Nearly spherical core-shell structure composite energetic material and preparation method thereof

A core-shell structure, near-spherical technology, applied in the preparation of microspheres, microcapsule preparations, ammonium perchlorate compositions, etc., can solve the problems of loose bonding, low bulk density, large diffusion distance, etc. The effect of high energy levels and small diffusion distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

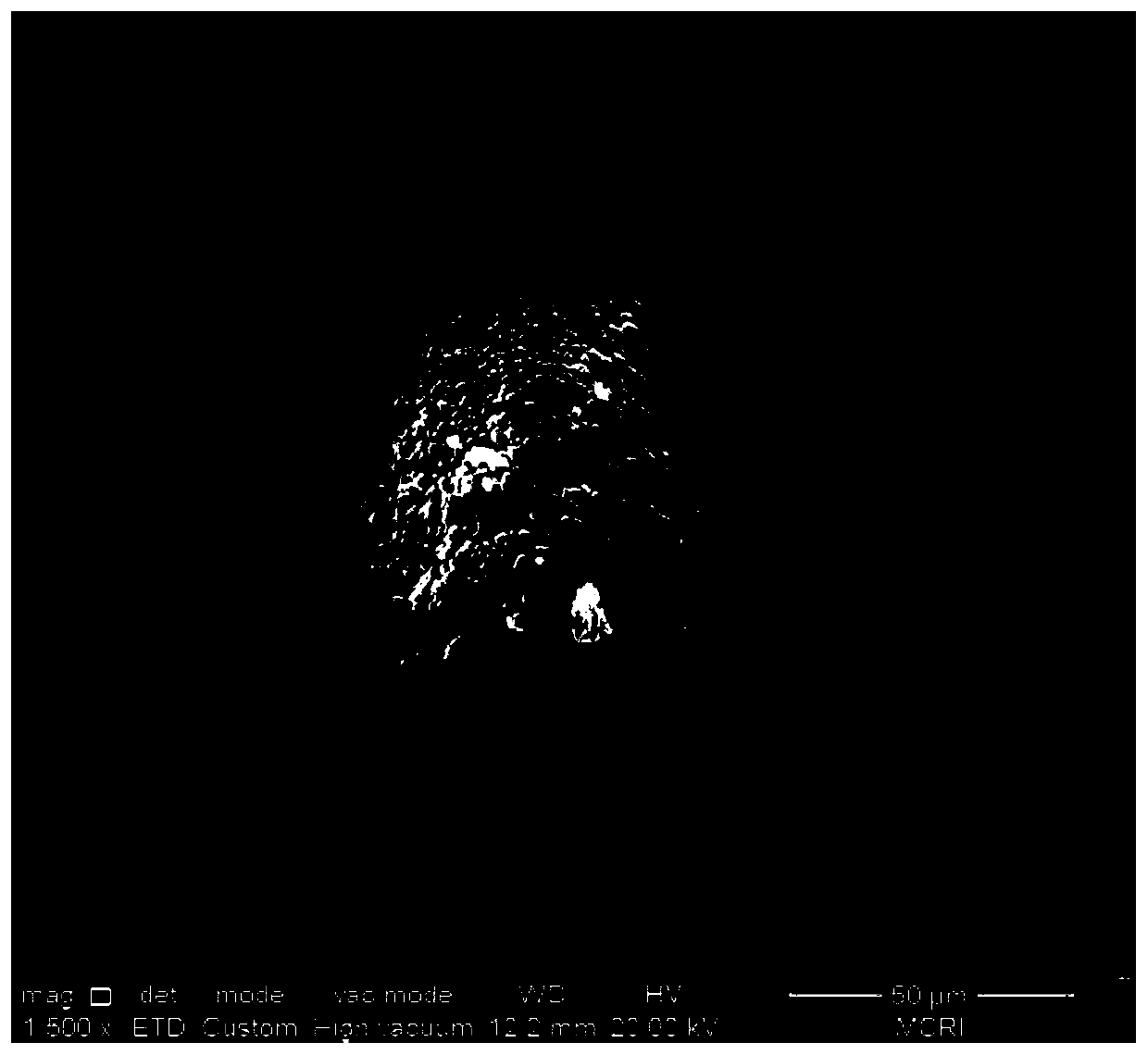

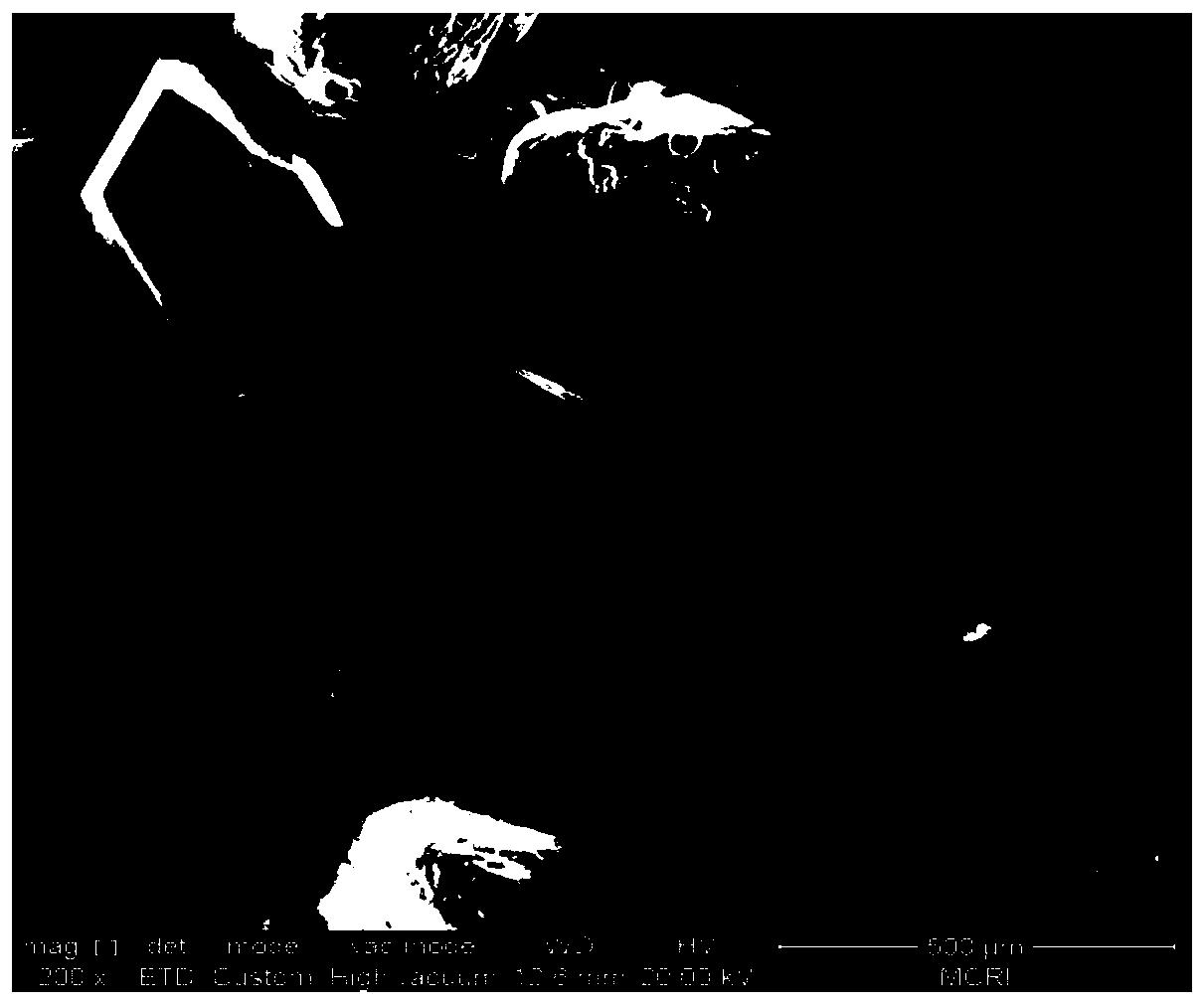

Image

Examples

Embodiment 1

[0021] This embodiment is implemented according to the following mass percentage composition: 55% of 1,1'-dihydroxy-5,5'-bistetrazole dihydroxylamine salt, and 45% of ammonium perchlorate solvent.

[0022] The preparation method of the present embodiment is as follows:

[0023] (1) Put 100g of 1,1'-dihydroxy-5,5'-dihydroxylamine salt into the colloid mill, set the colloid mill gap to 0.2mm, add 500mL of ethanol, cut for 60min, filter and dry to obtain nearly Spherical 1,1'-dihydroxy-5,5'-bistetrazolium dihydroxylamine salt sample, set aside.

[0024] (2) Weigh 45g of ammonium perchlorate and add it to 120mL of water, heat the temperature of the water bath to 70°C, stir and dissolve to form an aqueous ammonium perchlorate solution, and set aside;

[0025] (3) Weigh 55g of nearly spherical 1,1'-dihydroxy-5,5'-bistetrazolium dihydroxylamine salt, add it to the reaction kettle, and add it into a mixed solvent with a volume ratio of 120mL ethanol / 360mL ethyl acetate, mechanically ...

Embodiment 2

[0030] This embodiment is carried out with reference to the following composition by weight: 50% of 1,1'-dihydroxy-5,5'-bistetrazole dihydroxylamine salt, and 50% of ammonium perchlorate. The preparation steps refer to Example 1.

