Preparation method of aluminum and aluminum alloy welding wire electrochemically plated with Zn+Cu/Re composite coating and applied to robot welding

A technology of aluminum alloy welding wire and composite coating, which is applied in liquid chemical plating, coating, metal material coating process and other directions to achieve the effects of good compactness, good rust resistance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

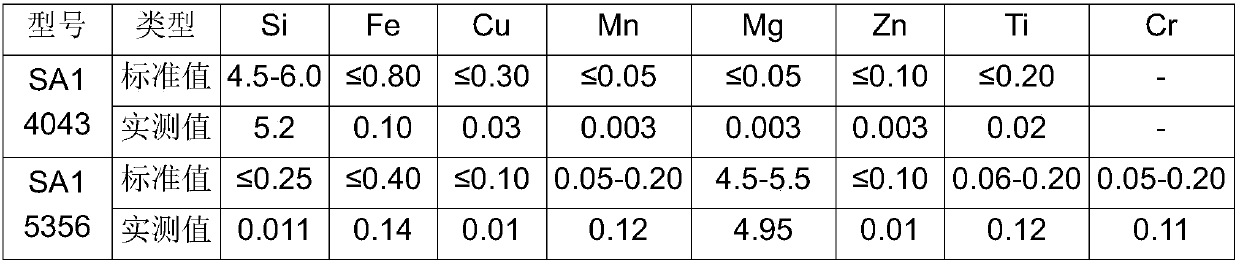

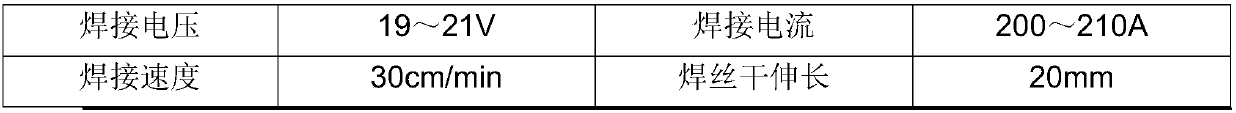

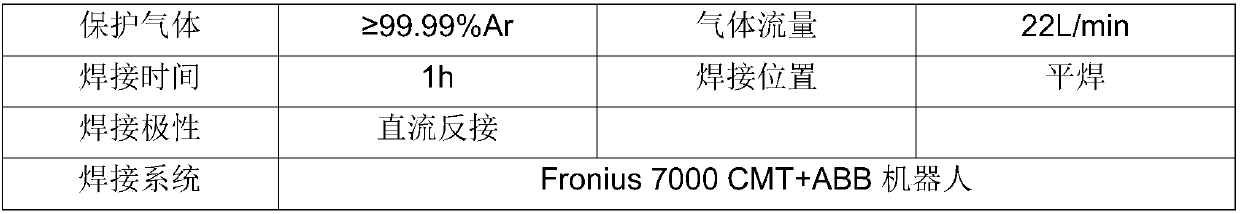

[0019] A preparation method of welding wire for aluminum and aluminum alloy robots with electrochemical Zn+Cu composite coating, the substrates are respectively SA1 4043 and SA1 5356 aluminum alloy wire rods, wherein the diameter of the wire rods is 9.5 mm, and the specific preparation steps are as follows:

[0020] (1) Pre-treatment includes ultrasonic + lye degreasing treatment, 2 high-pressure cold water rinses, ultrasonic + activation solution to remove oxide film, 2 high-pressure cold water rinses, completely remove grease, scale and oxide film on the surface of the wire rod, and make the substrate clean active crystal surface. Wherein, the lye is composed of 45g / L sodium hydroxide, 60g / L sodium carbonate, 56g / L sodium phosphate, 20g / L sodium silicate, 5g / L sodium pyrophosphate and tap water, and the degreasing reaction temperature is 60°C. The reaction time is 240s; the activation solution is composed of 500ml / L nitric acid and tap water, the reaction temperature for deo...

Embodiment 2

[0024] A preparation method of electrodeposited Zn+Cu / Re composite coating aluminum and aluminum alloy welding wire for robots. The substrates are respectively SA1 4043 and SA1 5356 aluminum alloy wire rods, wherein the diameter of the wire rod is 6.5 mm. The specific preparation steps as follows:

[0025](1) Pre-treatment includes ultrasonic + lye degreasing treatment, 2 high-pressure cold water rinses, ultrasonic + activation solution to remove oxide film, 2 high-pressure cold water rinses, completely remove grease, scale and oxide film on the surface of the wire rod, and make the substrate clean active crystal surface. Wherein, the lye is composed of 30g / L sodium hydroxide, 25g / L sodium carbonate, 40g / L sodium phosphate, 25g / L sodium silicate, 10g / L sodium pyrophosphate and tap water, and the degreasing reaction temperature is 60°C. The reaction time is 180s; the activation solution is composed of 400ml / L nitric acid and tap water, the reaction temperature for deoxidation ...

Embodiment 3

[0029] A preparation method of electrodeposited Zn+Cu / Re composite coating aluminum and aluminum alloy welding wire for robots. The substrates are respectively SA1 4043 and SA1 5356 aluminum alloy wire rods, wherein the diameter of the wire rods is 2.5 mm. Specific preparation steps as follows:

[0030] (1) Pre-treatment includes ultrasonic + lye degreasing treatment, 2 high-pressure cold water rinses, ultrasonic + activation solution to remove oxide film, 2 high-pressure cold water rinses, completely remove grease, scale and oxide film on the surface of the wire rod, and make the substrate clean active crystal surface. Wherein, the lye is composed of 15g / L sodium hydroxide, 20g / L sodium carbonate, 50g / L sodium phosphate, 30g / L sodium silicate, 15g / L sodium pyrophosphate and tap water, and the degreasing reaction temperature is 60°C. The reaction time is 90s; the activation solution is composed of 300ml / L nitric acid and tap water, the reaction temperature for deoxidation fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com