Patents

Literature

98results about How to "Dense grain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-plasticity cast aluminum alloy and extrusion casting preparation method thereof

The invention discloses a high-plasticity cast aluminum alloy and an extrusion casting preparation method thereof, belonging to the technical fields of metal materials and metallurgy. The alloy comprises the following components in percentage by weight: 7.5-13.5% of Si, 0.5-0.8% of Mg, 0.2-0.5% of Mn, 0.1-0.4% of Ti, 0.01-1.5% of RE, 0.6-1.3% of Fe, at most 100 ppm of P, 100-600 ppm of Sr and the balance of Al. The RE is one or more of Gd, Y, Nd, Sm, Er, Yb and La. After the high-plasticity cast aluminum alloy is subjected to extrusion casting and solid solution+artificial aging treatment, the elongation percentage delta of the alloy is greater than or equal to 22%. The alloy has the advantages of excellent casting performance and low cost. The method has the advantages of simple technique, high production efficiency and obvious progress, and widens the application range of the Al-Si cast aluminum alloy.

Owner:SHANGHAI JIAO TONG UNIV

High-plasticity cast aluminum alloy and gravity casting preparation method thereof

The invention discloses a high-plasticity cast aluminum alloy and a gravity casting preparation method thereof, and belongs to the fields of metal materials and metallurgy. The high-plasticity cast aluminum alloy is prepared from the following components in percentage by weight: 7.5 to 13.5% of Si, 0.5 to 0.8% of Mg, 0.2 to 0.5% of Mn, 0.1 to 0.4% of Ti, 0.01 to 1% of RE, not greater than 0.4% of Fe, not greater than 100ppm of P, 100 to 600ppm of Sr, and the balance of Al, wherein RE is one or some of Gd, Y, Nd, Sm, Er, Yb and La. After gravity casting, solid solution treatment and artificial aging treatment, the high-plasticity cast aluminum alloy has the elongation delta of being not less than 18%. The prepared alloy is outstanding in casting performance, low in cost, simple in process, high in production efficiency, and obvious in progress, and the applicable scope of Al-Si cast aluminum alloy is expanded.

Owner:SHANGHAI JIAO TONG UNIV

Lightweight high-strength microcrystal ceramic insulation board and preparation method thereof

The invention discloses a lightweight high-strength microcrystal ceramic insulation board. The lightweight high-strength microcrystal ceramic insulation board comprises the following chemical components in percentage by weight: 30 to 75 percent of silicon dioxide (SiO2), 5 to 20 percent of aluminium oxide (Al2O3), 1 to 20 percent of calcium oxide (CaO), 1 to 15 percent of magnesium oxide (MgO), 1 to 10 percent of ferric oxide and ferrous oxide (Fe2O3+FeO), 1 to 10 percent of sodium oxide, potassium oxide and lithium oxide (Na2O+K2O+Li2O) and 1 to 8 percent of nucleating agent. The lightweight high-strength microcrystal ceramic insulation board is prepared by the following steps of: mixing and crushing waste minerals, a foaming agent and a sintering modifier; mixing the crushed mixture with the nucleating agent; after ball-milling, filter-pressing, pelleting and staling the mixture, directly paving the powder in a fire-resistant mould fully, scraping the mould smoothly and allowing the mould to enter a kiln; and after performing high-temperature sintering, quick cooling, nucleating treatment, quick heating and crystallization, cooling again and then annealing to prepare the product. The lightweight high-strength microcrystal ceramic insulation board has the advantages that: the average grain diameter is between 0.5 and 5 mu m; and crystal grains are dense and uniformly distributed and develop well.

Owner:NANJING UNIV OF SCI & TECH

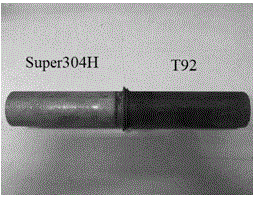

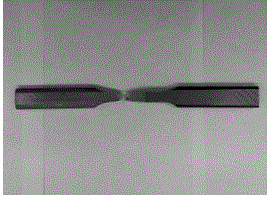

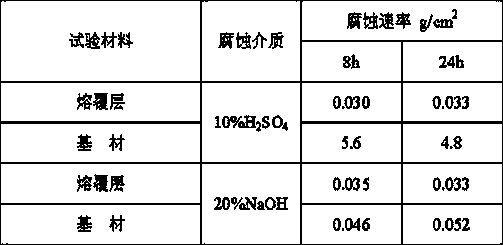

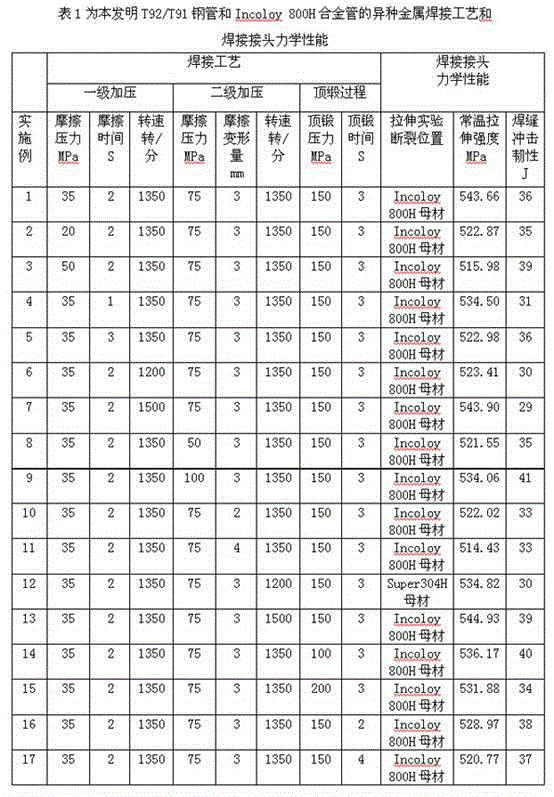

Dissimilar steel welding method for martensite heat-resisting steel and austenitic heat-resisting steel

InactiveCN104014928AImprove joint qualityQuality improvementFurnace typesWelding/soldering/cutting articlesFriction weldingAustenite

A dissimilar steel welding method for martensite heat-resisting steel and austenitic heat-resisting steel includes the following steps that (1) according to technical requirements of a friction welding machine, a martensite heat-resisting steel tube and an austenitic heat-resisting steel tube are respectively installed and clamped through a fixture of the friction welding machine and cannot shake, and the center line of the martensite heat-resisting steel tube and the center line of the austenitic heat-resisting steel tube are kept in the same horizontal line; (2) at a first-level pressurization stage, the rotation speed is 1200-1800 revolutions per minute, friction pressure is 25-75 MPa, and friction time is 4-6 seconds; (3) at a second-level pressurization stage, the rotation speed is 1200-1800 revolutions per minute, friction pressure is 100-200 MPa, and friction deformation is 4-8 mm; (4) at an upset forging stage, upset forging pressure is 150-250 MPa, and upset forging time is 4-6 seconds; (5) partial heat treatment needs to be carried out on a welded joint between the martensite heat-resisting steel tube and the austenitic heat-resisting steel tube after welding, so that residual stress is eliminated. The method has the advantages that quality of the joints is high, the method is suitable for welding of heterogeneous materials, production efficiency is high, production cost is low, energy is saved, and environment is protected.

Owner:XIAN SPECIAL EQUIP INSPECTION INST

Method for preparation of indium oxide transparent film with high electron mobility

InactiveCN101514440AStrong adhesionSmooth film surfaceVacuum evaporation coatingSputtering coatingIndiumRadio frequency magnetron sputtering

A method for the preparation of the indium oxide transparent film with high electron mobility adopts the double-chamber high- vacuum radio-frequency magnetron sputtering method, wherein the high-purity indium oxide with the purity of 99. 99 27634872s taken as the target material, the glass is taken as the substrate, one or two of the high-purity argon and oxygen with the purity of 99. 99 5869744s taken as the sputtering gas, the sputtering growth is performed in the magnetron sputtering device, thus the n-typed transparent In2O3semiconductor film material with different electron concentration and high electron mobility is obtained. The method has the advantages of easy control of the deposition parameter, reliable preparing process, good repetitiveness and lower cost of manufacture.

Owner:ZHEJIANG UNIV

Boro-carburizing microalloying method of shearer cutter

InactiveCN101323944ADense tissueHigh strengthSolid state diffusion coatingProcess efficiency improvementManganeseRoom temperature

The invention relates to a borocarbon diffusion micro alloying method for the pick of a coal mining machine. Alloy steel 35CrMo is adopted as pick material, and the method comprises the following processing steps that: step 1, acid cleaning; step 2, carburization, titanizing and manganizing treatment: carburizer and lanthana powder are carried out and evenly stirred and sent into an infiltration box; titanium powder and manganese power are adopted to coat on the cutting part at the tooth tops of the pick that is then vertically put into the infiltration box which is compacted and sealed; then the infiltration box is sent into a heating furnace, the temperature is rised to 650 DEG C + / - 10 DEG C, is kept for 1.5 to 2.5 hours, then continuously rised to 910 DEG C + / - 10 DEG C and is kept for 8 to 10 hours; then the temperature is lowered to 850 DEG C + / - 10 DEG C and is kept for 1.5 to 2.5 hours and continuously lowered to less than 800 DEG C and taken out of the furnace; the taken-out infiltration box is cooled to room temperature and opened; step3, boronizing, tungstenizing and chromizing treatment; step 4, salt-bath treatment; step 5, annealing treatment; step 6, tempering treatment; step 7, shot-peening treatment. The method of the invention is capable of improving the intensity, hardness and high-temperature abrasion resistance at the tooth tops of the pick of the coal mining machine and causes the handle of the pick to be difficult to break.

Owner:JIANGYIN XINHONG SCI & TECH

High-hardness cobalt-based alloy powder for laser cladding and preparation technology of high-hardness cobalt-based alloy powder for laser cladding

InactiveCN104195546AImprove wear resistanceAvoid crackingMetallic material coating processesAlloyCase hardening

The invention relates to the technical field of metal surface hardening treatment and in particular relates to high-hardness cobalt-based alloy powder for laser cladding and a preparation technology of the high-hardness cobalt-based alloy powder for laser cladding. According to the technical scheme, the high-hardness cobalt-based alloy powder for the laser cladding is prepared from the following components in percentage by weight: 1.2-1.55% of C, 28-31% of Cr, less than or equal to 3% of Fe, less than or equal to 0.5% of Mn, less than or equal to 1% of Mo, less than or equal to 3% of Ni, 0.7-1.5% of Si, 3.5-6.5% of W and the balance of Co. The preparation technology of the high-hardness cobalt-based alloy powder for the laser cladding comprises the following steps: a, preparing the components, and smelting; b, slagging and deoxidizing the smelted components obtained in the step a; c, preparing the components obtained in the step b into powder; d, collecting the powdery components obtained in the step c; and e, sieving the cooled powdery components obtained in the step d. By adopting the technical scheme, the high-hardness cobalt-based alloy powder, which hardly cracks, is hardly oxidized, is extremely low in porosity, has good self fluxing performance, is used for the laser cladding, and a preparation technology of the high-hardness cobalt-based alloy powder are provided.

Owner:浙江瑞莱士机械有限公司

Production method of oversized-diameter anode phosphorus copper ball

InactiveCN102615482AAvoid effectivenessEasy to controlMetal-working apparatusCrystal structureUltra fine

The invention belongs to the technical field of phosphorus copper balls for electroplating and particularly relates to a production method of an oversized-diameter anode phosphorus copper ball. The method comprises the following steps of: firstly melting pure copper and phosphorus copper intermediate alloy to obtain a phosphorus copper alloy solution and producing a phosphorus copper alloy rod by utilizing the uniformly mixed phosphorus copper alloy solution through an upward casting method; feeding the obtained phosphorus copper alloy rod into a continuous extruding machine for extrusion, wherein the phosphorus copper alloy rod is driven by an extrusion wheel to be forcedly pressed into an extrusion cavity and is extruded according to the designed size so as to obtain an ultra-fine grain phosphorus copper rod blank; and finally performing cold heading and molding on the obtained ultra-fine grain phosphorus copper rod blank by utilizing a cold header, so as to form phosphorus copper ball of design specification. The phosphorus copper ball obtained by utilizing the production method has a smooth, round and complete surface and a compact internal crystal structure, and has the advantage of obviously improved appearance and internal quality compared with the phosphorus copper ball obtained by utilizing an existing technology.

Owner:铜陵有色股份铜冠电工有限公司

Alloy material for valve casting and processing process thereof

The invention discloses an alloy material for valve casting. The alloy material comprises the following chemical components in percentage by mass: 0.2-0.3% of C, 0.1-0.3% of Si, 0.5-0.8% of Mn, 0.015-0.030% of P, 0.010-0.025% of S, 0.20-0.50% of Cr, 0.12-0.35% of Ni, 0.1-0.2% of Mo, 0.05-0.25% of Cu, 0.02-0.03% of V, 0.12-0.15% of rear earth and the balance of Fe and trace impurities. The invention further discloses a processing process of the alloy material for valve casting. The alloy material improves the corrosion resistance, the wear resistance and the oxidation resistance of a valve, so that the valve can be adapted to various harsh working environments and has high strength; the alloy material is long in service life, the cost is reduced, and the heat temperature resistance is improved.

Owner:YANCHENG OAK VALVE CO LTD

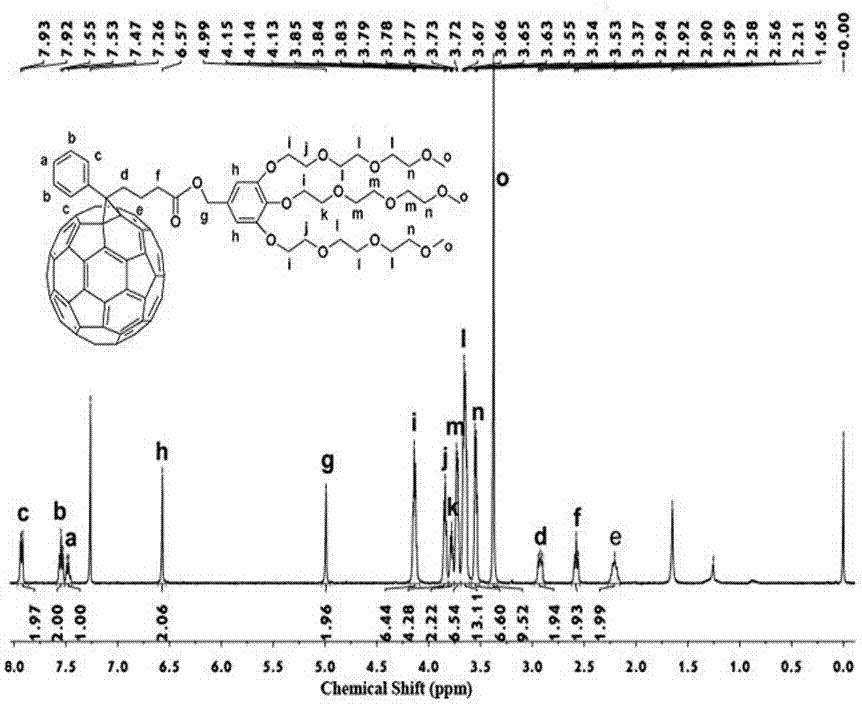

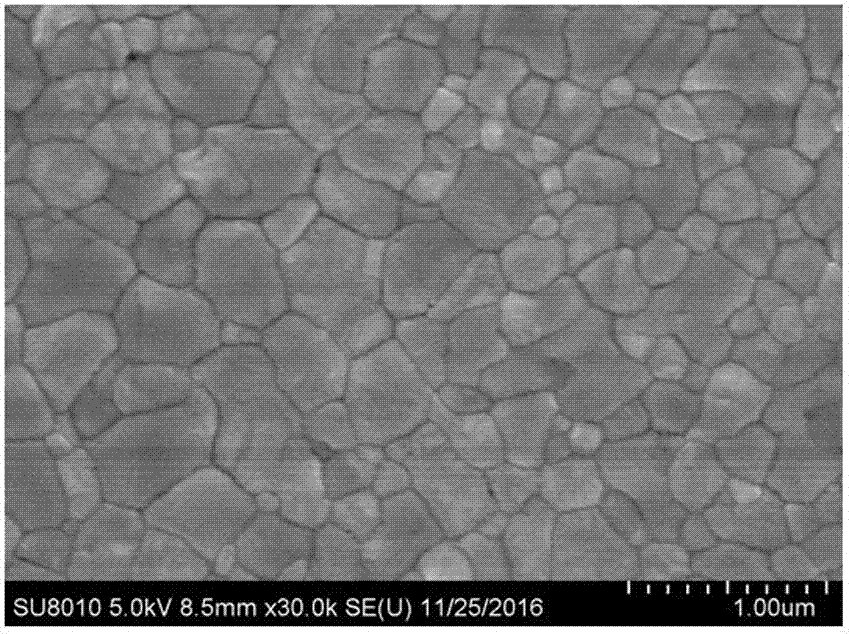

Application of alcohol soluble fullerene derivative in perovskite solar cell

ActiveCN107394047ALarge grainDense grainOrganic compound preparationOrganic chemistry methodsHole transport layerSpin coating

