Patents

Literature

94results about How to "Melted completely" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal spray spherical particles, and sprayed components

InactiveUS6916534B2High densityImprove adhesionMolten spray coatingSynthetic resin layered productsBreaking strengthThermal spraying

Spherical particles of a rare earth (inclusive of yttrium)-containing compound and having a breaking strength of 10-300 MPa and an average particle diameter of 10-80 μm are suitable for plasma spraying.

Owner:SHIN ETSU CHEM IND CO LTD

Processing of fine silicon powder to produce bulk silicon

InactiveUS20080295294A1Reduce pressureQuality improvementPolycrystalline material growthSiliconIngotArgon gas

A method for using substantial quantities of silicon powders as charge and processing it to produce a high quality silicon ingots suitable for photovoltaic use is disclosed. In a fused silica crucible, silicon feedstock containing more than about 5% by weight silicon powder is charged. The crucible with the charged silicon feedstock is placed into a furnace chamber and a vacuum is drawn to remove air. The vacuum is applied slowly. Then, the furnace chamber is backfilled with argon gas and heated to form molten silicon. Afterward, the molten silicon is solidified and annealed to form a multicrystalline silicon ingot.

Owner:GT SOLAR INC

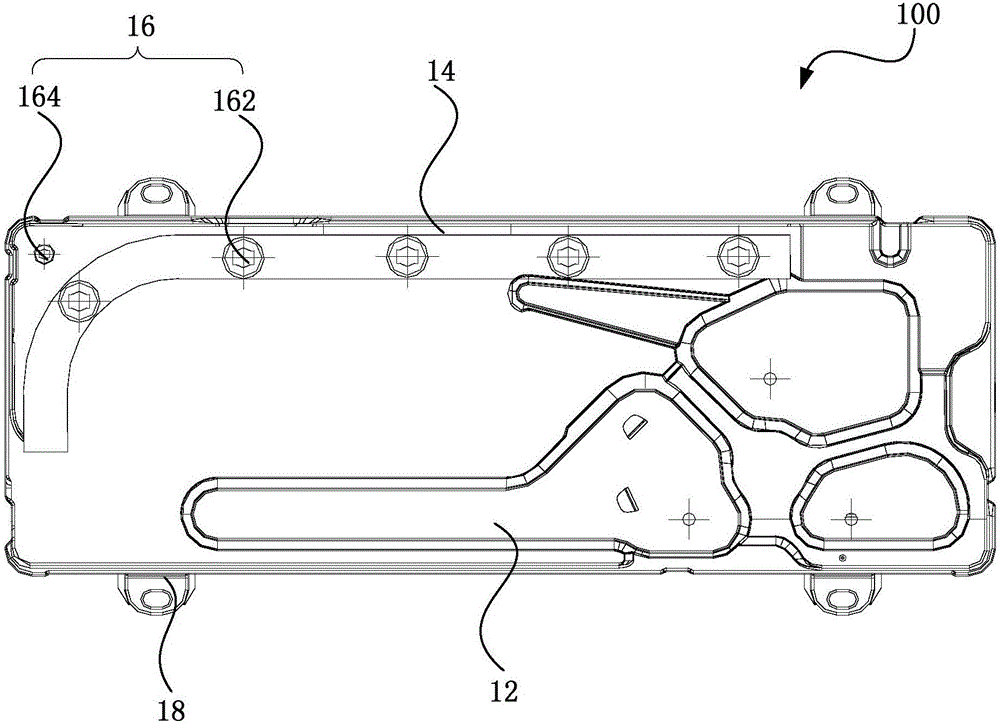

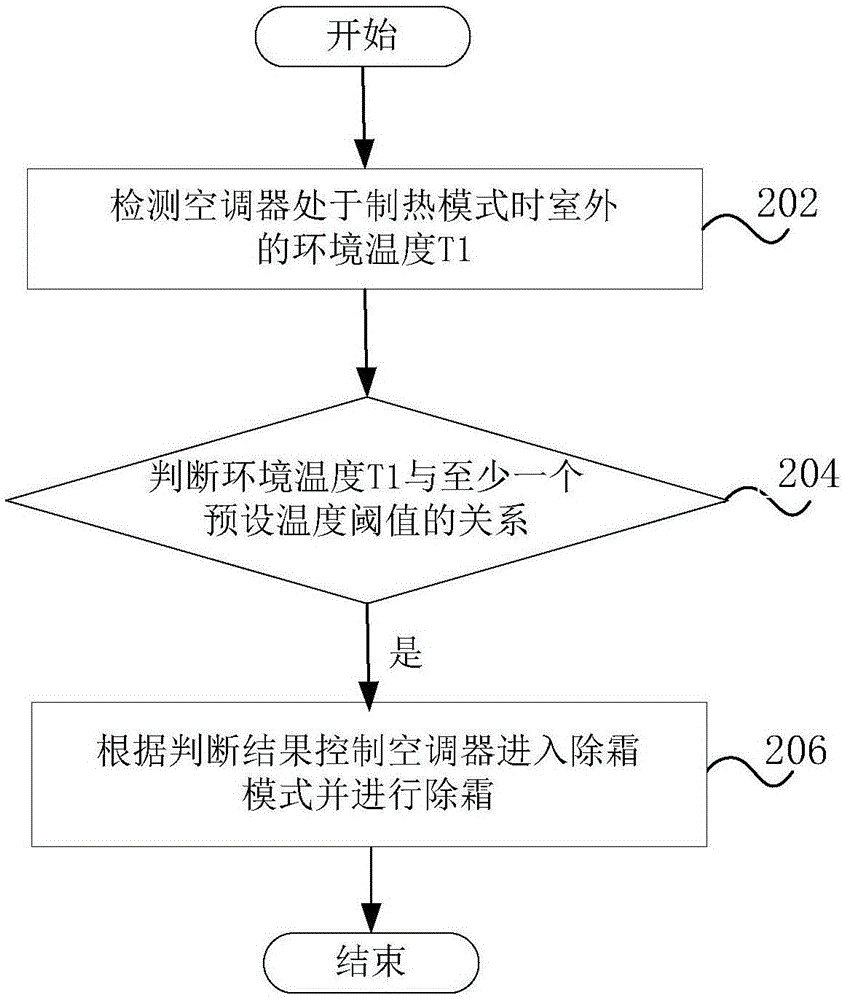

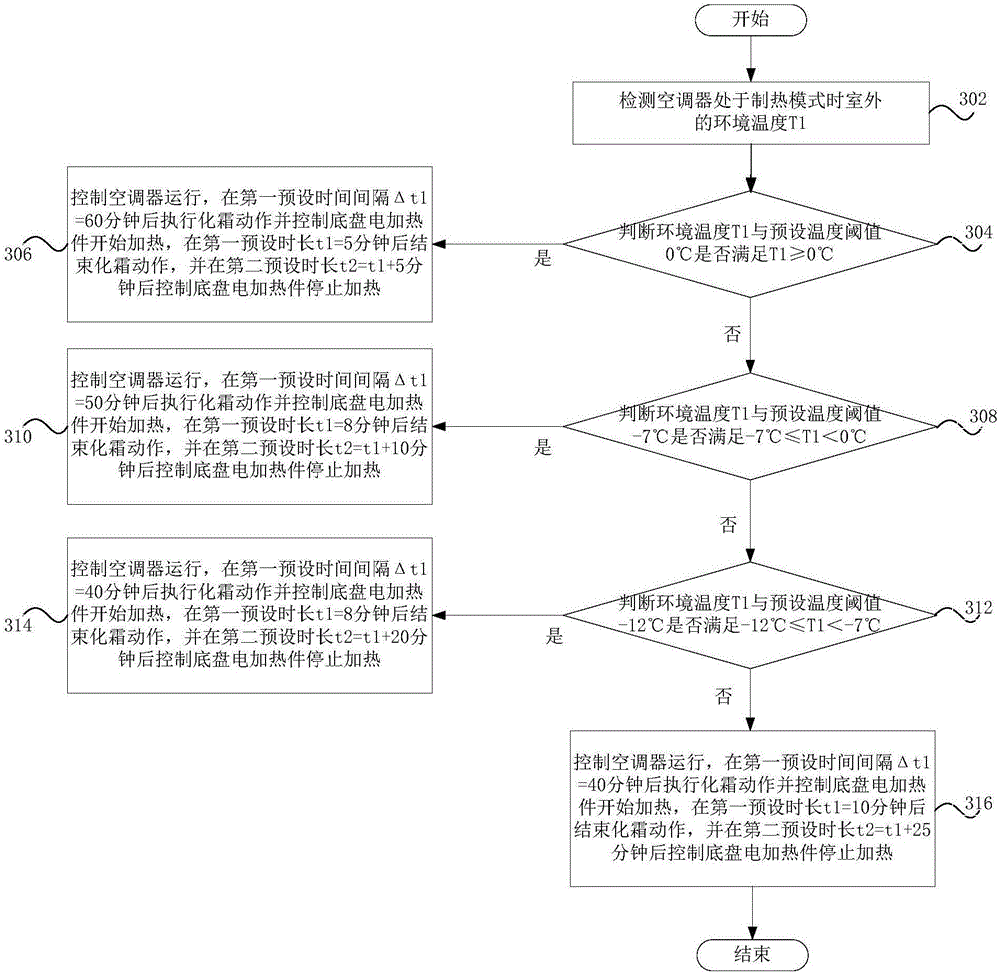

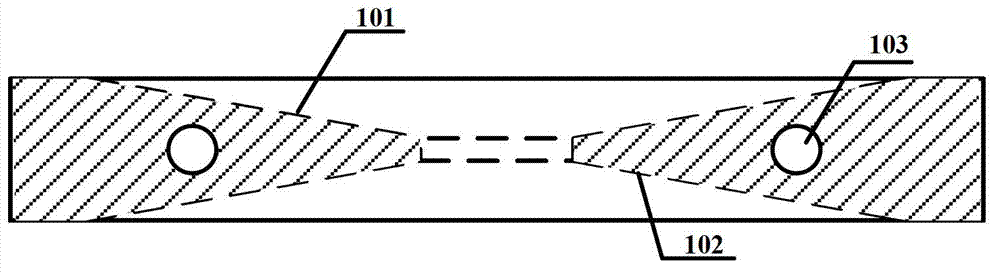

Base plate structure, air conditioner and defrosting control method for air conditioner

PendingCN106352443AHigh speedImprove defrosting efficiencyMechanical apparatusSpace heating and ventilation safety systemsFrostEngineering

The invention provides a base plate structure for an outdoor unit of an air conditioner, the outdoor unit of the air conditioner, the air conditioner and a defrosting control method for the air conditioner. The base plate structure for the outdoor unit of the air conditioner comprises an outdoor unit base plate, a base plate electric heating element and a drainage part, wherein a compressor fixing support is arranged on the outdoor unit base plate, and a condenser is installed on the outdoor unit base plate; the base plate electric heating element is arranged at the bottom of the condenser and located above the outdoor unit base plate; and the drainage part is arranged on the outdoor unit base plate and comprises at least one main drainage port, and the main drainage port is located below the base plate electric heating element. By adopting the base plate structure, when the air conditioner is heated for defrosting at a lower outdoor temperature, frost on the condenser and the outdoor unit base plate can be quickly and thoroughly thawed, and the thawed water quickly and smoothly flows out of the main drainage port, so the frost is thawed cleanly and thoroughly, the temperature of an indoor air port is improved, a good heating effect is guaranteed, and the market competitiveness of the product is improved.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP +1

