A kind of preparation method of high-strength wear-resistant feb material

A high-strength, industrial pure iron technology, applied in the field of preparation of high-strength and wear-resistant FeB materials, can solve the problems of long boronizing time, easy cracking, peeling, parts failure, etc., and achieves the effect of remarkable hardness, low price, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

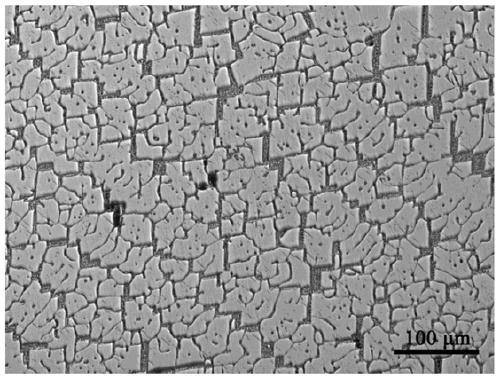

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing a high-strength wear-resistant FeB material, comprising the following steps:

[0025] S1. Industrial pure iron and ferroboron are polished and derusted respectively, and the raw materials are calculated and weighed according to a certain ratio;

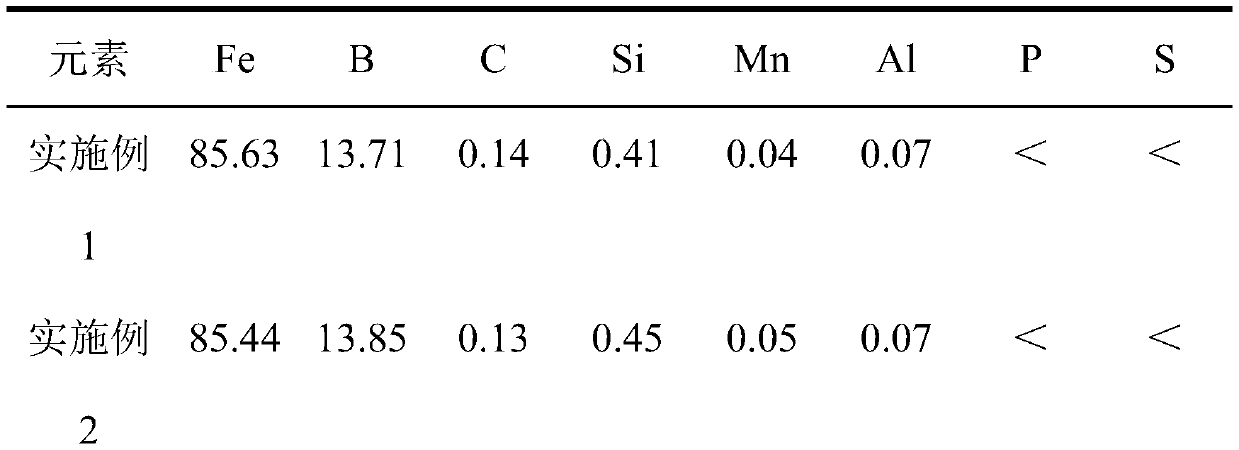

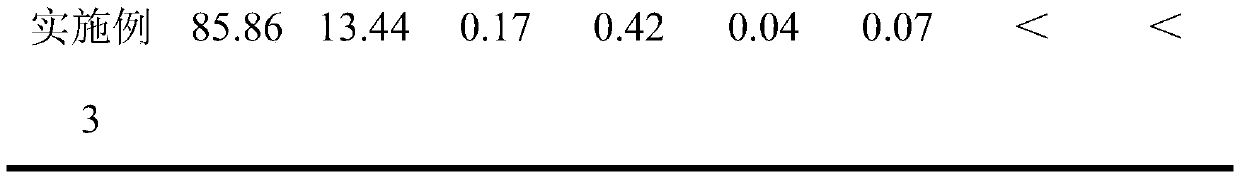

[0026] The chemical composition of pure iron, in terms of mass fraction, includes: ≥99.8% Fe, other elements ≤0.003% C, ≤0.02 Si, ≤0.15 Mn, ≤0.012% P, ≤0.01% S.

[0027] The chemical composition of ferroboron, in terms of mass fraction, includes: 19.5-20% of B, 0.6-0.8% of Si, 0.3-0.35% of C, 0.1-0.15% of Al, ≤0.04% of P, ≤0.01% of S, the balance is Fe.

[0028] When calculating the ratio of raw materials, the final mass fraction of boron element is 16.2%, and boron element needs to be added to achieve a burning loss rate of 8-10%.

[0029] S2. Fill pure iron into the smelting furnace, heat and melt it, when the temperature of the smelting furnace rises to 1550-1650°C, add aluminu...

Embodiment 1

[0037] According to the technical scheme of the present invention, the FeB material of the present invention is smelted in a 10kg intermediate frequency induction furnace, and the process steps are:

[0038] (1) Grinding and derusting industrial pure iron and ferroboron, weighing 1.107kg and 8.893kg respectively (considering the loss on ignition of 8% boron); (2) Filling pure iron into the smelting furnace , heating and melting, when the temperature of the smelting furnace rises to 1550°C, it is necessary to add aluminum wire to deoxidize the molten iron; (3) Break the ferroboron into pieces with a particle size of 5-15mm, and put it in a vacuum drying oven at 60°C Keep it warm for 10 hours and dry it. After the pure iron in the furnace is completely melted, add small pieces of ferroboron; (4) When the temperature reaches 1650°C, keep it warm for 10 minutes, and then pour it into a sand mold for casting. After cooling, a high-strength and wear-resistant FeB material is obtaine...

Embodiment 2

[0041] According to the technical scheme of the present invention, the FeB material of the present invention is smelted in a 10kg intermediate frequency induction furnace, and the process steps are:

[0042] (1) Grinding and derusting industrial pure iron and ferroboron, weighing 0.909kg and 9.091kg respectively (considering 10% loss on ignition of boron element); (2) Filling pure iron into the smelting furnace , heating and melting, when the temperature of the smelting furnace rises to 1600°C, it is necessary to add aluminum wire to deoxidize the molten iron; (3) Crush the ferroboron into pieces with a particle size of 5-15mm, and place it in a vacuum drying oven at 50°C Keep it warm for 15 hours and dry it. After the pure iron in the furnace is completely melted, add small pieces of ferroboron; (4) When the temperature reaches 1700°C, keep it warm for 10 minutes, and then pour it into a sand mold for casting. After cooling, a high-strength and wear-resistant FeB material is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com