The invention discloses an application of an alcohol soluble fullerene derivative in a perovskite solar cell. The preparation process of a cell includes the following steps: preparing a cavity transmission layer on a piece of clean electro-conductive glass; spin-coating the cavity transmission layer with DMF solution of PbI2, spin-coating methyl ammonium iodide (MAI) isopropanol solution doped with the alcohol soluble fullerene derivative, and then obtaining a perovskite layer through annealing; and preparing an electronic modification layer and electrodes on the perovskite layer, and obtaining a perovskite solar cell. The application of an alcohol soluble fullerene derivative in a perovskite solar cell enables the fullerene to be distributed in a perovskite film from top to bottom in a graded manner by means of a simple doping method, thus maximally improving the electron mobility so as to improve the current and fill factors of devices. Therefore, the application of an alcohol soluble fullerene derivative in a perovskite solar cell can obtain a perovskite solar cell with high performance and simplify the process of device preparation, and can obtain better device performance at the same time.

Owner:SUZHOU UNIV +1

Dissimilar metal welding method for martensite heat-resisting steel and high-temperature nickel base alloy

InactiveCN104014929AImprove joint qualityQuality improvementFurnace typesWelding/soldering/cutting articlesFriction weldingAlloy

A dissimilar metal welding method for martensite heat-resisting steel and high-temperature nickel base alloy includes the following steps that (1) according to technical requirements of a friction welding machine, a martensite heat-resisting steel tube and a high-temperature nickel base alloy tube are respectively installed and clamped through a fixture of the friction welding machine and cannot shake, and the center line of the martensite heat-resisting steel tube and the center line of the high-temperature nickel base alloy tube are kept in the same horizontal line; (2) at a first-level pressurization stage, the rotation speed is 1200-1500 revolutions per minute, friction pressure is 20-50 MPa, and friction time is 1-3 seconds; (3) at a second-level pressurization stage, the rotation speed is 1200-1500 revolutions per minute, friction pressure is 50-100 MPa, friction deformation is 1-4 mm, and friction time is shorter than 10 seconds; (4) at an upset forging stage, upset forging pressure is 100-200 MPa, and upset forging time is 2-4 seconds; (5) partial heat treatment needs to be carried out on a welded joint between the martensite heat-resisting steel tube and the high-temperature nickel base alloy tube after welding, so that residual stress is eliminated. The method has the advantages that quality of the joints is high, the method is suitable for welding of heterogeneous materials, production efficiency is high production cost is low, energy is saved, and environment is protected.

Owner:XIAN SPECIAL EQUIP INSPECTION INST

Formula of phosphatizing liquid for metal surface anti-rusting and phosphatizing process

InactiveCN1769522ADense grainUniform grainMetallic material coating processesPhosphorCompound (substance)

This invention discloses an anti-rust phosphor solution formula of a metal and its technology method, the formula is composed of the following materials: XMn(H2PO4)2íñYfe(H2PO4).4H2O is 20-100g / lú¼Mn(NO3)2íñ6H2O is 20-100g / lú¼Zn(NO3)2íñ6H2O is 100-200g / lú¼Ni+2 is 0.5-10g / lú¼exterior active formula is 0.5-20g / l, water takes up 2 / 3 of the whole chemical, there also has some proper crap irons. The technology method as followsú‘Firsly, preparing solution by the formula; secondly, adjusting the acid proportion of the solution; thirdly, doing the pretreatment on the surface of the metal; fourthly, phosphating; fifthly, ost-treatment, oiling. The phosphor film crystal grain made in this invention is dense, symmetrical, the film is thin, the phosphor coating is symmetrical and dense, and the color is plentiful.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

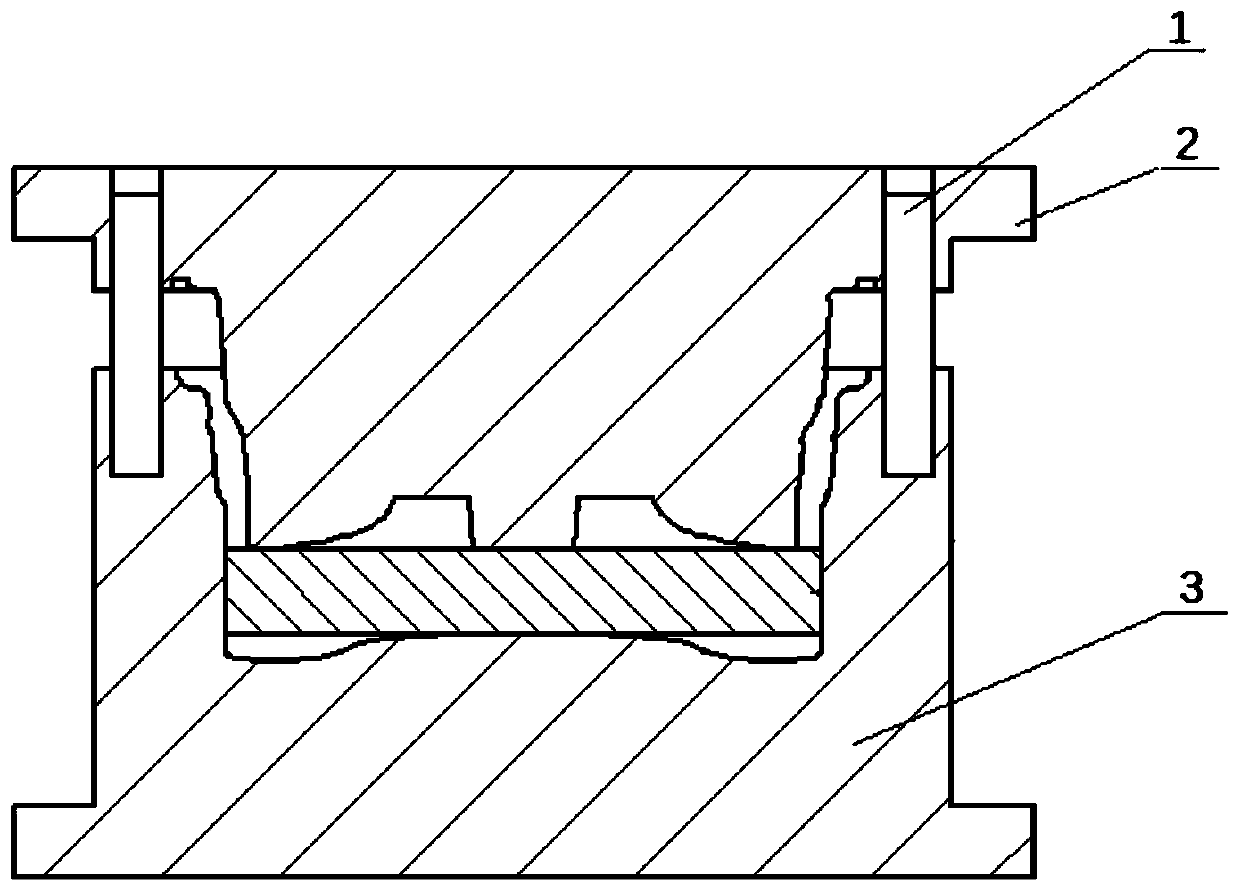

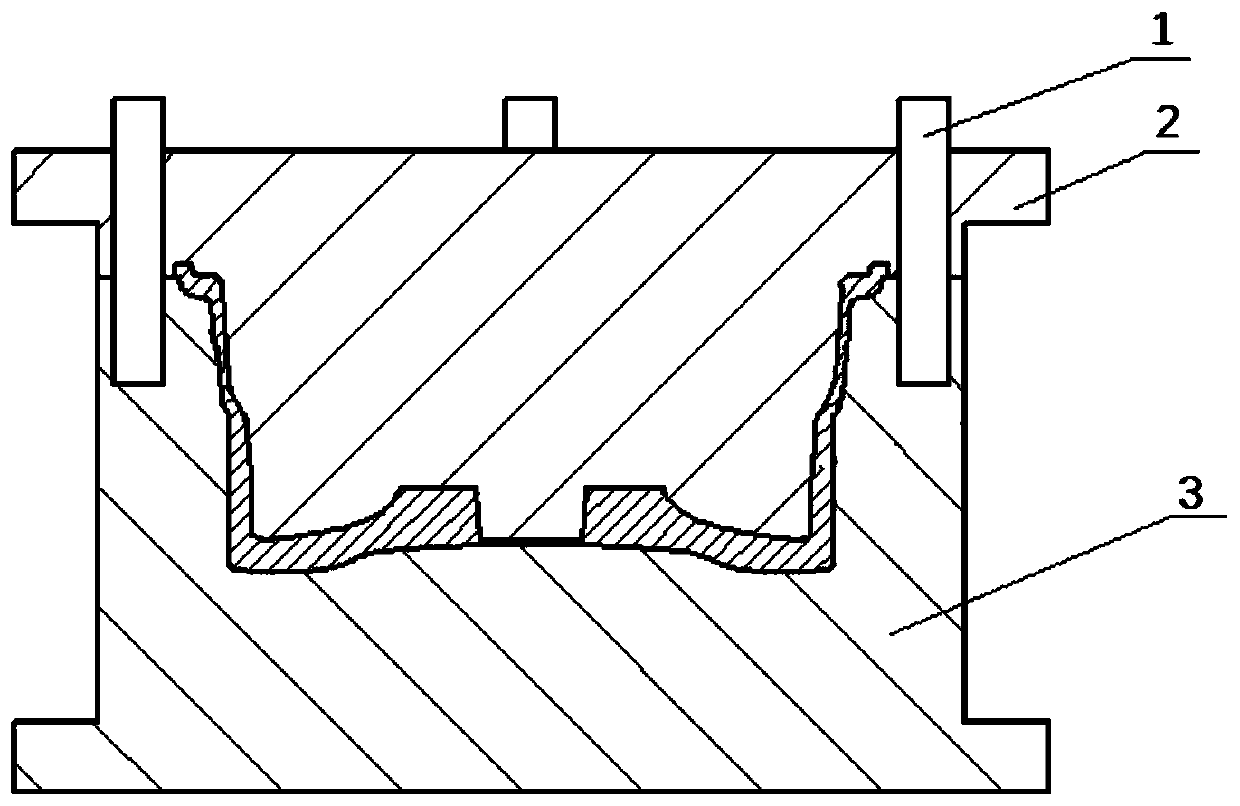

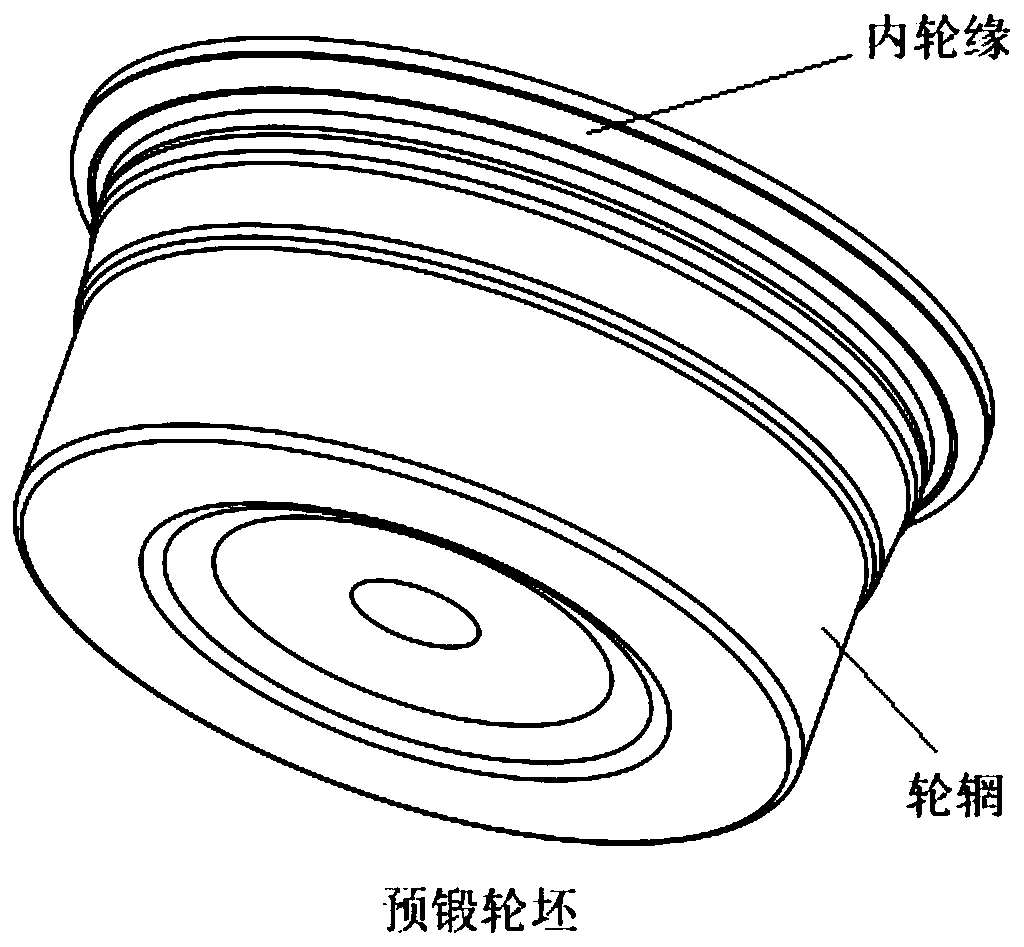

Hub extrusion forming method

ActiveCN110508737ASimple and easy forming processComplete formMetal-working apparatusWheelsEngineeringMechanical property

The invention discloses a hub extrusion forming method. A hub is produced and manufactured in a pre-forging and final forging two-step extrusion forming mode. In the pre-forging stage, a rim and an inner rim portion of the hub are extruded and formed through downward reverse extrusion motion of a pre-forging upper male die, and an outer rim and wheel arm parts of the hub are extruded and formed through the downward extruding motion of a final forging upper die in the final forging forming stage. The hub producing and manufacturing process by adopting the forming method is simple, the production efficiency is high, the forming pressure is smaller, the near-net forming material utilization rate is high, and the hub mechanical performance is more excellent.

