Preparation method of Ni/NiO/C composite material and supercapacitor

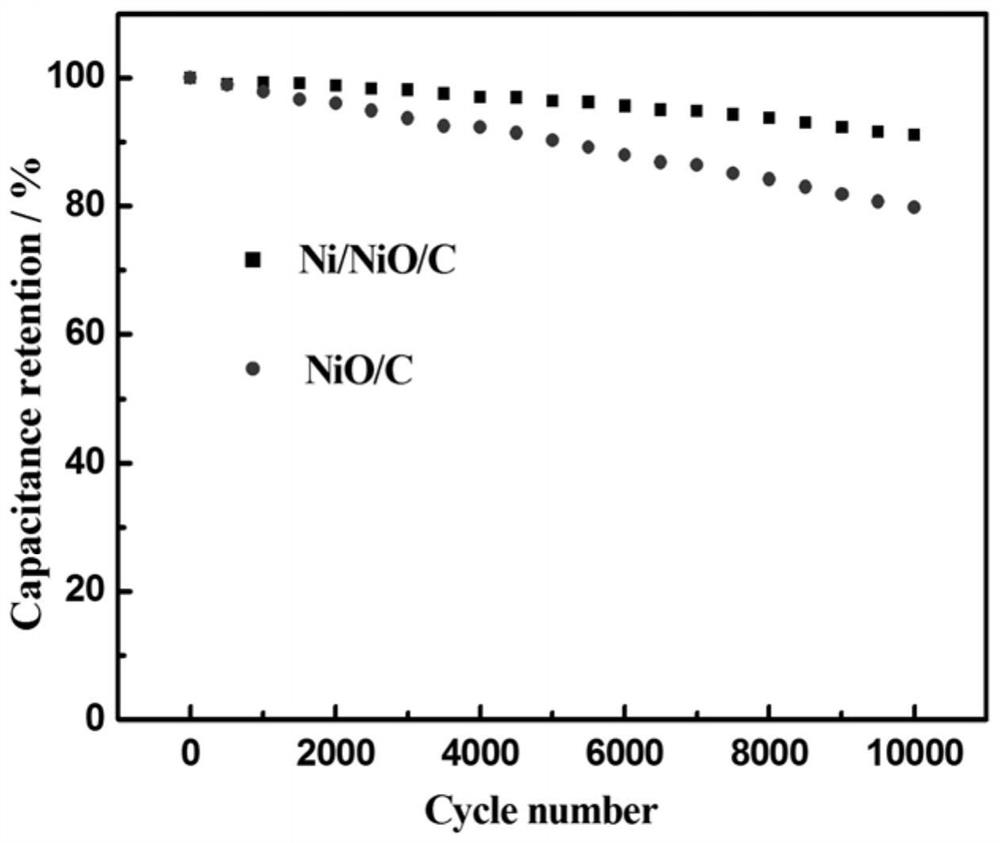

A technology of composite materials and mixtures, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., and can solve problems such as material deformation and weak conductivity of transition metal oxide materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

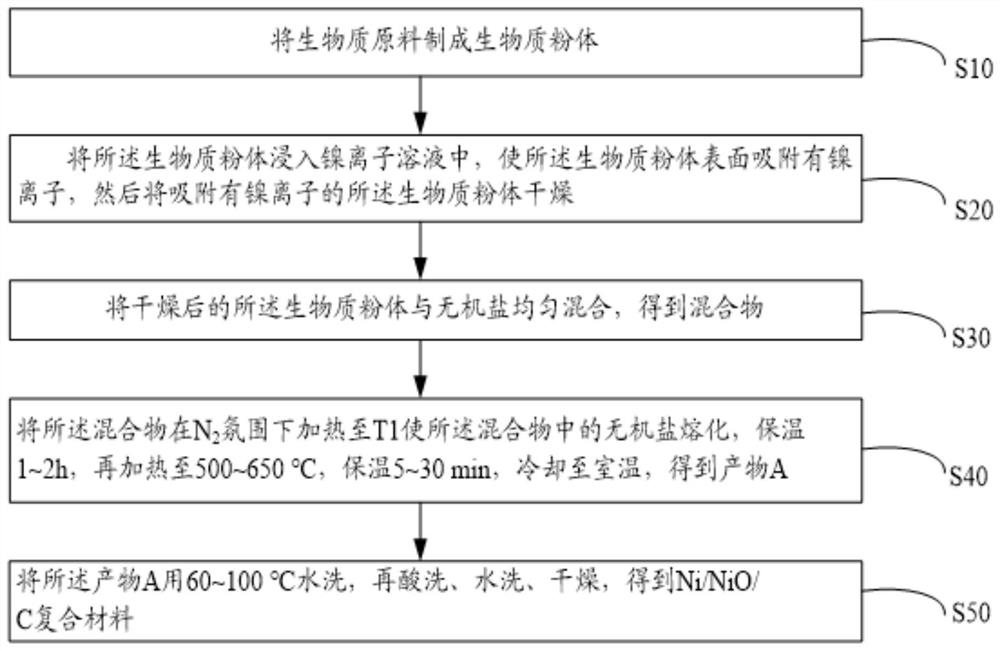

[0038] In view of this, the present invention proposes a method for preparing a Ni / NiO / C composite material, which can prepare a Ni / NiO / C composite material with good electrical conductivity and ease the volume change during charging and discharging. combine figure 1 The schematic flow sheet of an embodiment of the preparation method of proposed Ni / NiO / C composite material, the preparation method of described Ni / NiO / C composite material comprises the following steps:

[0039] Step S10, making the biomass raw material into biomass powder.

