Amorphous smelting flux and preparation method and application thereof

A technology of smelting flux and amorphous state, which is applied in the welding of structural steel for ships and ocean engineering, amorphous smelting flux and its preparation, can solve the problem of affecting the safe use performance of marine equipment, the decline of weld mechanical properties, and the inability to To meet service requirements and other issues, achieve the effects of reducing defects, improving mechanical properties, and improving low-temperature impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

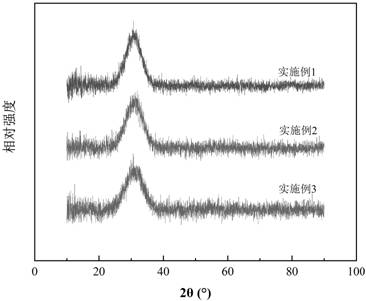

Embodiment 1

[0082] The amorphous smelting flux provided in this embodiment is made of the following components in terms of mass percentage: CaF 2 25%, CaO 35%, SiO 2 35% and TiO 2 5%.

[0083] The preparation method of the amorphous molten flux provided in this embodiment comprises the following steps:

[0084] (1) After crushing each raw material to a particle size of 80 mesh, weigh it according to the above mass percentage, then pour each weighed raw material into a blender, mix and stir for 30 minutes, and put it into an electric furnace for melting after stirring evenly. The temperature is 1450°C, and the temperature is kept for 20 minutes to obtain the molten material;

[0085] (2) Water quenching and granulation of the molten material obtained in step (1) to obtain a semi-finished product of gray-black amorphous flux particles; the mass ratio of the molten material to the water used for water quenching is 1:12;

[0086] (3) Put the semi-finished product of amorphous flux parti...

Embodiment 2

[0088] The amorphous smelting flux provided in this embodiment is made of the following components in terms of mass percentage: CaF 2 23%, CaO 33%, SiO 2 33% and TiO 2 11%.

[0089] The preparation method of the amorphous molten flux provided in this embodiment comprises the following steps:

[0090] (1) After crushing each raw material to a particle size of 120 mesh, weigh it according to the above mass percentage, then pour each weighed raw material into a blender, mix and stir for 20 minutes, and put it into an electric furnace for melting after stirring evenly. The temperature is 1480°C, and the temperature is kept for 20 minutes to obtain the molten material;

[0091] (2) Water-quenching and granulating the molten material obtained in step (1) to obtain a semi-finished product of gray-black amorphous flux particles; the mass ratio of the molten material to the water used for water quenching is 1:15;

[0092] (3) Put the semi-finished product of amorphous flux partic...

Embodiment 3

[0094] The amorphous smelting flux provided in this embodiment is made of the following components in terms of mass percentage: CaF 2 20%, CaO 32.5%, SiO 2 32.5% and TiO 2 15%.

[0095] The preparation method of the amorphous molten flux provided in this embodiment comprises the following steps:

[0096] (1) After crushing each raw material to a particle size of 100 mesh, weigh it according to the above mass percentage, then pour each weighed raw material into a blender, mix and stir for 25 minutes, and put it into an electric furnace for melting after stirring evenly. The temperature is 1500°C, and the temperature is kept for 15 minutes to obtain the molten material;

[0097] (2) Water-quenching and granulating the molten material obtained in step (1) to obtain a gray-black semi-finished product of amorphous flux particles; the mass ratio of the molten material to the water used for water quenching is 1:14;

[0098] (3) Put the semi-finished product of amorphous flux pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com