Method for preparing soil conditioner by in-situ hydrothermal combination of ceramsite and biochar

A soil conditioner and in-situ hydrothermal technology, applied in ceramic products, fertilizer mixtures, soil conditioning materials, etc., can solve environmental hazards, waste of land resources, surrounding air pollution, etc., to reduce pollution, enhance water retention performance, The effect of enhancing soil water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a soil conditioner by using ceramsite in-situ hydrothermal combination with biochar, comprising the following steps:

[0030] (1) Preparation of ceramsite

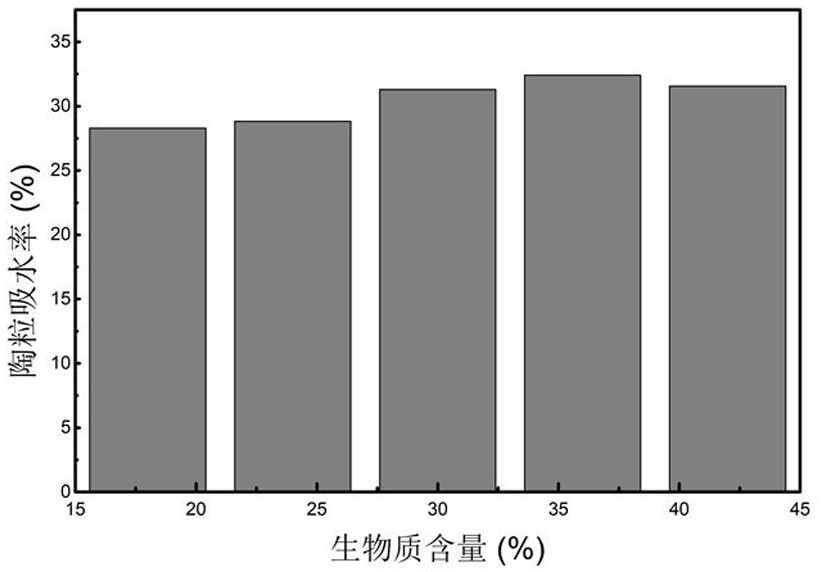

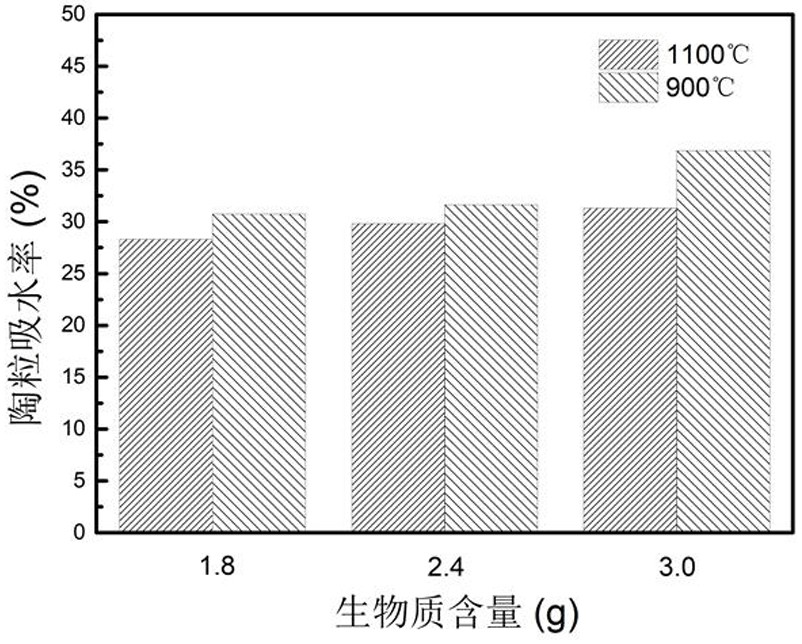

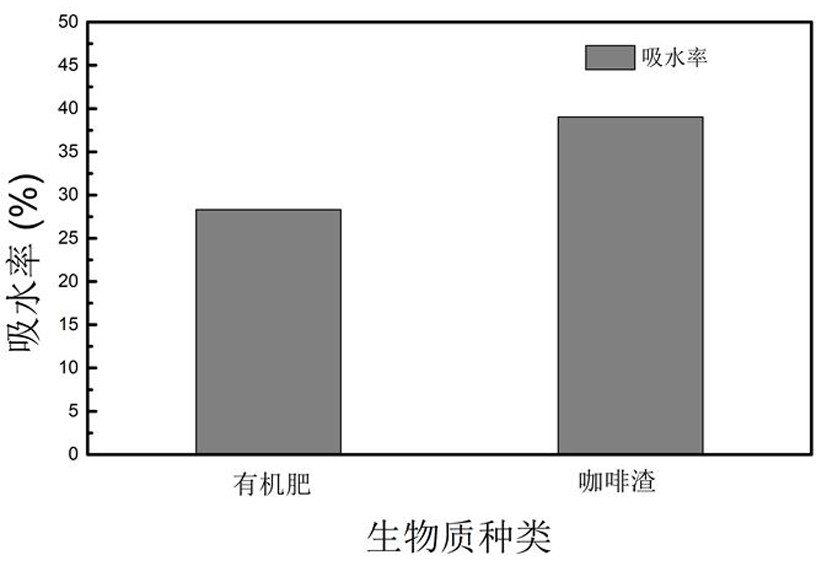

[0031] Mixing: Take 8.5g of fly ash, 1.5g of red mud, and a certain amount of biomass to pass through a 100-mesh sieve, mix the fly ash and red mud to form a fly ash-red mud mixture, add 1.5g to pass through a 100-mesh sieve Sieve phosphogypsum powder, and then mix biomass with fly ash-red mud to form ceramsite to prepare raw materials.

[0032] Ball making: add appropriate amount of water to the raw materials for ceramsite preparation, so that the raw materials for ceramsite preparation can be bonded and there is still a certain amount of moisture on the surface, and then manually make balls, and the raw materials for ceramsite preparation are made into a spherical green body with a diameter of 10mm, and the granulation is completed Then place it in a tray to air dry for 1 hour.

[0033] Th...

Embodiment 2

[0040] A method for preparing a soil conditioner by using ceramsite in-situ hydrothermal combination with biochar, comprising the following steps:

[0041] (1) Preparation of ceramsite:

[0042] Mixing: Take 8.0g fly ash, 3.0g red mud, 2.0g phosphogypsum, and pass a certain amount of biomass through a 100-mesh sieve, mix fly ash and red mud to form a fly ash-red mud mixture, add 1.5g phosphogypsum powder, and then mix biomass with fly ash-red mud to form ceramsite preparation raw material.

[0043] Ball making: Add appropriate amount of water to the raw materials for ceramsite preparation, so that the raw materials for ceramsite preparation can be bonded and there is still a certain amount of moisture on the surface. Manually make balls, and make the raw materials for ceramsite preparation into a spherical green body with a diameter of 5mm, and the granulation is completed. Then place it in a tray to air dry for 1 hour.

[0044] The ceramsite is roasted by a stepwise heating...

Embodiment 3

[0051] A method for preparing a soil conditioner by using ceramsite in-situ hydrothermal combination with biochar, comprising the following steps:

[0052] (1) Preparation of ceramsite:

[0053] Mixing: take 6.0g fly ash, 4.0g red mud, 3.0g phosphogypsum, and 3.0g biomass through a 100-mesh sieve, mix fly ash and red mud to form a fly ash-red mud mixture, add 1.5 g phosphogypsum powder, and then mix biomass with fly ash-red mud to form ceramsite as raw material.

[0054] Ball making: Add appropriate amount of water to the raw materials for ceramsite preparation, so that the raw materials for ceramsite preparation can be bonded and there is still a certain amount of moisture on the surface, and manually make balls, and the raw materials for ceramsite preparation are made into a spherical green body with a diameter of 8mm, and the granulation is completed Then place it in a tray to air dry for 1 hour.

[0055] The ceramsite is roasted by a stepwise heating method: drying stage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com