Titanium alloy plate welding method for improving welding performance

A welding performance and welding method technology, applied in welding/welding/cutting items, welding equipment, laser welding equipment, etc., to reduce the tendency of welding porosity, improve strength and plastic toughness, and improve the effect of thermal roughening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for welding titanium alloy plates that improves weldability, the steps of which are as follows:

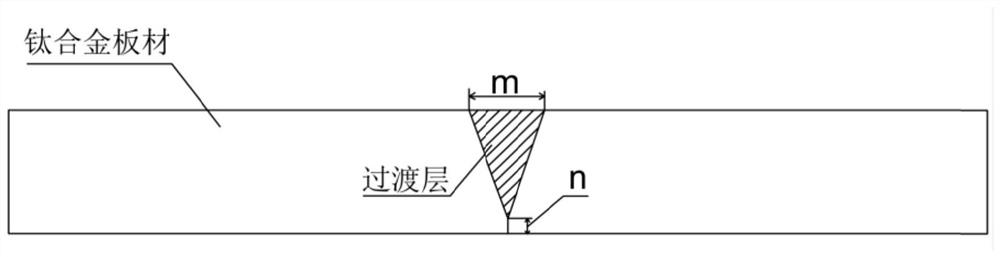

[0043] S1. Take a Ti6Al4V titanium alloy sheet with a thickness of 3mm, and open a V-shaped welding groove on the part to be welded of the titanium alloy sheet to form a butt joint. The groove angle of the welding groove is about 21°, and the upper opening width of the groove is 1.0 mm, the groove clearance is 0mm-1mm, and the blunt edge of the groove is 0.3mm;

[0044] S2. Weigh the metal particles according to the mass percentage of 6wt% Al, 4wt% V, 0.1wt% Ce, and the balance is Ti, prepare the alloy ingot by vacuum induction melting, and then utilize the method of electric discharge wire cutting to prepare the alloy ingot into the same The transition layer for welding groove adaptation of titanium alloy plates;

[0045] The specific method for preparing alloy ingots by vacuum induction melting is as follows:

[0046] S21. Put the weighed metal particles into t...

Embodiment 2

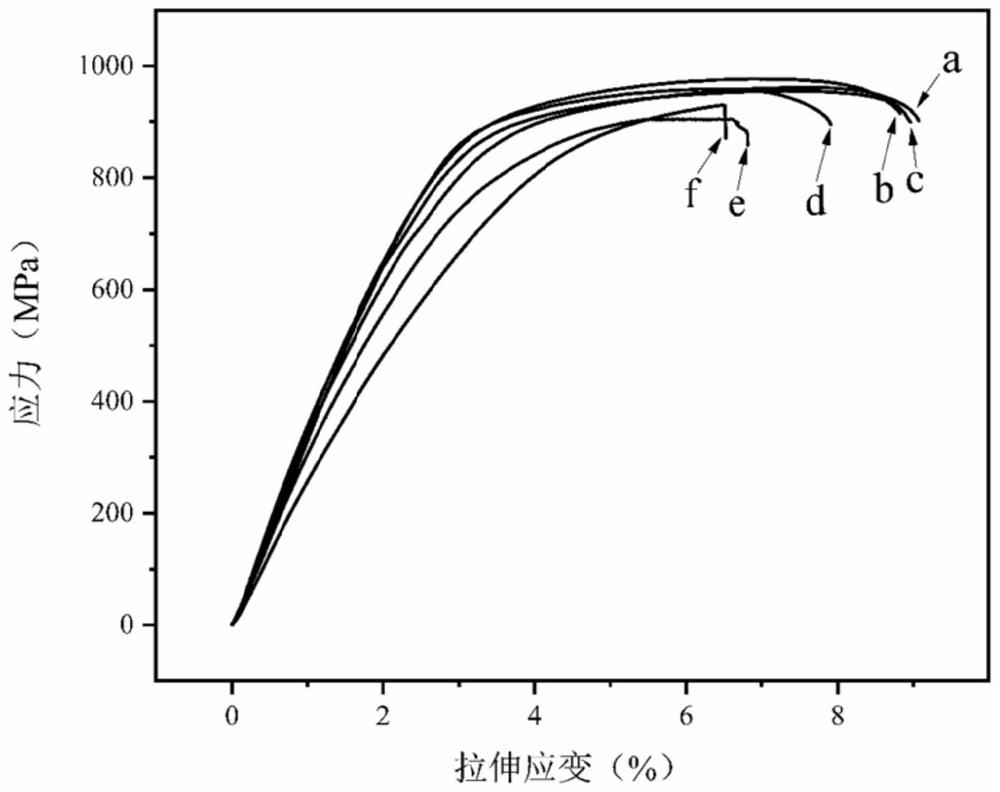

[0053] The technical features of this embodiment are basically the same as those of Embodiment 1, the only difference being that the mass percentage of cerium in the transition layer of this embodiment is 0.3%.

Embodiment 3

[0055] The technical features of this embodiment are basically the same as those of Embodiment 1, the only difference being that the mass percentage of cerium in the transition layer of this embodiment is 0.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com