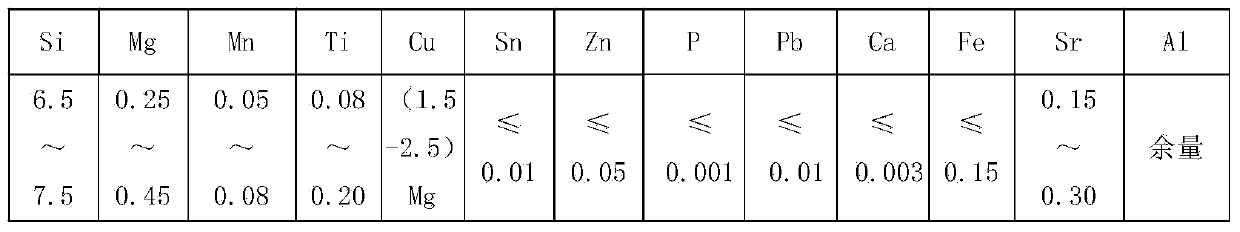

Hypoeutectic Al-Si alloy material for all-aluminum engine of high-grade car and preparation method of hypoeutectic Al-Si alloy material

A high-end automobile and aluminum-silicon alloy technology, applied in the field of aluminum-silicon alloy, can solve the problems of not meeting the requirements of high-end automobile engines and low alloy mechanical properties, and achieve the effect of short melting time, low melting temperature and complete melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of hypoeutectic aluminum-silicon alloy material for high-end automobile all-aluminum engine, the specific steps are:

[0036] ⑴ The upper limit of Cu and Sr elements and decalcifying agent is as follows: Si: 7.1%, Mg: 0.36%, Cu: 0.54% (Cu: Mg = 2.5:1), Ti: 0.11%, Mn: 0.063%, and Sr: 0.028 %, and receive industrial silicon, magnesium, copper, AlTi10, AlMn10, AlSr10, and aluminum ingots for remelting a total of 20t according to the ingredient card;

[0037] ⑵Weigh 40kg of Xuzhou Liwei Aluminum Decalcifying Agent;

[0038] ⑶ Put all the raw materials in step (1) and step (2) into a constant temperature preheating drying room at a temperature of 240°C and dry for 2 hours;

[0039] ⑷Put the dried aluminum ingots for remelting into the flame reflection melting furnace, and ignite natural gas to melt;

[0040] ⑸ After all the aluminum ingots are melted, adjust the temperature of the molten aluminum to 739℃ and prepare the converter;

[0041] ⑹Sprinkle the dried desc...

Embodiment 2

[0050] A preparation method of hypoeutectic aluminum-silicon alloy material for high-end automobile all-aluminum engine, the specific steps are:

[0051] ⑴Cu, Sr element and the lower limit of decalcifying agent, according to Si: 7.2%, Mg: 0.33%, Cu: 0.5% (Cu: Mg = 1.5:1), Mn: 0.072%, Ti: 0.11%, Sr: 0.018% The proportion of batching, and according to the batching card to receive industrial silicon, metal magnesium, copper rice, AlTi10, AlMn10, AlSr10, aluminum ingots for remelting a total of 20t;

[0052] ⑵ Weigh 30kg of Xuzhou Liwei Aluminum Decalcifying Agent;

[0053] ⑶ Put all the raw materials in step (1) and step (2) into a constant temperature preheating drying room at a temperature of 280°C for 2 hours;

[0054] ⑷Put the dried aluminum ingots for remelting into the flame reflection melting furnace, and ignite natural gas to melt;

[0055] ⑸ After all the aluminum ingots are melted, adjust the temperature of the molten aluminum to 739℃ and prepare the converter;

[0056] ⑹Sprinkl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com