Ceramic material as well as preparation method and application thereof

A technology of ceramic materials and alumina, which is applied in semiconductor/solid-state device parts, circuits, electric solid-state devices, etc., can solve problems such as low density and strength, high product defect rate, overstress failure, etc., and achieve improved mechanical properties , reduce the sintering temperature and sintering time, and refine the grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

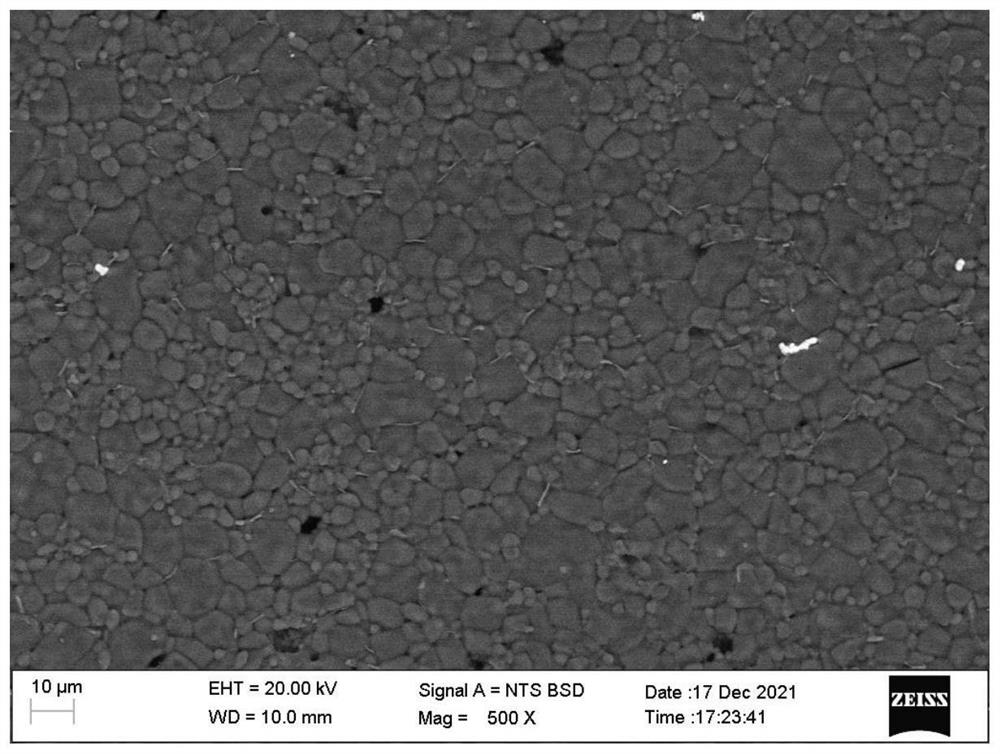

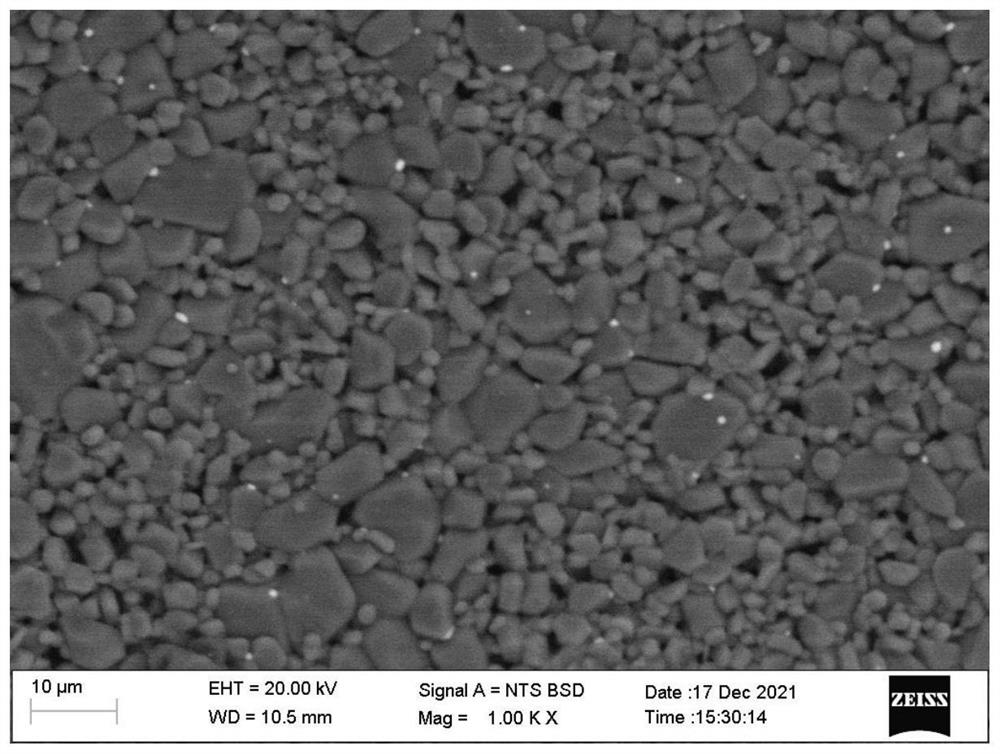

Image

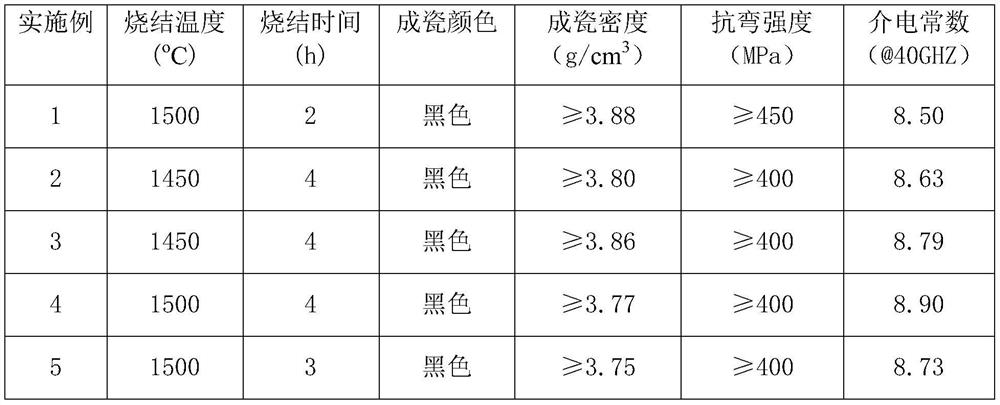

Examples

Embodiment 1

[0025] Step 1. Mix 92% of alumina, 3% of magnesium oxide, 2% of niobium pentoxide, 1% of yttrium trioxide and 2% of chromium trioxide according to the predetermined mass ratio, and add 0.8 times the mass of organic cast Auxiliary, ball milling for 2 hours, wherein the organic casting aid is a mixed solution composed of ethanol, polyvinyl butyral, glycerin and phthalate, and the mass ratio of each component is: 30:15 :3:2;

[0026] Step 2, tape-casting the mixture in step 1 to obtain a green body;

[0027] Step 3, heat treating the green body obtained in step 2 at 480° C. for 2 hours to obtain a green body;

[0028] Step 4, sintering the green compact obtained in Step 3 at 1500° C. for 2 hours to obtain a ceramic material.

Embodiment 2

