Patents

Literature

34results about How to "Grain stabilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

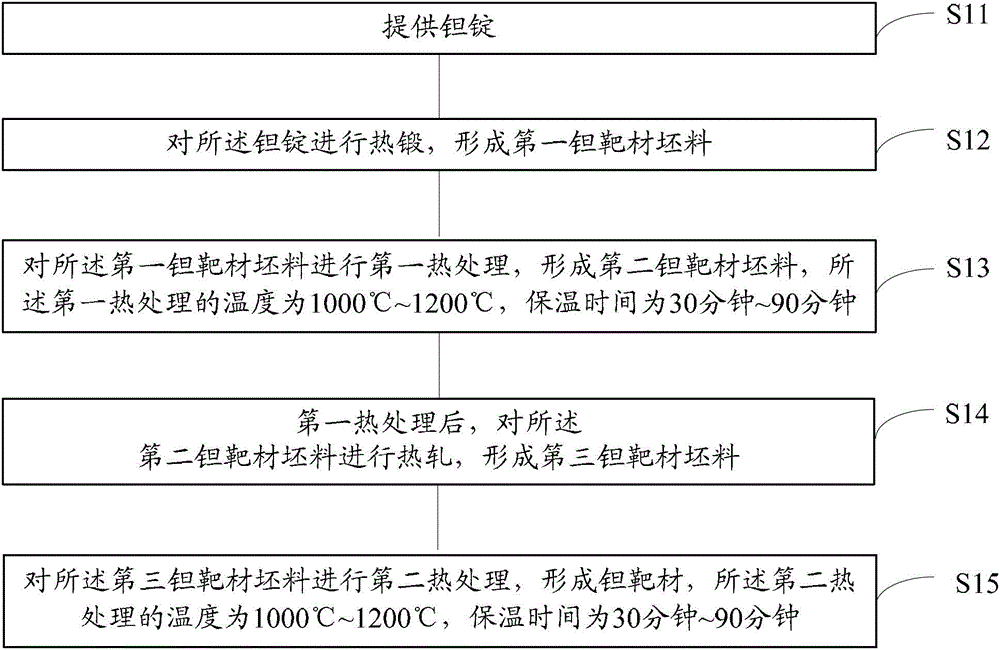

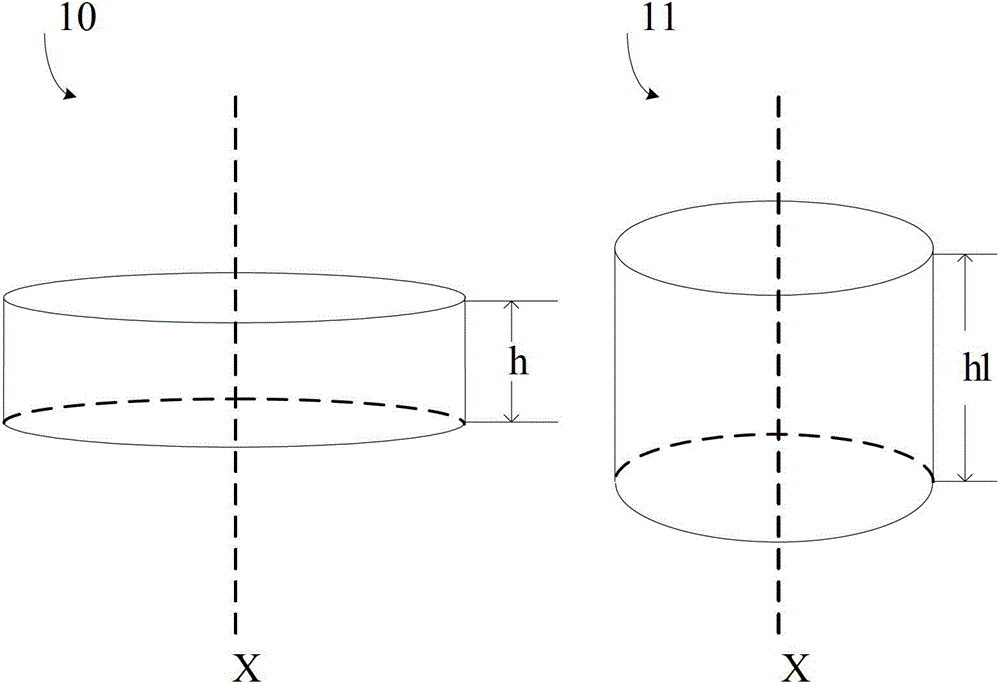

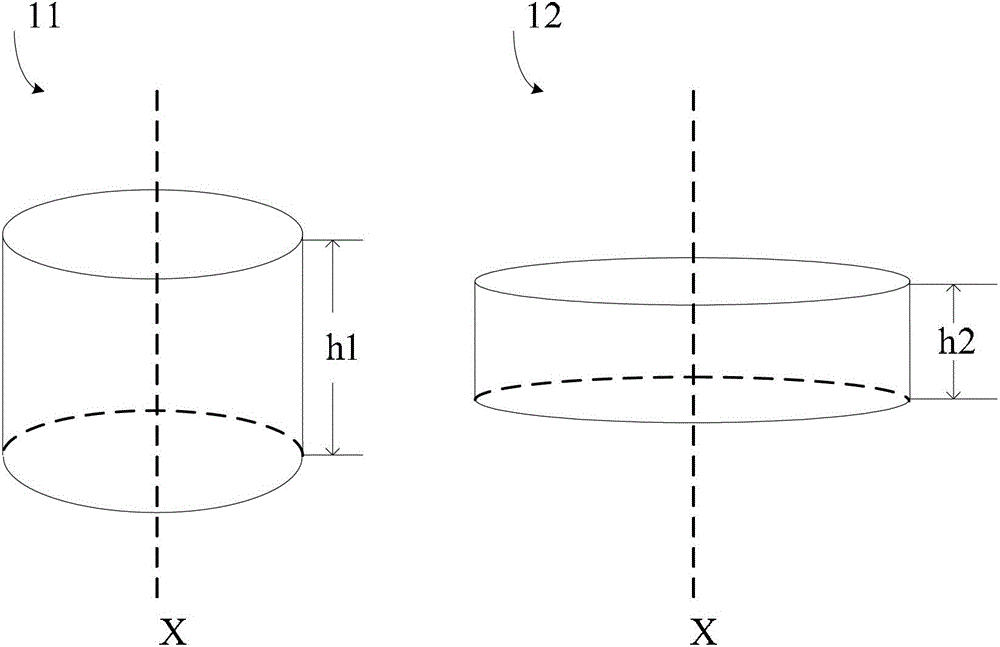

Production method of tantalum target and tantalum target component

ActiveCN103572225ADense tissueReduce unevennessVacuum evaporation coatingSputtering coatingIngotSemiconductor

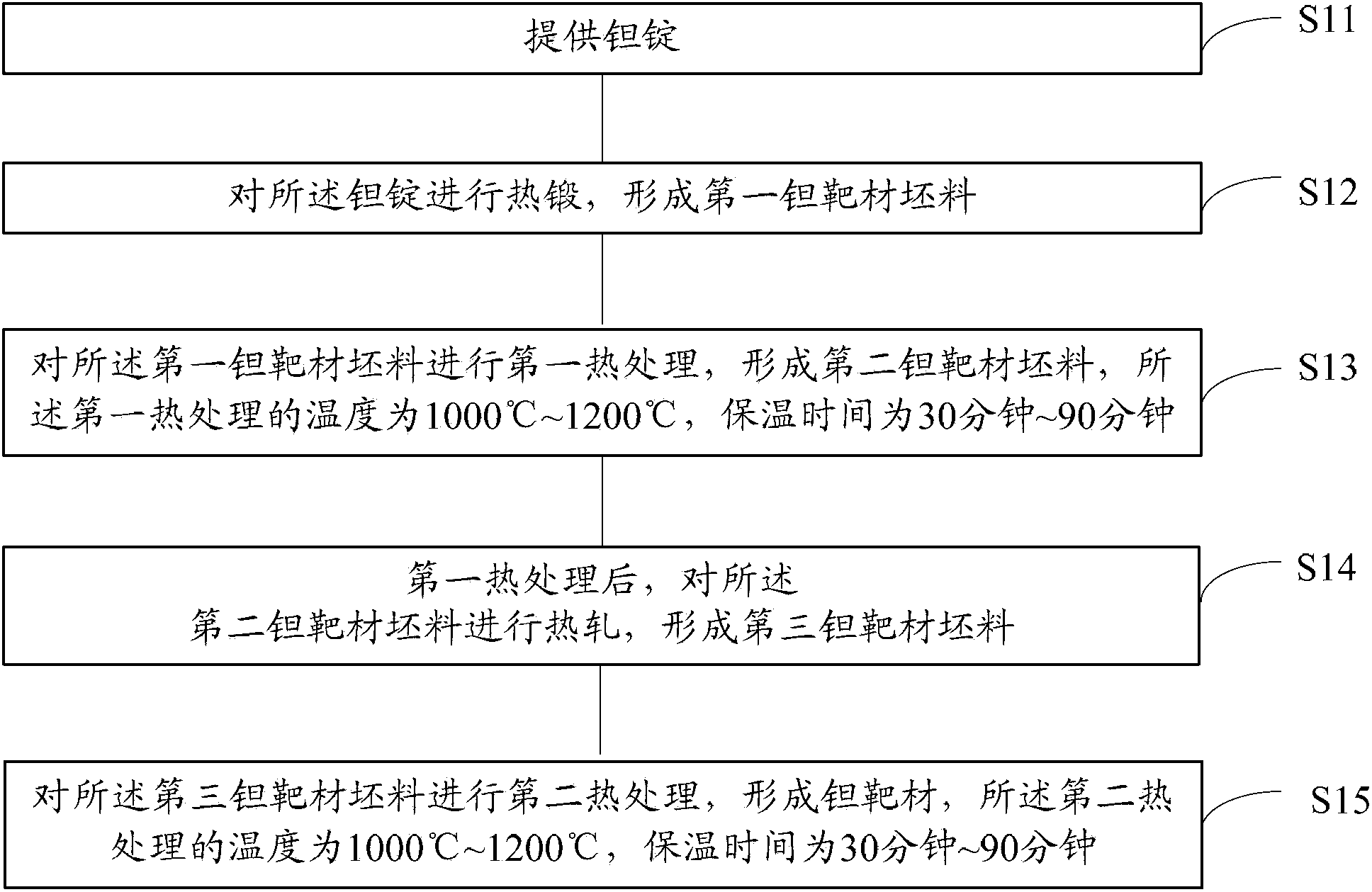

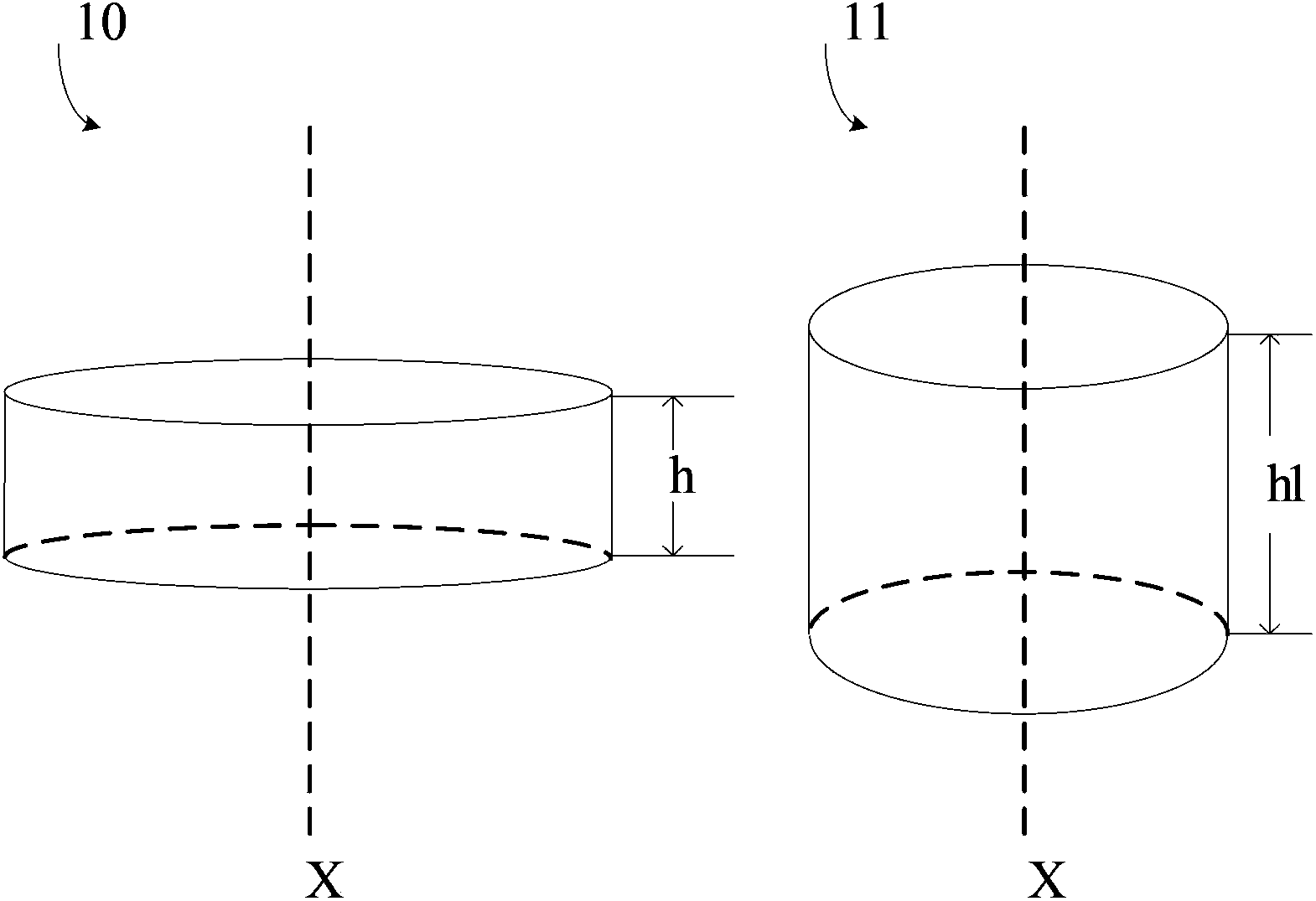

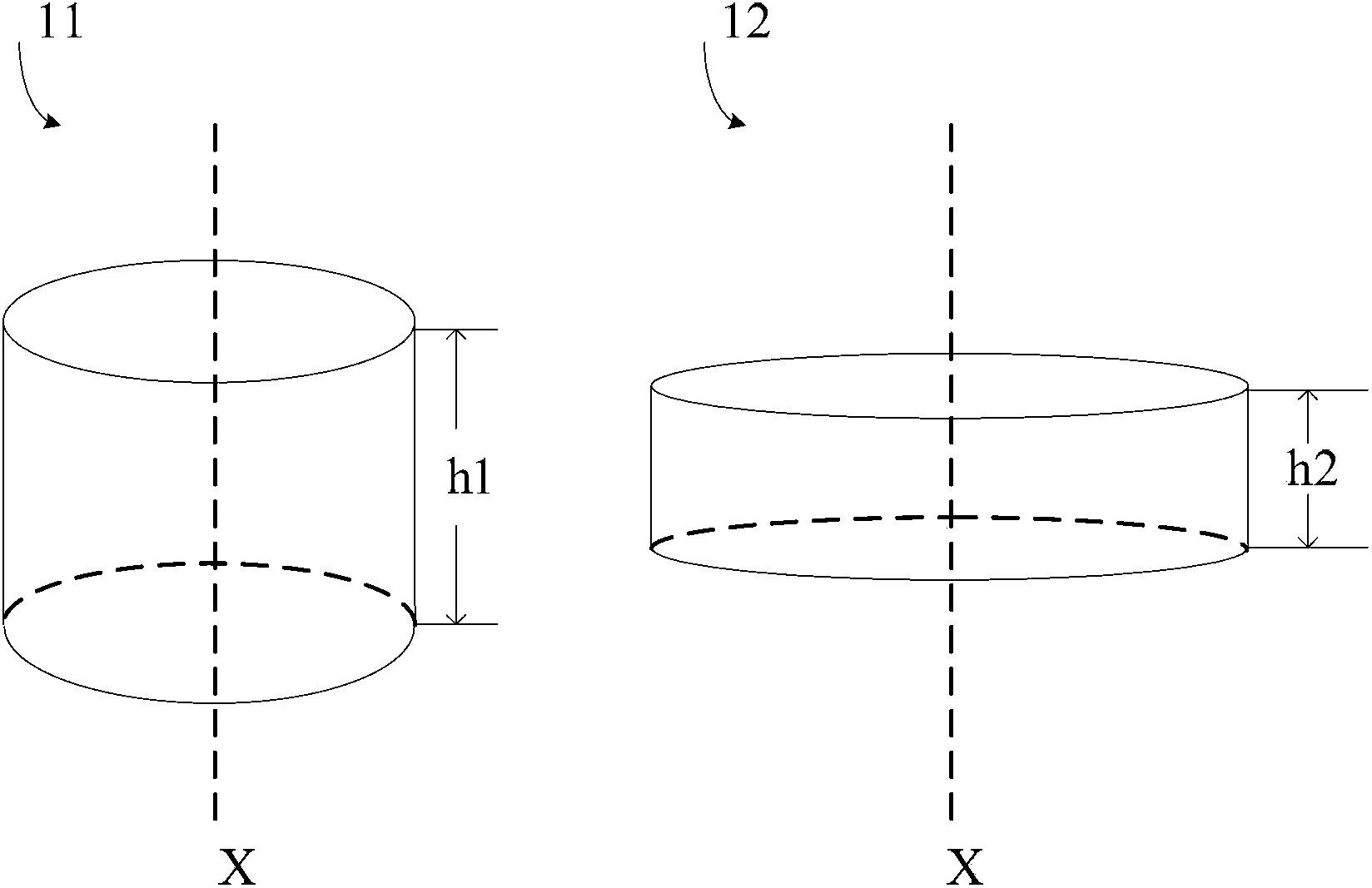

The invention provides a production method of a tantalum target and a tantalum target component. The production method of a tantalum target comprises the following steps of providing a tantalum ingot; performing hot forging on the tantalum ingot to form a first tantalum target blank; performing first heat treatment on the first tantalum target blank to form a second tantalum target blank, wherein the temperature of the first heat treatment is 1,000-1,200 DEG C, and the temperature is maintained for 30-90 minutes; after the first heat treatment, performing hot rolling on the second tantalum target material to form a third tantalum target blank; performing second heat treatment on the third tantalum target blank to form the tantalum target, wherein the temperature of the second heat treatment is 1,000-1,200 DEG C, and the temperature is maintained for 30-90 minutes. By adopting the technical scheme, the produced tantalum target has relatively uniform internal organization and good magnetic property; moreover, by adopting the tantalum target to produce a tantalum target component for a semiconductor, the formed film has relatively good quality.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

