Aluminum alloy refiner, preparation method therefor and use thereof

A technology of aluminum alloy and refining agent, applied in the field of aluminum alloy smelting, can solve the problems of complex use steps and processes, high cost, wide application, limited refining effect, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The first step is the preparation of rapid solidification refiner strips.

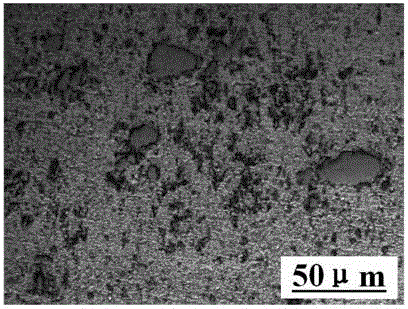

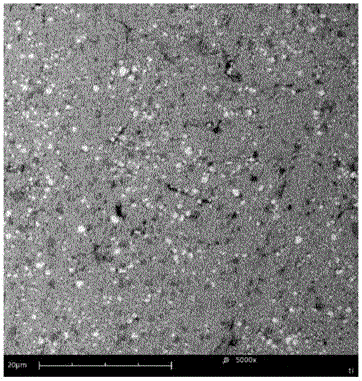

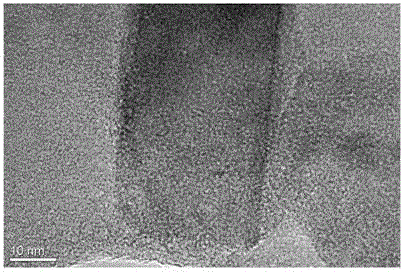

[0042] The small block of Al-Ti-B master alloy for industrial use (the length, width and height are not more than 6mm, the mass percentage of the constituent elements is: Ti5.0%, B1.0%, the sum of Fe, Cu, Mg, Mn is less than 0.15%, the balance Al, purchased from KBMAffilips company), Ti particles (diameter not greater than 2mm, purity 99.99%) and B particles (diameter not greater than 2mm, purity 99.99%) are made into Al-8Ti-3B composition, the above materials Mix (so that the element weight parts of Ti, B and Al are as shown in Table 1) and put into a quartz tube with a small hole with a diameter of 0.4 mm at the lower end. Heat the induction coil of the WK-IIB vacuum stripping machine until the test block in the quartz tube is completely melted, and spray the molten master alloy onto the copper roller with a rotation speed of 60 rpm to obtain a thickness of 8 μm and a width of 1.2 mm. The rap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com