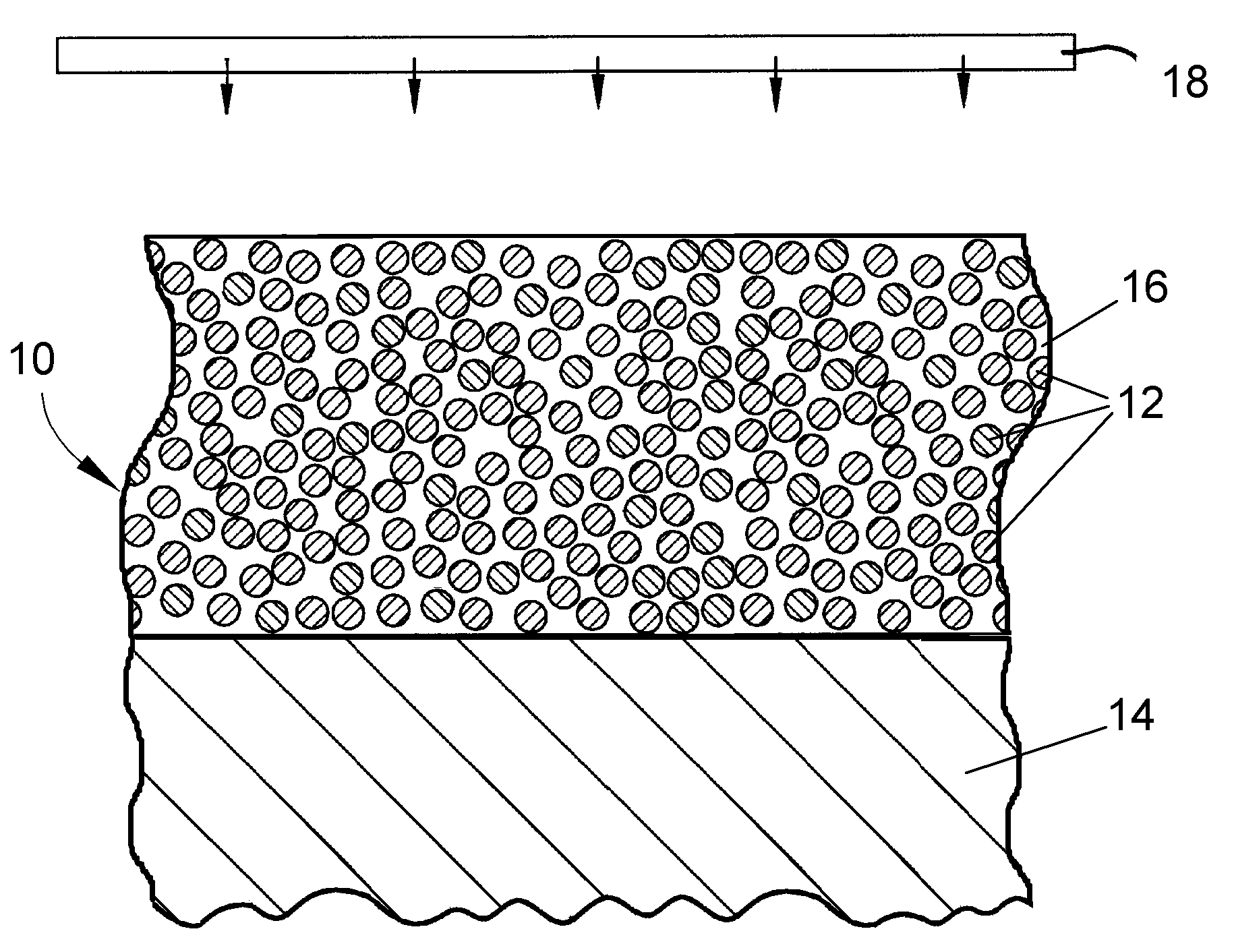

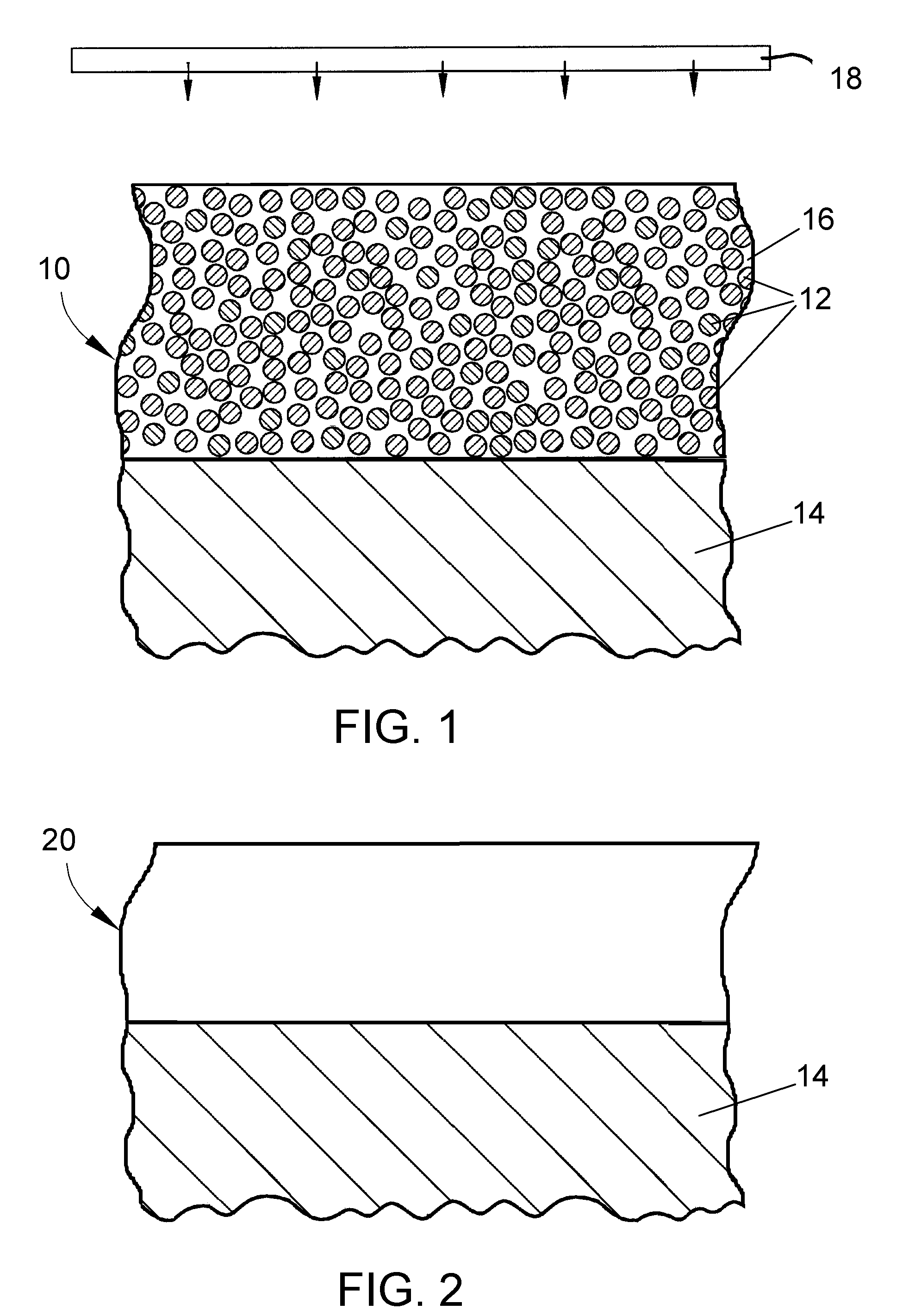

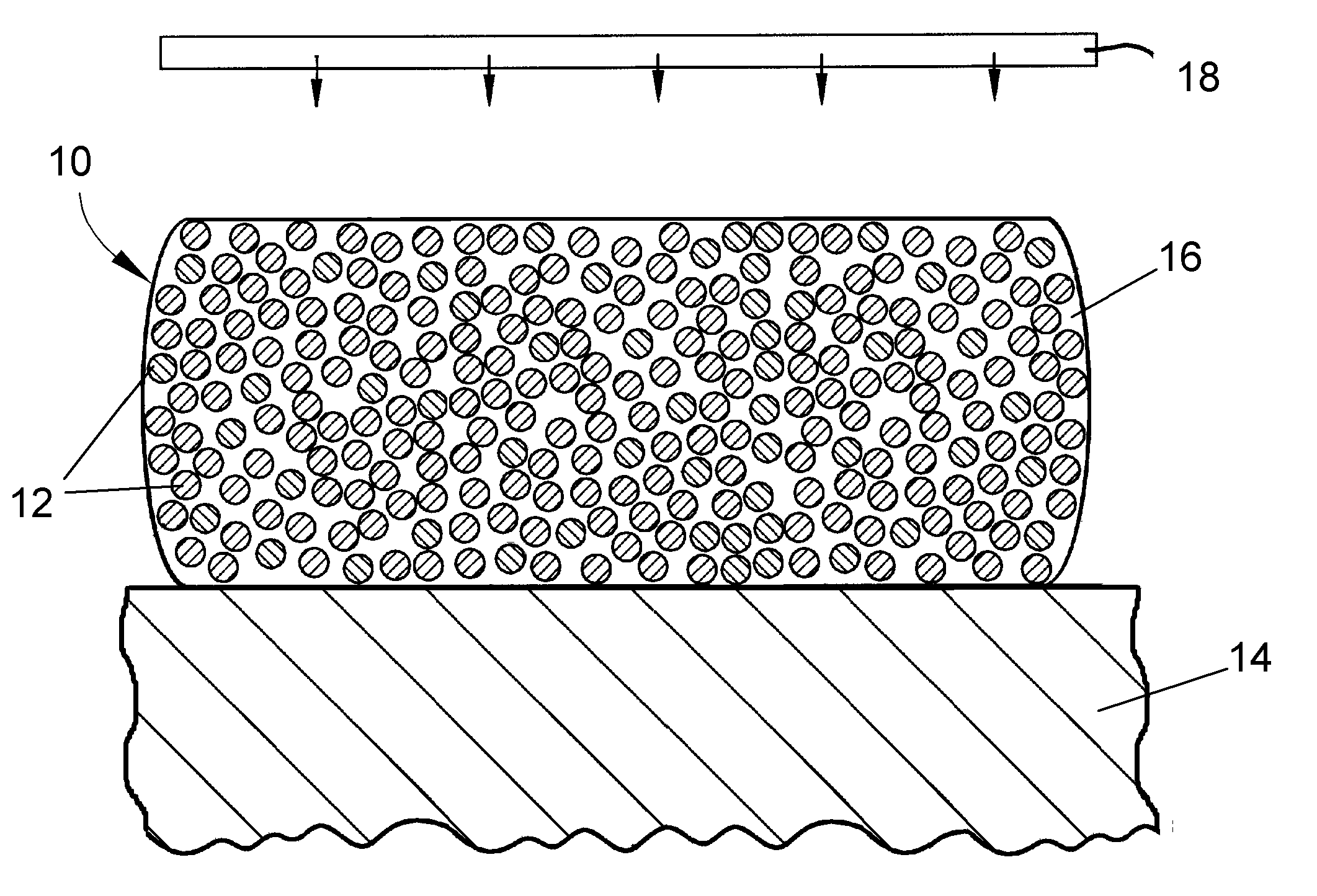

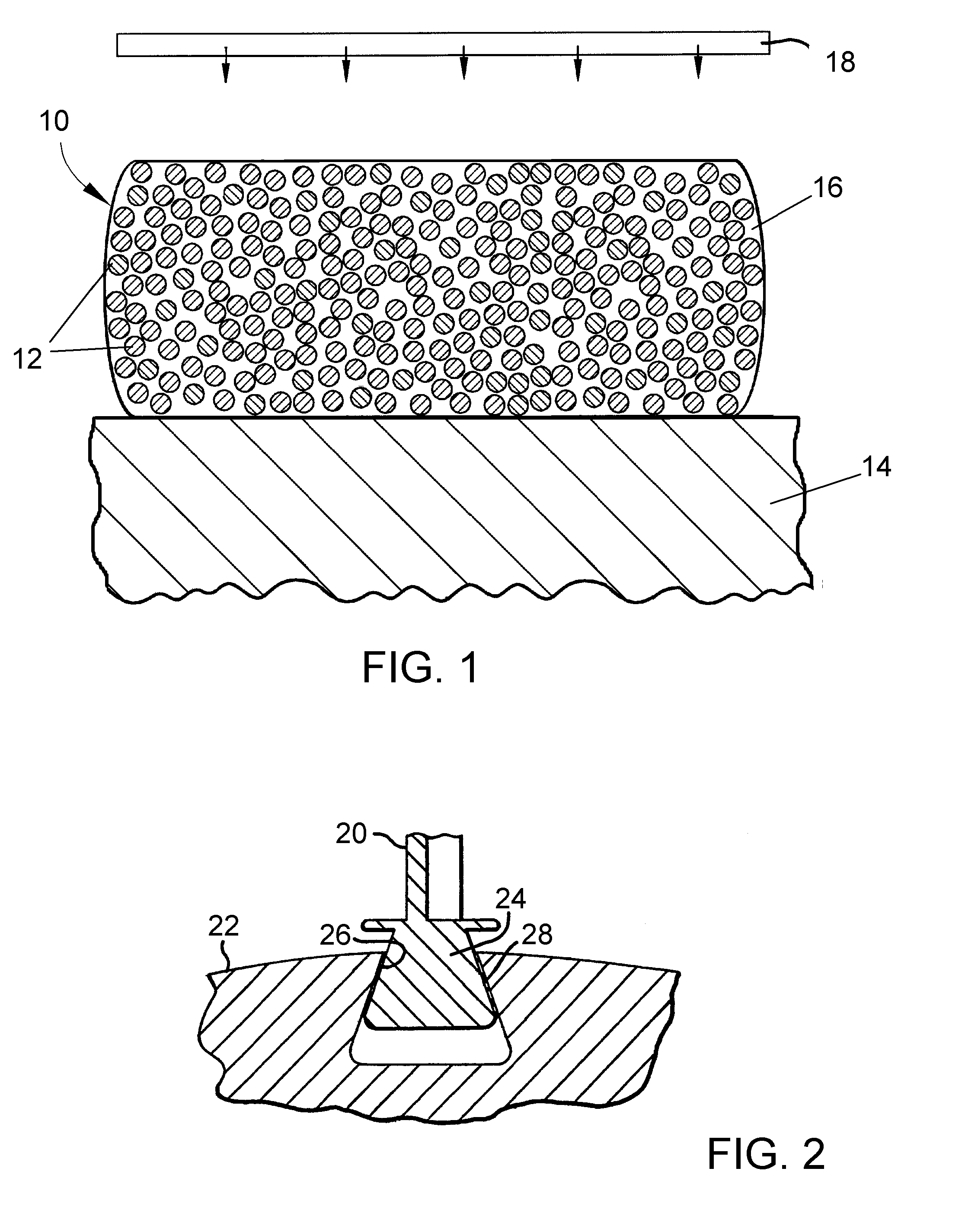

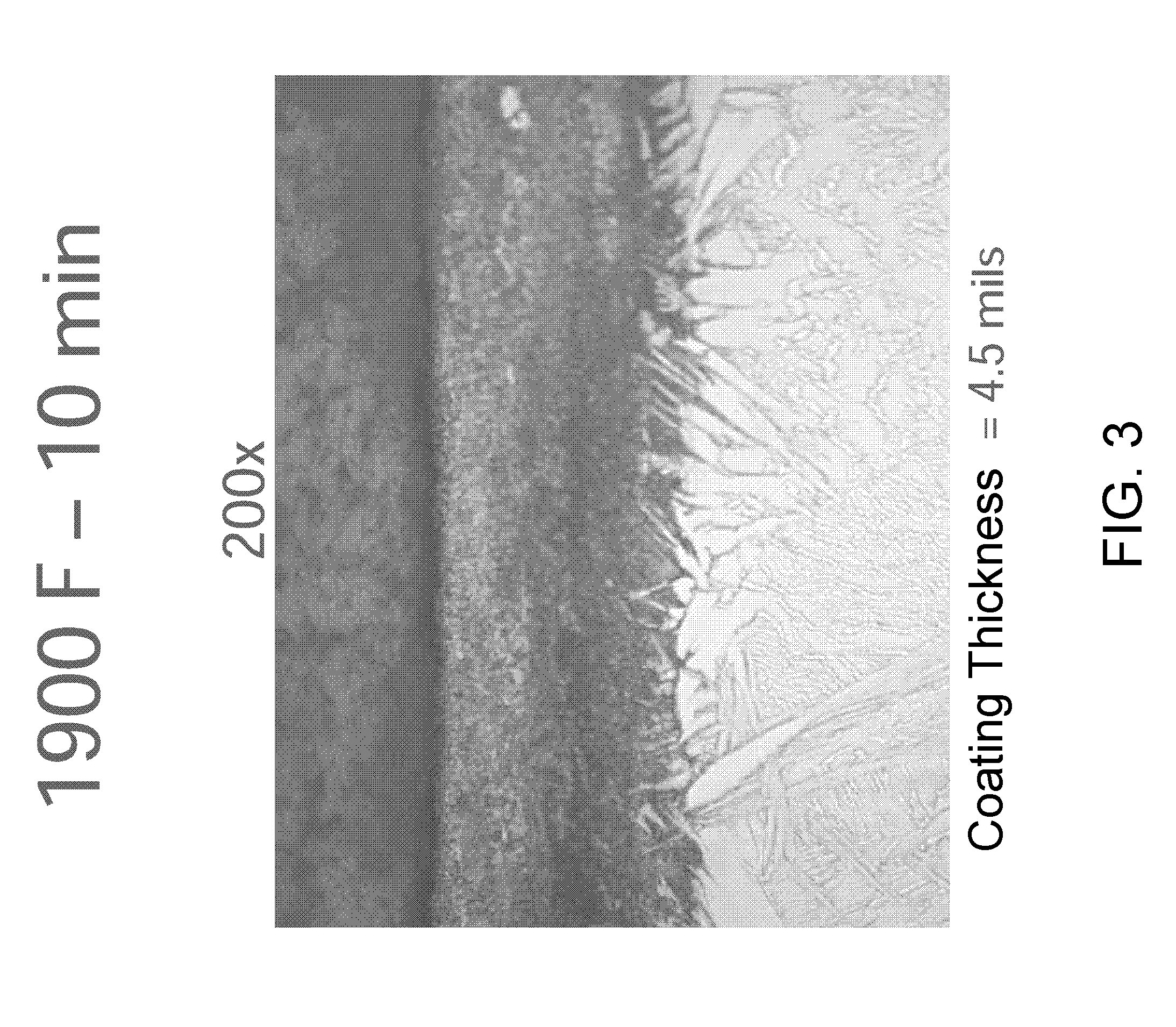

Microwave brazing process for forming coatings

ActiveUS20080145566A1Not to significantly degradeSelective heatingTurbinesRadiation applicationsMetallurgyMicrowave irradiation

A process for forming a coating on a surface of a substrate, so that heating of the coating material is selective and sufficient to cause at least partial melting of the coating material and permit bonding to the substrate without excessively heating the substrate so as not to significantly degrade its properties. The process generally entails forming a brazing paste containing powder particles dispersed in a binder. The particles are formed of a composition that is susceptible to microwave radiation. The brazing paste is then applied to the surface of the substrate and subjected to microwave radiation so that the particles couple with the microwave radiation and are sufficiently heated to burn off the binder and then at least partially melt to form an at least partially molten layer on the substrate. The microwave radiation is then interrupted to allow the at least partially molten layer to cool, solidify, and form the coating.

Owner:GENERAL ELECTRIC CO

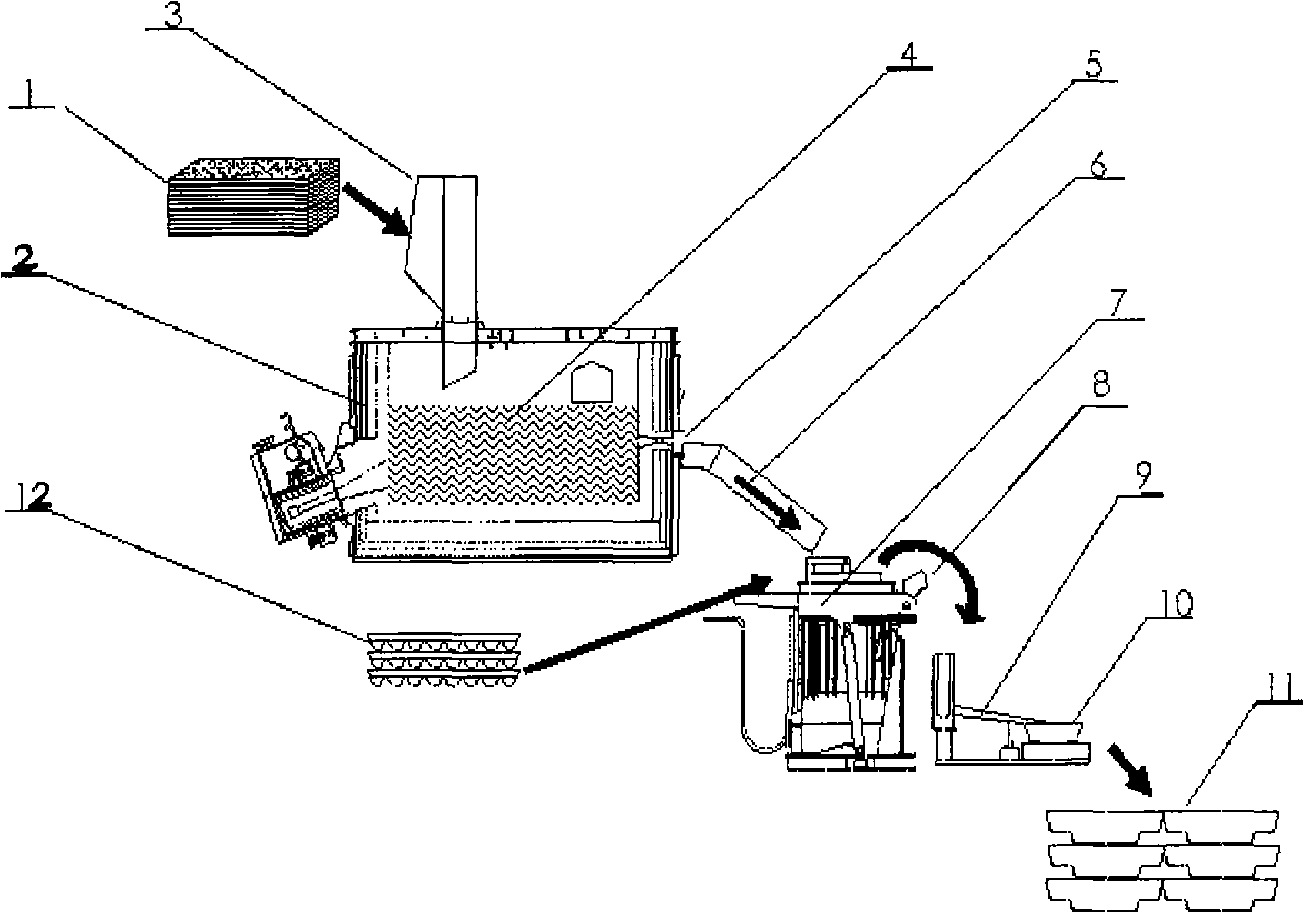

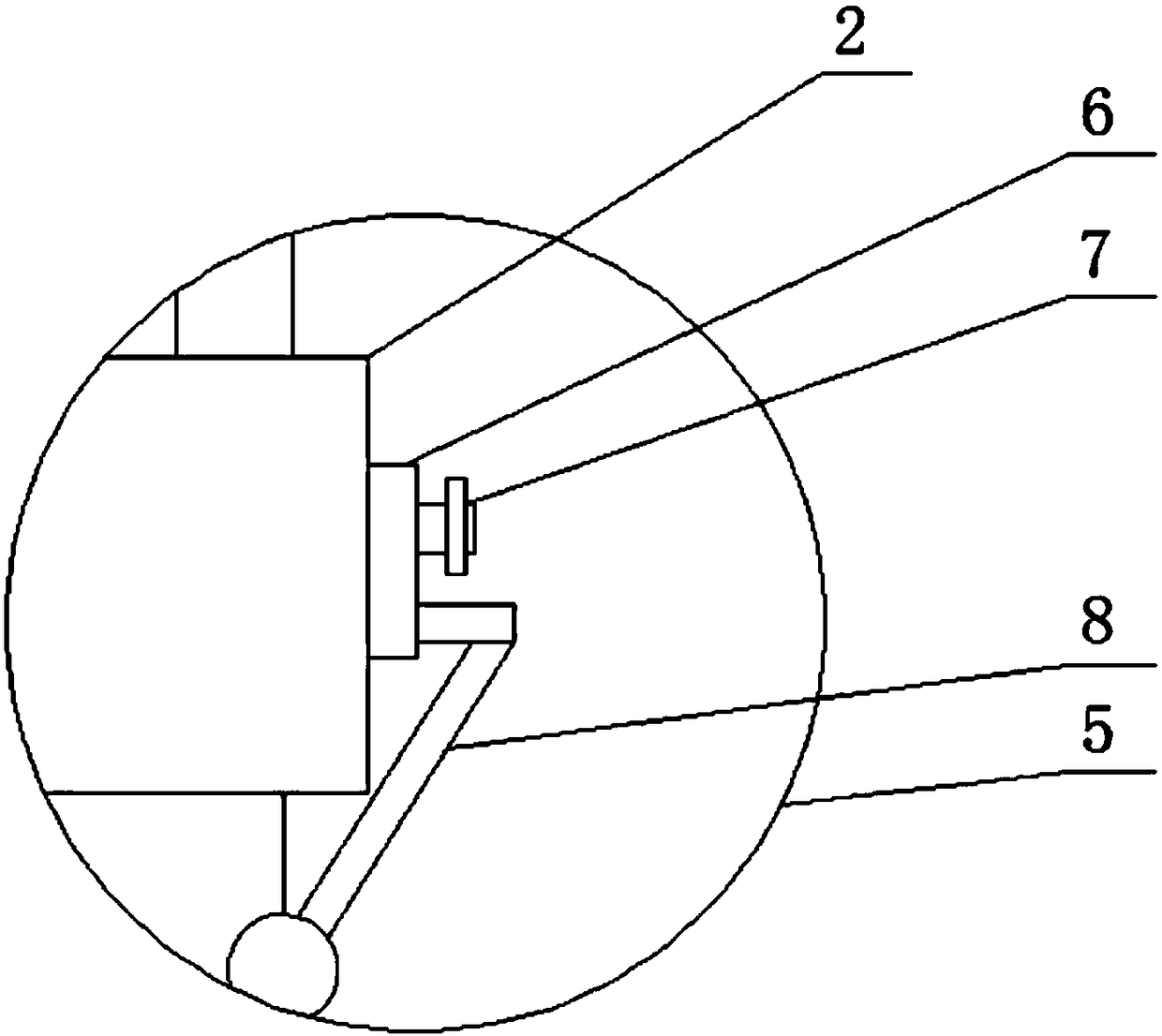

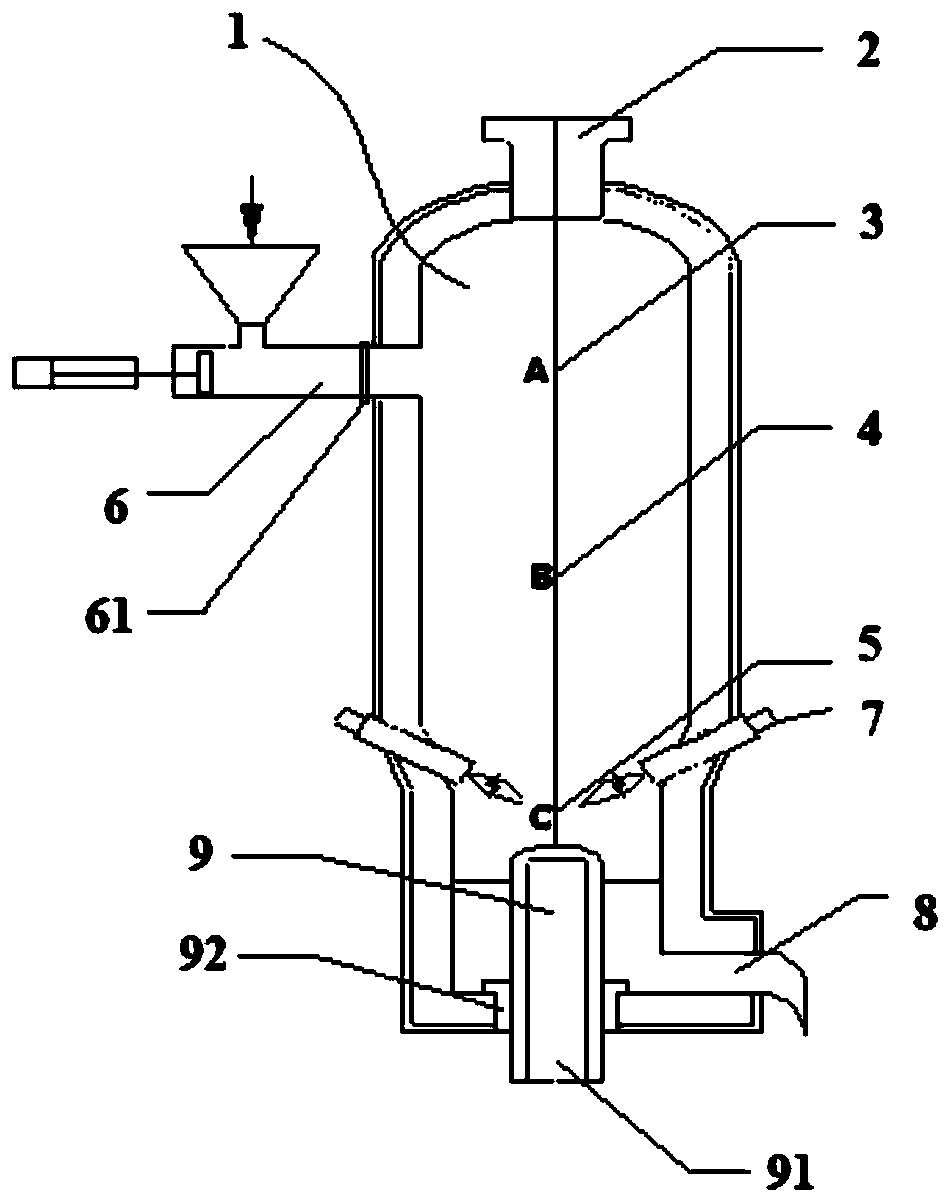

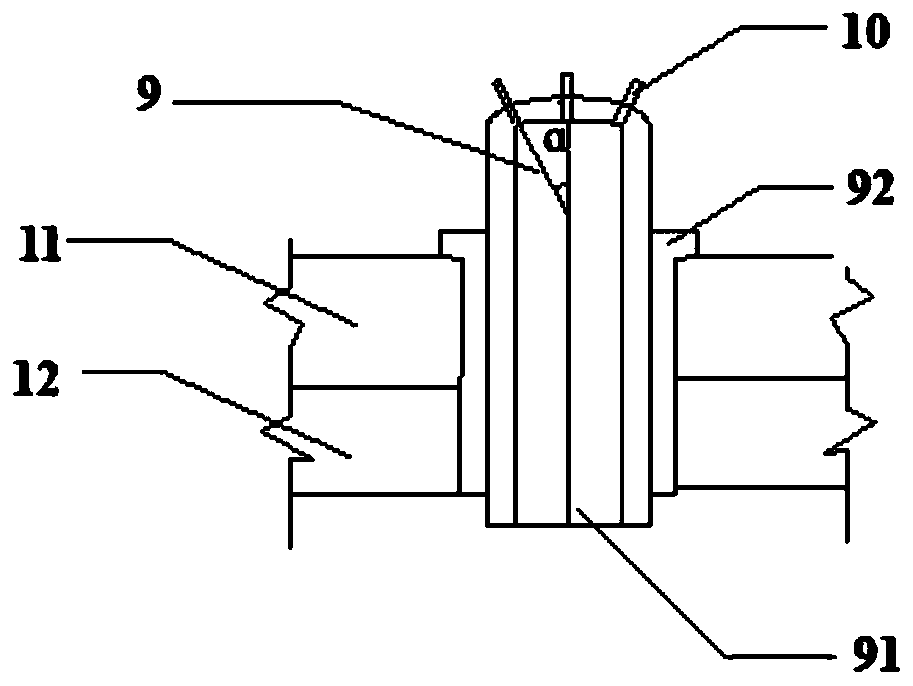

Combination metallurgical furnace for producing zinc alloy and zinc alloy combination producing method

InactiveCN101509727AStrong continuous melting abilityFast heatingIncreasing energy efficiencyCrucible furnacesZinc alloysIngot

The invention provides a combined metallurgical furnace and a combined production method for zinc alloy, comprising a cored line-frequency induction furnace (2) and at least two line-frequency coreless induction furnaces (7) with dumping devices (13); a convertible chute (6) is connected between a liquid outlet of the cored line-frequency induction furnace and a liquid inlet (14) of the line-frequency coreless induction furnaces; and a casting mechanism (9) is arranged correspondingly to a sprue (8) of the line-frequency coreless induction furnaces. The production method comprises the steps as follows: the zinc liquid which is melted in the cored line-frequency induction furnace is injected into each line-frequency coreless induction furnace in turn by the convertible chute and is then mixed with the middle alloy liquid which is smelted in advance in the line-frequency coreless induction furnaces; the non-contact melt mixing is realized by the electromagnetic induction force of the line-frequency coreless induction furnaces, thus preparing the zinc alloy ingot by pouring the zinc alloy liquid. The combined metallurgical furnace and the combined production method have high production efficiency, high yield, good quality of the produced zinc alloy, low energy consumption and small damage to the furnace body.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

Beef noodle soup concentrate as well as preparation method and using method thereof

ActiveCN103584211ADestroy the flavorIncrease umamiMulti-step food processesFood preparationBiotechnologyAnimal science

The invention provides beef noodle soup concentrate as well as a preparation method and a using method thereof. The beef noodle soup concentrate is prepared mainly through the following steps: (1) preparing soup seasonings; (2) putting cleaned and split large cattle bones, fresh beef and beef fat, the soup seasonings and water into a pot according to the weight ratio of (10-15):(25-35):(25-35):(0.3-0.4):100 for cooking; (3) fishing out and cutting the beef into blocks, fishing out and pulping the beef fat, removing the large cattle bones, and filtering out the soup seasonings and bone and meat residues to obtain soup concentrate; (4) canning the soup concentrate, the beef and the beef fat according to the weight ratio of 100:(100-120):(110-130), and sealing to obtain the canned soup concentrate; (5) sterilizing the soup concentrate cans at high temperature, and packaging and warehousing after the soup concentrate cans are inspected and qualified. The using method comprises the following steps: uniformly mixing the soup concentrate and clear water according to the weight ratio of (1:8)-10, adding flavorings, boiling for a while, and then using.

Owner:LANZHOU MONITOR NIU FOOD & BEVERAGE MANAGEMENT

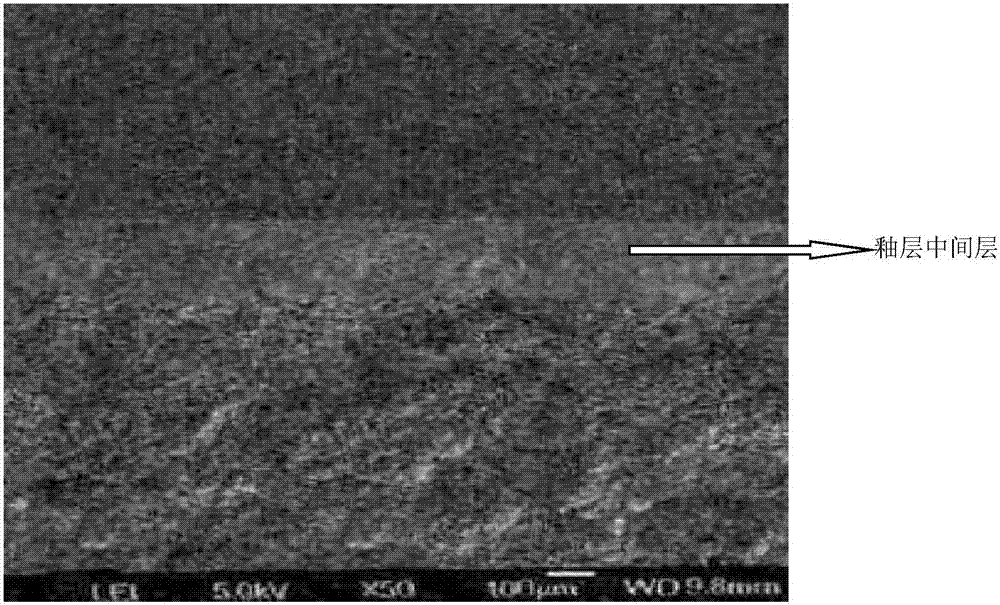

Ceramic inkjet penetrated overglaze containing lepidolite tailings

The invention discloses ceramic inkjet penetrated overglaze containing lepidolite tailings. The ceramic inkjet penetrated overglaze is prepared from potassium feldspar, albite, quartz, kaolin, calcined talc and lepidolite tailings. The ceramic inkjet penetrated overglaze has the advantages as follows: (1) the composition proportion of each mineral of glaze slip produced with the process is reasonable, mixing of melting substances of a green body and glaze is facilitated, the chemical composition and property of a middle layer are gradually transited from the composition of the green body to composition of the glaze, so that harmful stress caused by property difference is reduced, and defects of ceramic tile products are reduced; (2) the glaze has proper viscosity and good suspension property and thus conforms to the ceramic production process, and smooth and defect-free glaze can be obtained easily; (3) the glaze produced with the process is ground very fine and has the fineness being 325 meshes or below, all minerals are uniformly mixed, quartz is promoted to transform at the high temperature, melting tends to be complete, and the tendency of glaze crazing of an inkjet penetrated product can be reduced.