Owner:NANJING UNIV OF SCI & TECH

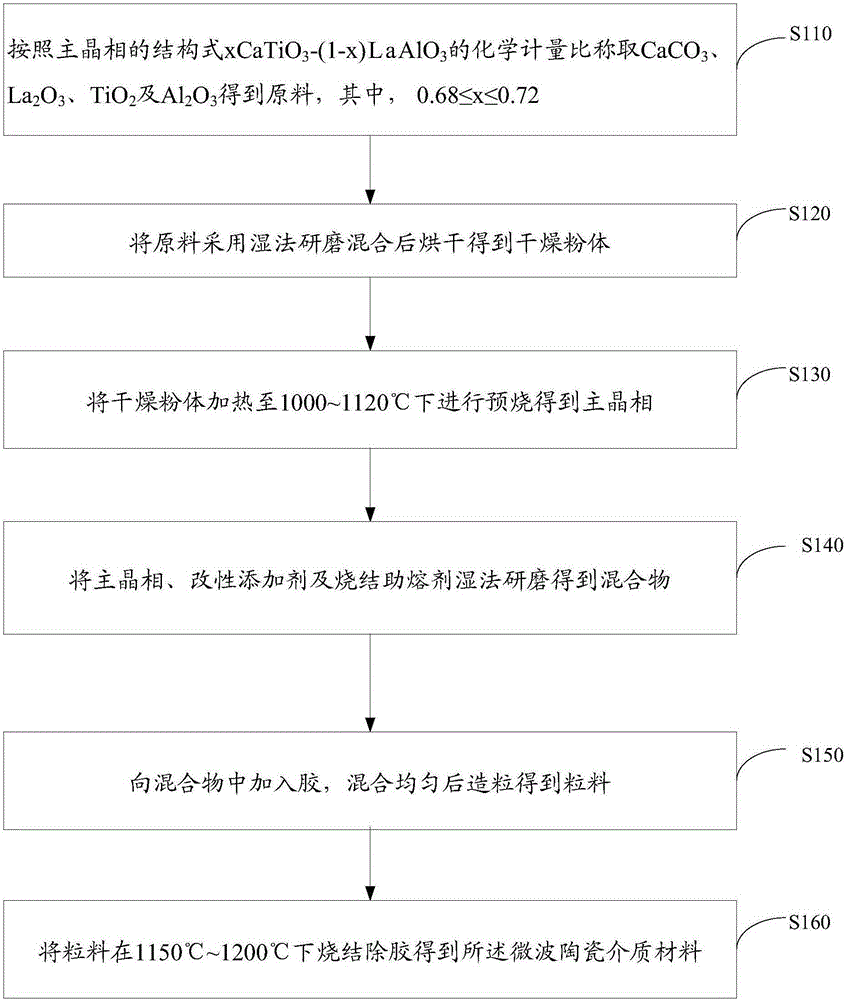

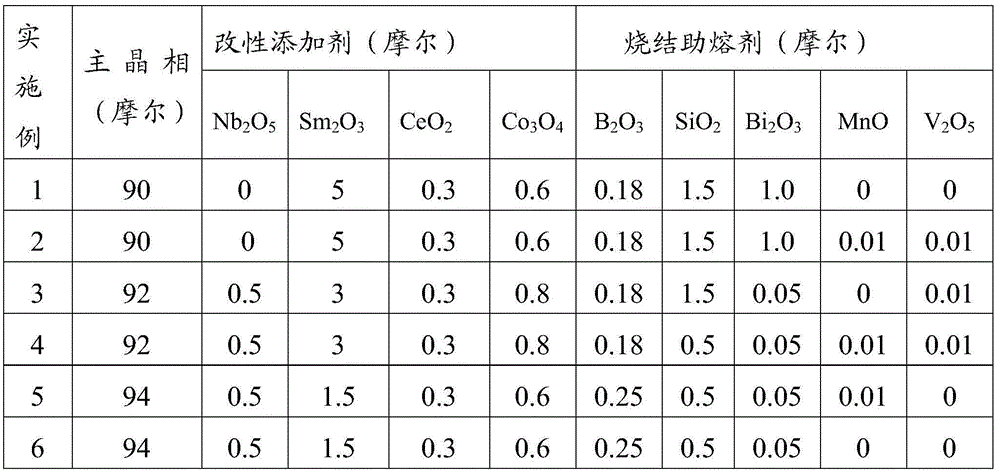

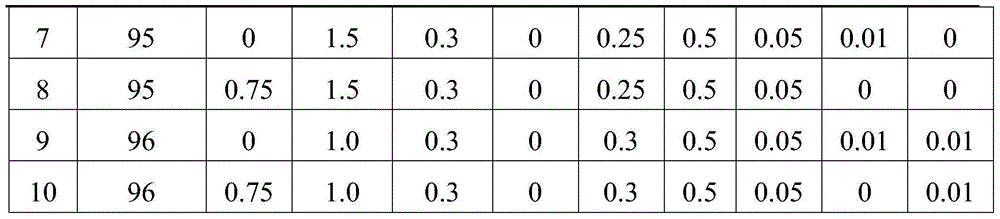

Microwave ceramic dielectric material and preparation method thereof

The invention provides a microwave ceramic dielectric material and a preparation method thereof. The microwave ceramic dielectric material comprises a main crystal phase, a modifying additive and a sintering cosolvent, and a structural formula of the main crystal phase is xCaTiO3-(1-x)LaAlO3, wherein x is greater than or equal to 0.68 and less than or equal to 0.72; according to molar content in microwave dielectric ceramic, the modifying additive comprises 0-1.0% of Nb2O5, 1-5% of Sm2O3, 0.1-0.5% of CeO2 and 0-1% of Co3O4, and the sintering cosolvent comprises 0-2% of B2O3, 0.5-4% of SiO2, 0-1% of Bi2O3, 0-0.5% of MnO and 0-0.5% of V2O5. The microwave ceramic dielectric material can be sintered at 1150 DEG C-1200 DEG C, cost can be saved, and high Qf value of 43000GHz-48000GHz can still be maintained.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Lamina wear-resisting phosphorization agent and preparation method thereof

ActiveCN101787524AHigh hardnessImprove wear resistanceMetallic material coating processesNitrateManganese

The invention relates to a lamina wear-resisting phosphorization agent and a preparation method thereof. The phosphorization agent has the following components and contents: 45-50g / l of manganous salt, 1-2ml / l phosphoric acid, 2-4g / l of nickel nitrate, 2-10g / l of nitrate of lime, 0.5-2g / l of zinc nitrate, 3-5g / l of scrap iron, 1-3g / l of citric acid, moderate amount of manganese carbonate for adjusting free acidity and the balance of water; total acidity of the phosphorization stands at 45-50 points, free acidity stands at 6.5-7.5 points and the proportion of the total acidity to the free acidity is 6:1 to 7:11.When the phosphorization agent is prepared, 40-45g / l of manganous salt is weighed and placed in water of 70 DEG C to be dissolved; water is supplemented after the manganous salt is completely dissolved; then the mixed solution is heated to boiling state and then cooled to 70 DEG C before adding 3-5g / l of scrap iron for carrying out reaction for 30-45min; then 0.5-2.0ml / l of phosphoric acid is added; sampling analysis is carried out and acidity of the solution is adjusted; then 2-4g / l of nickel nitrate, 2-10g / l of nitrate of lime, 0.5-2g / l of zinc nitrate are added; sampling analysis is carried out and acidity of the solution is adjusted again; after testing is passed, 1-3g / l of citric acid is added to obtain the phosphorization agent.

Owner:WUHAN MARINE MACHINERY PLANT

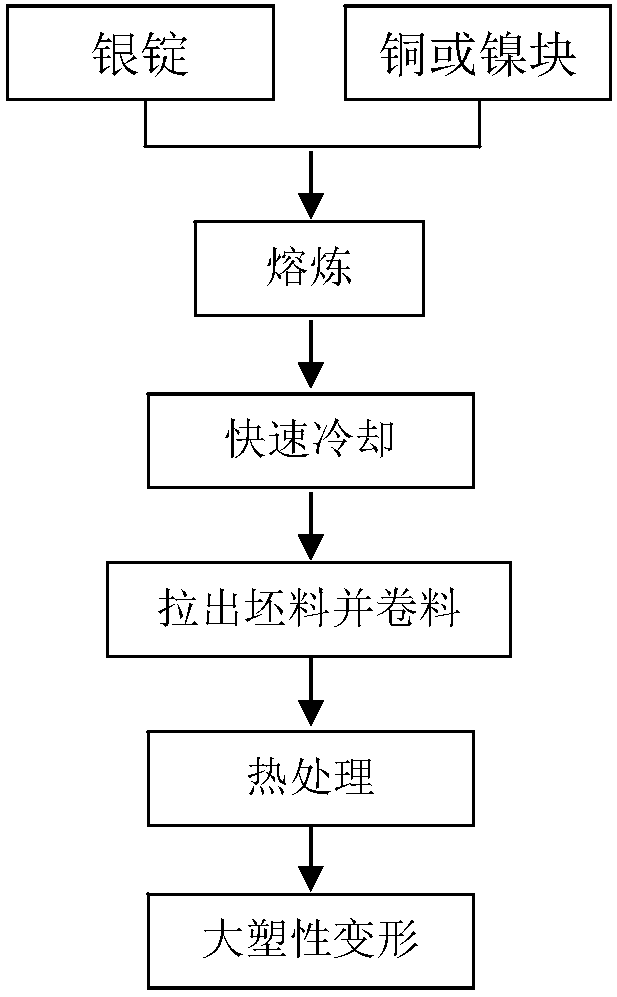

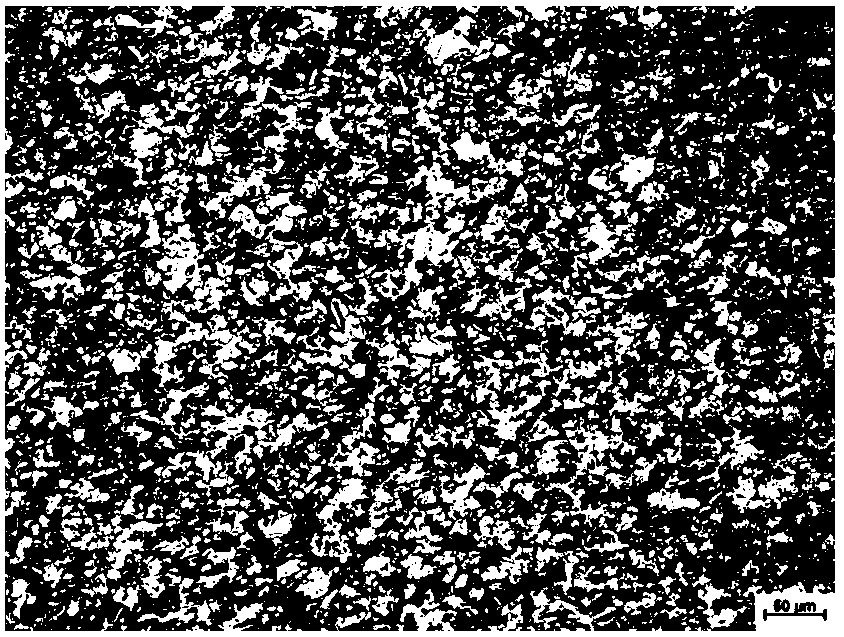

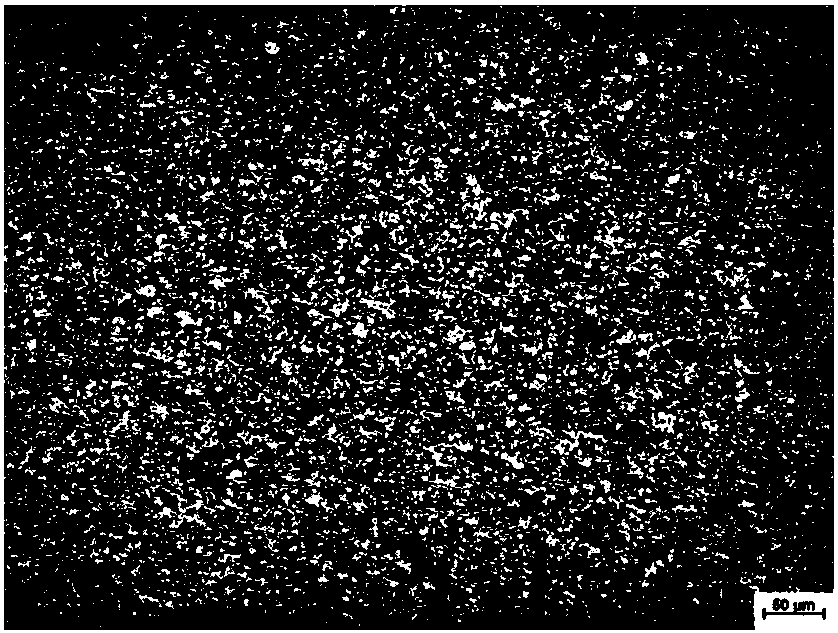

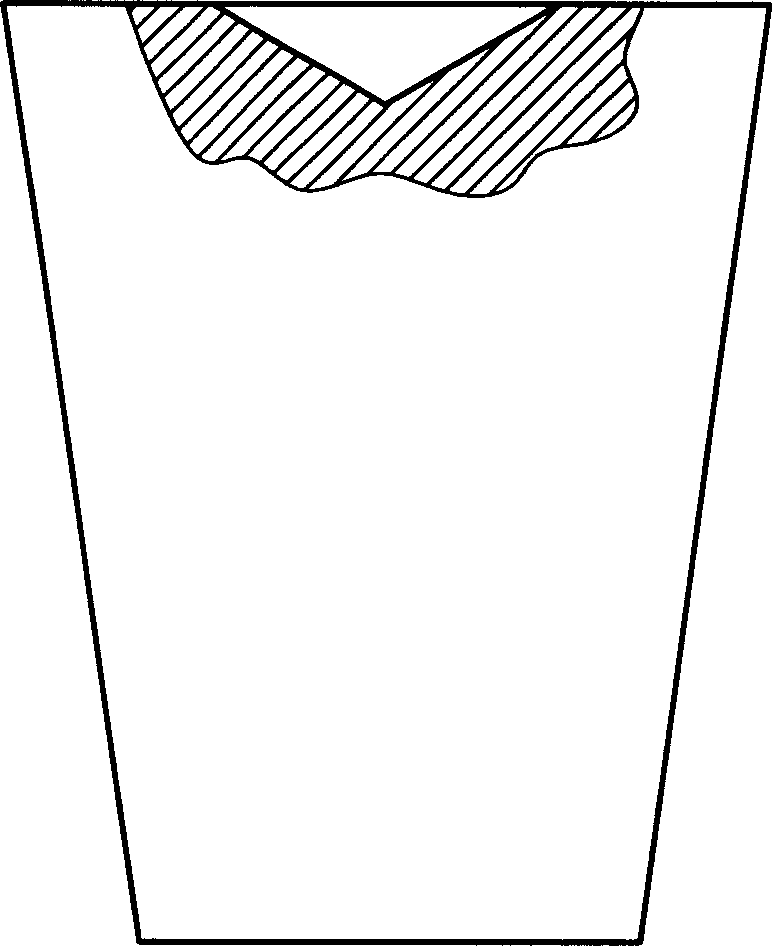

Fine-grained silver-based electrical contact material and preparation method thereof

InactiveCN107740019AAvoid uneven tissue distributionInhibition of grain growthPlastic propertyCopper