[0030] Step 1. Mix 97% of alumina, 1.5% of magnesium oxide, 0.5% of niobium pentoxide, 0.5% of yttrium trioxide and 0.5% of chromium trioxide according to the predetermined mass ratio, and add 1.2 times the mass ratio of organic fluid The casting aid is ball milled for 4 hours, wherein the organic casting aid is a mixed solution composed of ethanol, polyvinyl butyral, glycerin and phthalate, and the mass ratio of each component is: 30: 15:3:2;

[0031] Step 2, tape-casting the mixture in step 1 to obtain a green body;

[0032] Step 3, heat treating the green body obtained in step 2 at 480° C. for 4 hours to obtain a green body;

[0033] Step 4: Sinter the green body obtained in Step 3 at 1450° C. for 4 hours to obtain a ceramic material.

Embodiment 3

[0035] Step 1. Mix 95% of alumina, 2.5% of magnesium oxide, 1% of niobium pentoxide, 0.5% of yttrium trioxide and 1% of chromium trioxide according to the predetermined mass ratio, and add 1 times the mass ratio of organic fluid The casting aid is ball milled for 3 hours, wherein the organic casting aid is a mixed solution composed of ethanol, polyvinyl butyral, glycerin and phthalate, and the mass ratio of each component is: 30: 15:3:2;

[0036] Step 2, tape-casting the mixture in step 1 to obtain a green body;

[0037] Step 3, heat treating the green body obtained in step 2 at 480° C. for 3 hours to obtain a green body;

[0038] Step 4: Sinter the green body obtained in Step 3 at 1450° C. for 4 hours to obtain a ceramic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com