Owner:GUANGDONG DOWSTONE TECH

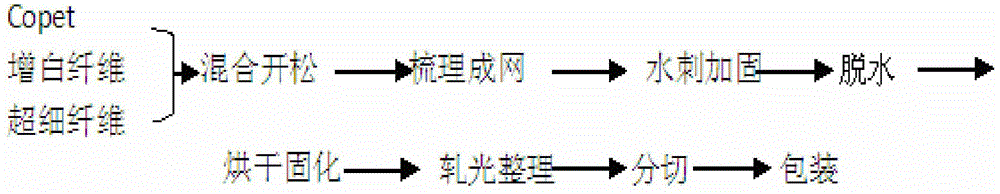

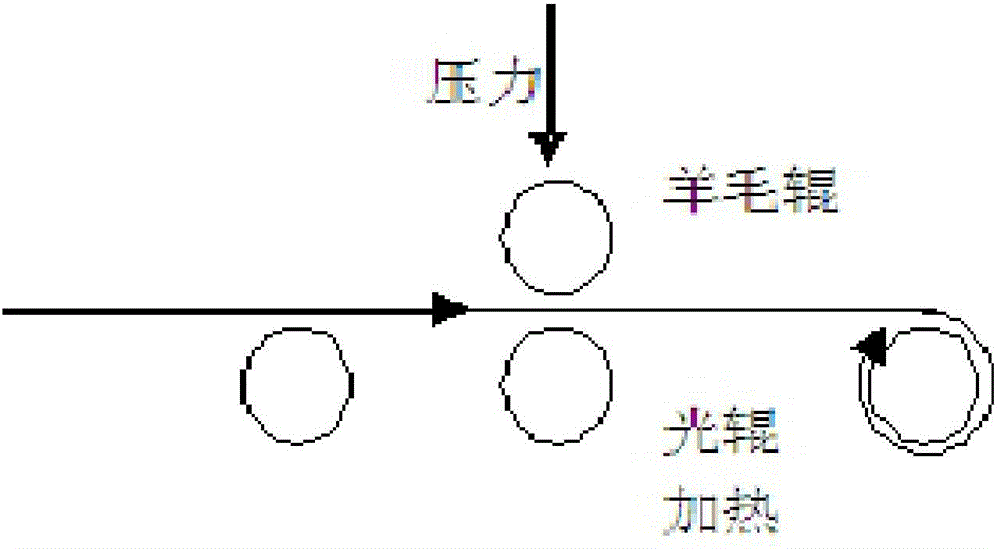

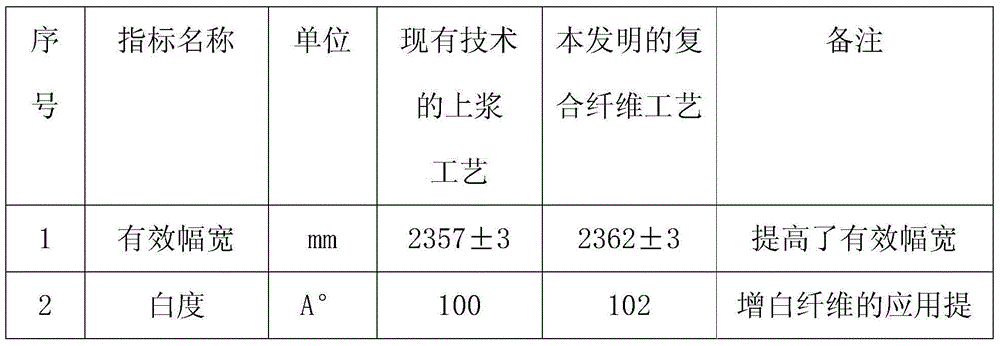

Spunlaced nonwovens and machining method for composite fiber curtain filtration

The invention discloses spunlaced nonwovens and a machining method for composite fiber curtain filtration. According to the method, copet composite fiber, whitening polyester fiber and superfine polyester fiber in the weight proportion 1.5: 2.5:1 are subjected to the following steps to form the spunlaced nonwovens, 1, the copet composite fiber, the whitening polyester fiber and the superfine polyester fiber are mixed in the weight proportion 1.5: 2.5:1; 2, the mixed material is conveyed to an air pressure cotton box carding machine through a draught fan after being subjected to mixing opening; 3, the mixed fiber is subjected to carding to form a mesh, and the mesh is conveyed to a spunlace machine; 4, spunlace machining is conducted on the mixed fiber on a spunlace machine; 5, dehydration treatment is conducted; 6, the mixed fiber is transferred to a dryer to be subjected to continuous drying solidification after the spunlace machining, the solidification temperature of a first drying oven is 160+-3 DEG C, the solidification temperature of a second drying oven is 170+-3 DEG C, and the speed is 45-50 m / min; 7, calendering finish is conducted; 8, the working procedures of slitting and packaging are conducted. The spunlaced nonwovens and machining method for the composite fiber curtain filtration has the advantages that the effects of printing and dyeing, bending and polishing are achieved, no sizing agent exists, and the cost is low.

Owner:SHANDONG PROVINCE WINSON NON WOVEN MATERIALS

Microwave process for forming a coating

InactiveUS20080138533A1Improve propertiesSelective heatingTurbinesEngine manufactureMetallurgySubstrate surface

A process for forming a coating on a surface of a substrate, in which the heating source for the coating process is microwave radiation so that heating of the coating material is selective and sufficient to melt and bond the coating material to the substrate without excessively heating the substrate. The process entails forming a coating material containing powder particles that are sufficiently small to be highly susceptible to microwave radiation. The coating material is applied to a surface of the substrate and subjected to microwave radiation so that the powder particles within the coating material couple with the microwave radiation and sufficiently melt to form a coating on the substrate surface. The microwave radiation is then interrupted to allow the coating to cool, solidify, and mechanically bond to the substrate.

Owner:GENERAL ELECTRIC CO

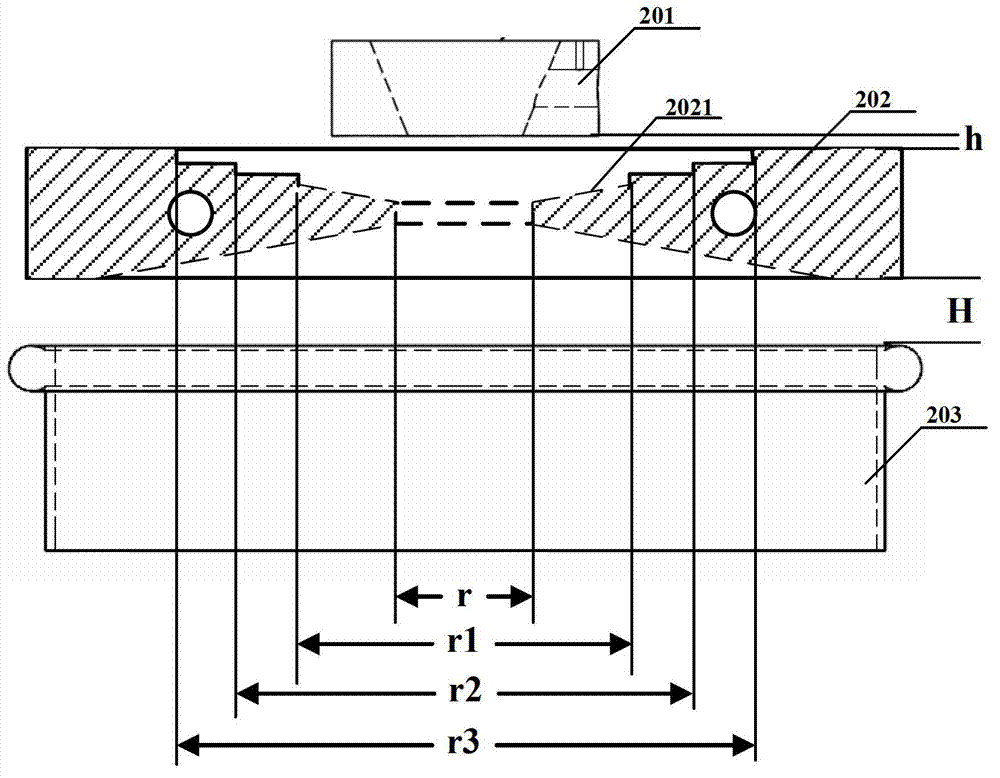

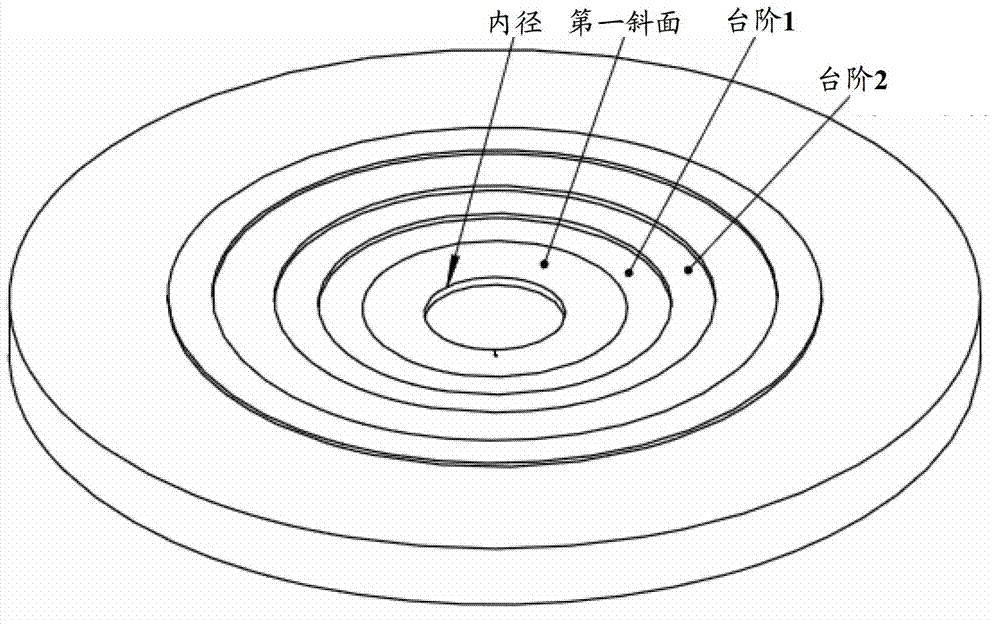

Float-zone monocrystalline silicon production process and float-zone thermal field

InactiveCN102808216AIncrease inner diameterMelted completelyPolycrystalline material growthBy zone-melting liquidsForce linesMetallurgy

The invention discloses a float-zone monocrystalline silicon production process and a float-zone thermal field and relates to a monocrystalline silicon production technique. Since the inner diameter of a heating coil is increased and is enabled to be more than or equal to 30mm and at least one stage of step platform is arranged outside the upper inclined surface of the heating coil, to change the effect of a magnetic force line, the float-zone thermal field provided by the embodiment of the invention has the advantages that the polycrystalline silicon with larger diameter can be thoroughly melted and the drawing of zone-melt monocrystalline silicon with larger diameter can be realized.

Owner:JINGYUNTONG TECH CO LTD

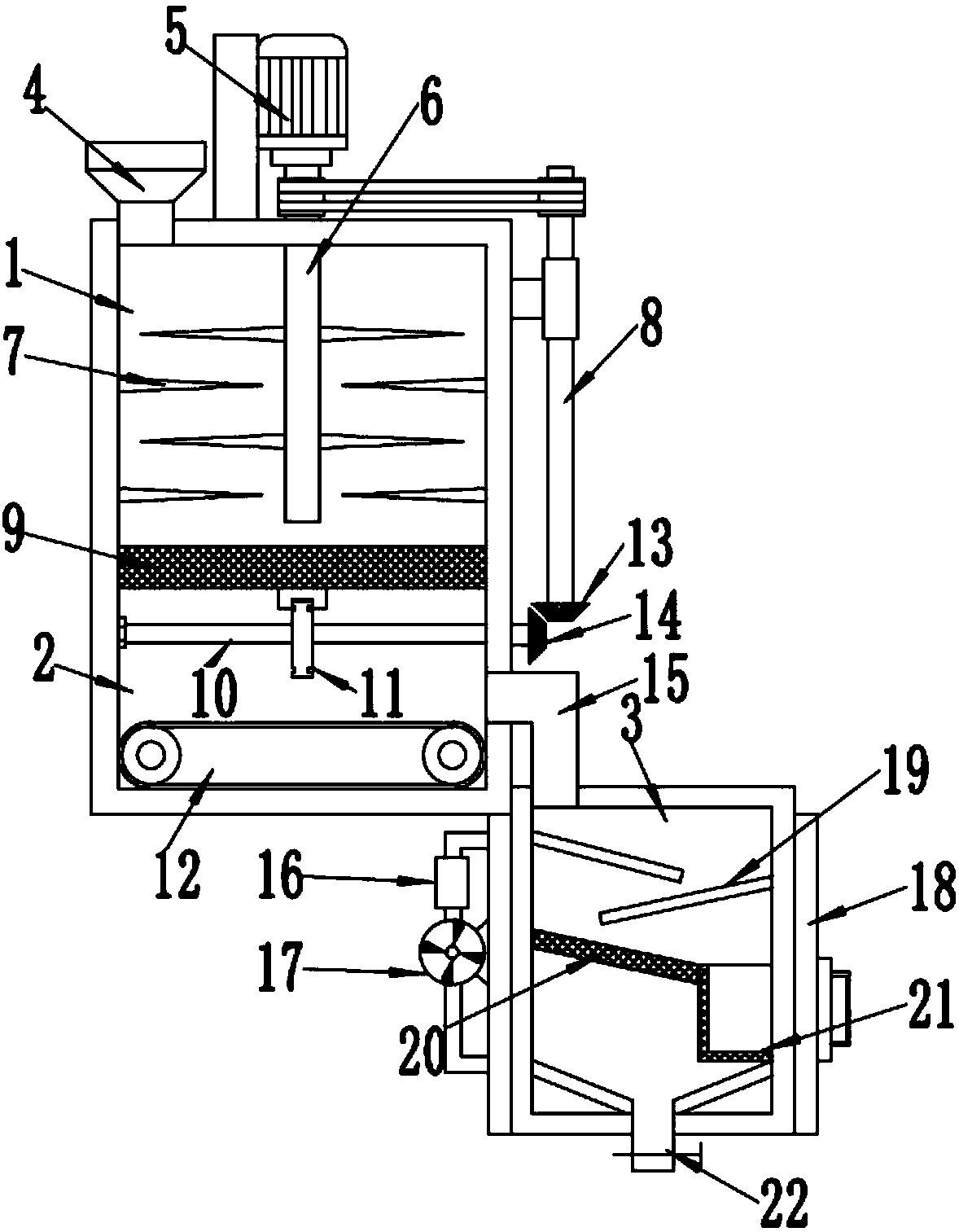

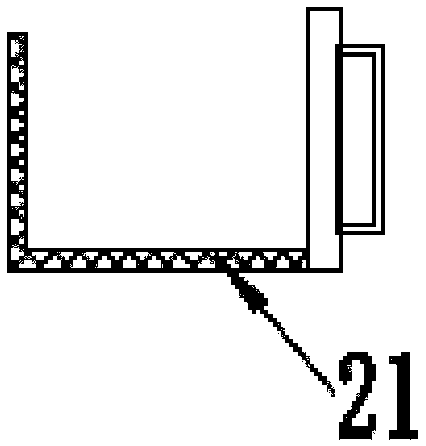

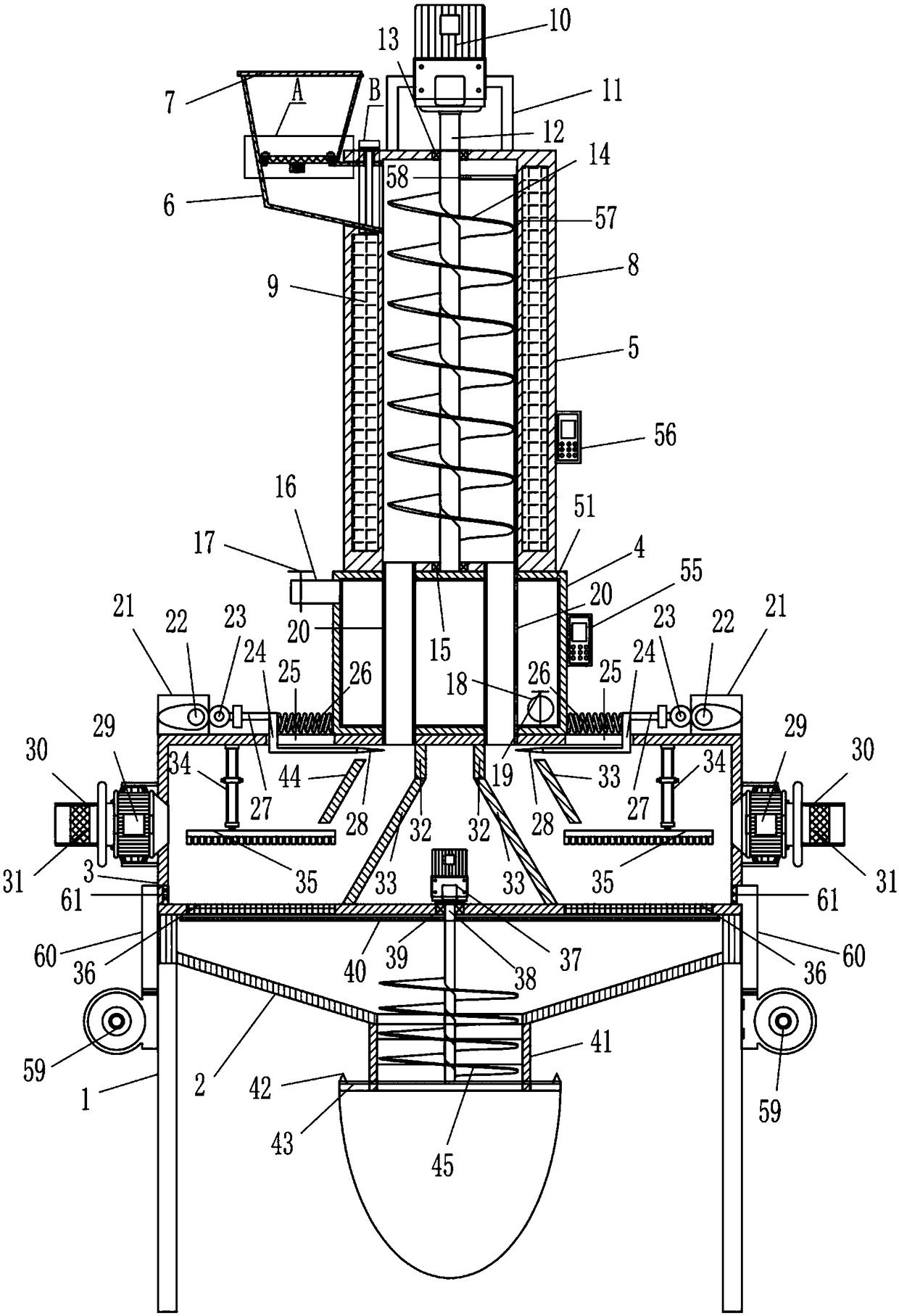

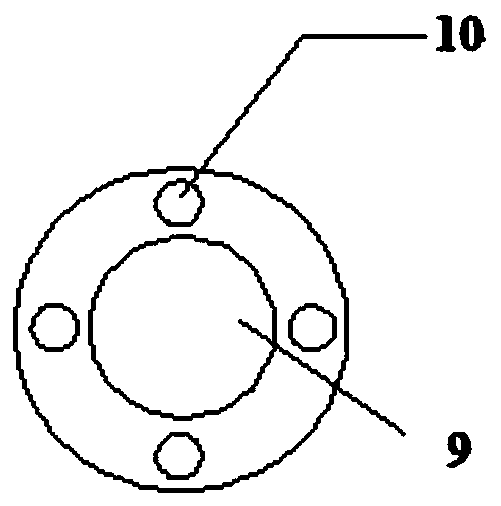

Fusing equipment for asphalt processing

InactiveCN108166351AImprove crushing efficiencyImprove melting effectRoads maintainenceGrain treatmentsAerospace engineeringAsphalt

The invention discloses fusing equipment for asphalt processing. The fusing equipment comprises a crushing cavity, a transmission cavity and a fusing cavity. The transmission cavity is formed in the lower end of the crushing cavity, and the crushing cavity and the transmission cavity are separated through a sieve plate. The transmission cavity communicates with the upper end of the fusing cavity through a material guiding pipe, and the outer side of the fusing cavity is wrapped with a heating cavity. A feeding hopper is arranged at the upper end of the crushing cavity, and a rotary motor is arranged on the right side of the feeding hopper. The output end of the rotary motor is fixedly connected with a first rotary shaft, and the first rotary shaft penetrates through the upper end of the crushing cavity to be rotatably connected with the crushing cavity. A cutting knife is fixedly mounted on the position, located on the inner side of the crushing cavity, of the first rotary shaft. The sieve plate is slidably arranged at the lower end of the crushing cavity, and the lower end of the sieve plate is provided with the transmission cavity. According to the fusing equipment, design is novel, operation is easy, through an arranged filter plate, separation discharging of non-fused impurities and an asphalt solution can be achieved, the asphalt fusing effect and quality are improved, theworking efficiency is high, and the automation degree is high.

Owner:HUNAN WANGLONG ENTERPRISE MANAGEMENT CONSULTING CO LTD

Method for manufacturing solar double-glass assembly

InactiveCN104183669AUniform temperature transferMelted completelySemiconductor/solid-state device testing/measurementFinal product manufactureEngineeringSurface layer

The invention discloses a method for manufacturing a solar double-glass assembly. The method includes the following steps that (1) a PVB adhesive film, a solar battery string, a PVB adhesive film and surface layer tempered glass are sequentially laid on bottom layer tempered glass, so that the solar double-glass assembly is formed; (2) whether hidden cracking pieces exist in solar battery pieces of the double-glass assembly in the first step is checked, and the hidden cracking pieces are removed; (3) the double-glass assembly is placed in a laminating machine under the -1 barometric pressure, the process is kept for 30-40 minutes, then an upper chamber of the laminating machine is placed at the pressure of -0.5 MPA, a lower chamber is placed at the pressure of -1 MPA, the process is kept for 20-30 minutes, afterwards, the temperature rises to be 140+ / -5 DEG C, and at the pressure of -0.5 MPA to -0.6 MPA, the process is kept for 20-30 minutes; (4) whether hidden cracking pieces exist in the solar battery pieces of the laminated double-glass assembly is checked, and the hidden cracking pieces are removed; (5) the double-glass assembly is fixed, the double-glass assembly is placed in an autoclave, and after a dehumidifier is used for dehumidifying, under the conditions of 20-150 DEG C and 0-1.3 MPA, the process is kept for 2-4 hours.

