Patents

Literature

274results about How to "Improve crystallization efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

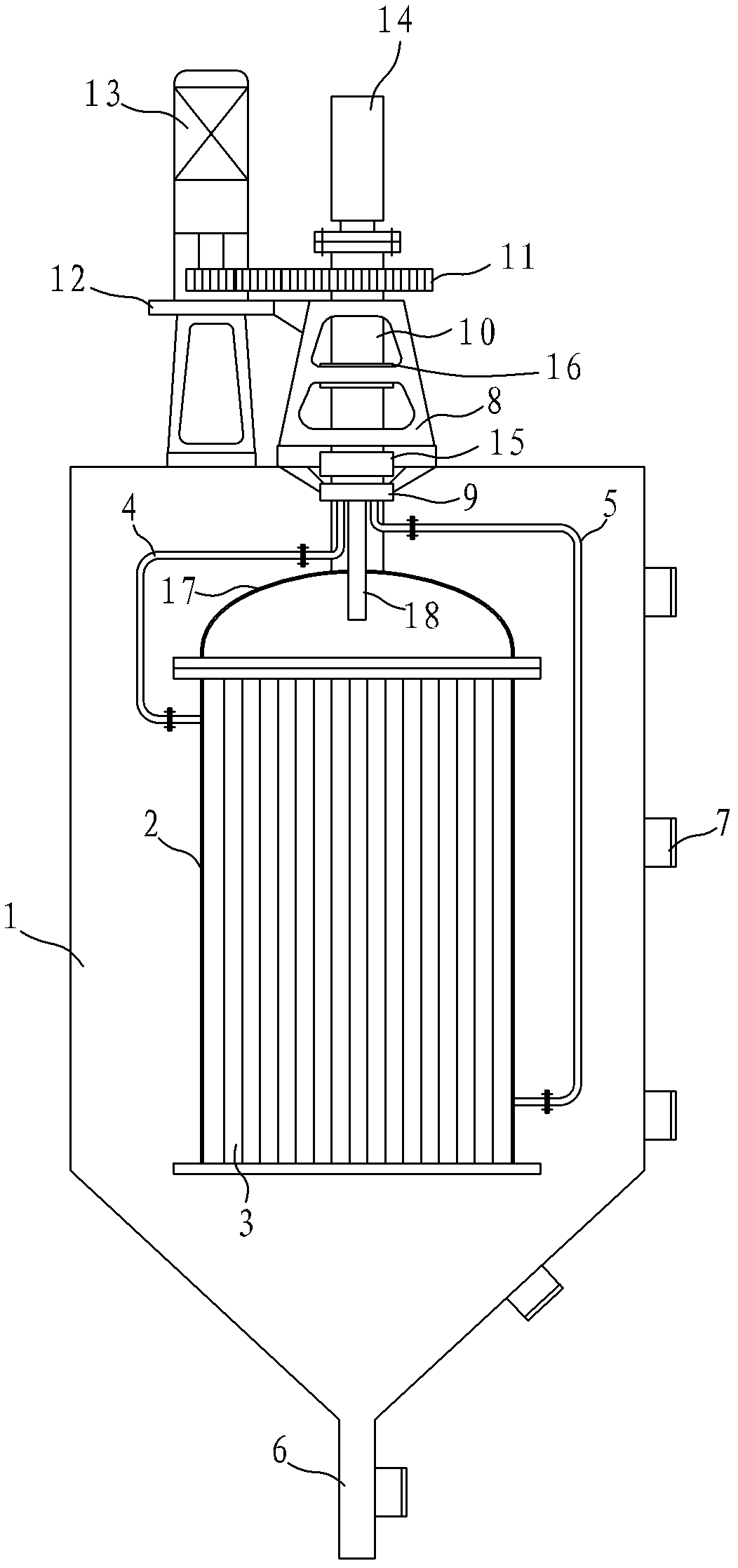

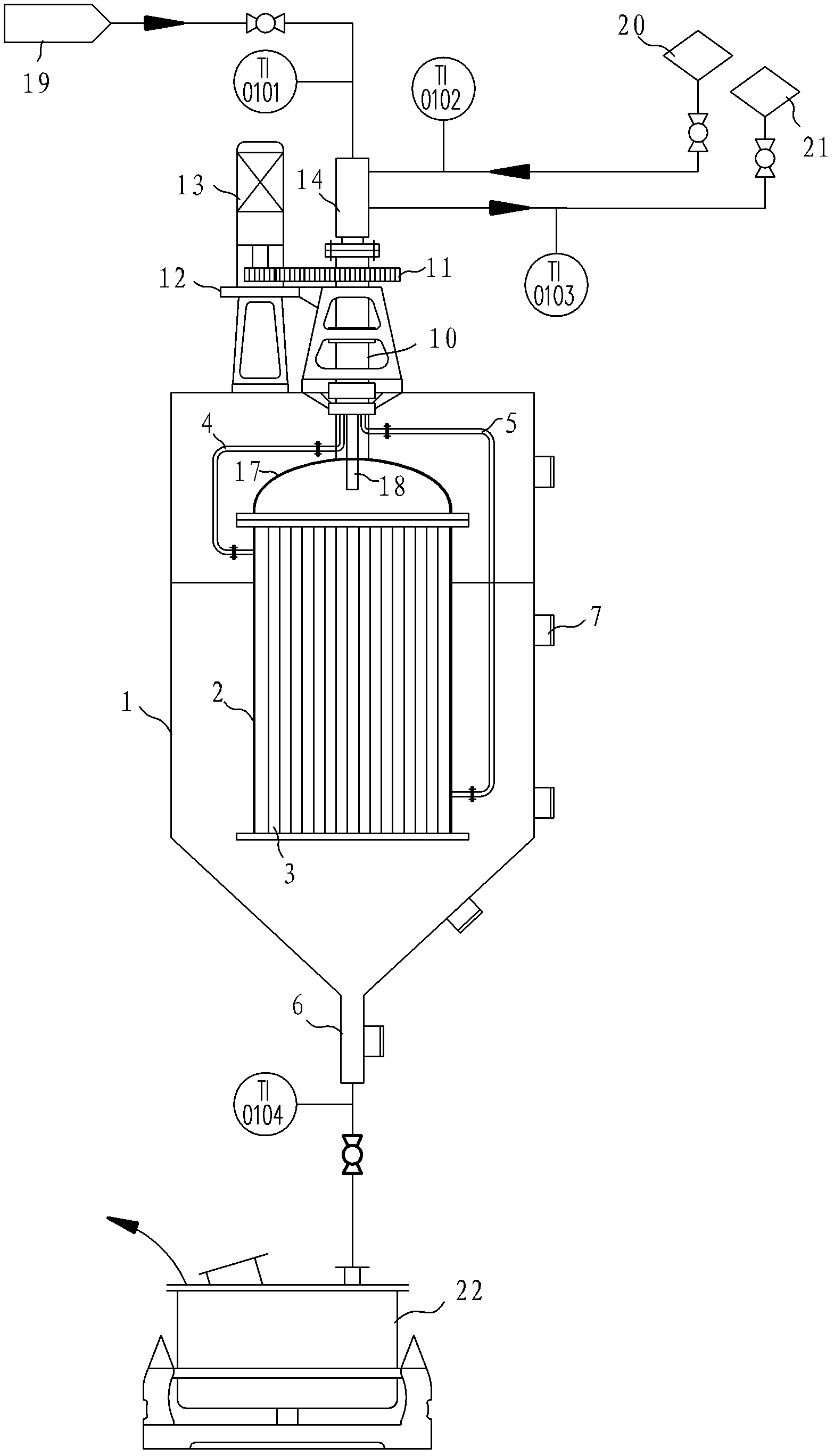

Erythritol crystal and preparation method of erythritol crystal

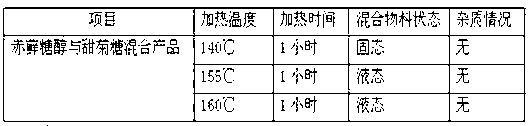

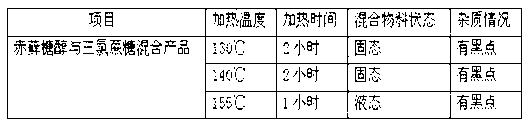

The invention relates to the technical field of compound sugar, in particular to an erythritol crystal, which comprises erythritol and sweet agents accounting for 1 to 2.5 percent of the weight of the erythritol. A preparation method of the erythritol crystal comprises the following steps that the erythritol and the sweet agents are mixed and dissolved to obtain liquid solution, the solution is simultaneously evaporated and crystallized, and the erythritol crystals are obtained; the erythritol and the sweet agents are mixed and are dissolved to obtain liquid solution, the liquid solution is subjected to non-evaporation crystallization, the filtering is carried out after the crystallization completion, and the erythritol crystals are obtained; the erythritol and the sweet agents are mixed in a solid from; and the mixed solids are subjected to melting, crystallization, crushing and drying to obtain the erythritol crystals. The sweetness of the erythritol is improved and reaches more than 80 percent of the sweetness of the cane sugar, the consistency of ingredients of compound products of the erythritol and the sweet agents is realized, the problem of cocrystallization of the erythritol and the sweet agents easily carbonized at high temperature is solved, the crystallization rate is improved to the maximum degree, the crystallization efficiency is 5 to 20 percent higher than that of the traditional crystallization technology, and the application field of the product is enlarged.

Owner:BAOLINGBAO BIOLOGY

Method for in-situ synthesis of Y-type molecular sieve

ActiveCN101618882AImprove crystallization efficiencyImprove propertiesFaujasite aluminosilicate zeoliteChemistryIn situ crystallization

The invention relates to a method for the synthesis of a Y-type molecular sieve, which comprises the following steps: (1) making coal-series kaolin and a binder into slurry; (2) spray drying the slurry and making the spray-drying product into microspheres; (3) roasting the microspheres; (4) mixing the microspheres with an alkaline crystallizing solution containing an organic template to crystallize the microspheres under a hydrothermal condition; and (5) obtaining an in-situ crystallization product by filtering and washing. Using the coal-series kaolin as a raw material for the in-situ molecular sieve synthesis, the method expands raw material sources and reduces the production cost of products. And the product of the method is large in specific surface area and high in crystallinity and can be used in reaction processes such as catalytic cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