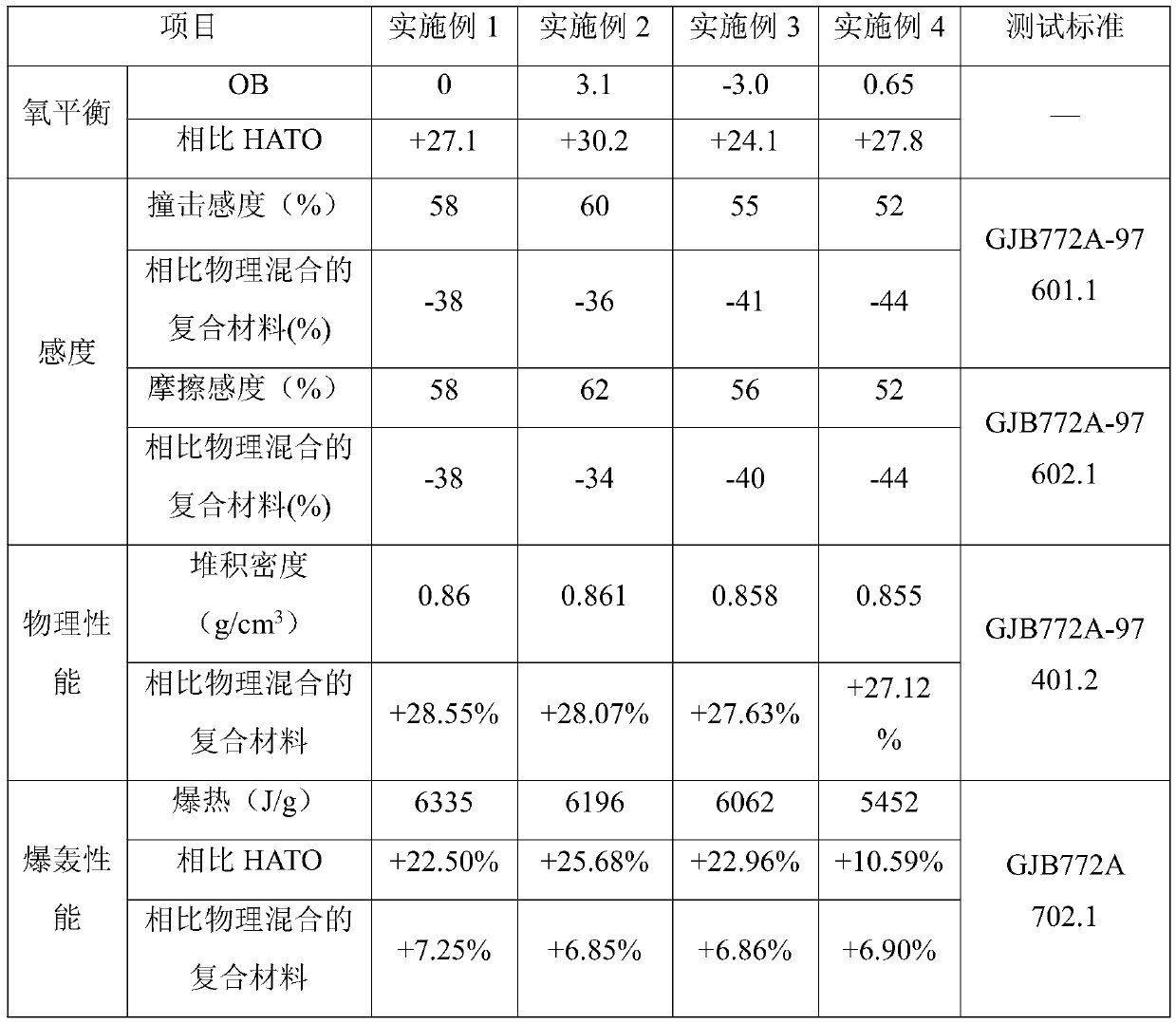

[0031] The performance test data shows that in this example, the nearly spherical 1,1'-dihydroxy-5,5'-bistetrazole dihydroxylamine salt / ammonium perchlorate core-shell structure composite energetic material is better than that of 1,1'-dihydroxy -5,5'-bistetrazole dihydroxylamine salt increased by 25.68%, the sensitivity was significantly lower than that of physically mixed composite materials, the bulk density was increased by 28.07%, and the explosive heat was increased by 6.85%.

Embodiment 3

[0033] This embodiment is carried out according to the following mass percentage composition: 60% of 1,1'-dihydroxy-5,5'-bistetrazole dihydroxylamine salt, and 40% of ammonium perchlorate. The preparation steps refer to Example 1.

[0034] The performance test data shows that in this example, the nearly spherical 1,1'-dihydroxy-5,5'-bistetrazole dihydroxylamine salt / ammonium perchlorate core-shell structure composite energetic material is better than that of 1,1'-dihydroxy -5,5'-bistetrazole dihydroxylamine salt increased by 22.96%, the sensitivity was significantly lower than the physically mixed composite material, the bulk density was increased by 27.63%, and the explosive heat was increased by 6.86%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com