Owner:JIANGSU CHENDIAN SOLAR PHOTOELECTRIC TECH

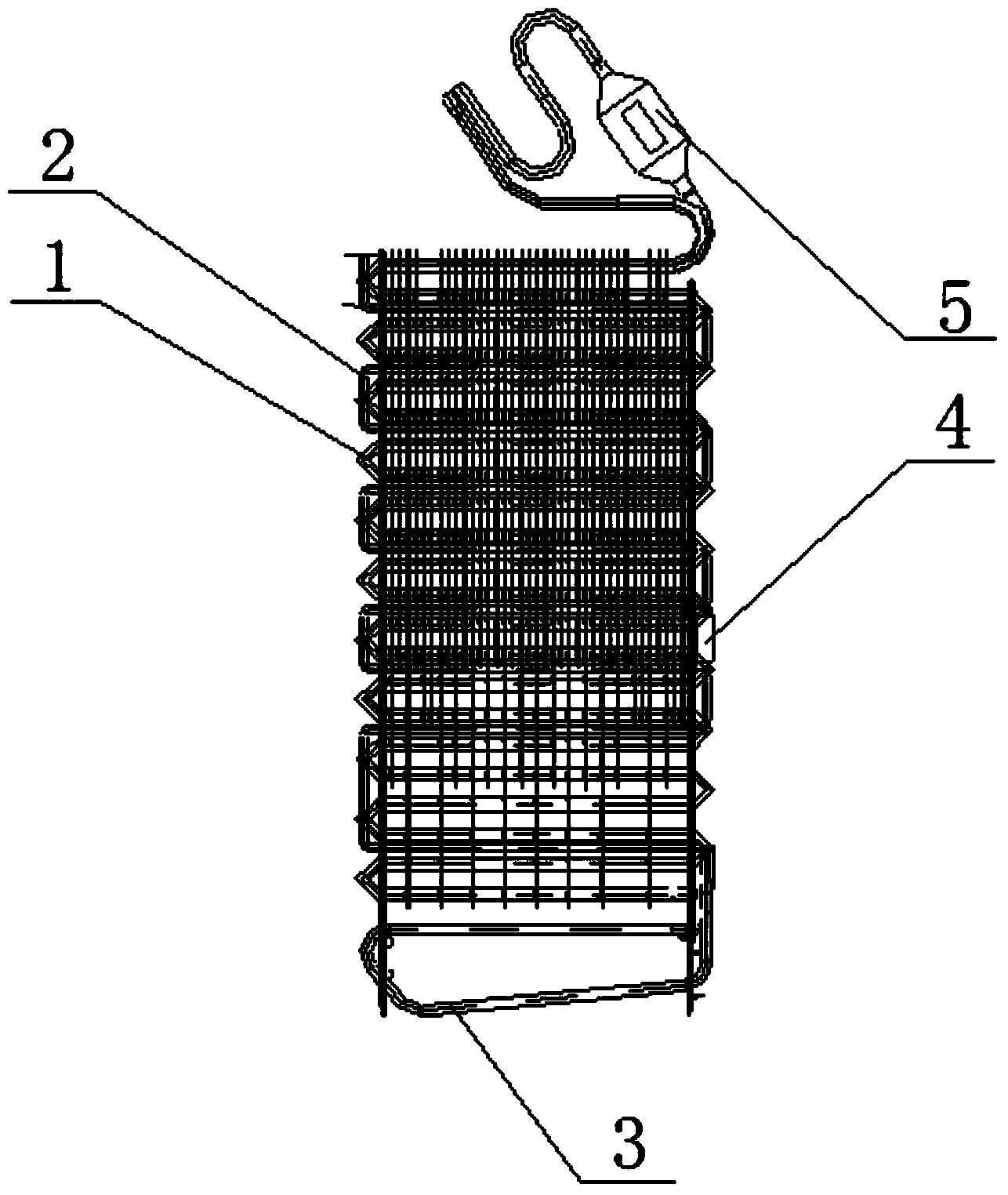

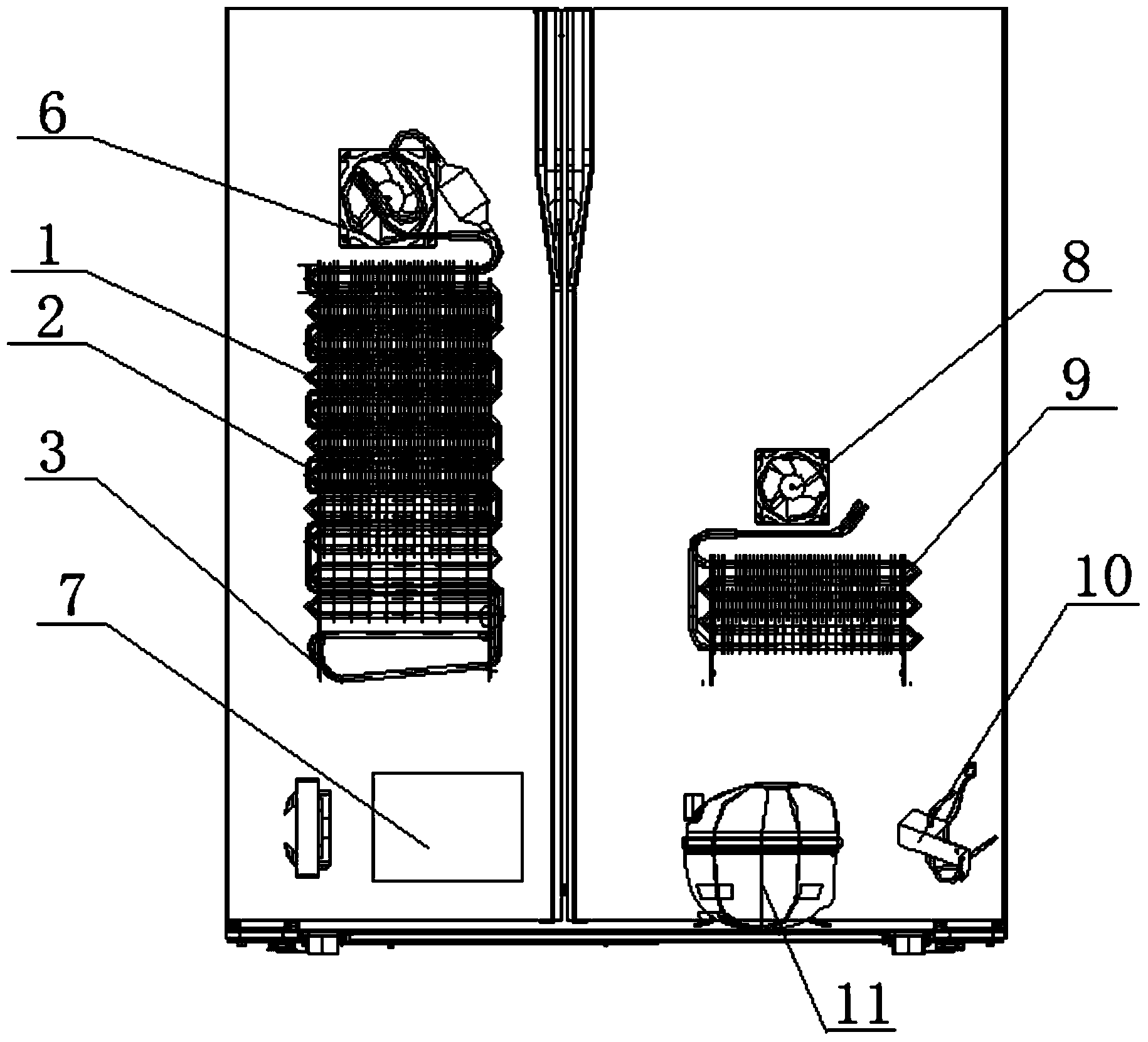

Defrosting system of air-cooled refrigerator, control method for defrosting system and air-cooled refrigerator

InactiveCN104390415AEvenly heatedAvoid the phenomenon of not being able to meltLighting and heating apparatusCooling fluid circulationFrostEngineering

The invention relates to the field of refrigerators and discloses a defrosting system of an air-cooled refrigerator, a control method for the defrosting system and the air-cooled refrigerator. The defrosting system of the air-cooled refrigerator comprises a freezing chamber evaporator; the freezing chamber evaporator is provided with a freezing chamber defrosting assembly; the freezing chamber defrosting assembly comprises a first defrosting component and a second defrosting component which are respectively arranged below the bottom part of the freezing chamber evaporator and on the side wall of the freezing chamber evaporator; the first defrosting component and the second defrosting component are connected with a circuit control board through a controller. According to the defrosting system of the air-cooled refrigerator, disclosed by the invention, the freezing chamber defrosting assembly comprises the first defrosting component and the second defrosting component which are respectively arranged below the bottom part of the freezing chamber evaporator and on the side wall of the freezing chamber evaporator, and the freezing chamber defrosting assembly is capable of respectively heating the bottom part and the side wall of the freezing chamber evaporator, so that the whole freezing chamber evaporator is heated more evenly, and the phenomenon that local frost cannot be melted during the defrosting process is avoided.

Owner:HEFEI KINGHOME ELECTRICAL CO LTD

Smelting method of chromium-molybdenum-copper-nickel-tin-antimony low-alloy wear-resistant cast iron

InactiveCN104178684AGuaranteed elemental compositionGuaranteed Concurrent Eligibility RequirementsWear resistantManganese

The invention discloses a smelting method of a chromium-molybdenum-copper-nickel-tin-antimony low-alloy wear-resistant cast iron, which comprises the following steps: raw material weighing: preparing and weighing raw materials and alloys according to the prescribed material specifications and weight proportion; smelting: sequentially adding the materials according to the technical charging sequence, and melting, wherein refractory molybdenum iron, chromium iron and pure nickel are added in the middle of the pig iron batch charging process, and scrap steel is added; component adjustment: adding silicon iron and manganese iron to adjust to acceptable components, heating, and adding a copper block which can be easily damaged by fire; and late inoculation in casting ladle: before tapping and after preheating the casting ladle, adding a tin block (accounting for 0.05% of the raw materials) and an antimony block (accounting for 0.01% of the raw materials) to the bottom of the ladle, and adding late inoculation silicon granules into the molten iron in the ladle in the casting process. The method solves the problem that the high-melting alloy added after all the iron liquid is completely molten is refractory, is capable of shortening the melting time and enhancing the smelting efficiency, promotes the formation of the fine lamellar pearlite, and ensures the element components, mechanical properties and metallurgical structure of the casting to simultaneously satisfy the requirements.

Owner:HEBEI FENGWEI MACHINERY

Smelting distributing method utilizing nickel beads as main raw material for vacuum induction furnace

ActiveCN105063389APrevent sinking difficultiesGood magnetic performanceElectric dischargeSmelting process

The invention relates to a smelting distributing method utilizing nickel beads as a main raw material for a vacuum induction furnace. The smelting distributing method comprises the following steps: (I) cleaning a smelting crucible of the vacuum induction furnace; (II) starting loading after the crucible is inclined by 10-15 degrees; (III) putting partial nickel beads into the bottom of the crucible until the bottom of the crucible is full; (IV) flatly paving 50%+ / -10% of Cr into the crucible; (V) adding the mixture of Ni and residual Cr into the crucible, wherein the area of Cr is 10%-25% of the flat paving area; rotating until the angle of the crucible is vertical to the horizontal direction; adding Ni beads, wherein the amount of the added Ni beads is more than 60% of the total added amount of Ni beads in the smelting process; and adding the residual Ni beads as a feed supplement in batches in the last stage of smelting; (VI)during distributing, tightly distributing materials at the bottom of crucible, and sparsely distributing materials at the middle upper part of the crucible; and (VII) adding easily-burnt elements including Al, Ti, B, Mg and Zr in the last stage of refining and an alloying stage. According to the smelting distributing method, an electric discharge phenomenon which appears on the surfaces of the Ni beads in the presence of induced current during smelting is avoided, and the phenomenon that the adjacent nickel beads are adhered after discharging is avoided.

