Low resistivity niobium-doped niobium oxide sputtering rotation target material and preparation method thereof

A low-resistivity, niobium oxide technology, applied in the direction of sputtering plating, metal material coating process, ion implantation plating, etc., can solve the problems of low transmittance and high resistivity, and achieve high transmittance, High density, progress-driven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Preparation of niobium oxide doped niobium sputtering rotating target

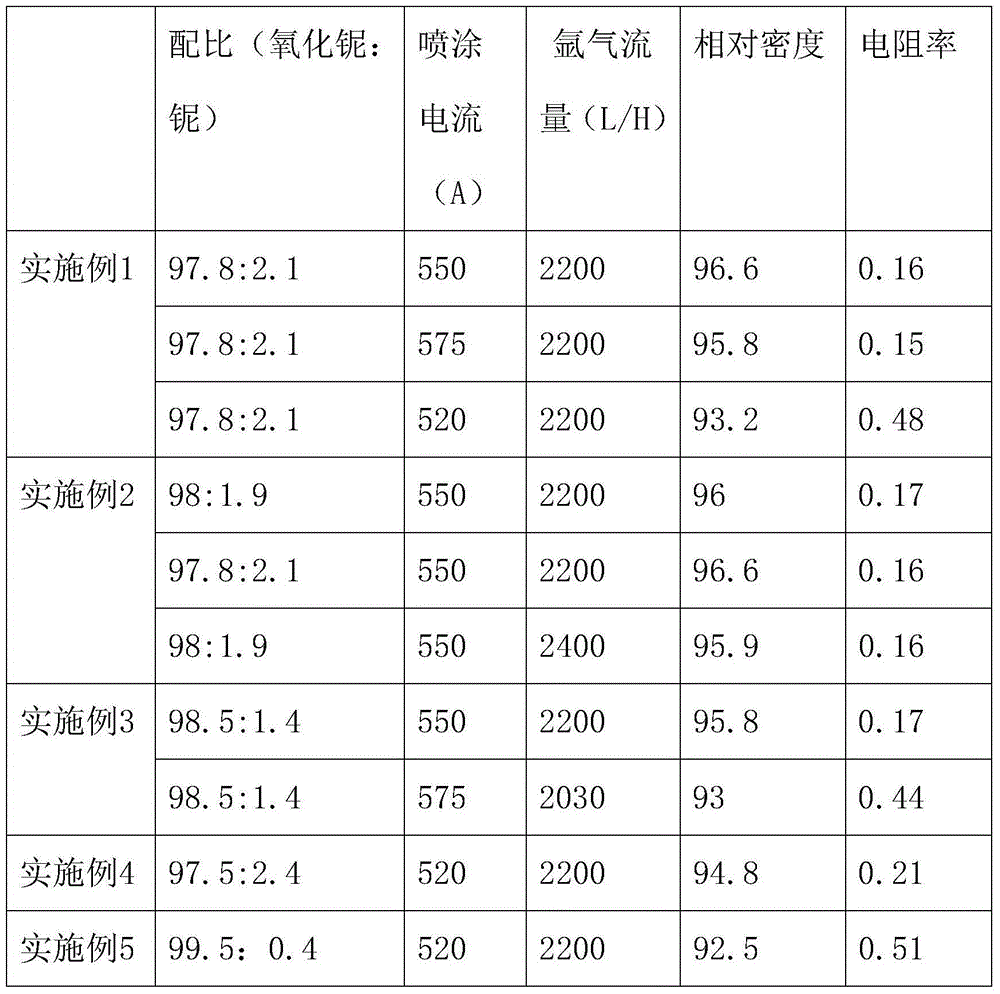

[0031] Table 1 Constituent dosage and parameter list of each embodiment

[0032]

[0033] The ingredients used are listed in Table 1.

[0034] Preparation of stainless steel back pipe: 1.1) Cutting: Use a sawing machine to take a 304 stainless steel pipe with a length of 1520mm. The inner diameter of the steel pipe is 125mm and the outer diameter is 133mm; Groove, bevel, etc.; 1.3) surface roughening: take out the stainless steel tube obtained in step 1.2, and use a sandblasting machine to sandblast its surface. The sandblasting material is brown corundum with a particle size of 80 mesh, and the sandblasting time is 1h; 1.4 ) Primer: Take out the roughened stainless steel pipe in step 1.3, and spray a layer of CuAl material layer on its surface by an arc spraying machine, the coating thickness is 0.5mm, 2. The preparation of niobium oxide coating includes the following four steps: 2.1...

Embodiment 2

[0038] Example 2: Preparation of niobium oxide doped niobium sputtering rotating target

[0039] The ingredients are shown in Table 1.

[0040] The preparation method is the same as in Example 1, and the parameters are shown in Table 1.

[0041] The relative density and resistivity detected by the Archimedes method are shown in Table 1.

[0042] It shows that under the same spraying process parameters, the content of niobium is slightly higher, the relative density is higher, and the resistivity is smaller.

Embodiment 3

[0043] Example 3: Preparation of niobium oxide doped niobium sputtering rotating target

[0044] The ingredients are shown in Table 1.

[0045] The preparation method is the same as in Example 1, and the parameters are shown in Table 1.

[0046] The relative density and resistivity detected by the Archimedes method are shown in Table 1.

[0047] It shows that when the proportion of the finished product is the same and the main gas does not reach a certain amount, simply increasing the current intensity cannot increase the density of the target and reduce the resistivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com