Method for improving Al0.3CoCrFeNi high-entropy alloy intensity

A high-entropy alloy, strength technology, applied in metal material coating process, ion implantation plating, coating and other directions, to achieve the effect of increased tensile strength, uniform structure, and reduced amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides an Al 0.3 The strengthening method of CoCrFeNi high-entropy alloy includes the following:

[0031] 1. The preparation of multi-principal element high-entropy alloy is a key step. The preparation process has the following steps in sequence:

[0032] (1) Raw material preparation: The alloy smelting raw materials used in the present invention are high-purity (≥99.9%) Al, Co, Cr, Fe and Ni elements, which are accurately weighed and proportioned according to the molar ratio. Before smelting, the metal surface The oxide is polished and cleaned with alcohol ultrasonic wave for use in smelting and preparing alloys. The quality of each component of the alloy is shown in Table 1.

[0033] Table 1 Quality of ingredients

[0034]

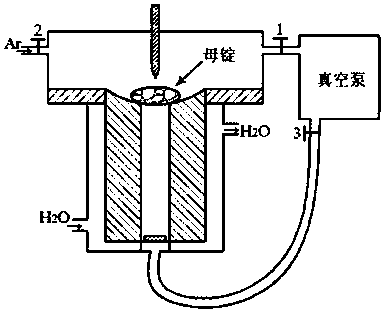

[0035] (2) Preparation of high-entropy alloy: The equipment used for smelting is WK-Ⅱ vacuum arc furnace. Before smelting, the water-cooled copper crucible in the furnace needs to be cleaned, and cotton is dipped in alcohol for wiping a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com