Patents

Literature

56results about How to "Guaranteed compositional uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-scandium-content aluminum and scandium alloy and preparing method thereof

ActiveCN106086567AEasy to operateIncrease profitVacuum evaporation coatingSputtering coatingGranularityBall mill

The invention provides a high-scandium-content aluminum and scandium alloy and a preparing method of the alloy, and belongs to the technical field of high-performance aluminum alloy materials. The high-scandium-content aluminum and scandium alloy comprises, by weight percent, 55% to 70% of scandium and the balance aluminum. The preparing method comprises the steps of firstly, powder screening, wherein aluminum powder and scandium powder pass through screens with different meshes, and raw materials with the needed granularity are screened out; secondly, material proportioning, wherein a certain amount of aluminum powder and a certain amount of scandium powder are weighed, and the aluminum powder and the scandium powder are mixed according to a certain mass proportion; thirdly, grinding, wherein the aluminum and scandium mixed powder is put into a ball grinding machine to be sufficiently ground, and mixing is uniform; and fourthly, sintering, wherein the aluminum and scandium mixed powder which is uniform in grinding is loaded into a mold, a hydraulic machine is used for carrying out pre-pressing, shove charging and sintering program setting are carried out, and the aluminum and scandium alloy is prepared in a sintered manner. The prepared aluminum and scandium alloy has the beneficial effects of being high in compactness, high in scandium content, good in component uniformity and good in subsequent machinability, and a reliable raw material can be provided for a sputtering target material in the special field.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

Method for preparing Al0.5CoCrFeNi high-entropy alloy

ActiveCN106756412AReduce volatilityGuaranteed compositional uniformityHigh entropy alloysSmelting process

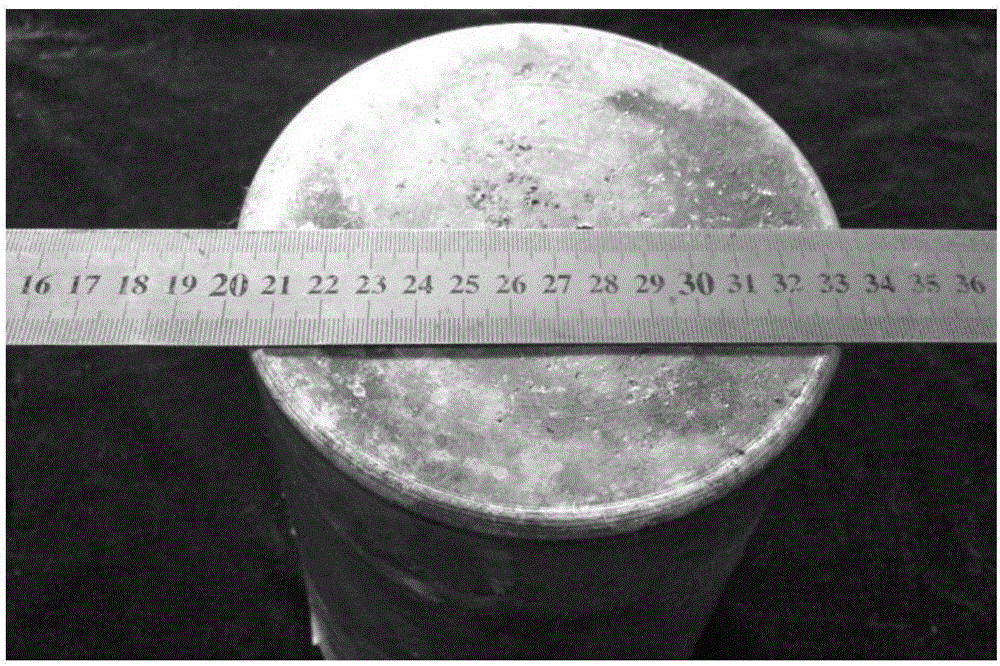

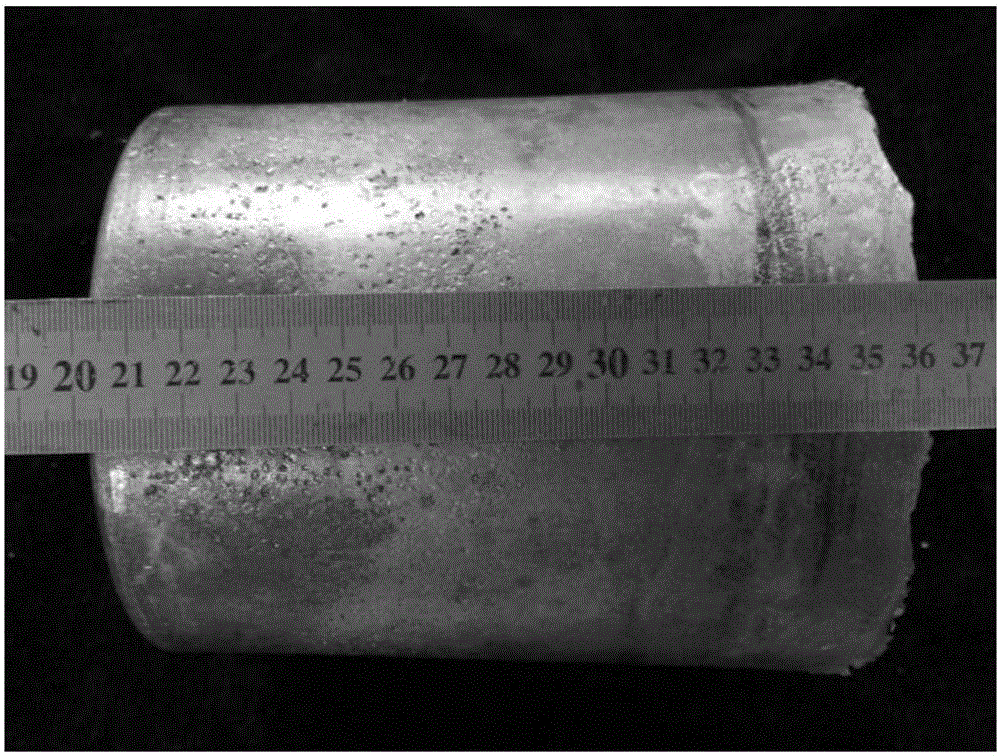

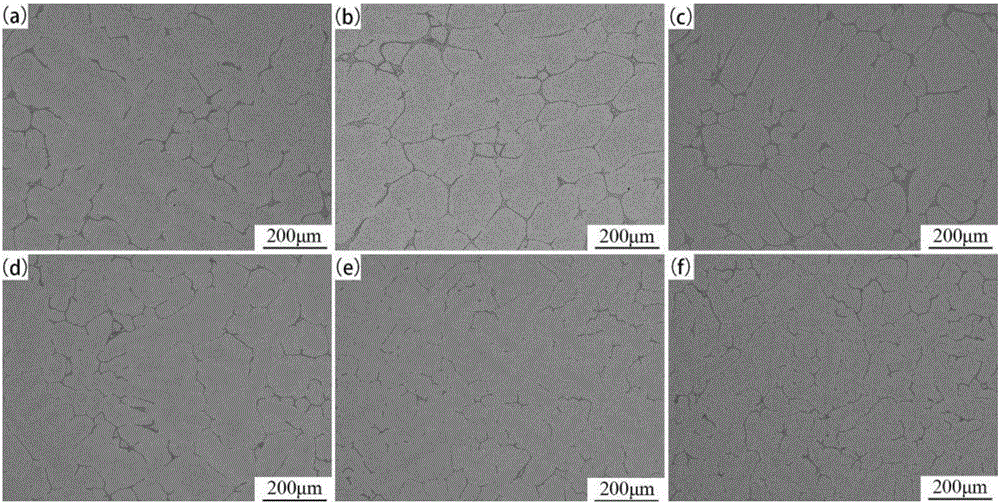

The invention discloses a method for preparing an Al0.5CoCrFeNi high-entropy alloy. An intermediate alloy serves as a raw material, and volatilization of a low-melting-point element Al in the smelting process is greatly reduced. Meanwhile, a vacuum induction heating device is adopted, the electromagnetic stirring effect of the induction heating device is utilized, and therefore the component uniformity of a cast ingot is guaranteed. According to the method, the melting point difference between the lowest-melting-point metal Al and the highest-melting-point metal Cr is indirectly reduced, the problem of excessive volatilization of the low-melting-point Al simple substance in the smelting process is solved, and the component uniformity of the multi-element high-entropy alloy is guaranteed through the electromagnetic stirring effect existing in induction heating. Through reasonable designing of the atmosphere, the air pressure, the die preheating temperature, the smelting temperature, the heat preservation time, the casting speed and other parameters in the smelting process, a large Al0.5CoCrFeNi high-entropy alloy cast ingot is successfully prepared.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

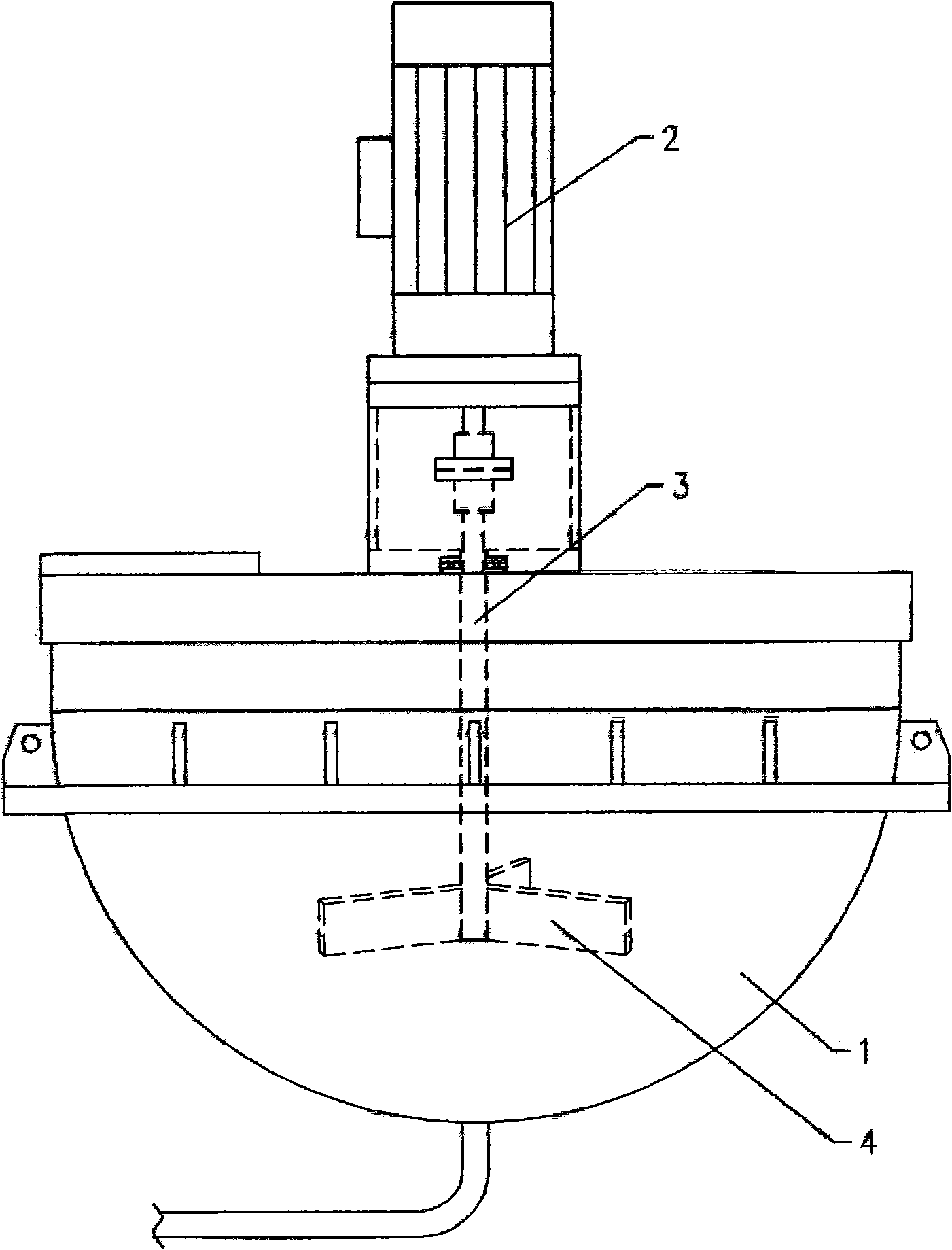

Preparation process of Pb-Ca-Sn-Al alloy

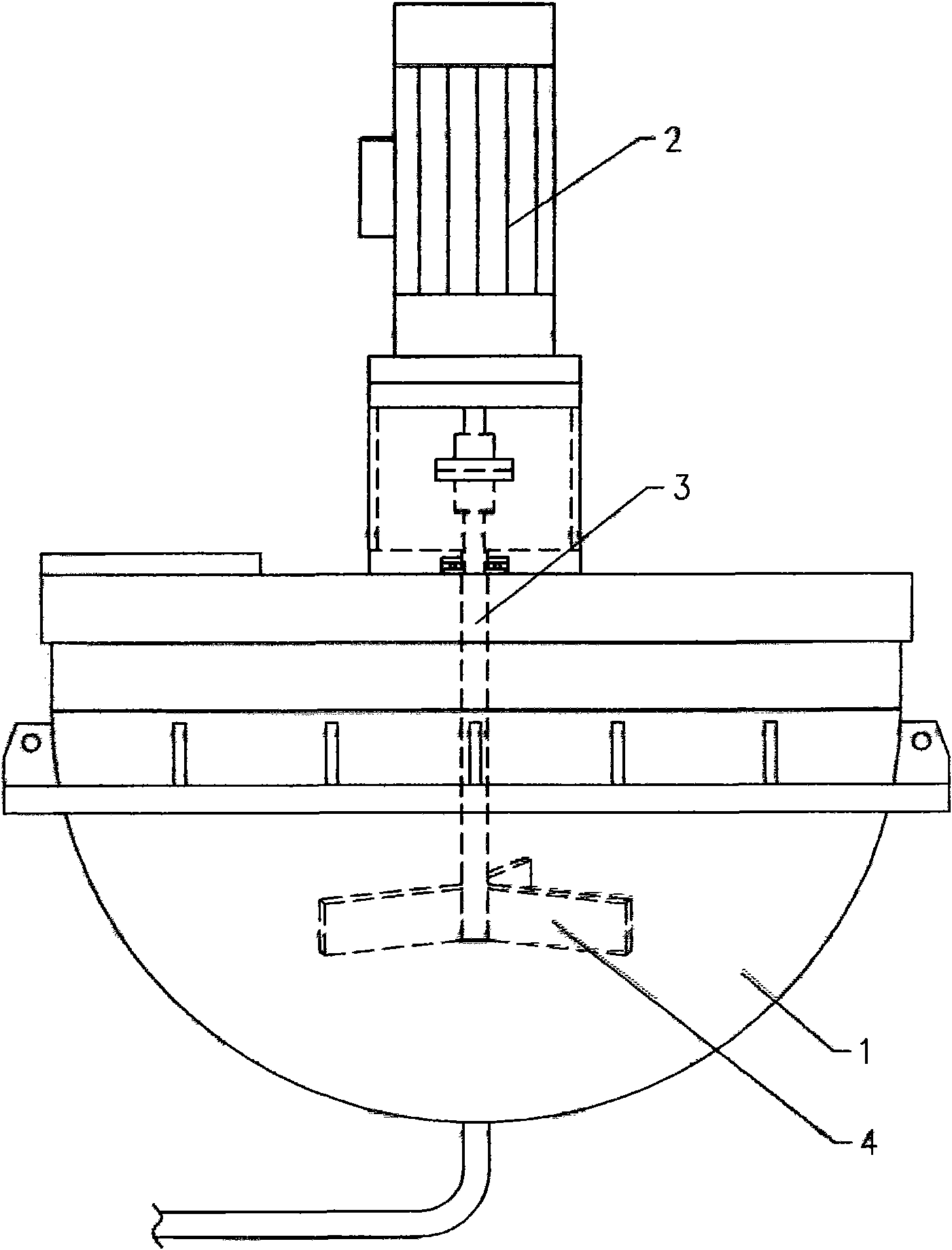

The invention discloses a preparation process of Pb-Ca-Sn-Al alloy. The invention is characterized in that (1) the lead with the required weight in the alloy formula is added for two times, and the lead which is added for the second time is fully used for cooling the molten liquid, thereby shortening the waiting time of cooling and reducing the fuel consumption; (2) a method of respectively adding aluminum ingots and calcium chips in the traditional production process is replaced by a method of directly adding Ca-Al intermediate alloy to reduce the adding frequency, and alloy blocks are directly stirred into a lead melting kettle by a stirring device to reduce the oxidation and the melting loss of calcium; and (3) a lead melting kettle with a hemispherical inner cavity is adopted, and a blade stirring device is arranged in the kettle, thereby shortening the stirring time and improving the stirring uniformity.