The invention provides a fine-grained silver-based electrical contact material and a preparation method thereof. The method comprises the following steps of 1, carrying out smelting and insulating onmetal silver and copper or silver and nickel so as to obtain the molten metal; 2, rapidly cooling the molten metal into a blank so as to inhibiting the grain growth in the alloy structure; 3, pullingout the blank to form a wire; 4, carrying out heat treatment on the wire; 5, performing large-plastic deformation on the heat-treated wire to obtain the fine-grained silver-based electric contact material. According to the fine-grained silver-based electrical contact material and the preparation method thereof, the horizontal continuous casting and large-plastic deformation technologies are combined, the prepared silver-based electric contact material has the advantages of being fine in crystal grain, compact in structure and good in mechanical property, the electric performance is greatly improved, and the material can be widely applied to a self-control switch, a thermostat, a thermostat, a baking machine, a baking oven timer, a computer and the like.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

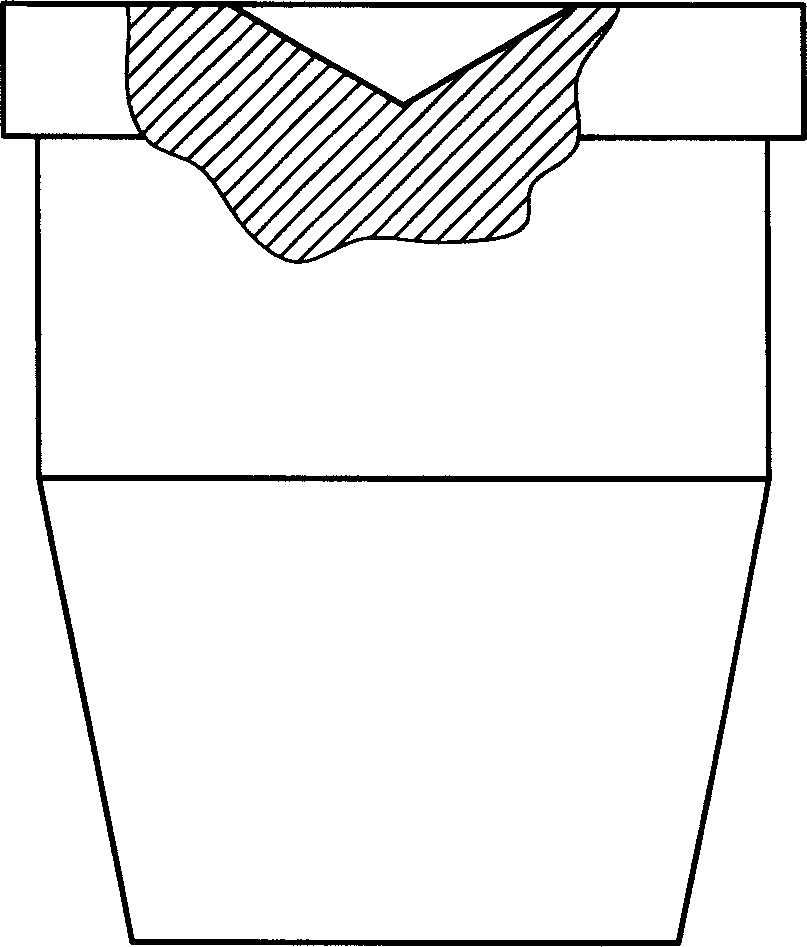

Anchorage device clamping piece blank cold extrusion process

The invention is a cold-extruding technique of semifinished ground tackle clamp pieces, used in prestressed ground tackle systems. Its technical flow: raw material phi20-30 20GmnTi circular stick-cutting by belt saw---burring by a grinder---annealing (at furnace temperature of 550-850 deg.C plus or minus 20 deg.C for at least a hour, cooling under 500deg.C with the furnace and the making air cooling)--phosphatization and saponification--punch molding, and its advantage: because the shape of the semifinished clamp piece is similar to that of the finished clamp piece, it extremely enhances the utilization ratio of the clamp pieces, relatively reduces the mechanically processing quantity, too, thus able to reduce the cost of the clamp pieces by a large margin.

Owner:阚柳凤

Fen-flavor liquor as well as preparation method and device thereof

InactiveCN105331503AStrong fragrancePromote fermentationDigestive systemAlcoholic beverage preparationYeastThroat

The invention discloses fen-flavor liquor as well as a preparation method and device thereof and belongs to the technical field of liquor. The fen-flavor liquor comprises raw materials in parts by weight as follows: 40-50 parts of rice, 3-8 parts of sorghum, 3-8 parts of glutinous rice, 3-8 parts of maize, 3-8 parts of millet, 3-8 parts of sago, 3-8 parts of oat, 3-8 parts of chickpeas, 3-8 parts of lotus seeds, 3-8 parts of lily bulbs, 3-8 parts of buckwheat, 180-320 parts of mountain spring water and 0.2-1 part of distiller's yeast. The invention further discloses the preparation method and device of the fen-flavor liquor. The fen-flavor liquor is prepared from 11 kinds of grain as basic raw materials, is fully transparent, milk white, soft and fragrant, has effects of cooling and moisturizing the throat, clearing the lung, realizing sweet aftertaste for a long time and the like and cannot cause headaches if a person drinks too much of the liquor; besides, the preparation method and device are simple, have the broad market prospect and are suitable for large-scale production.

Owner:张家友

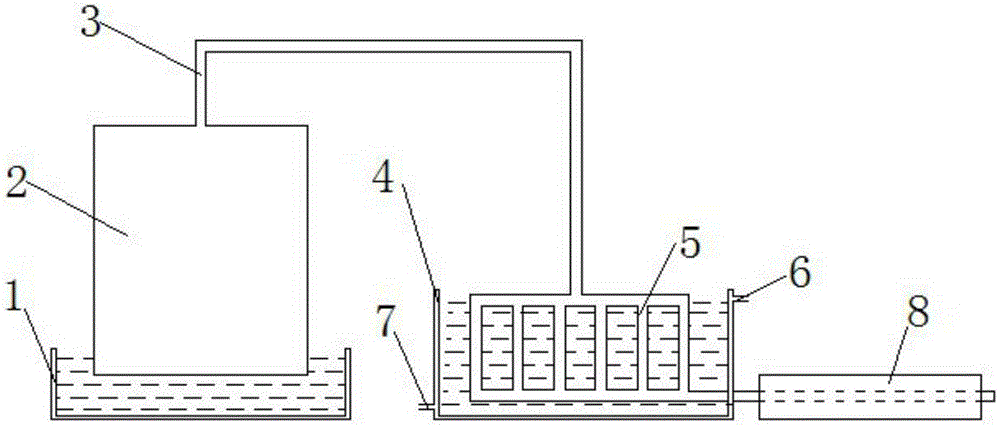

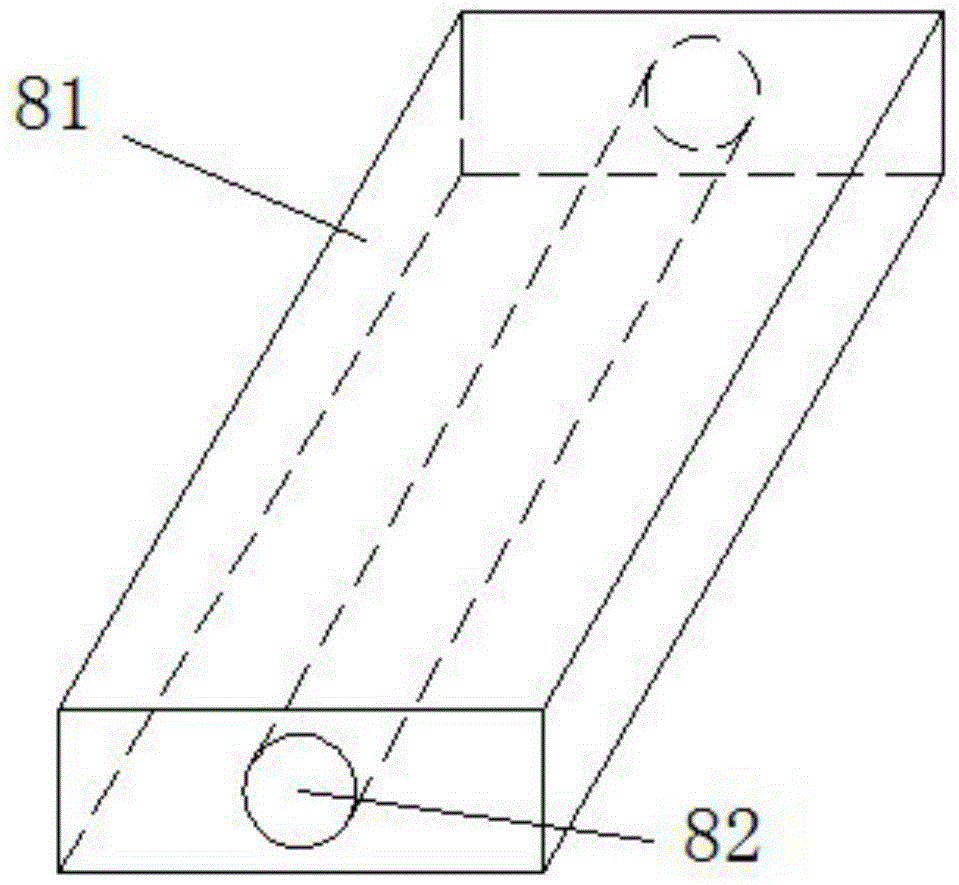

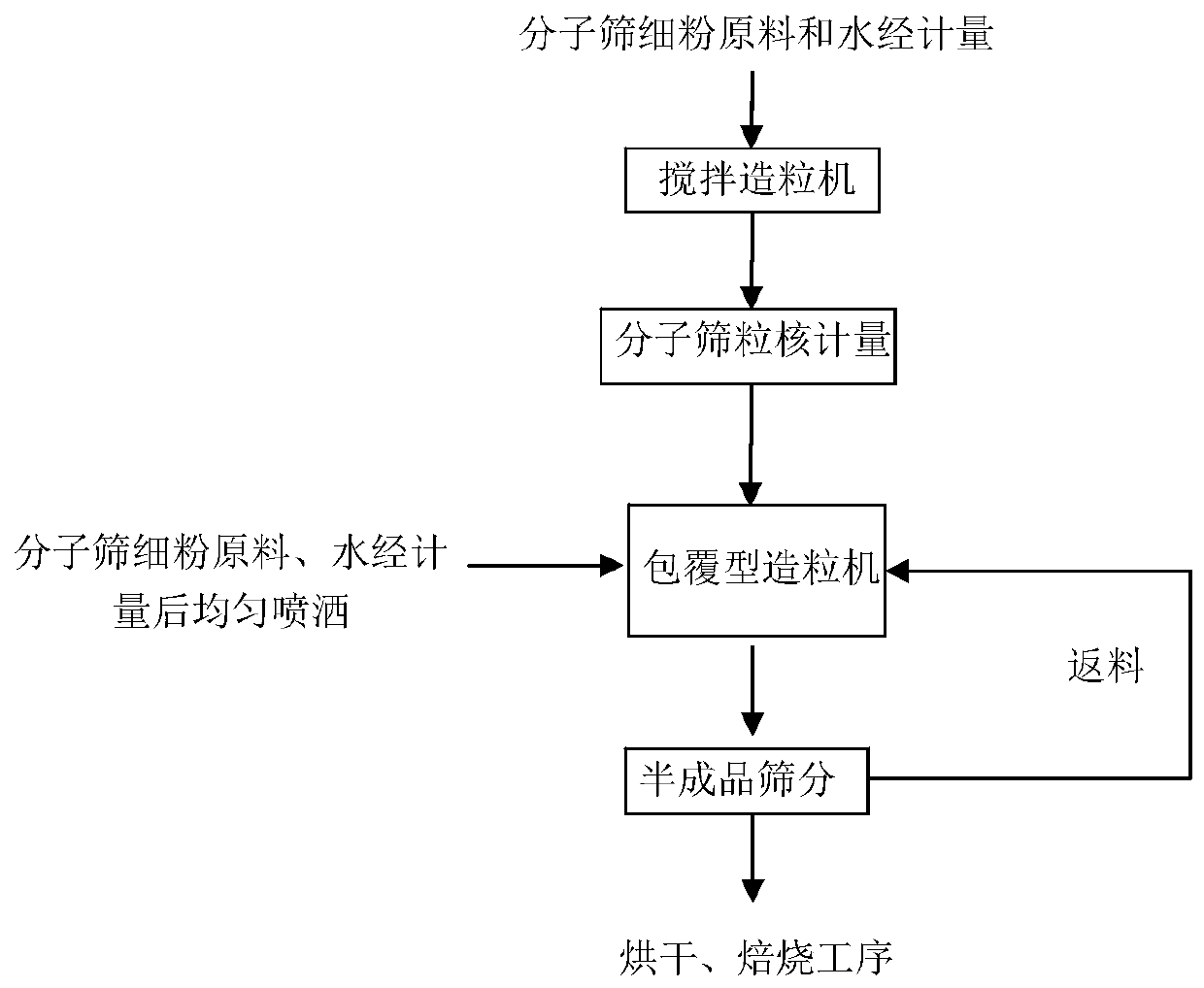

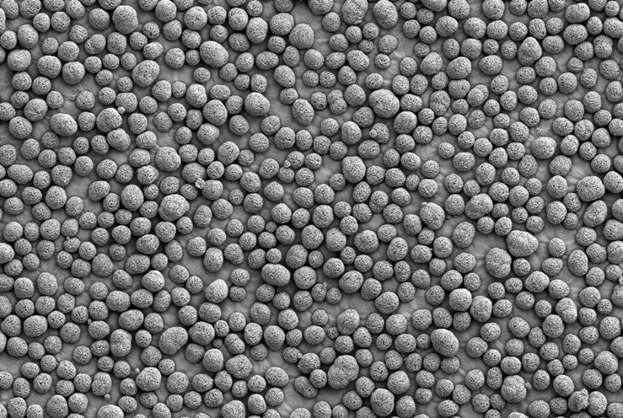

Method for preparing spherical molecular sieve

InactiveCN110237771AImprove ball forming efficiencyDense grainGranulation in stationary drums/troughsMolecular sieveSpherical shaped

The invention relates to a method for preparing a spherical molecular sieve. The method comprises the steps: (1) preparation of small-particle nuclei: adding a molecular sieve fine powder raw material and water to a stirring granulator, and performing stirring and granulation so as to obtain the small-particle nuclei with a particle diameter of 0.5-2.0 mm; (2) preparation of molecular sieve spherical particles: adding the small-particle nuclei, the molecular sieve fine powder raw material and water to a coating granulator so as to form the molecular sieve spherical particles; and (3) preparation of the finished product: performing sieving, drying and calcination on the molecular sieve spherical particles so as to obtain the spherical molecular sieve product. Compared with the prior art, the method has the advantages of a high pelletization rate of nuclei, energy saving, environmental protection and a simple preparation process, and the molecular sieve particles are compact, and has a rounded appearance and smooth appearance.