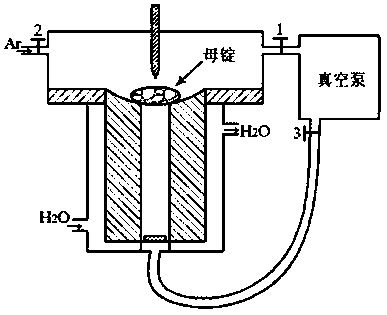

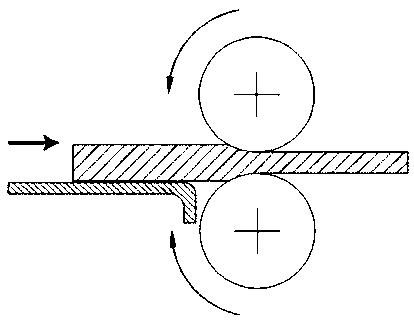

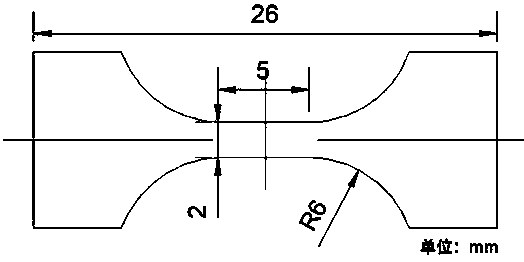

Method for improving Al0.3CoCrFeNi high-entropy alloy intensity

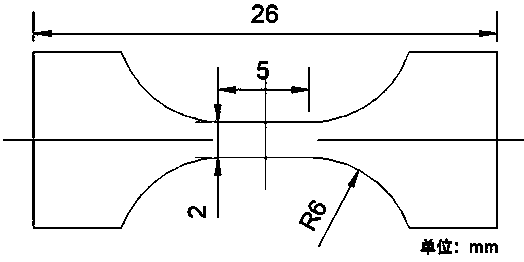

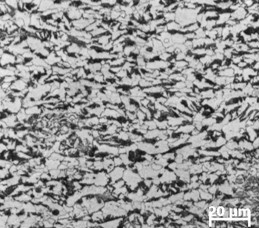

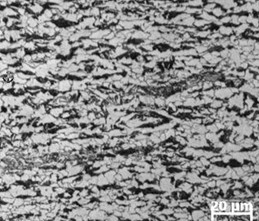

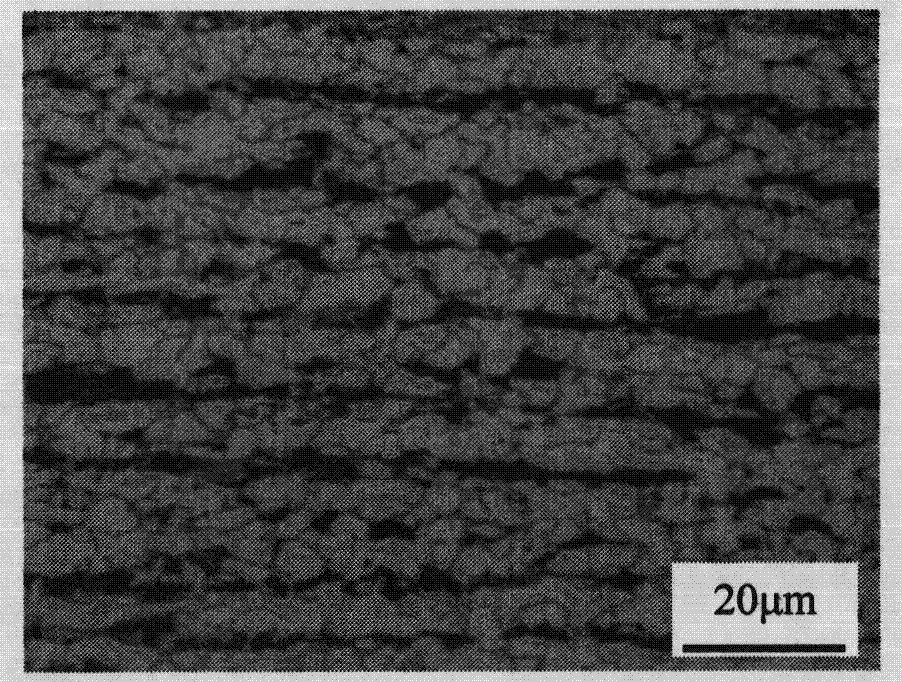

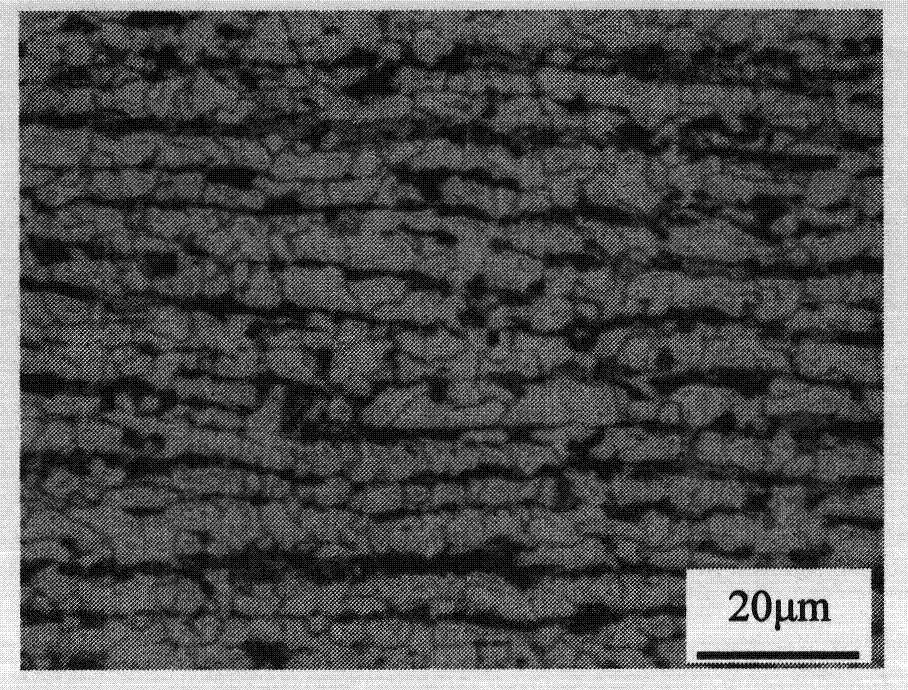

ActiveCN109797303AFine grain boundaryUniform tissueVacuum evaporation coatingSputtering coatingHigh entropy alloysWire cutting

The invention discloses a method for improving Al0.3CoCrFeNi high-entropy alloy intensity. Five kinds of analytical pure metals of Al, Co, Cr, Fe and Ni are blended according to the atomic ratio of 0.3 to 1 to 1 to 1 to 1, smelting is carried out in a vacuum arc melting furnace, the molten alloy is subjected to suction casting to form plate-shaped high-entropy alloy materials with 2mm thickness, 10mm width and 85mm length, and then a high-entropy alloy is subjected to cold rolling and annealing heat treatment to eliminate the residual internal stress, generated in the casting process, of the high-entropy alloy; and then a wire cutting machine is used for cutting bone-shaped standard tensile samples with a standard distance of 5mm, the front faces and back faces and the two side faces of the tensile samples are polished, and the polished samples are subjected to a double-glow chromizing test by using a double-glow metal furnace, and finally, the obtained samples are strengthened high-entropy alloy samples. According to the method for improving the Al0.3CoCrFeNi high-entropy alloy intensity, through a double-glow chromizing technology, the friction coefficient of the high-entropy alloy is reduced, and the amplitude is greatly reduced.

Owner:TAIYUAN UNIV OF TECH

Preparation method of boron-containing structural steel

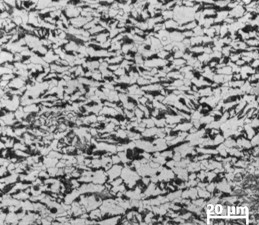

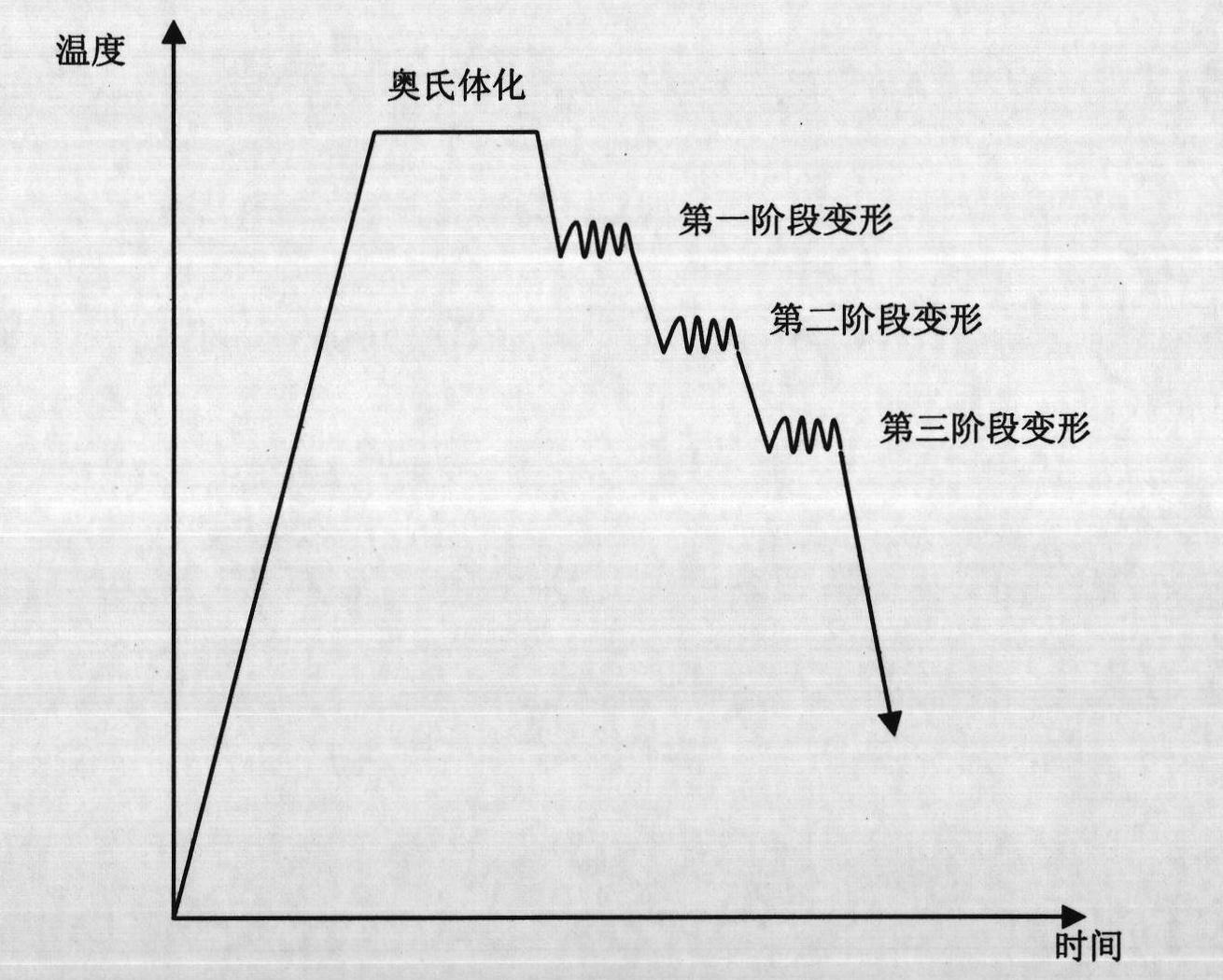

InactiveCN102080179AImprove performanceSimple rolling process and cooling processTemperature control devicePearliteChemical composition

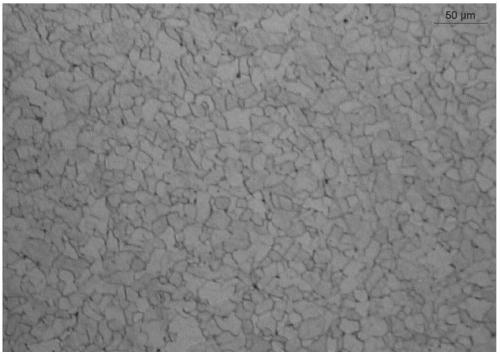

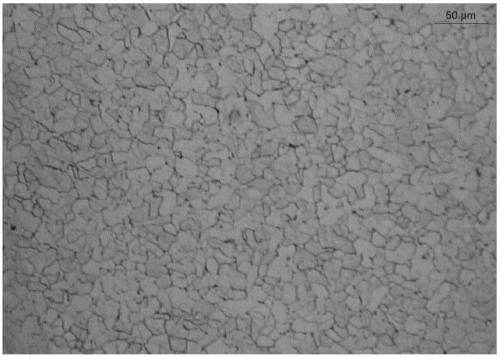

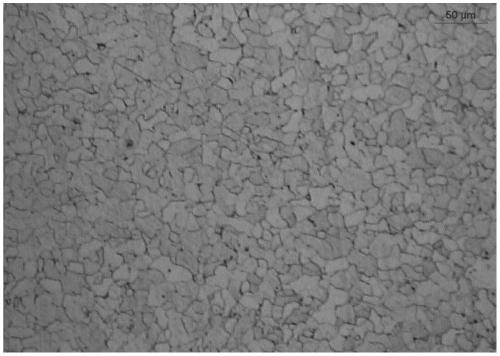

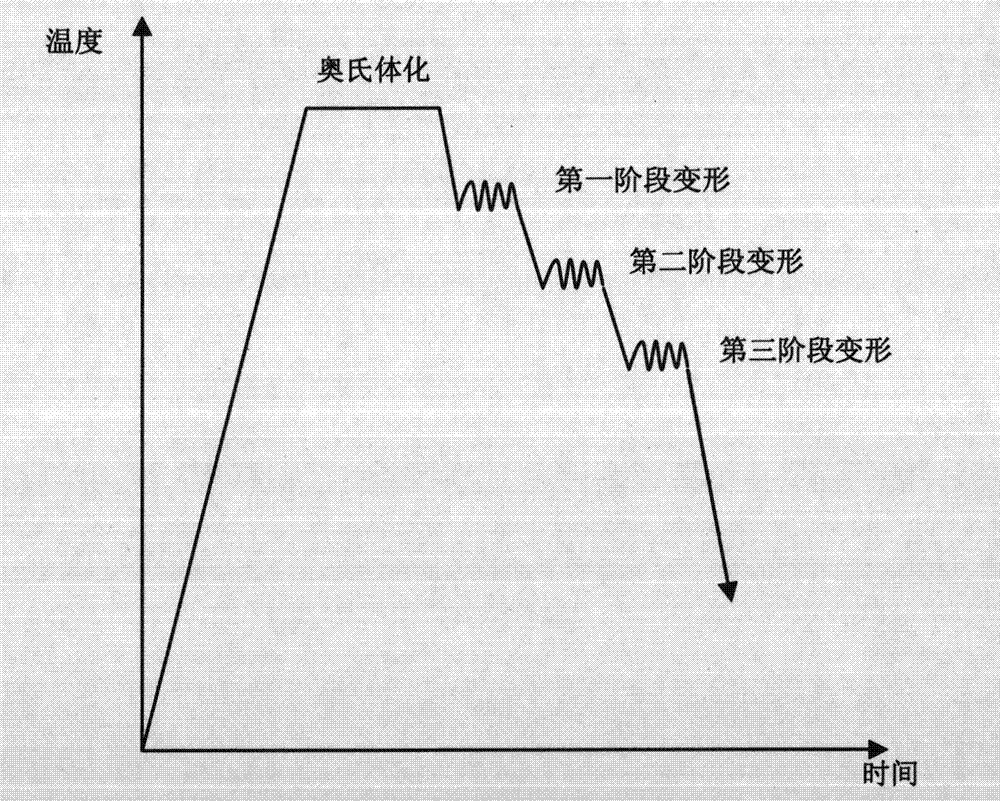

The invention discloses a preparation method of boron-containing structural steel. The boron-containing structural steel comprises the following chemical components by weight percent: 0.08-0.20% of C, 0.10-0.30% of Si, 0.80-1.50% of Mn, no more than 0.010% of P, no more than 0.010% of S, 0.0008-0.0030% of B and the balance of Fe and inevitable impurities. The preparation method comprises the following specific steps: heating to 1175-1225 DEG C for austenitization, and then performing multipass rolling, wherein the deformation temperature is between the austenitic recrystallization region and austenitic unrecrystallization region and the austenite-ferrite two-phase region; and then cooling to 600-660 DEG C at a cooling rate of 1-10 DEG C / s, and then performing air cooling. The boron-containing structural steel prepared by the method provided by the invention mainly contains ferrite, bainite and a small amount of pearlite. The structural steel has the advantages of uniform structure, fine grain and good strength and toughness.