Owner:TAIYUAN IRON & STEEL GROUP

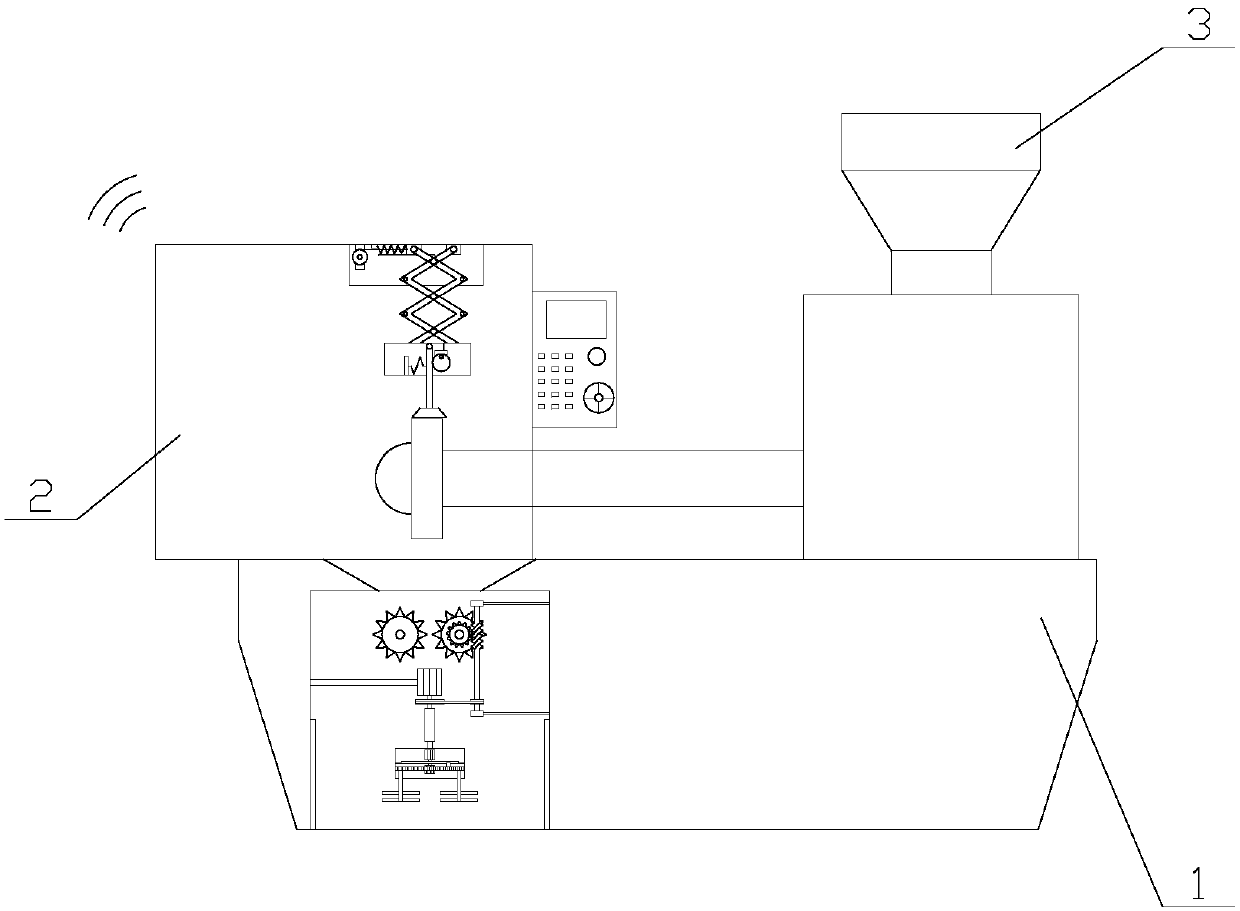

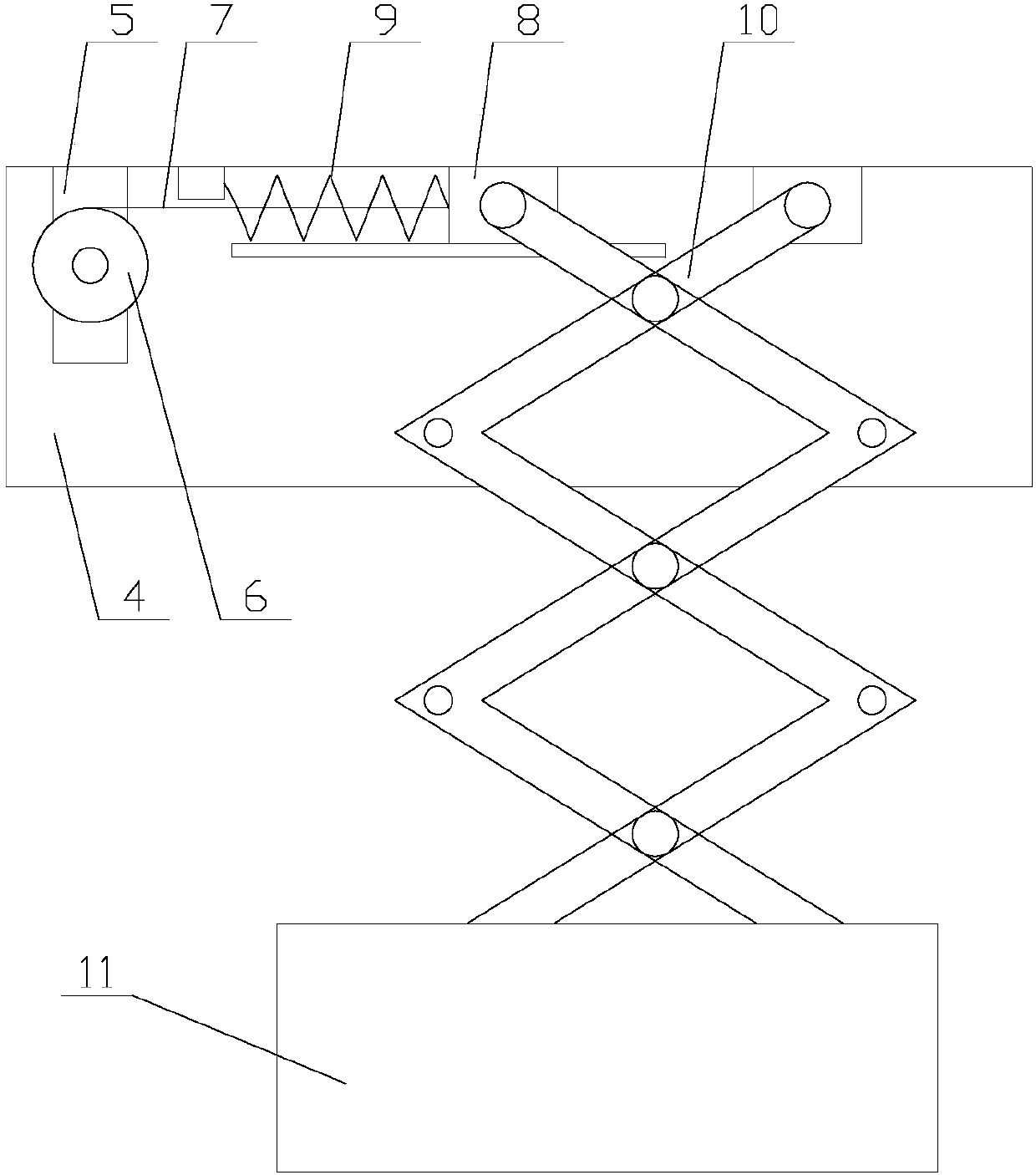

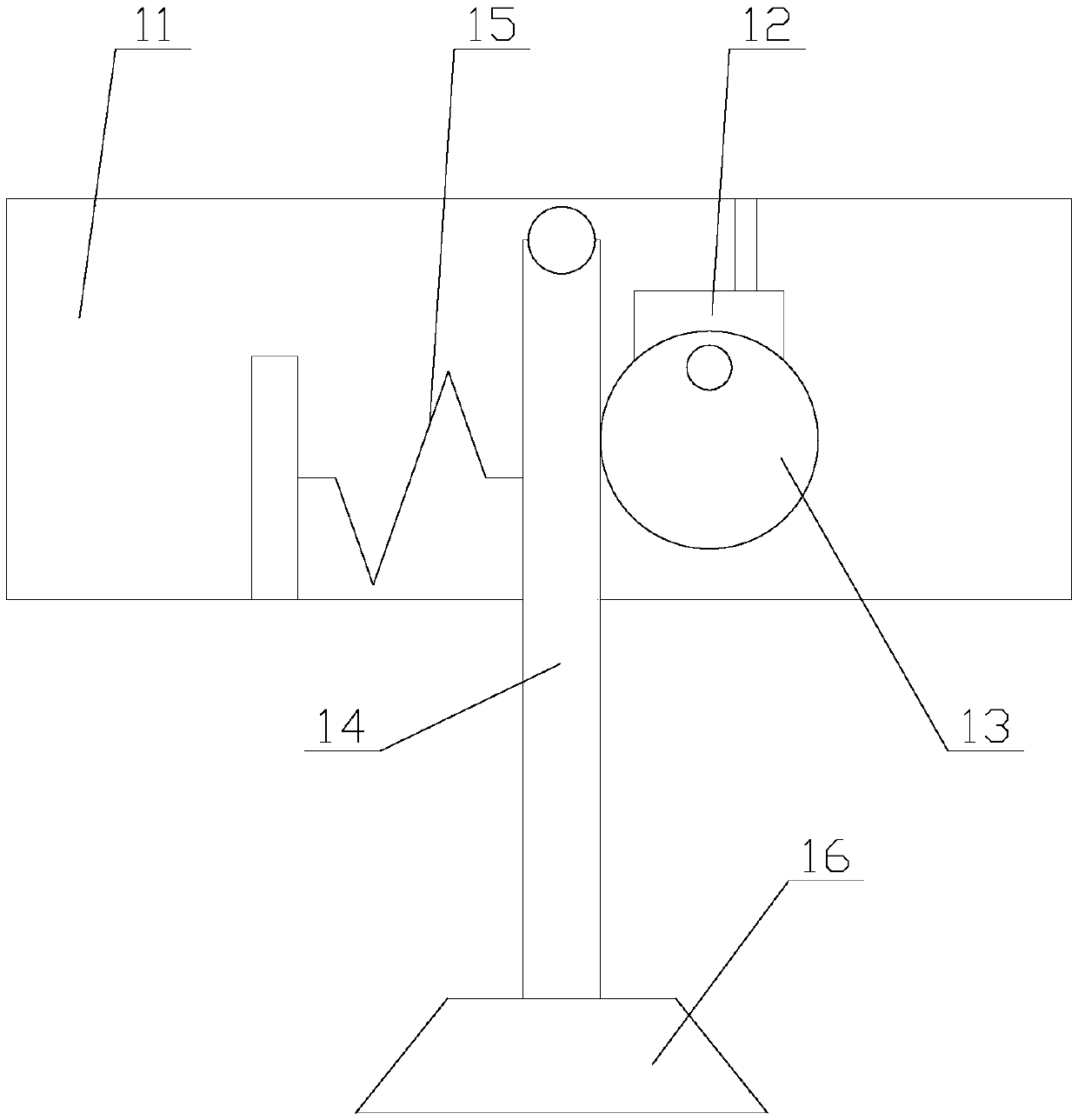

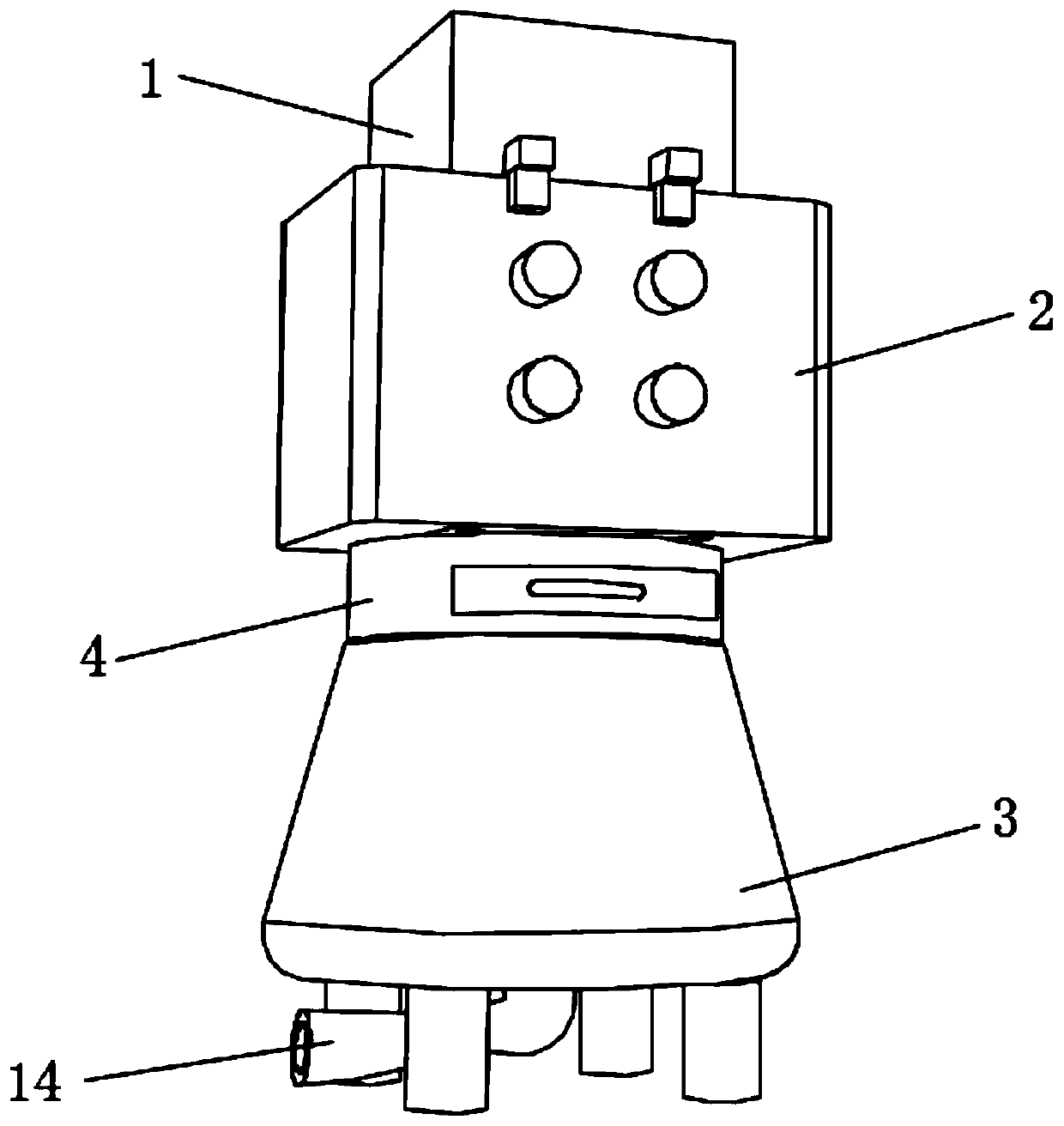

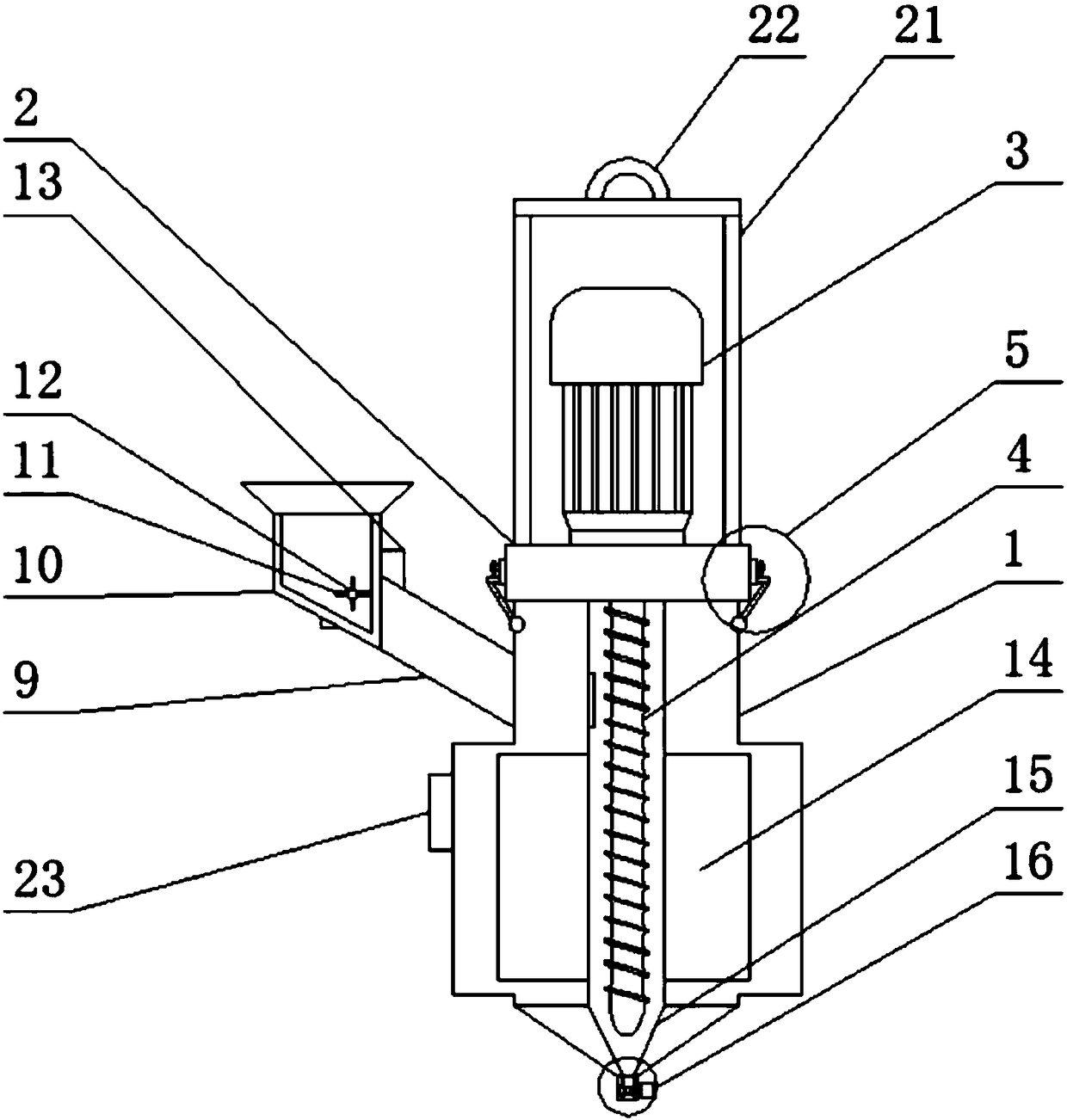

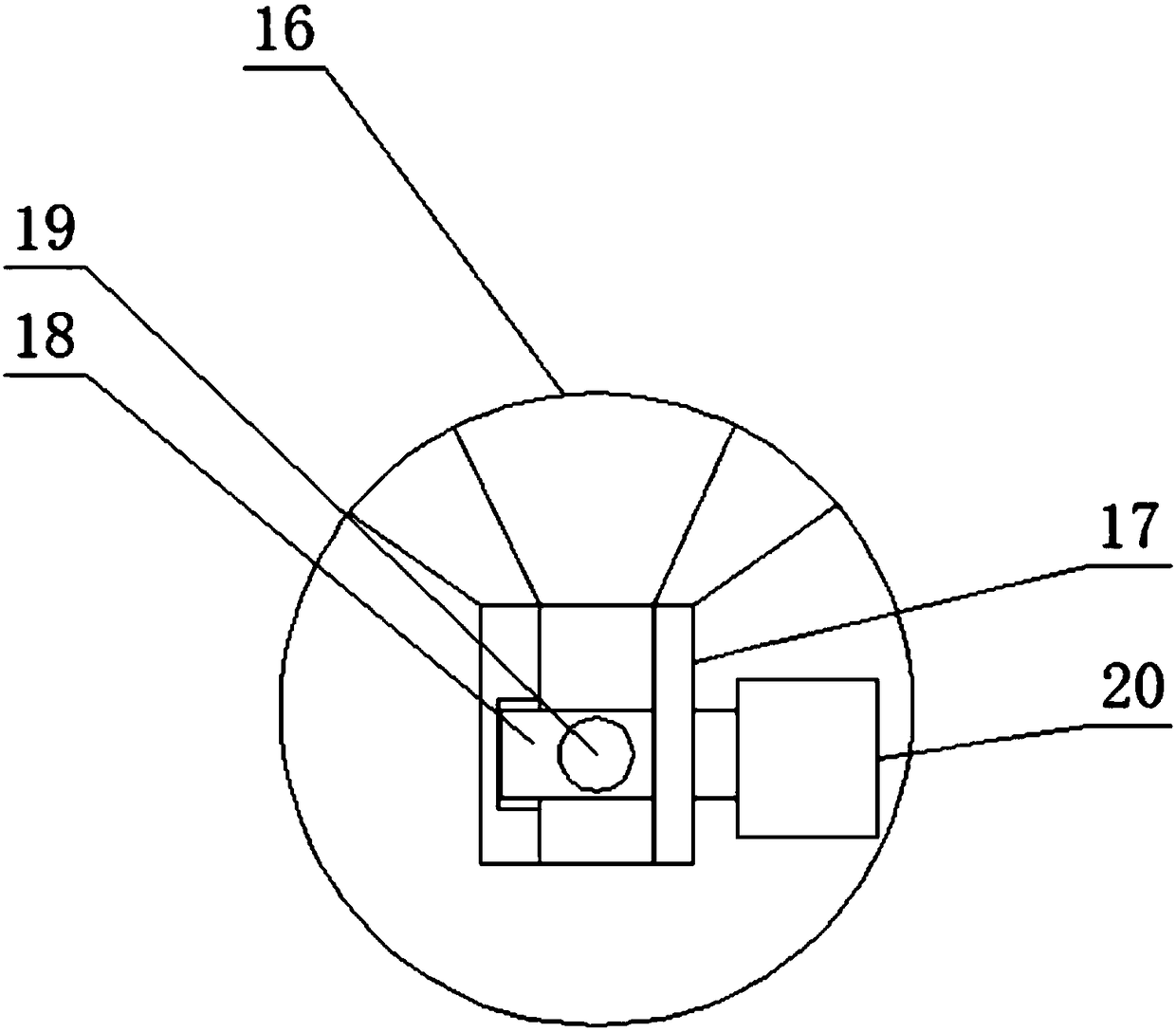

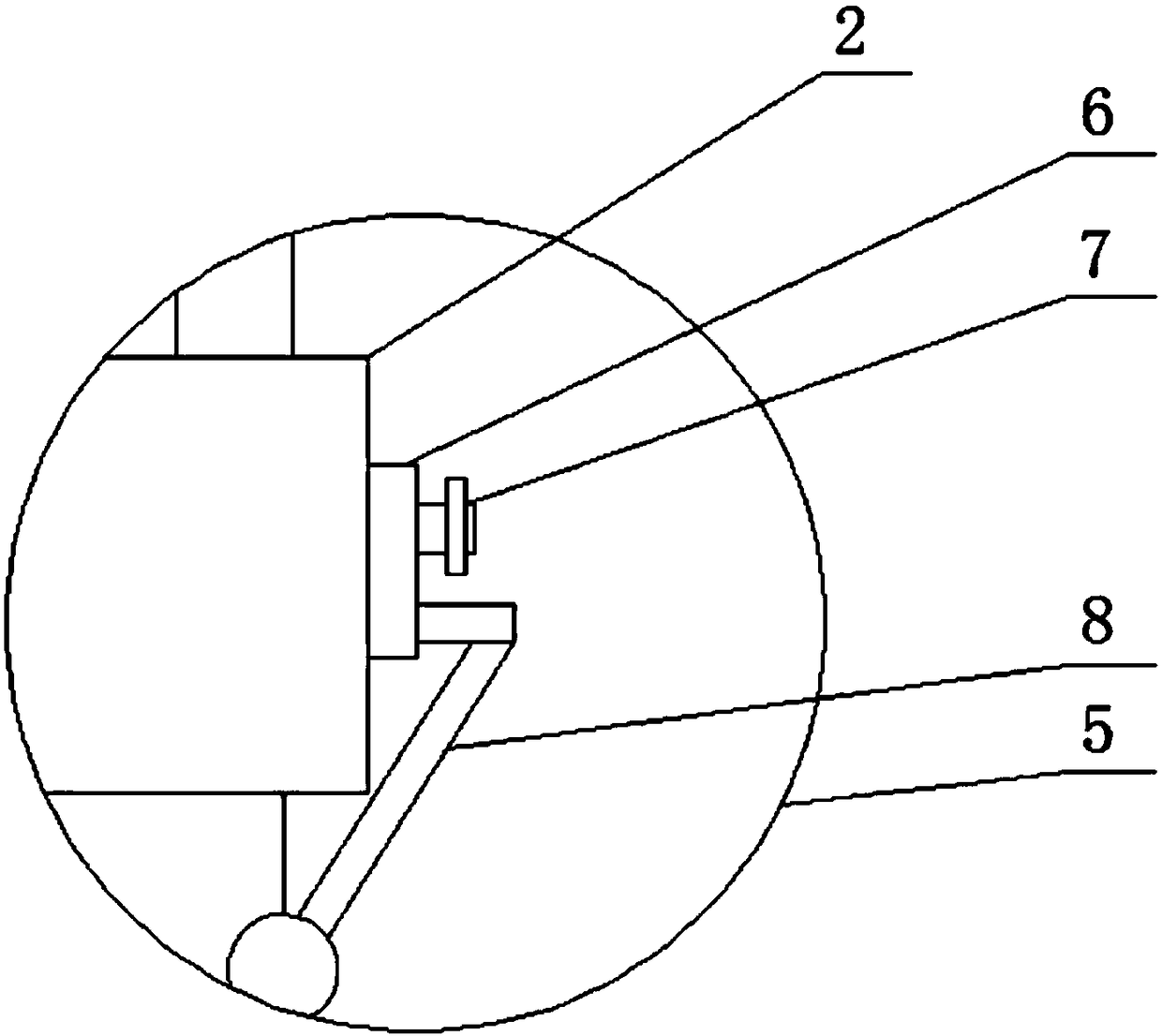

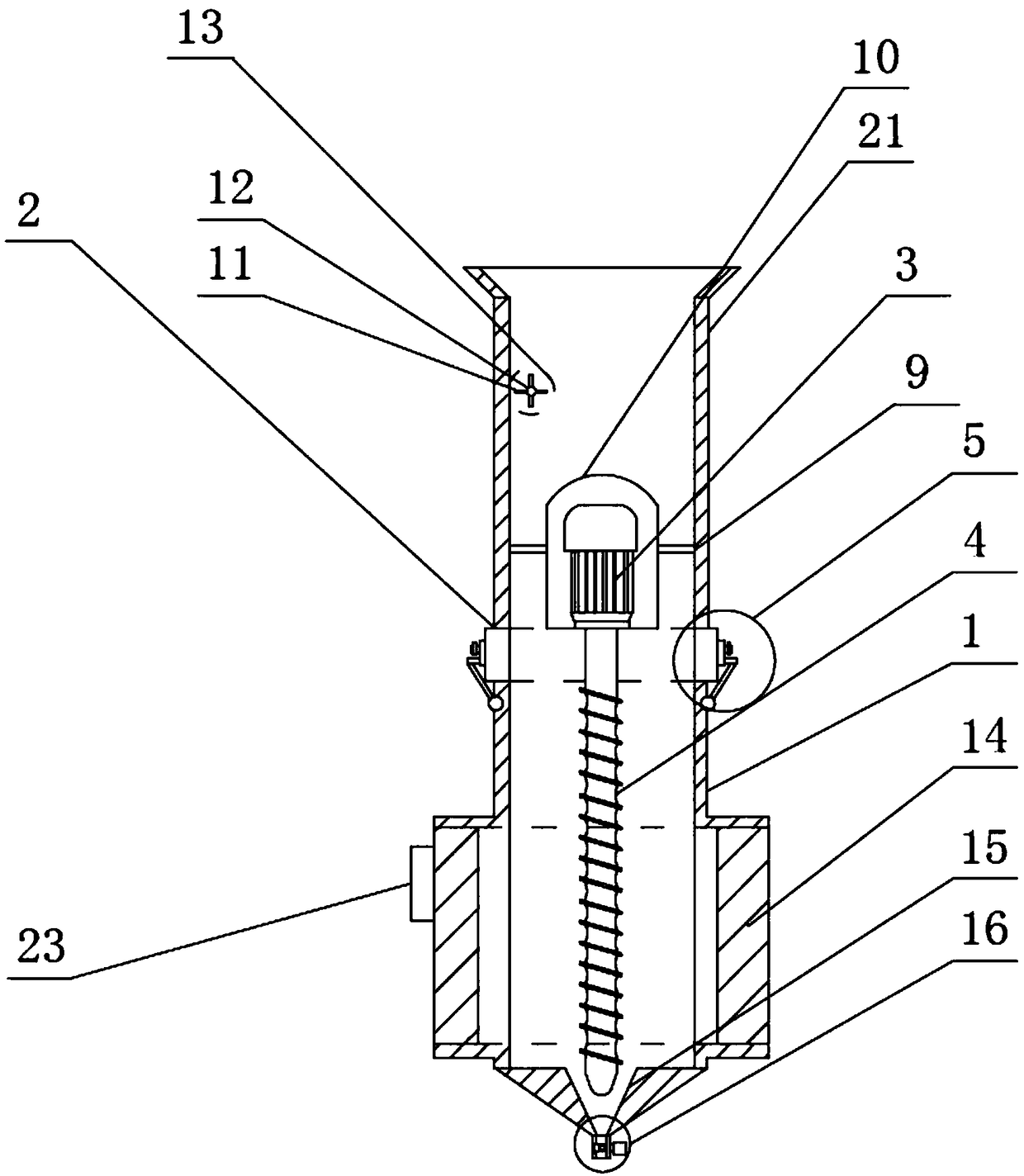

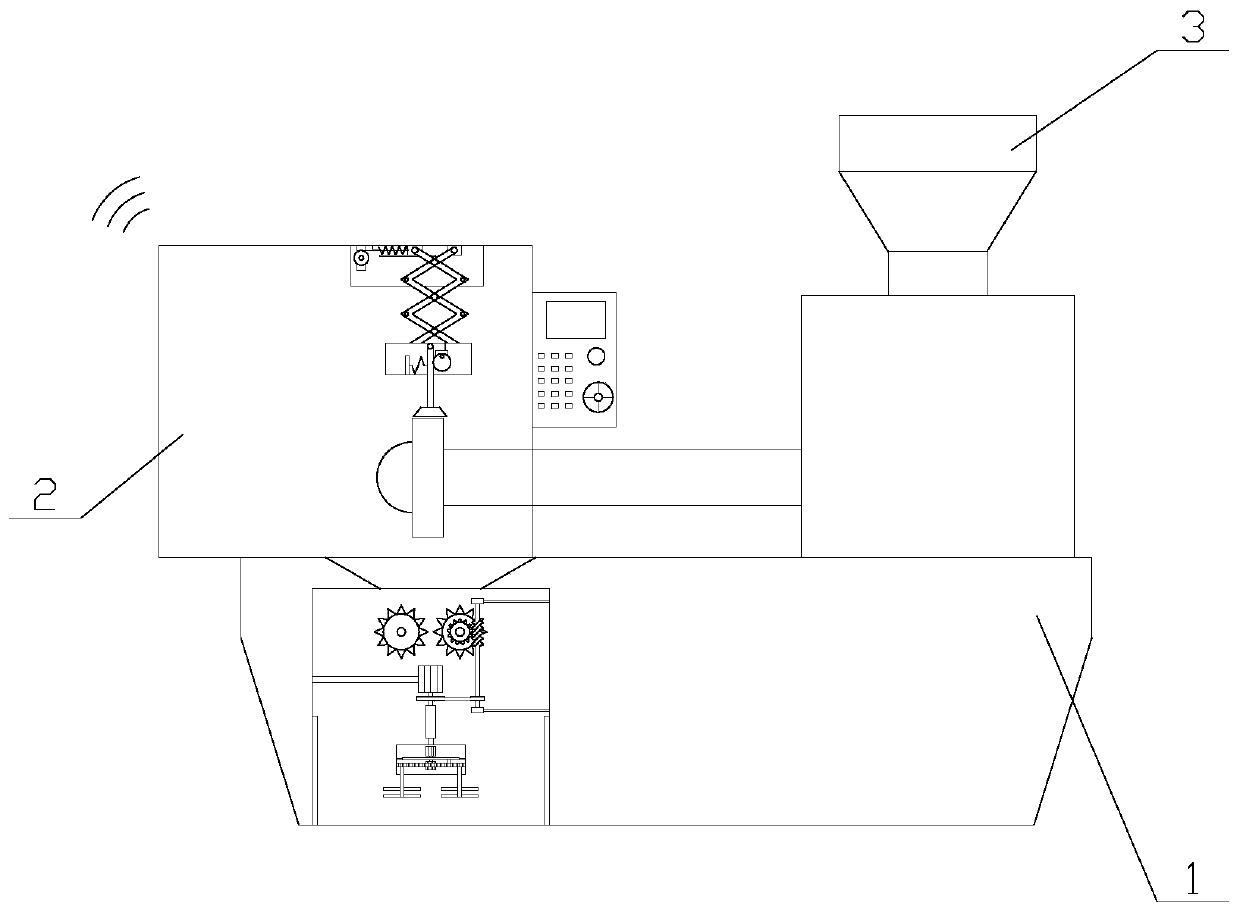

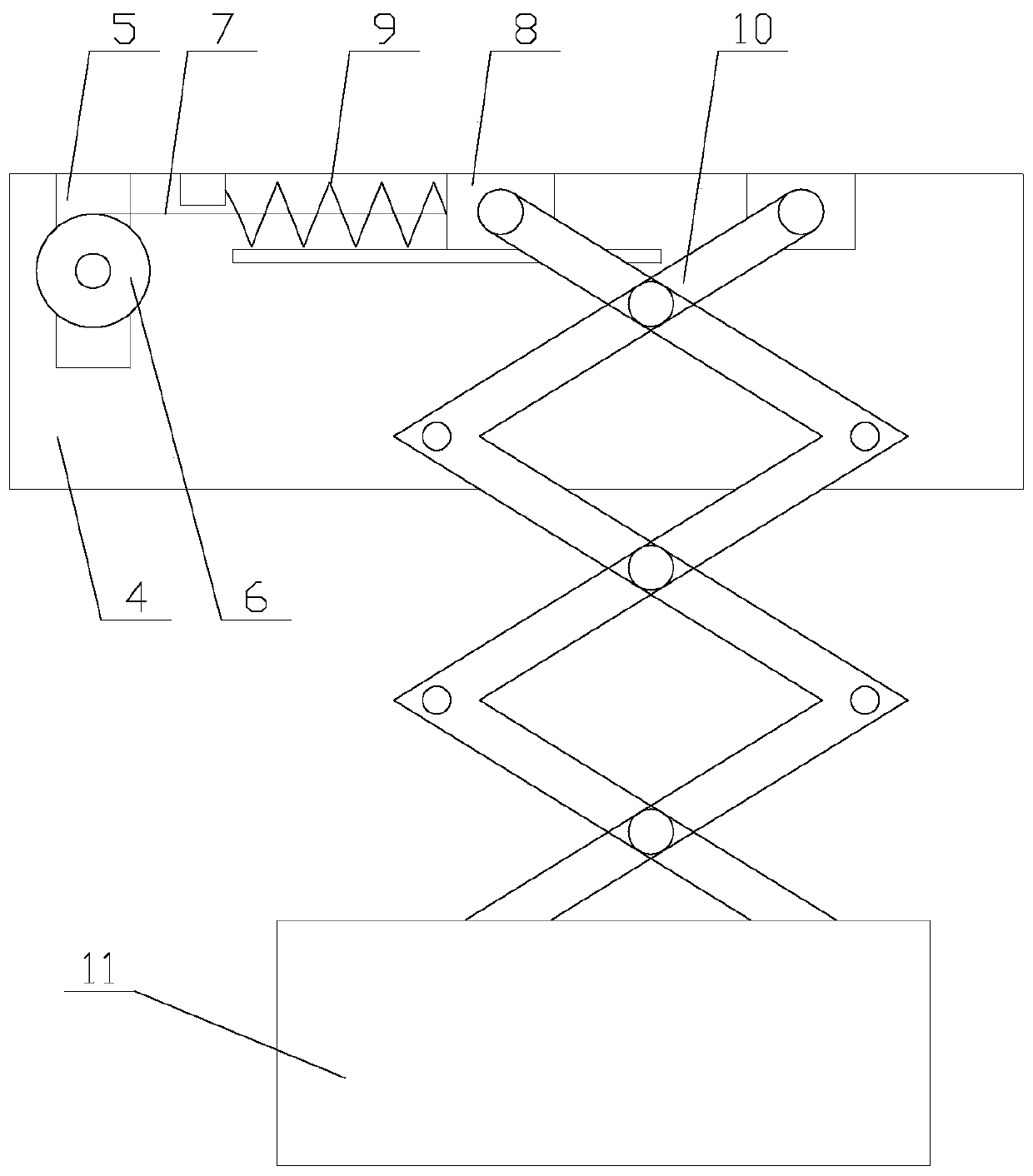

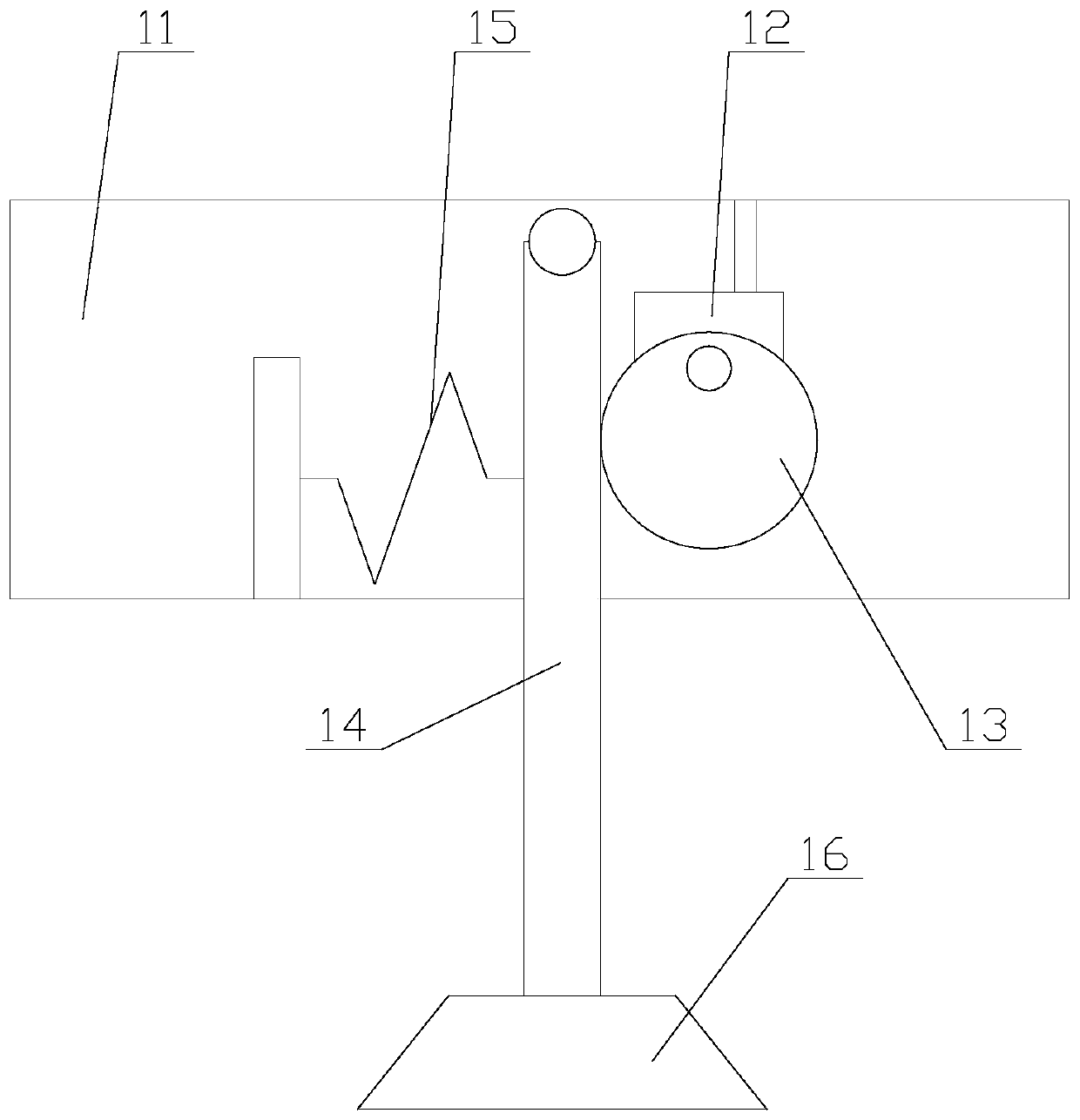

Intelligent injection molding equipment for vehicle part production

ActiveCN107825655AImprove practicalityAvoid affecting the injection molding effectPlastic recyclingEngineeringRecovery mechanism

The invention relates to intelligent injection molding equipment for vehicle part production. The equipment comprises a main body, a production chamber and a charging box, and further comprises a cleaning mechanism and a recovery mechanism; the cleaning mechanism comprises a lifting module and a cleaning module; the cleaning module comprises a driving chamber, a second motor, a rotating wheel, a swing rod and a cleaning brush; and the recovery mechanism comprises a recovery chamber, a crushing module and a stirring module. In the intelligent injection molding equipment for vehicle part production, the cleaning brush of the cleaning mechanism swings back and forth to sweep off accumulated materials on a nozzle to prevent influence on the injection molding effect, so that the product qualityis improved; compared with manual cleaning, the cleaning mode is safer and more efficient; wastes and the swept accumulated materials can be recovered and crushed through the recovery mechanism to achieve heating and melting; and through uniform stirring, the materials are thoroughly molten to achieve future reutilization, so that the cost investment is saved, and the practicability of the injection molding equipment is greatly improved.

Owner:南通柏源汽车零部件有限公司

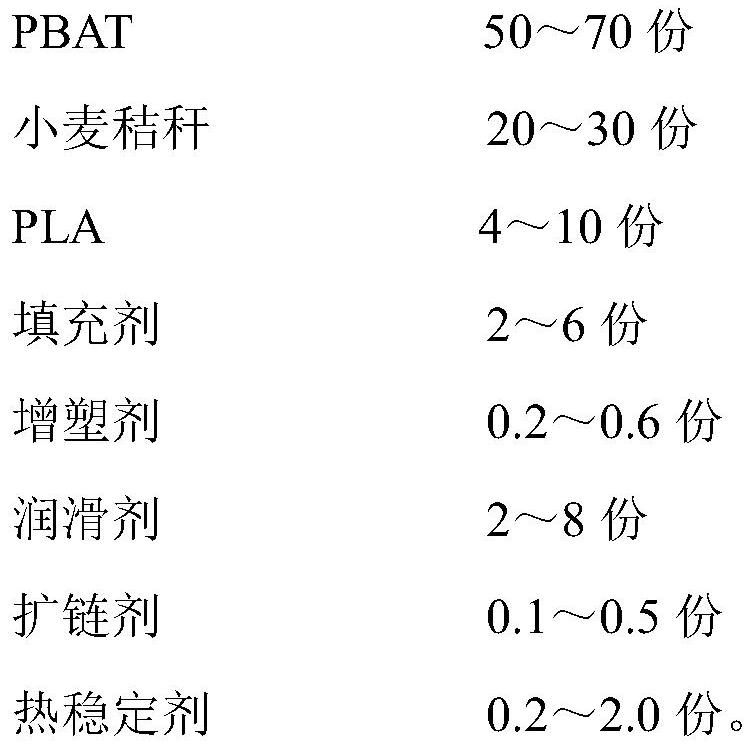

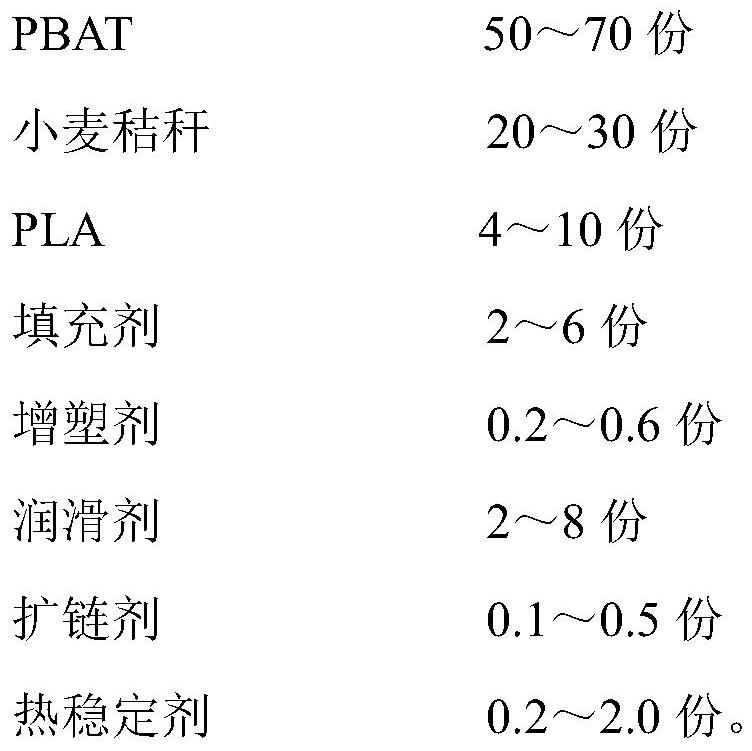

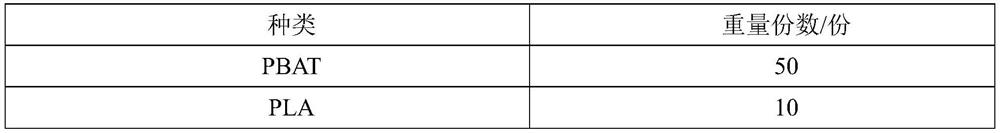

PBAT composite modified biodegradable material and preparation method thereof

PendingCN113429759AHigh breaking strengthImprove ductilityWood treatment detailsWood impregnation detailsPolymer sciencePlasticizer

The invention belongs to the technical field of biodegradable materials, and particularly relates to a PBAT composite modified biodegradable material and a preparation method thereof. The PBAT composite modified biodegradable material is prepared from the following components in parts by weight: 50-70 parts of PBAT, 20-30 parts of wheat straw, 4-10 parts of PLA, 2-6 parts of a filling agent, 0.2-0.6 part of a plasticizer, 2-8 parts of a lubricating agent, 0.1-0.5 part of a chain extender and 0.2-2.0 parts of a heat stabilizer. The PBAT composite modified biodegradable material provided by the invention has better ductility and elongation at break, strong flame retardant property and low cost, and is beneficial to market promotion; and the invention also provides a preparation method thereof.

