Anchorage device clamping piece blank cold extrusion process

A cold extrusion and clamping technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of high clamping cost, low material utilization rate, large processing volume, etc., so as to improve the material utilization rate and reduce the The effect of machining volume and clip cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

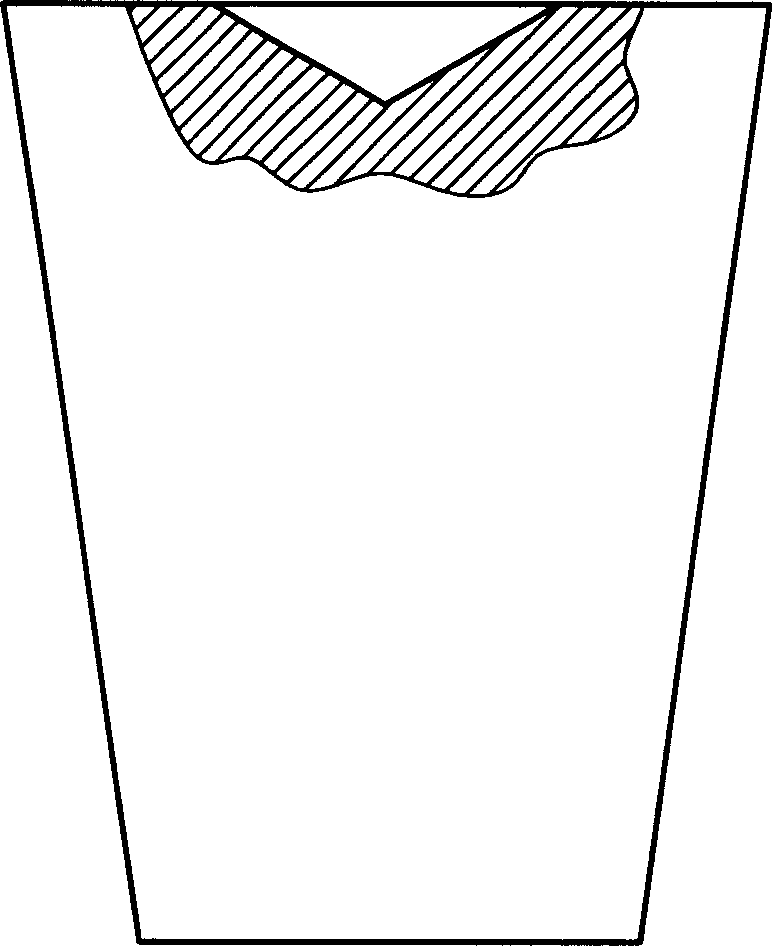

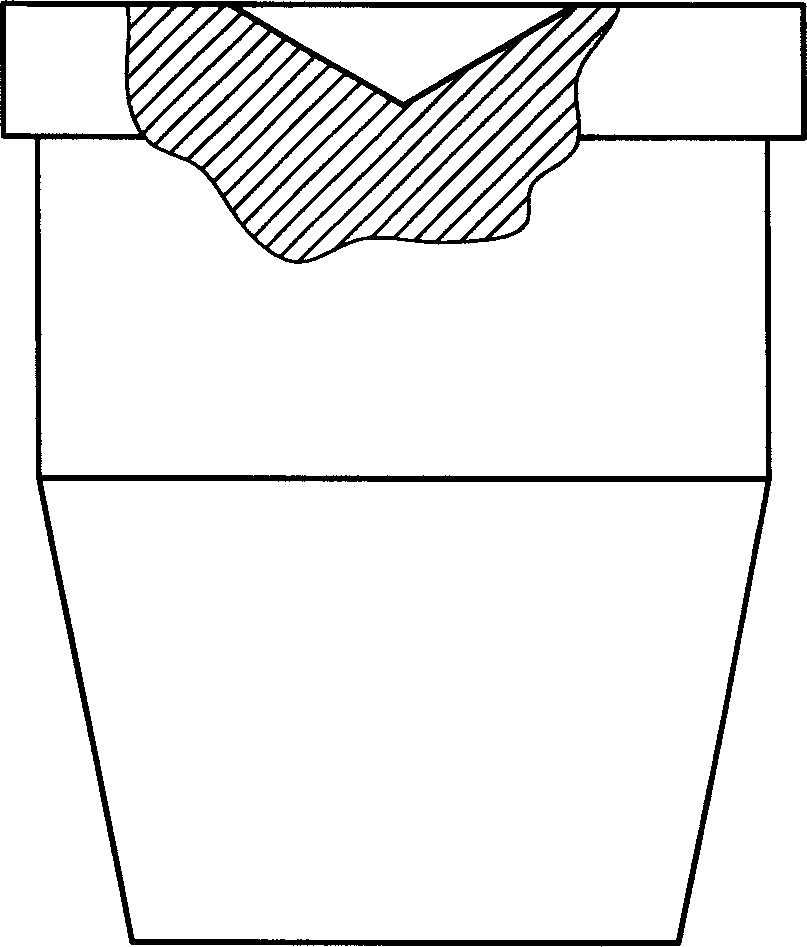

[0023] The present invention can be cold-extruded by one-time cold-extrusion forming process. If the pressure of the press is small, it can also be cold-extruded by secondary cold extrusion process.

[0024] 1. One-time cold extrusion molding process:

[0025] After selecting the round bar stock:

[0026] (1), blanking, if necessary, saw the round bar material into the required length;

[0027] (2), deburring, deburring as much as possible;

[0028] (3) Annealing, heat preservation at a furnace temperature of 550°C-850°C±20°C for no less than 1 hour, and cool with the furnace to below 500°C in air;

[0029] (4), phosphating saponification;

[0030] (5), forming, stamping forming with punch press.

[0031] In this embodiment, the material preparation is to use the round bar material 20GmnTi of Φ20-30 to prepare the material; when cutting the material, the length of the material is Φ26 (+0.4, -0.1) × 35.8 (+0.3, -0.3) The beating degree at both ends is not greater than 0.6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com