Owner:SHANGHAI RES INST OF CHEM IND

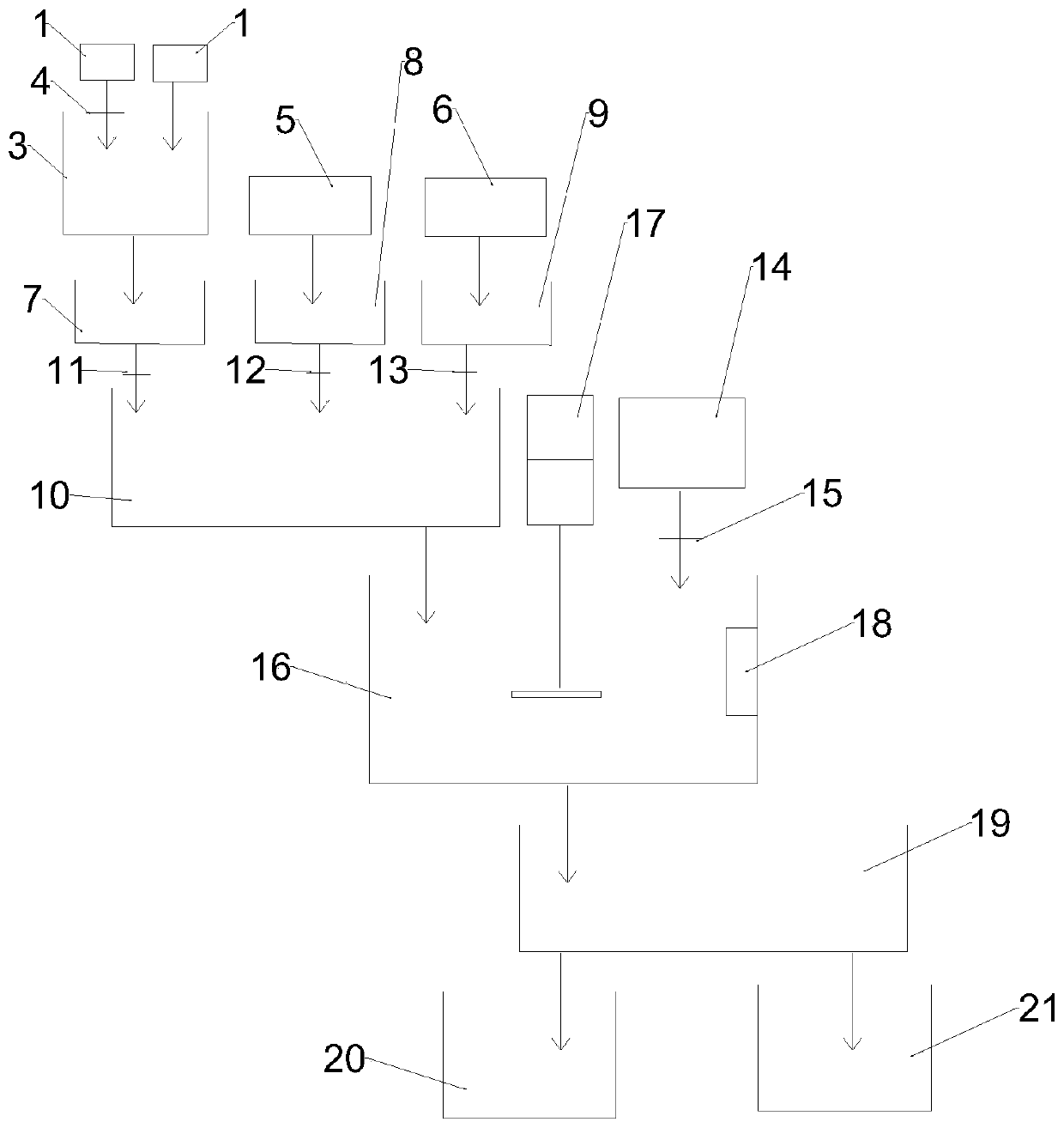

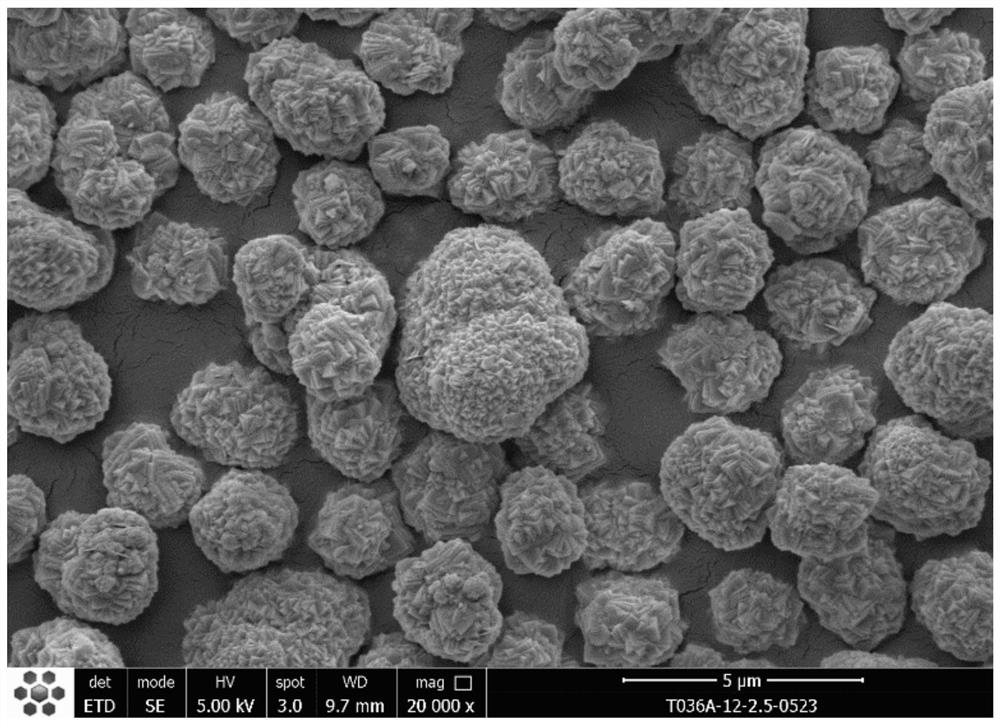

Ternary precursor preparation system

PendingCN110451587ADense grainGood sphericityCell electrodesTransportation and packagingAmmonium hydroxideChemistry

The invention discloses a ternary precursor preparation system which comprises a blending system, a synthesis control system, an aging system, a washing filter pressing system and a drying system, wherein the blending system comprises a mixed salt preparing kettle and an additive solution preparation tank; the synthesis control system comprises a reaction kettle, an alkali storage tank and an ammonium hydroxide storage tank; the reaction kettle communicates with the mixed salt preparation kettle; the alkali storage tank communicates with the reaction kettle through the ammonium hydroxide storage tank; the aging system comprises an aging kettle; the aging kettle communicates with the reaction kettle and the additive solution preparation tank respectively; the aging kettle is internally provided with a stirring device; the aging kettle is further provided with a jacket; the washing filter pressing system comprises a filter press and a mother liquid transfer tank; the aging kettle communicates with the sealed filter press and the mother liquid transfer tank respectively; and the drying system comprises a hot air circulation baking oven for drying a washed and filtered product. By adopting the system, precursor granules which are dense in granule, good in sphericity and narrow in particle size distribution can be prepared.

Owner:东莞市宏湖智能装备有限公司

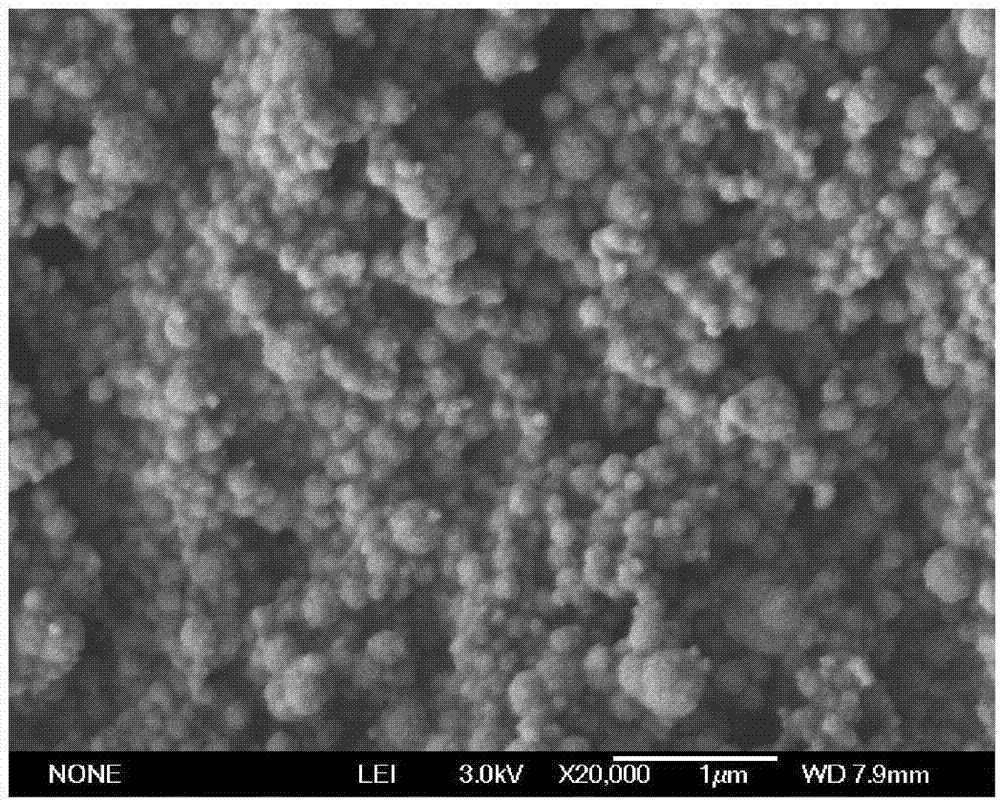

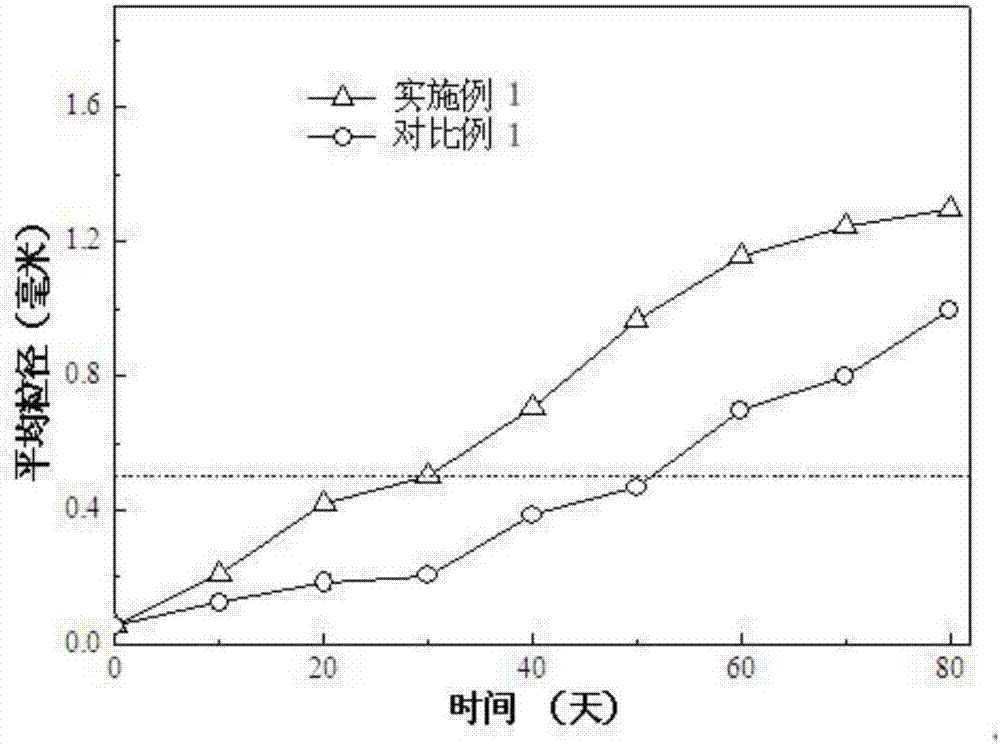

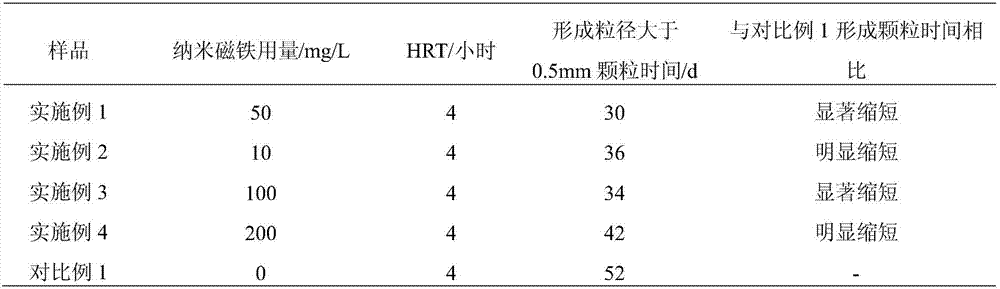

Method for promoting granulation of flocculent activated sludge by applying nano magnet

ActiveCN107235552AUnique superparamagnetic propertiesWith adsorptionBiological treatment apparatusSustainable biological treatmentActivated sludgeNanodot

The invention relates to a method for promoting the granulation of flocculent activated sludge by applying nano magnet. The method comprises the following steps: mixing the flocculent activated sludge, the nano magnet and sewage; promoting the granulation of the flocculent activated sludge by interaction between the nanodots and the flocculent activated sludge; performing the granulation process at room temperature according to a cycle, and sufficiently aerating within each cycle. According to the method disclosed by the invention, the granulation process of the activated sludge can be effectively shortened; by adding a small amount of the nano magnet, the granulation time of the sludge can be effectively shortened and the cost is low; in addition, obtained particles are denser and better in stability. The method disclosed by the invention has the advantages of simple process, mild reaction conditions, safety and no toxicity to environment and facilitation for engineering application; the method can be performed at normal temperature and normal pressure.