Owner:山东久力新能源集团有限公司

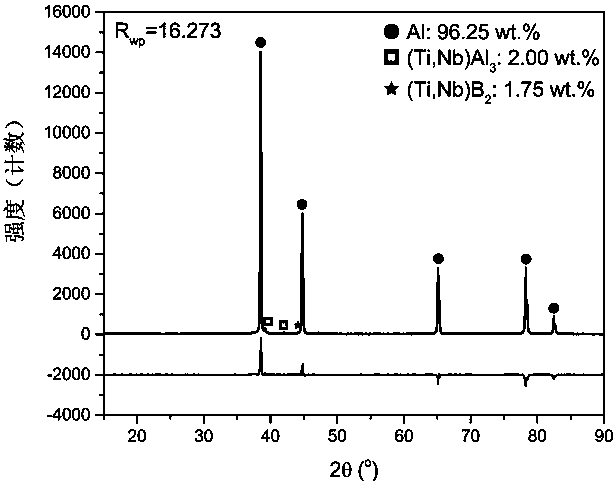

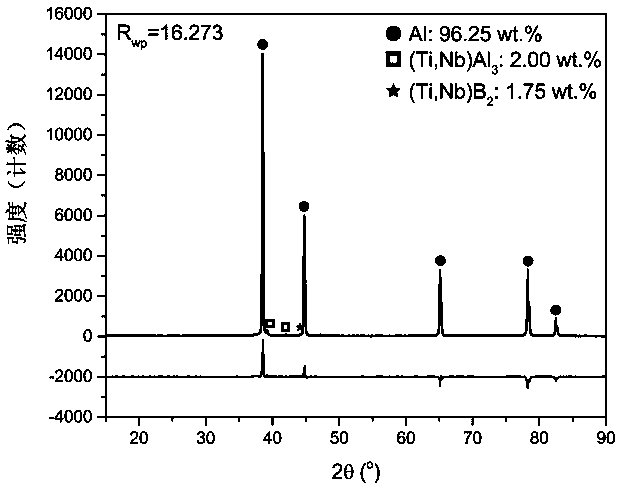

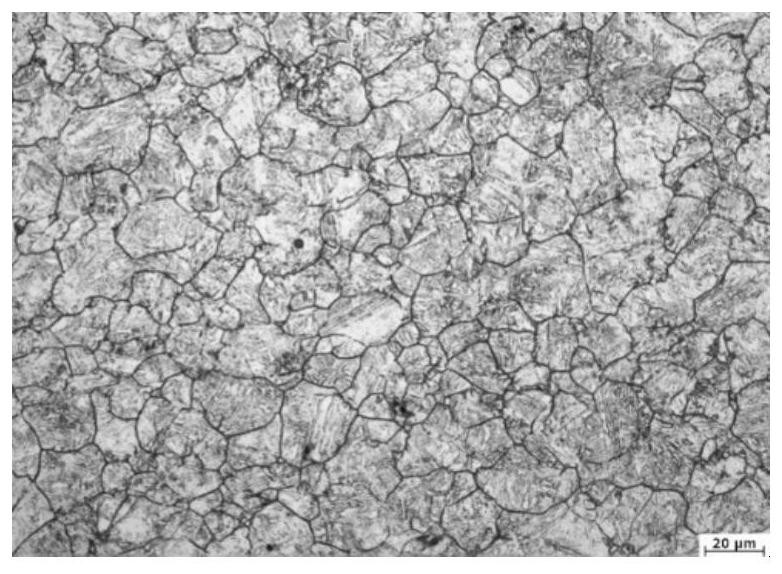

Al-Ti-Nb-B refiner for casting aluminum-silicon alloy as well as preparation method thereof and application thereof

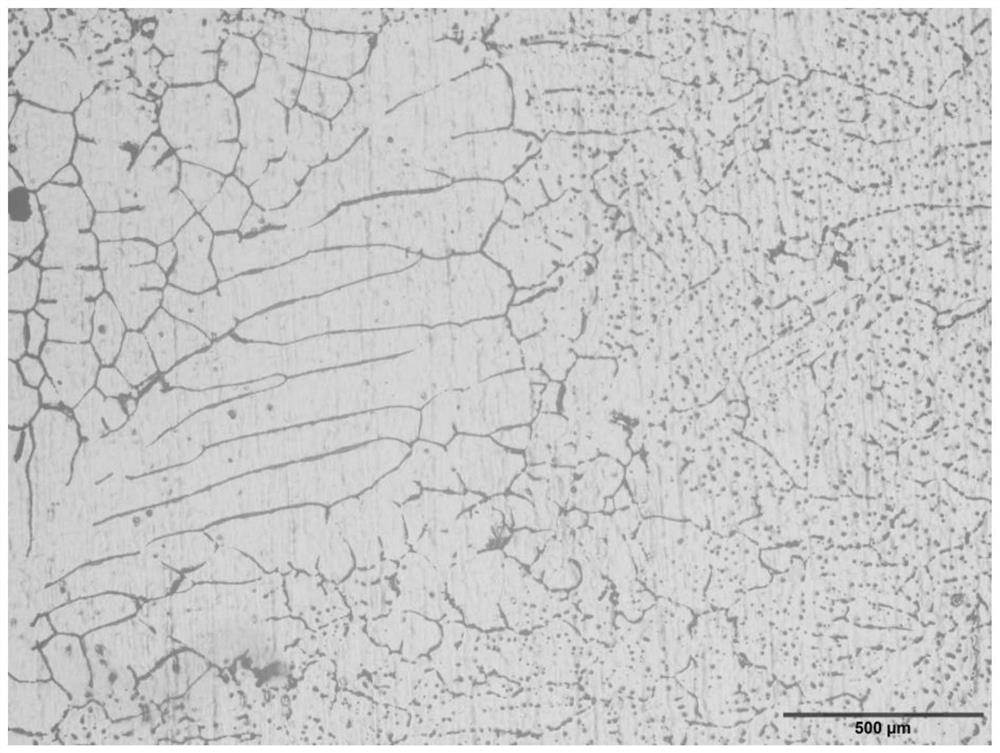

The invention discloses an Al-Ti-Nb-B refiner for casting aluminum-silicon alloy as well as a preparation method thereof and application thereof. The Al-Ti-Nb-B refiner for casting aluminum-silicon alloy is prepared from the following components in percentage by weight: 96.20-98.90wt% of Al, 0.30-1.30wt% of Ti, 0.50-2.0wt% of Nb, and 0.30-0.50wt% of B. The Al-Ti-Nb-B refiner comprises a refining particle phase MA13 and MB2 with mass percentage of 2-4% and particle dimension smaller than 20 microns, wherein M is Ti or Nb. The preparation method for the Al-Ti-Nb-B refiner for casting aluminum-silicon alloy comprises the following steps of: a, weighing raw materials; b, smelting a Ti-Nb-B intermediate alloy; and c, smelting the Al-Ti-Nb-B refiner. A method of applying the Al-Ti-Nb-B refiner to casting aluminum-silicon alloy comprises the following steps of: a, melting the aluminum-silicon alloy; b, adding the Al-Ti-Nb-B refiner; and c, casting. The Al-Ti-Nb-B refiner prepared by the preparation method can be used for refining the crystalline grain size of alpha-Al in the aluminum-silicon alloy to be 150-450 microns, so that Nb content is greatly reduced, raw material cost is reduced,and components and structure uniformity of the prepared Al-Ti-Nb-B refiner are guaranteed.

Owner:SHANGHAI UNIV

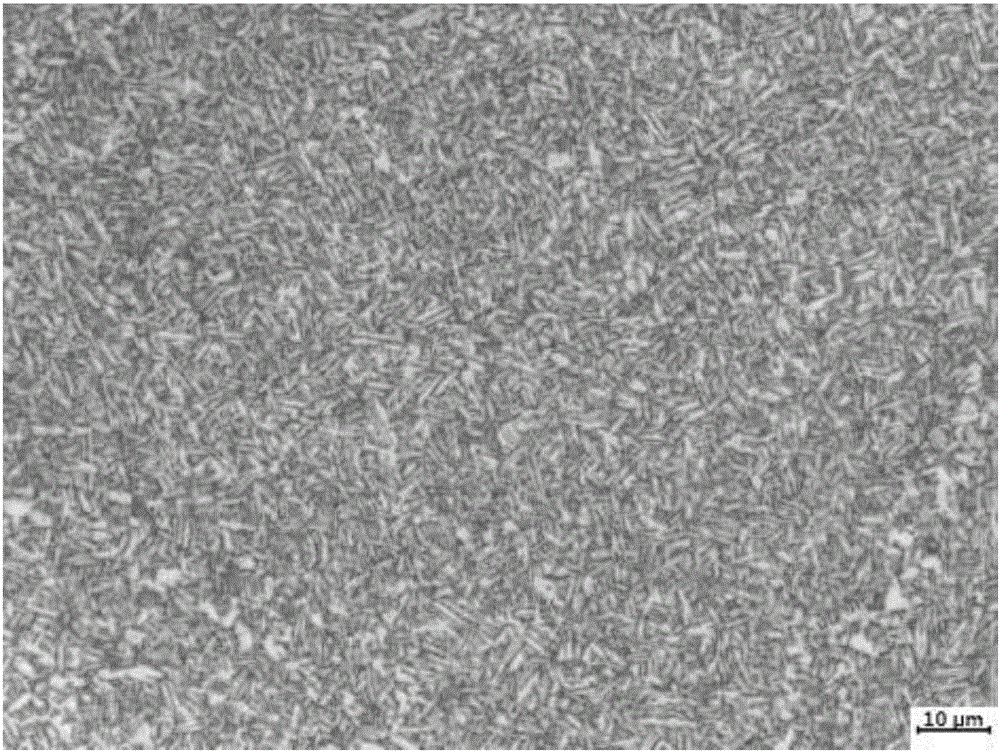

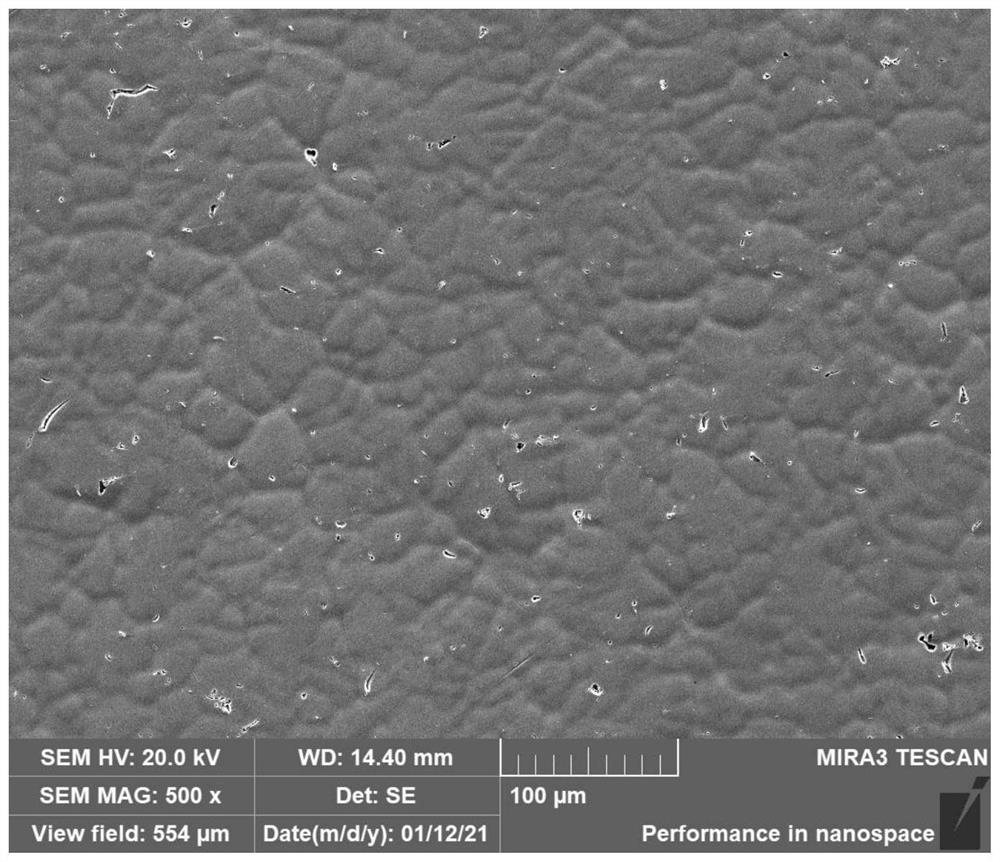

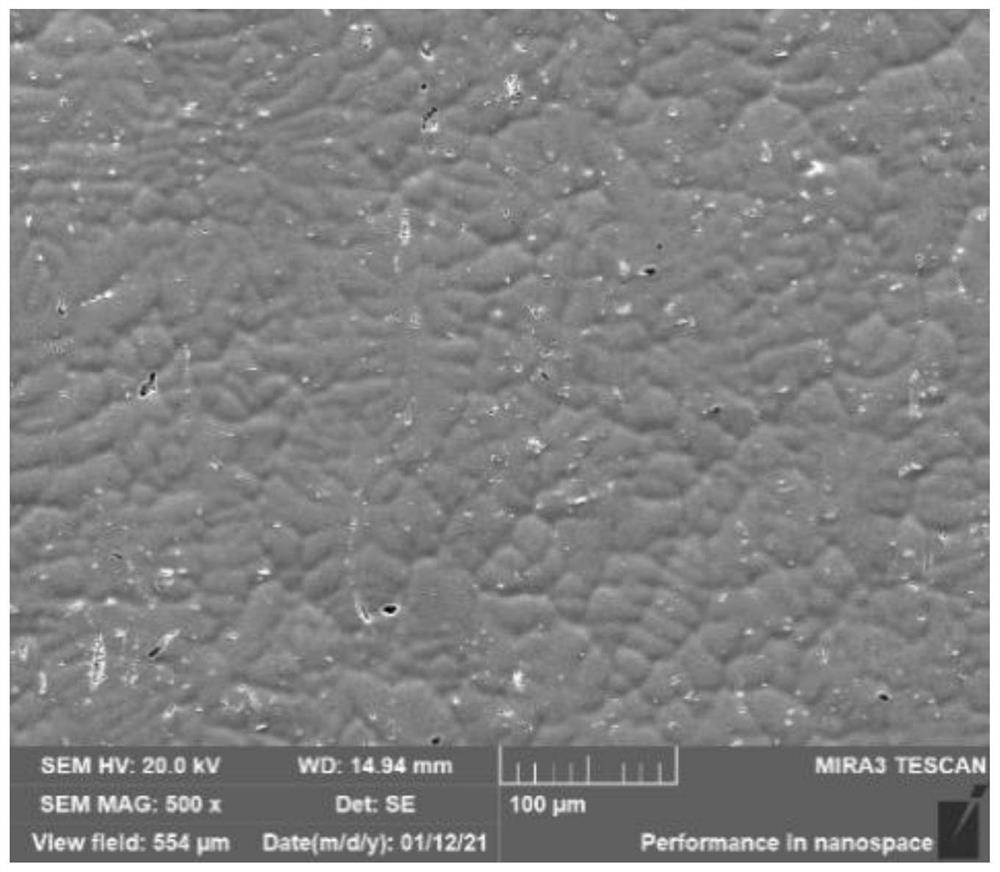

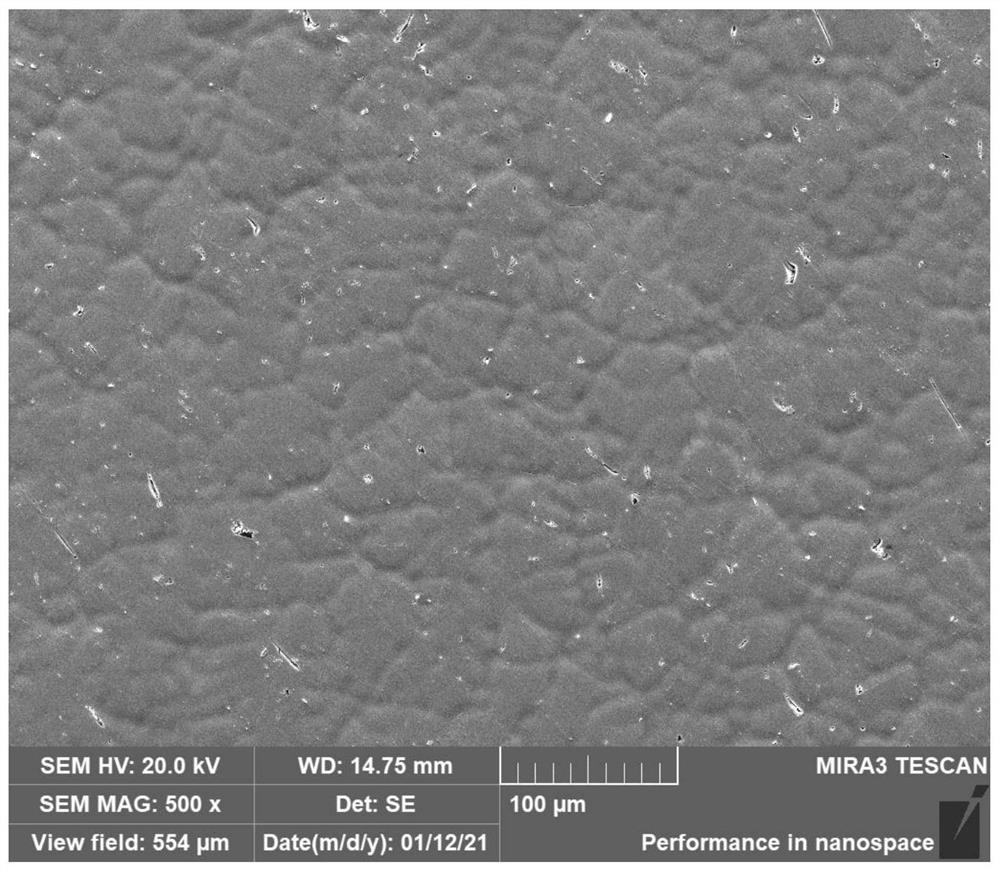

Preparation method of Ti2AlNb alloy material

ActiveCN106319236AImproves ingredient uniformityGood chemical uniformitySelf consumptionHeating time

The invention discloses a preparation method of a Ti2AlNb alloy material. The method comprises the steps of 1, preparing a Ti2AlNb alloy ingot through vacuum self-consumption electric arc melting, kish furnace smelting and vacuum self-consumption electric arc melting; 2, conducting primary homogenization treatment on the Ti2AlNb alloy ingot; and 3, wrapping the Ti2AlNb alloy ingot with asbestos cloth, then conducting heat-preservation heat treatment, and then sequentially conducting cogging forging, improved forging and finished product forging, so that the Ti2AlNb alloy material is finally obtained. The preparation method of the Ti2AlNb alloy material is simple in preparation process and reasonable in process design; an alloy is uniform in structure and stable in performance; the alloy ingot can be effectively refined, purified and homogenized through a smelting method; through the high-quality ingot, smooth implementation of subsequent hot working is guaranteed; by means of homogenization treatment, uniformity of alloy elements can be further improved through element diffusion; and wrapping treatment is conducted with the asbestos cloth, the temperature of the material can be effectively prevented from being lowered in the whole forging process, and large-deformation-amount forging for one heating time is achieved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

