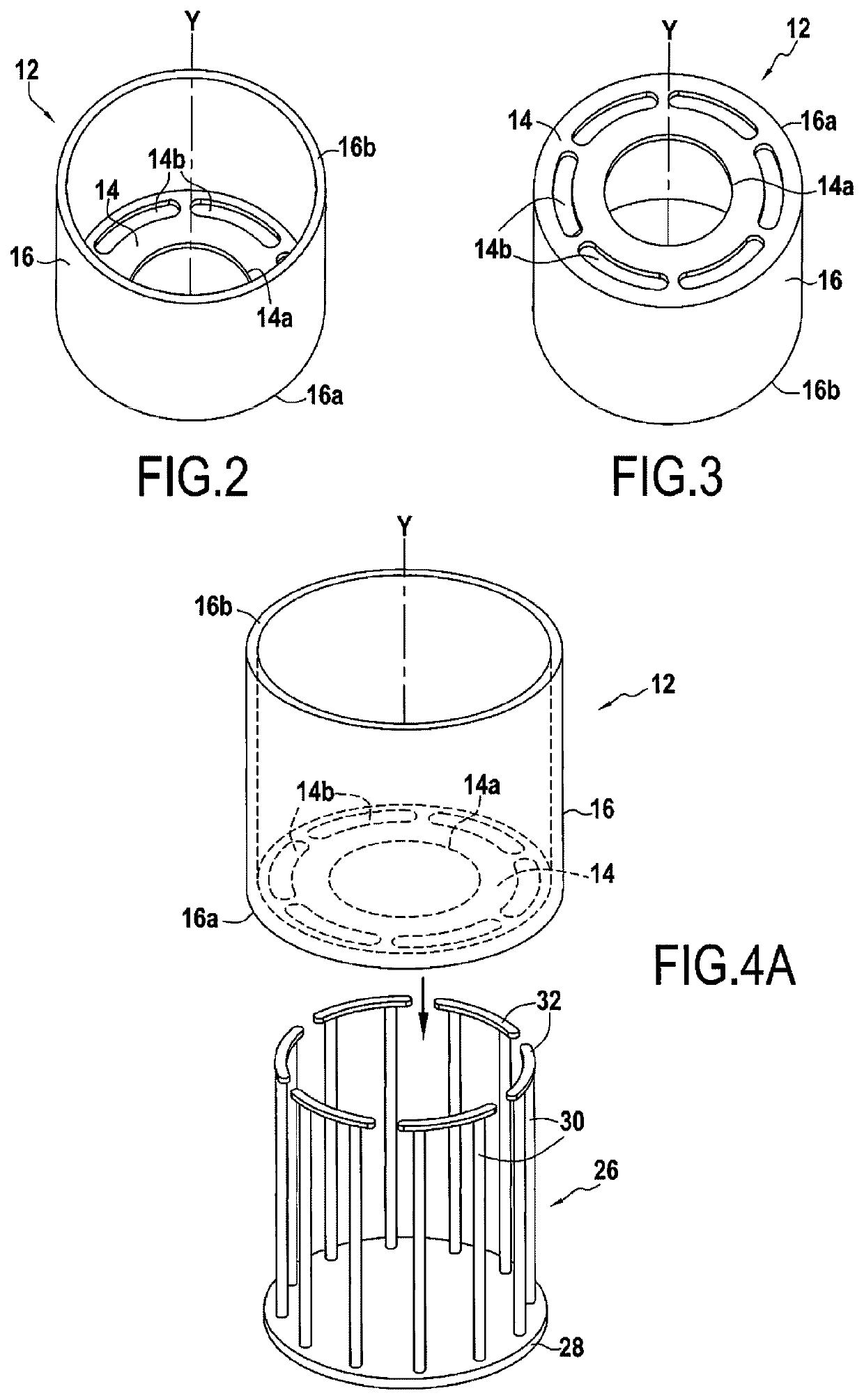

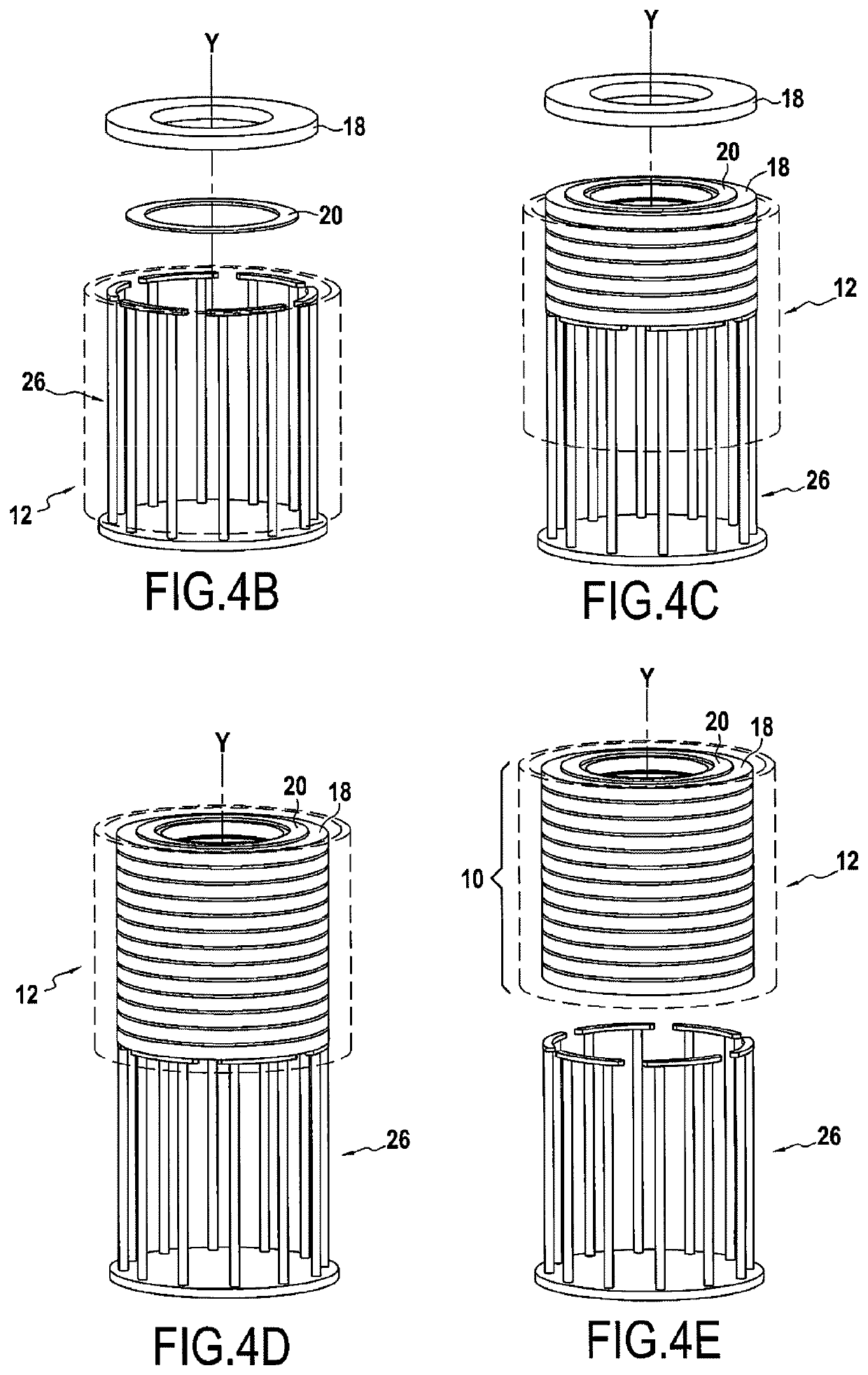

Device for Loading Porous Substrates of Three-Dimensional Shape in Order to be Densified by Directed Flow Chemical Vapor Infiltration

