Method for making ultrafine grained steel

A technology of ultra-fine grains and manufacturing methods, which is applied in manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of increasing production difficulty and cost due to cooling control requirements, and achieve stable grains, simple process, and lightening of rolling mills. load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

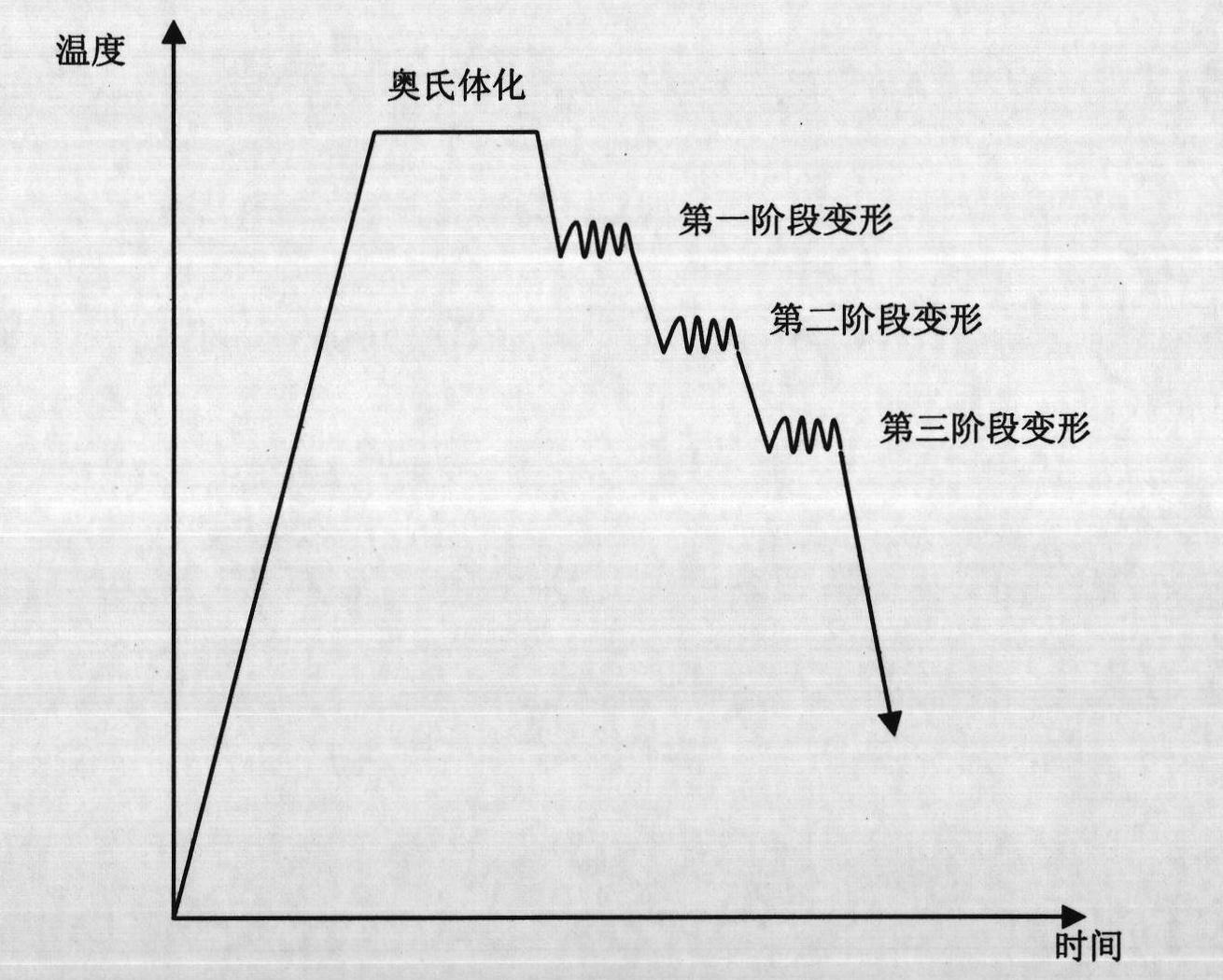

[0026] A kind of manufacturing method of ultra-fine-grained steel of the present invention, the chemical composition of material used is shown in Table 1, for the carbon steel with carbon content between 0.18% and manganese content between 0.54% in mass fraction , using the following hot deformation process to obtain ultra-fine grain steel, the deformation process is as follows figure 1 shown.

