High-performance bismuth series high-temperature superconducting strip and preparation method thereof

A high-temperature superconducting tape, high-performance technology, applied in the use of superconducting elements, superconducting devices, cable/conductor manufacturing, etc. grain connection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

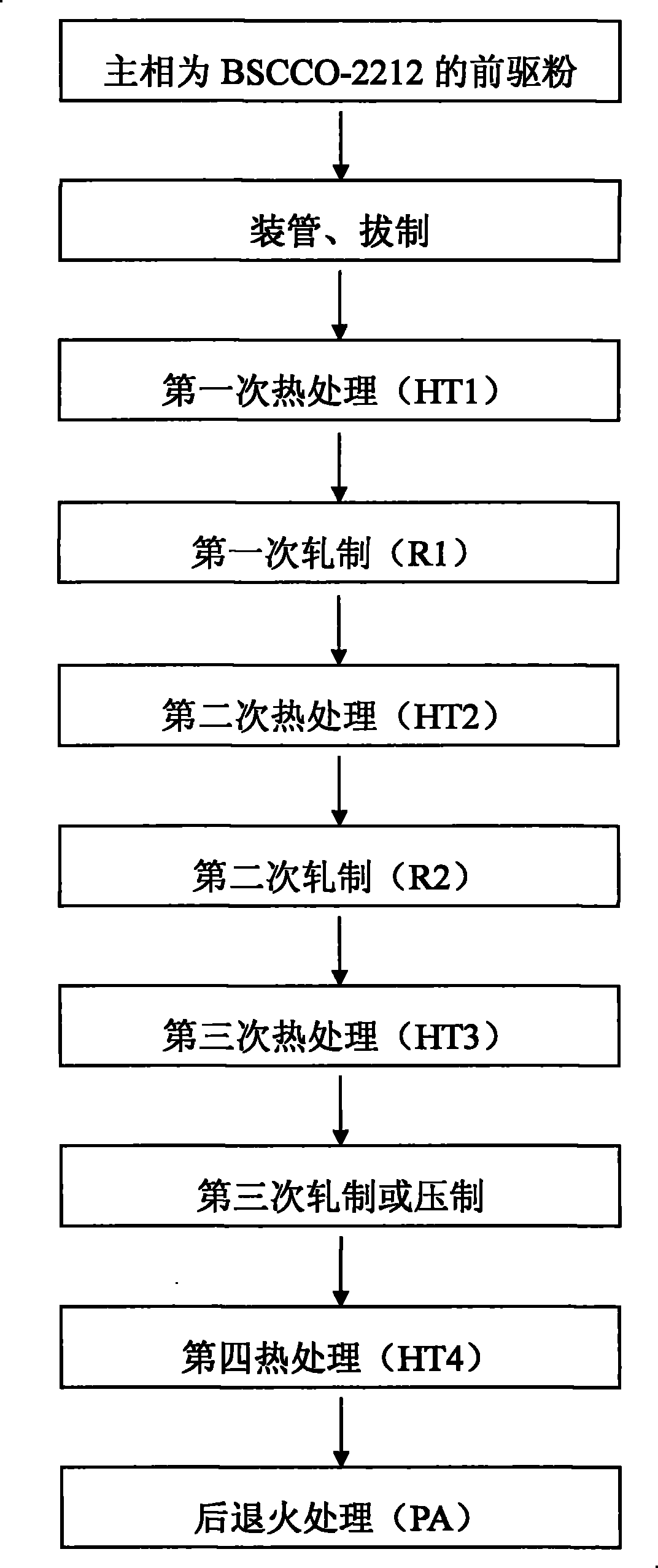

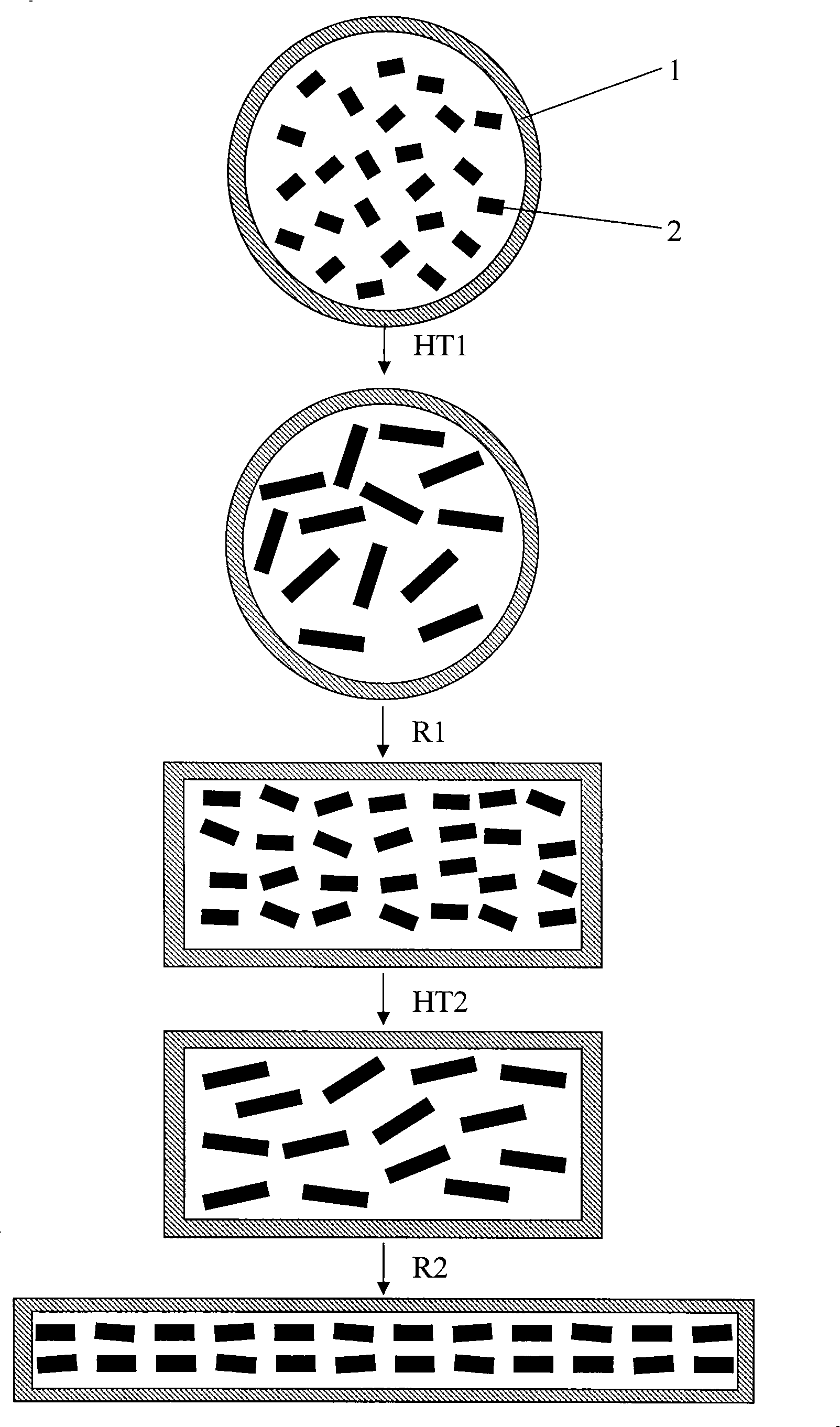

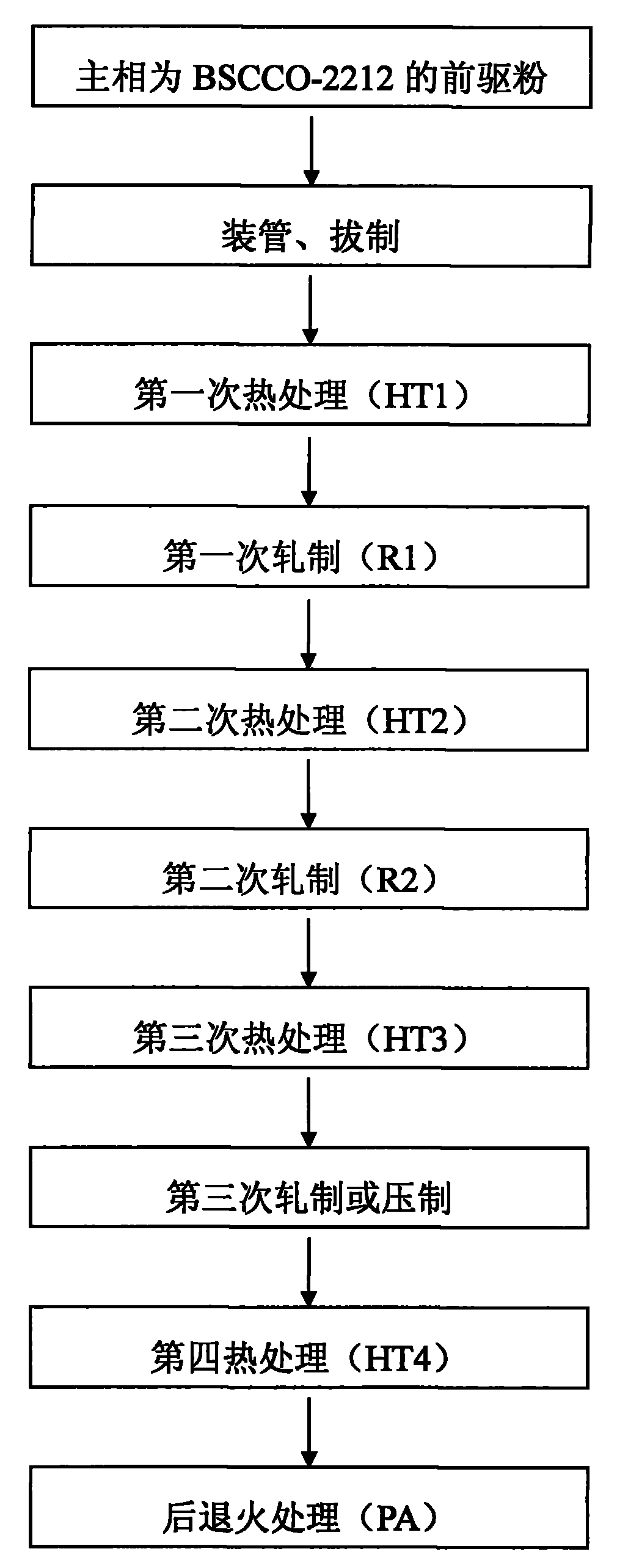

[0025] see figure 1 . Taking the single-core wire (ribbon) material as an example, take 15g of BSCCO-2212 precursor powder as the main phase, press the precursor powder 1 into a columnar shape, put it into the silver sleeve 2, and then undergo multi-pass drawing deformation (see Ueyama M, Hikata T, Kato K, et al. Microstructures and J c -BCharacteristics of Ag-Sheathed Bi-Based Superconducting Wires.Jpn.J.Appl.Phys.1991, 30:L1384-L1386) become the wire rod of single core round wire, the obtained wire rod is divided into 37 segments and put into silver alloy sleeve tube, and then through multiple passes of drawing to obtain a multi-core wire with a diameter of 1.5 mm. see figure 2 , the