Integrated temperature-control cooling equipment and cooling method thereof

A temperature-controlled cooling and cooling method technology, which is applied in the field of non-quenched and tempered steel cooling, can solve the problems of uneven refinement, slow cooling, and affecting the mechanical properties of forgings, so as to achieve uniform cooling, high production efficiency, and avoid uneven metallographic changes. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

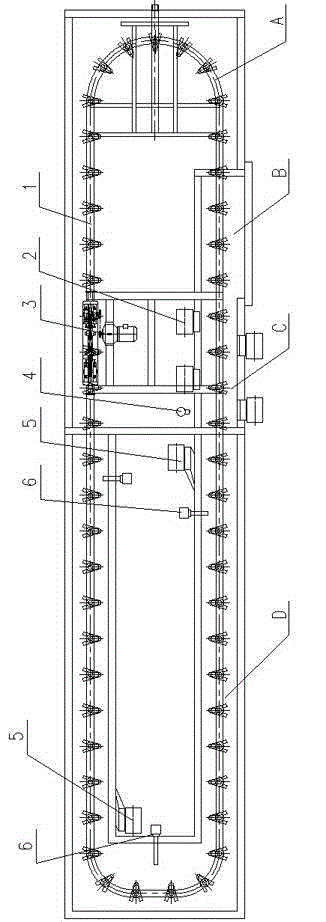

[0033] Example 1, such as figure 1 As shown, the integrated temperature-controlled cooling equipment of the present invention includes a loading and unloading area B, a fast cooling area C and a slow cooling area D, wherein the loading and unloading area B, the fast cooling area C and the slow cooling area D are connected in sequence, and the slow cooling Zone D is connected with an air-cooling zone A, and the air-cooling zone A is connected to the loading and unloading zone B, so that the air-cooling zone A, the loading and unloading zone B, the fast cooling zone C and the slow cooling zone D form a circular structure, thereby saving space , forming a circular cooling control system, achieving energy-saving effects.

[0034] The air-cooling zone A is mainly used for air-cooling the slow-cooled forgings. figure 1 Among them, the transmission mechanism in the air-cooling zone A is set on the bracket to support the entire transmission mechanism and the forgings on it. The lengt...

Embodiment 2

[0038] Embodiment 2, on the basis of Embodiment 1, the air cooling zone A is reduced, that is, the integrated temperature control cooling equipment of the present invention, including the loading and unloading zone B, the fast cooling zone C and the slow cooling zone D, wherein the loading and unloading zone B, The fast cooling zone C is connected with the slow cooling zone D in sequence. After the slow cooling zone D, it can be a storage zone directly. The area is preserved, so that the volume of the cooling equipment is minimized.

[0039] The cooling method of the integrated temperature control cooling equipment of the present invention is completed by the following steps:

[0040] Step 1, the temperature of the forging after forging is kept above 900°C, and the forging is hung on the transmission mechanism 1 in the loading and unloading area B;

[0041] Step 2, after the forging is transferred to the fast cooling zone C, the PLC control system controls the fast cooling fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com