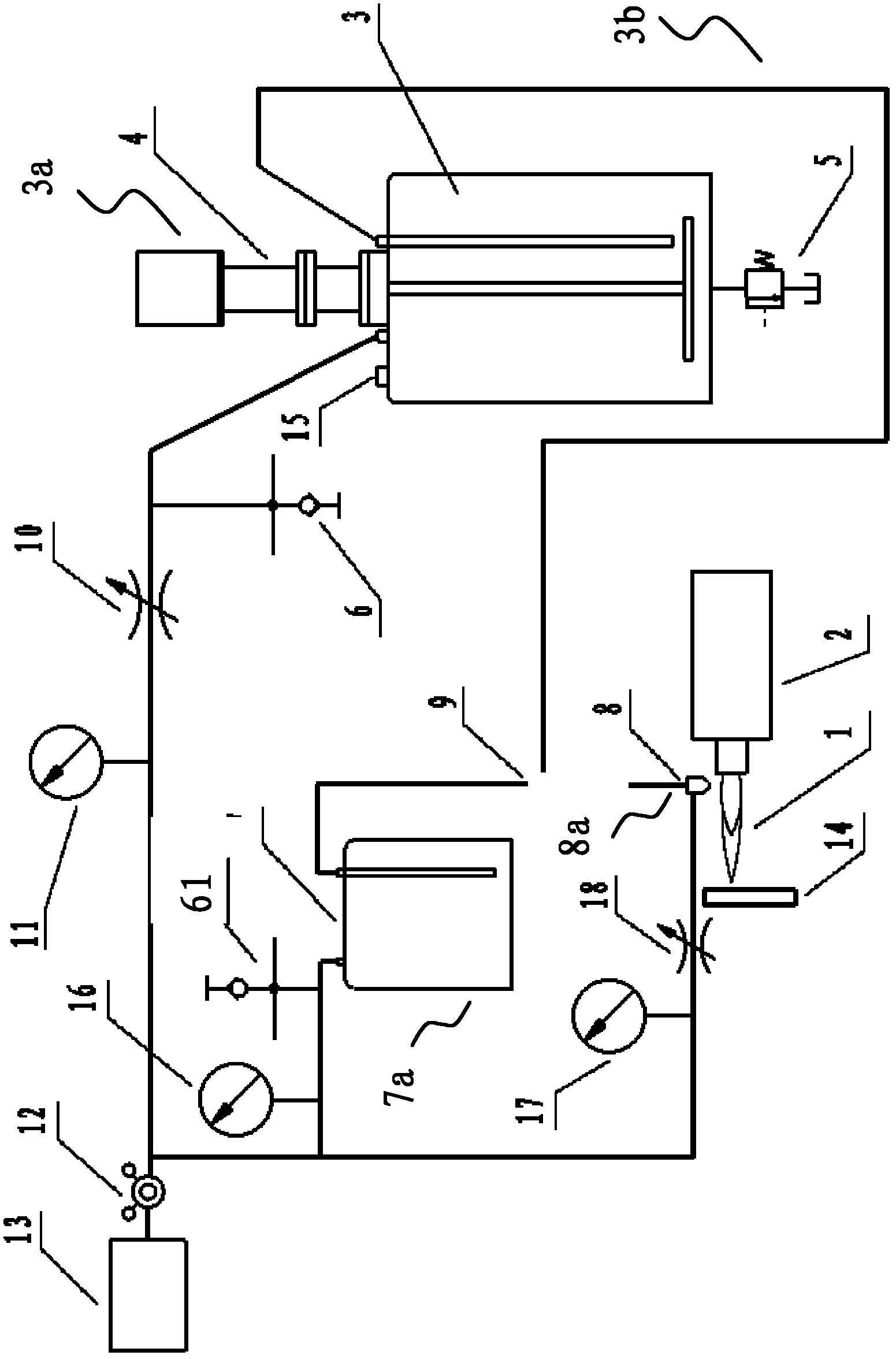

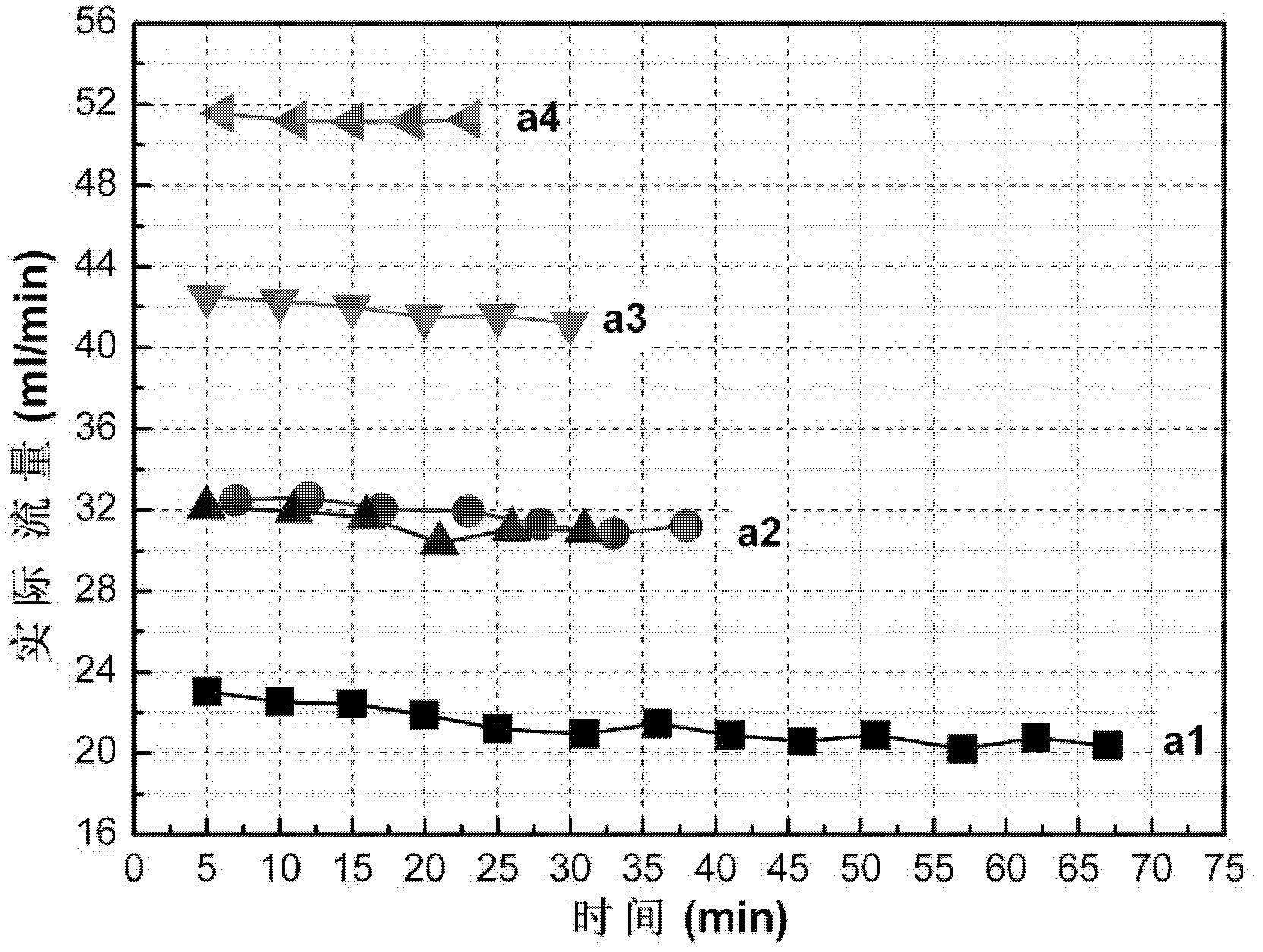

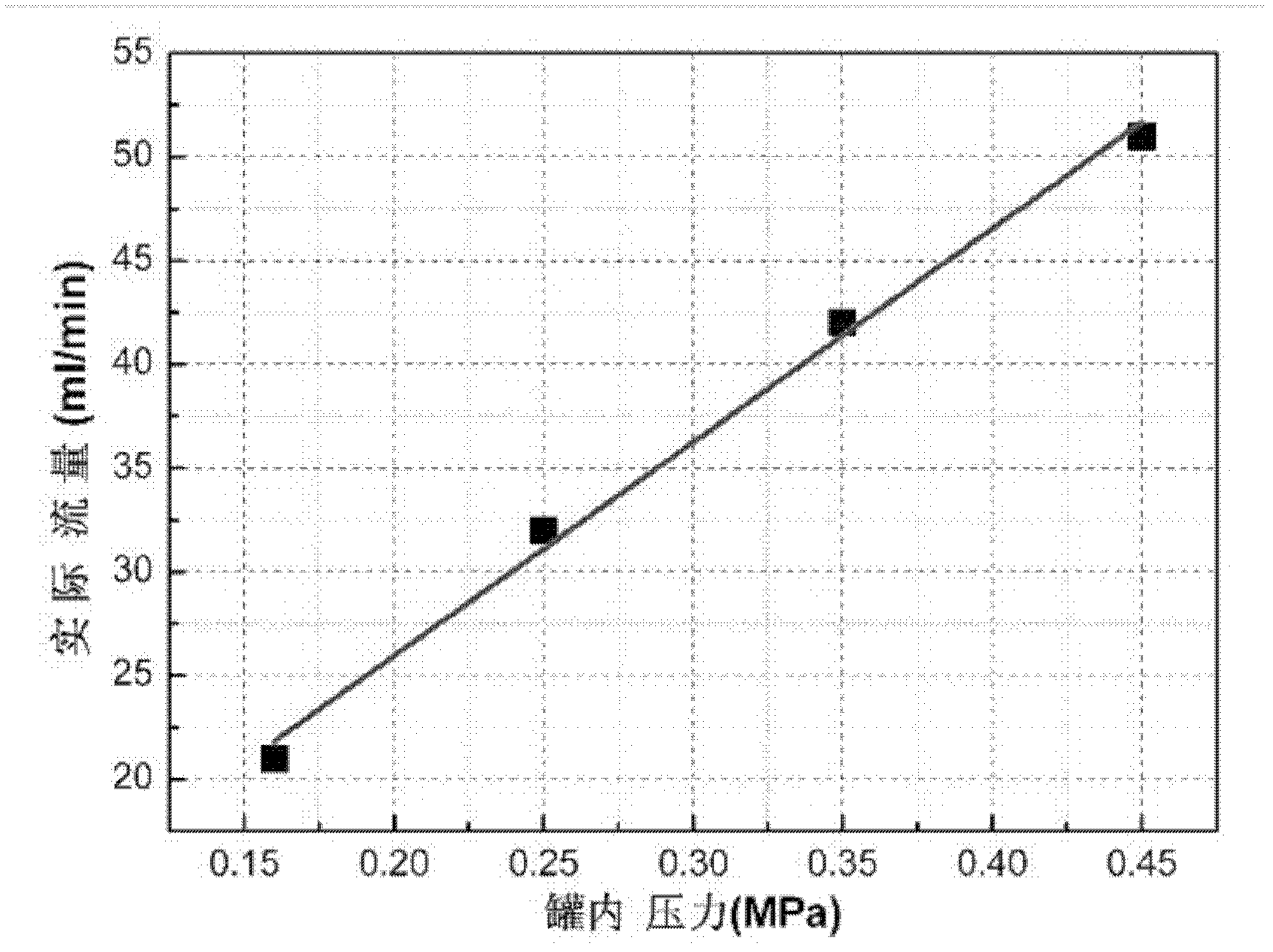

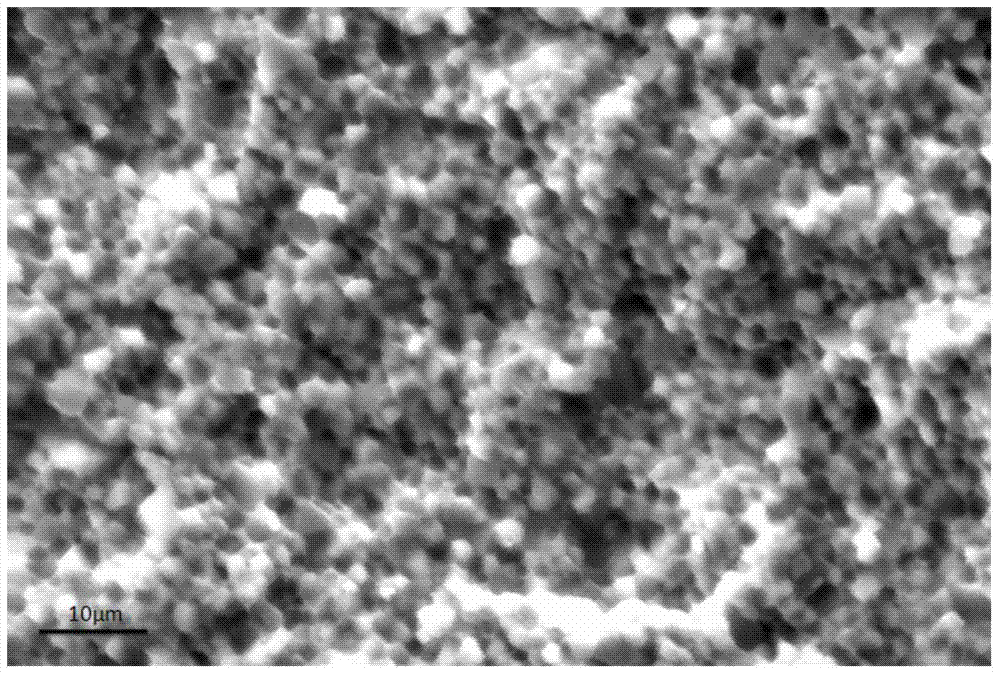

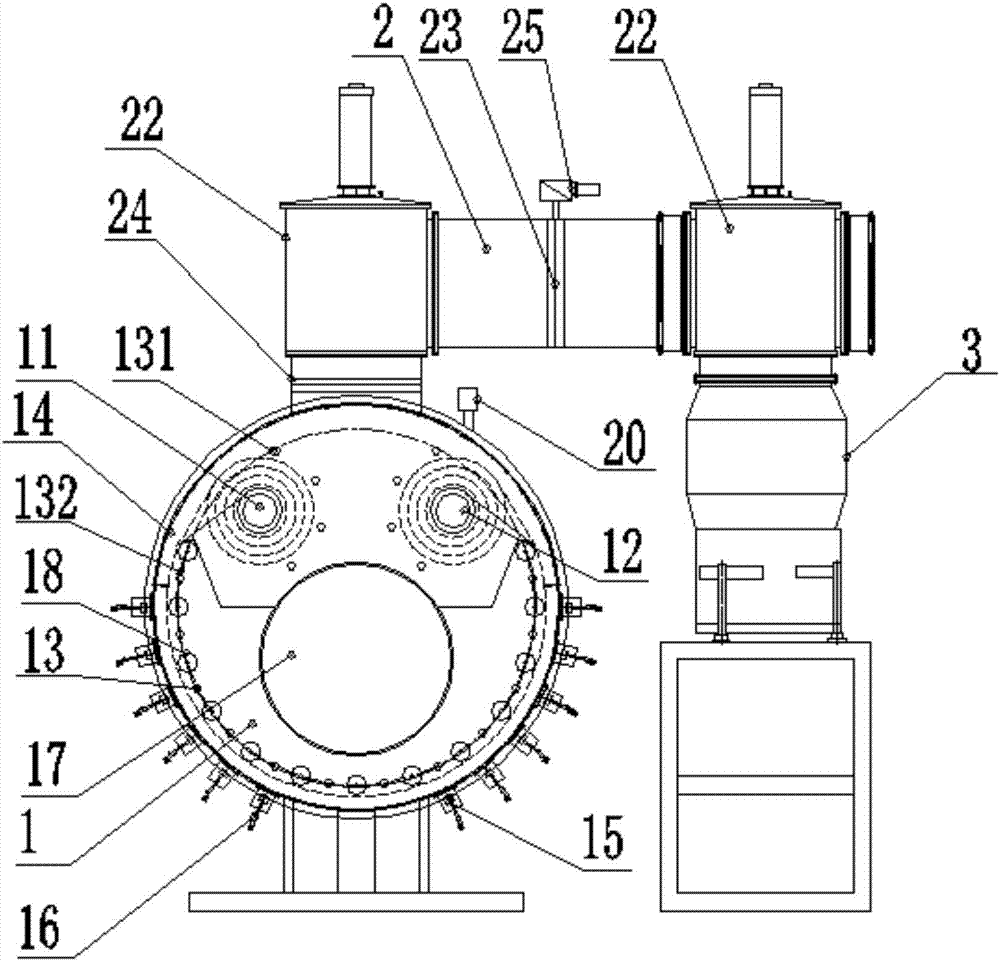

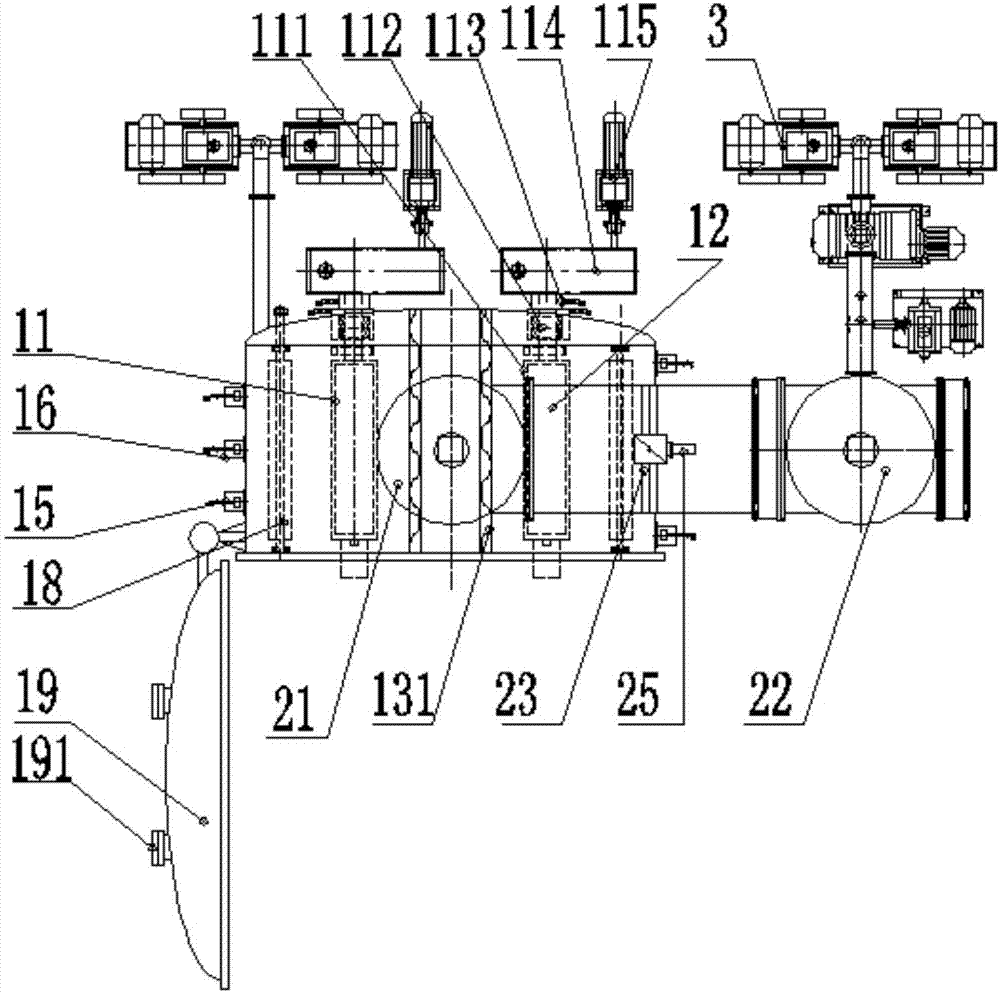

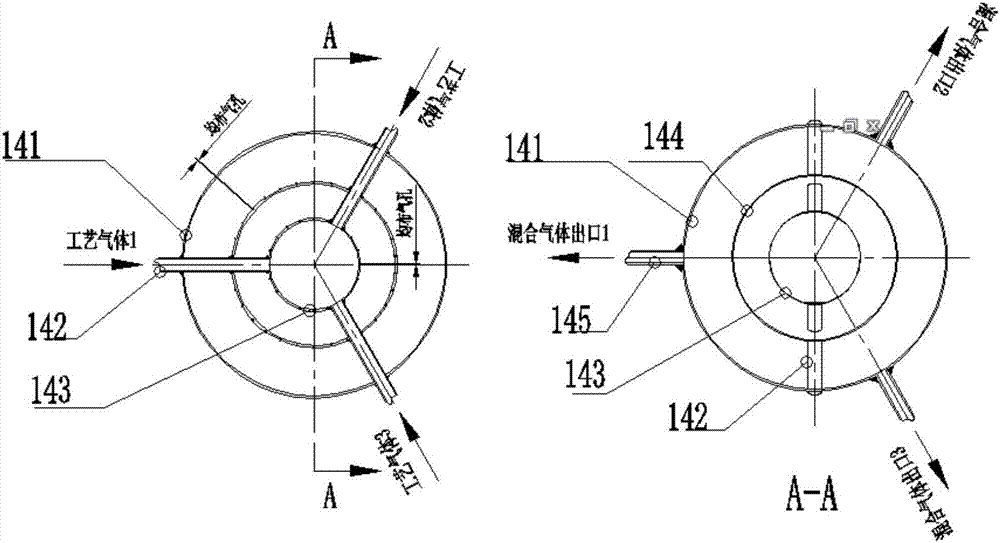

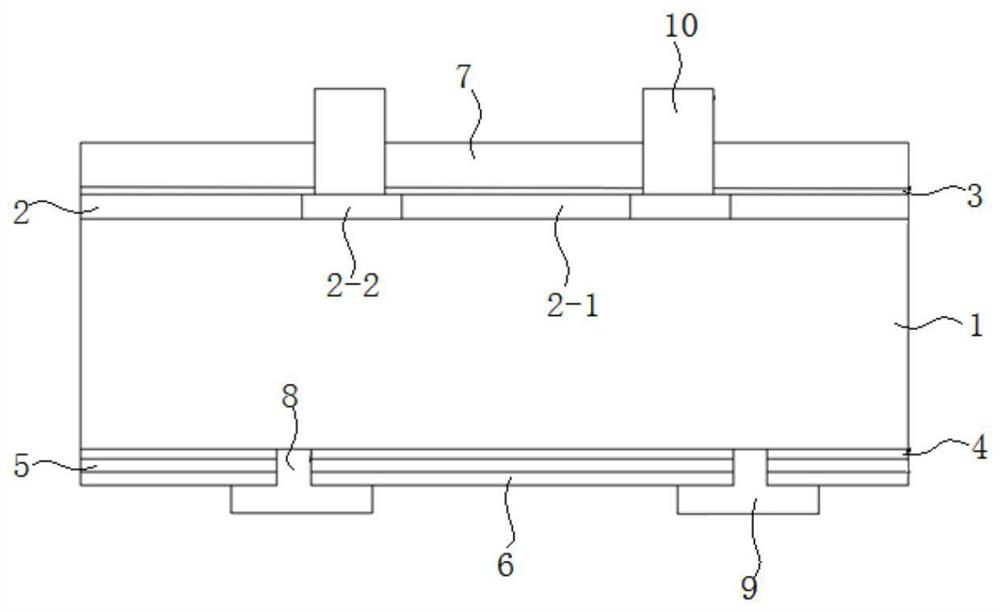

Liquid feedstock plasma spraying device

InactiveCN103031508AImprove production efficiencySkip powder preparationMolten spray coatingNanotechnologyPlasma jetNano structuring

The invention provides a liquid feedstock plasma spraying device, which is used for the preparation of a ceramic coating in a nano structure on a basal body. The liquid feedstock plasma spraying device comprises a plasma system and a liquid feedstock conveying device, wherein the liquid feedstock conveying device comprises a liquid feedstock conveying system and a liquid feedstock injection system; the liquid feedstock conveying system comprises a gas source and a liquid feedstock conveying power device; the liquid feedstock conveying power device is connected with the gas source; the liquid feedstock injection system comprises a two-fluid gas atomization spray nozzle; the two-fluid gas atomization spray nozzle is connected with the liquid feedstock conveying power device; meanwhile, the two-fluid gas atomization spray nozzle is arranged in a manner of corresponding to a high temperature area of plasma jet of the plasma system and further connected with the gas source; moreover, the two-fluid gas atomization spray nozzle atomizes a liquid feedstock in the liquid feedstock conveying power device into liquid drops with certain speed and further sends the liquid drops into the high temperature area of the plasma jet; and after being heated by the plasma jet to speed up, the liquid drops are deposited on the basal body for the formation of the ceramic coating in the nano structure.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +1

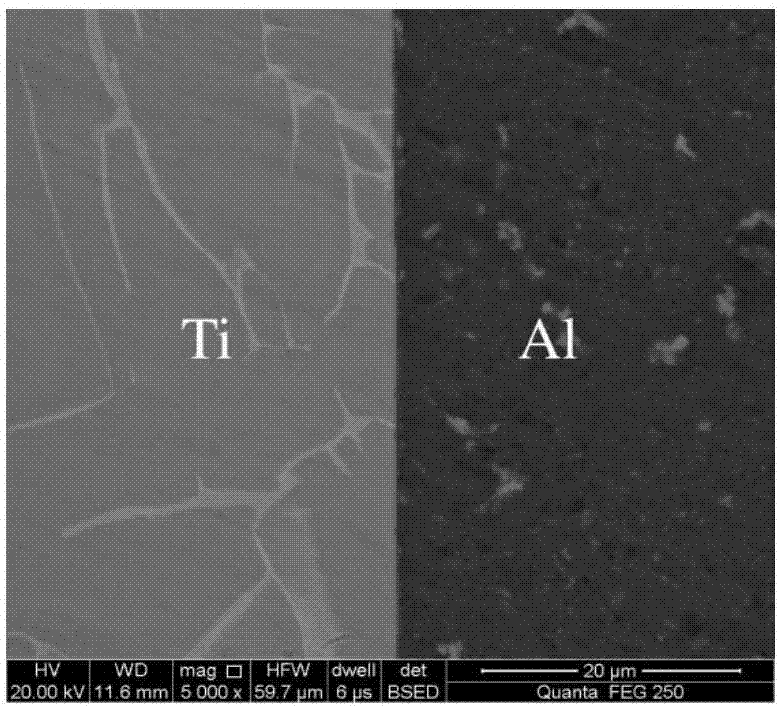

Titanium/aluminum gradient material and preparation method thereof

The invention relates to a high-performance material based on aerospace application and a preparation method, in particular to a powder metallurgy preparation technology of a titanium / aluminum gradient material, and aims to solve the problem of difficult obtaining of a titanium / aluminum gradient structure with high bonding strength due to high joining temperature, high residual stress and difficult interface reaction control in a traditional preparation process. A titanium sintering body and an aluminum presintering body are prepared by a powder metallurgy forming and sintering method; and then, two prefabricated bodies are laminated to be subjected to powder metallurgy sintering to obtain the high-performance titanium / aluminum gradient material. The obtained high-performance titanium / aluminum gradient material has no obvious matrix deformation, and reaches the interface stretching resistant strength of not less than 100 MPa. The preparation method is suitable for preparation of larger-size titanium / aluminum gradient material, and can be expanded to other dissimilar metal gradient structure. The preparation method is simple in operation, easy to control and convenient for industrial application.

