Graphene rare earth permanent magnet material and preparation method thereof

A rare earth permanent magnet and graphene technology, applied in the fields of magnetic materials, inorganic material magnetism, inductance/transformer/magnet manufacturing, etc. The problem of high cost is achieved, and the preparation process steps are simple and easy to control, the use of heavy rare earths is reduced, and the product quality is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

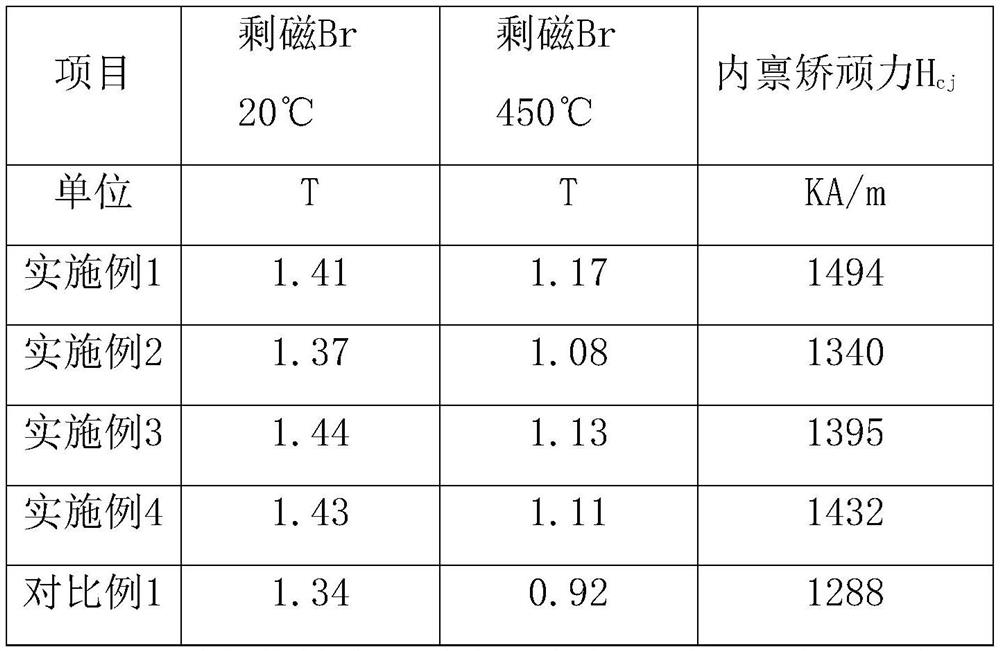

Examples

Embodiment 1

[0026] A graphene rare earth permanent magnet material, comprising the following raw materials in mass percentage: 21.5% neodymium, 6.9% praseodymium, 1.1% boron, 0.5% cobalt, 0.12% copper, 2.2% lanthanum, 1.9% cerium, 3% graphene, and The amount is iron.

[0027] The preparation method of above-mentioned graphene rare earth permanent magnet material, comprises the following steps:

[0028] S1. Mix graphene powder and magnet alloy powder in proportion to obtain graphene rare earth permanent magnet material powder. The magnet alloy powder is composed of neodymium, praseodymium, boron, cobalt, copper, lanthanum, cerium and iron in proportion ; The graphene rare earth permanent magnet material powder is oriented in a magnetic field under the protection of an inert gas, and pressed into shape to obtain a green body;

[0029] S2. The green body is subjected to isostatic pressing, placed in a sintering furnace for sintering, and then tempered to obtain a graphene rare earth permane...

Embodiment 2

[0043] A graphene rare earth permanent magnet material, comprising the following raw materials in mass percentage: 20.6% neodymium, 7.5% praseodymium, 0.95% boron, 0.4% cobalt, 0.11% copper, 2.4% lanthanum, 1.7% cerium, 1% graphene, and The amount is iron.

[0044] The preparation method of above-mentioned graphene rare earth permanent magnet material, comprises the following steps:

[0045] S1. Mix graphene powder and magnet alloy powder in proportion to obtain graphene rare earth permanent magnet material powder. The magnet alloy powder is composed of neodymium, praseodymium, boron, cobalt, copper, lanthanum, cerium and iron in proportion ; The graphene rare earth permanent magnet material powder is oriented in a magnetic field under the protection of an inert gas, and pressed into shape to obtain a green body;

[0046] S2. The green body is subjected to isostatic pressing, placed in a sintering furnace for sintering, and then tempered to obtain a graphene rare earth perman...

Embodiment 3

[0060] A graphene rare earth permanent magnet material, comprising the following raw materials in mass percentage: 23.4% neodymium, 6.6% praseodymium, 1.20% boron, 0.6% cobalt, 0.15% copper, 2.0% lanthanum, 2.1% cerium, 5% graphene, and The amount is iron.

[0061] The preparation method of above-mentioned graphene rare earth permanent magnet material, comprises the following steps:

[0062] S1. Mix graphene powder and magnet alloy powder in proportion to obtain graphene rare earth permanent magnet material powder. The magnet alloy powder is composed of neodymium, praseodymium, boron, cobalt, copper, lanthanum, cerium and iron in proportion ; The graphene rare earth permanent magnet material powder is oriented in a magnetic field under the protection of an inert gas, and pressed into shape to obtain a green body;

[0063] S2. The green body is subjected to isostatic pressing, placed in a sintering furnace for sintering, and then tempered to obtain a graphene rare earth perman...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com