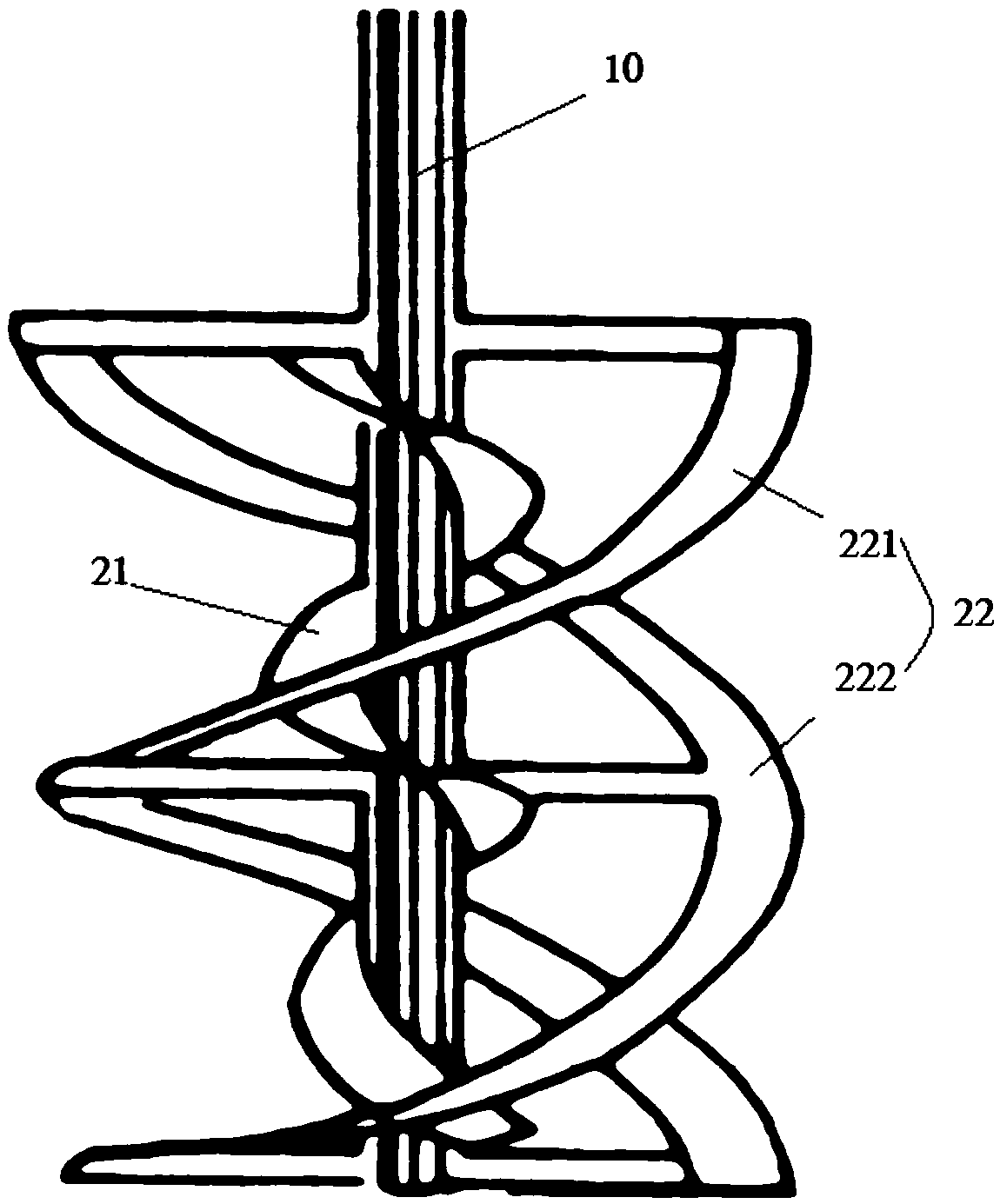

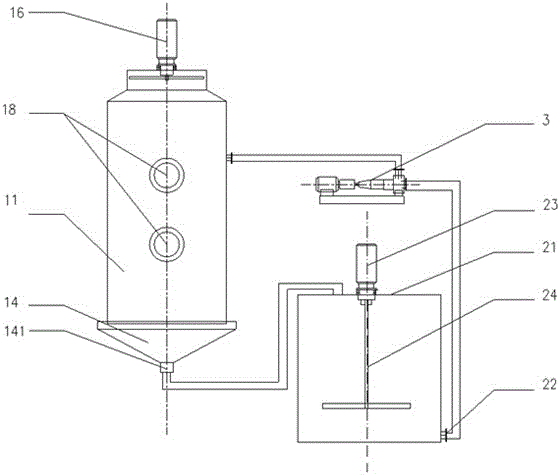

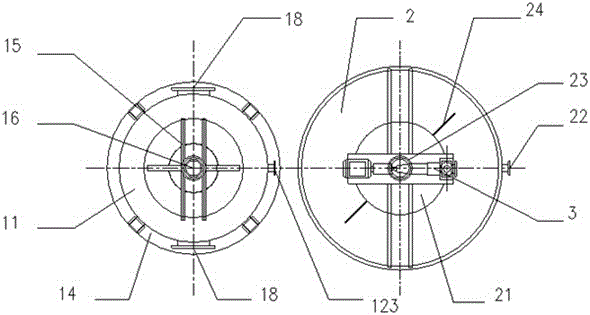

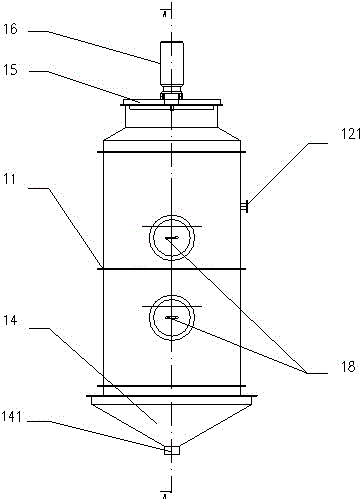

Continuous cooling crystallizer

InactiveCN102430261AImprove crystallization efficiencyNot easy to scaleSolution crystallizationCooling mediumPlate heat exchanger