Owner:SHANDONG UNIV

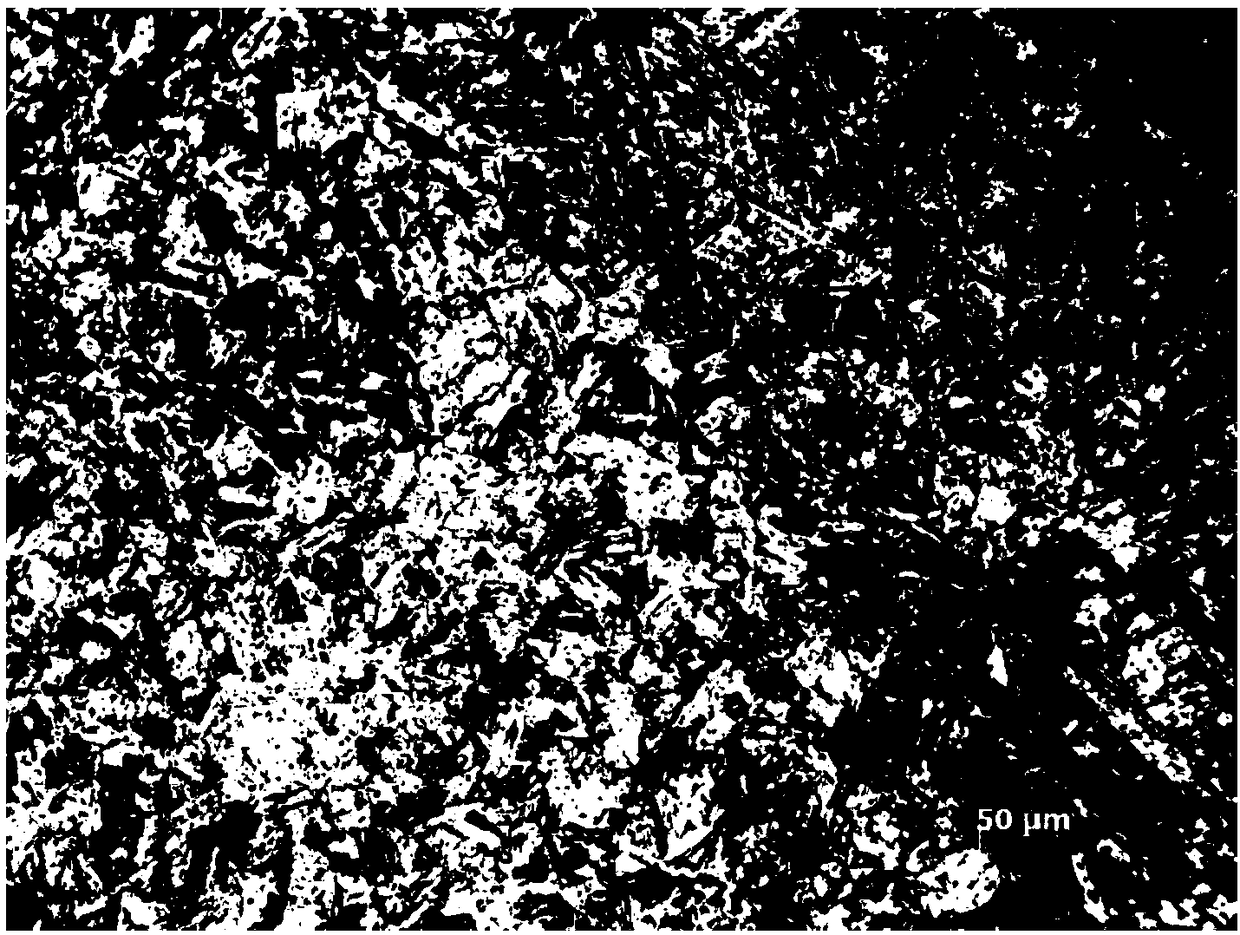

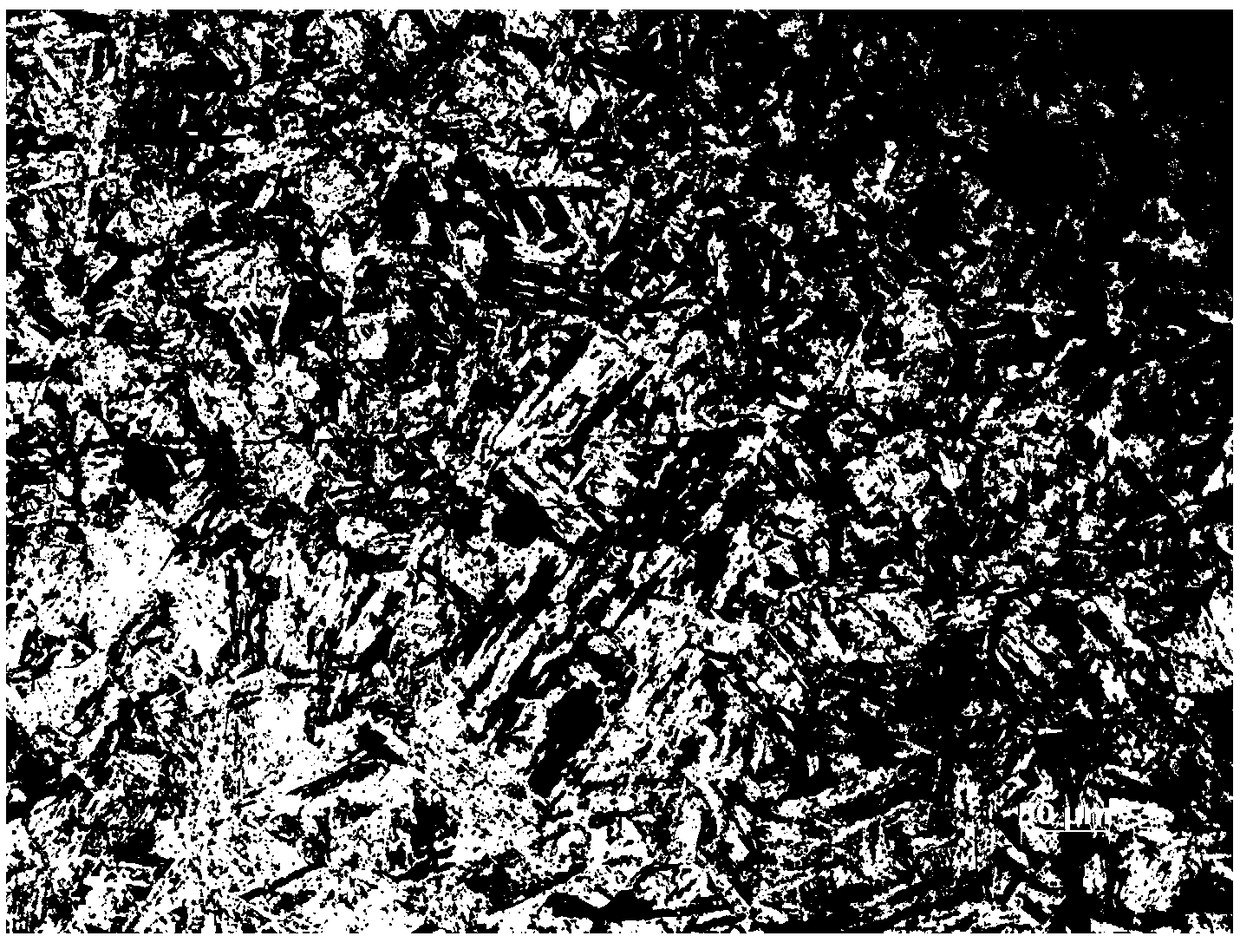

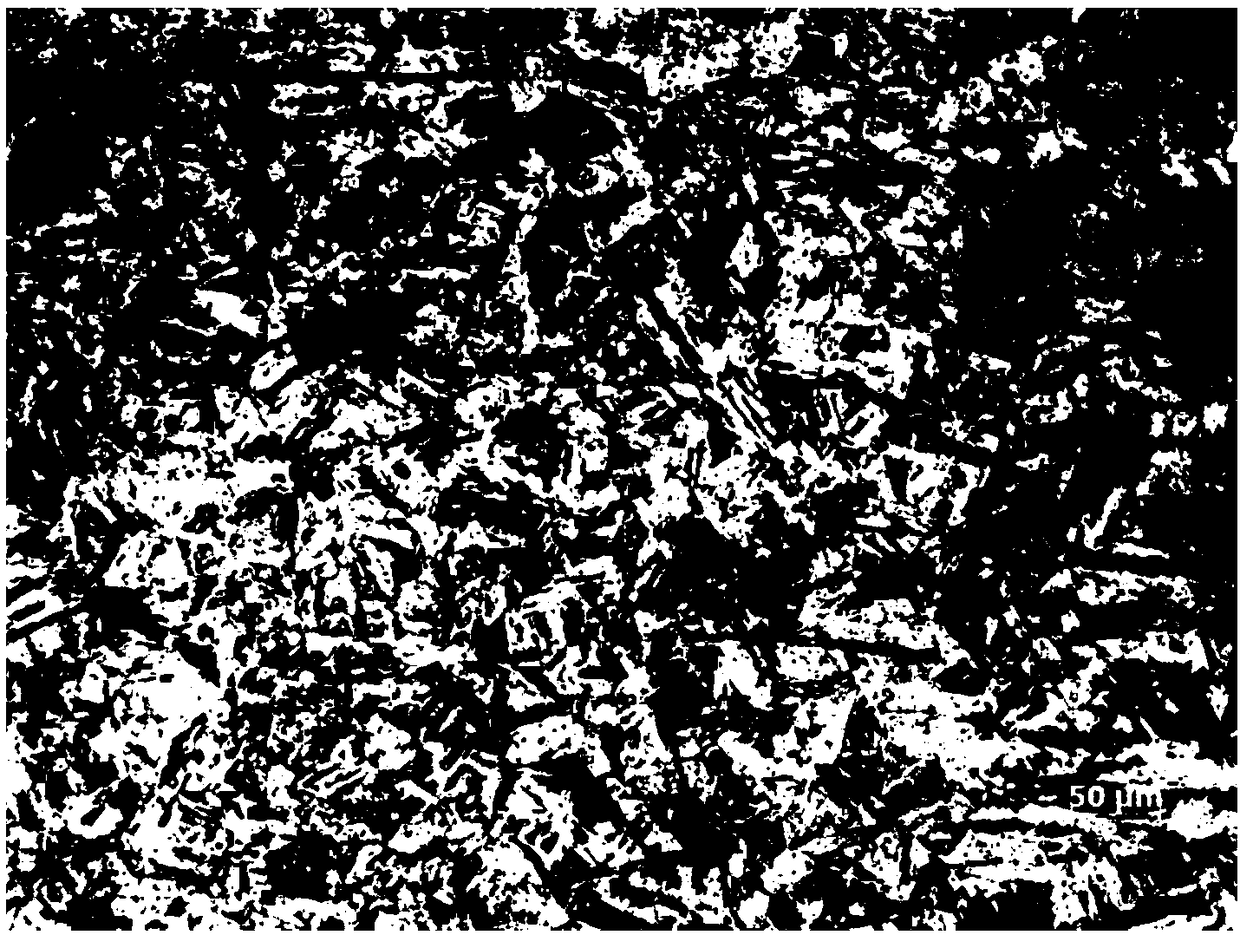

Novel martensitic heat-resistant steel and method for manufacturing thin-walled elbow of seamless steel pipe using same

ActiveCN108588579AAvoid Arc Position UncertaintyPrecise drop positionAdditive manufacturing apparatusIncreasing energy efficiencySteel tubeTungsten

The invention relates to the technical field of additive manufacturing, in particular to novel martensitic heat-resistant steel and a method for manufacturing a thin-walled elbow of a seamless steel pipe. The novel martensitic heat-resistant steel comprises the compositions of, by weight, 0.05-0.15% of carbon, 0.1-0.4% of silicon, 0.3-0.6% of manganese, 8.0-12.0% of chromium, 1.5-1.9% of tungsten,0.1-0.8% of molybdenum, 0.1-0.3% of vanadium, 0.1-0.3% of tantalum, 0.05-0.3% of lanthanum hexaboride and the balance iron. The thin-walled elbow of the seamless steel pipe prepared by the novel martensitic heat-resistant steel by adopting laser-CMT composite additive manufacturing is compact in structure, the alloy structure comprises lath martensite and dispersed carbide, crystal grains are fine and uniform, and no columnar crystal texture is generated; and due to the addition of LaB6 to the novel martensitic heat-resistant steel, the LaB6 reacts with O to form LaBO3, and then the LaBO3 decomposes into La2O3 and B2O3 which can be used for deoxidation and slag formation of a micro-melting bath in the additive manufacturing process, the formability and manufacturability are improved, theforming structure is improved, and the mechanical properties of formed parts are improved.

Owner:SUZHOU UNIV

Coating solution of coating electrode and preparation method of coating electrode

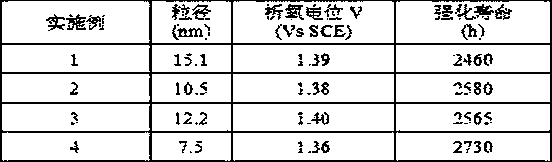

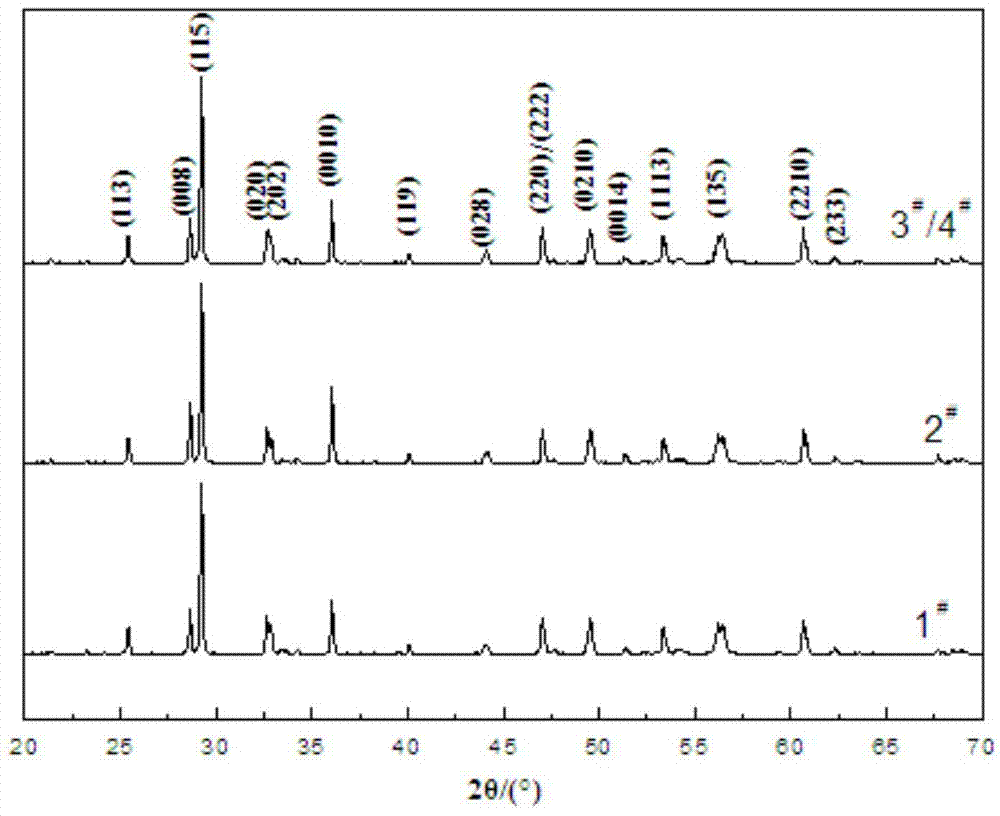

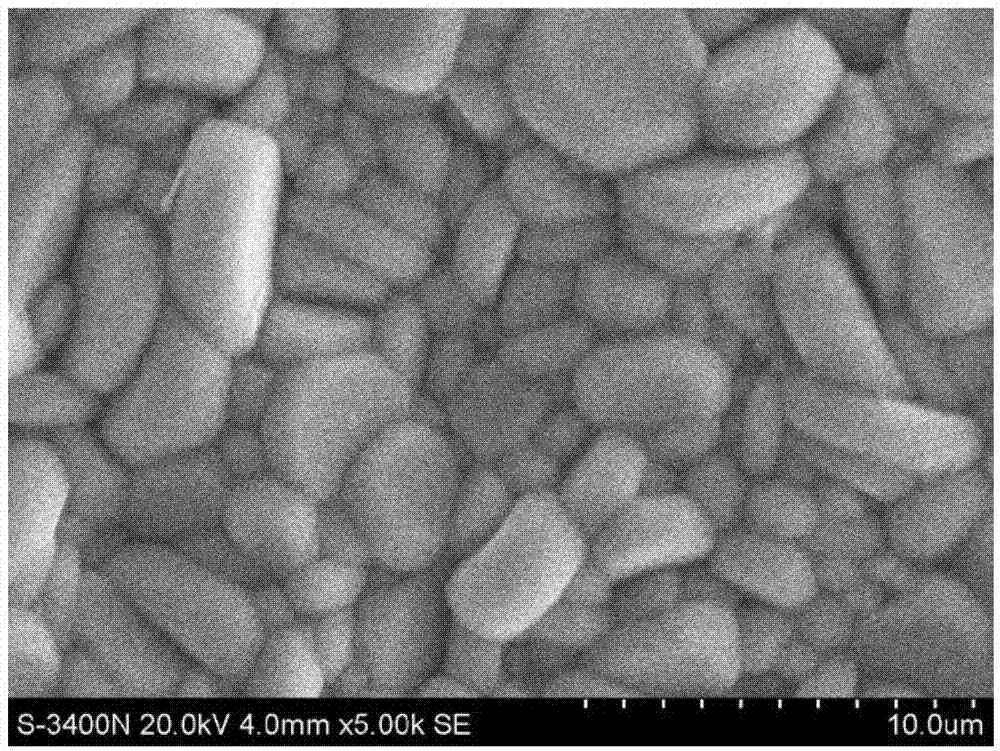

The invention discloses a coating solution of a coating electrode and a preparation method of the coating electrode. The coating solution is a solution composed of chloro-iridic acid, tantalum pentachloride, alpha-hydroxy acid, glycol and n-butyl alcohol, the volume ratio of the glycol to the n-butyl alcohol is 1 to 1, the concentration of the chloro-iridic acid is 30-38 g / L, and the mass percentof the chloro-iridic acid to the tantalum pentachloride to the alpha-hydroxy acid is 55-62 to 34-40 to 3-7. The preparation method of the coating electrode comprises the steps that a titanium plate isput into a sodium carbonate solution to be boiled, washed thoroughly with deionized water and dried; the titanium plate is put into an oxalic acid solution to be boiled, taken out to be washed thoroughly and dried; and a brush is used for coating the titanium plate with the coating solution, drying and hot air oxidation are carried out, after cooling, the processes are carried out repeatedly, after heat treatment, the coating solution is cooled to the normal temperature, and the coating electrode is prepared. The coating surface of the coating electrode prepared from the coating solution through the preparation method has no obvious cracks, the area of a plane region is large, the plane region is smooth, most crystal grains grow on the plane region, the coating is compact in bonding, thefortified life is obviously prolonged, and the performance is remarkably improved.

