Preparation method of boron-containing structural steel

A manufacturing method and technology of structural steel, which is applied in the field of steel material manufacturing, can solve problems such as large differences in structure, and achieve the effects of low cost, improved toughness, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for manufacturing boron-containing structural steel according to the present invention, the chemical composition of the materials used is shown in Table 1.

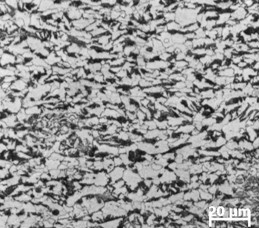

[0025] Heat the sample to 1175°C and hold it for 5 minutes. After it is completely austenitized, cool it to 1000°C, 850°C, and 780°C at a cooling rate of 5°C / s. %, 33.3%, 50%, single pass compression test, the strain rate of all deformation passes is 1s -1 . Then carry out 5°C / s controlled cooling method to cool down to 600°C, and finally place it in air for cooling. obtained organizations such as figure 1 shown. From figure 1 It can be seen that the structure is composed of a large number of polygonal ferrite and granular bainite, the grain size is small, and a small amount of pearlite is distributed on the polygonal ferrite.

[0026]

Embodiment 2

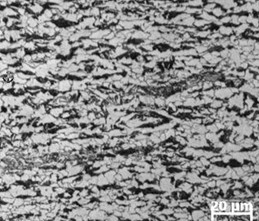

[0028] A method for manufacturing boron-containing structural steel according to the present invention, the material used is the same as in Example 1, the final cooling temperature in Example 1 is increased to 630°C in the controlled cooling process, and the strain rate of all deformation passes is 3s -1 . The obtained room temperature tissue is as figure 2 shown. The obtained structure is also composed of polygonal ferrite, acicular ferrite, pearlite and a large number of clustered granular bainite. Compared with Example 1, the grain size does not change much, and the acicular ferrite increases a lot , the volume fraction of pearlite increases.

Embodiment 3

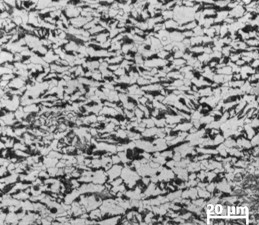

[0030] A method for manufacturing boron-containing structural steel according to the present invention, the materials used are the same as in Examples 1 and 2, the final cooling temperature is increased to 660°C in the controlled cooling process, and the strain rate of all deformation passes is 5s -1 . The obtained room temperature tissue is as image 3 shown. The obtained structure is composed of a large amount of ferrite, a small amount of polygonal ferrite, a very small amount of pearlite and granular bainite, and the grain size is increased compared with Examples 1 and 2, but the increase is not obvious.

[0031] It can be seen that the boron-containing steel obtained according to the present invention has excellent structure and properties, fine grain size, average grain size of ferrite less than 5 μm, simple process and low cost.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com