Combination metallurgical furnace for producing zinc alloy and zinc alloy combination producing method

A production method and technology of zinc alloy, applied in furnaces, crucible furnaces, furnace types, etc., can solve the problems of limited effective production time, insufficient stirring, small stirring range of blades, etc., and achieve extended effective production time, uniformity and stability. The effect of improving performance and continuous melting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

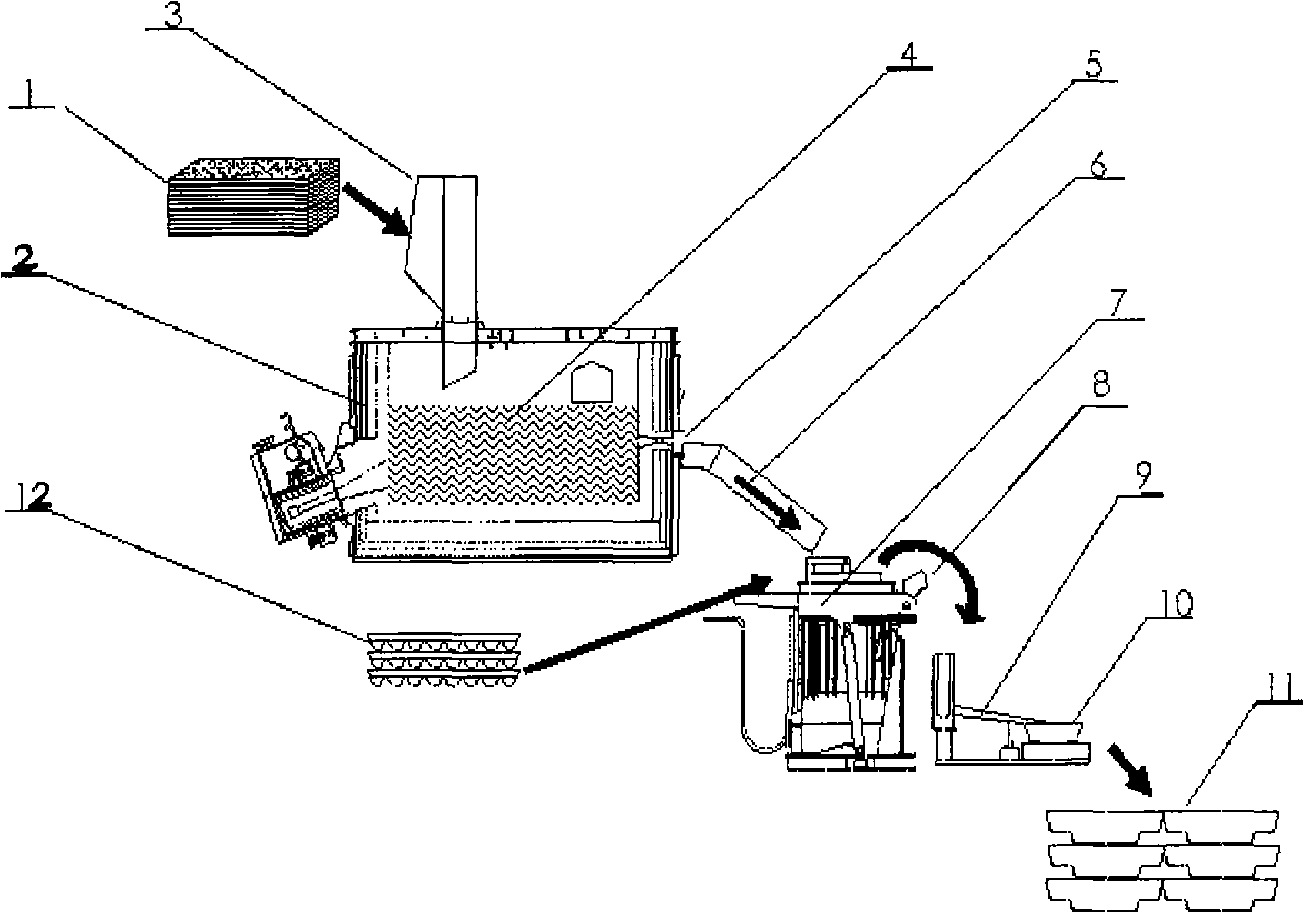

[0029] As shown in the figure, the combined metallurgical furnace of the present invention includes a cored power frequency induction furnace 2 and at least two coreless power frequency induction furnaces 7 with a dumping device 13, at the liquid outlet of the cored power frequency induction furnace 2 5 and the liquid inlet 14 of the coreless power frequency induction furnace 7 are connected with a convertible chute 6 . According to production capacity requirements, the selection and configuration of cored power frequency induction furnace 2 and coreless power frequency induction furnace 7 can be flexibly determined, for example, a 45t high-power cored power frequency induction furnace is used to configure two 10t coreless power frequency induction furnaces To form a satellite furnace system, a 45t coreless power frequency induction furnace is used to melt zinc around the clock, and the zinc liquid is poured into two 10t power frequency coreless induction furnaces in turn throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com