ActiveUS20150075428A1Increase load capacityMinimizing densification gradientChemical vapor deposition coatingPorous substrateGas phase

A loader device for loading porous substrates of three-dimensional shapes extending mainly in a longitudinal direction into a reaction chamber of an infiltration oven for densification of the preforms by directed flow chemical vapor infiltration. The device comprising at least one annular loader stage formed by first and second annular vertical walls arranged coaxially relative to each other and defining between them an annular loader space for the porous substrates to be densified. First and second plates respectively cover the bottom portion and the top portion of the annular loader space. The first and second annular vertical walls include support elements arranged in the annular loader space so as to define between them unit loader cells, each for receiving a respective substrate to be densified. The device also comprises gas feed orifices and gas exhaust orifices in the vicinity of each unit loader cell.

Owner:SAFRAN CERAMICS SA

Carbon/carbon composite material as well as preparation method and application thereof

PendingCN112225577AImprove high temperature oxidation resistanceImprove mechanical propertiesCarbon compositesCarbon deposition

The invention relates to a carbon / carbon composite material as well as a preparation method and application thereof. The preparation method of the carbon / carbon composite material comprises the following steps: sequentially carrying out carbon deposition and silicon carbide deposition on a carbon fiber preform by adopting a chemical vapor deposition method to obtain a silicon carbide-containing carbon / carbon composite rough blank, dipping the carbon / carbon composite rough blank in a molybdenum source solution, baking the carbon / carbon composite rough blank, carrying out reduction reaction in areducing atmosphere to obtain a carbon / carbon composite precursor containing elemental molybdenum, and finally, carrying out melt siliconizing treatment on the carbon / carbon composite precursor to obtain the carbon / carbon composite material containing silicon carbide and molybdenum silicide. The internal components of the carbon / carbon composite material prepared by the preparation method are uniform and stable, the difference between the internal and external layer components is small, the difference between the internal thermal expansion coefficients of the material is small, and the carbon / carbon composite material has excellent high-temperature oxidation resistance and mechanical properties.

Owner:HUNAN KINGBO CARBON CARBON COMPOSITES CO LTD

Method for producing synthetic quartz glass

ActiveUS8973407B2Uniform densificationEasy to produceMaterial analysis by optical meansGlass shaping apparatusOctamethylcyclotetrasiloxaneSoot

A method for producing synthetic quartz glass comprises providing a liquid SiO2 feedstock material containing mainly octamethylcyclotetrasiloxane D4, vaporizing the SiO2 feedstock material into a feedstock vapor, converting the feedstock vapor into SiO2 particles, depositing the SiO2 particles on a deposition surface while forming a porous SiO2 soot body, and vitrifying the SiO2 soot body while forming the synthetic quartz glass. To produce large-volume cylindrical soot bodies with outer diameters of more than 300 mm of improved material homogeneity, the liquid feedstock material contains additional components comprising hexamethylcyclotrisiloxane D3 and its linear homolog with a weight fraction mD3, dodecamethylcyclohexasiloxane D6 and its linear homolog with a weight fraction mD6, and tetradecamethylcycloheptasiloxane D7 and / or hexadecamethylcyclooctasiloxane D8 and its linear homologs with a weight fraction mD7+. The weight ratio mD3 / mD6 is in a range between 0.5 and 500 and the weight fraction mD7+ is at least 20 wt. ppm.

