Powder type polyether ether ketone material top power type 3D printer

A 3D printer and polyether ether ketone technology, applied in the field of 3D printing, can solve the problems of 3D printing of unmedical products, non-adjustable output thickness, and easy cooling of plastic fibers, so as to prevent the decline in use quality and long growth cycle , the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

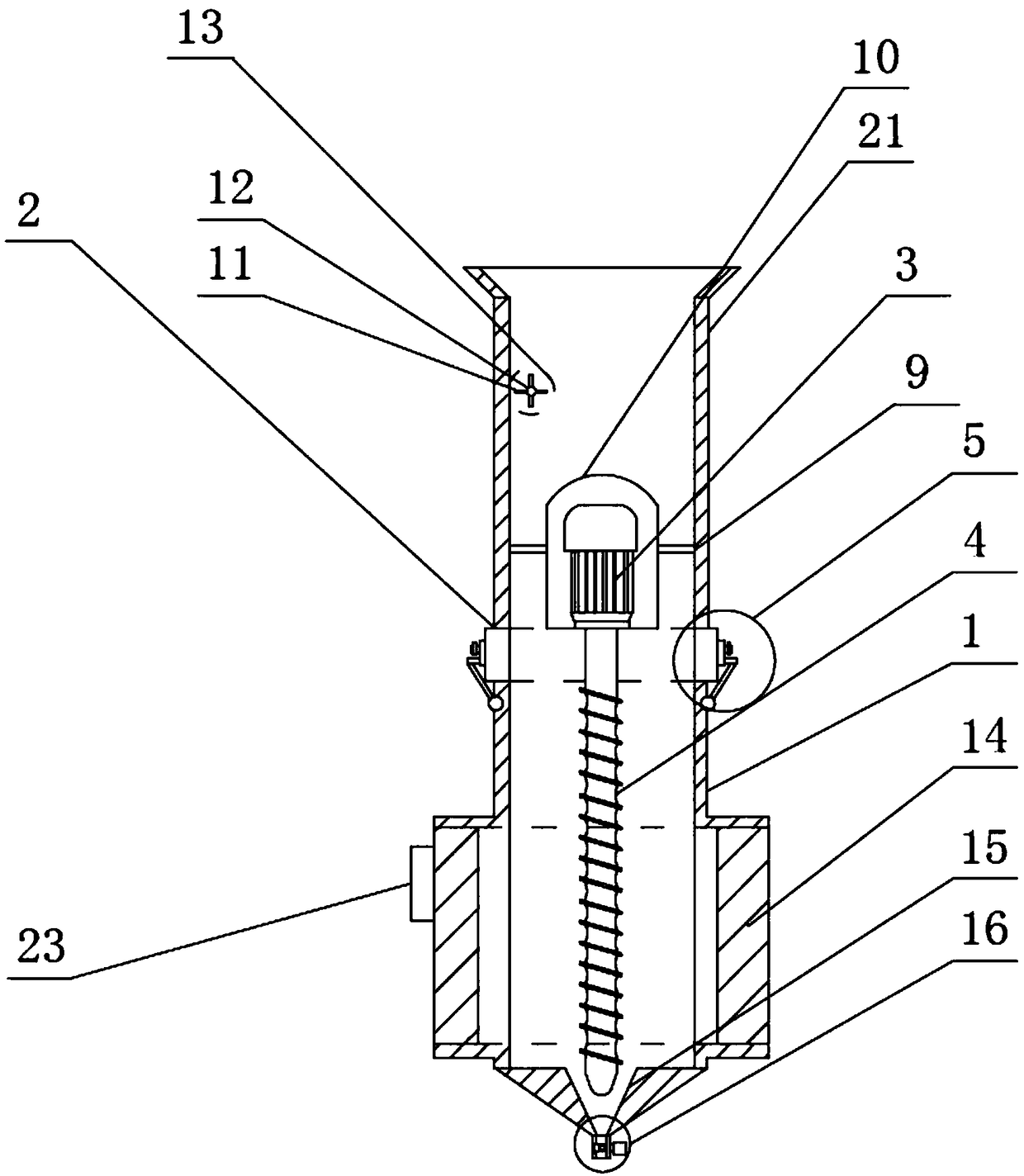

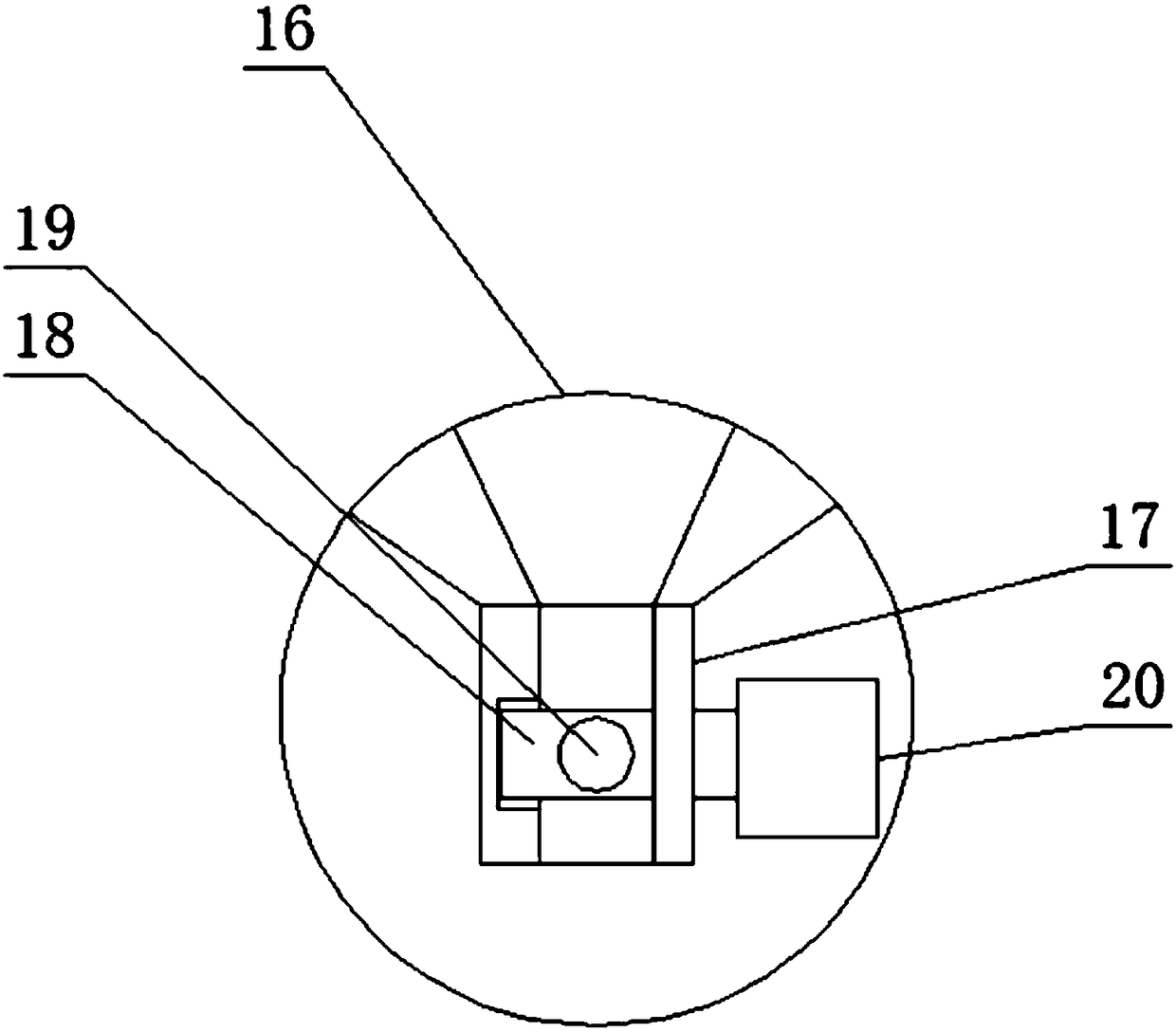

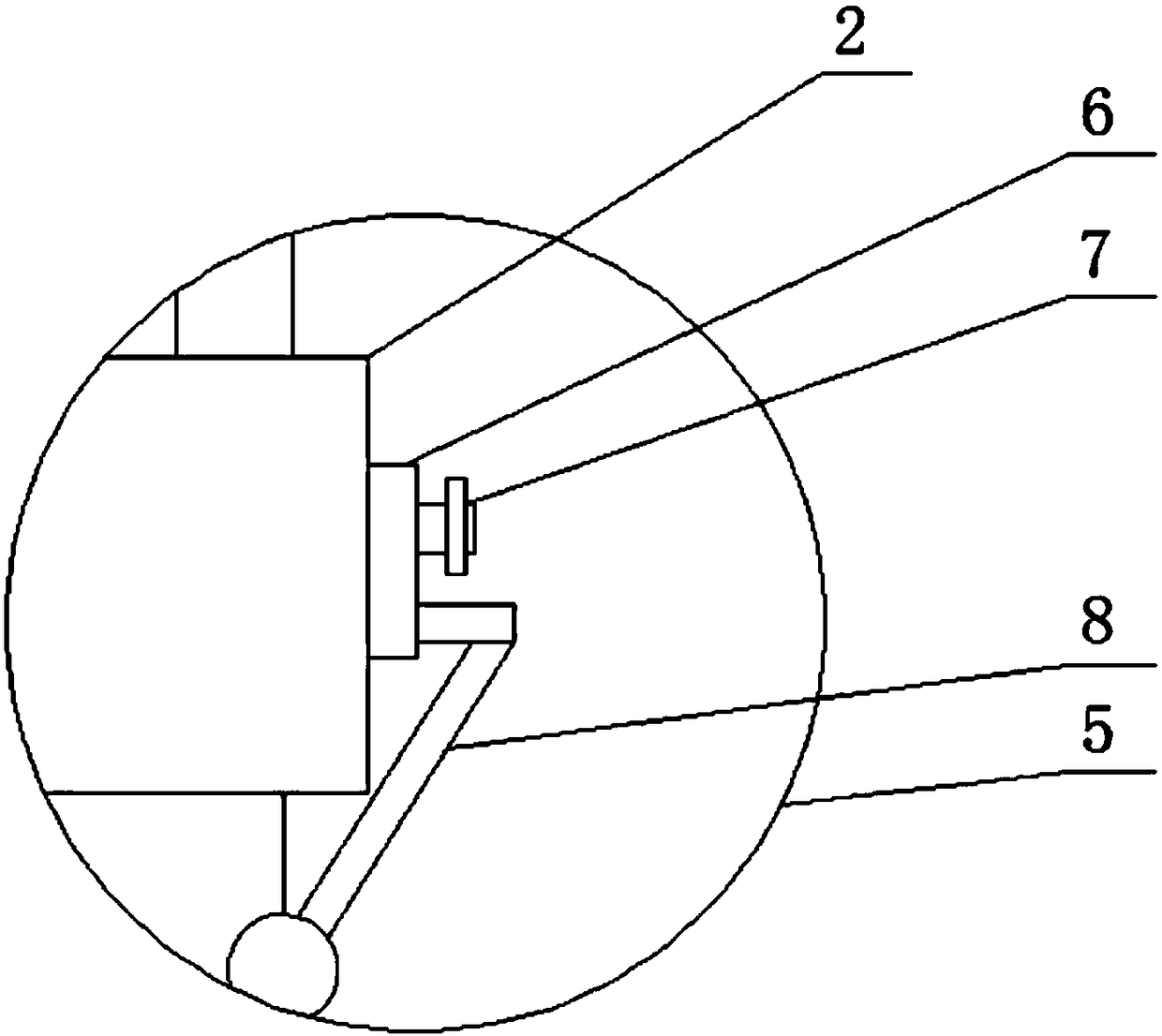

[0019] The present invention provides such Figure 1-3 The top-powered 3D printer of a powdered polyetheretherketone material includes a housing 1, a fixed cover 2 is provided in the middle of the housing 1, and the inner wall of the upper part of the housing 1 is fixedly connected to a sealed cabin 10 through a connecting rod 9. The first motor 3 is arranged in the airtight cabin 10, the lower end of the first motor 3 is provided with a connecting screw 4, and both sides of the fixed cover 2 are provided with a fixing device 5, and the fixing device 5 includes a fixing plate 6. Bolts 7 are provided on the surface of the fixed plate 6, and the fixed plate 6 is fixedly connected with the fixed cover 2 through the bolts 7. A fixed rod 8 is provided on one side of the fixed cover 2, and the housing 1 includes a The feed channel 21 and the heating channel 22 fixed on the lower end of the fixed cover 2, the upper end of the feed channel 21 is fixedly connected to the feed hopper 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com