multi-core wire is subjected to the first heat treatment (HT1) at 650° C., argon and oxygen or nitrogen and oxygen are used as protective gases, and the oxygen partial pressure is 0.02 atm, and the heat treatment time is 10 hours. Then, the wire rod was rolled into a strip of 0.6 mm (thickn...

Embodiment 2

[0027] Press 20 grams of the precursor powder whose main phase is BSCCO-2212 into a columnar shape and put it into a silver sleeve. After mechanical deformation, a single-core round wire is obtained. The obtained round wire is divided into 61 segments and loaded into a silver alloy sleeve. Drawing and making diameter is the multi-core garden wire rod of 1.6 millimeters. The multi-core wire is subjected to heat treatment (HT1) at 820° C., argon and oxygen or nitrogen and oxygen are used as protective gases, the oxygen partial pressure is 0.2 atm, and the heat treatment time is 25 hours. Then, the wire rod was rolled into a strip of 1.0 mm (thickness)×1.5 mm (width). The strip was heat-treated at 820° C. for 25 hours (HT2), argon and oxygen or nitrogen and oxygen were used as protective gases, and the oxygen partial pressure was 0.2 atm. The wire rod was then rolled into a strip having dimensions 0.23 mm (thickness) x 4.1 mm (width).

[0028]Five short samples of the supercond...

Embodiment 3

[0030] Press 10 grams of the precursor powder whose main phase is BSCCO-2212 into a columnar shape and put it into a silver sleeve, then obtain a single-core round wire through mechanical deformation, divide the obtained round wire into 19 segments and put it into a silver alloy sleeve. Pull out and make diameter again and be the multi-core garden wire rod of 1.75 millimeters. The multi-core wire is subjected to heat treatment (HT1) at 720° C., argon and oxygen or nitrogen and oxygen are used as protective gases, the oxygen partial pressure is 0.1 atm, and the heat treatment time is 10 hours. Then, the wire rod was rolled into a strip of 0.5 mm (thickness)×0.7 mm (width). The strip was heat-treated at 720° C. for 15 hours (HT2), in which argon and oxygen or nitrogen and oxygen were used as protective gases, and the oxygen partial pressure was 0.1 atm. The wire rod was then rolled into a strip having dimensions 0.21 mm (thickness) x 4.2 mm (width).

[0031] Cut 10 short sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com