Owner:CENT SOUTH UNIV

A kind of al-ti-nb-b refiner for cast aluminum-silicon alloy and its preparation method and application

The invention discloses an Al-Ti-Nb-B refiner for casting aluminum-silicon alloy as well as a preparation method thereof and application thereof. The Al-Ti-Nb-B refiner for casting aluminum-silicon alloy is prepared from the following components in percentage by weight: 96.20-98.90wt% of Al, 0.30-1.30wt% of Ti, 0.50-2.0wt% of Nb, and 0.30-0.50wt% of B. The Al-Ti-Nb-B refiner comprises a refining particle phase MA13 and MB2 with mass percentage of 2-4% and particle dimension smaller than 20 microns, wherein M is Ti or Nb. The preparation method for the Al-Ti-Nb-B refiner for casting aluminum-silicon alloy comprises the following steps of: a, weighing raw materials; b, smelting a Ti-Nb-B intermediate alloy; and c, smelting the Al-Ti-Nb-B refiner. A method of applying the Al-Ti-Nb-B refiner to casting aluminum-silicon alloy comprises the following steps of: a, melting the aluminum-silicon alloy; b, adding the Al-Ti-Nb-B refiner; and c, casting. The Al-Ti-Nb-B refiner prepared by the preparation method can be used for refining the crystalline grain size of alpha-Al in the aluminum-silicon alloy to be 150-450 microns, so that Nb content is greatly reduced, raw material cost is reduced,and components and structure uniformity of the prepared Al-Ti-Nb-B refiner are guaranteed.

Owner:SHANGHAI UNIV

Multi-component hot spraying flexible wire and preparation method thereof

ActiveCN101177771AHigh bonding strengthImprove abradabilityMolten spray coatingAlloyMechanical equipment

The invention relates to a multi-components hot spray flexible wire and a preparation method thereof. A flexible wire which is good in spraying technology adaptability is prepared through a method of mechanical milling, rubber mixing and squeezing by a slow vernier hydraulic press. The wire comprises Ni, Al, Cr, W, Co, Mo, Ti, Cu, C, BN and Si oxide or salts thereof, wherein the raw materials can be simple substance powder or alloy or compound, while the oxides can be one or more or the combination of a few materials. The binder can be inorganic materials, and the combination of some additives and addition agents is also included. The coating prepared by the wire has the advantages that the coating combines well with a matrix, the wearable performance is good, and the thermal shock resistance and salt-fog resistance are excellent. The wire has a wide application range, which can be applied in the surface modification and the reproduction of mechanical equipment.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