Owner:NANJING IRON & STEEL CO LTD

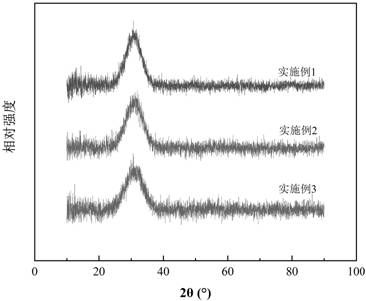

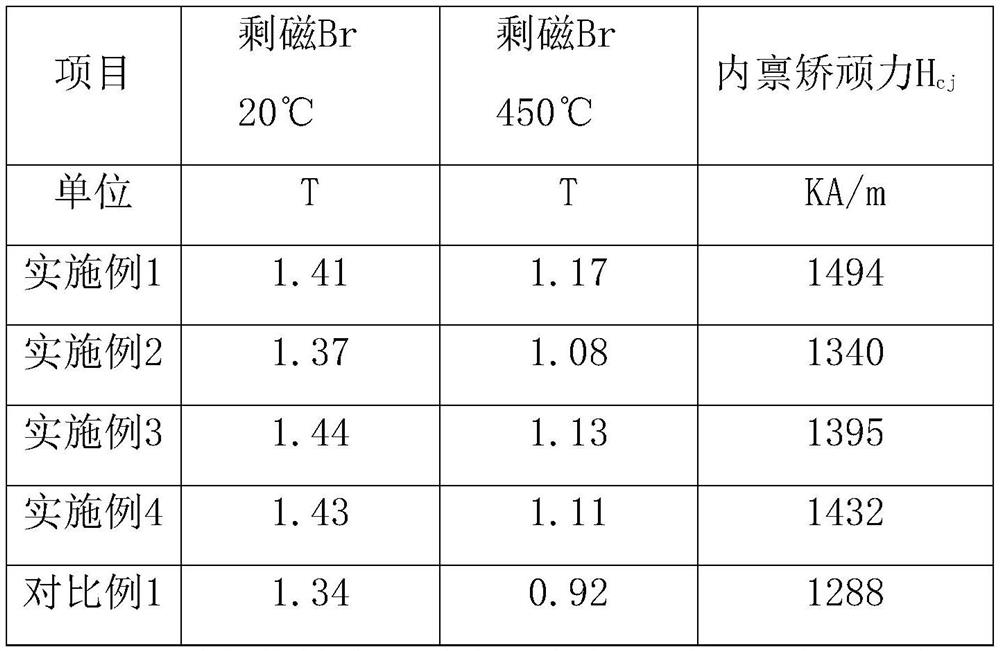

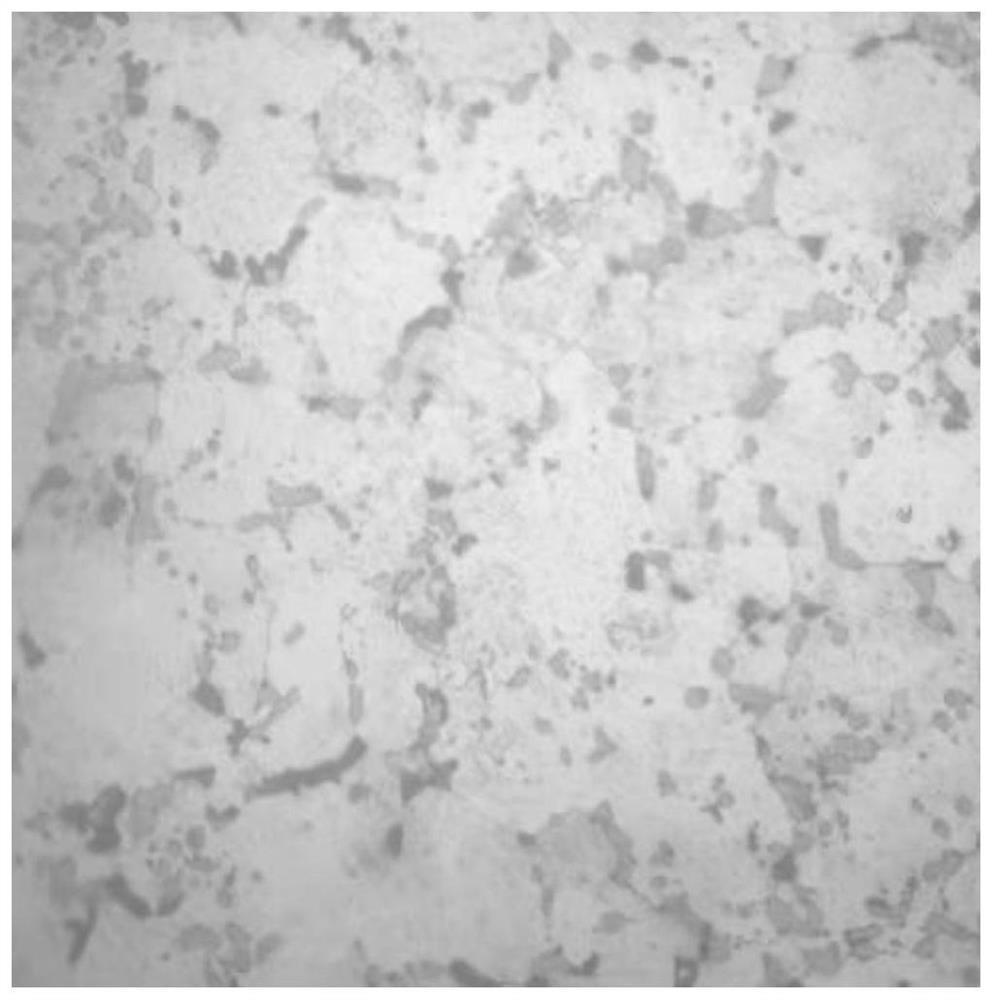

Neodymium iron boron permanent magnet material and preparation method thereof

ActiveCN108364736AImprove magnetic and mechanical propertiesUniform grainInorganic material magnetismAluminiumMachinability

The invention relates to the technical field of permanent magnet materials, in particular to a neodymium iron boron permanent magnet material and a preparation method thereof. The neodymium iron boronpermanent magnet material is prepared from, by mass, 21.85%-24.15% of neodymium, 0.91%-1.01% of boron, 7.5%-8.5% of praseodymium, 0.6%-0.8% of aluminum, 0.55%-0.65% of dysprosium, 0.15%-0.25% of gallium,0.13%-0.17% of copper, 0.11%-0.13% of zirconium, 1%-6% graphene and the balance iron. The preparation method of the material comprises the steps that raw materials except graphene, copper and aluminum are subject to smelting and ingot casting in advance and then are proportionally mixed with nano copper powder, nano aluminum powder and nano graphene sheets, the mixture is put in an oriented magnetic field for pressing and formation, and sintering is performed after isostatic pressing. The preparation method is simple in process, easy to control, the product performance is superior, the product quality is stable, and the prepared neodymium iron boron permanent magnet material is good in corrosivity, high in mechanical strength and good in machinability.