Owner:GUANGDONG INST OF RARE METALS

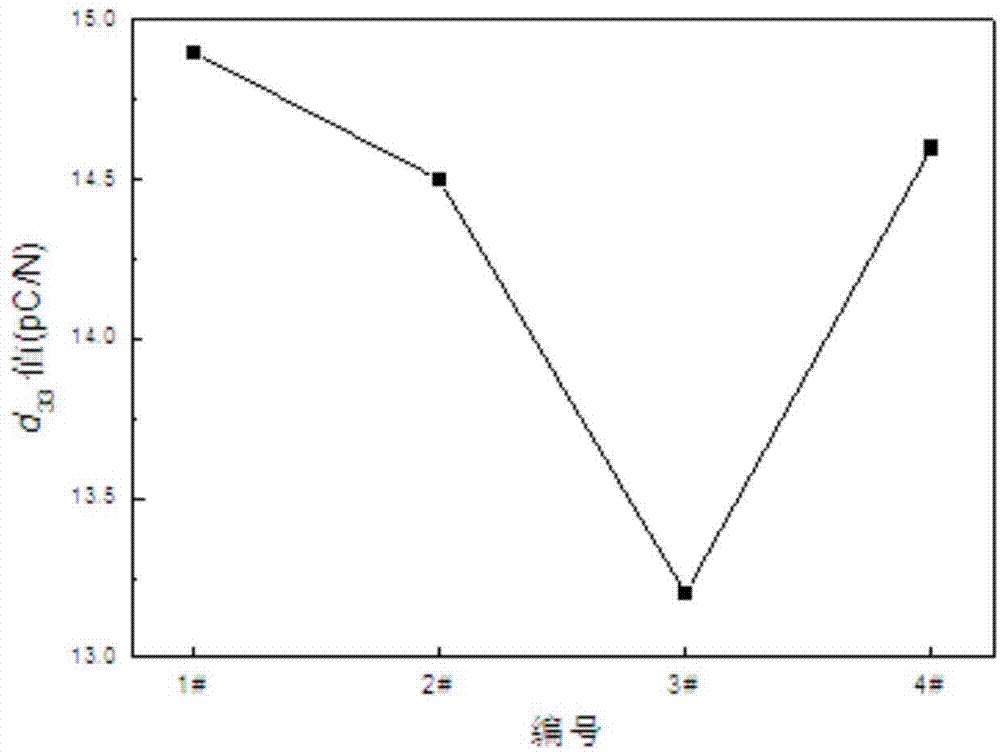

Lithium-cerium-tantalum codoping niobic acid-bismuth-calcium based piezoceramic material and preparation method thereof

ActiveCN103922722AImprove densification performanceImprove sintering performanceLithiumDielectric loss

The invention discloses a lithium-cerium-tantalum codoping niobic acid-bismuth-calcium based piezoceramic material and a preparation method thereof. The lithium-cerium-tantalum codoping niobic acid-bismuth-calcium based piezoceramic material is characterized by being expressed by a general formula Ca1-x(Li,Ce)x / 2Bi2Nb2-yTayO9, wherein x is greater than or equal to 0.02 and is less than or equal to 0.15, y is greater than or equal to 0.01 and is less than or equal to 0.3, x expresses the molar fractions of lithium and cerium on the site A, and y expresses the molar fraction of tantalum on the site B. The preparation method of the piezoceramic material comprises the following steps: preparing a niobic acid-bismuth-calcium (CNB) ceramic powder material by adopting a solid phase method, wherein the doping amounts of the lithium and cerium (Li, Ce) on the site A and the tantalum (Ta) on the site B in the niobic acid-bismuth-calcium (CNB) ceramic powder material are different; and then preparing the lithium-cerium-tantalum codoping CBN based piezoceramic material by pelleting, tabletting, discharging rubber, sintering, silvering and polarizing. The results show that the crystal particles of the lithium-cerium-tantalum codoping CBN based piezoceramic material obtained by preparation at a relatively low sintering temperature of 1100 DEG C are relatively compact and uniform, the sintering activity and compactness of ceramics are improved, and the sintering effect is relatively good; the piezoceramic performance of the piezoceramic material is greatly improved, and the dielectric loss of the piezoceramic material is reduced.

Owner:SICHUAN UNIV

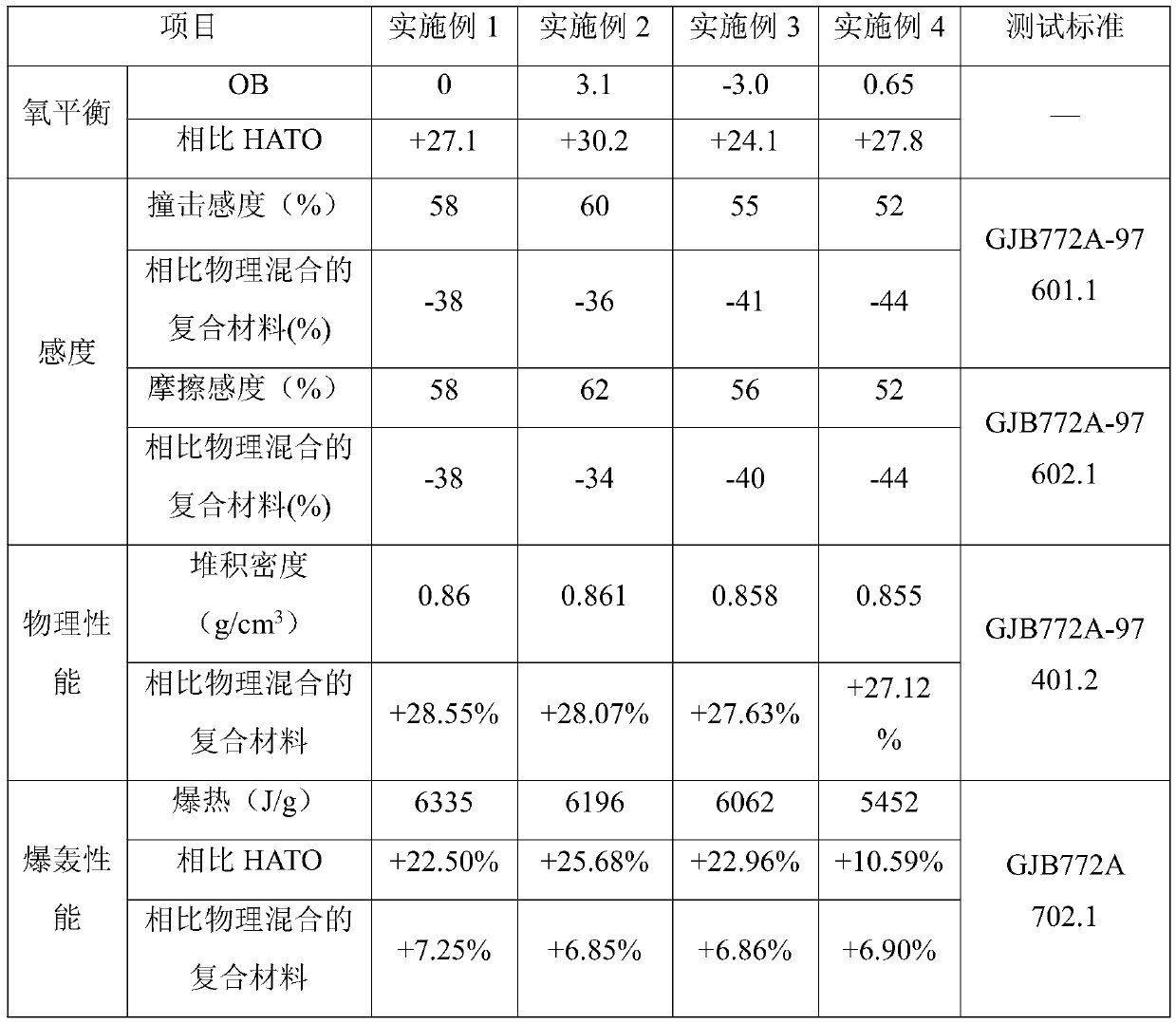

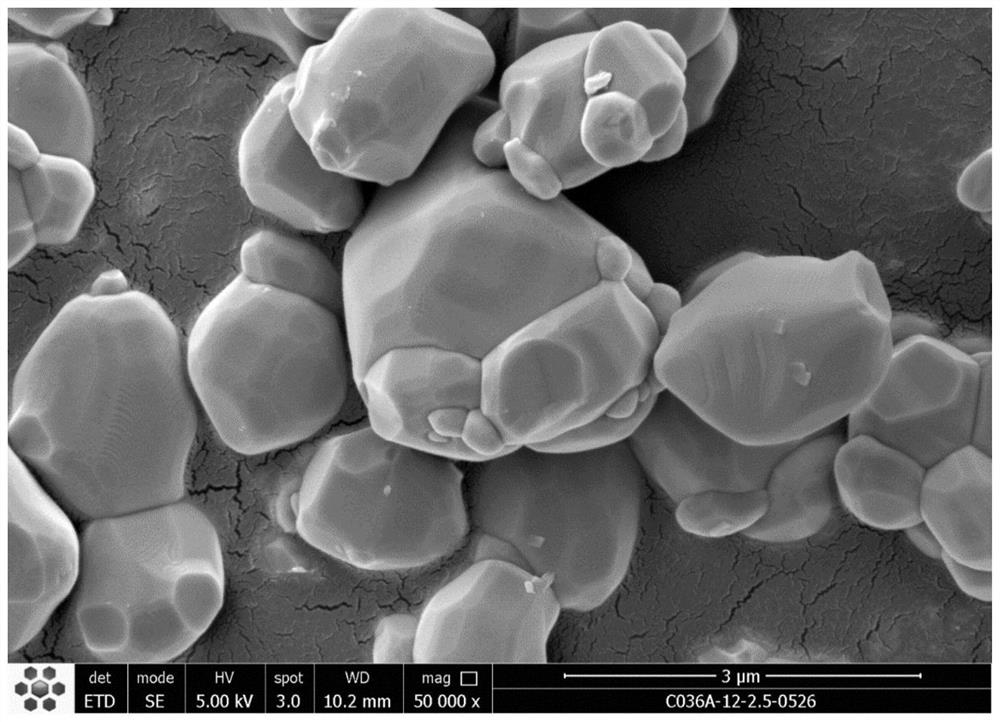

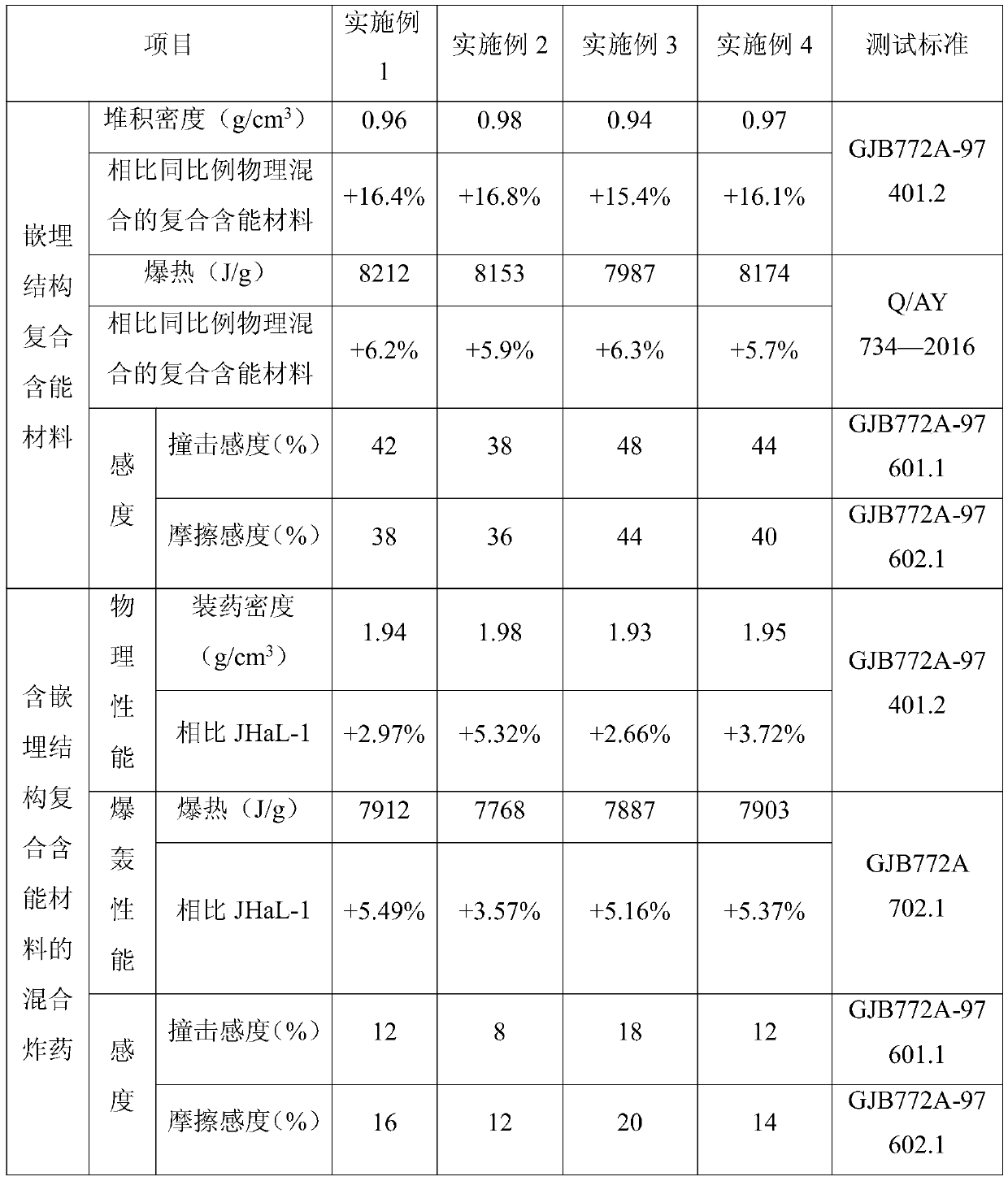

Nearly spherical core-shell structure composite energetic material and preparation method thereof

ActiveCN110655432AHigh bulk densityDense grainMicroballoon preparationAmmonium perchlorate explosive compositionsEthyl acetateSolvent

The invention discloses a nearly spherical core-shell structure composite energetic material and a preparation method thereof. Recrystallization is carried out by a solvent-non-solvent method, and dihydroxylammonium 5,5'-bistetrazole-1,1'-diolate is sheared by a colloid mill to obtain nearly spherical dihydroxylammonium 5,5'-bistetrazole-1,1'-diolate particles; ammonium perchlorate is dissolved inwater, the dihydroxylammonium 5,5'-bistetrazole-1,1'-diolate particles are added into an ethanol / ethyl acetate mixed solvent and stirred, an ammonium perchlorate aqueous solution is dripped into dihydroxylammonium 5,5'-bistetrazole-1,1'-diolate suspension, and the ammonium perchlorate is saturated and separated out to obtain the core-shell structure composite energetic material with the ammoniumperchlorate tightly coating the dihydroxylammonium 5,5'-bistetrazole-1,1'-diolate. The composite energetic material prepared by the method provided by the invention has the advantages of high bulk density, low sensitivity and high explosion heat, and can effectively improve the explosion heat of the dihydroxylammonium 5,5'-bistetrazole-1,1'-diolate and improve the oxygen balance of the dihydroxylammonium 5,5'-bistetrazole-1,1'-diolate.