Owner:SHANDONG RUIFENG CHEM

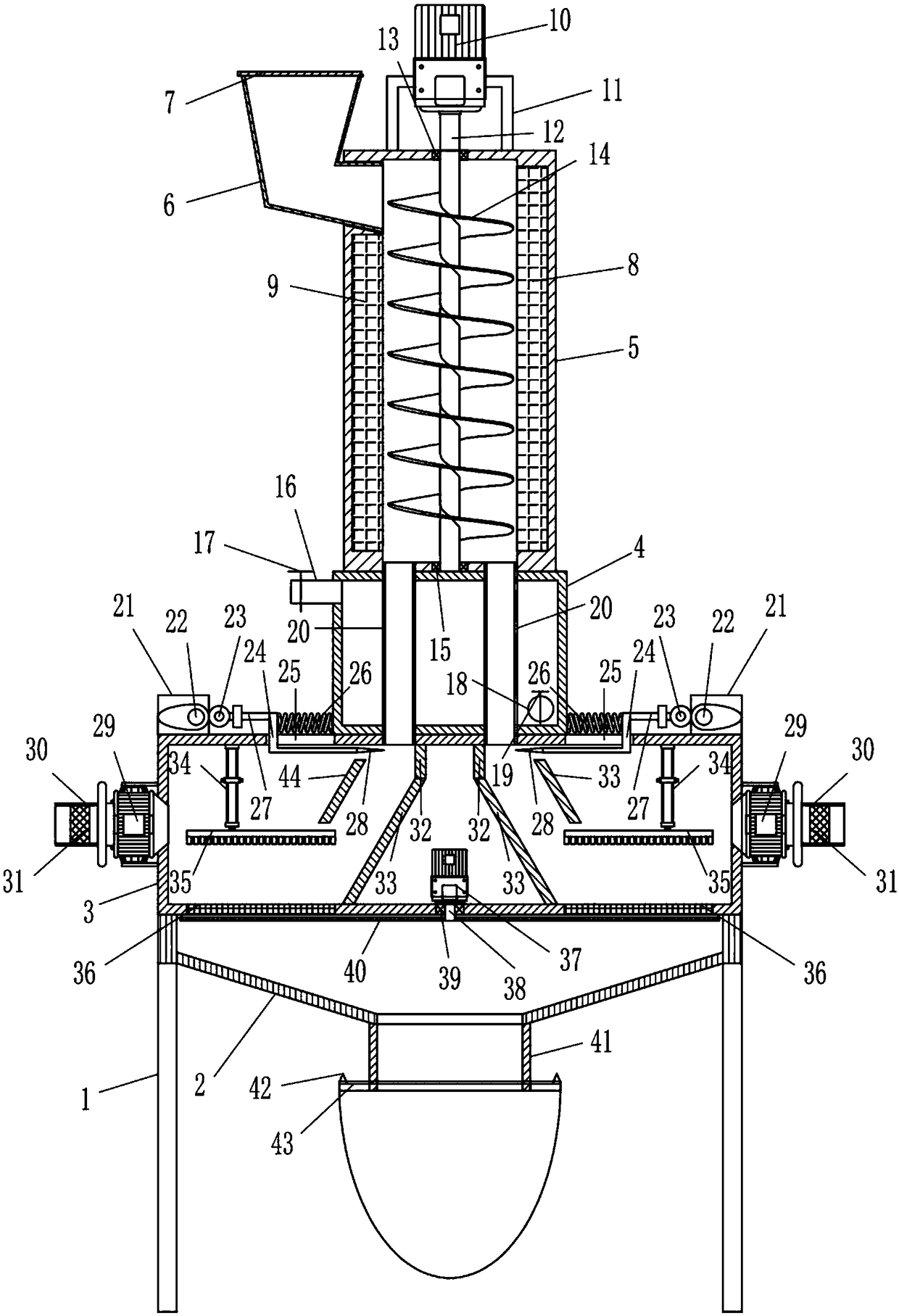

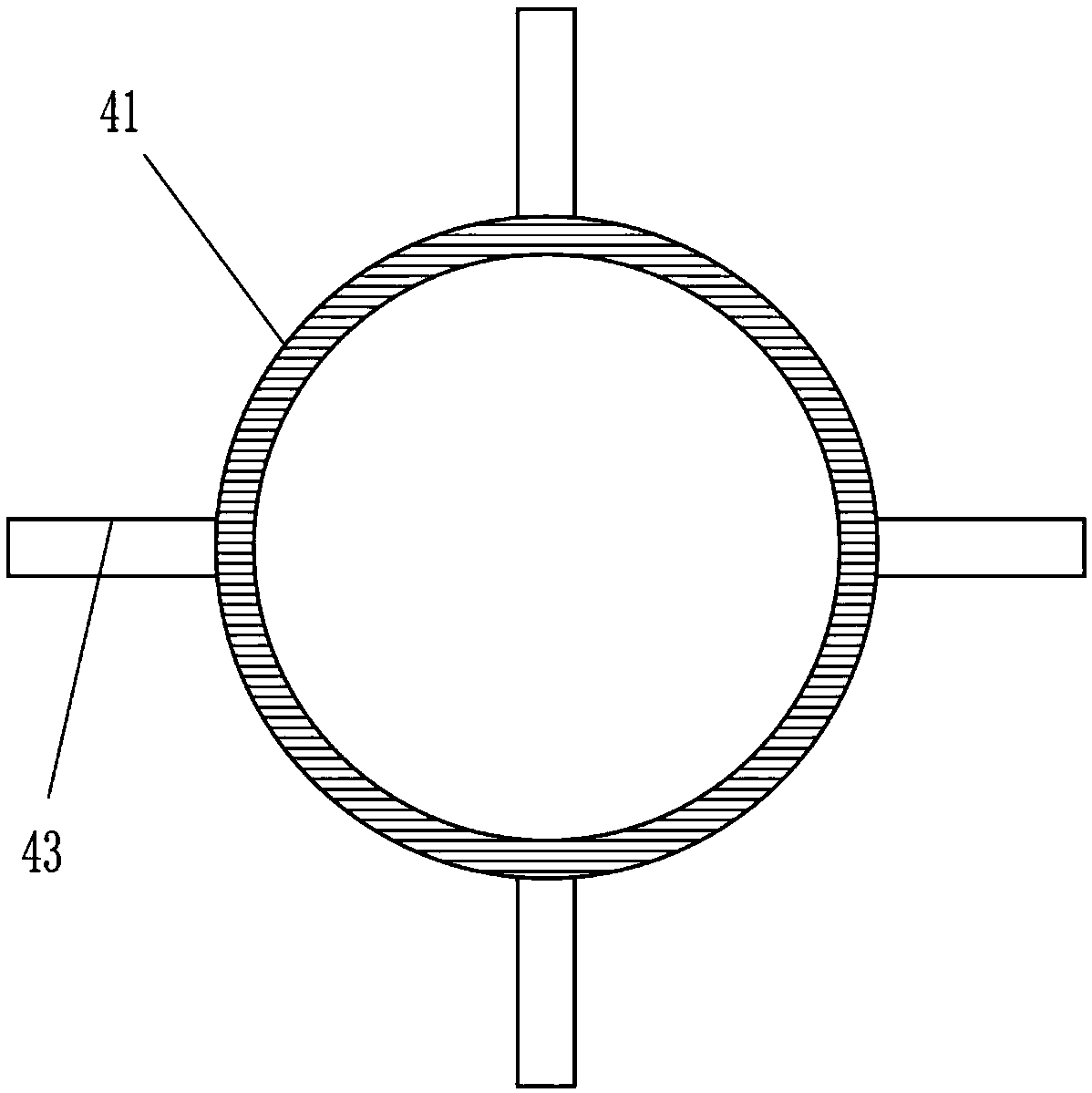

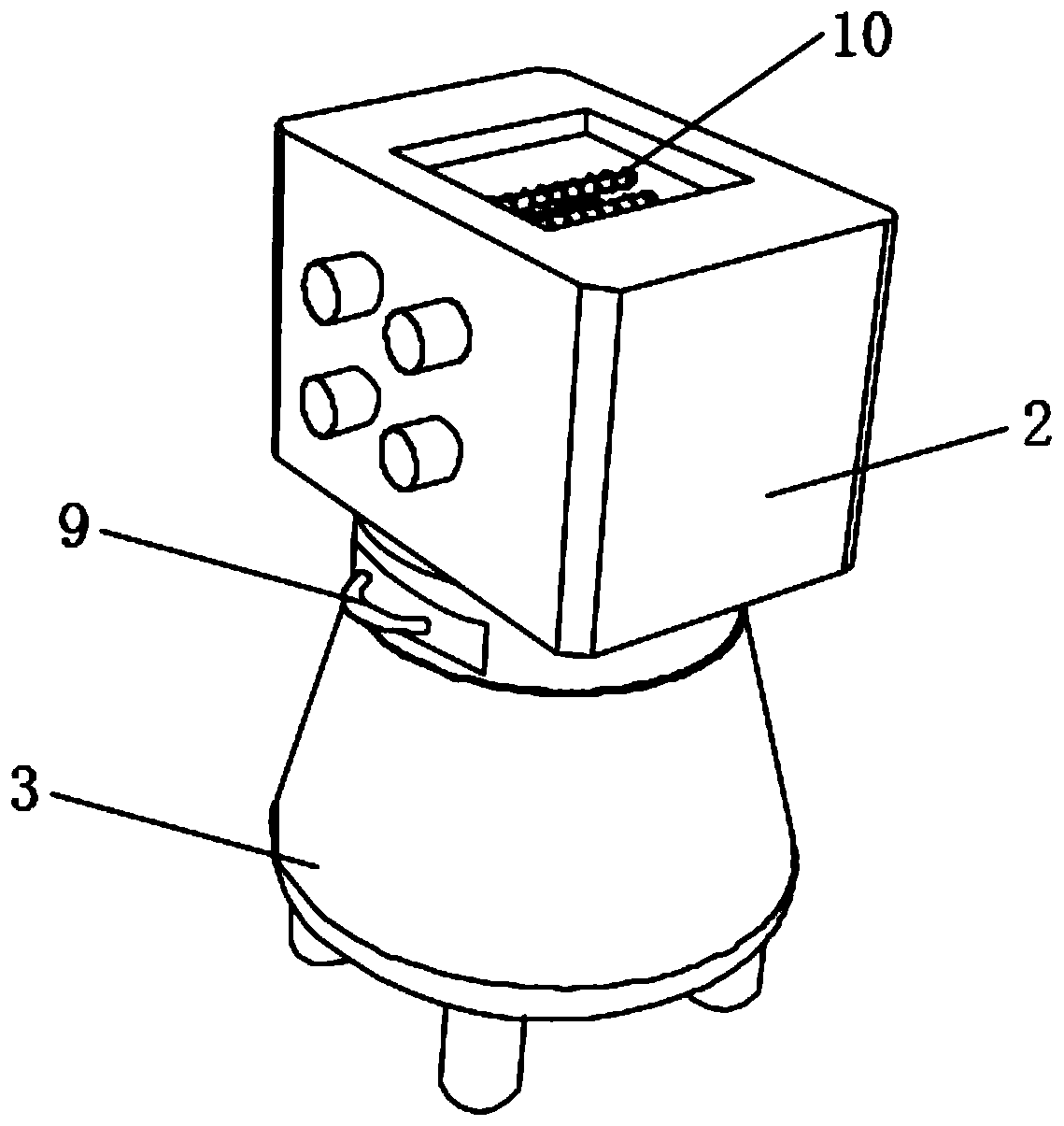

Efficient pelletizer for polyvinyl chloride resin recovery

ActiveCN108995082AImprove granulation efficiencyImprove work efficiencyPlastic recyclingSolid materialProduct recoveryPolymer chemistry

The invention belongs to the field of polyvinyl chloride resin product recovery equipment, particularly relates to an efficient pelletizer for polyvinyl chloride resin recovery and aims at solving thetechnical problem of providing the efficient pelletizer for polyvinyl chloride resin recovery, capable of performing filtering treatment on wastes in the cooling and shaping process, automatically performing bagging after formation and pelleting of the polyvinyl chloride resin and thoroughly melting the resin. The efficient pelletizer for polyvinyl chloride resin recovery comprises a first bracket, a collection funnel, a pelleting tank, a cooling tank, a melting cylinder, a first motor and a fixed spine; the pelleting tank is fixedly connected to the top of the first bracket; and the collection funnel is fixedly connected to the bottom of the first bracket. The efficient pelletizer for polyvinyl chloride resin recovery achieves the effects that the filtering treatment can be performed onthe wastes in the cooling and shaping process, bagging can be automatically performed after formation and pelleting of the polyvinyl chloride resin, the resin is thoroughly molten, and the pelleting efficiency is high.

Owner:徐州大塑人机械有限公司

Asphalt melting device for highway engineering

The invention discloses an asphalt melting device for highway engineering, and belongs to the field of highway engineering. The asphalt melting device for highway engineering includes a crushing mechanism, a melting mechanism, a filtering mechanism and an insulation mechanism, a fixing clamping piece is fixedly connected to the side end of the crushing mechanism, and the crushing mechanism is connected to the upper end of the melting mechanism through the fixing clamping piece in a clamped mode; and the outer end of the melting mechanism is fixedly connected with an auxiliary motor unit, the auxiliary motor unit includes two pairs of auxiliary motors, a through hole matched with the auxiliary motor unit is formed in the side end of the melting mechanism, the power output ends of the auxiliary motors penetrate through the through hole and are fixedly connected with rotary heating spike assemblies, the two pairs of rotary heating spike assemblies are arranged in the melting area, and opposite rotation of the two adjacent pairs of rotary heating spike assemblies is used for making asphalt blocks mix evenly. On the one hand, the multiple crushing effect is further achieved, on the other hand, the melting time of the asphalt blocks in melting mechanism can be prolonged, and compared with original melting devices, the melting rate can be increased.