Owner:DONGGUAN JINCONN NEW MATERIAL CO LTD

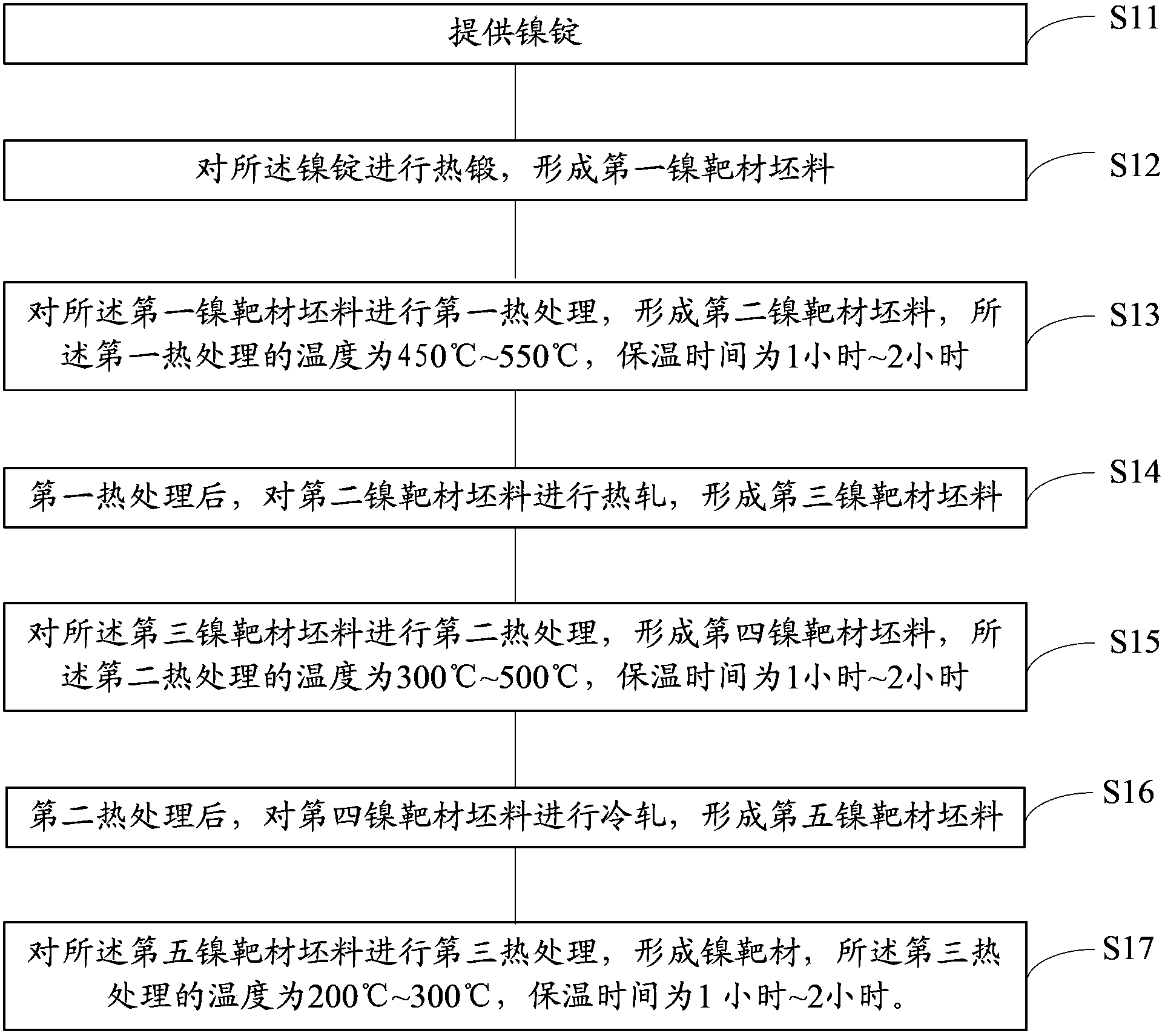

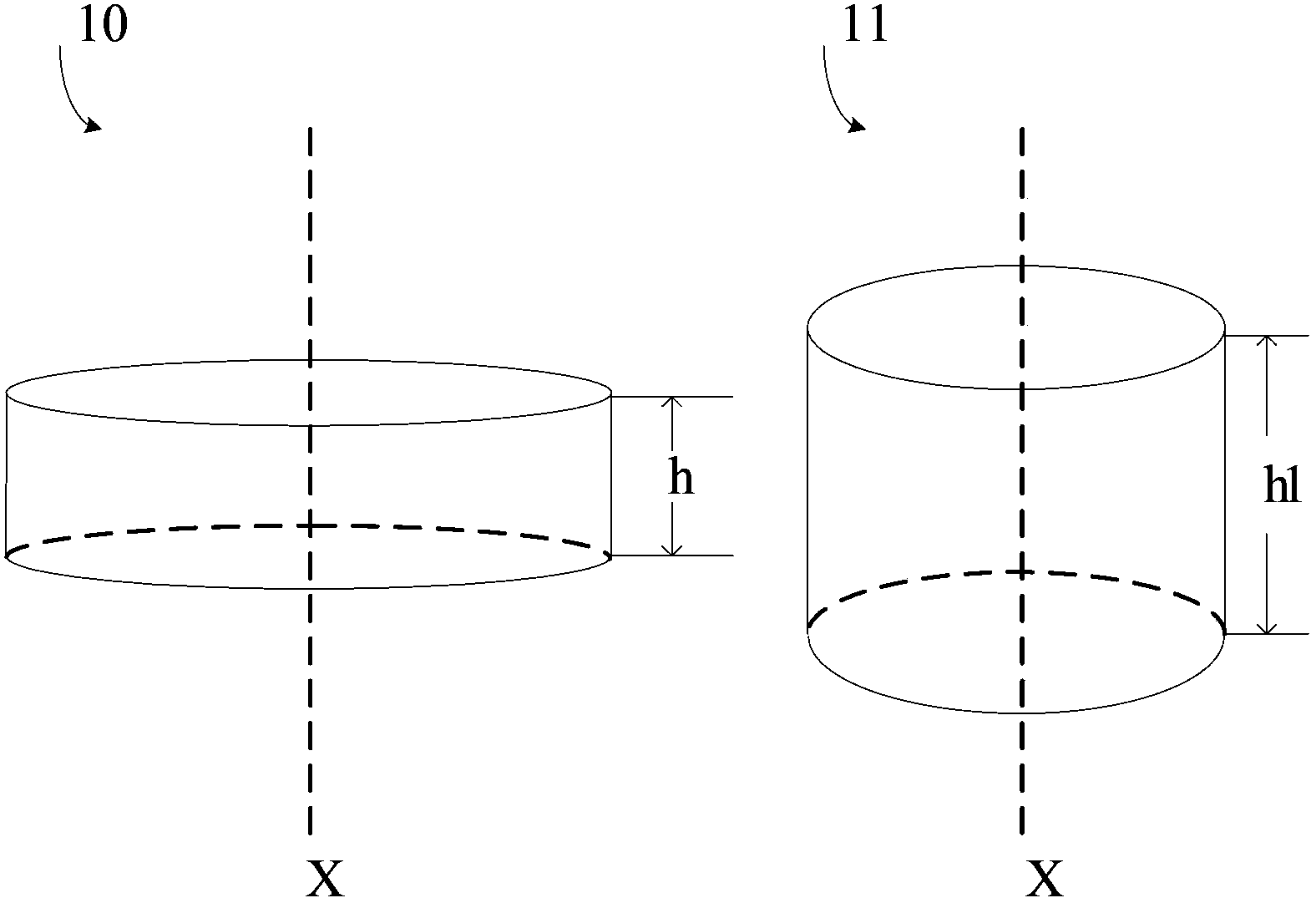

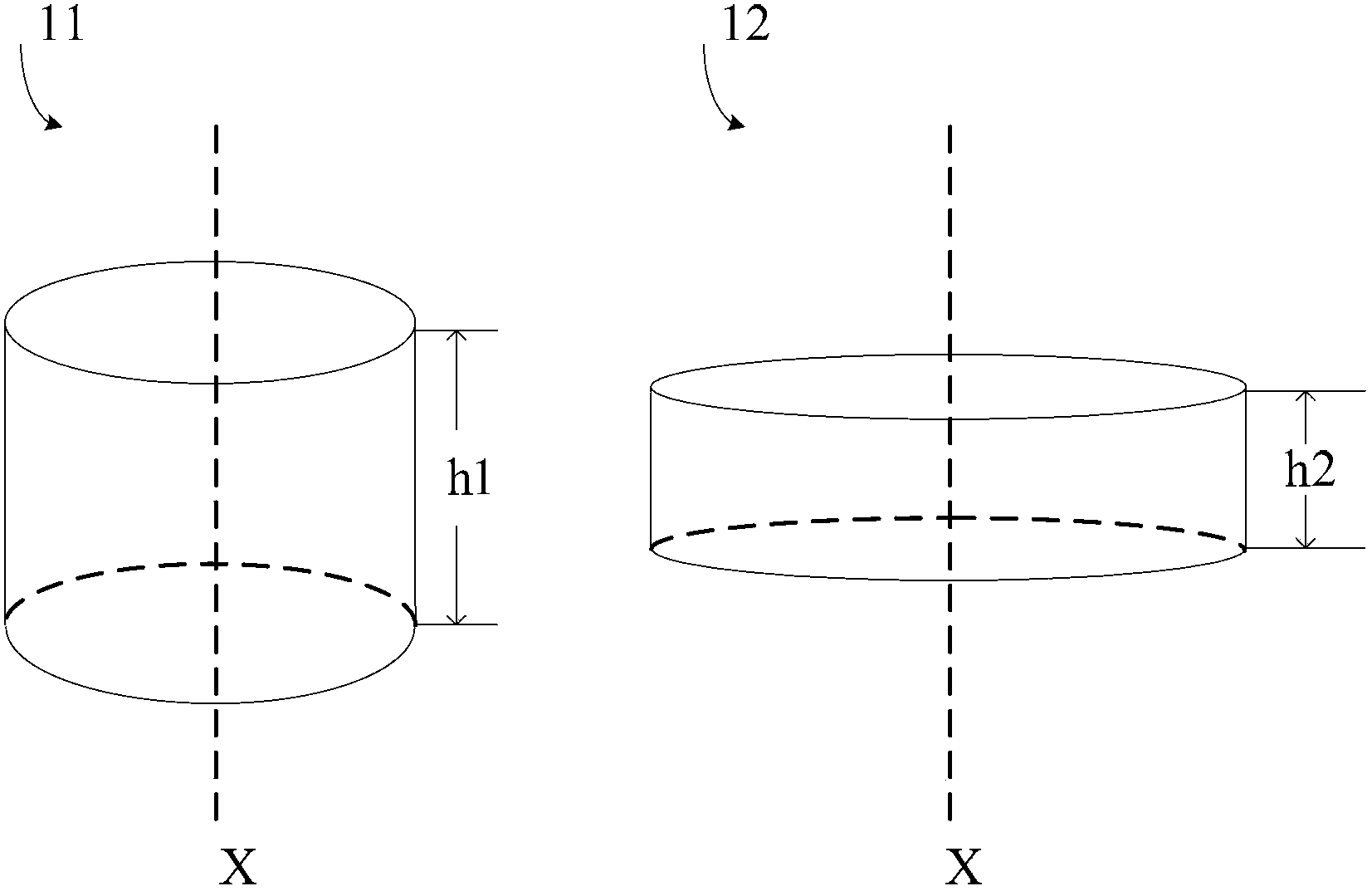

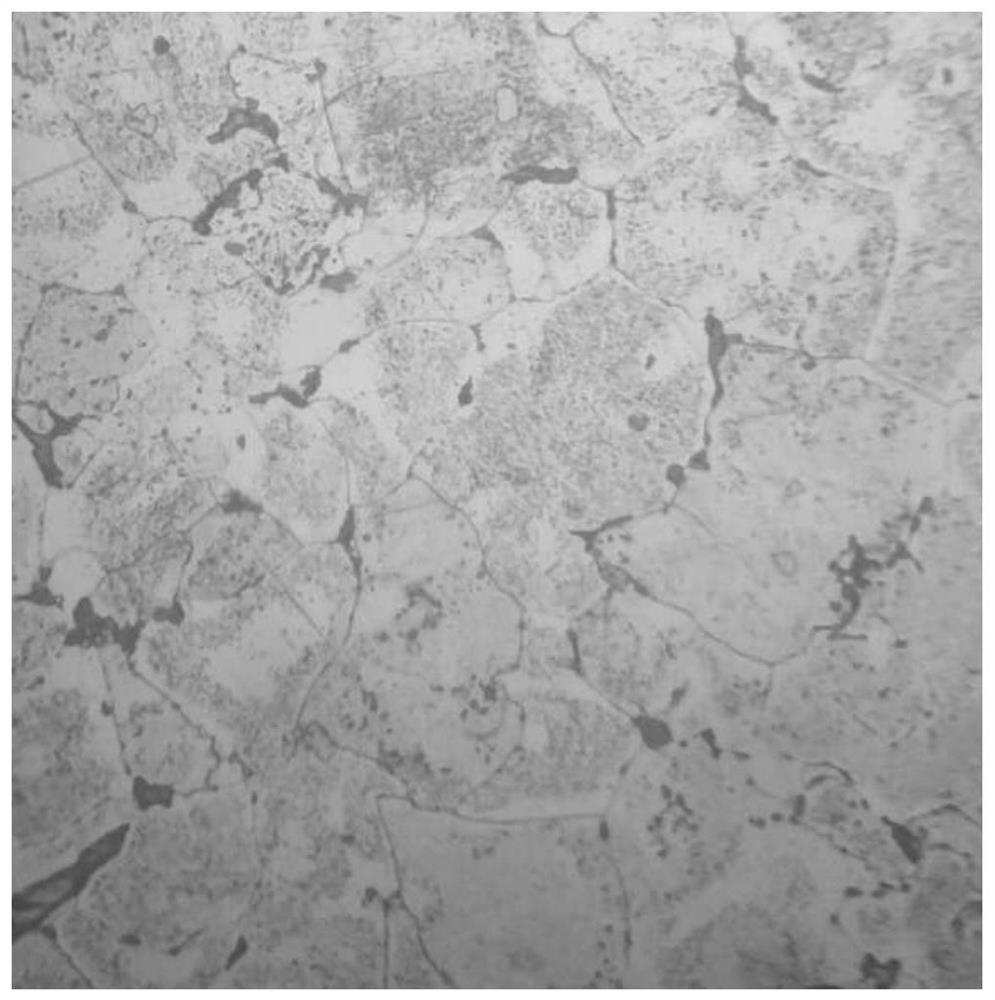

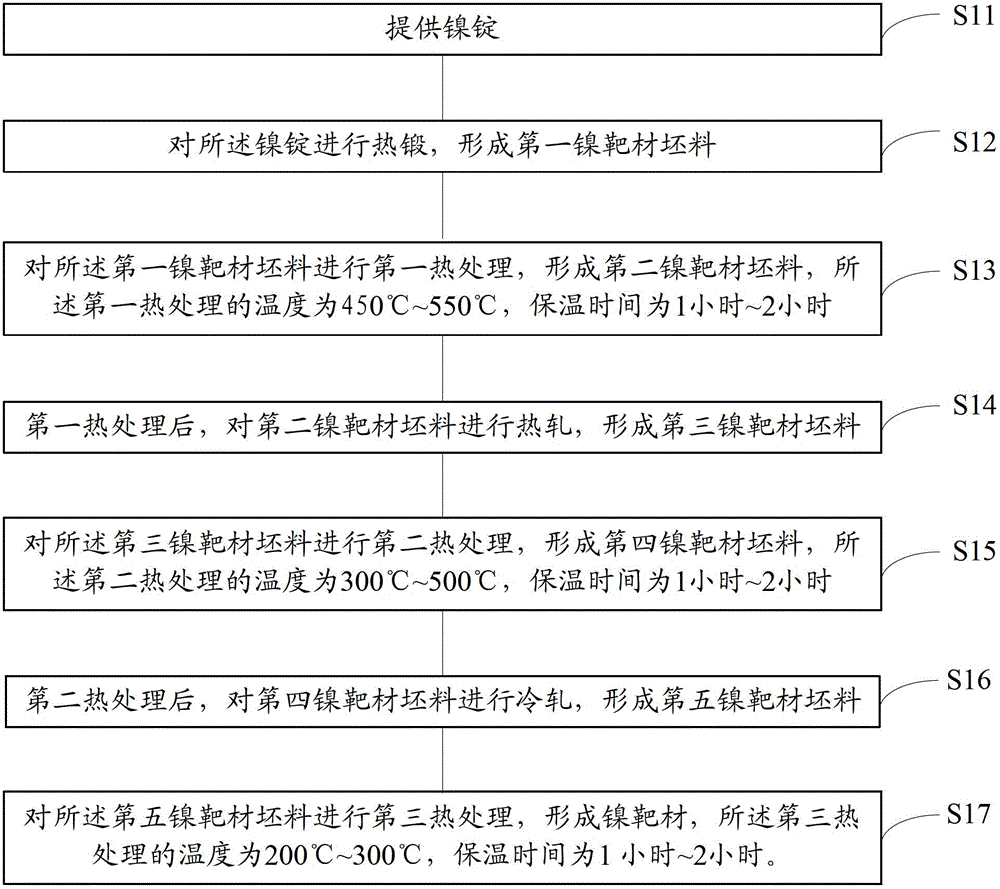

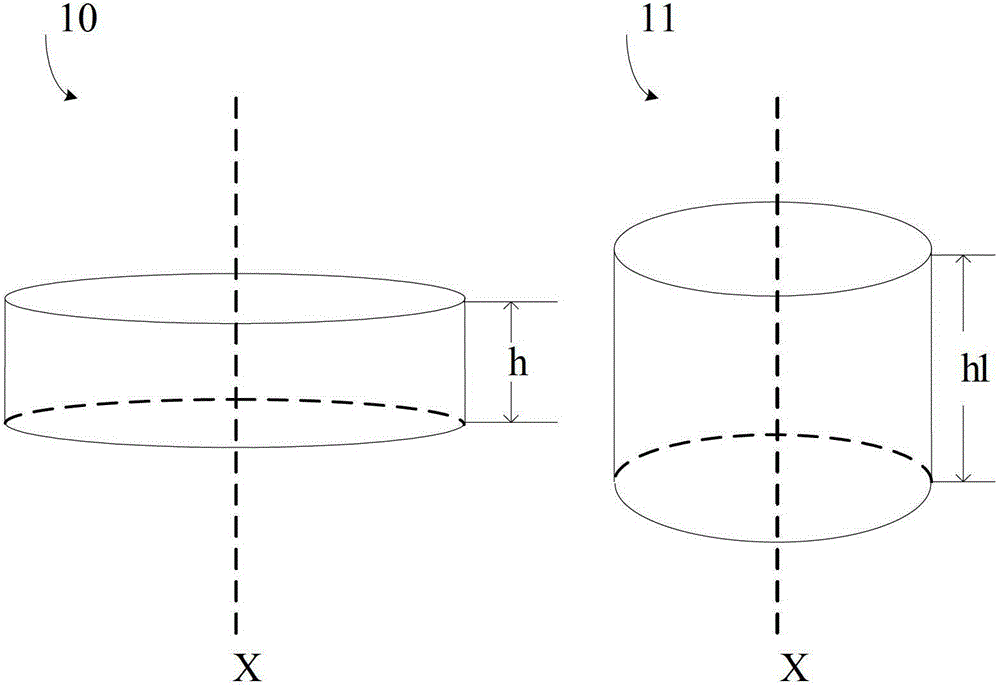

Production method of nickel target and nickel target component

ActiveCN103572224ADense tissueReduce hardnessVacuum evaporation coatingSputtering coatingIngotMaterials science

The invention provides a production method of a nickel target and a nickel target component. The production method of the nickel target comprises the following steps of providing a nickel ingot; performing hot forging on the nickel ingot to form a first nickel target blank; performing first heat treatment on the first nickel target blank to form a second nickel target blank, wherein the temperature of the first heat treatment is 450-550 DEG C, and the temperature is maintained for 1-2 hours; after the first heat treatment, performing hot rolling on the second nickel target blank to form a third nickel target blank; performing second heat treatment on the third nickel target blank to form a fourth nickel target blank, wherein the temperature of the second heat treatment is 300-500 DEG C, and the temperature is maintained for 1-2 hours; after the second heat treatment, performing cold rolling on the fourth nickel target blank to form a fifth nickel target blank; performing third heat treatment on the fifth nickel target blank to form the nickel target, wherein the temperature of the third heat treatment is 200-300 DEG C, and the temperature is maintained for 1-2 hours. By adopting the technical scheme, the produced nickel target has relatively uniform internal organization and good magnetic property.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Method for making ultrafine grained steel

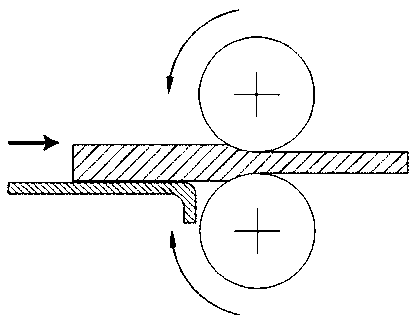

InactiveCN102011045AGrain stabilizationInhibition of inverse phase transitionRoll mill control devicesMetal rolling arrangementsMass storageManganese

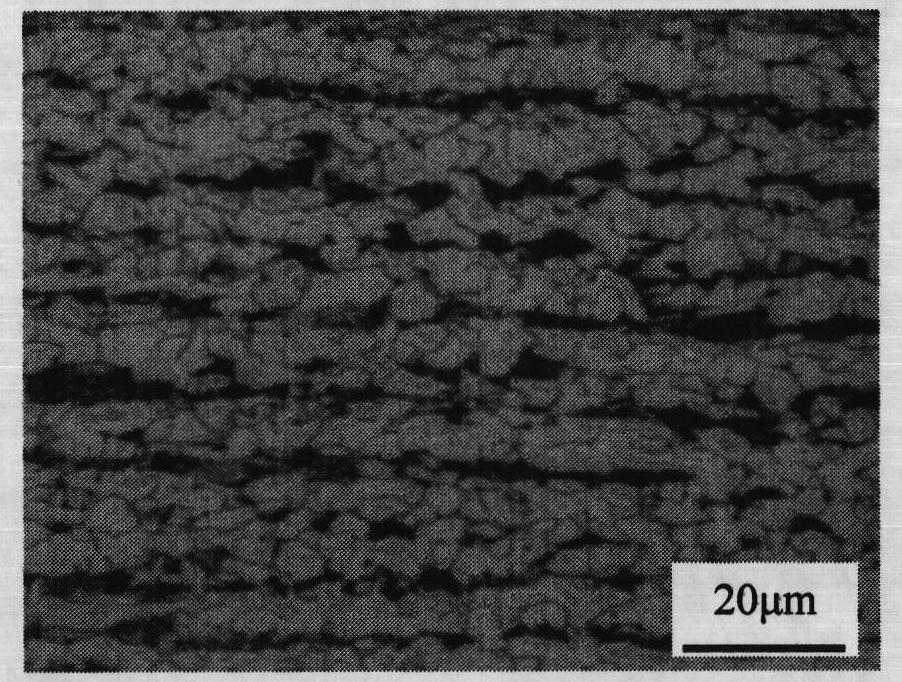

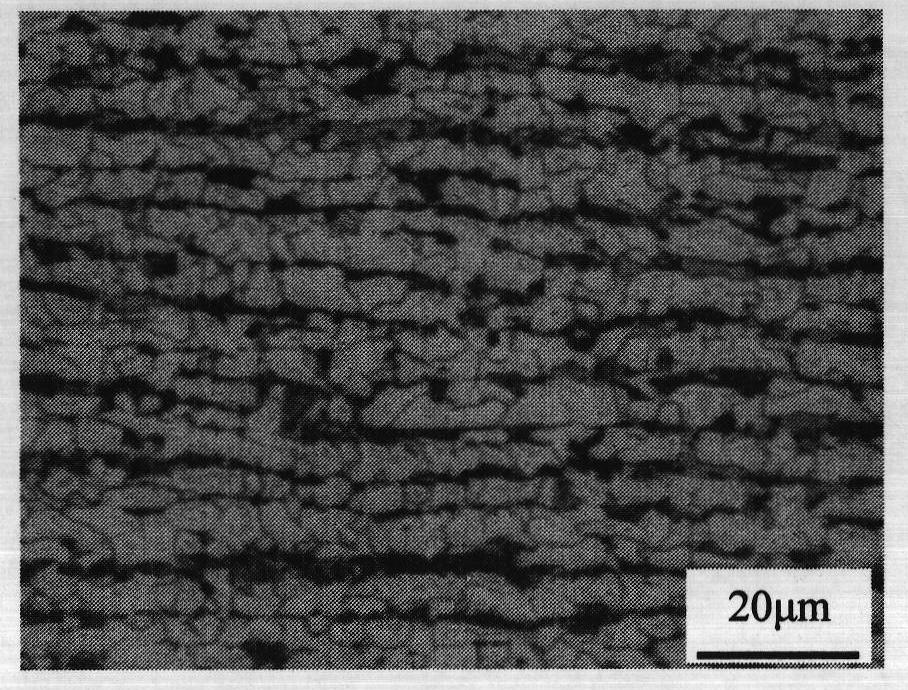

The invention discloses a method for making ultrafine grained steel, comprising the steps of: heating carbon steel to a temperature of 1200-1240DEG C to carry out austenization, wherein the carbon steel contains 0.02-0.20% of carbon and 0.40-1.60% of manganese by mass fraction; controlling to roll by using an austenite recrystallization area and an austenite non-recrystallization area; performing another deformation near an Ar3 temperature by combining the deformation induced ferrite transformation technology so as to restrain the reverse transformation from the ferrite to the austenite after twice transformation, accumulate mass storage energy of the second transformation, increase the nucleation points of the ferrite, and promote the increase of the volume fraction of the ferrite; and finally cooling to a temperature of 600-650DEG C at a cooling speed of 1-10DEG C / micron for air cooling. The ferrite grain dimension of the prepared ultrafine grained ferrite steel is less than 3.0 microns. The manufacturing method of the ultrafine grained steel does not need large deformation and ultrafast cooling process, and has small mill load and simple process; and the obtained room-temperature ultrafine ferrite grains are stable.

