A kind of al-ti-nb-b refiner for cast aluminum-silicon alloy and its preparation method and application

An al-ti-nb-b, aluminum-silicon alloy technology, which is applied in the field of aluminum alloy smelting, can solve the problems of high cost, poor refining effect and high Nb content, and achieves reduction of raw material cost, good refining effect, and guaranteed composition. and the effect of tissue uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the present embodiment Al-Ti-Nb-B refiner comprises the following steps:

[0034] Step 1) The weighing of raw materials is carried out according to the nominal composition: 97.52 wt.% Al, 1.24 wt.% Ti, 0.80 wt.%Nb and 0.44 wt.% B, and the Al block (length, width and height are not greater than 8 mm, purity 99.9 wt.%) 19.695 g, Ti particles (diameter not larger than 3 mm, purity 99.9 wt.%) 0.255 g, Nb particles (diameter not larger than 3 mm, purity 99.9 wt.%) 0.168 g and B particles (diameter not greater than 2 mm, purity 99.5 wt.%) 0.089 g as raw material, additionally weigh 1% of the above-mentioned Al mass as burning loss;

[0035] Step 2) The smelting of Ti-Nb-B master alloy adopts a non-consumable arc melting furnace, under the protection of high-purity argon, and smelts the Ti-Nb-B master alloy according to a conventional process;

[0036] Step 3) Melting of Al-Ti-Nb-B refining agent, adding Al block to Ti-Nb-B master alloy for smelting,...

Embodiment 2

[0047] The preparation steps not specifically described are the same as in Example 1, except that: the step 1) weighing of raw materials, according to the nominal composition: 97.58 wt. %Al, 0.70 wt. % Ti, 1.34 wt.% Nb and 0.38 wt. % B, weigh 19.716 grams of Al block, 0.143 grams of Ti particles, 0.264 grams of Nb particles and 0.076 grams of B particles as raw materials.

[0048] The final alloy obtained in this embodiment is recorded as Al-0.70Ti-1.34Nb-0.38B.

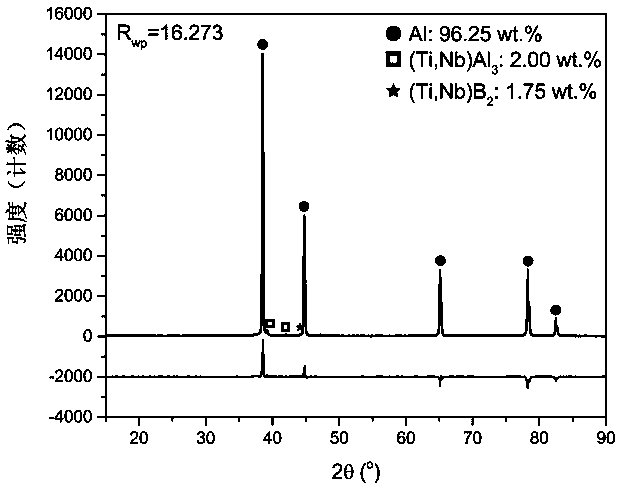

[0049] The microstructure of the Al-Ti-Nb-B refiner prepared in this embodiment is analyzed by X-ray diffraction, as Figure 5 As shown, its phase composition is 97.29 wt.% of α-Al, 1.55 wt.% of (Ti,Nb)Al 3 and 0.86 wt.% of (Ti,Nb,Al)B 2 .

[0050] The microstructure of the Al-Ti-Nb-B refiner prepared in this embodiment is analyzed by scanning electron microscope, as Figure 6 Shown, (Ti,Nb)Al 3 The particle size is 2~3 microns, dispersed in the alloy in an irregular shape; (Ti,Nb,Al)B 2 The particle size is 1~...

Embodiment 3

[0054] The preparation steps not specifically described are the same as in Example 1, except that: the step 1) weighing of raw materials, according to the nominal composition: 97.48 wt. %Al, 0.32 wt. % Ti, 1.87 wt.% Nb and 0.33 wt. % B, weigh 19.689 grams of Al block, 0.064 grams of Ti particles, 0.382 grams of Nb particles and 0.068 grams of B particles as raw materials.

[0055] The final alloy obtained in this embodiment is recorded as Al-0.32Ti-1.87Nb-0.33B.

[0056] The microstructure of the Al-Ti-Nb-B refiner prepared in this embodiment is analyzed by X-ray diffraction, as Figure 8 As shown, its phase composition is 97.77 wt.% of α-Al, 1.44 wt.% of (Ti,Nb)Al 3 and 0.79 wt.% of (Ti,Nb,Al)B 2 .

[0057] The microstructure of the Al-Ti-Nb-B refiner prepared in this embodiment is analyzed by scanning electron microscope, as Figure 9 Shown, (Ti,Nb)Al 3 The particle size is less than 20 microns, dispersed in the alloy in an irregular shape; (Ti, Nb, Al) B 2 The particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com