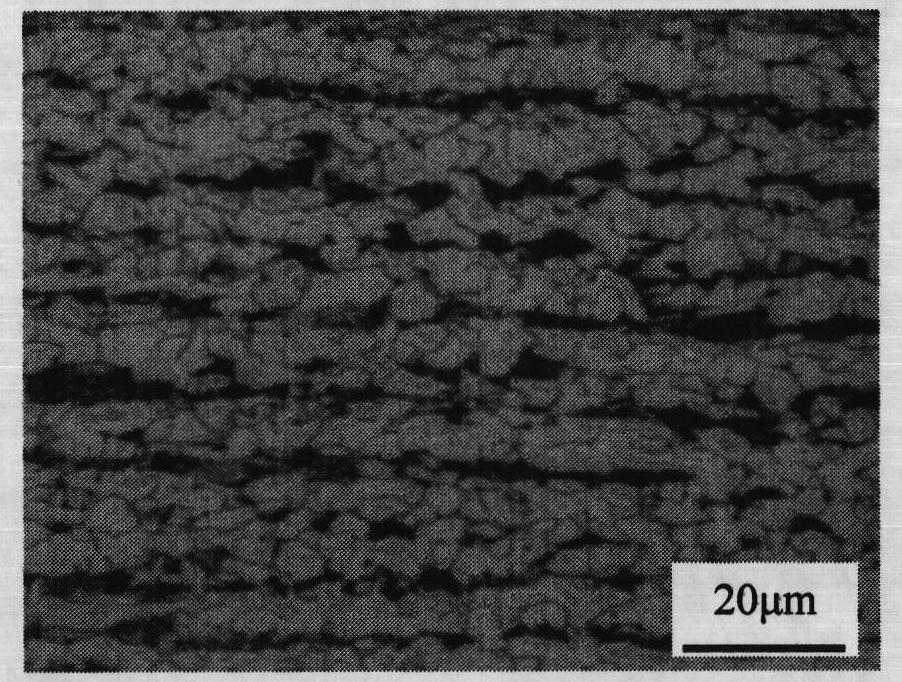

[0027] Heat the sample to 1200°C and hold it for 5 minutes. After it is fully austenitized, cool it to 1000°C, 850°C, and 780°C respectively at a cooling rate of 5°C / s. , 50%, 50%, uniaxial compression test, the strain rate of all deformation passes is Then carry out 5°C / s controlled cooling method to cool down to 600°C, and finally place it in air for cooling. obtained organizations such as figure 2 shown. from figure 2 It can be seen from the figure that the ferrite in the structure is composed of equiaxed ferrite and deformed ferrite, among which the grains of equiaxed ferri...

Embodiment 2

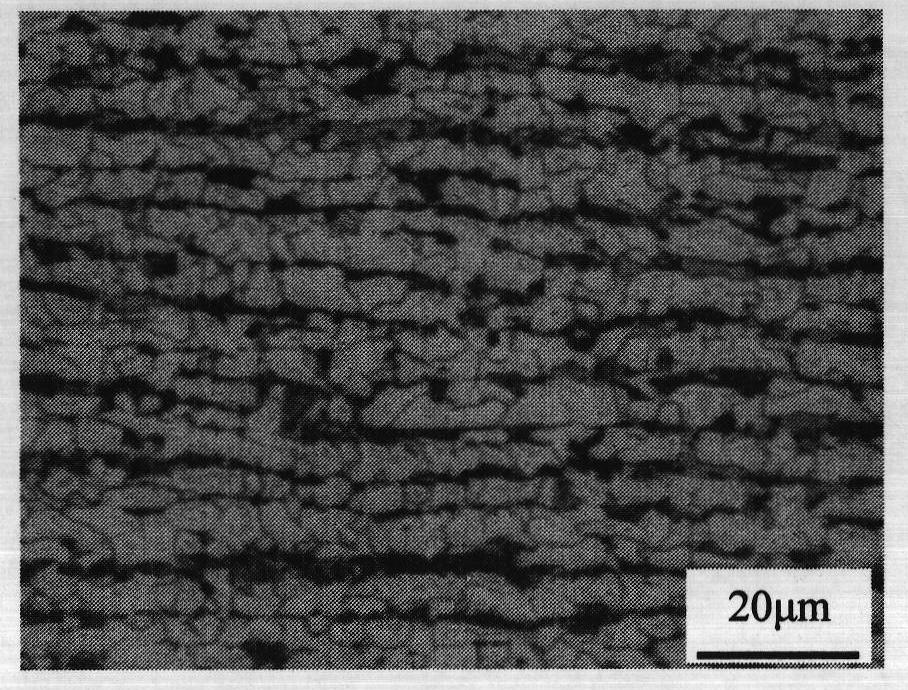

[0031] Yet another method for manufacturing ultra-fine grain steel according to the present invention, the material used is the same as in Example 1, and the post-rolling cooling rate in Example 1 is increased to 10°C / s in the deformation process, and the obtained room temperature microstructure Such as image 3 shown. The ferrite grains in the obtained structure are finer and more uniform than those obtained in Example 1. The average ferrite grain size measured by the intercept method is 2.29 μm.

[0032] It can be seen that the ultra-fine grain steel obtained according to the present invention has small grain size, simple process and low cost.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com