Owner:NANJING IRON & STEEL CO LTD

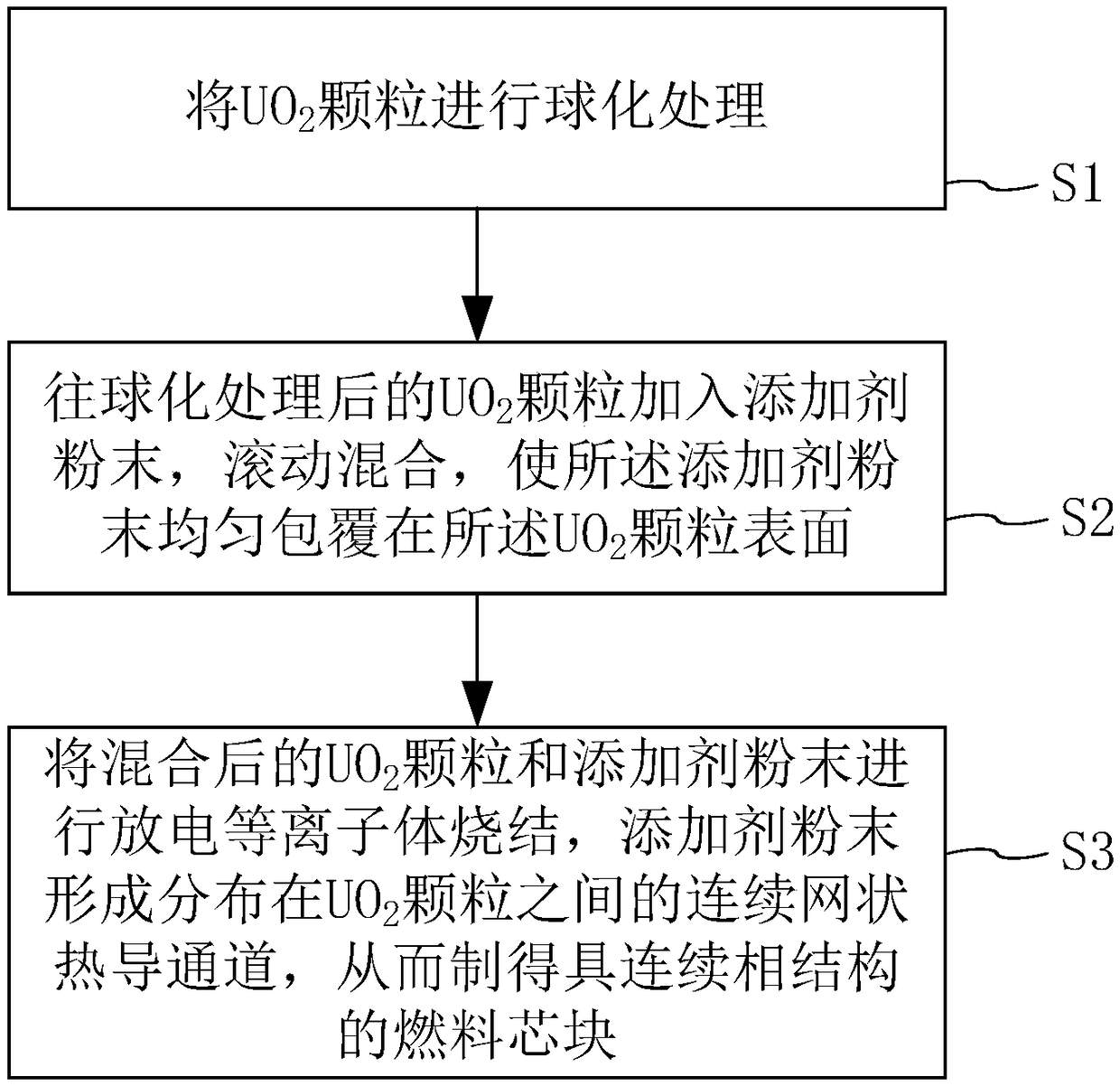

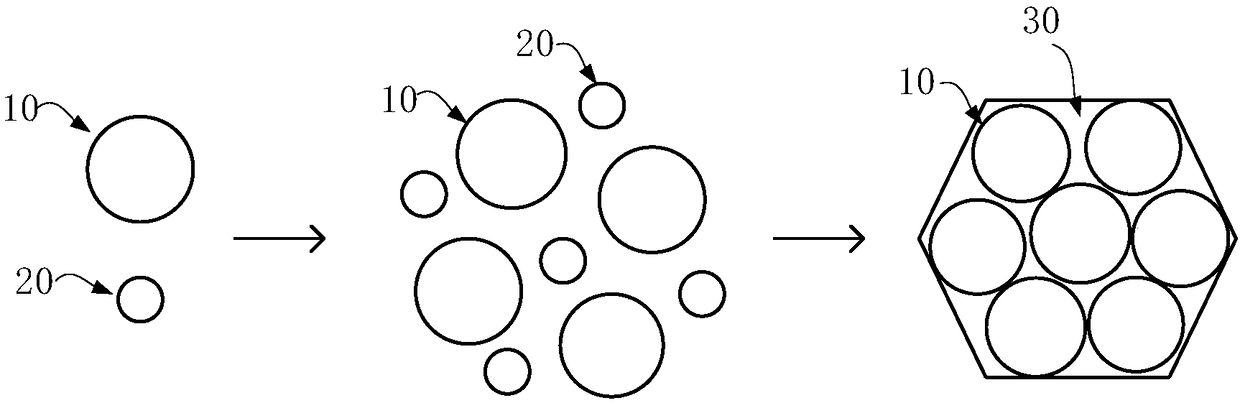

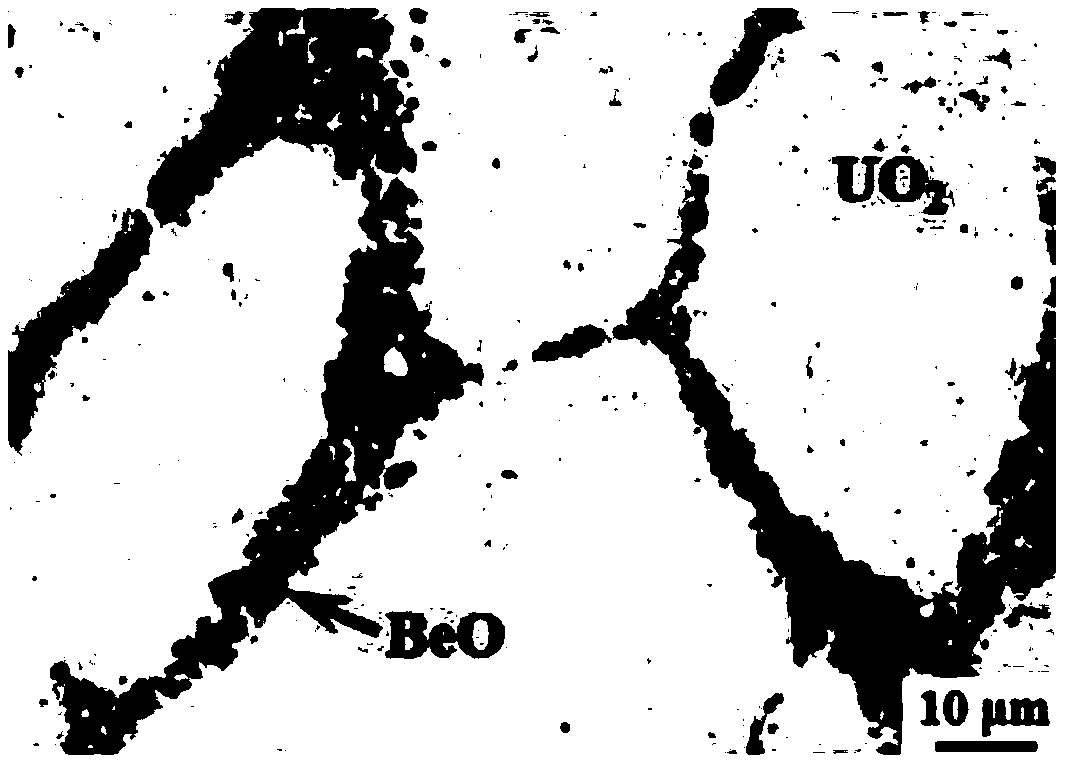

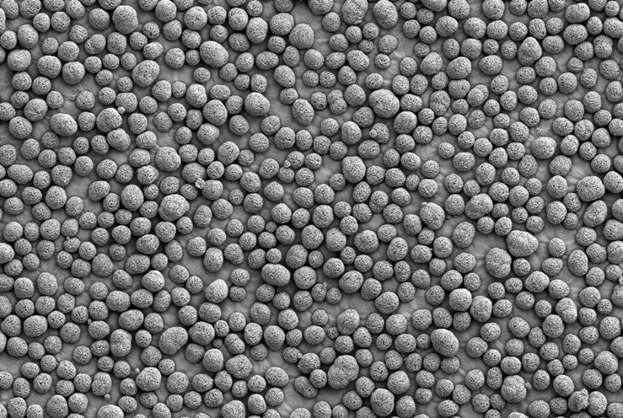

Fuel pellet with continuous phase structure and preparation method of fuel pellet

InactiveCN108831575AHigh thermal conductivityImprove performanceNuclear energy generationReactors manufactureMetallurgyThermal conductivity

The invention discloses a fuel pellet with a continuous phase structure and a preparation method of the fuel pellet. The preparation method comprises the following steps: S1, spheroidizing UO2 particles; S2, adding additive powder into the spheroidized UO2 particles, and mixing the additive powder and the spheroidized UO2 particles in a rolling manner to uniformly cover the surfaces of the UO2 particles with the additive powder; and S3, performing discharge plasma sintering on the mixed UO2 particles and additive powder to allow the additive powder to form continuous meshed thermal conductancechannels distributed between the UO2 particles, thereby preparing the fuel pellet with the continuous phase structure. In the preparation method disclosed by the invention, the surfaces of the spheroidized UO2 particles are coated with the additive powder at first, and then the discharge plasma sintering is performed, so that the continuous meshed phase structure can be formed in the fuel pelletto reduce the preparation difficulty, and then the thermal conductivity and the comprehensive performance of the fuel pellet are improved, the sintering time is shortened, and the sintering efficiencyis improved.

Owner:GUANGDONG NUCLEAR POWER JOINT VENTURE +3

Method for producing crystal maltose alcohol

InactiveCN101486740AImprove crystallization efficiencyUniform grainSugar derivativesSugar derivatives preparationAlcoholMaltitol

The invention discloses a method for producing crystal maltol, which comprises the following contents: a maltol solution is evaporated and concentrated to be supersaturated to obtain a maltol massecuite; maltol crystal seeds are added to the massecuite and the supersaturation degree and viscosity of the solution are controlled; the maltol massecuite is continuously evaporated and crystallized, the solution maintains boiling and maltol solution is added to continuously; when the grain quantity in the massecuite reaches 50 percent to 90 percent, the massecuite is transferred into a homoiothermal reserve tank and stirred until the temperature thereof is reduced to 20 DEG C to 40 DEG C; and then centrifugal separation is conducted to obtain a finished product of crystal maltol. The method can improve the crystallization efficiency of the maltol and render the grain be even and stable.

Owner:山东福田科技集团有限公司

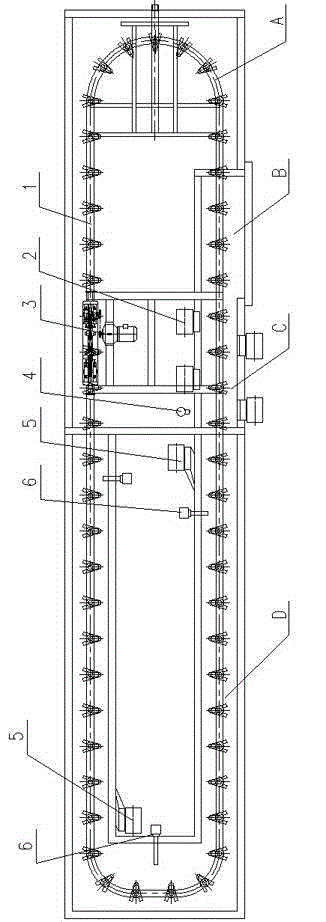

Integrated temperature-control cooling equipment and cooling method thereof

ActiveCN102719634AAvoid the effects of coolingEnsure that the mechanical performance indicators meet the requirementsTemperature controlEngineering

The invention discloses integrated temperature-control cooling equipment and a cooling method thereof and belongs to the technical field of cooling of non-quenched and tempered steel. The integrated temperature-control cooling equipment comprises a feeding-discharging area, a rapid cooling area, a slow cooling area and an air cooling area which are in sequential connection, and the air cooling area is connected onto the feeding-discharging area to form a closed circulation structure. The cooling equipment is simple in structure, high in degree of automation, simple and convenient to operate and suitable for popularization and application. The cooling method includes the steps: 1, hooking forgings; 2, rapidly cooling the forgings to the temperature ranging from 630 DEG C to 670 DEG C in the rapid cooling area; 3, decreasing the temperature of the forgings to 280 DEG C to 320 DEG C in the slow cooling area; and 4, performing air cooling for the forgings to enable the temperature of the forgings to be lower than 100 DEG C in the air cooling area, returning the forgings to the feeding-discharging area and taking the forgings down. The cooling method is simple, convenient, applicable and high in production efficiency, production cost can be greatly reduced, and internal and external quality of the forgings after cooling can be guaranteed.

Owner:SICHUAN HAOTE JINGGONG EQUIP CO LTD

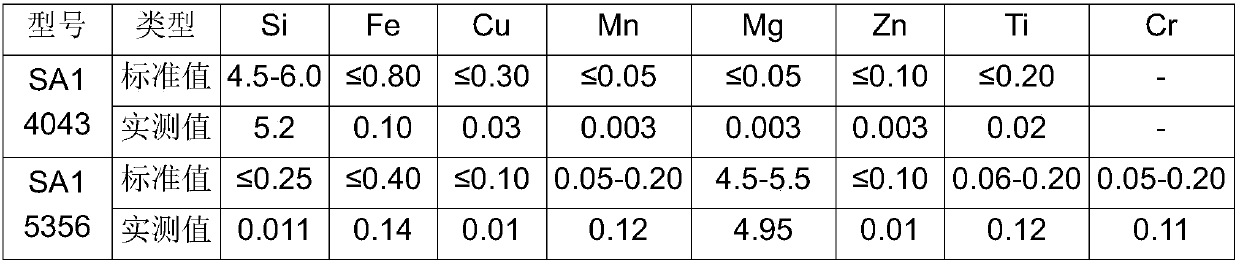

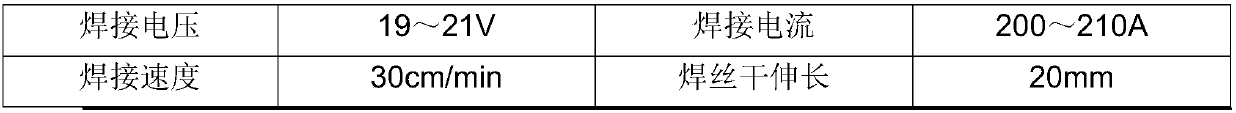

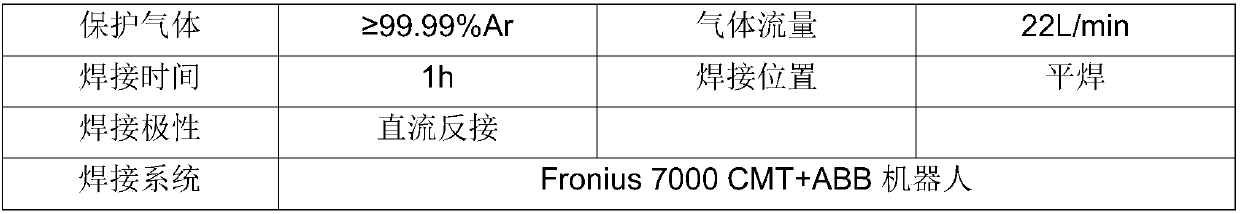

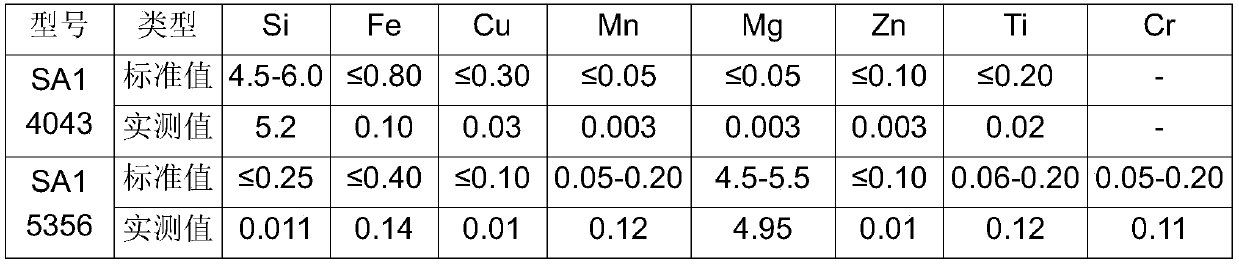

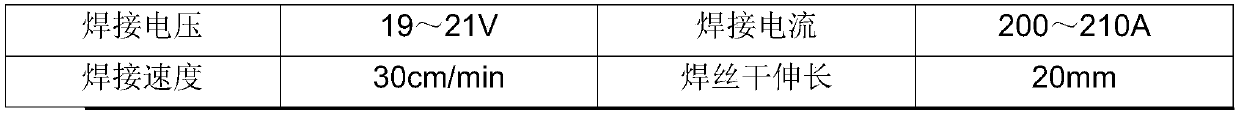

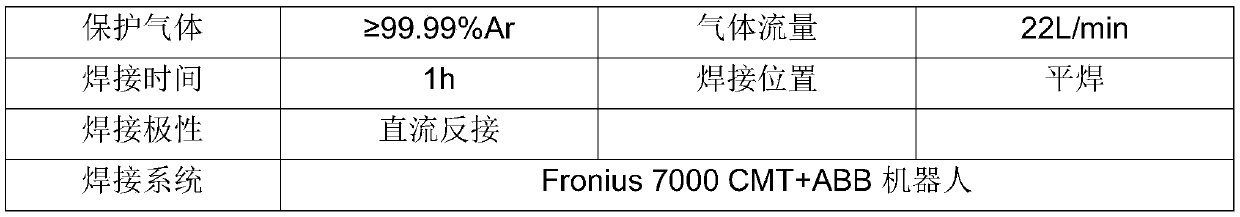

Preparation method of aluminum and aluminum alloy welding wire electrochemically plated with Zn+Cu/Re composite coating and applied to robot welding

ActiveCN107904576AImprove the lubrication effectCrystallizationLiquid/solution decomposition chemical coatingPorosityMolten bath

The invention relates to the field of welding wire manufacturing, in particular to a preparation method of an aluminum and aluminum alloy welding wire electrochemically plated with a Zn+Cu / Re composite coating and applied to robot welding. A pure aluminum or aluminum alloy wire rod is used as the matrix. Pretreatment, electrochemical plating of the Zn+Cu / Re composite coating and post-treatment areconducted on the surface. The electrochemically plated Zn+Cu / Re composite coating has the functions of reducing welding smoke, improving the porosity resistance of the welding wire and improving solid lubrication and meanwhile fills up pits in the surface of the welding wire matrix, and the electric conductivity and surface quality of the welding wire are improved; the bonding force and strengthof the Zn+Cu / Re composite coating are high, the aluminum or copper peeling phenomenon is avoided, the Zn+Cu / Re composite coating is high in compactness, good in rust resistance and resistant to wear,Zn can reduce welding smoke and splashes, and Re can refine plating layer crystals and reduce the void ratio; and meanwhile, molten bath stirring is enhanced, a molten bath is purified, crystals are refined, pores on the surface and on the inner portion of a welding joint are thoroughly eradicated, and the porosity resistance of the welding wire is improved.