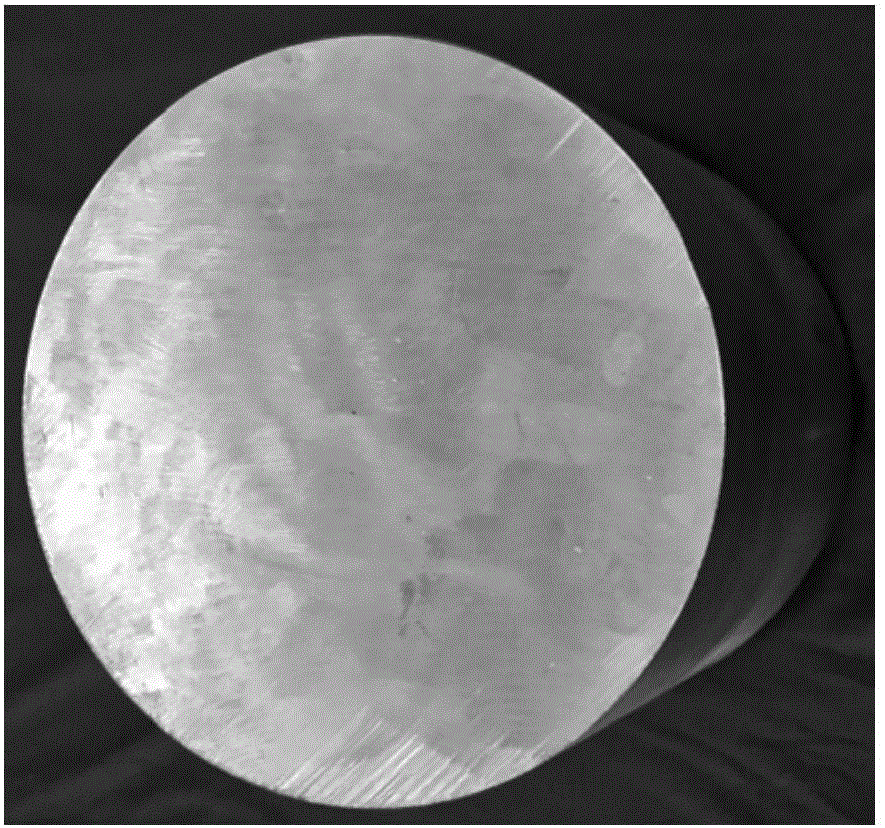

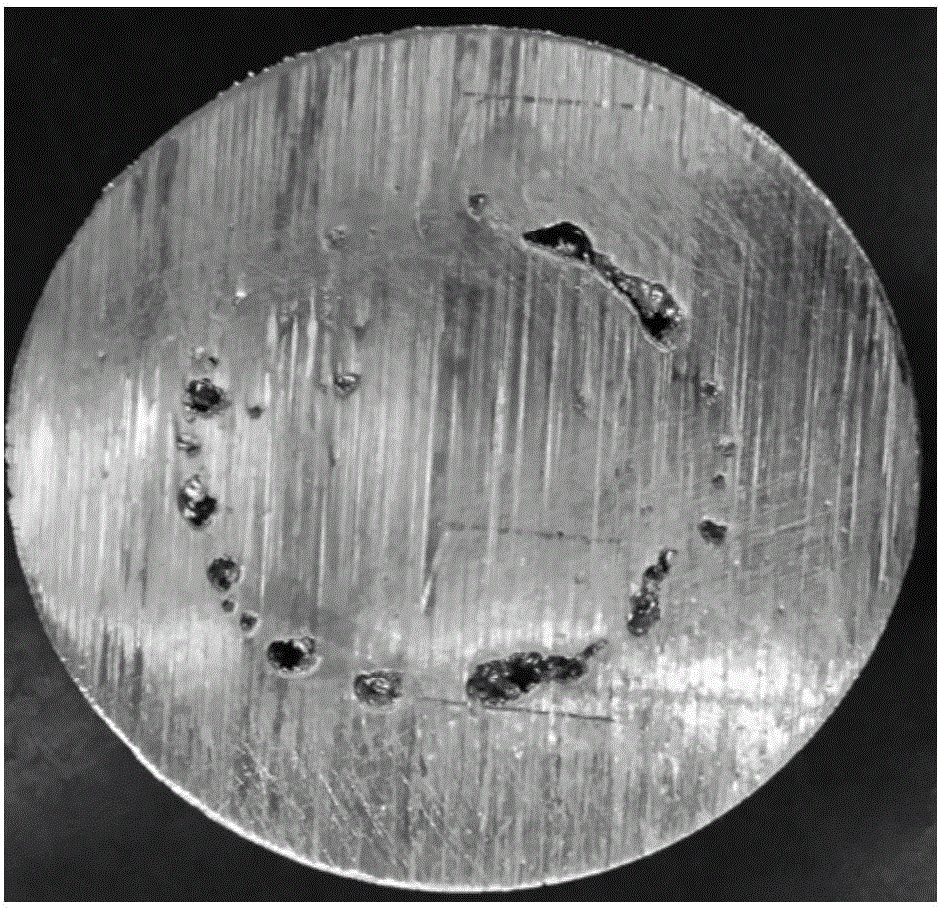

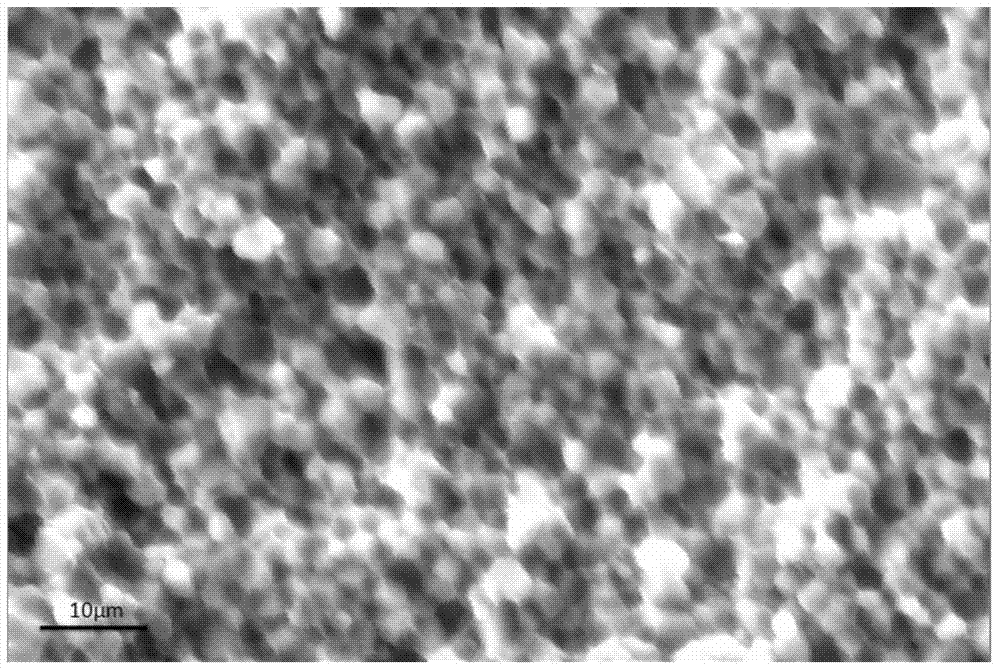

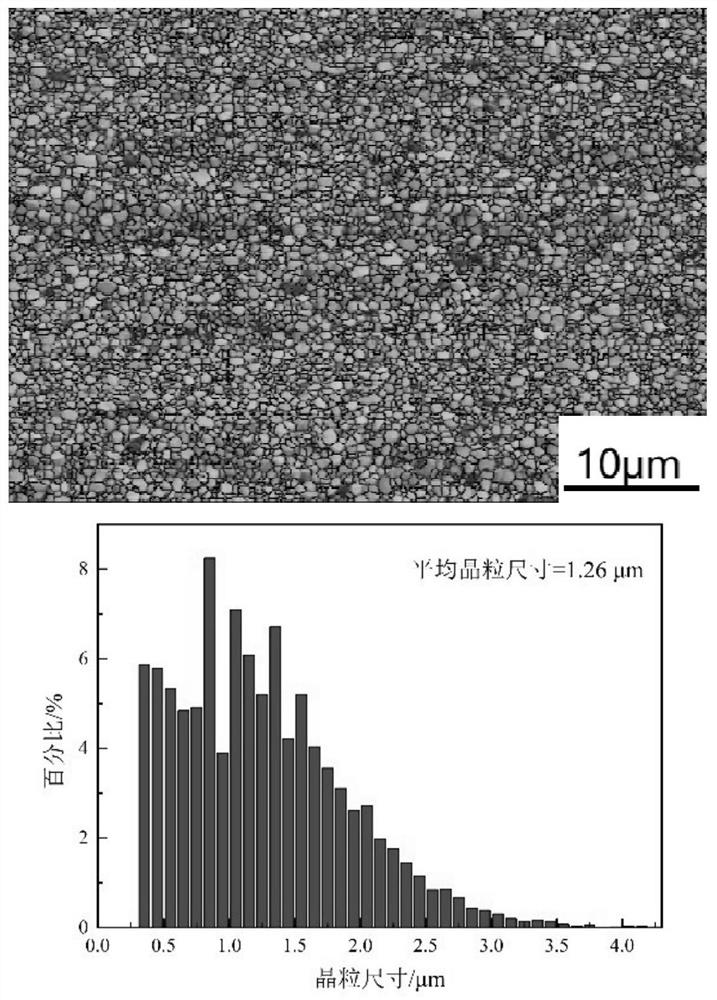

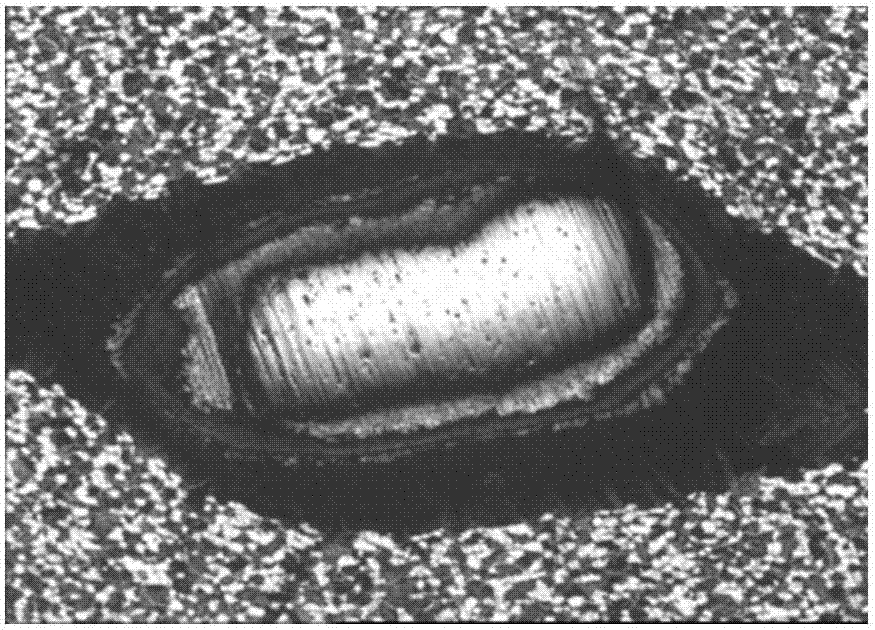

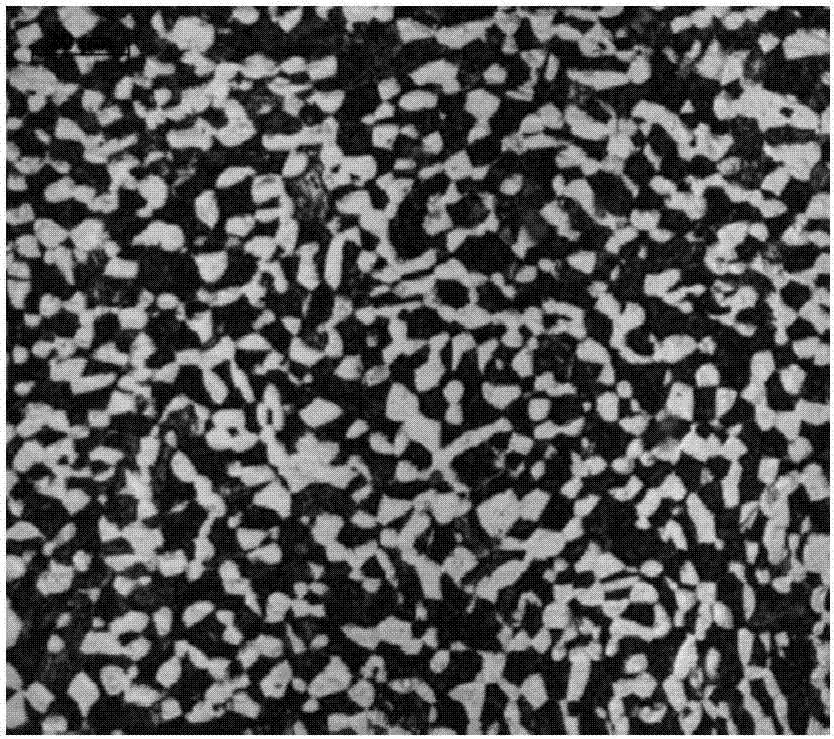

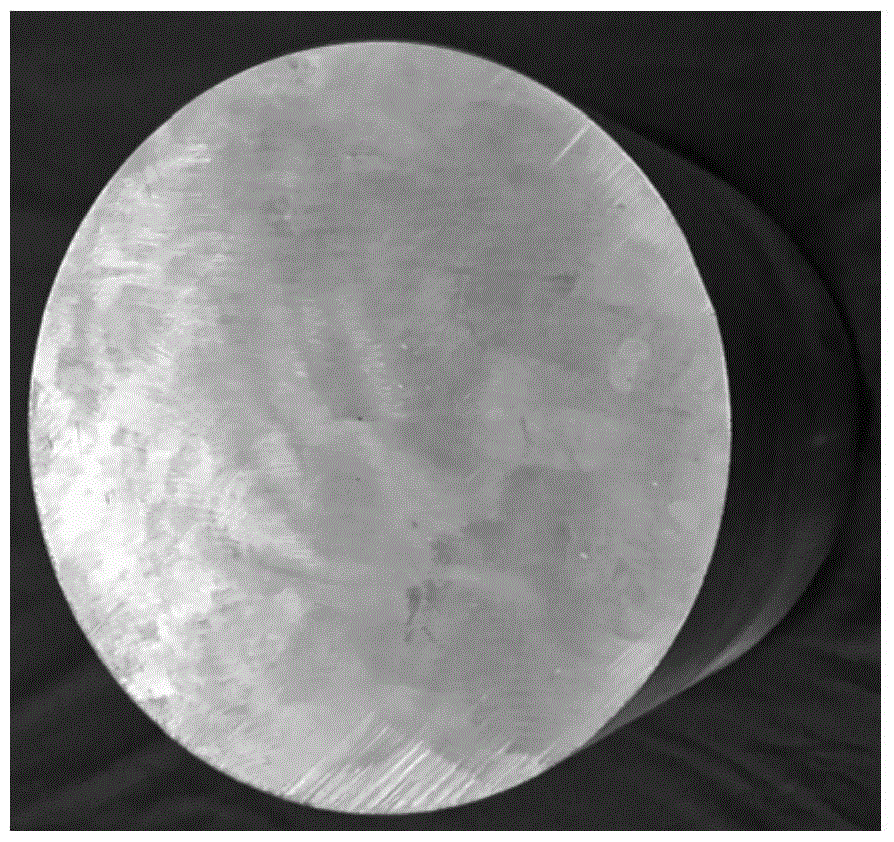

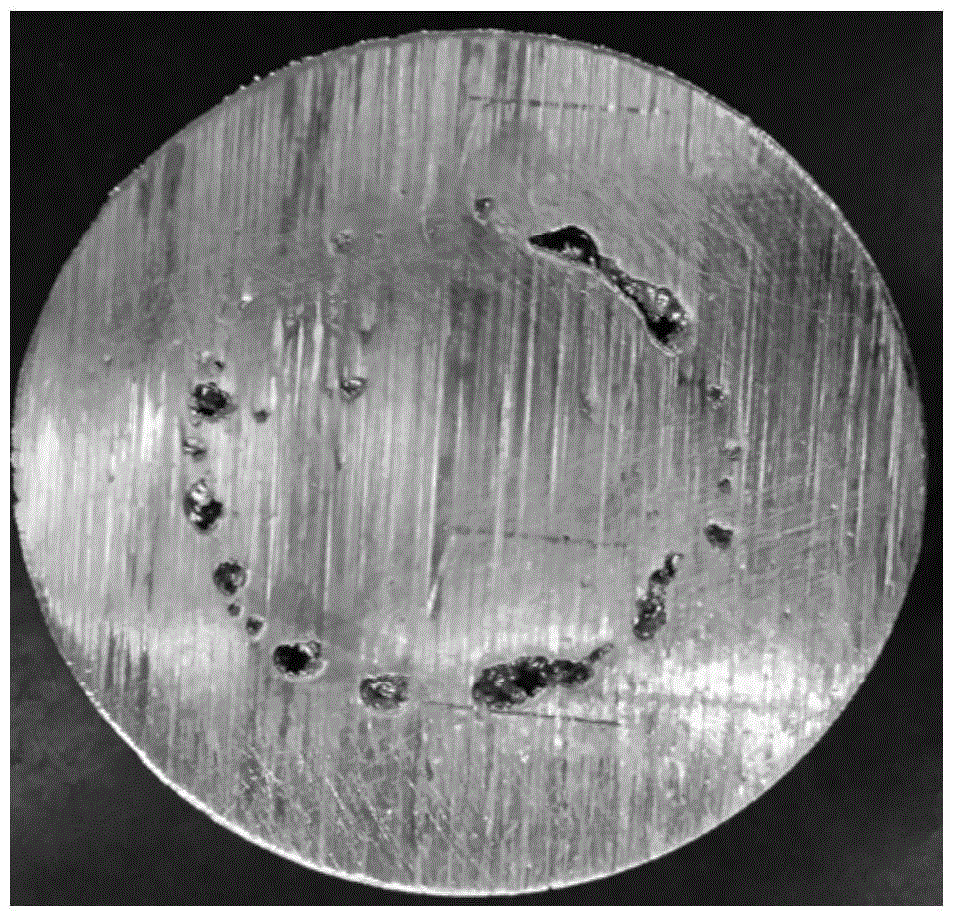

Aluminum-scandium alloy target with high scandium content and preparation method thereof

ActiveCN111455327ASmall grain sizeHigh densityVacuum evaporation coatingSputtering coatingMetallic aluminumThermal deformation

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

Preparation method for nickel-based alloy ingot

The invention discloses a preparation method for a nickel-based alloy ingot. The method includes the steps that firstly, nickel powder and metal element powder are evenly mixed and then pressed, so that a block to be sintered is obtained; secondly, the block to be sintered is sintered under the hydrogen protection condition, so that a block to be molten is obtained; thirdly, the block to be molten is placed in a medium-frequency induction melting furnace to be subjected to medium-frequency induction melting treatment, so that nickel-based alloy melt is obtained, and then the nickel-based alloy melt is poured to obtain a melting electrode; and fourthly, the melting electrode is placed in a vacuum arc melting furnace to be subjected to vacuum arc melting treatment, so that the nickel-based alloy ingot is obtained. According to the method, the nickel-based alloy ingot is prepared by combining technological processes of medium-frequency induction melting treatment and vacuum arc melting treatment, the advantages of the two melting technologies are fully used, the defects of the two melting technologies are also overcome, and the obtained nickel-based alloy ingot has uniform macro components and a compact microstructure.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Six-element intermediate alloy for preparation of high-strength titanium alloy and preparation method thereof

The invention discloses a six-element intermediate alloy for preparation of a high-strength titanium alloy. The six-element intermediate alloy comprises, by weight, 19-27% of Al, 20-25% of Mo, 20-25% of V, 8-16% of Cr, 0.8-3% of Fe and the balance Ti. The invention also discloses a preparation method of the six-element intermediate alloy for preparation of a high-strength titanium alloy. The high-strength high-toughness titanium alloy prepared from the six-element intermediate alloy has high strength and good plasticity, can substantially reduce hidden trouble caused by incomplete melting of high-melting point elements such as Mo, V and Cr in melting and ingot casting, improves ingot casting purity and component uniformity and prevents quality defects caused by high density inclusion and beta spots.

