Efficient pelletizer for polyvinyl chloride resin recovery

A technology of polyvinyl chloride resin and granulator, which is applied in the direction of recycling technology, plastic recycling, packaging item types, etc. It can solve the problems of inability to filter, bagging, and incomplete resin melting, so as to avoid mutual adhesion, High granulation efficiency and high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

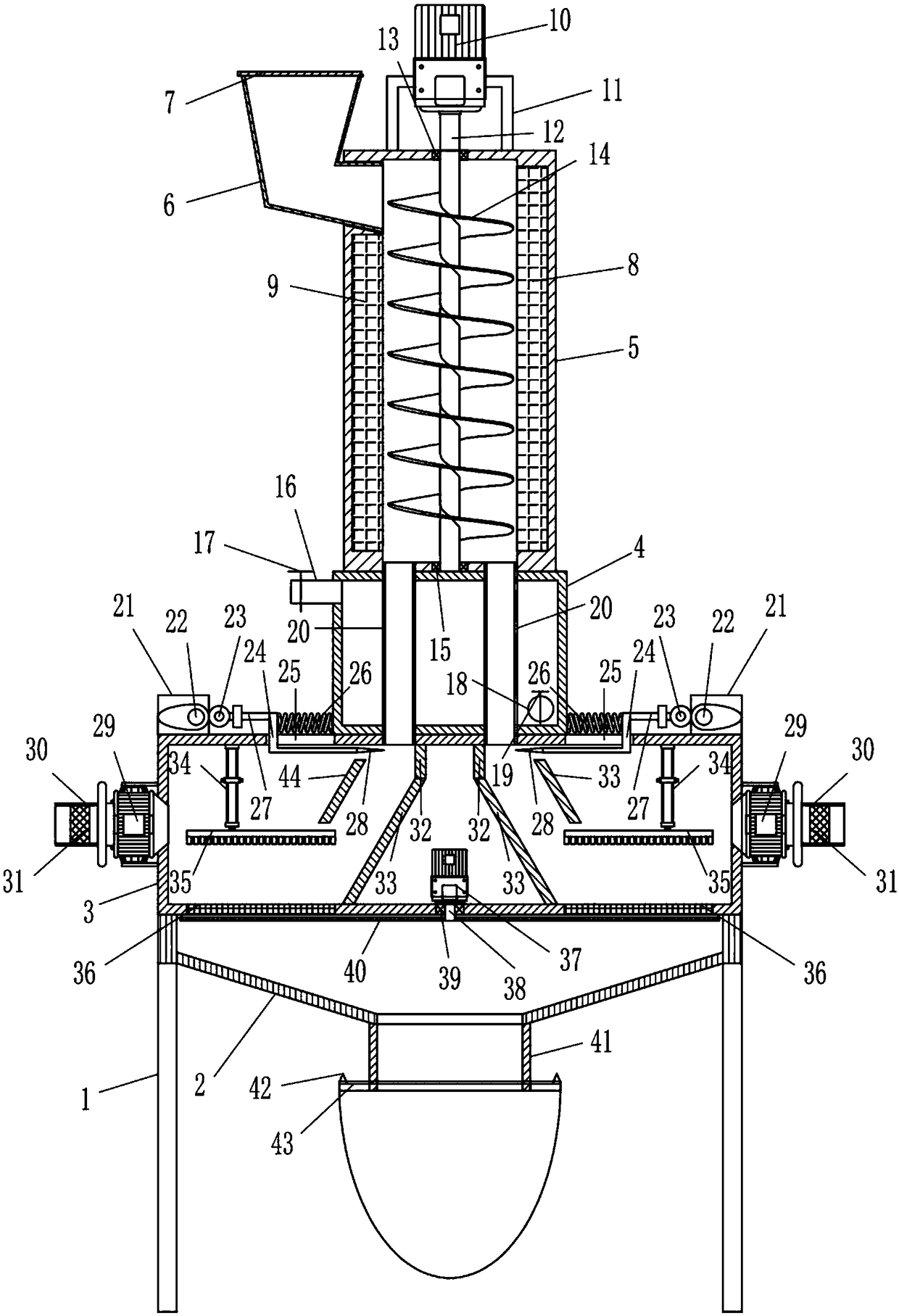

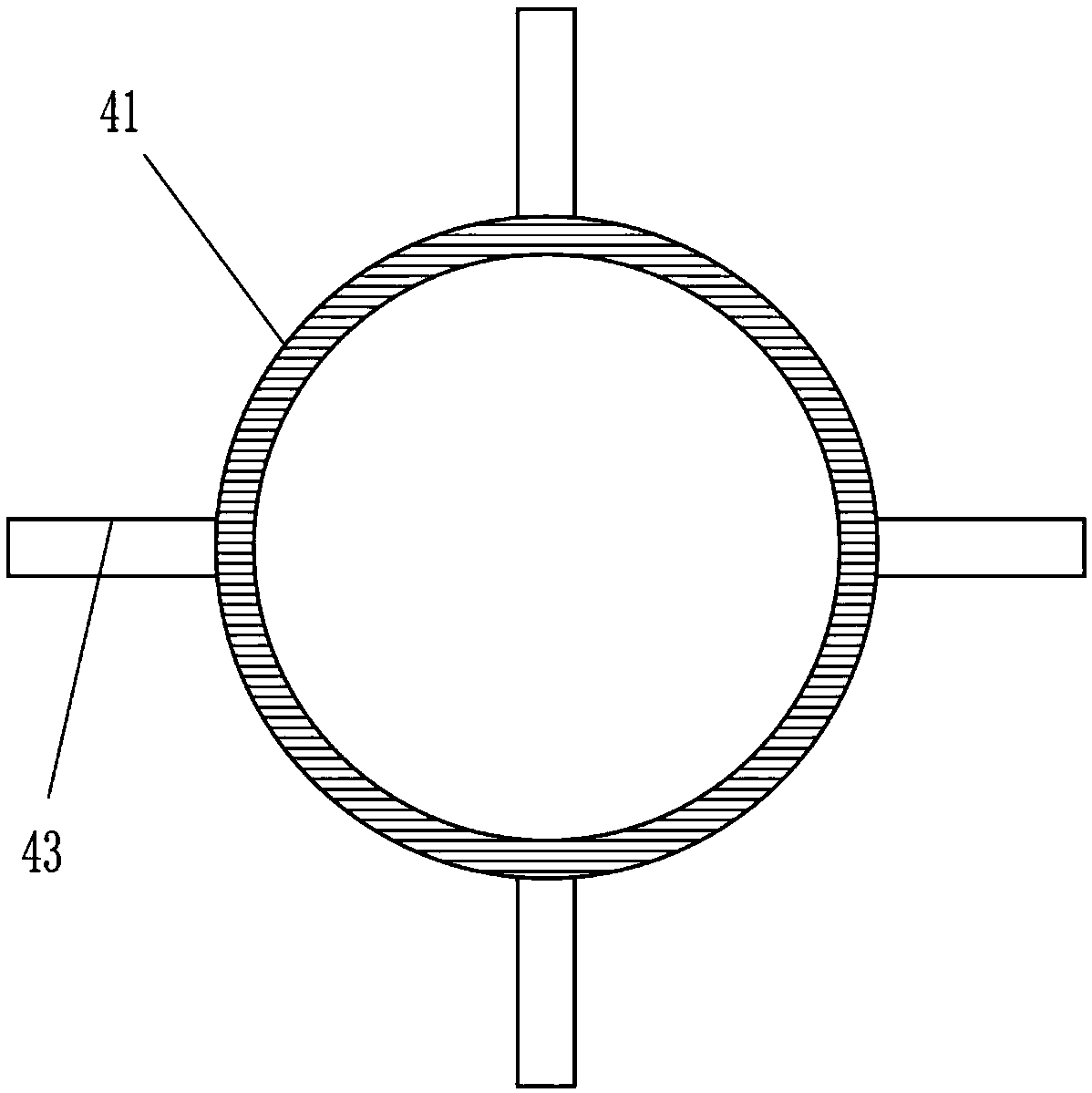