Owner:HERAEUS QUARZGLAS

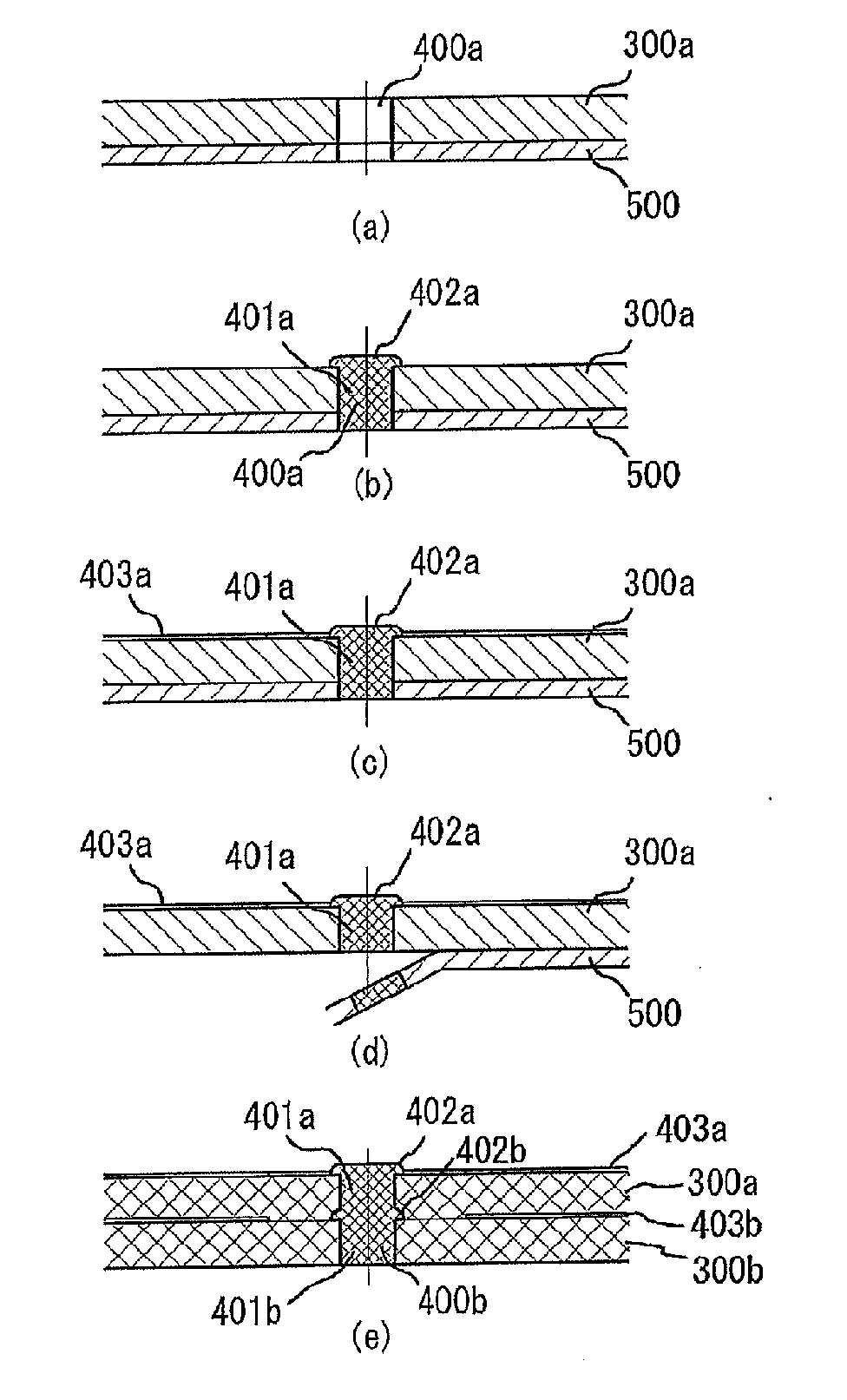

A method for CVI densification of an open container and a gas pipeline structure

ActiveCN105463410BIncrease deposition rateImprove deposition qualityChemical vapor deposition coatingExhaust pipeVacuum pump

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

Method for preparing suspension arm with stage

ActiveCN102689351AUniform densificationConsistent density uniformityCeramic shaping apparatusMaterials scienceDry pressing

The invention relates to a method for preparing a suspension arm with a stage, which comprises the following steps of: (1) preparing materials by aluminum oxide, dry-pressing and forming the materials by a device having a buffer function to acquire a forming blank body; and (2) performing isostatic cool pressing on the forming blank body, and sintering and refine-machining the forming blank body to acquire the suspension arm with the stage. With the adoption of the method, the dry-pressing and formation problem of a structural member of a stage structure can be solved, so that the production efficiency and the yield are high, the scale production can be realized, the product structure is not abnormally deformed, and the density is over 98 percent; and therefore, the method has good application prospect.

