Manufacturing method of nickel target material and nickel target material assembly

A manufacturing method and nickel target technology, applied in the field of target processing, can solve problems such as uneven internal structure, inability to meet the requirements of semiconductor sputtering process, and coarse crystal grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

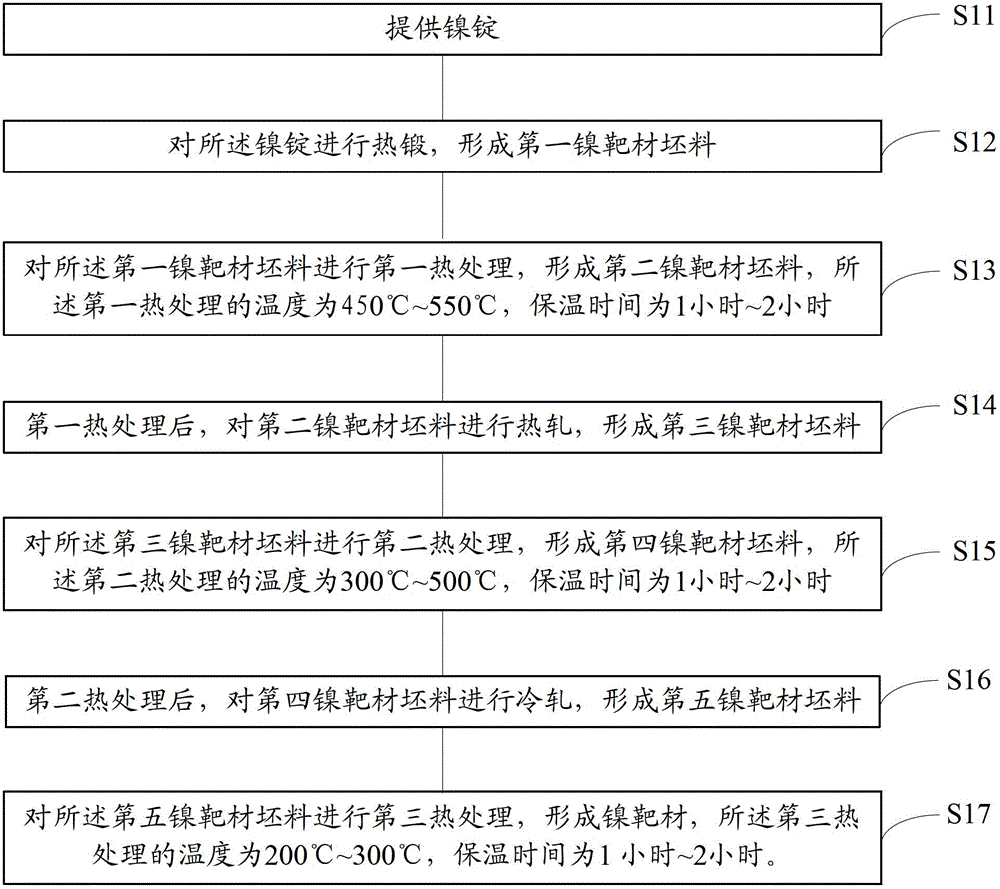

Method used

Image

Examples

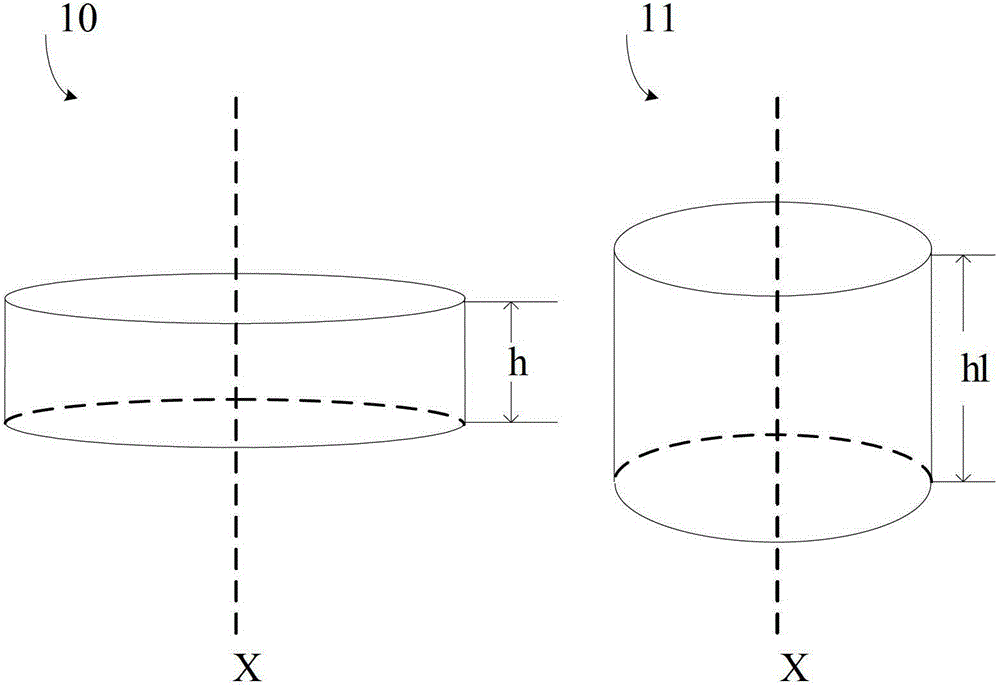

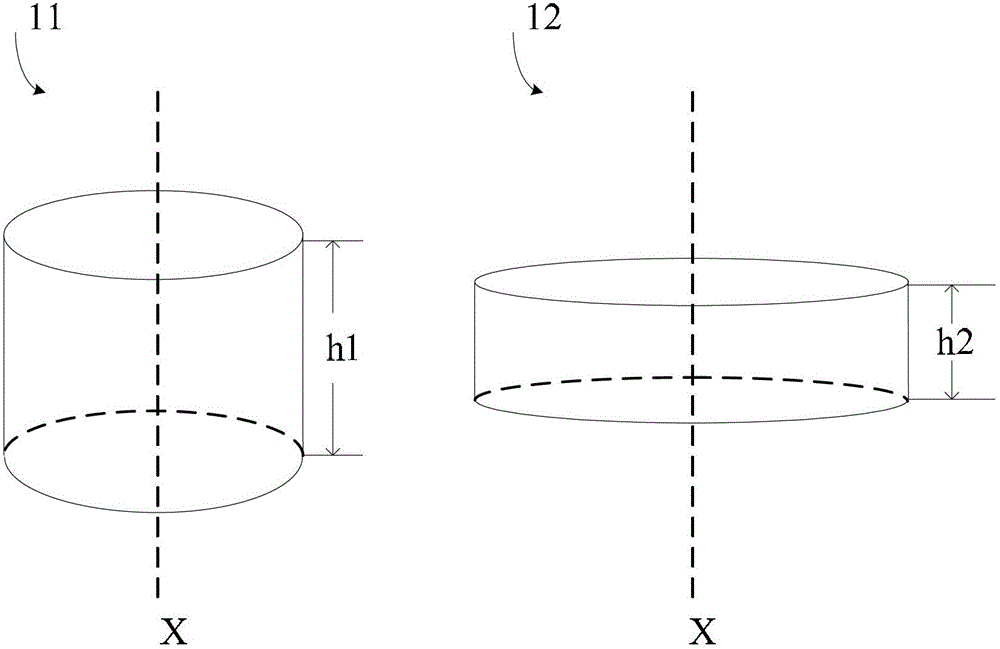

Embodiment Construction

[0063] As described in the background art, in the prior art, the processing technology of plastically deforming high-purity nickel ingots to produce high-purity nickel targets for semiconductors is less involved and incomplete. Therefore, how to produce nickel that meets the requirements The target material has become one of the most important problems to be solved at present.

[0064] PVD is usually carried out by magnetron sputtering. The so-called magnetron sputtering means that the plasma generated by the rare gas bombards the surface of the cathode sputtering target under the interaction of the electric field and the magnetic field, so that the molecules on the surface of the target, Atoms and electrons are sputtered out, and the sputtered particles have a certain kinetic energy, and shoot to the surface of the substrate in a certain direction, and deposit on the surface of the substrate to form a coating. The inventors found that in the process of coating by magnetron sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com