Narrow-distribution small-particle-size nickel-cobalt-aluminum hydroxide and preparation method thereof

A technology of hydroxide and nickel-cobalt-aluminum, which is applied in the preparation of aluminum hydroxide, aluminum oxide/aluminum hydroxide, nickel compounds, etc., can solve the problem of difficult spherical large particle precipitation, unsatisfactory NCA material performance indicators, and unsatisfactory effects, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

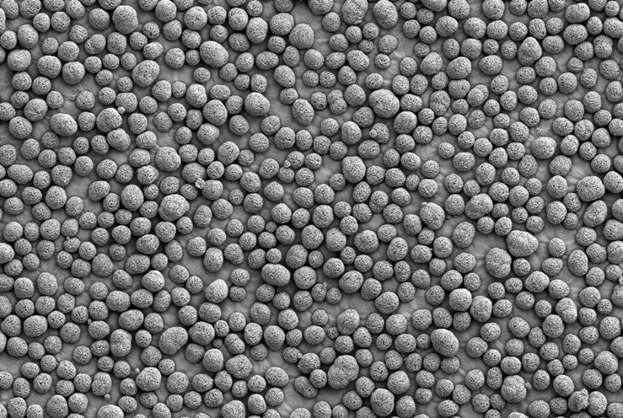

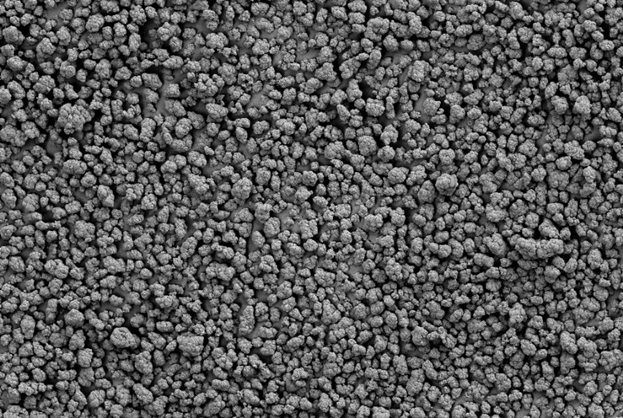

[0037] A narrow distribution of small particle size nickel cobalt aluminum hydroxide, the narrow distribution of small particle size nickel cobalt aluminum hydroxide is spherical or quasi-spherical particles, the narrow distribution of small particle size nickel cobalt aluminum hydroxide particles It consists of an inner core and an outer shell layer, the inner core of the particle is aluminum hydroxide, and the outer shell layer is composed of the general formula Ni 0.9 Co 0.07 Al 0.03 (OH) 2.03It means that the skeleton of the grain cation layer of the outer shell layer contains nickel, cobalt, and aluminum elements. The nickel-cobalt-aluminum hydroxide particles have the characteristics of narrow distribution, K90=(D90-D10) / D50≤0.90, D50 is 3.6μm, and the preparation method is as follows:

[0038] Step 1, according to the required molar ratio of nickel, cobalt and aluminum elements, that is, 0.9:0.07:0.03, select nickel sulfate, cobalt sulfate, aluminum sulfate as raw ma...

Embodiment 2

[0049] A narrow distribution of small particle size nickel cobalt aluminum hydroxide, the narrow distribution of small particle size nickel cobalt aluminum hydroxide is spherical or quasi-spherical particles, the narrow distribution of small particle size nickel cobalt aluminum hydroxide particles It consists of an inner core and an outer shell layer, the inner core of the particle is aluminum hydroxide, and the outer shell layer is composed of the general formula Ni 0.88 Co 0.09 Al 0.03 (OH) 2.03 It means that the skeleton of the grain cation layer of the outer shell layer contains nickel, cobalt, and aluminum elements. The nickel-cobalt-aluminum hydroxide particles have the characteristics of narrow distribution, K90=(D90-D10) / D50≤0.90, D50 is 5.7μm, and the preparation method is as follows:

[0050] Step 1, according to the required molar ratio of nickel, cobalt and aluminum elements, that is, 0.88:0.09:0.03, select nickel chloride, cobalt chloride and aluminum chloride ...

Embodiment 3

[0061] A narrow distribution of small particle size nickel cobalt aluminum hydroxide, the narrow distribution of small particle size nickel cobalt aluminum hydroxide is spherical or quasi-spherical particles, the narrow distribution of small particle size nickel cobalt aluminum hydroxide particles It consists of an inner core and an outer shell layer, the inner core of the particle is aluminum hydroxide, and the outer shell layer is composed of the general formula Ni 0.92 Co 0.06 Al 0.02 (OH) 2.02 It means that the skeleton of the grain cation layer of the outer shell layer contains nickel, cobalt, and aluminum elements. The nickel-cobalt-aluminum hydroxide particles have the characteristics of narrow distribution, K90=(D90-D10) / D50≤0.90, D50 is 2.5μm, and the preparation method is as follows:

[0062] Step 1, according to the required molar ratio of nickel, cobalt, and aluminum elements, that is, 0.92:0.06:0.02, select nickel nitrate, cobalt nitrate, and aluminum nitrate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com