Owner:SHANGHAI COMPANION PRECISION CERAMICS

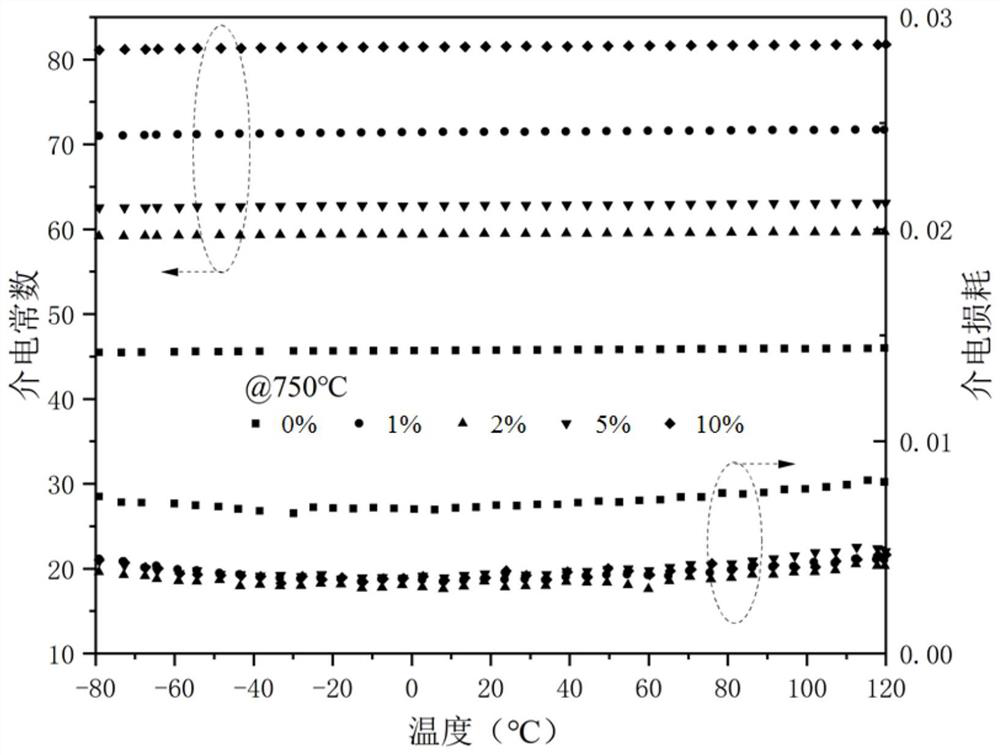

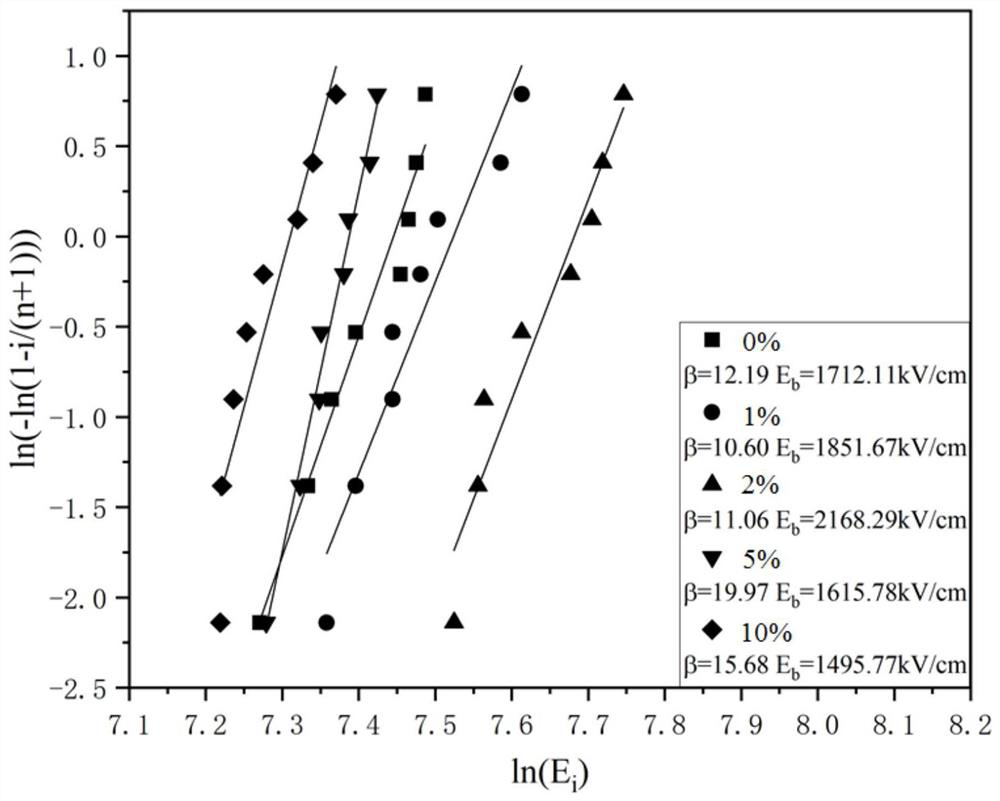

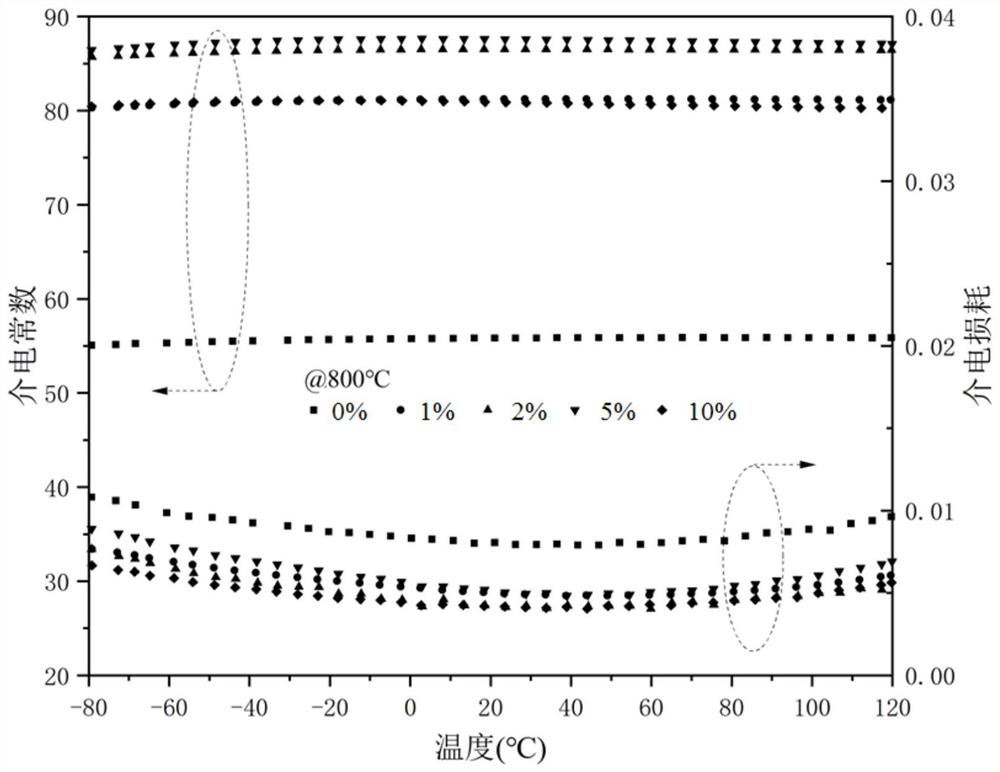

A ta with low dielectric loss 2 o 5 Doped niobate-based glass-ceramic material and its preparation method and application

ActiveCN112390535BHigh dielectric constantHigh breakdown strengthHybrid capacitor separatorsGlass shaping apparatusBreakdown strengthCeramic composite

Owner:TONGJI UNIV

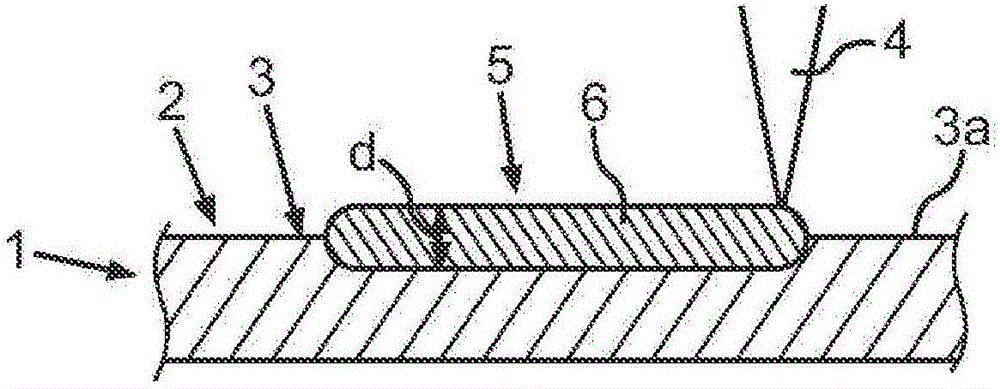

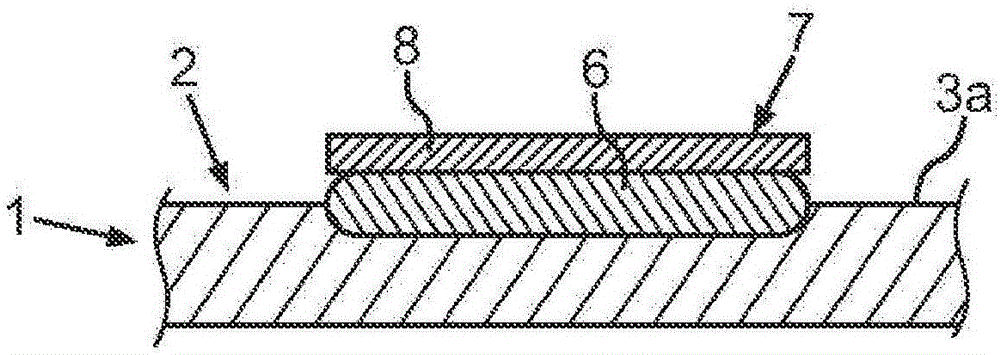

Method for producing a household appliance component as well as household appliance component

ActiveCN106457628AImprove mechanical stabilityReduce scrap rateDecorative surface effectsDuplicating/marking methodsPlastic foamEngineering

The invention relates to a method for producing a household appliance component (1), in which a base part (2) of the household appliance component (1) is provided, which is formed of plastic at least one a top side (3) and a mark (5) is generated with a laser (4) on the top side (3), wherein a plastic foam area (6) is formed on the top side (3) by means of the laser (4) for the mark (5), wherein the plastic foam area (6) is reduced in thickness (d) and / or increased in density afterwards. The invention also relates to a household appliance component (1).