Owner:刘文伟 +6

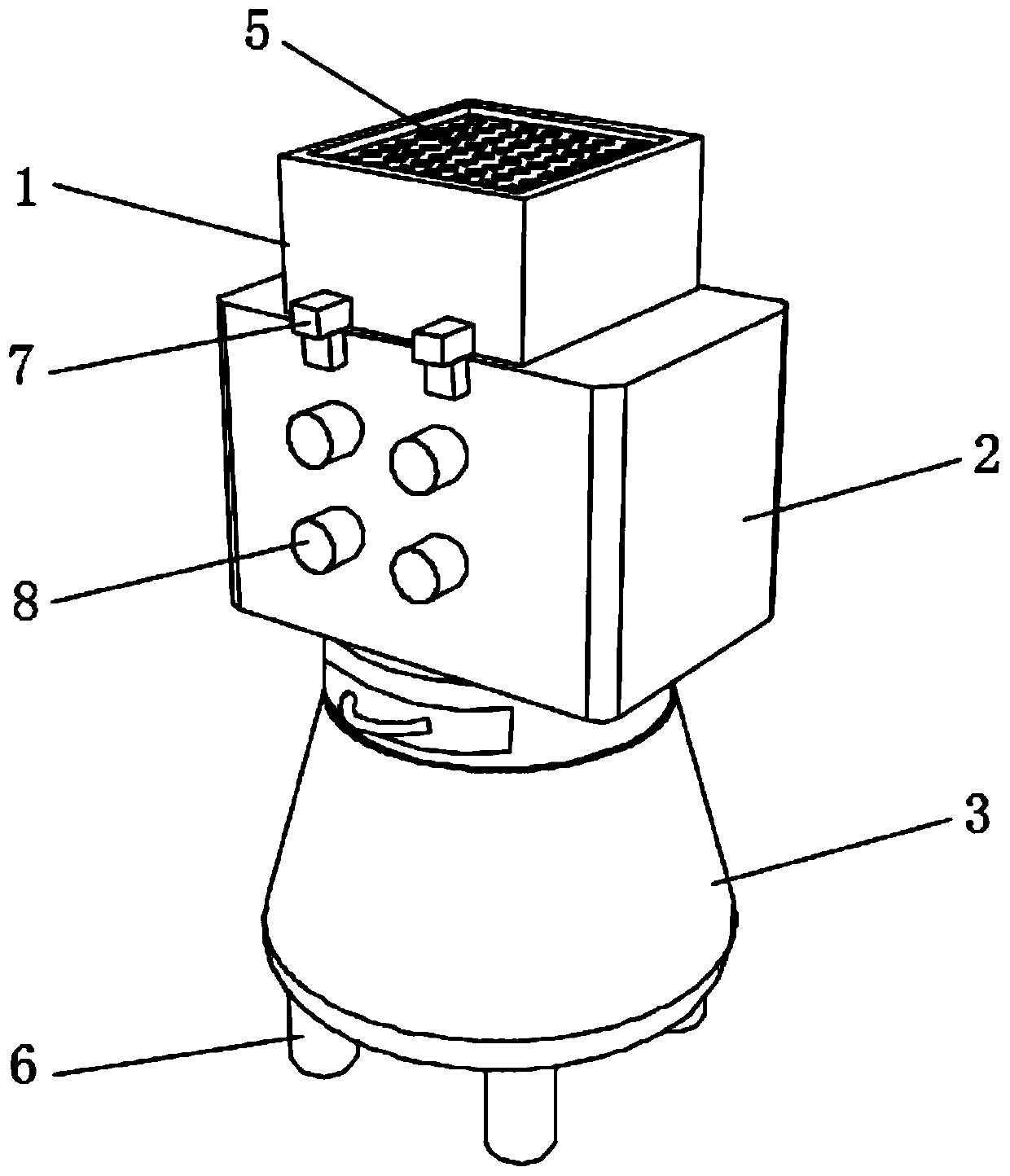

Powdery polyether-ether-ketone material sideways feeding type 3D printer

PendingCN108215156AAvoid cloggingIncrease delivery speedAdditive manufacturing apparatusAdditive manufacturing with liquidsHuman bodyDisease

The invention discloses a powdery polyether-ether-ketone material sideways feeding type 3D printer. The powdery polyether-ether-ketone material sideways feeding type 3D printer comprises a shell. A fixed cover is arranged on the top of the shell. A first motor is arranged on the top of the fixed cover. A threaded rod is arranged at the bottom of the fixed cover. Fixing devices are arranged on boththe two sides of the outside of the fixed cover. Each fixing device comprises a fixing plate. A bolt is arranged on the surface of the fixing plate. Because the technology does not exist in the traditional technologies, the growth cycle of a doctor is long, and a new doctor cannot make accurate judgment on many diseases because of experience lack. When a user uses the product of the powdery polyether-ether-ketone material sideways feeding type 3D printer, the printer can print the model simulating a morbid human body to facilitate the study and training of a doctor for surgery such as puncture surgery, the study speed of a student is greatly increased, the model of the morbid body of a patient can be accurately copied for doctors on diagnosis, medical discussion and communication and research on difficult and baffling diseases.

Owner:大连派思益科技有限公司

Powder type polyether ether ketone material top power type 3D printer

ActiveCN108177333AAvoid cloggingIncrease delivery speedManufacturing driving meansIncreasing energy efficiencyEngineeringPolyether ether ketone

The invention discloses a powder type polyether ether ketone material top power type 3D printer. The 3D printer comprises a shell, wherein a fixed cover is arranged at the middle part of the shell; the inner wall of the upper part of the shell is fixedly connected with a sealed cabin through a connecting rod; a first motor is arranged in the sealed cabin; a connecting screw is arranged at the lower end of the first motor; fixing devices are arranged on both sides outside the fixed cover; the fixing device comprises a fixing plate; bolts are arranged on the surface of the fixing plate; the fixing plate is fixedly connected with the fixed cover through bolts; and one side of the fixed cover is provided with a fixed rod. According to the 3D printer provided by the invention, a feed box and atoggle plate are arranged, so that a granular material pushed in the feed box can be quickly toggled to the inside of a connecting channel, the granular material is prevented from blocking the feed box, and the conveying speed of the granular material is increased.

Owner:辽宁禾润新材料科技有限公司

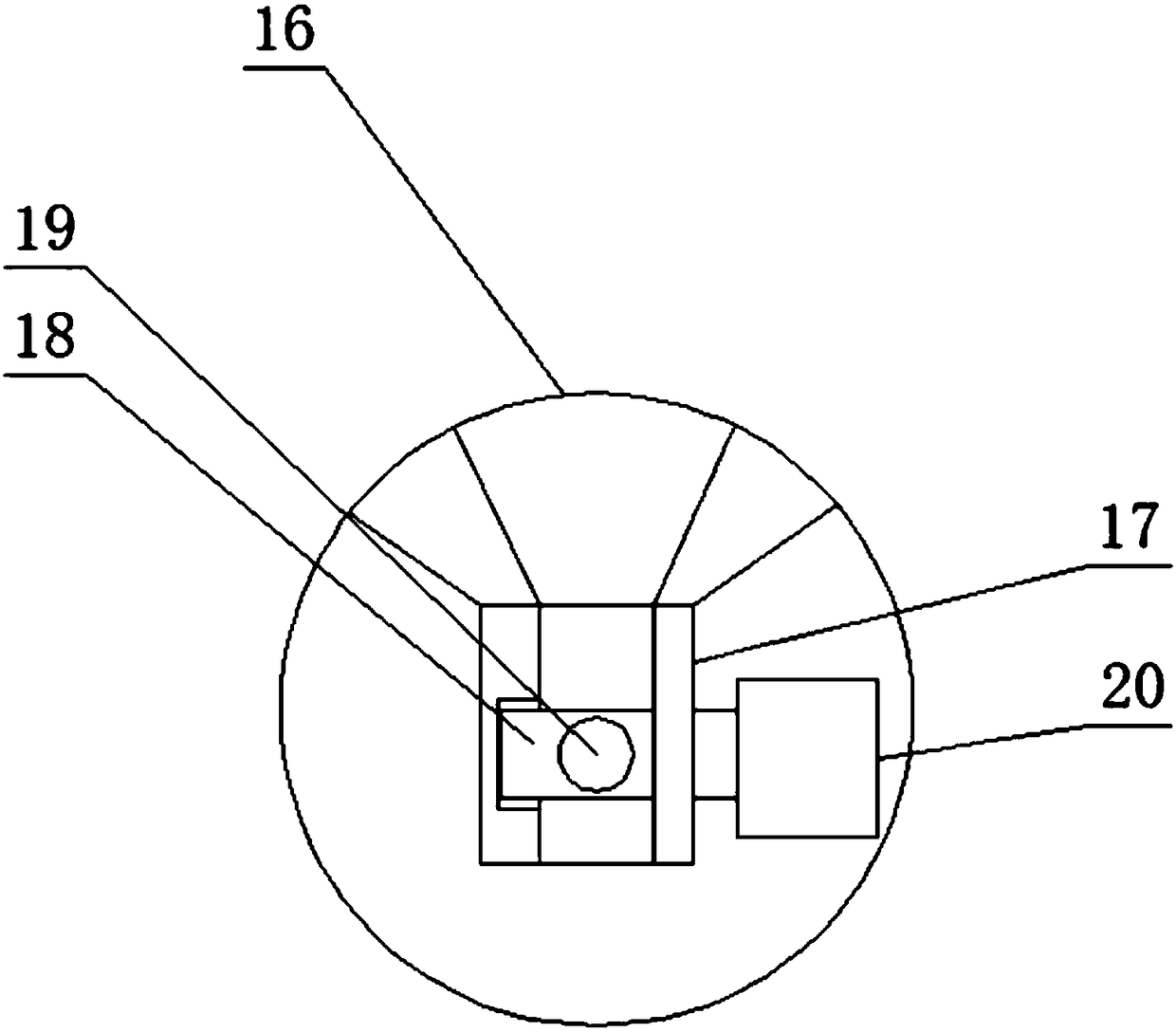

Bottom-blowing pure oxygen enhanced type plasma gasification melting furnace

PendingCN110425541AHigh melting temperatureImprove melting effectIndirect carbon-dioxide mitigationIncinerator apparatusCombustionCentral oxygen supply

The invention discloses a bottom-blowing pure oxygen enhanced type plasma gasification melting furnace. The bottom-blowing pure oxygen enhanced type plasma gasification melting furnace comprises a furnace body, wherein a drying area, a pyrolysis area and a melting area are sequentially arranged in the furnace body from top to bottom, the diameter of a lower hearth is smaller than that of an upperhearth, a dangerous waste material inlet is formed in the drying area of the hearth, the upper hearth and the lower hearth are connected through a conical structure, and two plasma torches are symmetrically arranged on the lower hearth. A cylindrical central oxygen supply pipe is arranged at the bottom of the melting area at the bottom of the furnace body and is fixed on refractory bricks and heatpreservation bricks through a protective sleeve pipe and can be detached and replaced conveniently; pure oxygen is sprayed into the central oxygen supply pipe to provide the required oxygen amount ofresidual carbon with incomplete pyrolysis gasification reaction; the heat generated by combustion of the residual carbon can be supplied to the gasification of the carbonaceous substance; the meltingeffect and the combustion efficiency of the plasma furnace are improved; and meanwhile, the temperature of the hearth can be increased faster and higher.

Owner:XIAN AEROSPACE SOURCE POWER ENG CO LTD

An intelligent injection molding equipment for the production of auto parts

ActiveCN107825655BImprove practicalityAvoid affecting the injection molding effectPlastic recyclingRecovery mechanismScrap

The invention relates to intelligent injection molding equipment for vehicle part production. The equipment comprises a main body, a production chamber and a charging box, and further comprises a cleaning mechanism and a recovery mechanism; the cleaning mechanism comprises a lifting module and a cleaning module; the cleaning module comprises a driving chamber, a second motor, a rotating wheel, a swing rod and a cleaning brush; and the recovery mechanism comprises a recovery chamber, a crushing module and a stirring module. In the intelligent injection molding equipment for vehicle part production, the cleaning brush of the cleaning mechanism swings back and forth to sweep off accumulated materials on a nozzle to prevent influence on the injection molding effect, so that the product qualityis improved; compared with manual cleaning, the cleaning mode is safer and more efficient; wastes and the swept accumulated materials can be recovered and crushed through the recovery mechanism to achieve heating and melting; and through uniform stirring, the materials are thoroughly molten to achieve future reutilization, so that the cost investment is saved, and the practicability of the injection molding equipment is greatly improved.

Owner:南通柏源汽车零部件有限公司

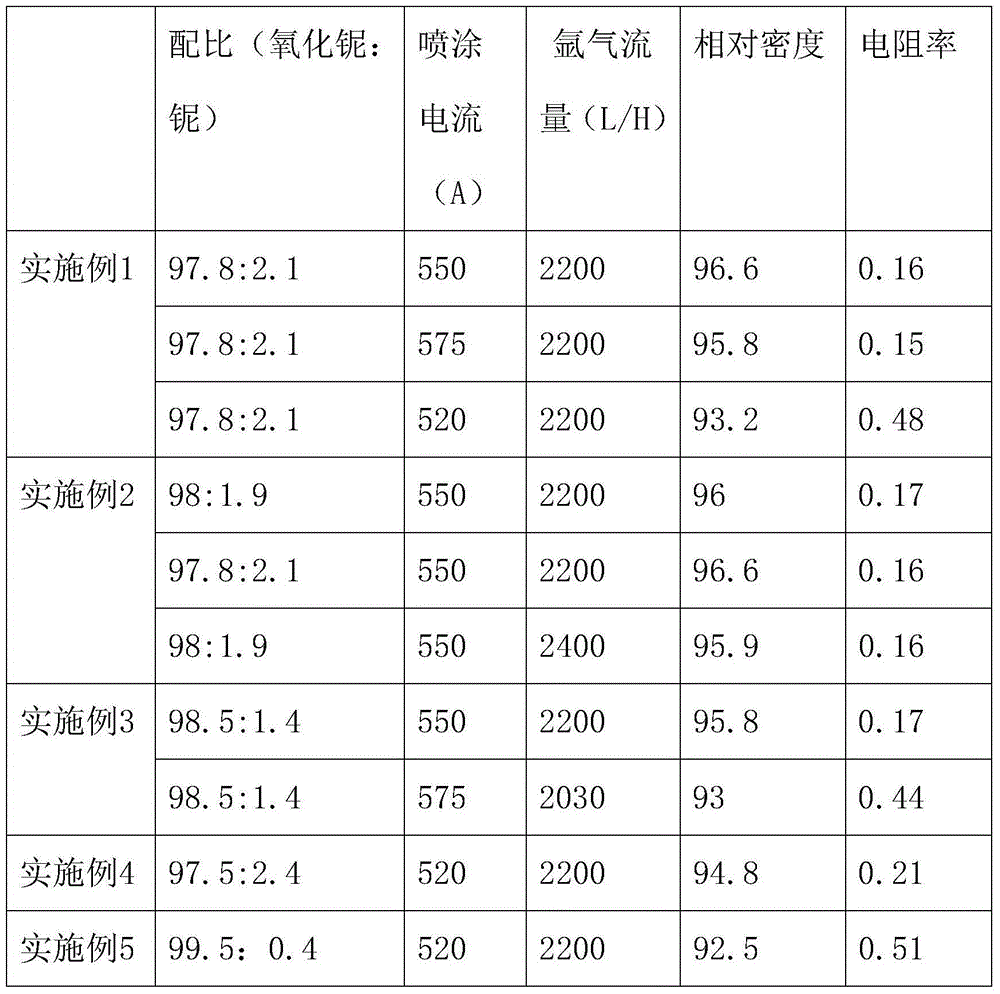

Low resistivity niobium-doped niobium oxide sputtering rotation target material and preparation method thereof

ActiveCN104831243ALow product resistivityImprove transmittanceMolten spray coatingVacuum evaporation coatingHigh transmittanceMachining

The invention discloses a low resistivity niobium-doped niobium oxide sputtering rotation target material and a preparation method thereof. The target material comprises 97.5-99.5wt% of NbOx, 0.4-2.4wt% of Nb, and the balance of impurities, wherein x is greater than 0.05 and lower than 2.5, and preferably greater than 2 and lower than 2.5. The preparation method comprises the following steps: producing a stainless steel back tube; and mixing powders, drying, carrying out vacuum plasma spraying, and machining. The target material obtained by adopting the above formula and introducing a new production technology has the advantages of low resistivity, high transmittance and greatly improved performances. The transmittance is mainly related with the thickness and the composition structure of a film designed by a downstream film plating manufacturer, and the transmittance of the thickness with same thickness in the film plating process is high if the compactness of the target material is high. The target material can be widely used in fields of touch screens, optical glass plating films, TFT and the like, and greatly promotes the process of the industry.

Owner:WUHU YINGRI TECH CO LTD

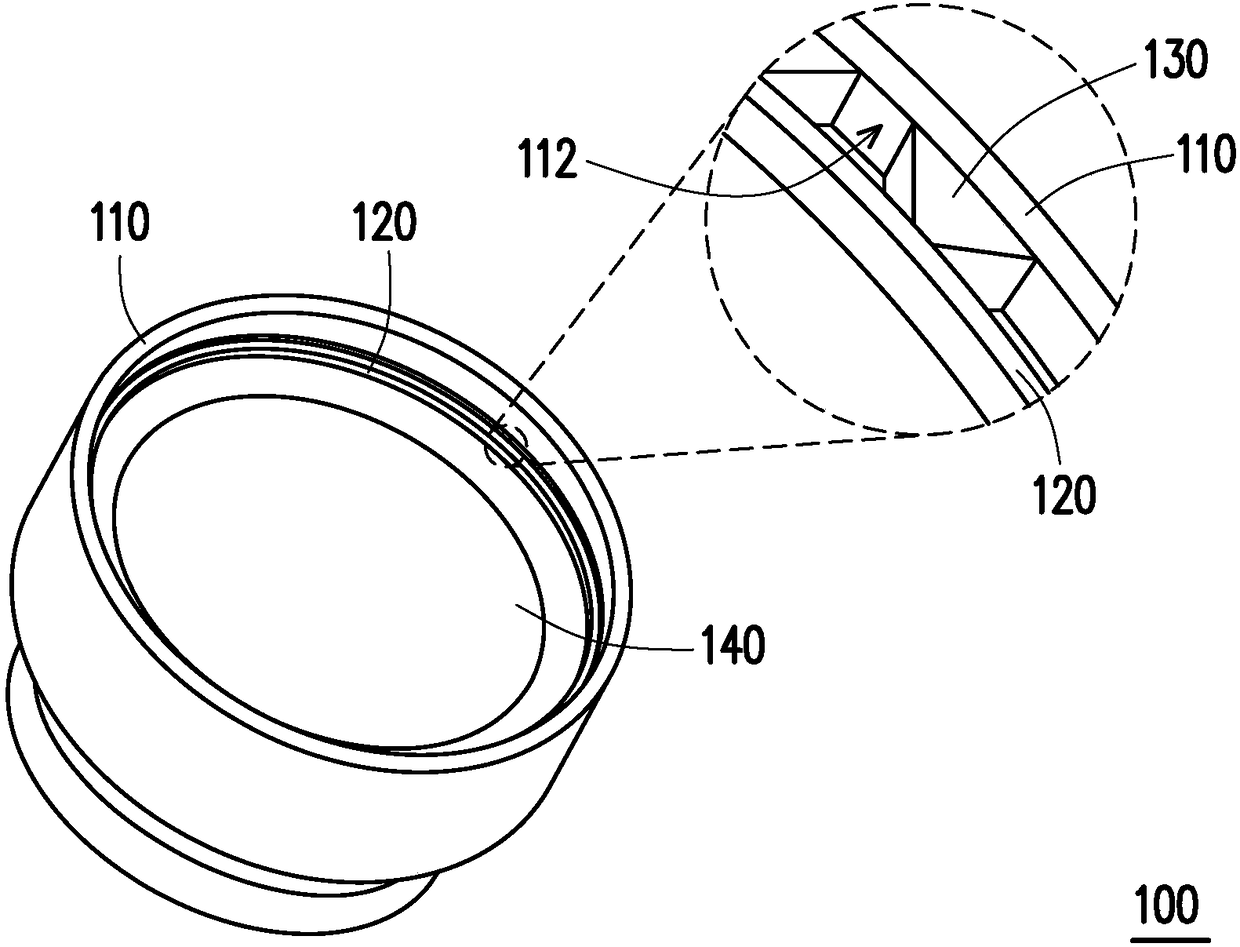

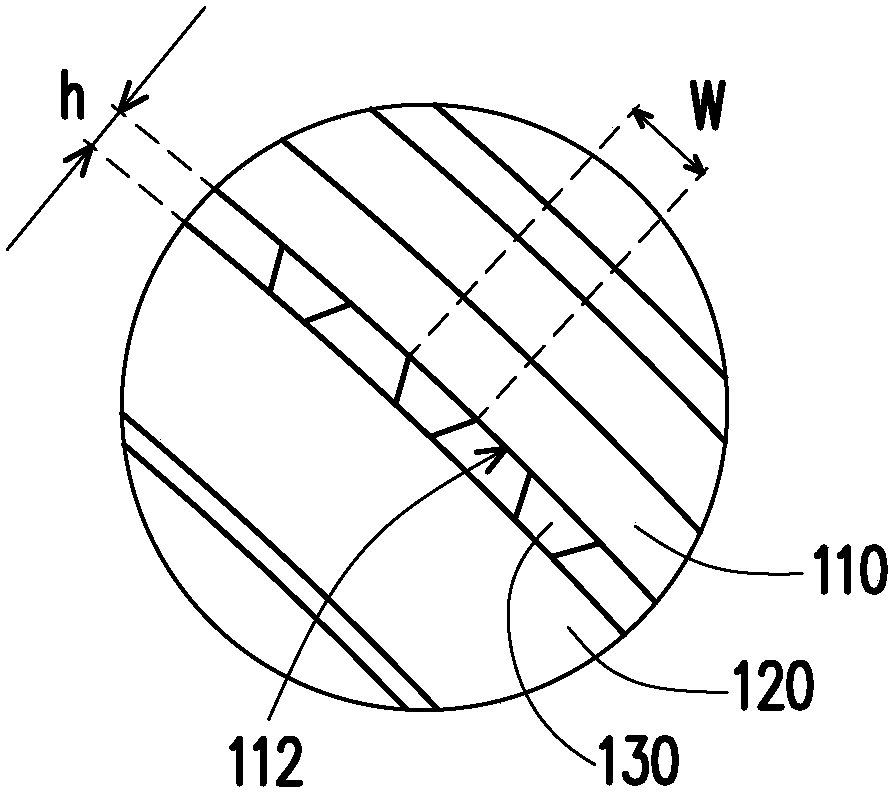

Optics lens and assembly method and lens barrel thereof

The invention discloses an optics lens including a lens barrel, a fixing ring and at least one optics lens element. A joint surface is arranged along the inner edge of one end of the lens barrel. Thejoint surface is provided with a plurality of microstructures arranged on a circle. The microstructures are convex on the joint surface. The fixing ring is arranged in the joint surface of the lens barrel. The optics lens elements are arranged in the lens barrel. The microstructures and the fixing ring on the joint surface are dissolved by using a solvent to fixedly arrange the optics lens elements in the lens barrel. Furthermore, the invention also provides an assembly method and lens barrel of the optics lens. The optics lens with high reliability and durability can be manufactured accordingto the invention.