Owner:ZHEJIANG HUAYI ENG DESIGN

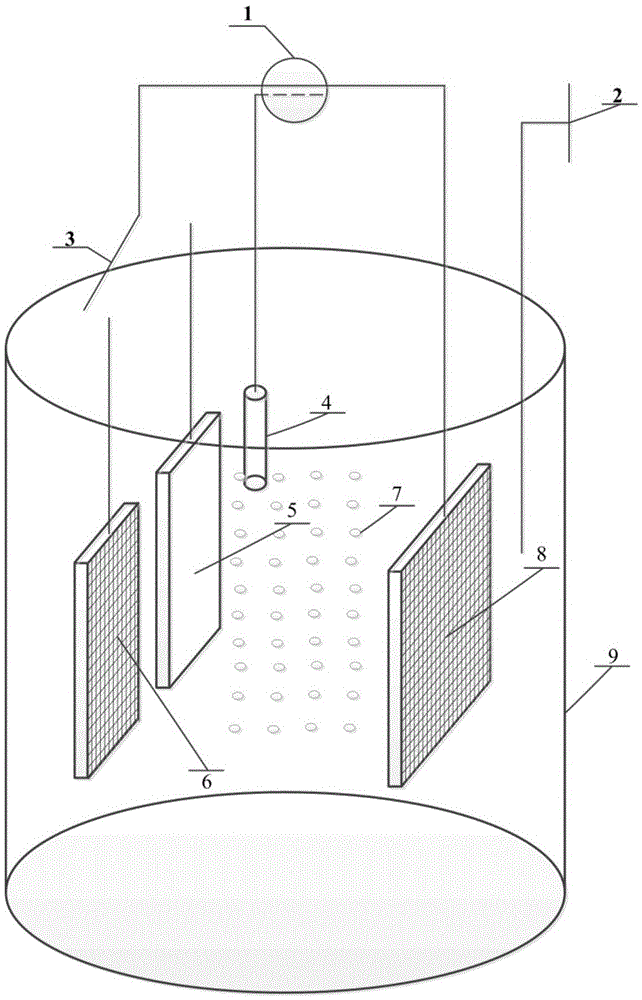

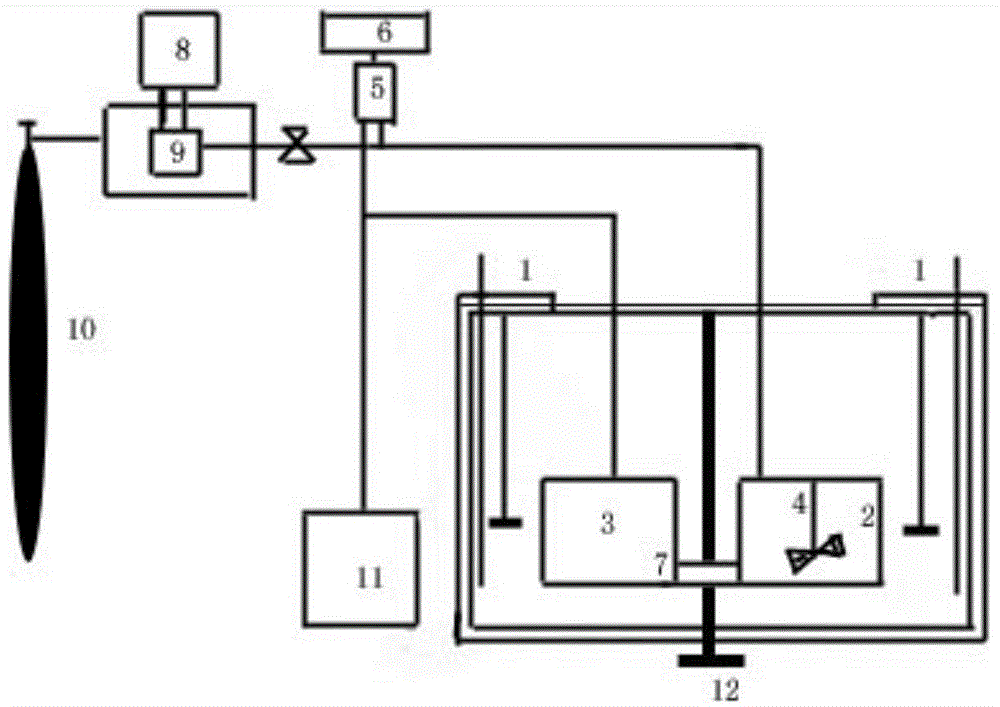

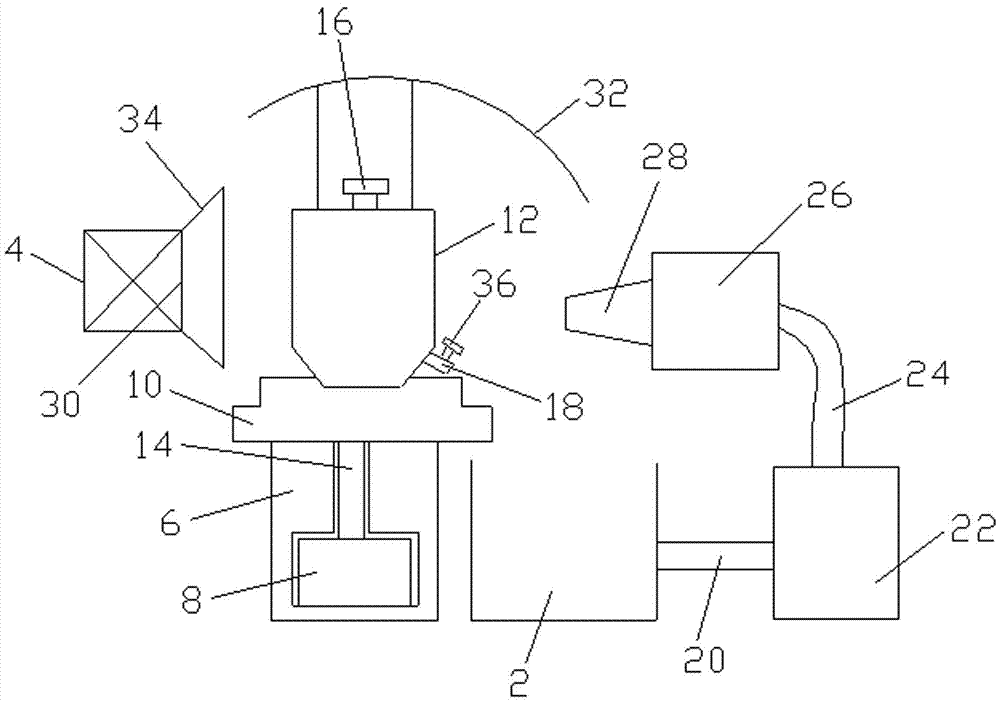

Magnesium ammonium phosphate-electrooxidation integrated device and simultaneous nitrogen and phosphorus removing method thereof

ActiveCN105668717ASave on medicine costsSynchronous removalWater contaminantsPhosphorus compoundsNitrogenMagnesium ammonium phosphate

The invention discloses a magnesium ammonium phosphate-electrooxidation integrated device and a simultaneous nitrogen and phosphorus removing method thereof and belongs to the field of wastewater treatment.The magnesium ammonium phosphate-electrooxidation integrated device comprises a magnesium ammonium phosphate-electrooxidation crystallization system and a nitrogen electrooxidation system.The magnesium ammonium phosphate-electrooxidation crystallization system comprises a reaction base and an anode B.The nitrogen electrooxidation system comprises a reaction base and an anode A.Each reaction base comprises an electrochemical instrument, a selector switch, a reference electrode, scrap iron, a cathode and a reactor, wherein the reference electrode and the cathode are connected in parallel through wires and vertically suspended in the reactor after being connected with the electrochemical instrument, the scrap iron can be suspended in the reactor through magnetic force stirring, and the selector switch is connected with the electrochemical instrument through a wire and then are connected with the anode A and the anode B in a switching mode.Just through simple electrode switching, the simultaneous nitrogen and phosphorus removing effect can be achieved, operation is easy, automatic running can be achieved, and no new pollution sources are generated.