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

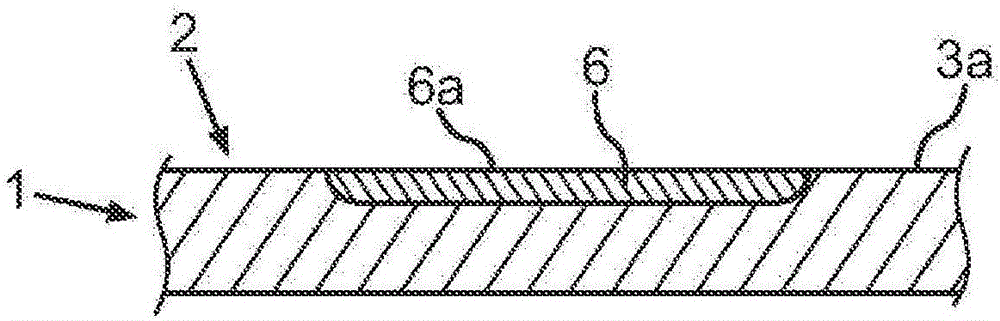

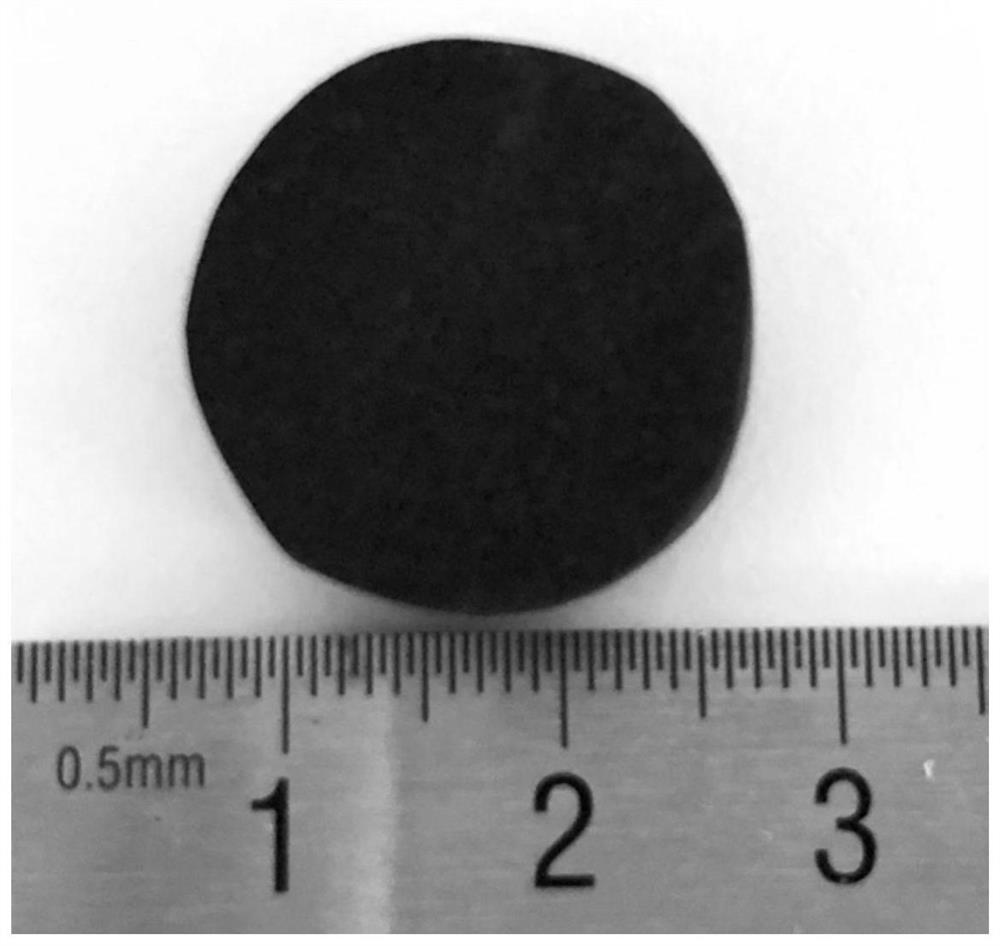

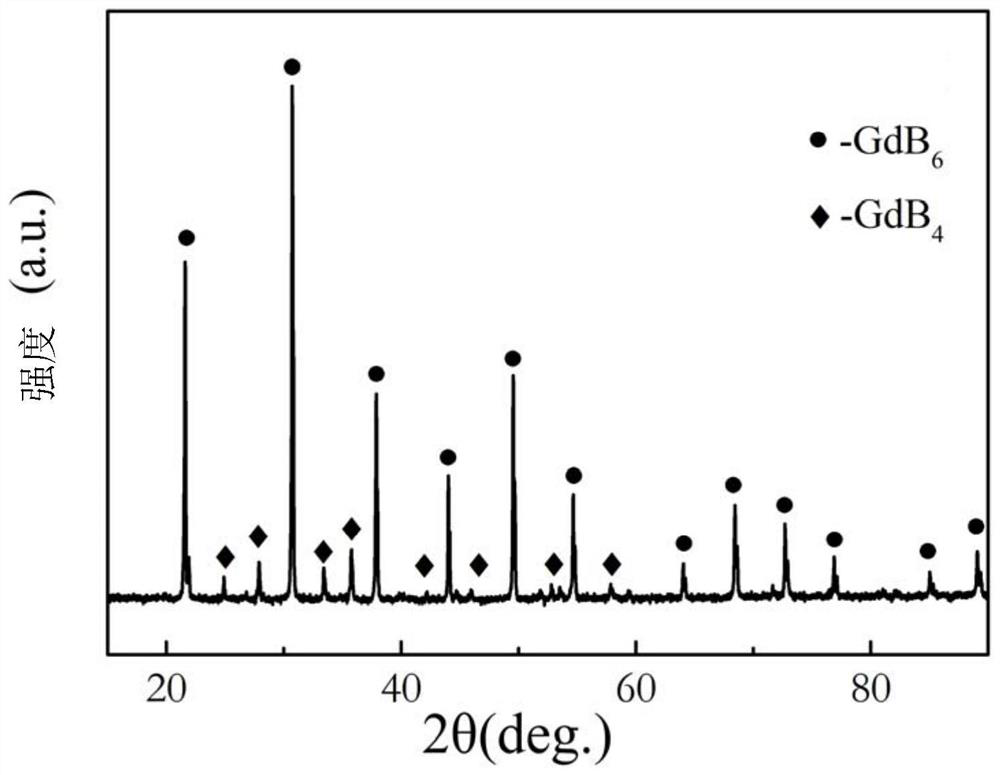

High-purity gadolinium hexaboride polycrystal and preparation method thereof

ActiveCN111793823AHigh sintering activityRapid densificationPolycrystalline material growthFrom solid stateCrystallographyPhysical chemistry

The invention discloses a high-purity gadolinium hexaboride polycrystal and a preparation method thereof. The gadolinium hexaboride polycrystal does not contain gadolinium tetraboride impurities; andpreferably, the density of the gadolinium hexaboride polycrystal exceeds 80%, and the diameter of the gadolinium hexaboride polycrystal is 15 mm or above.