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

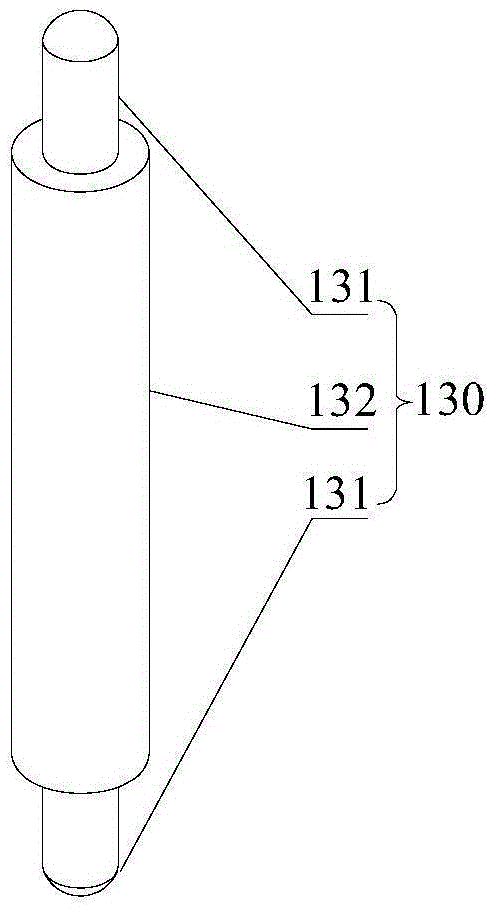

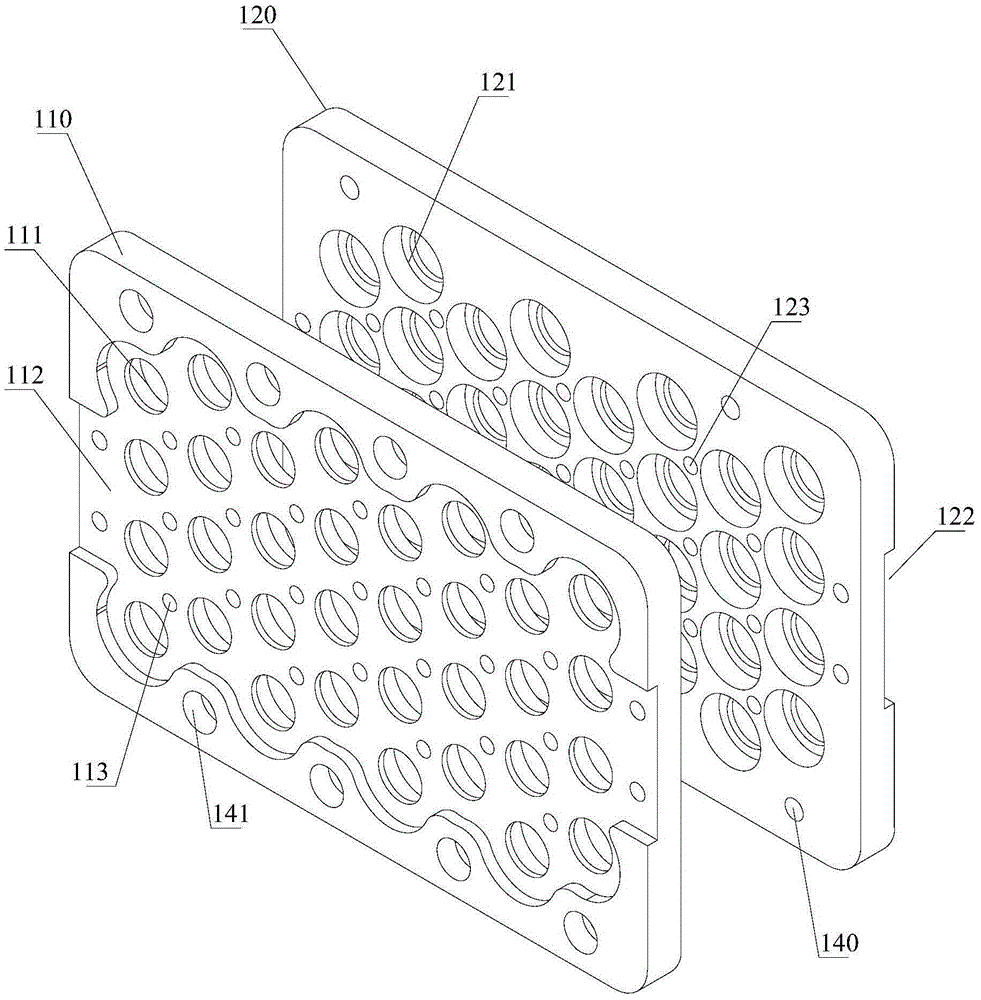

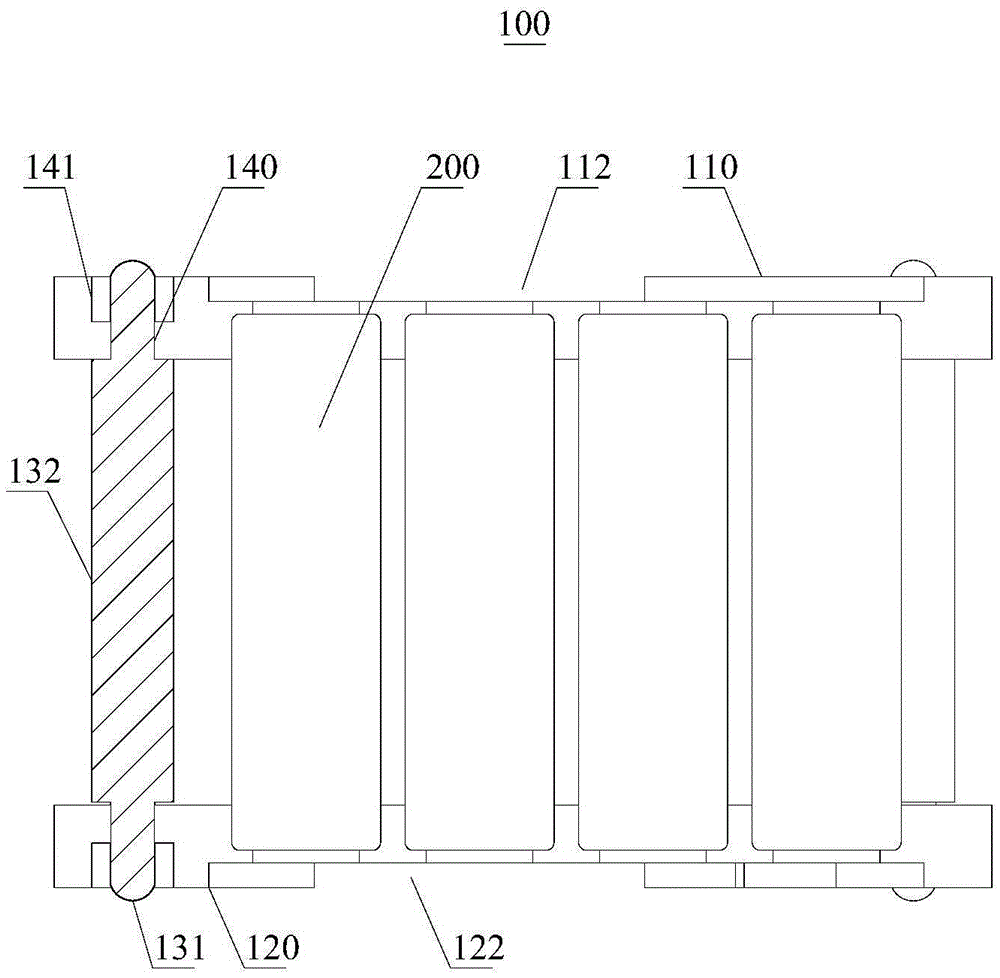

Battery pack support

InactiveCN105576170AFirmly connectedAvoid relative motionCell component detailsControl systemElectronic control system

The invention discloses a battery pack support, wherein support columns are connected with a first fixing plate and a second fixing plate in a hot melting way not by bolts; by hot melting connection, the connection between the support columns and the first fixing plate and the second plate is more steady and firm, the relative moving between the first fixing plate and the second fixing plate, which is caused by bolt looseness, can be eradicated effectively, such problems as the power output is stable during th running process of a vehicle, an electronic control system works abnormally and accessory equipment works abnormally can be solved.

Owner:华霆(常州)动力技术有限公司

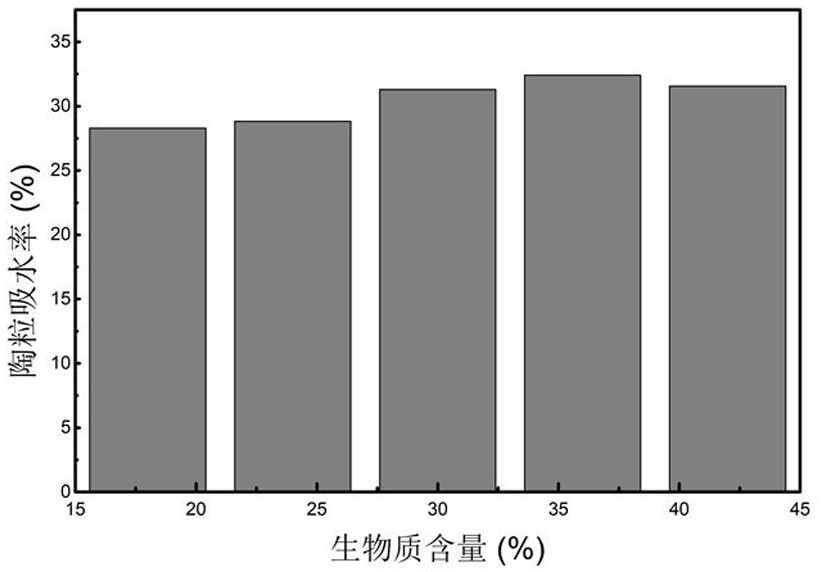

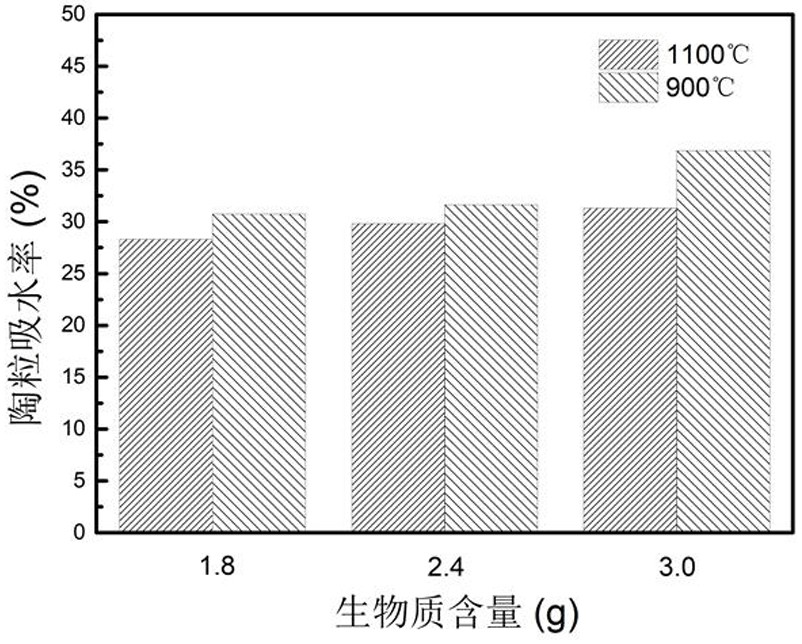

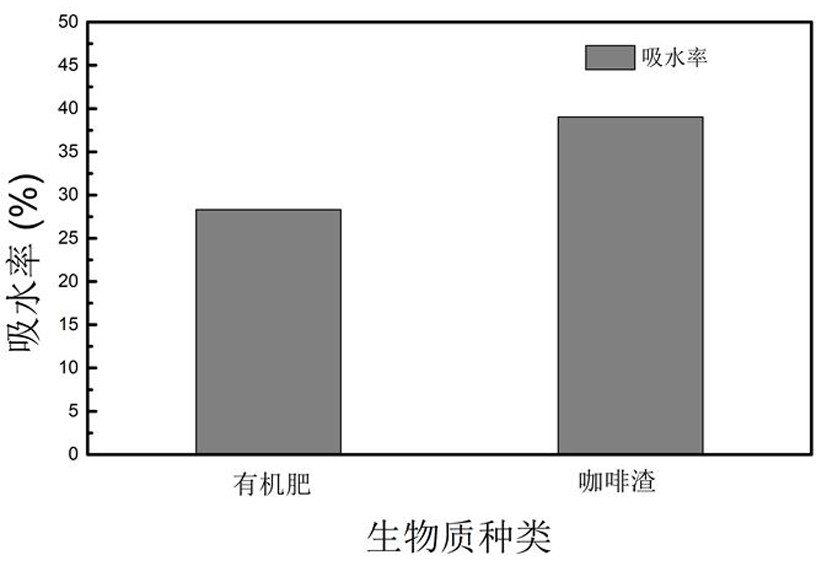

Method for preparing soil conditioner by in-situ hydrothermal combination of ceramsite and biochar

PendingCN113481013ARealize resource utilizationReduce pollutionAgriculture tools and machinesOrganic fertilisersHazardous substanceEnvironmental engineering

The invention discloses a method for preparing a soil conditioner by in-situ hydrothermal combination of ceramsite and biochar. The method comprises the following steps: crushing industrial waste, then conducting mixing and granulating, carrying out roasting through stepped heating, and carrying out cooling to room temperature to obtain ceramsite. According to the invention, biomass waste and ceramsite are combined through a hydrothermal carbonization method, and solid waste is adopted as a preparation raw materials, so production cost is reduced while the solid waste is fully utilized. As biomass and ceramsite are combined, preparation of combined biochar and ceramsite is achieved, a porous structure enables ceramsite to have higher water absorption and adsorption performance, the water retention property of soil is enhanced, and harmful substances can be adsorbed at the same time; and moreover, the functional groups of biomass waste raw materials can also effectively adsorb pollutants. In addition, heavy metal ions in ceramsite are fixed after being fired, so secondary pollution to the environment is avoided; and therefore, the ceramsite can become a good soil conditioner.

Owner:KUNMING UNIV OF SCI & TECH

Straw-containing wood-plastic outdoor floor and production method thereof

The invention relates to a formula of a straw-containing wood-plastic outdoor floor and a production method of the straw-containing wood-plastic outdoor floor.The straw-containing wood-plastic outdoor floor comprises, by weight, 100 parts of recycled polypropylene plastics, 150-200 parts of wheat straw wood fiber, 1-3 parts of maleic anhydride grafted polypropylene, 2-5 parts of activated calcium carbonate, 1-3 parts of vinyl amine distearate, 2-8 parts of flake graphite, 1-8 parts of nano-zinc oxide, 10-15 parts of glass fiber, 2-10 parts of ultraviolet absorber UV-327, 5-8 parts of light stabilizer GW-944, 3-12 parts of antioxidant 2,6-tert-butyl-4-methylphenol and 3-6 parts of iron oxide red.The production method includes subjecting wheat straws to airing, impurity removing, pulverizing, screening and drying, subjecting the polypropylene plastics to washing, airing and cutting, drying the auxiliaries, and performing melting, hot pressing and cooling so as to obtain the outdoor floor.The straw-containing wood-plastic outdoor floor is high in durability and ageing resistance and free of natural defects of wood and can be recycled.

Owner:河南金土地科技服务有限公司

Control method for 3D printing wire forming quality

A control method for the 3D printing wire forming quality comprises the steps that extrusion materials with high melting point are put into a tray, then the tray is put into a drying box to be heatedand dried, and the dried extrusion materials with high melting point are put into a vacuum box; a wire is extruded out through a parallel double- screw extrusion machine; extrusion process parametersare adjusted, and the stable, controlled and continuous wire is extruded out; and finally, the extruded wire is printed through 3D printing equipment, a printing process is adjusted, and a needed model is printed and finally applied. The control method achieves qualified 3D printing of the materials with high melting point, greatly improves the preparation efficiency and reduces the preparation cost.

Owner:SHAANXI HENGTONG INTELLIGENT MACHINE

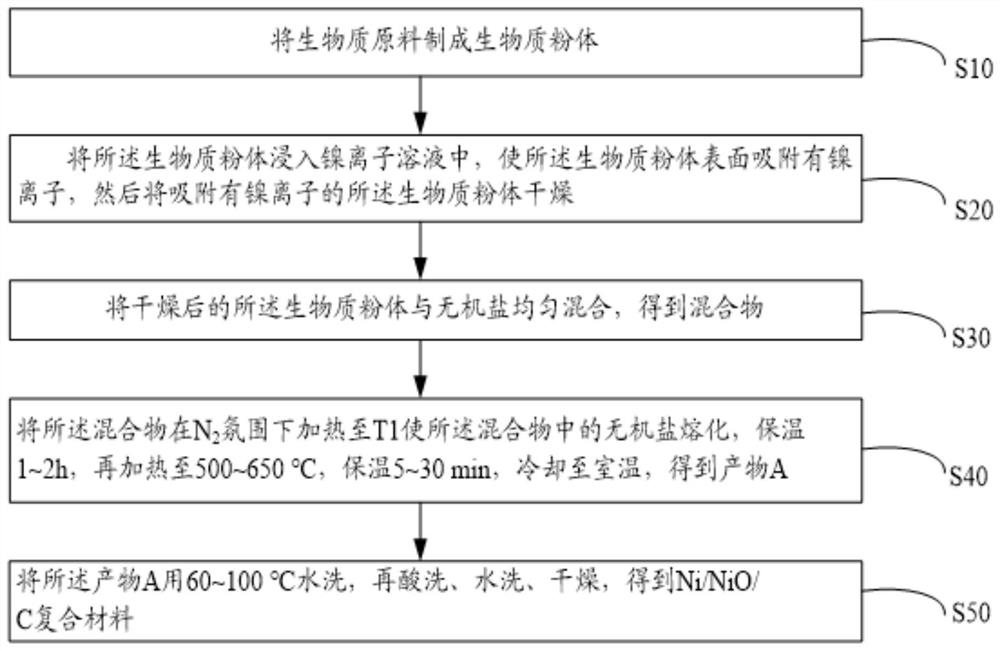

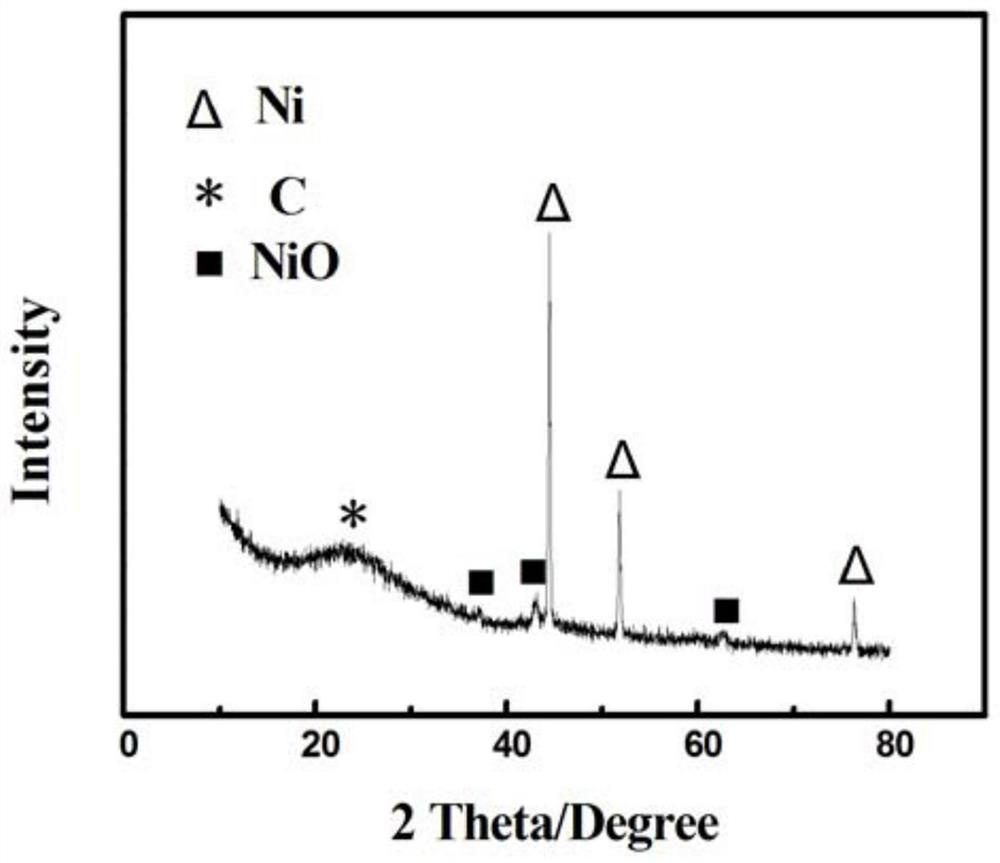

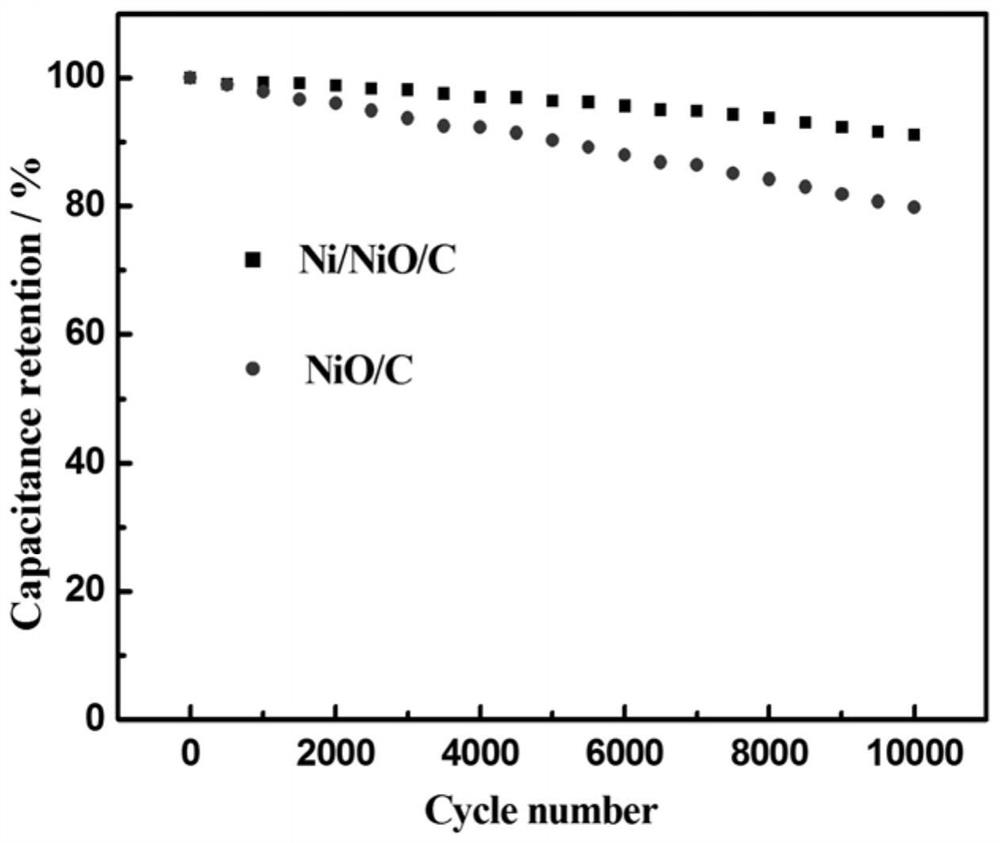

Preparation method of Ni/NiO/C composite material and supercapacitor

ActiveCN111668032AMelted completelyIncrease profitHybrid capacitor electrodesHybrid/EDL manufactureInorganic saltsCapacitor

The invention discloses a preparation method of a Ni / NiO / C composite material and a supercapacitor. The preparation method of the Ni / NiO / C composite material comprises the following steps: preparing biomass powder from a biomass raw material; immersing the biomass powder into a nickel ion solution to enable the biomass powder to adsorb nickel ions, and then drying the biomass powder which adsorbsthe nickel ions; uniformly mixing the dried biomass powder with inorganic salt to obtain a mixture; heating the mixture to T1 in an N2 atmosphere to melt inorganic salt in the mixture, keeping the temperature for 1-2 hours, then heating to 500-650 DEG C, keeping the temperature for 5-30 minutes, and cooling to room temperature to obtain a product A; washing the product A with water at 60-100 DEG C, and then pickling, washing and drying to obtain the Ni / NiO / C composite material. The Ni / NiO / C composite material prepared by the method is good in conductivity, the Ni / NiO / C composite material is used as an electrode material of the supercapacitor, the problem of stability caused by volume change in the NiO charging and discharging process is relieved, the electrochemical performance of the supercapacitor is improved, the cycling stability is relatively good, and the cycle life is long.

Owner:HUBEI UNIV OF ARTS & SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com