[0040] Specifically, the biomass is washed, dried, pulverized, and sieved to obtain biomass powder. Wherein, the drying temperature is 80-100° C., and the drying time is 10-12 hours; the sieving is 200-300 mesh sieves. In this embodiment, the biomass raw material is any one of waste biomass materials such as corncobs, peanut shells, straws, leaves, lotus pod shells, etc. The nutrient channels of these biomass raw materials are beneficial t...

Embodiment 1

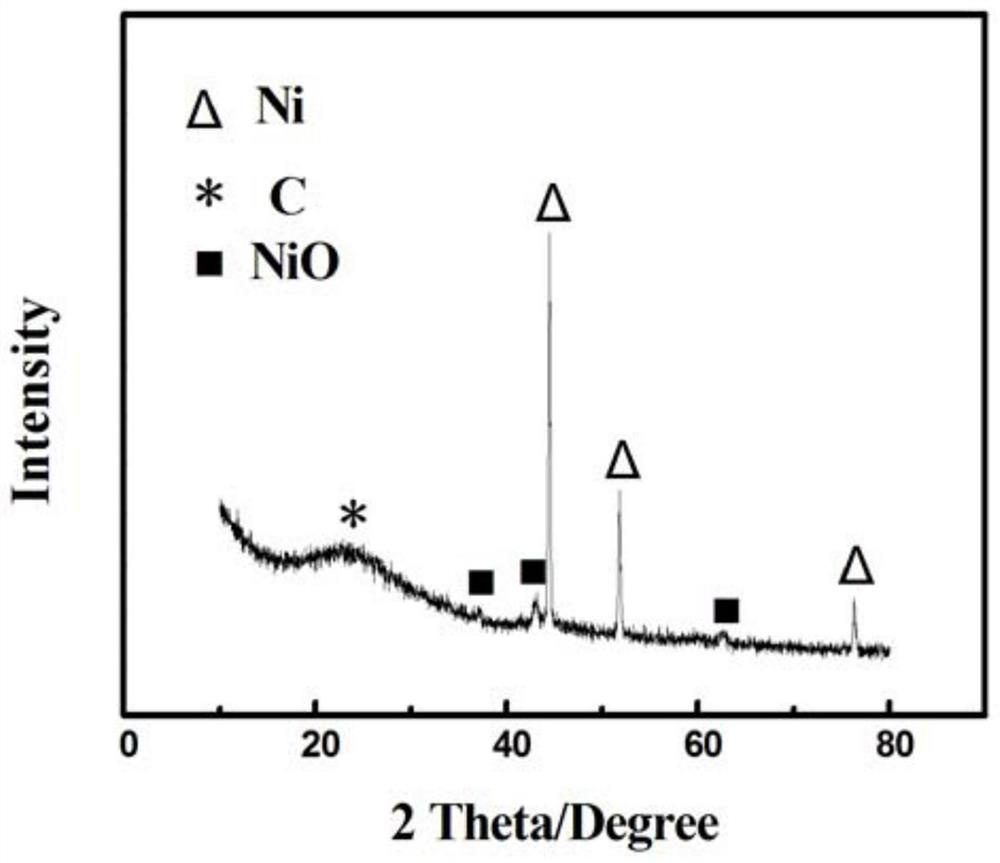

[0057] Wash the corn cobs, dry them, crush them, and pass through a 300-mesh sieve to obtain corn cob powders; take 1 g of corn cob powders and immerse them in 8 mL of nickel chloride aqueous solution (molar concentration is 0.1 mol / L), soak for 72 hours, and then soak them at 120 Dry at ℃ for 4 hours; mix the dried corn cob powder with LiCl-KCl mixed salt (the molar fraction of LiCl is 0.58) (the mass ratio of corn cob powder and LiCl-KCl is 1:4) to obtain a mixture; Then put the mixture into N 2 In a tube furnace under the atmosphere, heat to 400°C, hold for 2 hours, heat to 650°C, hold for 5 minutes, cool to room temperature to obtain product A; wash product A with water at 60°C, pickle, wash with water, and dry to obtain The specific surface area is 1182m 2 / g and resistivity 3.1×10 -4 Ω.m Ni / NiO / C composite material.

Embodiment 2

[0059] Wash the rice straw, dry it, crush it, and pass it through a 200-mesh sieve to obtain the rice straw powder; take 1g of the rice straw powder and immerse it in 7mL of nickel chloride aqueous solution (molar concentration is 0.26mol / L), soak it for 24h, and then put it in 100 Dry at ℃ for 5 hours; mix the dried rice straw powder with LiCl-KCl mixed salt (the molar fraction of LiCl is 0.65) (the mass ratio of rice straw powder to LiCl-KCl is 1:3) to obtain a mixture; Then put the mixture into N 2 In a tube furnace under atmosphere, heat to 450°C, keep it warm for 1h, then heat to 510°C, keep it for 25min, cool to room temperature, and get product A; wash product A with water at 80°C, pickle, wash with water, and dry to get The specific surface area is 652m 2 / g and resistivity 2.4×10 -3 Ω.m Ni / NiO / C composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com