Owner:HEFEI UNIV OF TECH

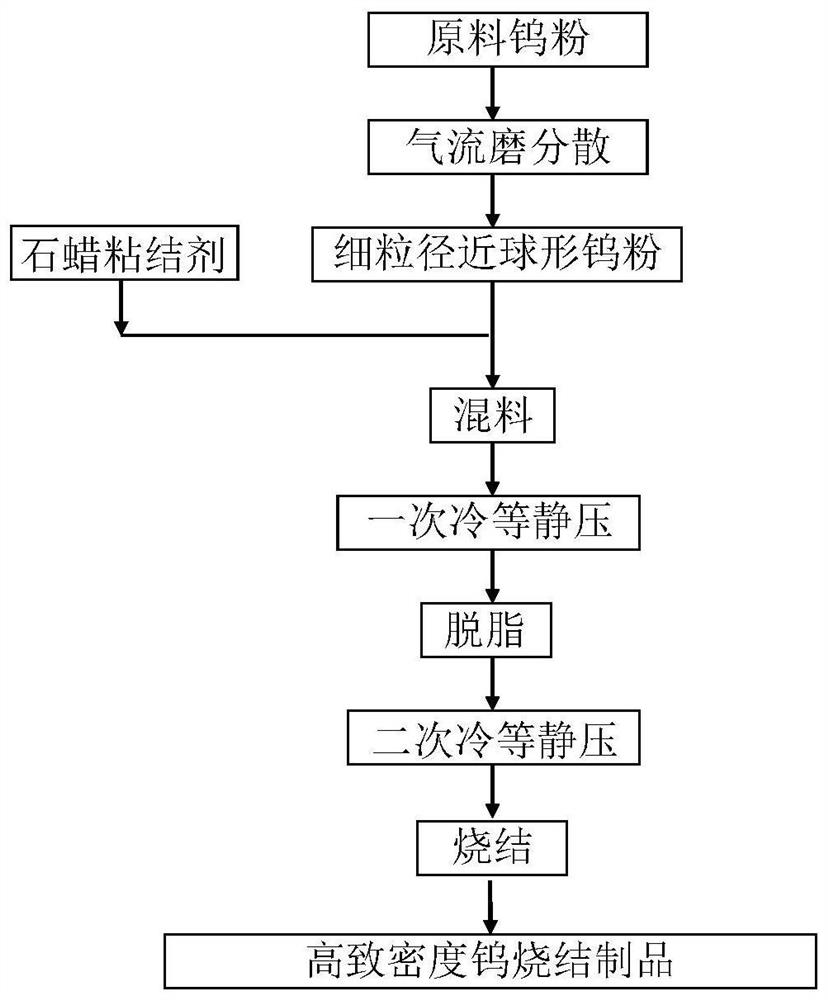

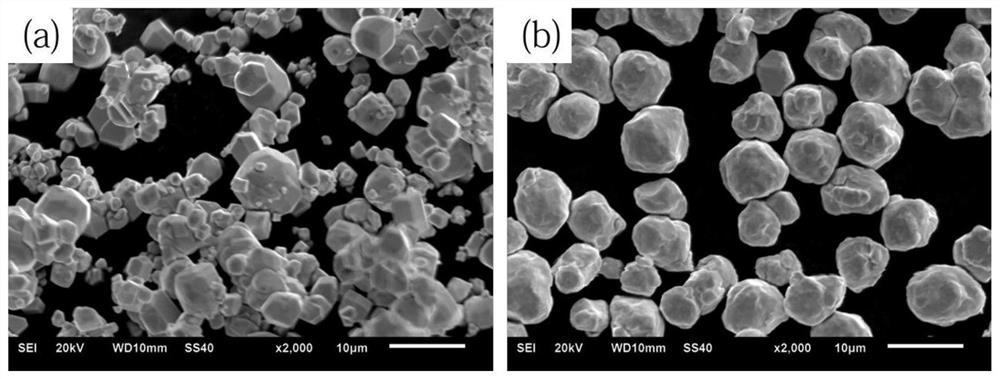

A method for preparing high-density tungsten sintered products

ActiveCN109047780BGood dispersionHigh sintering activityTransportation and packagingMetal-working apparatusParaffin waxCrazing

Owner:UNIV OF SCI & TECH BEIJING

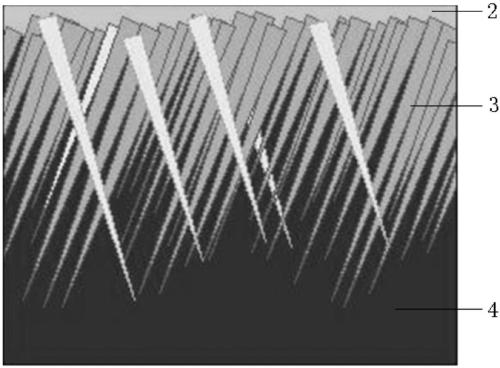

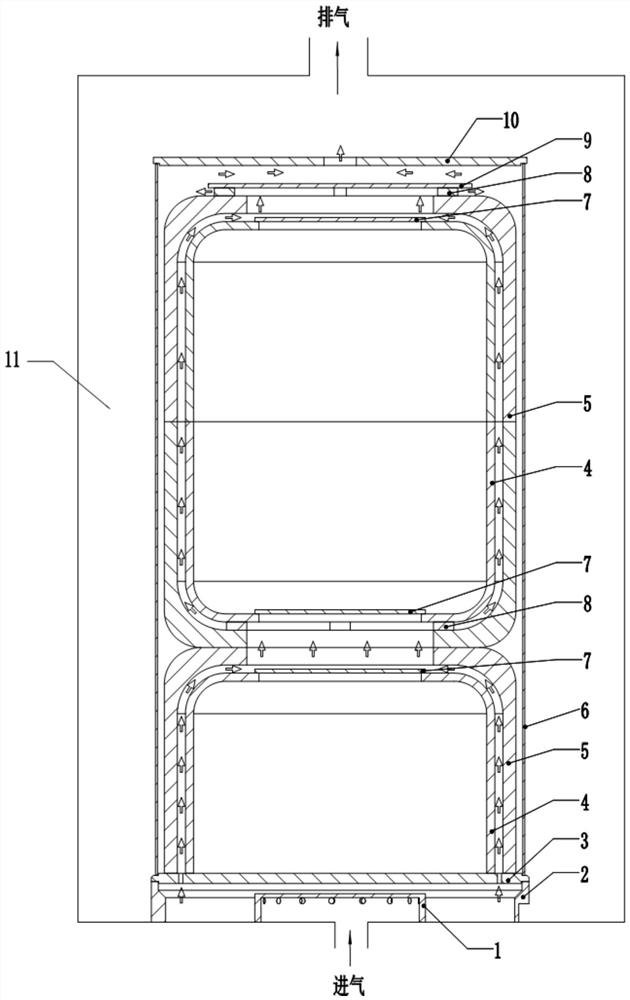

Deposition device for densification of prefabricated body and charging structure

PendingCN114875377AAvoid surface crustingUniform densificationChemical vapor deposition coatingComposite materialCarbon source