Owner:宝钢特钢有限公司

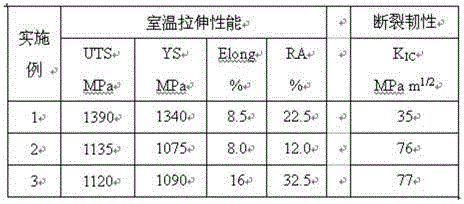

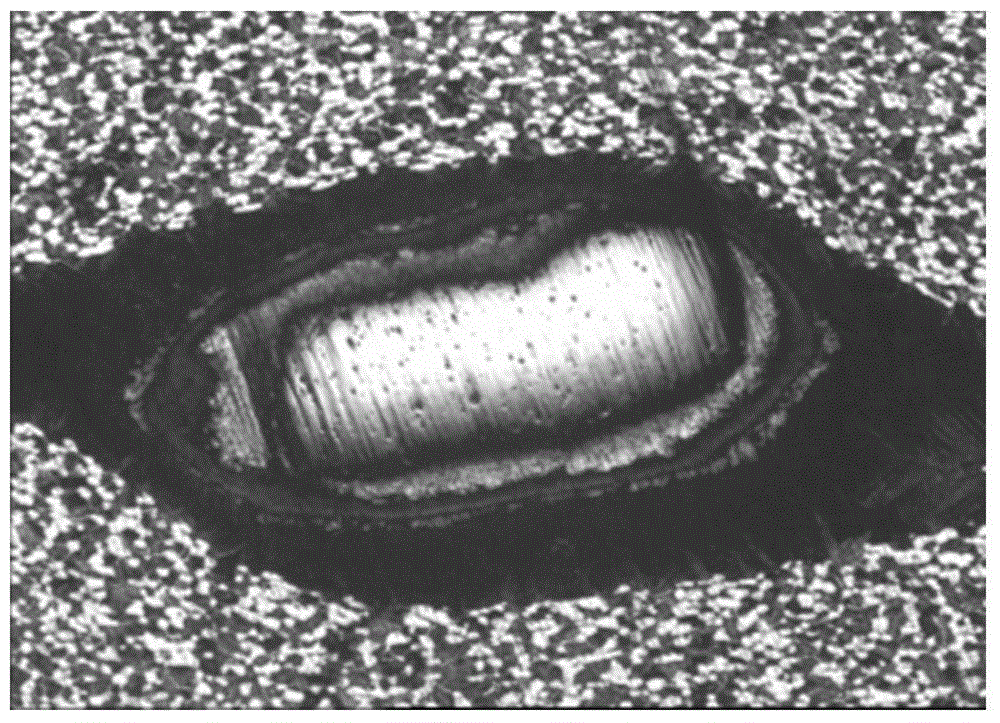

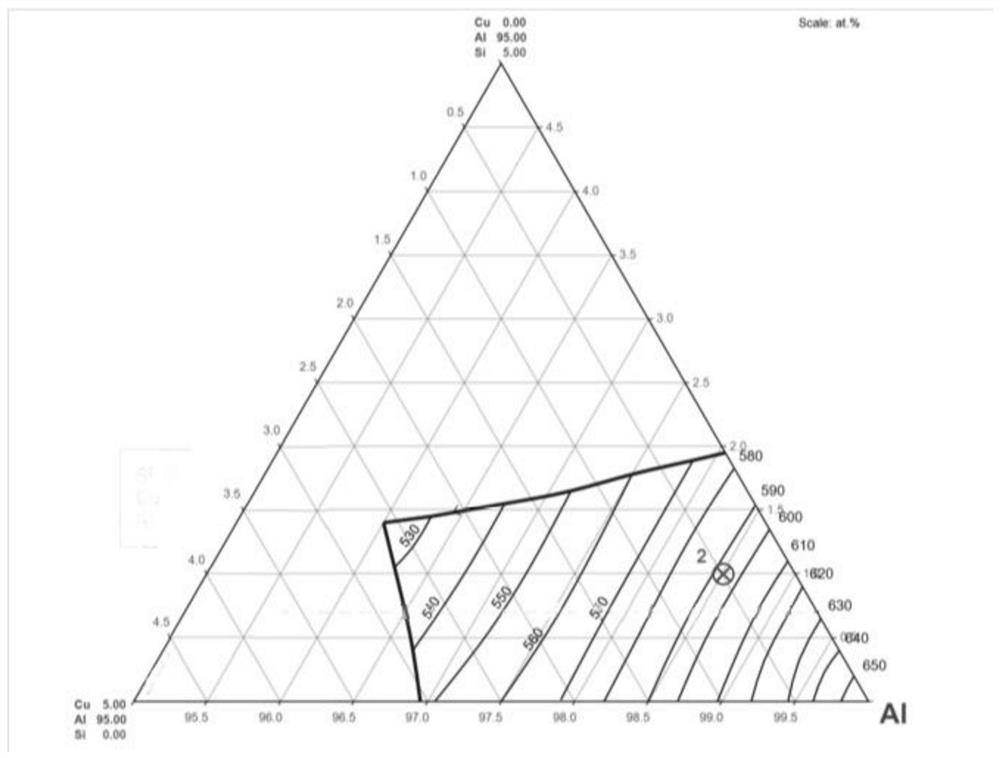

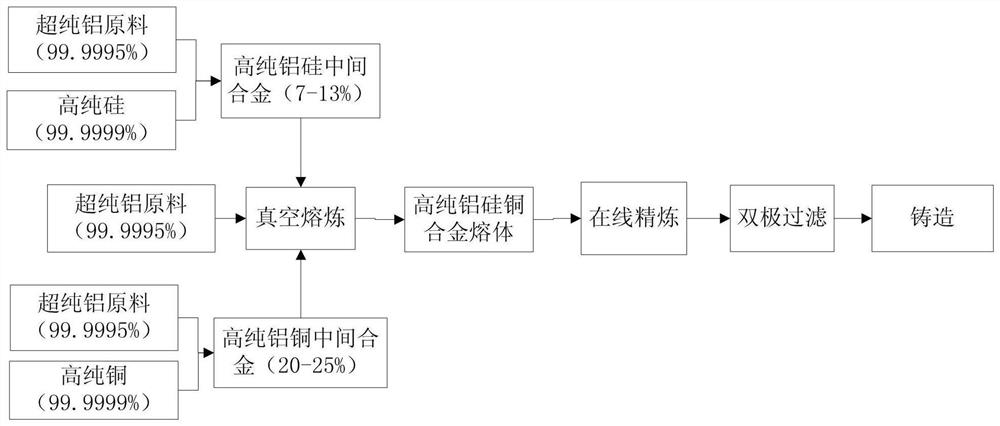

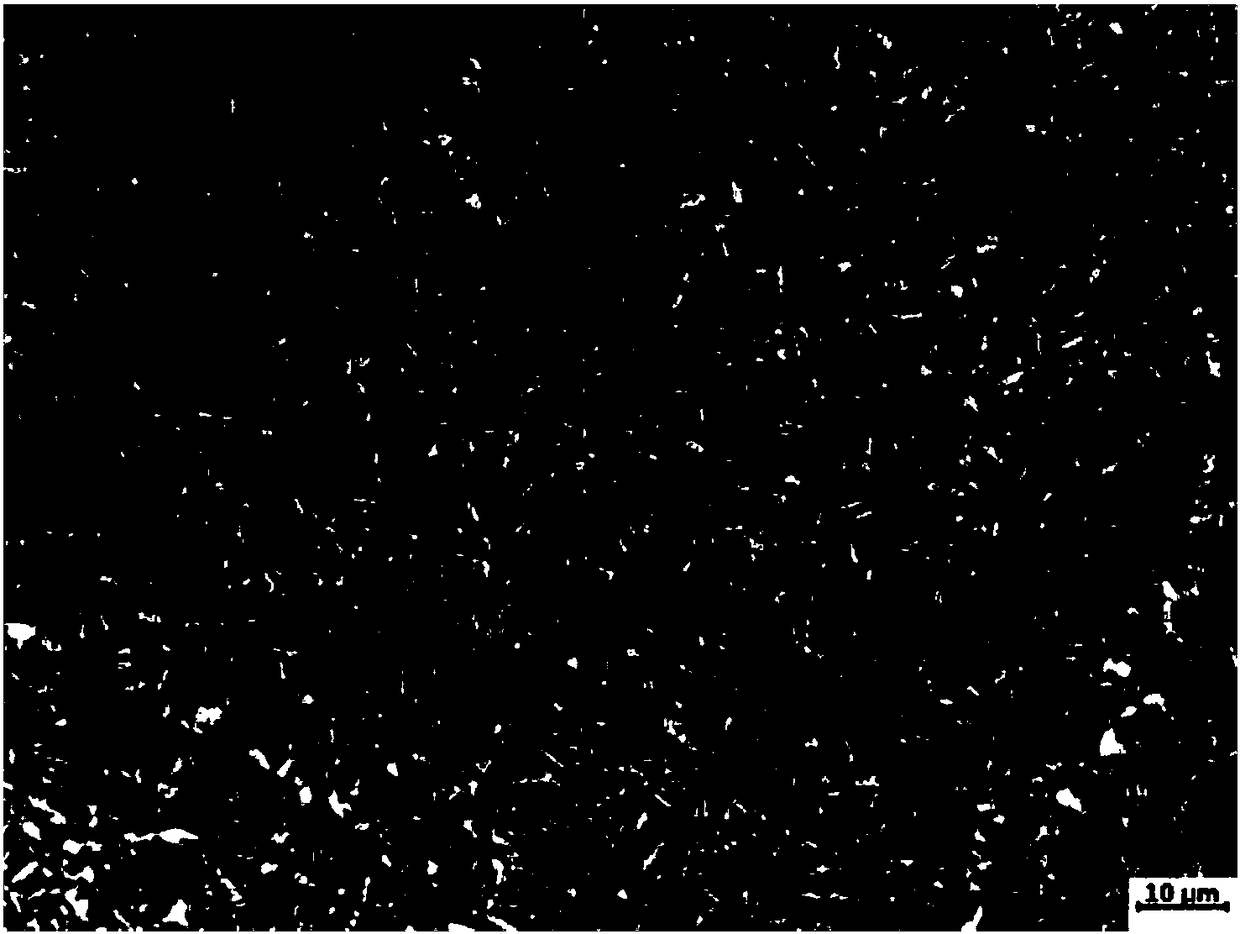

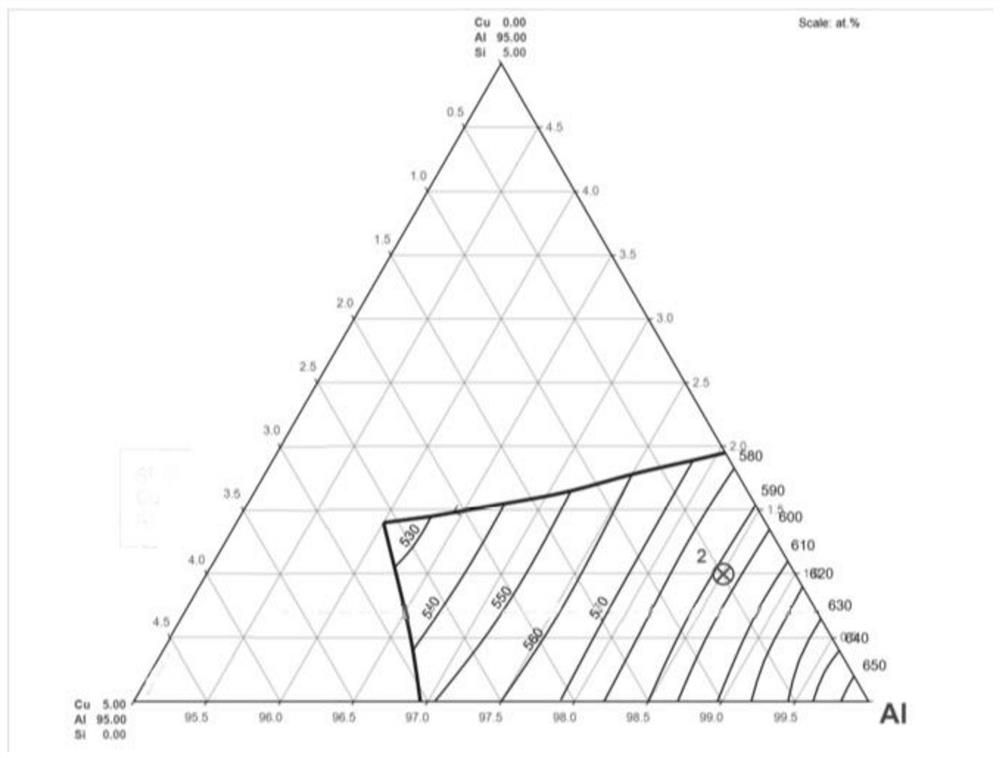

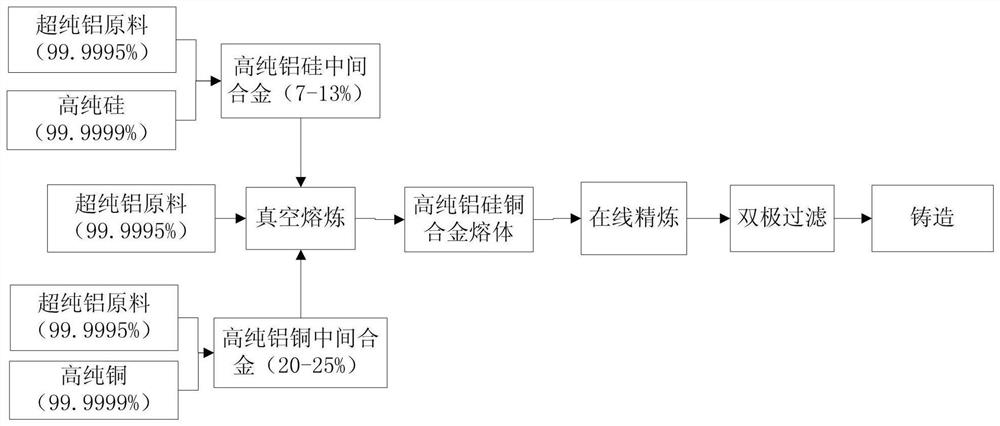

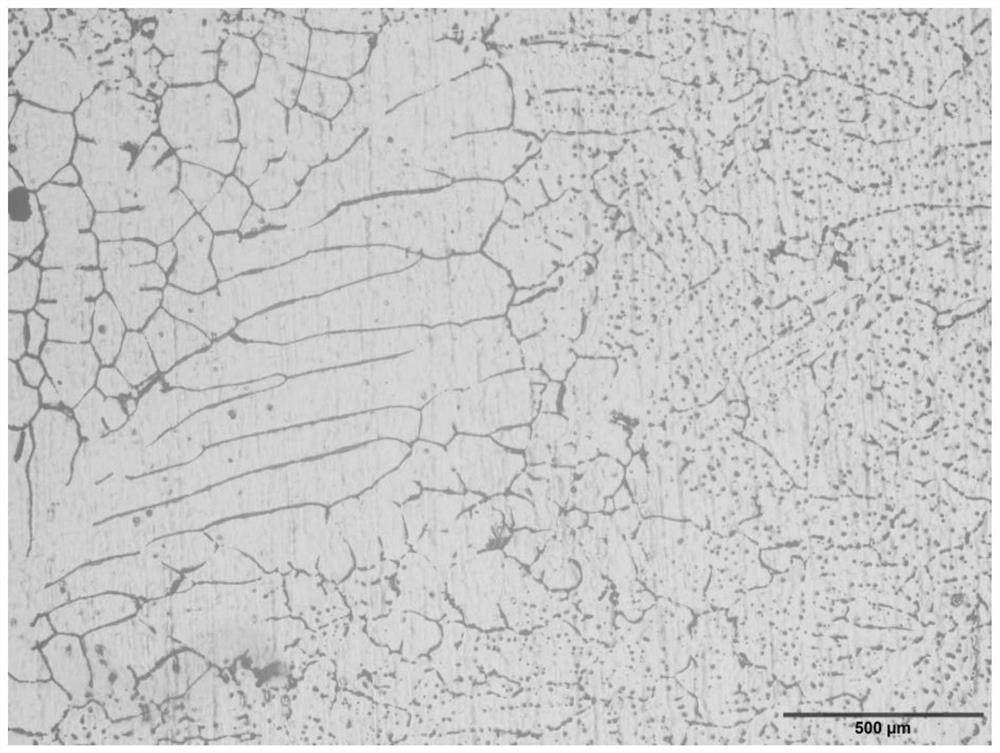

Preparation method of fine-grained high-purity aluminum silicon copper alloy target blank for sputtering

ActiveCN111719059AUniform compositionLow content of impurities and trace elementsVacuum evaporation coatingSputtering coatingAluminiumCopper alloy

The invention discloses a preparation method of a fine-grained high-purity aluminum silicon copper alloy target blank for sputtering. The preparation method of the fine-grained high-purity aluminum silicon copper alloy target blank for sputtering comprises the steps that S10, an intermediate alloy is prepared, specifically, the intermediate alloy is an aluminum copper intermediate alloy and an aluminum silicon intermediate alloy; S20, the intermediate alloy is melted with high-purity aluminum with 99.9995% purity in a vacuum smelting furnace, alloy liquid is obtained after complete melting, and in the alloy liquid, the silicon content is 0.9-1.1 wt%, and the copper content is 0.45-0.55 wt%; S30, the alloy liquid is subjected to on-line refining with high-purity argon; S40, the alloy liquidafter on-line refining is subjected to two-stage filtration; and S50, the alloy liquid after two-stage filtration is casted into a phi 120-164 mm bar blank to obtain the fine-grained high-purity aluminum silicon copper alloy target blank for sputtering. According to the preparation method of the fine-grained high-purity aluminum silicon copper alloy target blank for sputtering, the prepared high-purity AL-1 wt% Si-0.5 wt% Cu target blank for sputtering has very low content of trace impurity elements, good sputtering film-forming performance and uniform composition.

Owner:XINJIANG JOINWORLD CO LTD

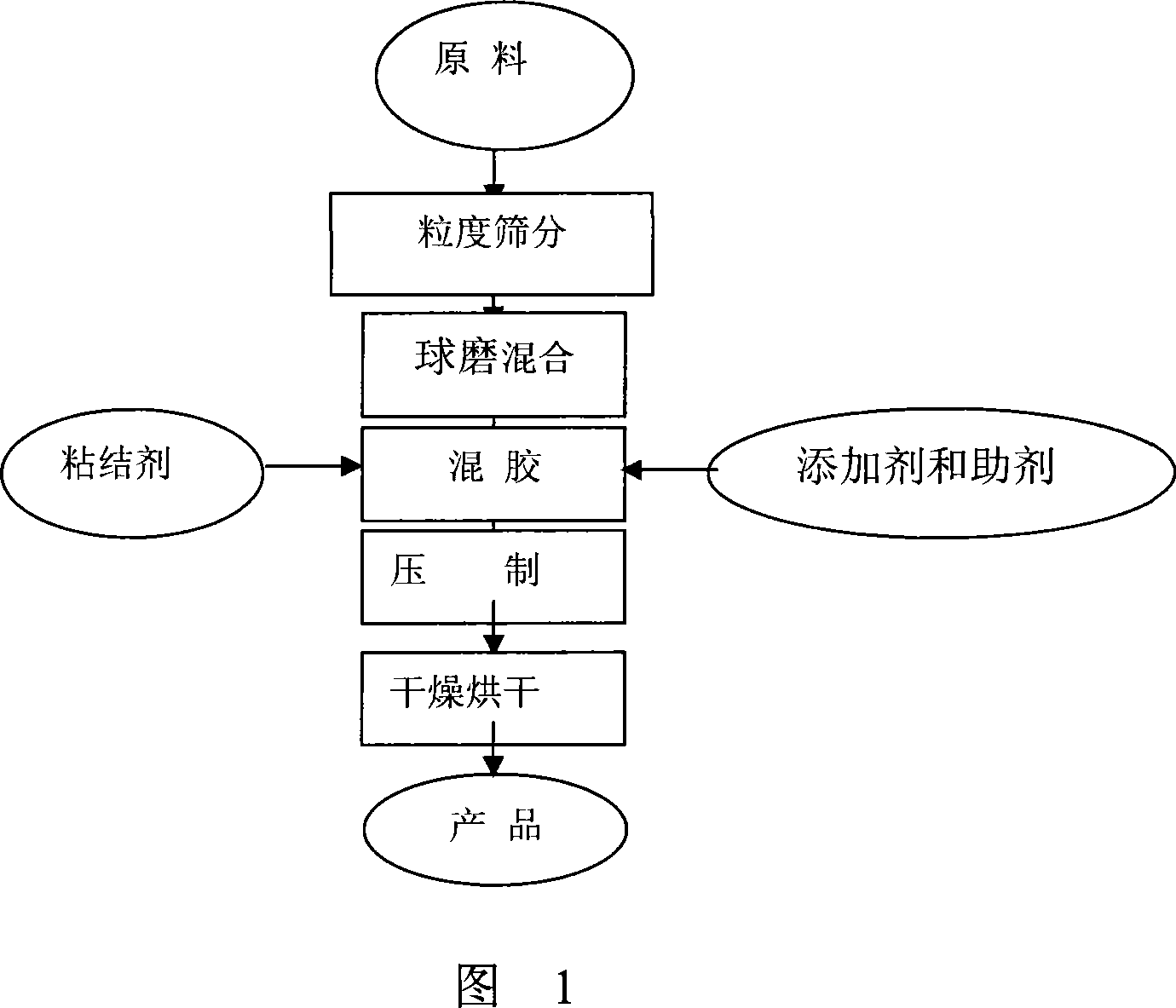

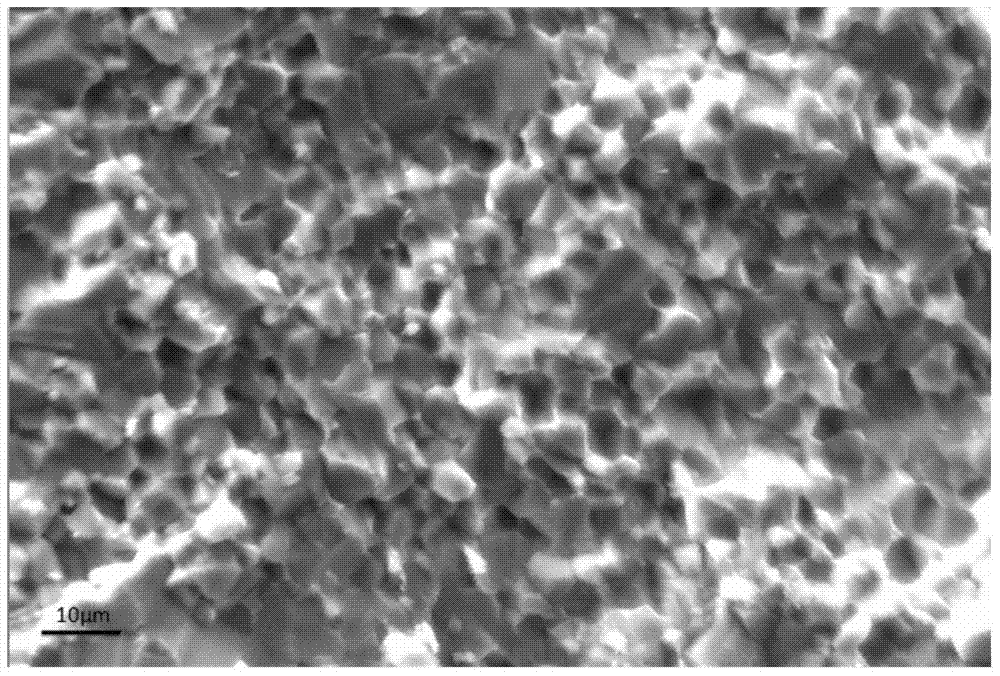

Preparation method of AlN ceramic base plate for microelectronic packaging

InactiveCN103539457AGuaranteed compositional uniformityGuaranteed uniformityCeramic sinteringCompression molding

