Fuel pellet with continuous phase structure and preparation method of fuel pellet

A technology of fuel pellets and phase structure, which is used in the manufacture of reactors, climate sustainability, reactors, etc., can solve the problems of long sintering cycle, difficult collection, environmental pollution, etc., to improve thermal conductivity and comprehensive performance, and shorten sintering. time, the effect of increasing the sintering rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

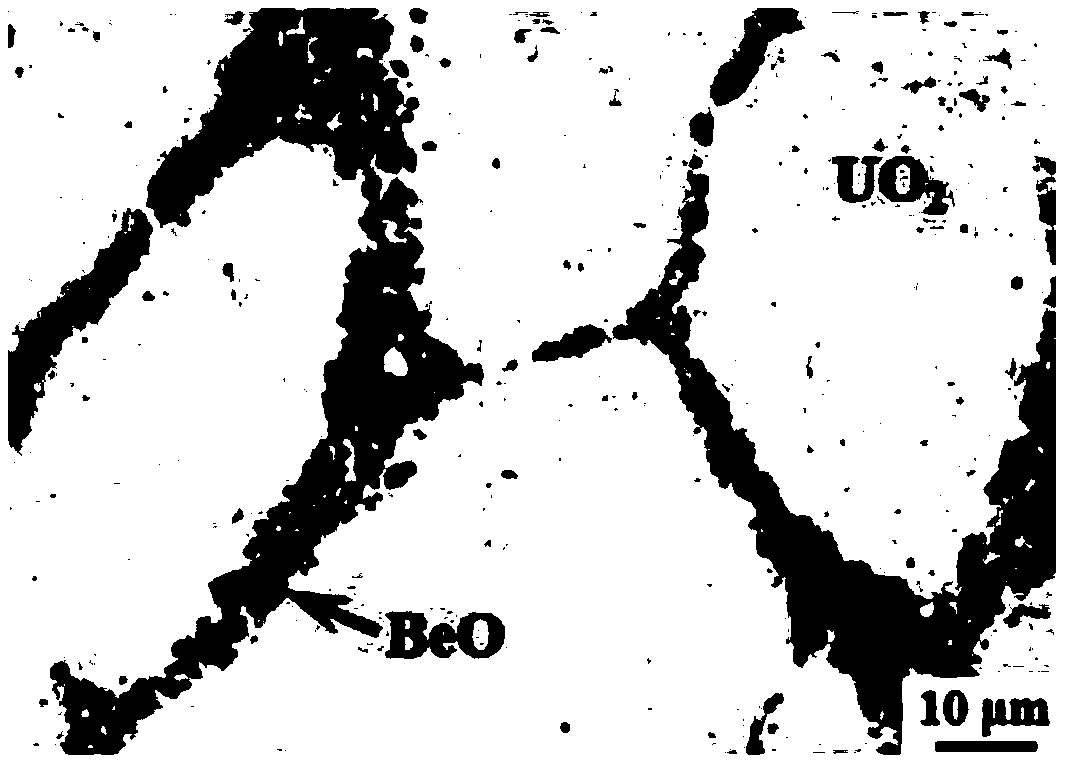

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

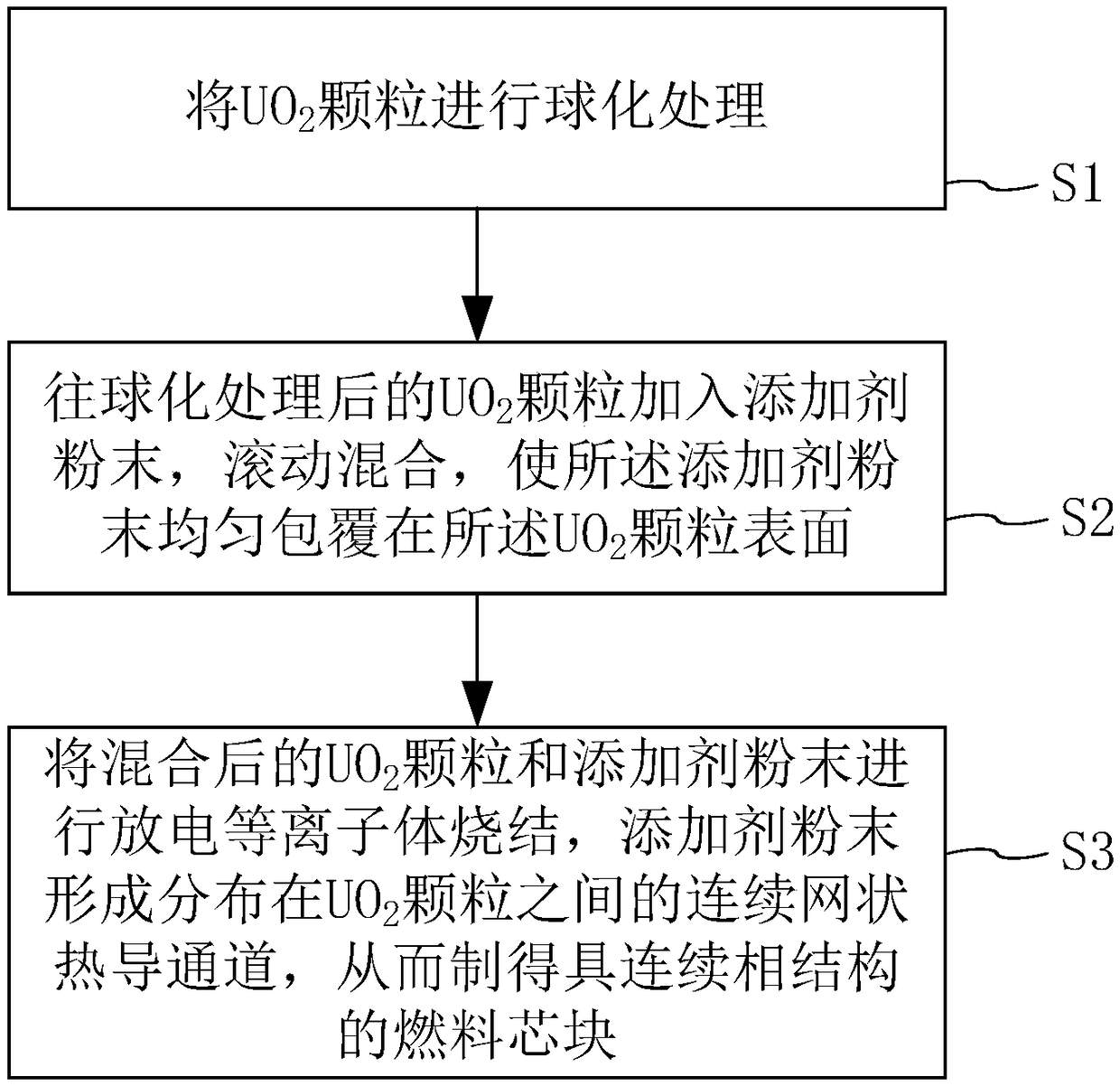

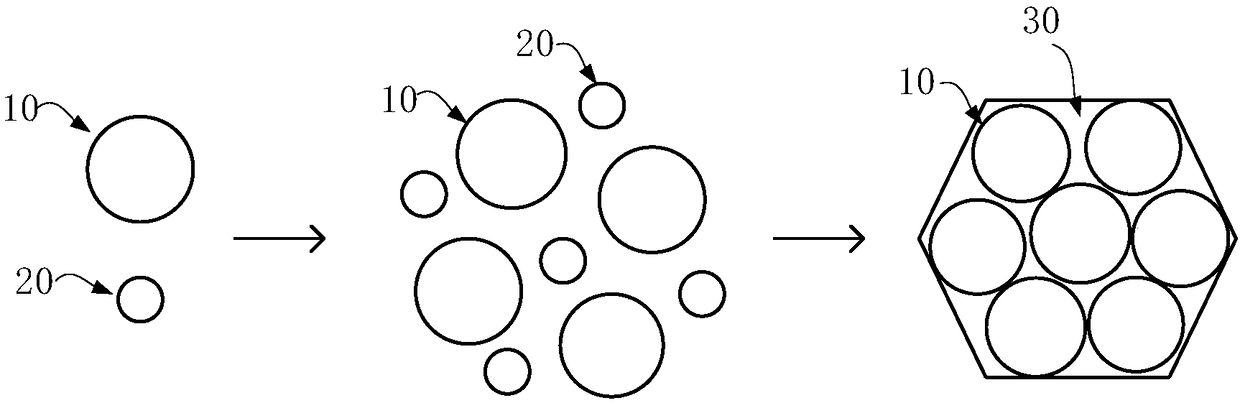

[0030] combine figure 1 , 2 , the method for preparing fuel pellets with a continuous phase structure according to an embodiment of the present invention may include the following steps:

[0031] S1, put UO 2 The (uranium dioxide) particles 10 are spheroidized.

[0032] UO after spheroidization 2 The particles 10 are spherical or nearly spherical. UO 2 The spheroidization treatment of the particles 10 ensures the encapsulation effect of the subsequent additive powder 20 on it, facilitates the uniform distribution of the additive powder 20 at the grain boundary after sintering, and can also inhibit the microcracks generated during the sintering process.

[0033] When this step S1 is carried out, the pre-processed U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com