Owner:江苏恒熠金属制品有限公司

Diffusion welding process for thermal spraying coating of crystallizer copper plate

PendingCN112176273AImprove wear resistanceImprove corrosion resistanceMolten spray coatingNon-electric welding apparatusCopperThermal conductivity

The invention discloses a diffusion welding process for a thermal spraying coating of a crystallizer copper plate. The diffusion welding process comprises the steps of copper plate spraying pretreatment, coating material selection, thermal spraying, diffusion welding of the thermal spraying coating, cooling and discharging. As for the coating material selection, thermal spraying powder comprises 0.3-0.8% of C, 10-20% of Cr, 7-10% of Si, 4-6% of B, 5-10% of Cu, 2-5% of Mo, 1-2% of Al and the balance Ni. The diffusion welding of the thermal spraying coating comprises the steps that inert gas isintroduced into a heat preservation furnace, and diffusion welding treatment is conducted on the coating at a certain temperature within a certain period of time. Metallurgical bonding can be effectively formed between a crystallizer copper plate base body and the thermal spraying coating, the coating is good in performance and has excellent thermal conductivity, abrasion resistance and corrosionresistance, and the service life of the continuous casting crystallizer copper plate is prolonged.

Owner:泰尔(安徽)工业科技服务有限公司

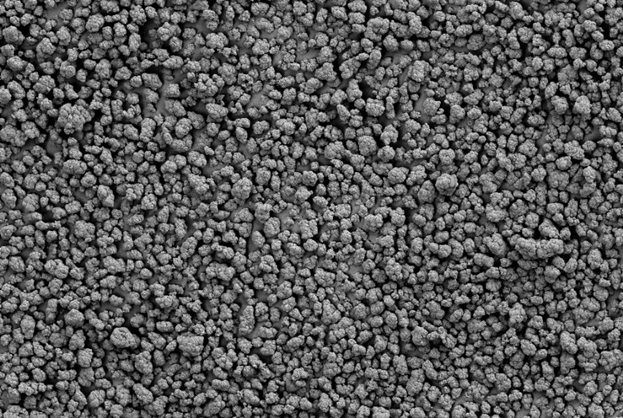

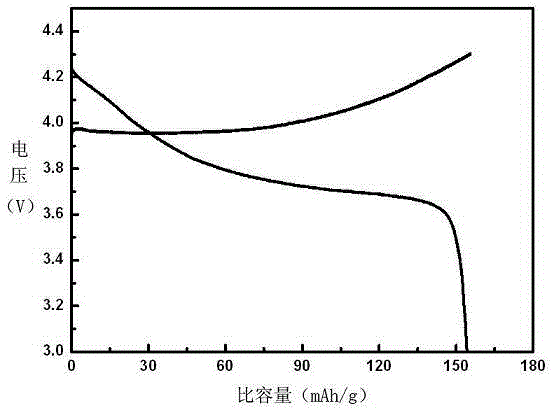

Narrow-distribution small-particle-size nickel-cobalt-aluminum hydroxide and preparation method thereof

ActiveCN111717938AIncrease energy densityImprove cycle performanceSecondary cellsPositive electrodesElectrical batteryAluminium hydroxide

A narrow-distribution small-particle-size nickel-cobalt-aluminum hydroxide serves as a precursor of a nickel-cobalt-lithium aluminate battery positive electrode material active substance, an inner core of secondary spherical particles of the precursor is aluminum hydroxide, a crystal grain cation layer framework of an outer shell layer contains nickel-cobalt-aluminum elements, and the mole percentof nickel is 85-98%; and secondary spherical particles of the precursor have the characteristic of narrow distribution, K90 is (D90-D10) / D50 and is less than or equal to 0.90, D50 is 2.0-6.0 [mu]m, and the energy density and the cycle performance of the battery can be further improved when the secondary spherical particles are used as a positive electrode material of the lithium battery. The invention discloses a preparation method of the narrow-distribution small-particle-size nickel-cobalt-aluminum hydroxide. On one hand, the defect that a precursor synthesized by a solid phase method cannot achieve atomic-level uniformity is overcome, and on the other hand, aluminum hydroxide flocculent precipitate generated in the synthesis process of a conventional liquid phase method is also overcome, so that the precursor with a core-shell structure, good sphericity, compact particles, stable structure and high consistency is obtained.

Owner:HUAYOU NEW ENERGY TECH (QUZHOU) CO LTD +1

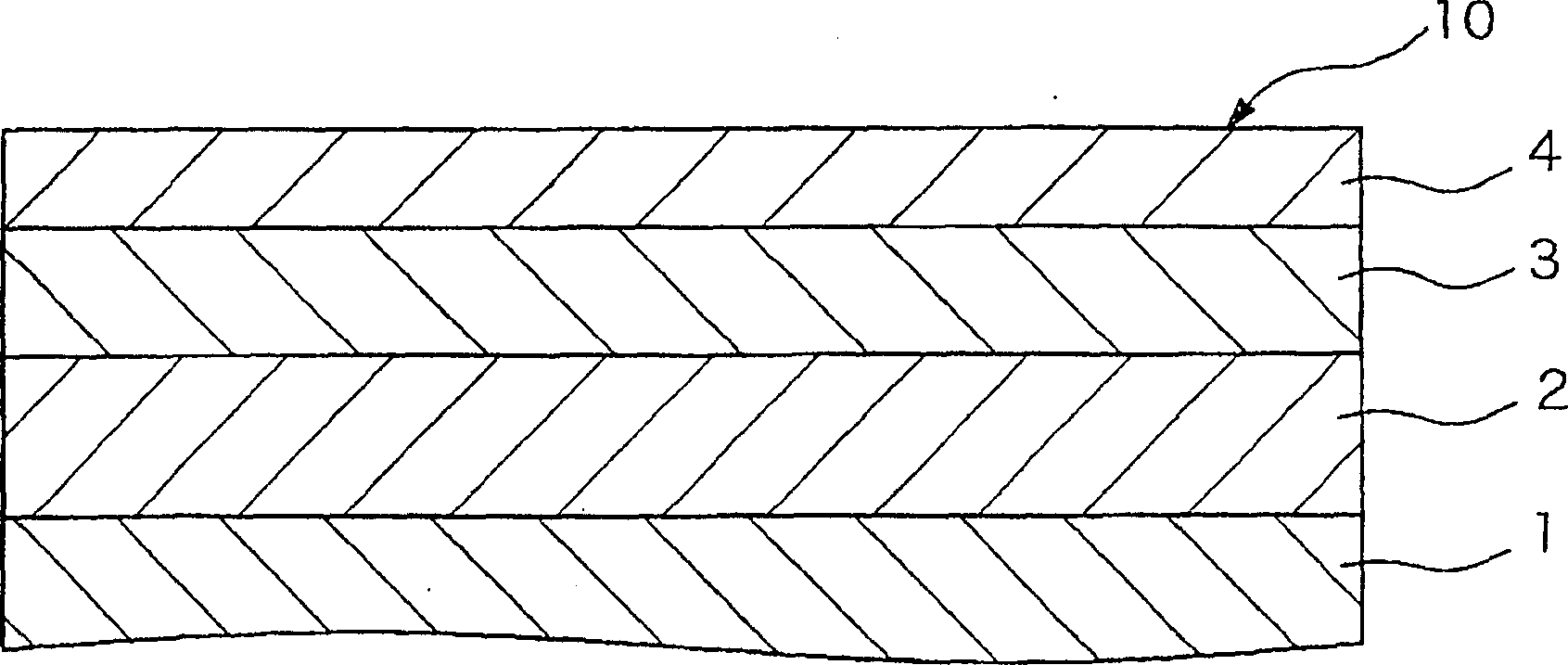

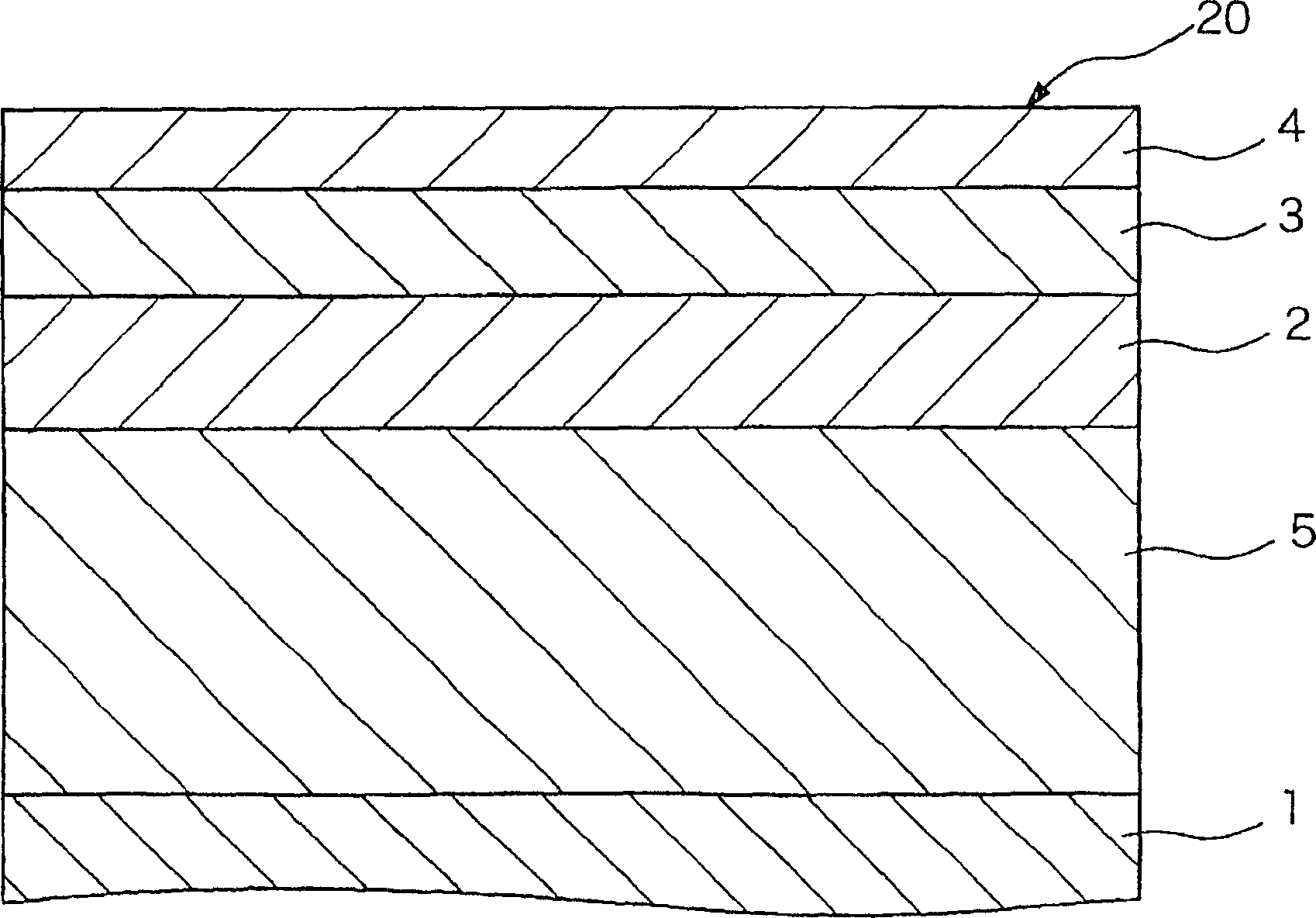

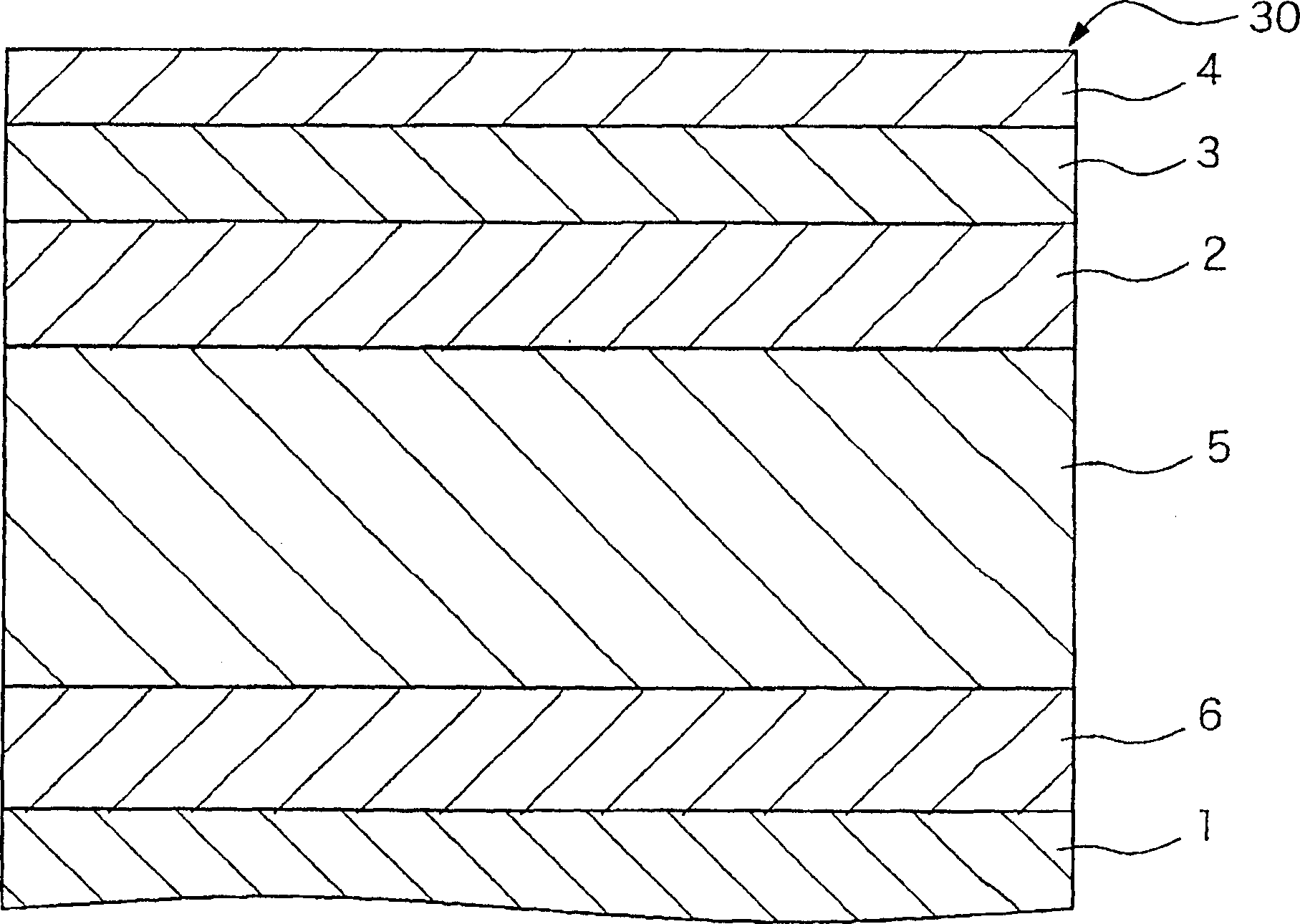

Perpendicular magnetic recording medium and magnetic recording/reproducing apparatus

InactiveCN1856823AImproved crystal orientation and magnetic propertiesFine magnetic particlesRecord information storageMagnetic recordingCrystalliteMagnetic layer

To make possible high density recording by making the structure of the perpendicular magnetic recording layer finer. A perpendicular magnetic recording medium 10 includes at least a nonmagnetic under layer 2, a perpendicular magnetic layer 3, and a protective layer which are stacked on a nonmagnetic substrate 1, wherein the perpendicular magnetic layer includes ferromagnetic crystal grains and nonmagnetic crystal grain boundary regions, wherein the crystal grain boundary region includes at least two kinds of oxide.