The invention relates to the technical field of chemical vapor infiltration of carbon-carbon composite materials, and discloses a deposition device for densification of a preform and a charging structure. A flow limiting channel is formed between the preform to be densified and the side wall of an inner flow limiting cylinder, and an overflowing opening is formed in the top of the preform to be densified; and a flow limiting path which sequentially leads to the flow limiting channel, the overflowing opening and the furnace cavity outlet from the furnace cavity inlet is formed in the furnace cavity. In the deposition process, the temperature of a thermal field in a furnace chamber is gradually reduced from outside to inside, the deposition speed is increased exponentially along with temperature increase, carbon source gas permeates from the inner surface to the outer side with the high temperature for deposition densification, the temperature in the prefabricated body to be densified is continuously increased, and the deposition surface is continuously pushed inwards during deposition; and the whole to-be-densified prefabricated body is completely deposited, so that the surface crusting of the to-be-densified prefabricated body is avoided, and the densification density of the to-be-densified prefabricated body is uniform. In addition, through the flow limiting path, the carbon source gas activity space can be effectively compressed, the active group collision probability is increased, and therefore the deposition efficiency is greatly improved.

Owner:BAOSHAN LONGI SILICON MATERIALS CO LTD

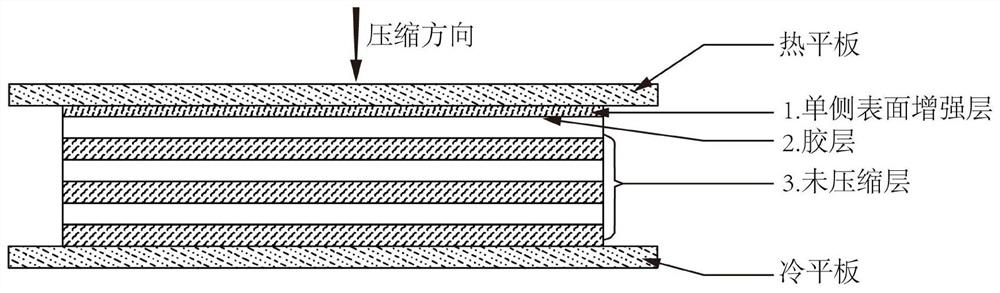

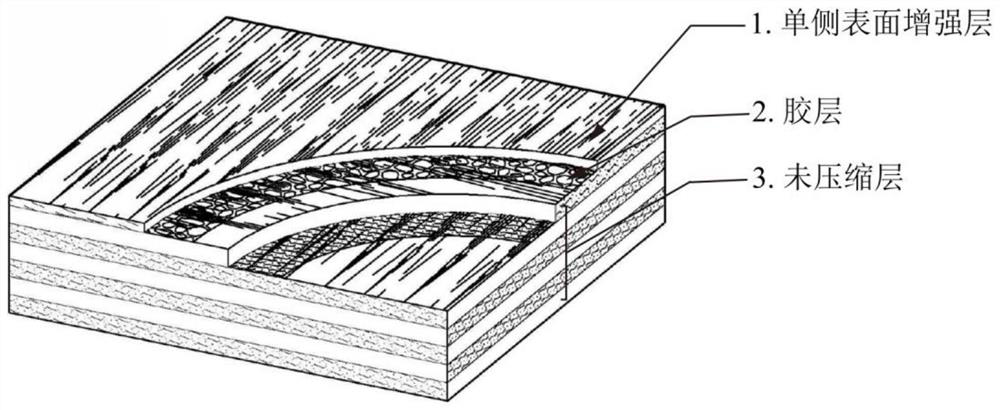

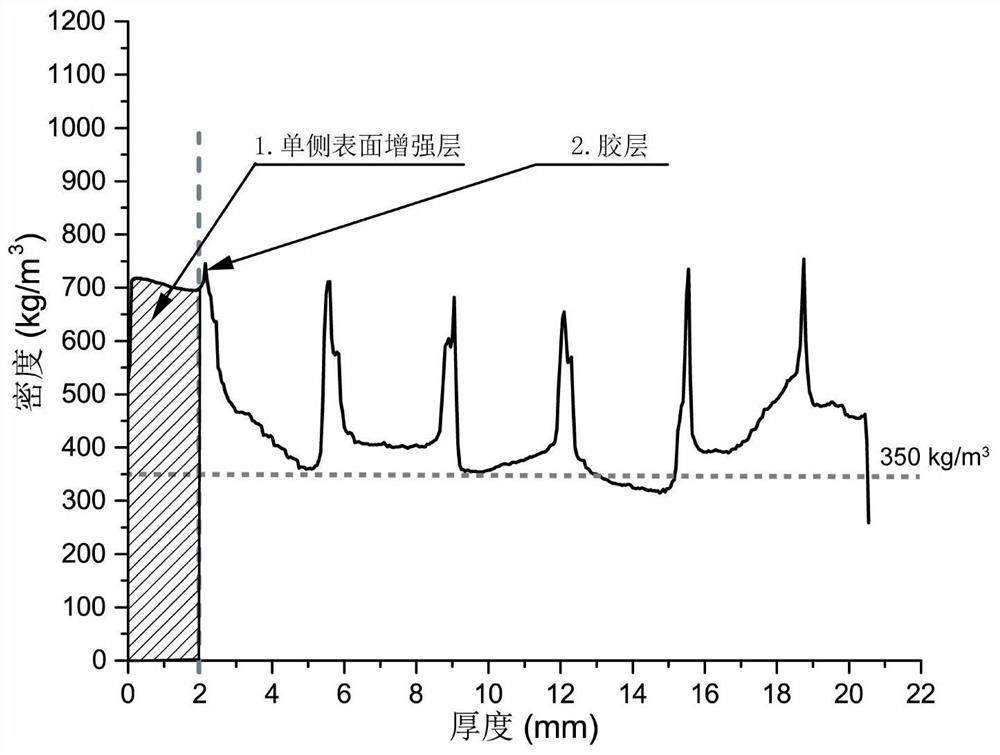

A kind of plywood unilateral surface reinforced profile and its preparation method and application

ActiveCN112476668BHigh densityHigh hardnessPlywood pressesWood treatment detailsSolid woodHigh density

The invention belongs to the technical field of wood decoration material enhancement and modification and wood product production technology, and discloses a single-side surface reinforced profile of plywood and a preparation method and application thereof. The method adopts the water vapor spraying method, the asymmetric heating and hot pressing method, the surface mechanical compression strengthening method and the in-situ pressure-holding drying and fixing method to plasticize, soften, compress and strengthen and dry and shape the single-sided surface layer of the plywood. Plywood single-sided surface reinforcement profile. The method of the invention has the advantages of simple process, low production energy consumption, high production efficiency, large-scale continuous production can be realized, and good economic benefits are reflected. The single-side surface reinforcement layer of the prepared plywood single-side surface reinforcement profile has high density, hardness and good dimensional stability, and the profile can be widely used in solid wood composite floors, wooden furniture, wooden doors, cabinets and other wood products. manufacture.

