Optics lens and assembly method and lens barrel thereof

一种光学镜头、组装方法的技术,应用在光学、光学元件、安装等方向,能够解决影响光学镜片于镜筒排列、固定环移动或脱落、溶融状态不平均等问题,达到增加黏固成效、降低固定环偏斜、间隙平均的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

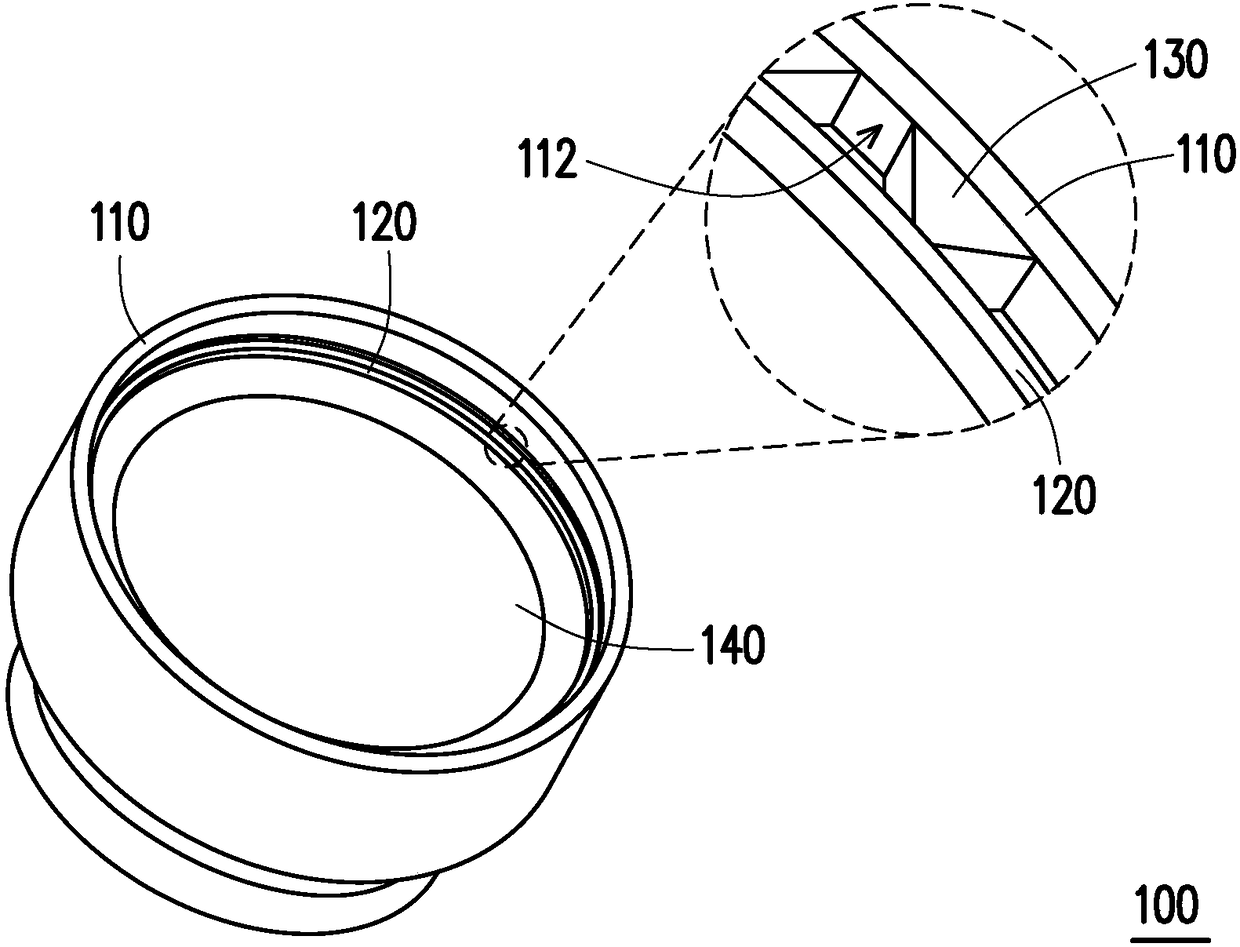

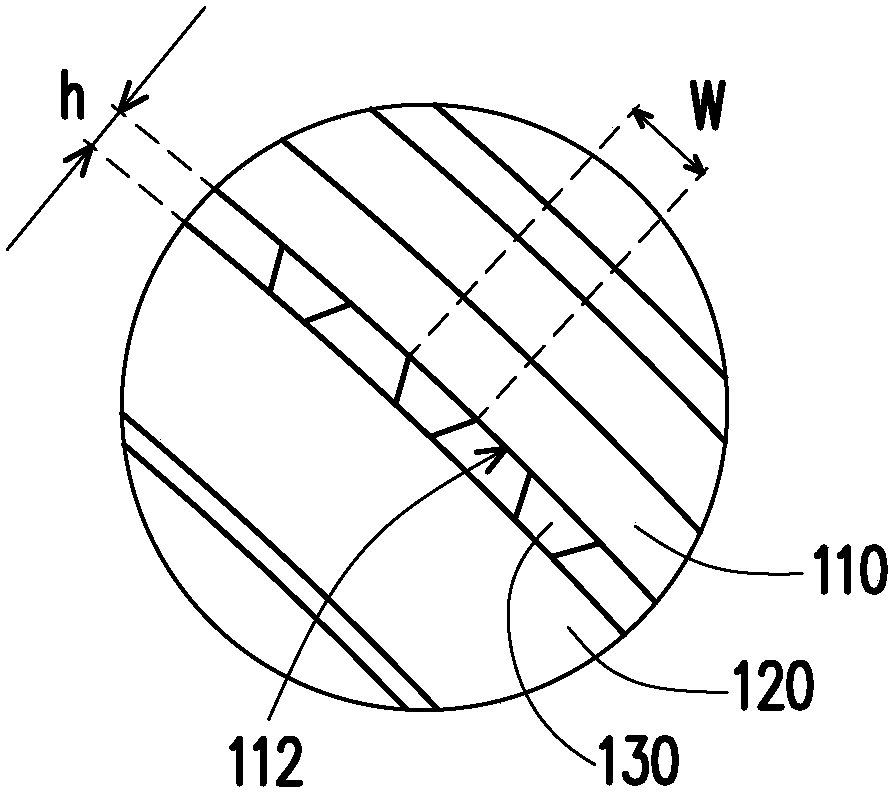

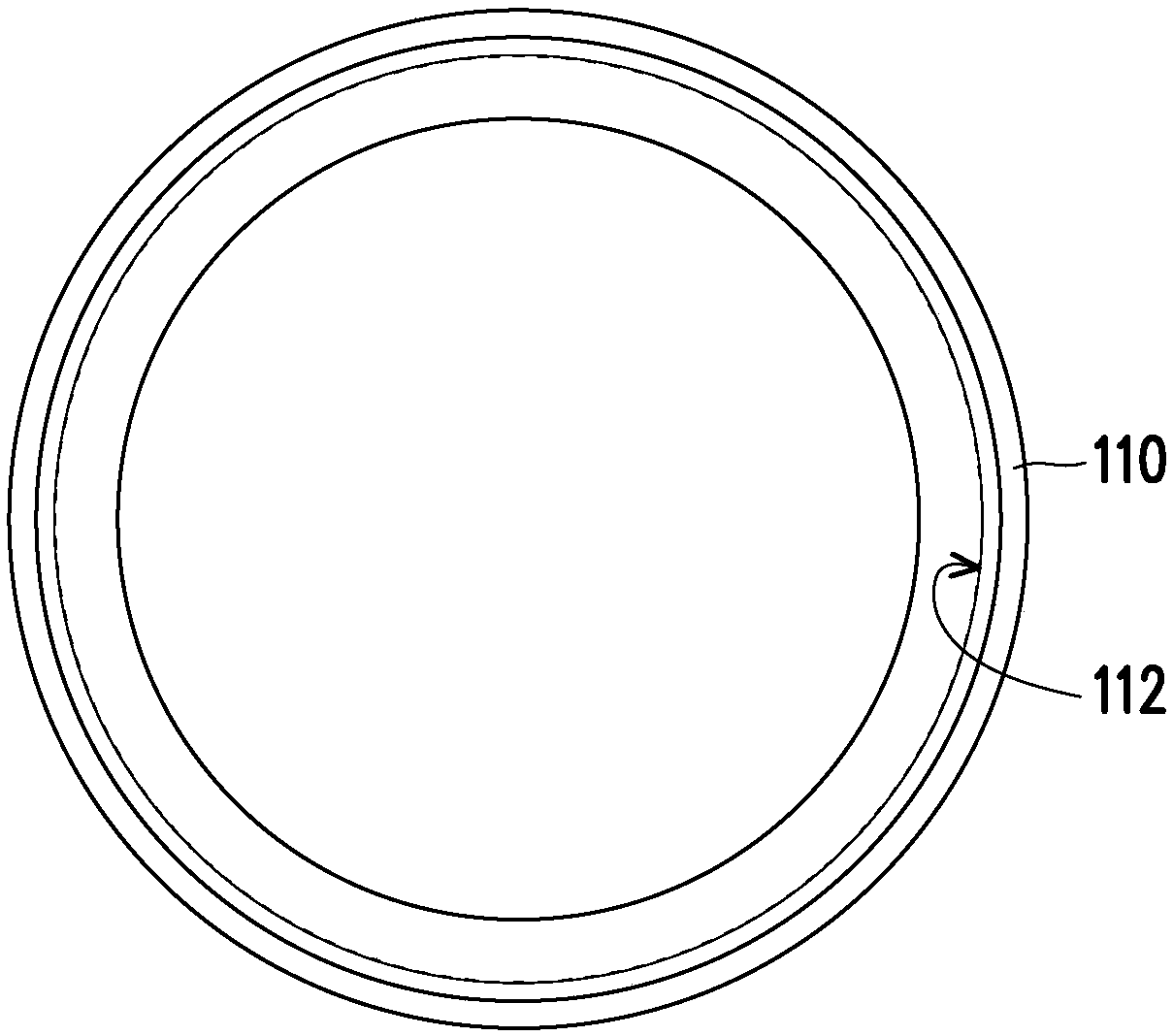

[0020] Figure 1A is a stereoscopic schematic diagram of an optical lens according to an embodiment of the present invention, Figure 1B yes Figure 1A The partial cross-sectional schematic diagram of the optical lens, Figure 2A yes Figure 1A Schematic diagram of the rear view of the lens barrel and optical lens, Figure 2B yes Figure 2A Schematic diagram of the cross-section of the lens barrel and optical lens, Figure 3A yes Figure 1A The three-dimensional schematic diagram of the fixed ring, and Figure 3B yes Figure 1A A schematic cross-sectional view of the retaining ring. Figure 4 yes Figure 1A Schematic diagram of the cross-section of the optical lens. Please refer to Figure 1A to Figure 3B The optical lens 100 of this embodiment includes a lens barrel 110 , a fixing ring 120 and at least one optical lens 140 (a plurality of optical lenses 140 are taken as an example in this embodiment). The lens barrel 110 has a joint surface 112 along the inner side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com