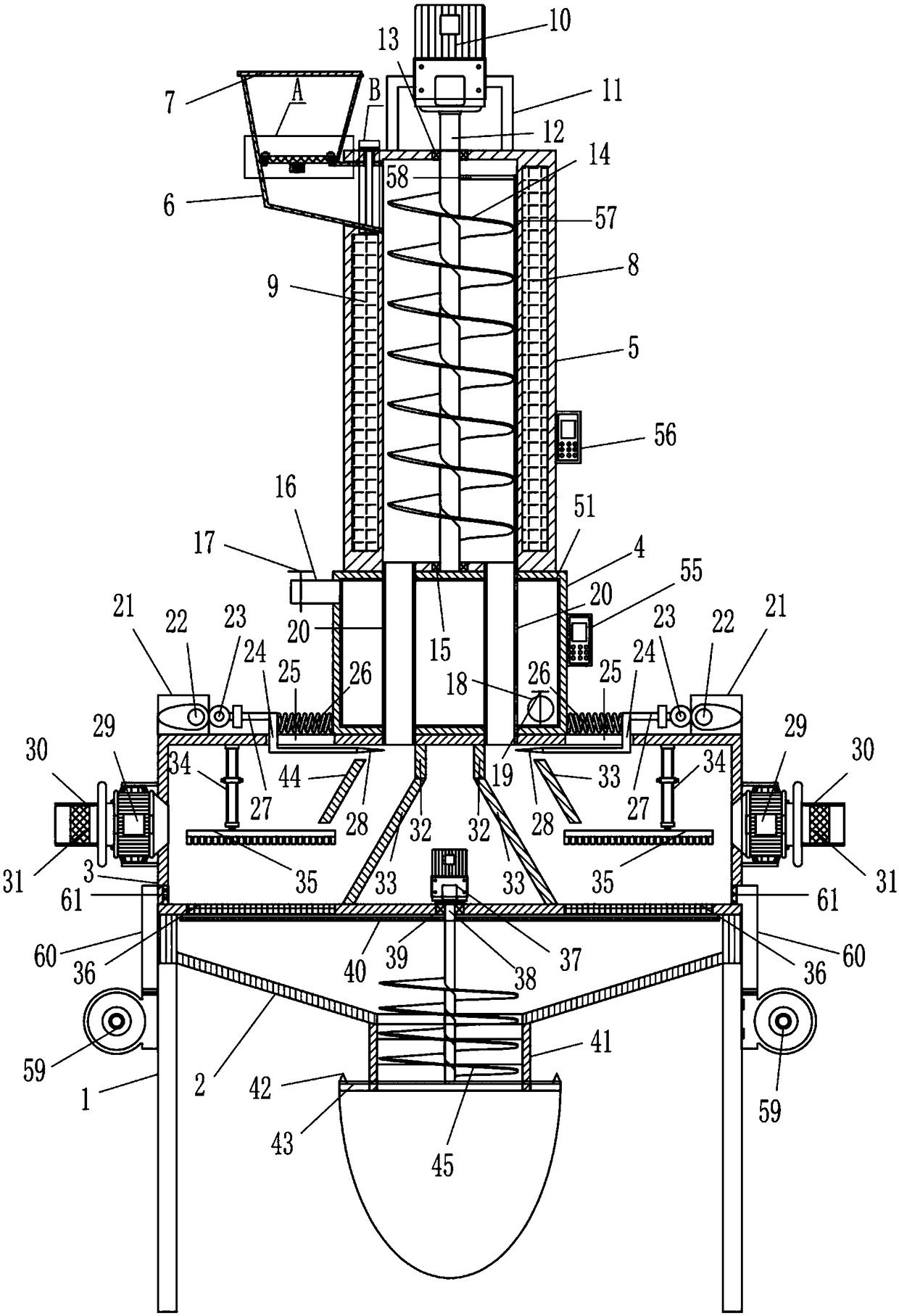

[0031] A high-efficiency granulator for recycling polyvinyl chloride resin, such as Figure 1-5 As shown, it includes a first support 1, a collection hopper 2, a granulation box 3, a cooling box 4, a melting cylinder 5, a feed channel 6, a first heating pipe 8, a second heating pipe 9, a first motor 10, a first Two brackets 11, the first rotating shaft 12, the first bearing seat 13, the first screw conveying rod 14, the second bearing seat 15, the water injection pipe 16, the first valve 17, the water outlet pipe 18, the second valve 19, the forming pipe 20, Mounting plate 21, cam motor 22, roller 23, T-shaped movable bar 27, elastic member 26, L-shaped connecting rod 24, first cutter 28, air extractor 29, filter cartridge 30, active carbon layer 31, shear plate 32. Inclined guide plate 33, telescopic cylinder 34, pressure cutting plate 35, mesh cutter plate 36, second motor 37, second rotating shaft 38, third bearing seat 39, second cutter 40, discharge channel 41, The first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com