Owner:HEFEI UNIV OF TECH +1

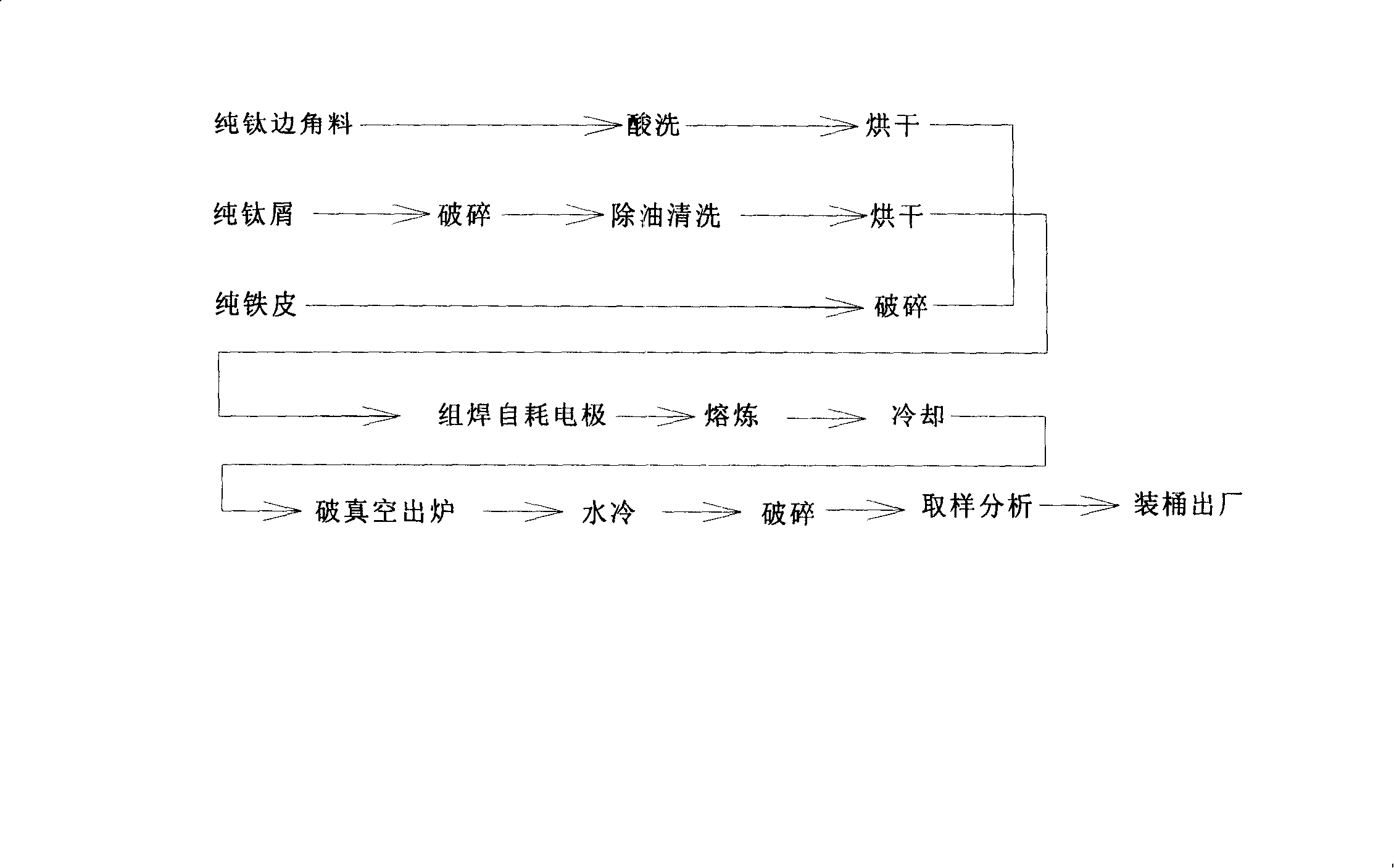

Method for manufacturing high-titanium ferrotitanium

The invention discloses a method of preparing high-Ti ferrotitanium. Leftover material of pure Ti, Ti crumbs and pure iron can be used as raw materials and then can be cut, broken, washed, and pressed into self-fluxing or consumable electrodes according to the weight proportion of 40 percent to 80 percent of Ti content; and then the product can be achieved by melting and cooling consumable electrodes under vacuum condition. Compared with other production manners, the invention has the advantages of less melting pollution, less inclusion and high Ti recycling rate. By comparing Multi-point sampling after the melting with the components which need to be added according to the theory, the difference value is equal or less than 1 percent, which meets the requirements of ISO 5454-1980 (E).

Owner:南京宝泰特种材料股份有限公司

Ti-rich high-entropy alloy with high specific strength, high plasticity and high toughness and preparation of Ti-rich high-entropy alloy

ActiveCN113652591AUniform compositionGood corrosion resistanceIncreasing energy efficiencyHigh entropy alloysCorrosion resistant

The invention relates to a Ti-rich high-entropy alloy with high specific strength, high plasticity and high toughness and a preparation method of the Ti-rich high-entropy alloy. The atomic percent expression of the high-entropy alloy is TiaZrbNbcVdAle, wherein a is greater than or equal to 42 and smaller than or equal to 46, b is greater than or equal to 21 and smaller than or equal to 23, c is greater than 13 and smaller than or equal to 16, d is greater than or equal to 13 and smaller than or equal to 15, e is greater than or equal to 0 and smaller than or equal to 10, a / b is equal to 2, and a + b + c + d + e is equal to 100. A single-BCC-phase high-entropy alloy is obtained by regulating and controlling the alloy components and the preparation process. Compared with a traditional metal material, the alloy has the advantages of being high in specific strength, excellent in tensile plasticity, high in impact toughness and the like, and the problem that the traditional metal material or high-entropy alloy is difficult to have high strength, high plasticity and high toughness at the same time is solved. The Ti-rich high-entropy alloy has a relatively low melting point by limiting the component ratio of Ti to Zr, can be used for preparing alloy ingots of tonnage or above by adopting a conventional smelting method, is easy to form and simple in preparation process and facilitates implementation of industrial application. The alloy contains Zr, Nb and other elements, and has good corrosion resistance. The alloy has wide application prospects in the fields of ocean, aerospace and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Strip vacuum plasma film-plating system

ActiveCN106917070ASimple structureEasy to makeVacuum evaporation coatingSputtering coatingEngineeringAutomation

The invention discloses a strip vacuum plasma film-plating system. A vacuum obtaining system is connected to multiple continuous type film-plating chambers through a vacuum connection pipeline. Each continuous type film-plating chamber comprises an unreeling device, a reeling device, and a heating tube mechanism, which are arranged in the continuous type film-plating chamber, and also comprises an inlet air and outlet air mixing device and a filter cathode target generation device, which are arranged on the lateral wall of the continuous type film-plating chamber. A first valve and a second valve are arranged on the vacuum connection pipeline. The first valve is arranged in the outlet of the vacuum obtaining system. The second valve is arranged above the joint between the vacuum connection pipe and the continuous type film-plating chambers. The design of the provided strip vacuum plasma film-plating system is scientific and reasonable. The operation is stable, the deviation is avoided, the automation degree is improved, at the same time, the product quality is largely improved, the production efficiency is improved, and more economic benefits are generated.

Owner:广州市中昊装饰材料有限公司

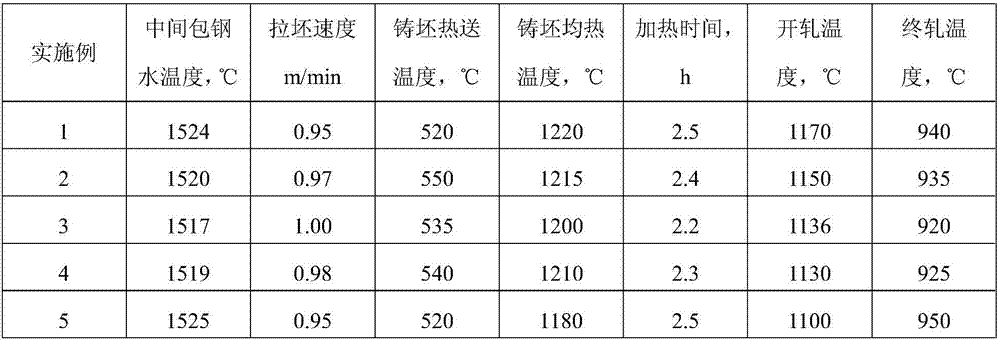

Production process of continuous casting gear steel bar for rail transit

InactiveCN113817951AFully deoxygenatedFull desulfurization removalElectric furnaceProcess efficiency improvementTemperingSlow cooling

The invention discloses a production process of a continuous casting gear steel bar for rail transit, and relates to the technical field of steel production. The production process adopts a production mode of continuous casting and continuous rolling to replace a production mode of die casting and forging. The production process comprises the steps of EAF smelting, LF refining, VD refining, wire feeding, fine component adjustment, static stirring, continuous casting, casting blank slow cooling, heating, rolling, pit entering slow cooling, high-temperature tempering, straightening, peeling, ultrasonic flaw detection, finished product inspection, packaging, marking, weighing and warehousing. The production process aims at the purity control problem, the segregation control problem and the hardness control problem in the production process, the preparation method is provided, and the gear steel with the purity, the structure, the hardenability, the grain size and the surface quality meeting the rail transit requirements can be prepared.

Owner:NANJING IRON & STEEL CO LTD

Zinc alloy material for degradable cardiovascular stent and preparation method of zinc alloy material

PendingCN113444919AReduced Galvanic CorrosionImprove degradation uniformitySurgeryMagnesiumChloroethane

The invention relates to a zinc alloy material for a degradable cardiovascular stent and a preparation method of the zinc alloy material, and belongs to the technical field of materials. The zinc alloy material comprises, by weight, 0.03-0.07% of Mg, 0.03-0.07% of Mn, less than or equal to 10ppm of inevitable impurities and the balance Zn. The preparation method comprises the following steps that (1) pure zinc is heated to 600 + / -5 DEG C, melted, magnesium metal, manganese metal and phosphorus are sequentially added, and uniformly stirred, the temperature is reduced to 550 + / -5 DEG C, hexachloroethane is pressed to preserve heat and stand for 10-20 minutes, and metal melt is cooled to 500 + / -10 DEG C, and cast; (2) secondary magnetic suspension smelting is carried out, so that the component uniformity deviation is smaller than + / -0.02 wt.%; (3) heat is preserved at 350 DEG C for 5 hours, temperature is raised to 370 DEG C, heat is preserved for 5 hours, and cooling is performed to the room temperature in water; (4) heat preservation is conducted for 60-80 min at the temperature of 300-400 DEG C, and then hot forging deformation is conducted at the temperature of 300-400 DEG C; and (5) heat preservation is conducted for 30 min at the temperature of 150 DEG C, and then reverse hot extrusion deformation is conducted at the temperature of 150 DEG C. According to the zinc alloy material for the degradable cardiovascular stent and the preparation method of the zinc alloy material, a Zn-Mg-Mn alloy is excellent in mechanical property and uniform in tissue component, and can be used for preparing the biodegradable cardiovascular stent.

Owner:NORTHEASTERN UNIV

A kind of titanium/aluminum gradient material and preparation method thereof

The invention relates to a high-performance material based on aerospace application and a preparation method, in particular to a powder metallurgy preparation technology of a titanium / aluminum gradient material, and aims to solve the problem of difficult obtaining of a titanium / aluminum gradient structure with high bonding strength due to high joining temperature, high residual stress and difficult interface reaction control in a traditional preparation process. A titanium sintering body and an aluminum presintering body are prepared by a powder metallurgy forming and sintering method; and then, two prefabricated bodies are laminated to be subjected to powder metallurgy sintering to obtain the high-performance titanium / aluminum gradient material. The obtained high-performance titanium / aluminum gradient material has no obvious matrix deformation, and reaches the interface stretching resistant strength of not less than 100 MPa. The preparation method is suitable for preparation of larger-size titanium / aluminum gradient material, and can be expanded to other dissimilar metal gradient structure. The preparation method is simple in operation, easy to control and convenient for industrial application.

Owner:CENT SOUTH UNIV

Anti-PID-effect double-sided battery and preparation method thereof

PendingCN112864279AReduce failureAvoid accessFinal product manufactureChemical vapor deposition coatingPhysicsSilicon chip

The invention discloses an anti-PID-effect double-sided battery and a preparation method thereof, and belongs to the technical field of battery preparation. According to the preparation method of the anti-PID-effect double-sided battery, a layer of silicon oxide film is grown between a back aluminum oxide passivation layer and a back silicon nitride passivation and the protection layer of thedouble-sided battery by adopting an atomic layer deposition or plasma enhanced atomic layer deposition mode, so that on the basis that the passivation effect of an aluminum oxide field is not influenced, alkali metal ions are effectively prevented from entering the surface of the silicon wafer, and polarization and corrosive PID failure caused by the alkali metal ions is reduced. Meanwhile, on the interface of the aluminum oxide and the silicon nitride, the polarization effect caused by the K+center in the silicon nitride can be effectively reduced, and the PID failure caused by the silicon nitride layer is reduced.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID

A kind of preparation method of ti2alnb alloy material

ActiveCN106319236BImproves ingredient uniformityGood chemical uniformitySelf consumptionHeating time

The invention discloses a preparation method of a Ti2AlNb alloy material. The method comprises the steps of 1, preparing a Ti2AlNb alloy ingot through vacuum self-consumption electric arc melting, kish furnace smelting and vacuum self-consumption electric arc melting; 2, conducting primary homogenization treatment on the Ti2AlNb alloy ingot; and 3, wrapping the Ti2AlNb alloy ingot with asbestos cloth, then conducting heat-preservation heat treatment, and then sequentially conducting cogging forging, improved forging and finished product forging, so that the Ti2AlNb alloy material is finally obtained. The preparation method of the Ti2AlNb alloy material is simple in preparation process and reasonable in process design; an alloy is uniform in structure and stable in performance; the alloy ingot can be effectively refined, purified and homogenized through a smelting method; through the high-quality ingot, smooth implementation of subsequent hot working is guaranteed; by means of homogenization treatment, uniformity of alloy elements can be further improved through element diffusion; and wrapping treatment is conducted with the asbestos cloth, the temperature of the material can be effectively prevented from being lowered in the whole forging process, and large-deformation-amount forging for one heating time is achieved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Nodulizing agent for high-nickel austenite ductile iron as well as preparation and application methods of nodulizing agent

ActiveCN103882280AIncrease profitGood spherical effectProcess efficiency improvementRare earthDuctile iron

The invention relates to a nodulizing agent for high-nickel austenite ductile iron. The nodulizing agent comprises the following components by mass percent: 25-35% of nickel, 8-15% of magnesium, more than 30-40% of silicon, not more than 0.1% of rare earth, and the balance being iron and inevitable impurities, wherein the particle size of the nodulizing agent is 10-20mm. The nodulizing agent has the characteristics that the magnesium oxide content can be reduced, the yield of magnesium can be improved, the nodulizing rate and the production efficiency are improved, and the manufacturing cost is low.

Owner:CRRC CHANGZHOU AUTO PARTS CO LTD +1

Limestone mine tailings dolomite used in cement production batching method

ActiveCN112573842BImprove pass rateRaise the upper limit of MgO contentUnderground miningCement productionMining engineeringCrusher

The invention provides a method for mixing limestone mine tailings dolomite in cement production, which includes the following steps: drilling and sampling before mining, detecting the content of MgO in the mineral material, and selecting the sampling point where the MgO content difference exceeds 0.5%. Divide into different areas and mine in different areas; crush the ores in each area with a hammer crusher; use round piles in the homogenization silo to store them, and determine the size and height of the round piles according to the daily processing capacity of cement production. Results Calculation of the proportion of mineral materials mined in different areas in the round heap, so that the MgO content in the round heap after stockpiling is not more than 2.7%. The invention ensures the compositional uniformity of each batch of raw materials in the cement production process, avoids the influence of loading speed on the batching uniformity, increases the qualified rate of cement raw materials from 65% to more than 88%, and improves the qualified rate of cement; The invention also improves the utilization rate of dolomite, reduces mining cost and protects the environment.

Owner:SINOHYDRO BUREAU 9

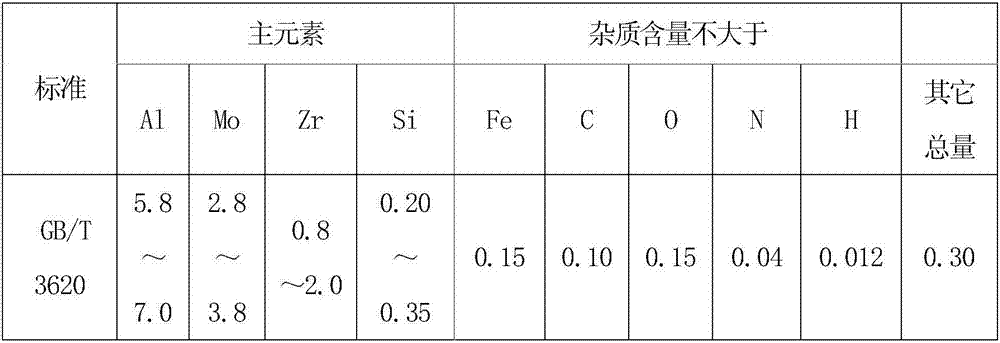

Ternary alloy for improving titanium alloy ingredient homogeneity and preparing method and application of ternary alloy

The invention relates to a ternary alloy for improving the titanium alloy ingredient homogeneity and a preparing method and application of the ternary alloy. A ternary intermediate alloy for improving the TC11 titanium alloy ingredient homogeneity is provided, and is basically composed of 5%-6% of Si, 55%-60% of Mo and the balance Al. Meanwhile, a preparing method and application of the ternary intermediate alloy are further provided. The ternary intermediate alloy is suitable for serving as a raw material of a high-strength high-temperature titanium alloy TC11; compared with other ternary alloys, the weight percentage of the Si is improved, the ingredient scope of the high-melting-point element Mo is shrunk, and therefore the smelting process of the ternary alloy is controllable, smelted cast condition blocks are better in crushing performance, powder-like products with the granularity smaller than or equal to 1 mm can be obtained, the ingredient homogeneity of the main elements including Si, Mo and Al in the TC11 alloy can be effectively improved, the probability that the high-melting-point element Mo forms high density inclusion segregation defects in the cast ingot smelting process is reduced, and the ingredient homogeneity of TC11 titanium alloy cast ingots and titanium materials is guaranteed.

