PBAT composite modified biodegradable material and preparation method thereof

A technology of biodegradable materials and composite modification, which is applied in the field of PBAT composite modified biodegradable materials and its preparation, can solve the problems of large proportion of PLA, variable quality, and cost reduction, and achieve good ductility and elongation at break High efficiency, good heat resistance and impact performance, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

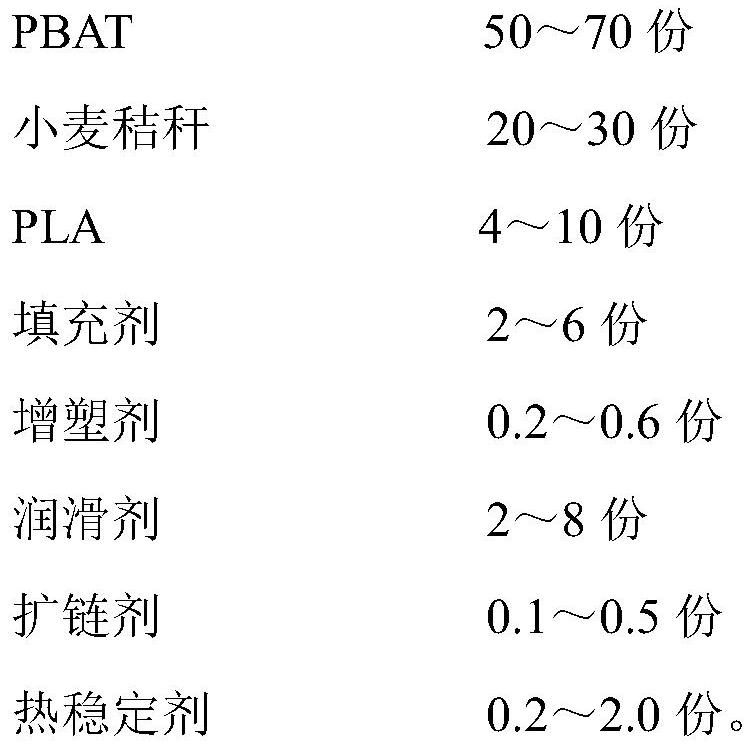

Method used

Image

Examples

Embodiment 1

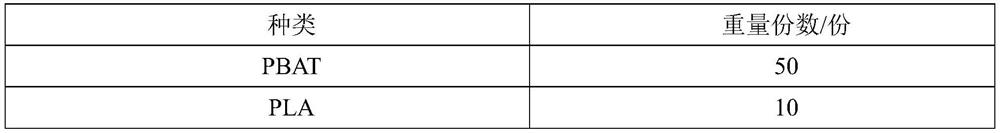

[0034] The PBAT composite modified biodegradable material is made of the components in parts by weight of Table 1:

[0035] Table 1 raw material component formula

[0036]

[0037]

[0038] The preparation method of PBAT composite modified biodegradable material comprises the following steps:

[0039] (1) Dry PBAT, PLA, and wheat straw at 80°C for 8 hours;

[0040] (2) Wheat straw pretreatment: first crush the wheat straw to less than 3mm, then mix the wheat straw, ammonium sulfate and glycerol according to the mass ratio of 8:1:1, stir and soften, and the softening temperature is 90°C. The softening time is 20min;

[0041] (3) Combine the pretreated wheat straw with PBAT, PLA, starch, acetyl citrate, erucamide, isocyanate, and tris(2,4-di-tert-butylphenyl) phosphite according to the formulation amount in Table 1 , added to the high mixer and stirred, the speed of the high mixer was 1000r / min, the mixing time was 10min, and the mixing temperature was 70°C to obtain th...

Embodiment 2

[0044] The PBAT composite modified biodegradable material is made of the components in parts by weight of Table 2:

[0045] Table 2 raw material component formula

[0046] type parts by weight / part PBAT 55 PLA 10 wheat straw 25 calcium carbonate 4.5 PEG-400 0.3 paraffin 4 Resorcinol dihydroxyethyl ether 0.2 Pentaerythritol bisphosphite 1.0

[0047] The preparation method of PBAT composite modified biodegradable material comprises the following steps:

[0048] (1) Dry PBAT, PLA, and wheat straw at 90°C for 10 hours;

[0049](2) Wheat straw pretreatment: first crush the wheat straw to less than 3mm, then mix the wheat straw, ammonium sulfate and glycerol according to the mass ratio of 8:1:1, stir and soften, and the softening temperature is 95°C. The softening time is 15min;

[0050] (3) Add the pretreated wheat straw, PBAT, PLA, calcium carbonate, PEG-400, paraffin, resorcinol dihydroxyethyl ether, and pentaeryth...

Embodiment 3

[0053] The PBAT composite modified biodegradable material is made of the components in parts by weight of Table 3:

[0054] Table 3 raw material component formula

[0055] type parts by weight / part PBAT 60 PLA 8 wheat straw 20 talcum powder 6.0 Epoxidized soybean oil 0.5 stearic acid 3 Hydroquinone dihydroxyethyl ether 0.3 Phenyl diisodecyl phosphite 1.7

[0056] The preparation method of PBAT composite modified biodegradable material comprises the following steps:

[0057] (1) Dry PBAT, PLA, and wheat straw at 80°C for 12 hours;

[0058] (2) Wheat straw pretreatment: first crush the wheat straw to less than 3mm, then mix the wheat straw, ammonium sulfate and glycerol according to the mass ratio of 8:1:1, stir and soften, and the softening temperature is 95°C. The softening time is 20min;

[0059] (3) Combine the pretreated wheat straw with PBAT, PLA, talcum powder, epoxy soybean oil, stearic acid, hydroquinone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com