Battery pack support

A technology for battery packs and fixed batteries, applied to battery pack components, circuits, electrical components, etc., can solve problems such as unstable power output, abnormal operation of electronic control systems, and abnormal operation of auxiliary equipment, so as to improve production efficiency and improve The power output is unstable and the effect of avoiding connection failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] In an electric vehicle, a specific large-capacity battery pack composed of multiple battery cells connected in series and parallel is used as a power source, and such a battery pack provides electric energy for the operation of the electric vehicle.

[0067] However, after the existing electric vehicles have been working for a period of time, there are problems such as unstable power output, abnormal operation of the electronic control system, and abnormal operation of auxiliary equipment (such as dimming of the light brightness) during driving.

[0068] The existing view is that the above situation is caused by the performance degradation of the battery pack after a period of operation and the unstable power supply caused by improper battery management strategies. Therefore, the current countermeasure is to replace the battery pack with better performance parameters and optimize the battery management software to provide a better battery management strategy. However, a...

Embodiment 2

[0083] This embodiment is further described on the basis of Embodiment 1.

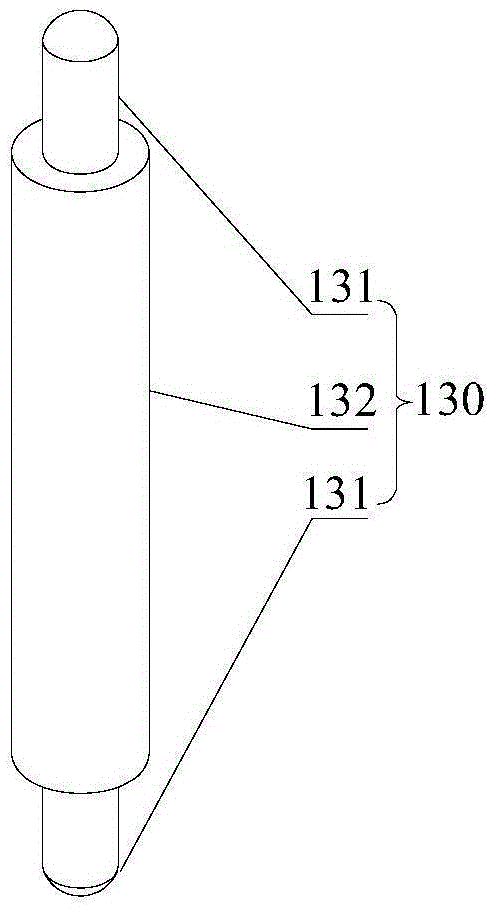

[0084] In this embodiment, the hot-melt connection is formed by melting the two ends of the support column 130 after being heated.

[0085] The two ends of the support column 130 are heated and melted. Compared with the first fixing plate 110 and the second fixing plate 120, the processing process is simpler, the processing process is more controllable, and the range of heating and melting is smaller, which is conducive to maintaining the first fixed plate 110 and the second fixed plate 120. The structural strength of the first fixed plate 110 and the second fixed plate 120 .

[0086] There are many ways of hot-melt connection, for example, the two ends of the support column 130 are heated and melted and enter the holes or grooves provided on the first fixing plate 110 and the second fixing plate 120 to form an integral connection; the two ends of the support column 130 are heated After being melted, ...

Embodiment 3

[0100] This embodiment is further described on the basis of embodiment 1 or 2.