Owner:宝武特种冶金有限公司

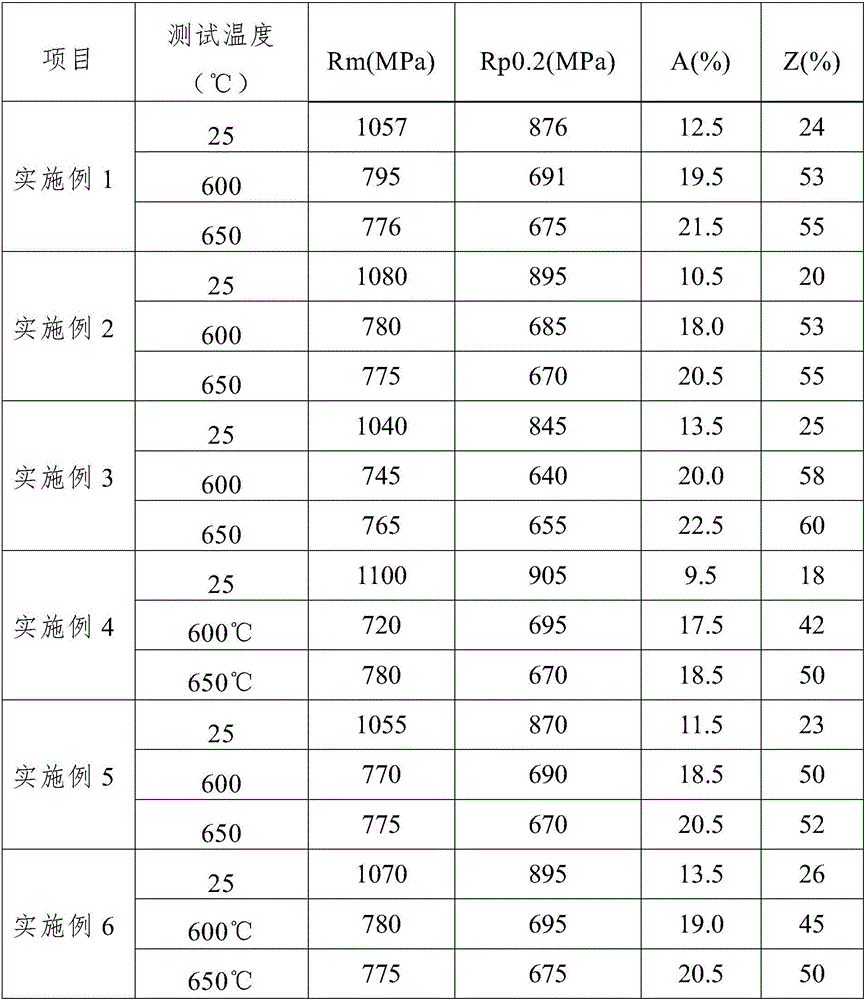

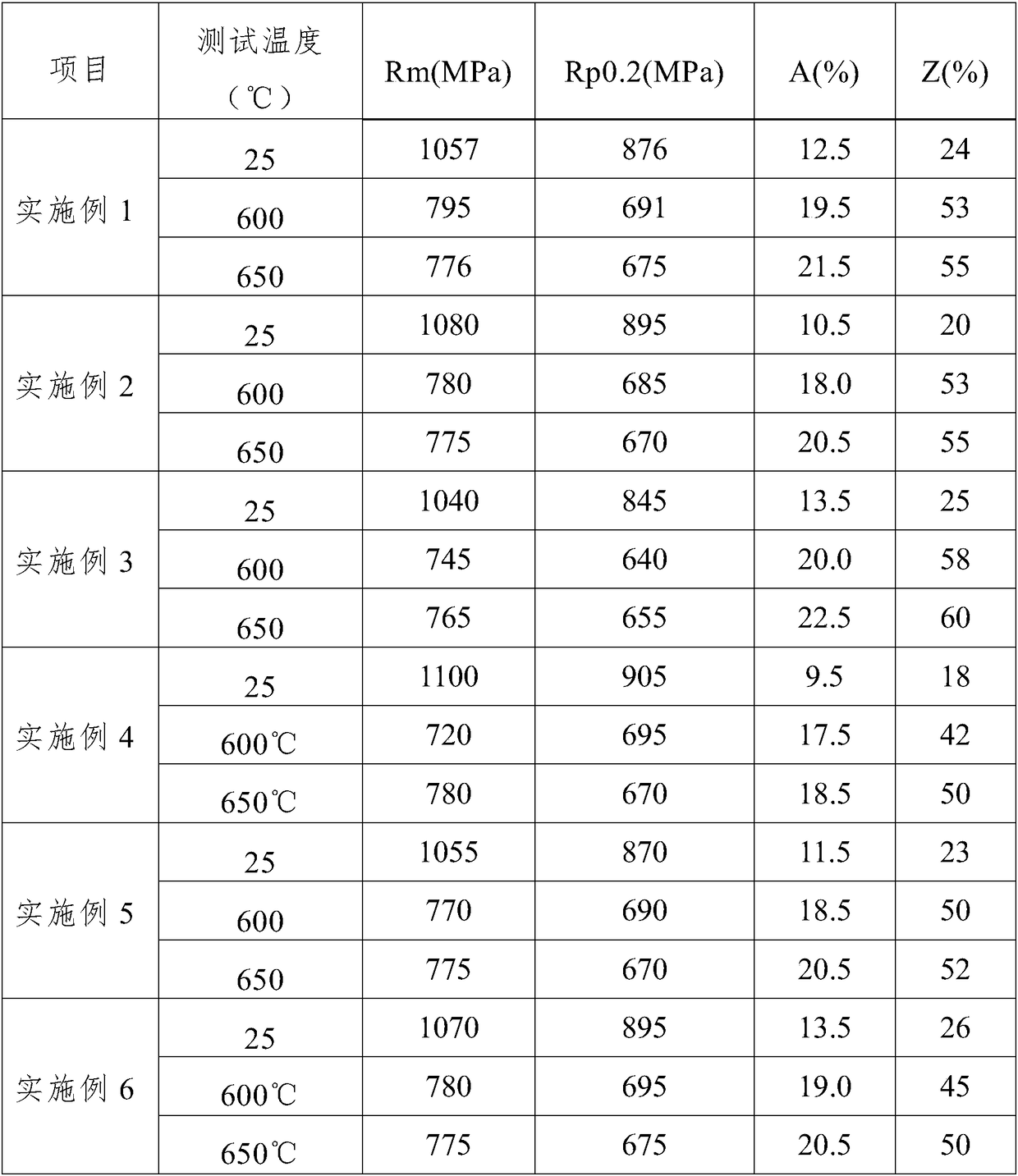

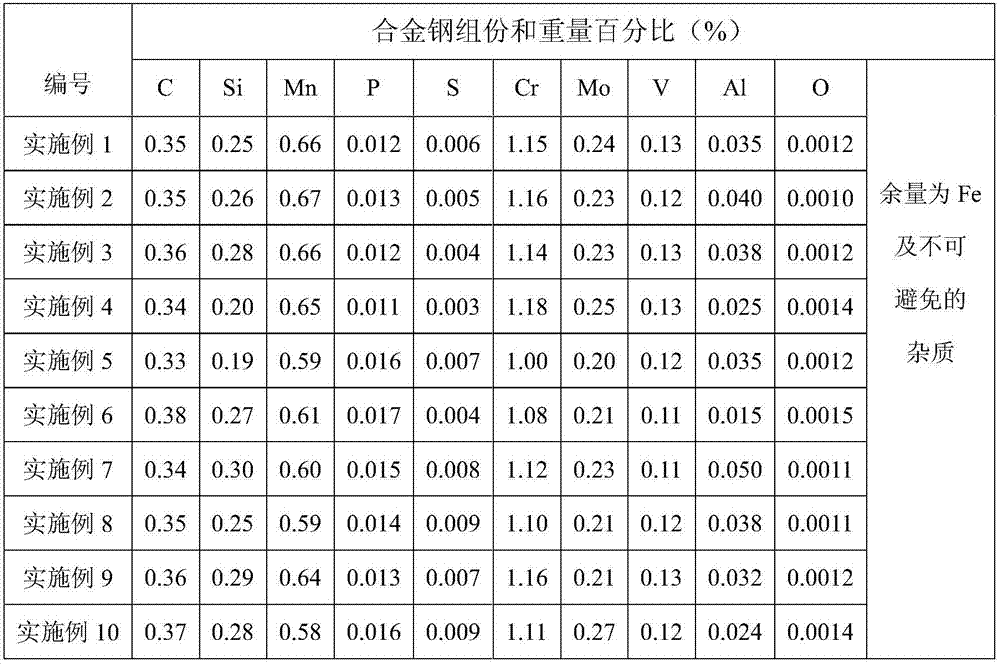

Medium-carbon vanadium-containing alloy steel for drill rod and preparation method thereof

The invention provides vanadium-containing medium-carbon alloy steel for a drill rod and a preparation method of the vanadium-containing medium-carbon alloy steel. The alloy steel comprises, by weight, 0.33-0.38% of C, 0.17-0.37% of Si, 0.50-0.70% of Mn, 1.00-1.20% of Cr, 0-0.025% of P, 0-0.020% of S, 0.20-0.30% of Mo, 0.10-0.15% of V, 0.015-0.060% of Al, 0-0.0015% of O and the balance Fe and inevitable impurities. The preparation method comprises the steps of electric furnace smelting, LF refining, VD vacuum degassing treatment, casting blank pouring through integral tundish continuous casting, hot charging rolling and round steel preparation. The vanadium-containing medium-carbon alloy steel for the drill rod has great machining performance, good hardenability and abrasion resistance, high high-temperature endurance strength, and corrosion resistance to a certain extent.

Owner:SHANDONG IRON & STEEL CO LTD

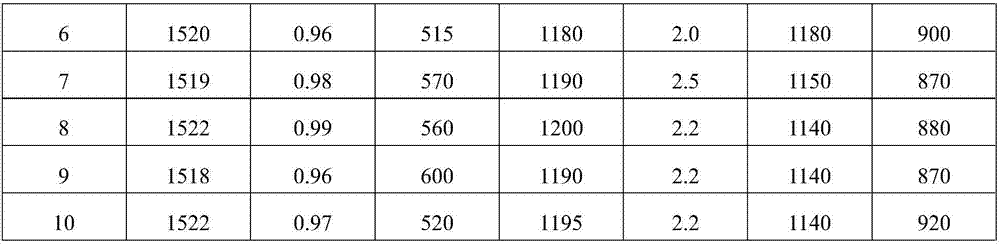

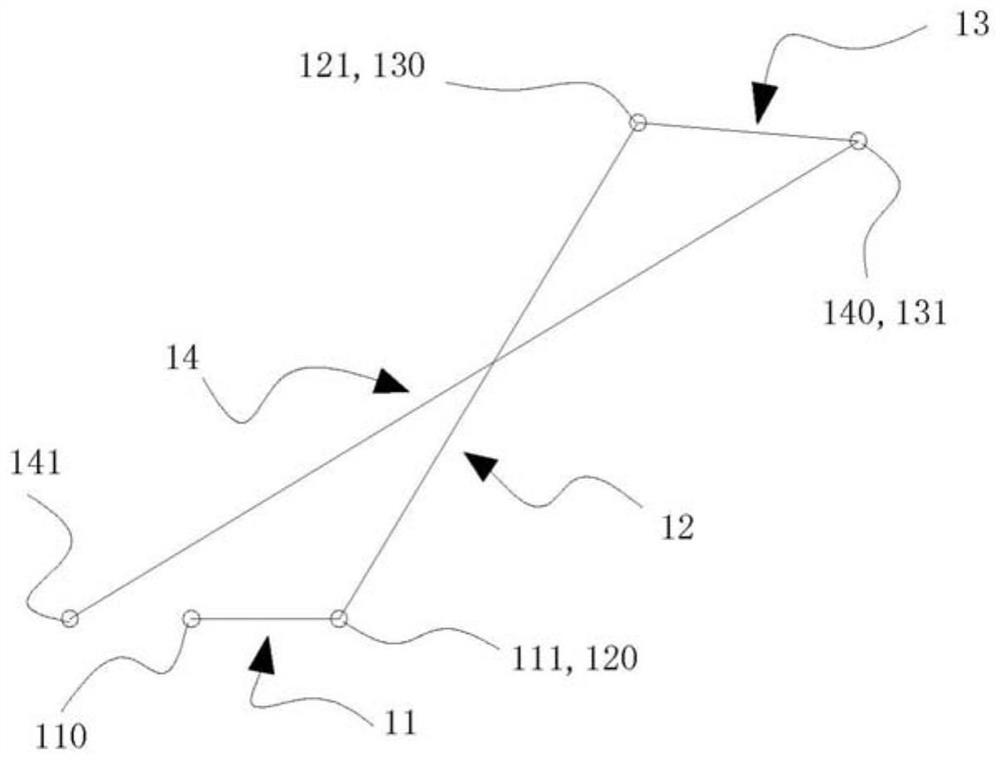

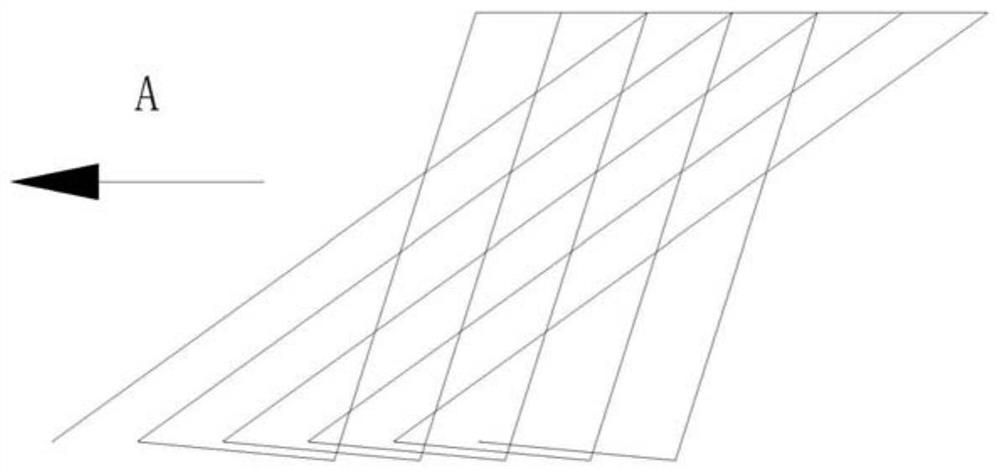

A kind of mag horizontal welding welding method and process

ActiveCN108941857BSimplify process control volumeLarge swing angleArc welding apparatusWeld seamMetal

The invention discloses an MAG horizontal welding method and technology. A plurality of track units are continuously distributed at a welded seam between weldments in the positive direction of weldingoperation; and each track unit comprises a plurality of welding tracks, and according to the welding sequence, operation of the first track located at the first station is conducted in the negative direction of welding operation. The invention further discloses the welding technology based on the welding method. Welding operation is conducted by adopting large technological parameters, the welding efficiency is improved, the fusion depth of parent metal at the welded seam is ensured, and in addition, the undercut and weld flash problems are solved to the great extent.

Owner:CRRC QINGDAO SIFANG CO LTD

A preparation method of fine-grained high-purity aluminum-silicon-copper alloy target blank for sputtering

ActiveCN111719059BReduce purityControl UniformityVacuum evaporation coatingSputtering coatingSputteringSilicon

The invention relates to a method for preparing a fine-grained high-purity aluminum-silicon-copper alloy target blank for sputtering. A method for preparing a fine-grained high-purity aluminum-silicon-copper alloy target blank for sputtering, comprising: S10 preparing a master alloy: the master alloy is an aluminum-copper master alloy and an aluminum-silicon master alloy; S20: making the master alloy The alloy and high-purity aluminum with a purity of 99.9995% are melted in a vacuum melting furnace, and after complete melting, an alloy liquid is obtained; the silicon content in the alloy liquid is 0.9-1.1wt%, and the copper content is 0.45-0.55wt%; S30: The alloy liquid is refined on-line with high-purity argon; S40: the alloy liquid that has been refined on-line is subjected to bipolar filtration; S50: the alloy liquid that has been filtered by two stages is cast into a φ120-164mm bar blank, and the obtained The above-mentioned fine-grained high-purity aluminum-silicon-copper alloy target blank for sputtering. According to the preparation method of a fine-grained high-purity aluminum-silicon-copper alloy target blank for sputtering according to the present invention, the content of trace impurity elements in the prepared high-purity AL‑1wt%Si‑0.5wt%Cu target blank for sputtering Very low, sputtering film formation performance is good, and the composition is uniform.

Owner:XINJIANG JOINWORLD CO LTD

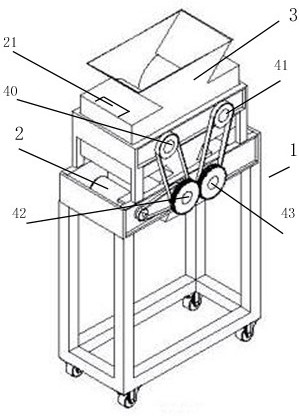

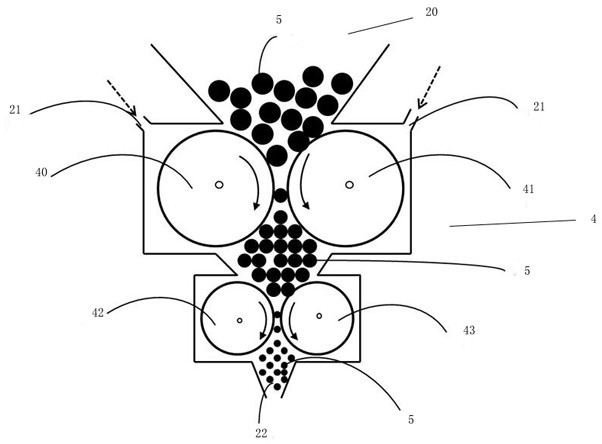

A kind of preparation method and preparation device of au-x nano alloy powder

ActiveCN108031852BReduce segregationGuaranteed compositional uniformityTransportation and packagingMetal-working apparatusMechanical crushingCrystal structure

A method for preparing Au-X nano-alloy powder and its preparation device. The invention includes three processes of alloy vacuum smelting, inert atmosphere protection mechanical crushing and wet high-energy ball milling: the alloy vacuum smelting can ensure the uniformity of the composition of the material and form a common crystal structure to reduce component segregation; mechanical crushing under the protection of inert atmosphere breaks the bulk material after alloy smelting into millimeter size; finally, the alloy powder particles after wet high energy ball milling are nanometer level. The Au-X (Sn, Ge, Si) nano-alloy powder prepared by the invention can be effectively used in welding products in the field of optical / microelectronic packaging, and its product reliability is higher. In addition, the process method has low requirements on equipment, is conducive to realizing large-scale industrialization, and its cost can be greatly reduced.

Owner:SHANWEI SOURCE ADVANCED MATERIALS CORP

A kind of preparation method of nickel base alloy ingot

The invention discloses a preparation method for a nickel-based alloy ingot. The method includes the steps that firstly, nickel powder and metal element powder are evenly mixed and then pressed, so that a block to be sintered is obtained; secondly, the block to be sintered is sintered under the hydrogen protection condition, so that a block to be molten is obtained; thirdly, the block to be molten is placed in a medium-frequency induction melting furnace to be subjected to medium-frequency induction melting treatment, so that nickel-based alloy melt is obtained, and then the nickel-based alloy melt is poured to obtain a melting electrode; and fourthly, the melting electrode is placed in a vacuum arc melting furnace to be subjected to vacuum arc melting treatment, so that the nickel-based alloy ingot is obtained. According to the method, the nickel-based alloy ingot is prepared by combining technological processes of medium-frequency induction melting treatment and vacuum arc melting treatment, the advantages of the two melting technologies are fully used, the defects of the two melting technologies are also overcome, and the obtained nickel-based alloy ingot has uniform macro components and a compact microstructure.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com