Owner:KK TOSHIBA +1

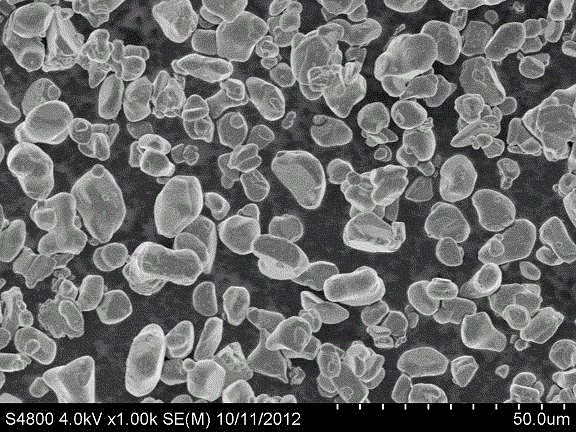

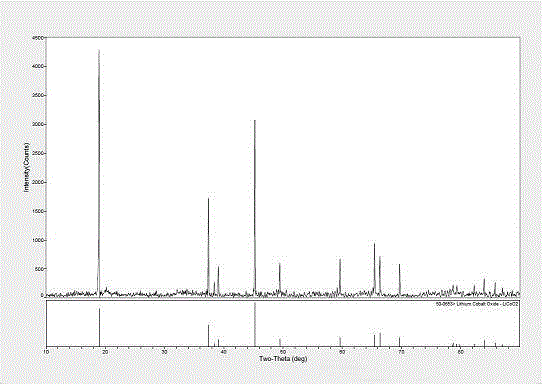

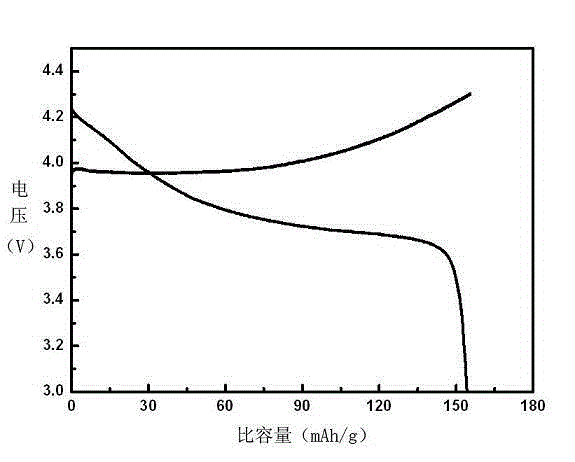

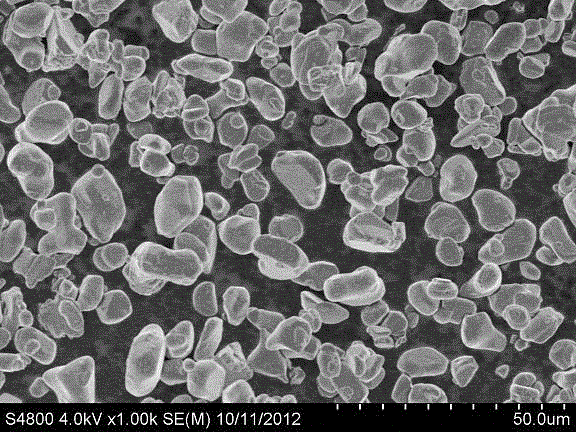

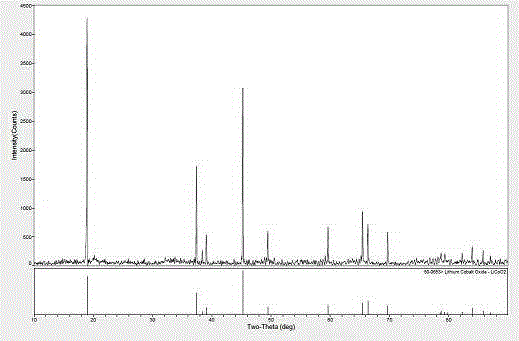

Preparation method of lithium cobalt oxide

ActiveCN103151517AUniform compositionComponents can always be evenly distributed evenlyCell electrodesCobalt compoundsLithiumPhysical chemistry

The invention discloses a preparation method of lithium cobalt oxide. The preparation method of the lithium cobalt oxide solves the problems that an existing preparation method of the lithium cobalt oxide is high in temperature, the lithium cobalt oxide obtained through the existing preparation method is uneven in particle, the agglomeration phenomenon exists, the high temperature process causes uneven content of cobalt and lithium in materials and leads to the lithium element to be separated out. The preparation method of the lithium cobalt oxide includes the following steps of weighting out a certain amount of lithium salt, measuring water-solubility organics based on the molar weight of the lithium salt according to the ratio that the total molar weight of the water-solubility organics is 50%-70% of the molar weight of the lithium salt, mixing the water-solubility organics and the lithium salt, adding water to mixture, conducting ball-milling, obtaining pre-reaction slurry, adding materials with cobalt and water to the pre-reaction slurry wherein the molar ratio of the lithium to the cobalt is 0.95-1.2: 1, conducting the ball-milling, obtaining reaction slurry, drying the reaction slurry, calcining the slurry, and obtaining the lithium cobalt oxide. The preparation method of the lithium cobalt oxide has the advantages that the lithium cobalt oxide obtained through the preparation method is good in evenness, small in crystal particle, even in particle size, and less in agglomeration. In addition, the preparation method of the lithium cobalt oxide has the advantages of being simple in technology process, appropriate for large batch production, low in calcination temperature and the like.

Owner:NINGBO VEKEN BATTERY

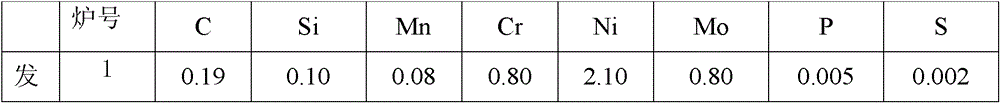

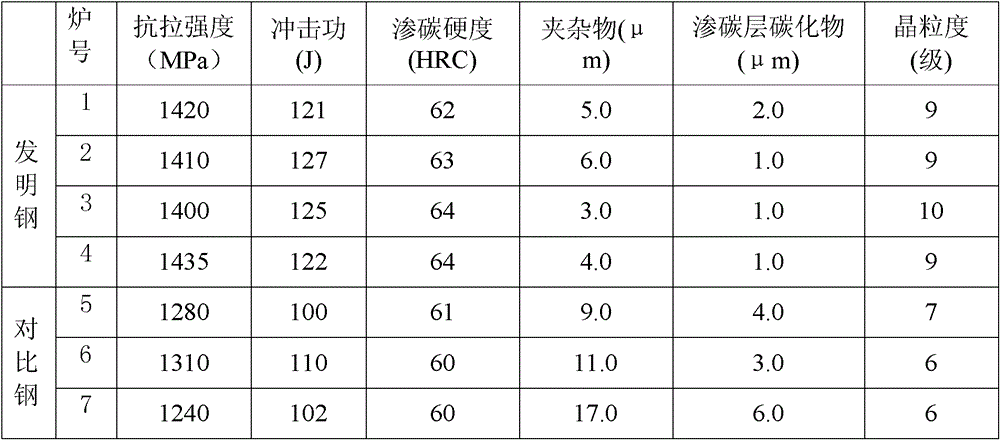

High-toughness carburized bearing steel with ultra-long contact fatigue life and preparation method thereof

The invention relates to a high-toughness carburized bearing steel with ultra-long contact fatigue life and a preparation method thereof, belonging to the technical field of alloy steel. The steel comprises the following chemical components in percentage by weight: 0.16-0.24% of C, at most 0.10% of Si, at most 0.10% of Mn, 0.30-1.50% of Cr, 1.5-4.5% of Ni, 0.30-1.50% of Mo, 0.02-0.10% of Nb, 0.3-0.9% of V, and the balance of Fe and inevitable impurities, wherein [N]+[O]+[H]+P+S<=0.0080%, and Ti<=0.0030%. The invention particularly relates to a high-toughness carburized bearing steel which has the advantages of high shock resistance load, stable dimension and ultra-long contact fatigue life in the serve process. Compared with the prior art, the invention has the advantages of high surface hardness, high core toughness, high dimensional stability, high bending fatigue strength limit and ultra-long contact fatigue life.

Owner:CENT IRON & STEEL RES INST

Tantalum target and method for manufacturing tantalum target assembly

ActiveCN103572225BDense tissueReduce unevennessVacuum evaporation coatingSputtering coatingIngotSemiconductor

The invention provides a production method of a tantalum target and a tantalum target component. The production method of a tantalum target comprises the following steps of providing a tantalum ingot; performing hot forging on the tantalum ingot to form a first tantalum target blank; performing first heat treatment on the first tantalum target blank to form a second tantalum target blank, wherein the temperature of the first heat treatment is 1,000-1,200 DEG C, and the temperature is maintained for 30-90 minutes; after the first heat treatment, performing hot rolling on the second tantalum target material to form a third tantalum target blank; performing second heat treatment on the third tantalum target blank to form the tantalum target, wherein the temperature of the second heat treatment is 1,000-1,200 DEG C, and the temperature is maintained for 30-90 minutes. By adopting the technical scheme, the produced tantalum target has relatively uniform internal organization and good magnetic property; moreover, by adopting the tantalum target to produce a tantalum target component for a semiconductor, the formed film has relatively good quality.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Method for controlling close limit hardness of steel used for compressor shell

ActiveCN109402353AInhibition of element migration activityReduce the precipitation of secondary cementite at the grain boundaryCrystalliteHardness

The invention discloses a method for controlling close limit hardness of steel used for a compressor shell. The method comprises the processes of heating a casting blank, controlling rolling, controlling cooling and reeling; during the process of controlling rolling, roughing pass is 3+3 and thickness of intermediate billet is 38-45mm; during the process of controlling rolling, temperature at finish rolling inlet is at 980-1050 DEG C and finishing temperature is at 865-895 DEG C; during the process of reeling, reeling temperature is at 580-620 DEG C. According to the invention, a stable fine grain tissue is acquired through reasonable rolling pattern design and reeling temperature and by refining grain size; the influence of grain size fluctuation on hardness is eliminated; migratory movement of supersaturated C element is restrained by lower reeling temperature, secondary cementite separation on grain boundary is reduced and the influence of fluctuation of composition percentage of cementite caused by larger C content control scope on hardness of steel coil is eliminated.

Owner:HANDAN IRON & STEEL GROUP +1

Method for making ultrafine grained steel

InactiveCN102011045BGrain stabilizationInhibition of inverse phase transitionRoll mill control devicesMetal rolling arrangementsMass storageManganese

Owner:NANJING IRON & STEEL CO LTD

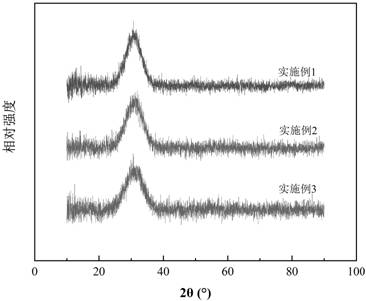

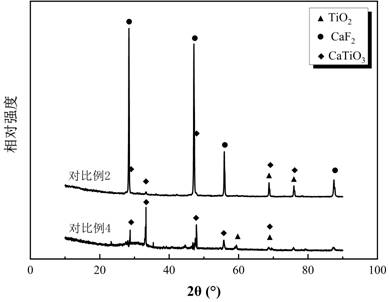

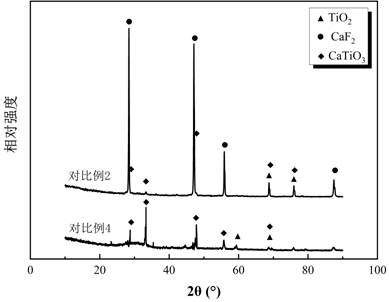

Amorphous smelting flux and preparation method and application thereof

ActiveCN113695788AAdjust oxygen contentAdjust contentArc welding apparatusWelding/cutting media/materialsSlag (welding)Weld seam

The invention relates to the technical field of welding, in particular to an amorphous smelting flux and a preparation method and application thereof. The amorphous smelting flux is prepared from the following components including, by mass percent, 20%-25% of CaF2, 30%-35% of CaO, 30%-35% of SiO2 and 5%-15% of TiO2. The amorphous smelting flux has the advantages of being free of moisture absorption, good in slag detachability, capable of effectively reducing the contents of harmful elements such as P and S in a welding seam and the like by adopting the specific components and dosages thereof. Meanwhile, the flux is in an amorphous state, the welding seam obtained after welding is uniform in composition, the mechanical property of the welding seam is excellent, and particularly the low-temperature toughness of the welding seam is good.

Owner:NORTHEASTERN UNIV LIAONING

a raised al 0.3 A method for the strength of cocrfeni high-entropy alloys

ActiveCN109797303BFine grain boundaryUniform tissueVacuum evaporation coatingSputtering coatingHigh entropy alloysWire cutting

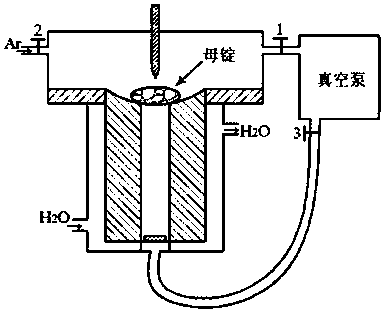

The invention discloses a method for improving Al0.3CoCrFeNi high-entropy alloy intensity. Five kinds of analytical pure metals of Al, Co, Cr, Fe and Ni are blended according to the atomic ratio of 0.3 to 1 to 1 to 1 to 1, smelting is carried out in a vacuum arc melting furnace, the molten alloy is subjected to suction casting to form plate-shaped high-entropy alloy materials with 2mm thickness, 10mm width and 85mm length, and then a high-entropy alloy is subjected to cold rolling and annealing heat treatment to eliminate the residual internal stress, generated in the casting process, of the high-entropy alloy; and then a wire cutting machine is used for cutting bone-shaped standard tensile samples with a standard distance of 5mm, the front faces and back faces and the two side faces of the tensile samples are polished, and the polished samples are subjected to a double-glow chromizing test by using a double-glow metal furnace, and finally, the obtained samples are strengthened high-entropy alloy samples. According to the method for improving the Al0.3CoCrFeNi high-entropy alloy intensity, through a double-glow chromizing technology, the friction coefficient of the high-entropy alloy is reduced, and the amplitude is greatly reduced.

Owner:TAIYUAN UNIV OF TECH

Method for producing crystal maltose alcohol

InactiveCN101486740BImprove crystallization efficiencyUniform grainSugar derivativesSugar derivatives preparationAlcoholMaltitol

The invention discloses a method for producing crystal maltol, which comprises the following contents: a maltol solution is evaporated and concentrated to be supersaturated to obtain a maltol massecuite; maltol crystal seeds are added to the massecuite and the supersaturation degree and viscosity of the solution are controlled; the maltol massecuite is continuously evaporated and crystallized, the solution maintains boiling and maltol solution is added to continuously; when the grain quantity in the massecuite reaches 50 percent to 90 percent, the massecuite is transferred into a homoiothermal reserve tank and stirred until the temperature thereof is reduced to 20 DEG C to 40 DEG C; and then centrifugal separation is conducted to obtain a finished product of crystal maltol. The method canimprove the crystallization efficiency of the maltol and render the grain be even and stable.

Owner:山东福田科技集团有限公司

A kind of amorphous melting flux and its preparation method and application

ActiveCN113695788BAdjust oxygen contentAdjust contentArc welding apparatusWelding/cutting media/materialsSlag (welding)Weld seam

The invention relates to the field of welding technology, in particular to an amorphous melting flux and its preparation method and application. Amorphous melting flux is made of the following components in mass percent: CaF 2 20%~25%, CaO 30%~35%, SiO 2 30%~35% and TiO 2 5%~15%. The amorphous smelting flux has the advantages of no moisture absorption, good slag detachability, and effective reduction of harmful elements such as P and S in the weld by adopting specific components and dosages thereof. At the same time, the flux is in an amorphous state, and the composition of the weld seam obtained after welding is uniform, and the mechanical properties of the weld seam are excellent, especially the low temperature toughness of the weld seam is good.

Owner:NORTHEASTERN UNIV LIAONING

Graphene rare earth permanent magnet material and preparation method thereof

InactiveCN113053606AImprove bindingProtectInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementCerium

The invention relates to the technical field of permanent magnet materials, in particular to a graphene rare earth permanent magnet material and a preparation method thereof. The graphene rare earth permanent magnet material comprises the following raw materials in percentage by mass: 20.6%-23.4% of neodymium, 6.6%-7.5% of praseodymium, 0.95%-1.20% of boron, 0.4%-0.6% of cobalt, 0.11%-0.15% of copper, 2.0%-2.4% of lanthanum, 1.7%-2.1% of cerium, 1%-5% of graphene and the balance of iron. The graphene rare earth permanent magnet material has good temperature resistance, conductivity and magnetic performance and does not contain terbium and dysprosium heavy rare earth elements, the cost of a rare earth permanent magnet is greatly reduced while the graphene rare earth permanent magnet material with excellent performance is obtained, effective utilization of rare earth resources is facilitated, and the product yield is increased; and the preparation method is simple in process, convenient to control, low in production cost and high in production efficiency, and the prepared product is stable in performance.