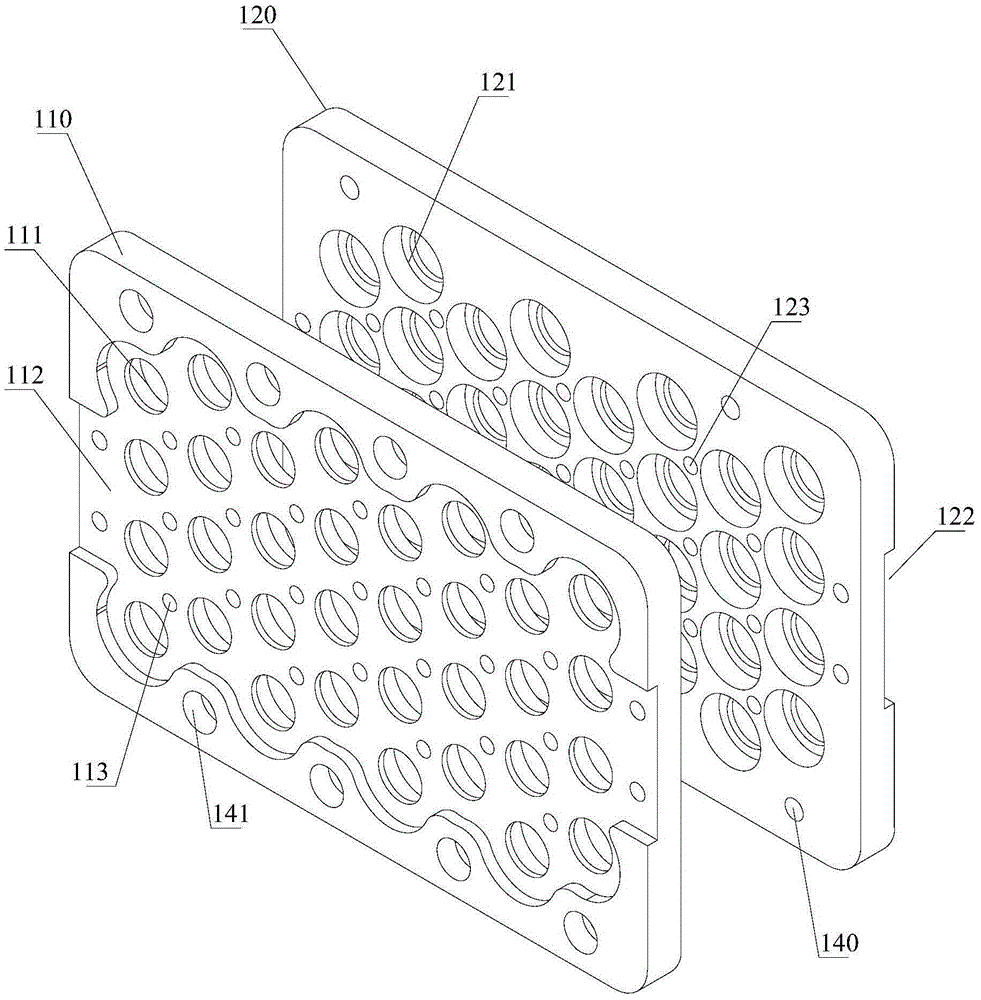

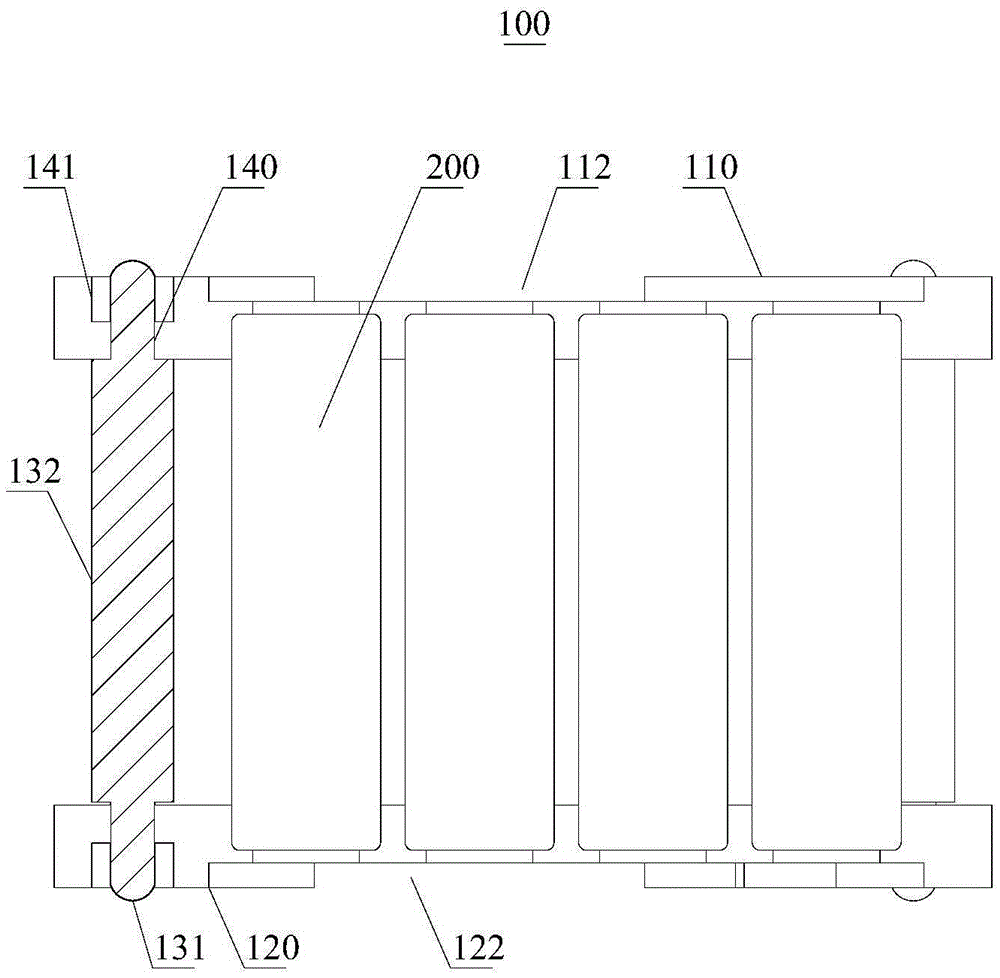

[0101] like figure 2 and Figure 5 As shown, the edge of the surface of the first fixing plate 110 away from the second fixing plate 120 protrudes upwards to enclose the first receiving groove 112, and the first fixing hole 111 is opened at the bottom of the first receiving groove 112;

[0102] The edge of the second fixing plate 120 away from the first fixing plate 110 protrudes upwards to enclose the second receiving groove 122 , and the second fixing hole 121 is defined at the bottom of the second receiving groove 122 .

[0103] The shape of the first receiving groove 112 and the second receiving groove 122 is the same as that of the current collecting plate, so as to accommodate the current collecting plate.

[0104] like figure 2 As shown, a plurality of first collector plate fixing holes 113 distributed among the first fixing holes 111 may also be provided at the bottom of the first rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com