Owner:SOUTH CHINA AGRI UNIV

A uniform dense tib 2 Layered titanium-based cathode material and preparation method thereof

ActiveCN109695044BIncreasing the thicknessAvoid corrosionSurface reaction electrolytic coatingAluminium electrolysisTitanium

Owner:GUANGXI NORMAL UNIV

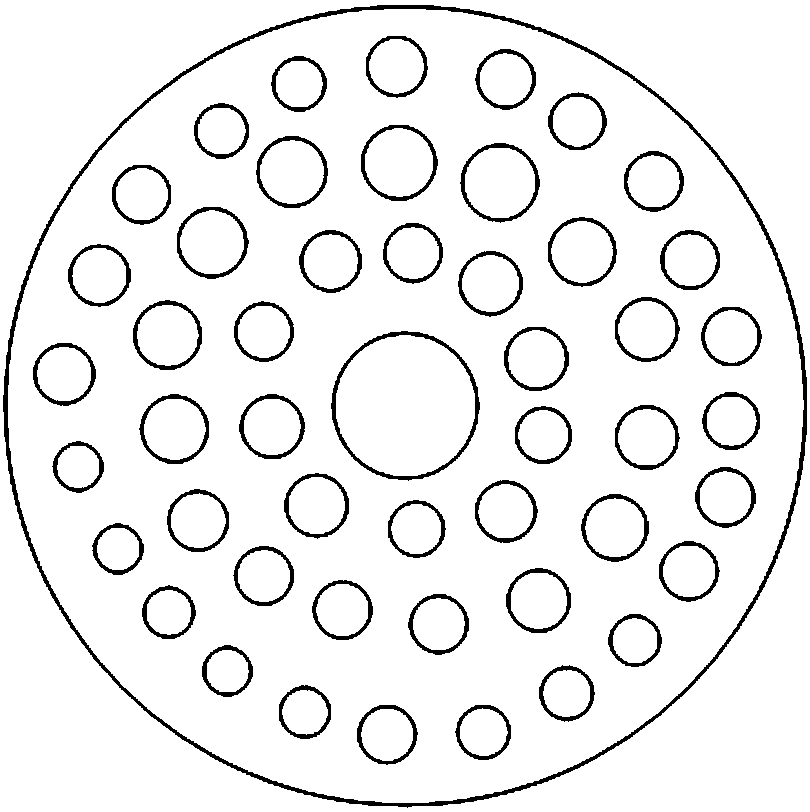

Method for densifying porous annular substrates by chemical vapour infiltration

ActiveUS20210246549A1Reduce in quantityReduce temperature gradientChemical vapor deposition coatingPorous substrateHost material

A process for densifying annular porous substrates by chemical vapour infiltration, includes providing a plurality of unit modules including a support plate on which is formed a stack of substrates, the support plate including a central gas inlet opening communicating with an internal volume formed by the central passages of the stacked substrates and gas outlet openings distributed angularly around the central opening, and a thermal mass cylinder disposed around the stack of substrates having a first end integral with the support plate and a second free end, forming stacks of unit modules in the chamber of a densification furnace, and injecting into the stacks of unit modules a gas phase including a gas precursor of a matrix material to be deposited within the porosity of the substrates.

Owner:SAFRAN CERAMICS

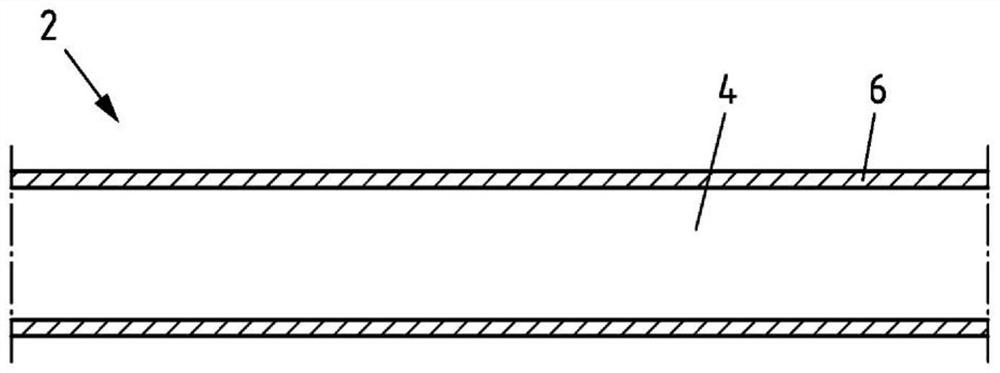

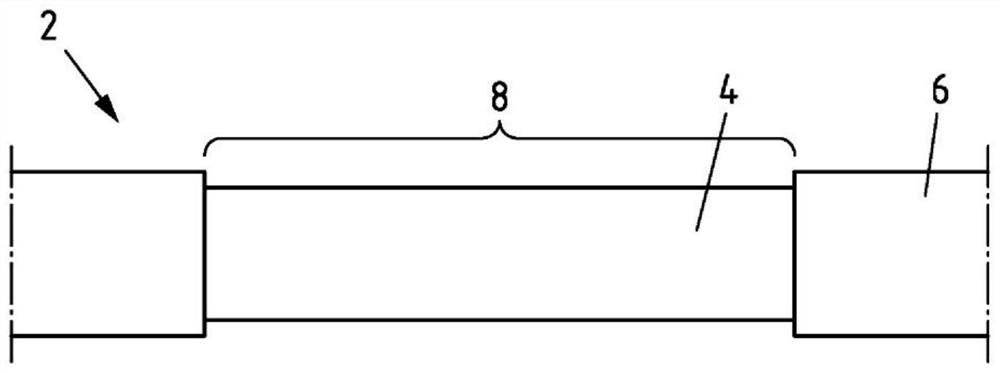

Method for establishing a connection between an electric connection element for a motor vehicle electrical system and a cable of the motor vehicle electrical system

PendingCN111886756AReduce process stepsReduce weightSoldered/welded conductive connectionsCoupling contact membersIn vehicleAutomotive engineering

The invention relates to a method for establishing a connection between an electric connection element for a motor vehicle electrical system and a cable of the motor vehicle electrical system, in which method: the cable (2) is provided with a metal stranded conductor (4); then the metal stranded conductor is mechanically compressed such that a planar region is formed, an integral connection beingformed between strands of the stranded conductor (4) during said compression; and subsequently the connection element is integrally bonded to the planar region.

Owner:AUTO KABEL MANAGEMENTGMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com