Owner:DONGGUAN JINCONN NEW MATERIAL CO LTD

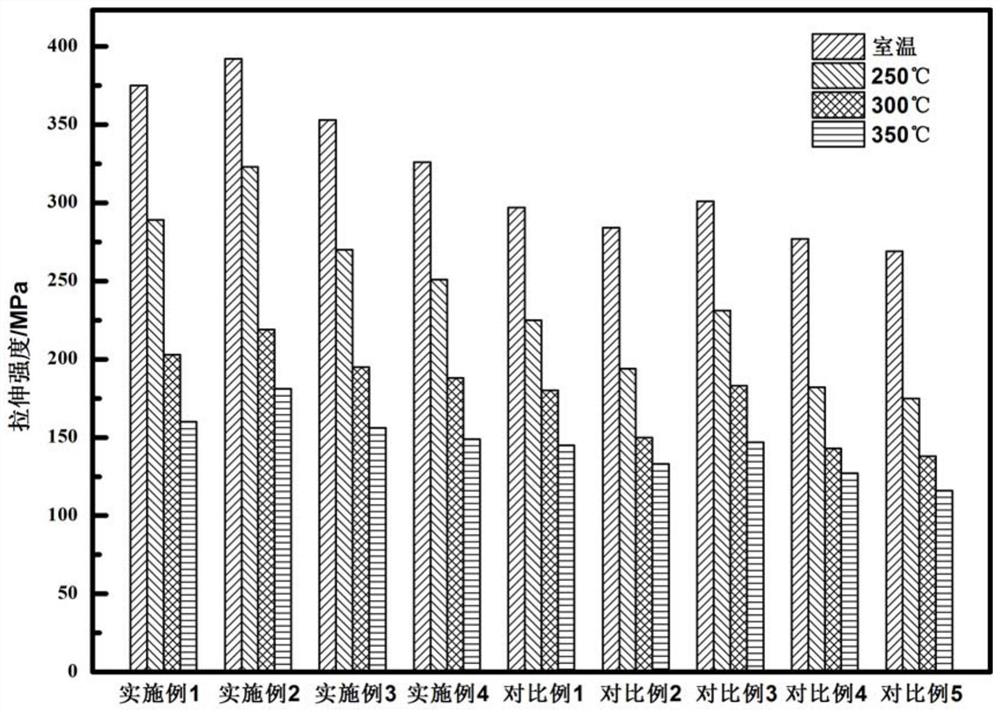

Aluminum alloy material and preparation method and application thereof

ActiveCN114318088AReduce pollutionImprove high temperature strengthUltimate tensile strengthHigh heat

The invention relates to an aluminum alloy material and a preparation method and application thereof, and the aluminum alloy material comprises the following components in percentage by mass: 7.0 wt% to 9.0 wt% of Cu, 1.0 wt% to 3.5 wt% of Ni, 0.6 wt% to 1.1 wt% of Mn, 0.1 wt% to 0.2 wt% of Ti, 0.1 wt% to 0.3 wt% of Sc, 0.03 wt% to 0.20 wt% of Ce, 0.05 wt% to 0.15 wt% of Zr, 0.01 wt% to 0.03 wt% of Be, 0.01 wt% to 0.03 wt% of Co, 0.01 wt% to 0.03 wt% of Mo and the balance of Al. All the elements of the aluminum alloy material are matched according to a specific proportion and have a synergistic effect, so that the aluminum alloy material has high tensile strength under the room temperature condition and the high temperature condition.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

Manufacturing method of nickel target material and nickel target material assembly

ActiveCN103572224BDense tissueReduce hardnessVacuum evaporation coatingSputtering coatingIngotHeat treated

The invention provides a production method of a nickel target and a nickel target component. The production method of the nickel target comprises the following steps of providing a nickel ingot; performing hot forging on the nickel ingot to form a first nickel target blank; performing first heat treatment on the first nickel target blank to form a second nickel target blank, wherein the temperature of the first heat treatment is 450-550 DEG C, and the temperature is maintained for 1-2 hours; after the first heat treatment, performing hot rolling on the second nickel target blank to form a third nickel target blank; performing second heat treatment on the third nickel target blank to form a fourth nickel target blank, wherein the temperature of the second heat treatment is 300-500 DEG C, and the temperature is maintained for 1-2 hours; after the second heat treatment, performing cold rolling on the fourth nickel target blank to form a fifth nickel target blank; performing third heat treatment on the fifth nickel target blank to form the nickel target, wherein the temperature of the third heat treatment is 200-300 DEG C, and the temperature is maintained for 1-2 hours. By adopting the technical scheme, the produced nickel target has relatively uniform internal organization and good magnetic property.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

A kind of NdFeB permanent magnet material and preparation method thereof

ActiveCN108364736BImprove magnetic propertiesImprove mechanical propertiesInorganic material magnetismGalliumNeodymium iron boron

Owner:DONGGUAN JINCONN NEW MATERIAL CO LTD

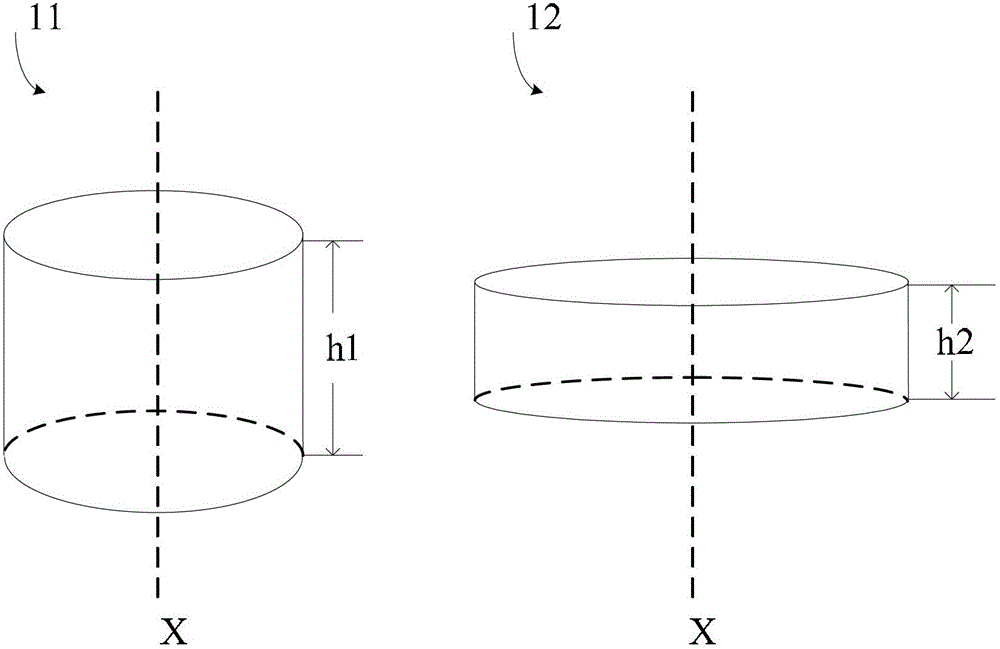

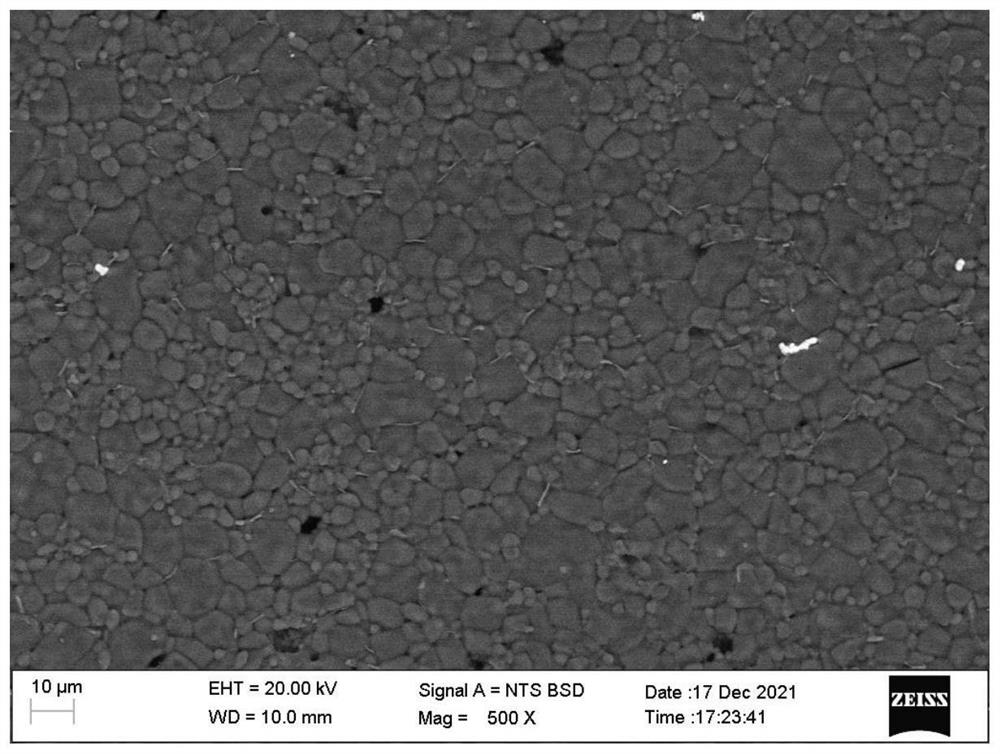

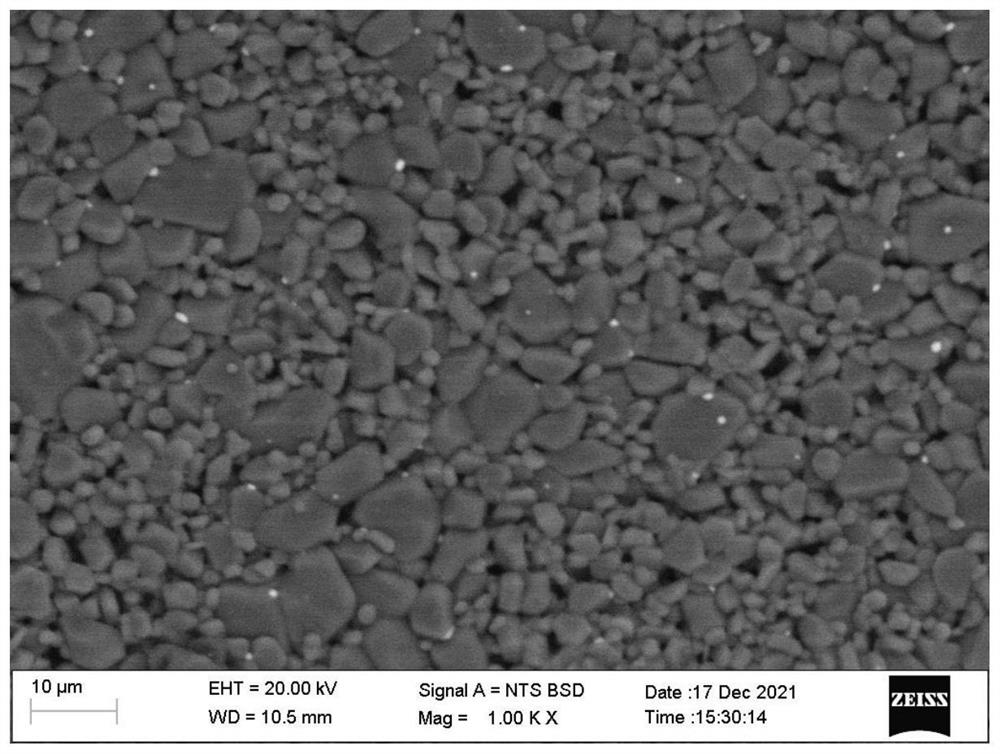

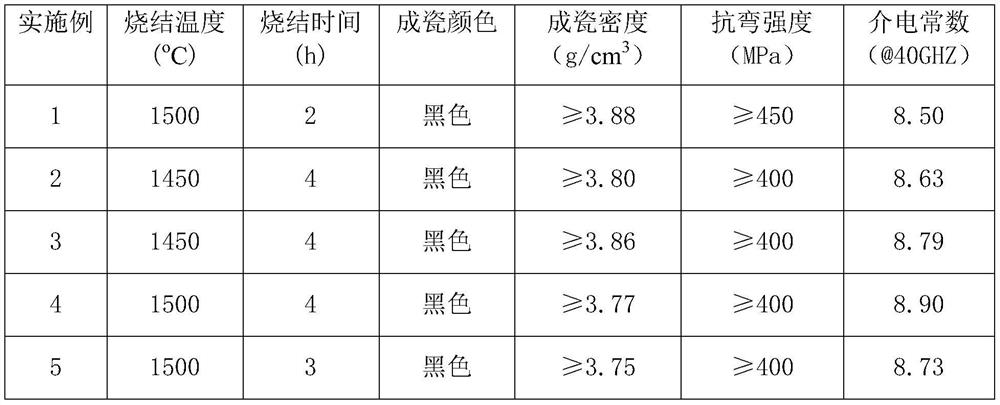

Ceramic material as well as preparation method and application thereof

PendingCN114394825AHigh strengthLower activation energySemiconductor/solid-state device detailsSolid-state devicesChromium sesquioxideYttrium

The invention provides a ceramic material and a preparation method and application thereof.The ceramic material is prepared from 92%-97% of aluminum oxide, 1.5%-3% of magnesium oxide, 0.5%-2% of niobium pentoxide, 0.5%-1% of yttrium oxide and 0.5%-2% of chromium sesquioxide, and the ceramic material has good density, good strength, low shrinkage rate and low dielectric constant and can be applied to packaging of electronic devices.

Owner:NINGBO INST OF NORTHWESTERN POLYTECHNICAL UNIV

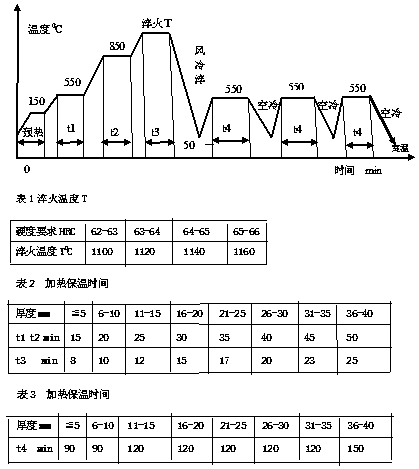

Accurate heat treatment quenching technology of powder metallurgy high-speed steel precise part

InactiveCN108774676AExtended service lifeImprove mechanical propertiesFurnace typesHeat treatment furnacesTemperingWear resistance

The invention provides an accurate heat treatment quenching technology of a powder metallurgy high-speed steel precise part and belongs to the field of heat treatment of high-speed steel materials. The accurate heat treatment quenching technology is provided for the precise part made of a high-speed steel ASSAB ASP23 material imported from Sweden and comprising the main alloy ingredients of 1.28%of C, 4.2% of Cr, 6.4% of W, 5.0% of Mo and 3.1% of V. According to the accurate heat treatment quenching technology, based on different workpiece hardness requirements, different quenching temperatures are adopted, so that a small designed hardness difference needed by two interactional precise parts can be achieved; different temperature keeping times are adopted for different workpiece thicknesses, so that the hardenability of the material is reliably guaranteed, the crystal structure in the material can be accurately controlled to be refined, uniform and stable, and the parts can be good in wear resistance, long in service life, high in reliability and stable in dimension and meets the use demands for the precise parts. The accurate heat treatment quenching technology comprises the technical scheme that (1) workpieces with the thickness difference smaller than 5 mm are placed in a quenching furnace and preheated to 150 DEG C in two steps; (2) the workpieces are heated to the quenching temperature T in three steps and keep the temperature for the time t in the quenching furnace; (3) the workpieces are discharged from the furnace and air cooled to 50-70 DEG C; (4) the workpiecesare fed into a tempering furnace to be heated to 550 DEG C for tempering and keep the temperature for the time of t three times, and then the workpieces are discharged from the tempering furnace and air cooled (please refer to the figure 1).

Owner:黄石高校智源技术咨询服务有限公司

Preparation method of lithium cobalt oxide

ActiveCN103151517BUniform compositionComponents can always be evenly distributed evenlyCell electrodesCobalt compoundsLithiumPhysical chemistry

The invention discloses a preparation method of lithium cobalt oxide. The preparation method of the lithium cobalt oxide solves the problems that an existing preparation method of the lithium cobalt oxide is high in temperature, the lithium cobalt oxide obtained through the existing preparation method is uneven in particle, the agglomeration phenomenon exists, the high temperature process causes uneven content of cobalt and lithium in materials and leads to the lithium element to be separated out. The preparation method of the lithium cobalt oxide includes the following steps of weighting out a certain amount of lithium salt, measuring water-solubility organics based on the molar weight of the lithium salt according to the ratio that the total molar weight of the water-solubility organics is 50%-70% of the molar weight of the lithium salt, mixing the water-solubility organics and the lithium salt, adding water to mixture, conducting ball-milling, obtaining pre-reaction slurry, adding materials with cobalt and water to the pre-reaction slurry wherein the molar ratio of the lithium to the cobalt is 0.95-1.2: 1, conducting the ball-milling, obtaining reaction slurry, drying the reaction slurry, calcining the slurry, and obtaining the lithium cobalt oxide. The preparation method of the lithium cobalt oxide has the advantages that the lithium cobalt oxide obtained through the preparation method is good in evenness, small in crystal particle, even in particle size, and less in agglomeration. In addition, the preparation method of the lithium cobalt oxide has the advantages of being simple in technology process, appropriate for large batch production, low in calcination temperature and the like.

Owner:NINGBO VEKEN BATTERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com