Float-zone monocrystalline silicon production process and float-zone thermal field

A single crystal silicon and thermal field technology, which is applied in the directions of single crystal growth, self-regional melting method, crystal growth, etc., can solve the problems of inability to pull large-diameter zone-melted single crystal silicon and low output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

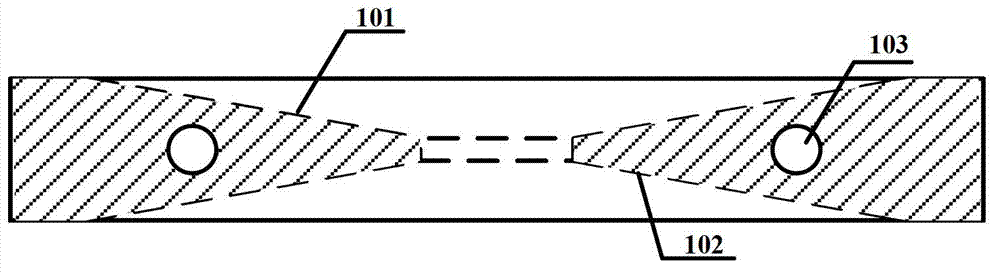

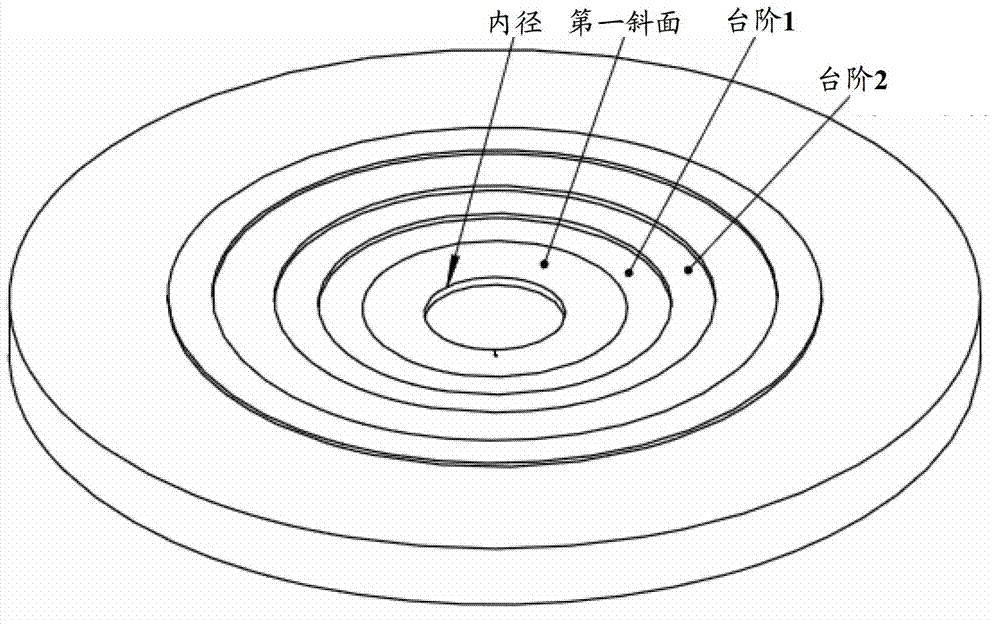

[0036] The embodiment of the present invention provides a zone-melting monocrystalline silicon production process and a zone-melting heat field, which expands the inner diameter of the heating coil so that the inner diameter of the heating coil is greater than or equal to 30mm, and at the same time, at least one is set outside the upper slope of the heating coil Step platform, so as to change the effect of the magnetic force lines, so that the polysilicon material with a larger diameter can be completely melted, and then the zone-melted single crystal silicon with a larger diameter can be drawn.

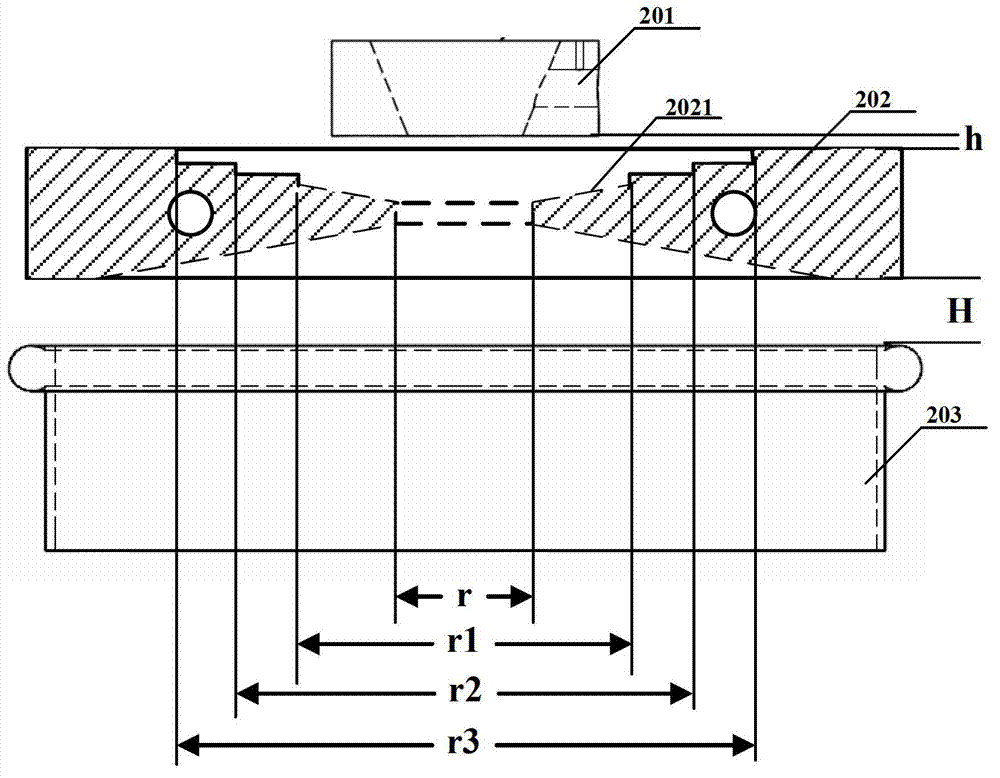

[0037] Such as figure 2 As shown, the zone melting heat field provided by the embodiment of the present invention includes: a preheating ring 201, a heating coil 202, and a heat preservation cover 203, wherein:

[0038] At least one stepped platform is provided outside the upper slope 2021 of the heating coil 202, and the inner diameter r of the heating coil is greater than or equal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com