Owner:XIAN MODERN CHEM RES INST

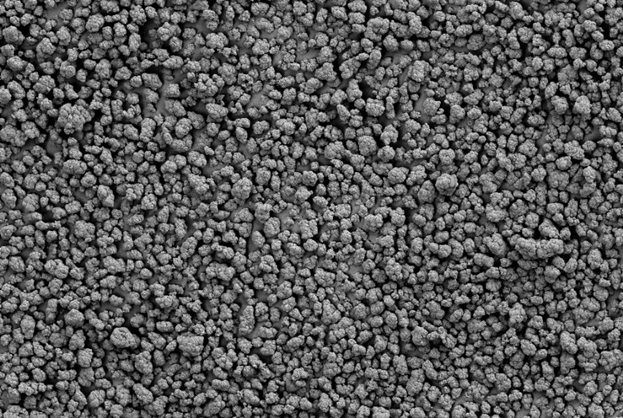

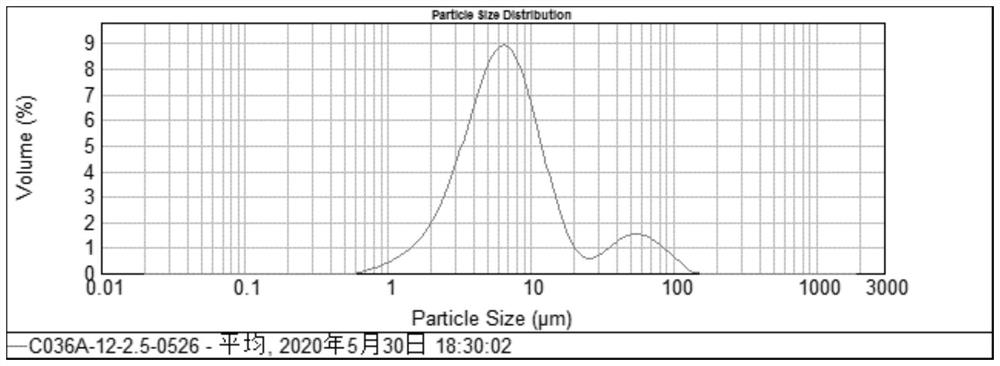

Narrow-distribution small-particle-size nickel-cobalt-aluminum hydroxide and preparation method thereof

ActiveCN111717938AIncrease energy densityImprove cycle performanceSecondary cellsPositive electrodesElectrical batteryAluminium hydroxide

A narrow-distribution small-particle-size nickel-cobalt-aluminum hydroxide serves as a precursor of a nickel-cobalt-lithium aluminate battery positive electrode material active substance, an inner core of secondary spherical particles of the precursor is aluminum hydroxide, a crystal grain cation layer framework of an outer shell layer contains nickel-cobalt-aluminum elements, and the mole percentof nickel is 85-98%; and secondary spherical particles of the precursor have the characteristic of narrow distribution, K90 is (D90-D10) / D50 and is less than or equal to 0.90, D50 is 2.0-6.0 [mu]m, and the energy density and the cycle performance of the battery can be further improved when the secondary spherical particles are used as a positive electrode material of the lithium battery. The invention discloses a preparation method of the narrow-distribution small-particle-size nickel-cobalt-aluminum hydroxide. On one hand, the defect that a precursor synthesized by a solid phase method cannot achieve atomic-level uniformity is overcome, and on the other hand, aluminum hydroxide flocculent precipitate generated in the synthesis process of a conventional liquid phase method is also overcome, so that the precursor with a core-shell structure, good sphericity, compact particles, stable structure and high consistency is obtained.

Owner:HUAYOU NEW ENERGY TECH (QUZHOU) CO LTD +1

Doped cobaltosic oxide and preparation method thereof

PendingCN112760710AIncrease compaction densityIncrease growth ratePolycrystalline material growthFrom normal temperature solutionsHigh energyCobalt(II,III) oxide

The invention discloses doped cobaltosic oxide; the morphology of the doped cobaltosic oxide is single-crystal particles or single-crystal-like aggregates, the primary grain size is 200-500 nm, and the half-peak width of the 311 crystal face is 0.2-0.6. The preparation method comprises the steps: adjusting the pH value of a reaction kettle base solution to 7.1+ / -0.05; adding a mixed salt solution containing cobalt and doped elements and an ammonium bicarbonate solution into a reaction kettle for reaction, and controlling the pH value of a reaction system to be 7.1+ / -0.05; standing and clarifying the slurry overflowing from the full liquid level of the reaction kettle, removing the supernatant, controlling the solid content of the slurry, returning the slurry to the reaction kettle for reaction, and stopping feeding until the reaction reaches the target particle size; and washing, drying, sieving and calcining the obtained material to obtain the doped cobaltosic oxide. The doped cobaltosic oxide has a monocrystal or monocrystal-like aggregate morphology, the compaction density is obviously higher, and a guarantee is provided for synthesis of a lithium cobalt oxide positive electrode material with high energy density.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

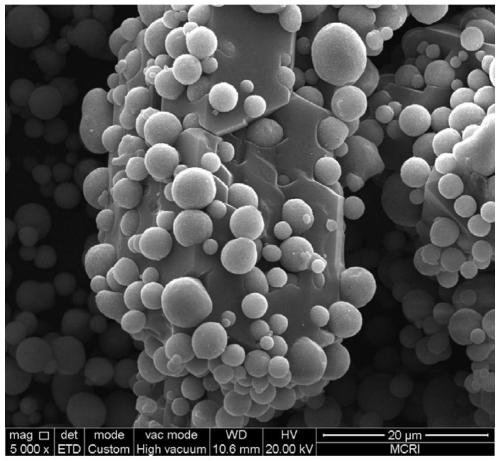

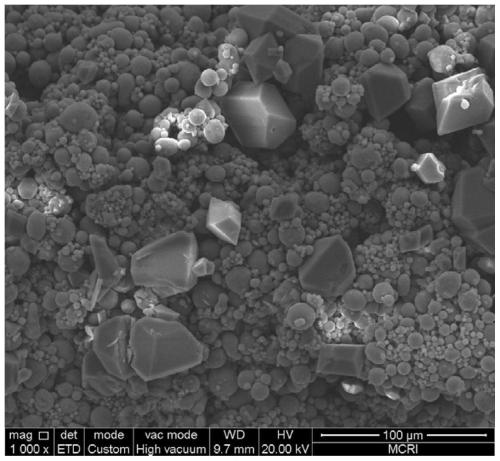

Composite energetic material with embedded structure and preparation method thereof

ActiveCN111470924AShorten the diffusion distanceHigh bulk densityExplosive ingredient compoundingFurazanExplosive Agents

The invention discloses a composite energetic material with an embedded structure and a preparation method of the composite energetic material. A 3,4-dinitrofurazan-based furazan oxide / aluminum powdercomposite energetic material with an embedded structure is prepared by adopting a solvent-non-solvent method; 3,4-dinitrofurazan-based furazan oxide is dissolved into ethyl acetate, the solution is dropwise added into n-hexane turbid liquid of aluminum powder, and the dropwise adding speed, the stirring speed and the preparation time are controlled to obtain the embedded composite energetic material. The method provided by the invention can be used for effectively reducing the diffusion distance between 3,4-dinitrofurazanyl furazan oxide and aluminum powder, the crystal morphology and the surface state of 3,4-dinitrofurazanyl furazan oxide are optimized, the prepared composite energetic material has the advantages of being high in stacking density, low in sensitivity and high in detonation heat, and the detonation heat of the 3,4-dinitrofurazanyl furazan oxide pressed aluminum-containing explosive can be effectively improved. The composite energetic material having the embedded structure is prepared from the following components in percentage by mass: 60 to 75 percent of the 3,4-dinitrofurazanyl furazan oxide and 25-40% of the aluminum powder.

Owner:XIAN MODERN CHEM RES INST

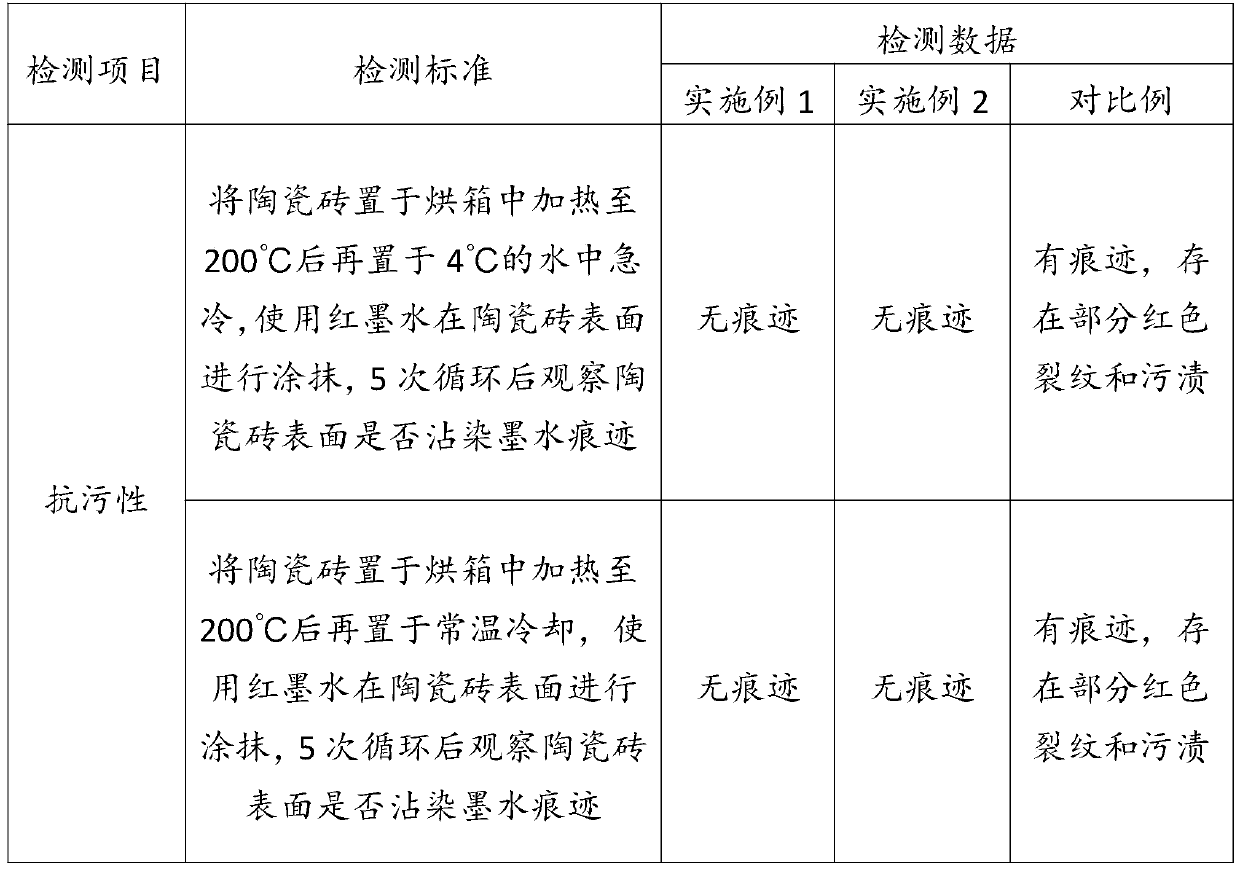

Super stain-resistant ceramic tile color-retaining glaze, stain-resistant ceramic tile and preparation process of stain-resistant ceramic tile

ActiveCN111170638ADense tissueExpand the melting rangeCeramic materials productionCalcium biphosphateGlaze

The invention discloses a super-stain-resistant ceramic tile color-retaining glaze, a stain-resistant ceramic tile and a preparation process of the stain-resistant ceramic tile. The super-stain-resistant ceramic tile color-retaining glaze is prepared from the following components in percentage by weight: 20 to 25 percent of potassium feldspar, 15 to 20 percent of albite, 6 to 15 percent of kaolin,0.5 to 3 percent of talc, 6 to 10 percent of quartz, 2 to 3 percent of zinc oxide, 2.5 to 3 percent of boron-zirconium frit, 10.5 to 20 percent of attapulgite and 5 to 9 percent of calcium phosphate;wherein the mass ratio of the boron-zirconium frit to the attapulgite to the calcium phosphate is 1: (3-6): (2-3). According to the invention, attapulgite with a layered structure is added; both theglaze and agreen body contain a large amount of bound water; during firing, the glaze discharges water; more air holes are generated in the drainage process; formed capillary channels are used for allowing gas generated in the sintering process of carbonate raw materials in the subsequent glaze to escape; the glaze continues to be heated, the components are further molten to fill and level up thecapillary channels, pores in the surface of the ceramic tile are reduced, gas generated during firing is discharged along the capillary channels, the pores of the ceramic tile are obviously reduced, the surface is smooth, and the stain-resistant effect of the super-stain-resistant ceramic tile color-retenting glaze is enhanced.

Owner:广东和陶立方陶瓷有限公司

High-toughness aluminum sheet strip for new energy automobile and production method of high-toughness aluminum sheet strip

The invention discloses a high-toughness aluminum sheet strip for a new energy automobile and a production method of the high-toughness aluminum sheet strip. The high-toughness aluminum sheet strip for the new energy automobile comprises, by weight percentage, 0.01-0.08% of Si, 0.06-0.12% of Fe, 0.001-0.02% of Cu, 0.45-0.5% of Mn, 4.1-4.3% of Mg, 0.005-0.02% of Cr, 0.002-0.005% of La, 0.002-0.005%of Ce, 0.01-0.018 % of Ti and the balance Al. The production method of the high-toughness aluminum sheet strip comprises the steps of smelting, casting, milling, soaking, heating, hot rough rolling,hot finish rolling, cold rolling, annealing, finishing and the like. The prepared aluminum sheet strip has excellent properties such as high strength, high toughness, high elongation and high indentation resistance, is smooth in surface, free of orange peels and free of cracking when the stamping depth is 300 mm and can be widely applied to inner plates and outer plates of automobiles.

Owner:河南明泰科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com