Owner:JINGDEZHEN CERAMIC UNIV

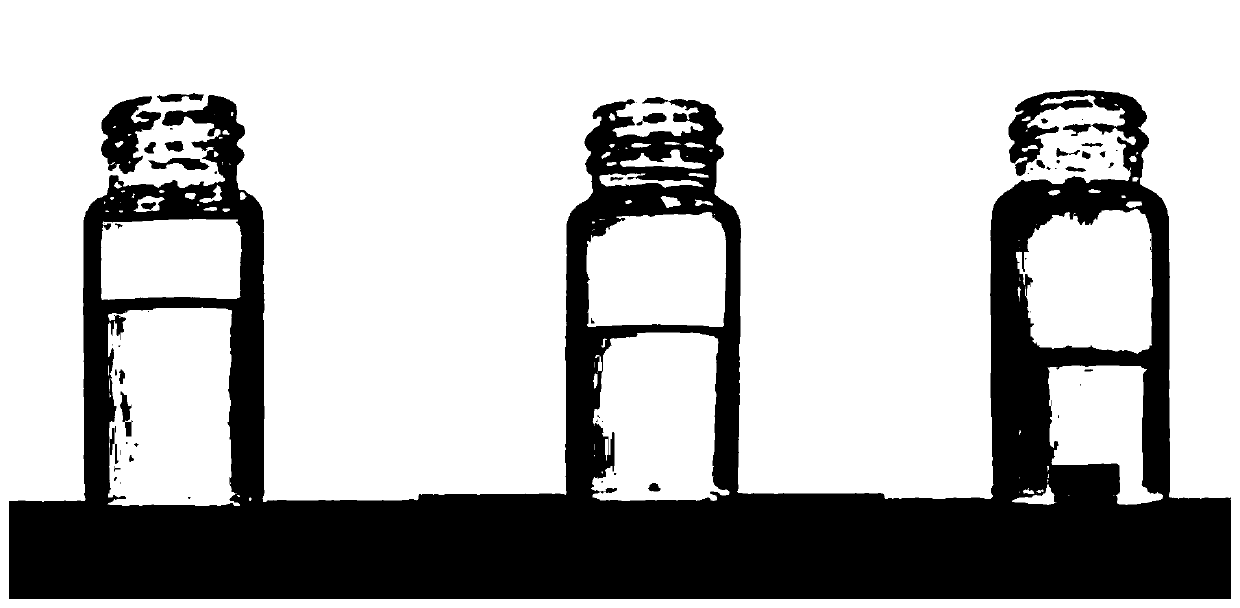

Crystallized honey and making method thereof

ActiveCN105010928AThe taste is dense and waxyUniform and dense grainFood preparationAdditive ingredientSeed crystal

The invention provides a making method of crystallized honey. According to the method, seed crystal is prepared by a twice crystallization process of firstly carrying out quantitative inoculation and secondly carrying out natural crystallization; and then, the crystallized honey product is prepared by a crystallization process of repeated alternate steps of air agitation and standing. The prepared crystallized honey has uniform and dense crystalline grains and has good ductility. The crystallized honey will not be obviously molten or layered when being stored at 30 DEG C or below, not influencing choices of consumers due to appearance of the crystallized honey. The crystallized honey is convenient to take and tastes dense and fine. In addition, other ingredients are not added, and honey is completely used as the raw material to prepare the crystallized honey. Thus, consumers' fear for the harm of other added additives is eliminated. Besides, the making method of the crystallized honey has high crystallization efficiency, and a creamy crystallization state with particle size according with requirements can be obtained within 24-48 hours.

Owner:COFCO GROUP +2

Ammonium rhenate solution crystallization method

ActiveCN102992407AIncrease productionImprove crystallization efficiencyRhenium compoundsRoom temperatureAmmonia

The invention provides an ammonium rhenate solution crystallization method. The technical scheme of the invention is characterized in that the method comprises the following steps: 1, placing an ammonium rhenate solution having a temperature of 30-90DEG C and a concentration of not less than 15g / L in an open container, wherein the ammonium rhenate solution is obtained after evaporating concentration; 2, adding a substance which can hydrolyze to generate NH4<+> into the ammonium rhenate solution in order to adjust the pH value of the ammonium rhenate solution to 8-11, wherein the substance is ammonia water; 3, blowing the ammonium rhenate solution by a wind source commonly used in the industry in order to cool the ammonium rhenate solution to room temperature, and preliminarily crystallizing the ammonium rhenate solution in the cooling process; 4, cooling the ammonium rhenate solution in an environment having a temperature of -10-0DEG C for above 6h; and 5, taking the ammonium rhenate solution out of the environment, and carrying out solid-liquid separation to obtain crude ammonium rhenate. The ammonium rhenate solution crystallization method has the advantages of crystallization efficiency improvement and ammonium rhenate product output improvement.

Owner:JIANGXI COPPER

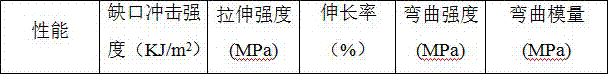

LCP/PBT/PET ternary alloy material and preparation method thereof

InactiveCN107383807AStrong impact resistanceHigh tensile strengthPolytetramethylene terephthalatePolybutylene

The invention relates to the technical field of a high-molecular material, and more specifically relates to a LCP / PBT / PET ternary alloy material and a preparation method thereof. The LCP / PBT / PET ternary alloy material comprises the following raw materials in parts by weight: 10-40 parts of a liquid crystal polymer, 10-40 parts of polybutylene telephthalate, 10-40 parts of polyethylene glycol terephthalate, 5-40 parts of glass fiber, 3-15 parts of a compatilizer, 3-15 parts of a fire retardant, 0.1-0.5 parts of an anti-oxidant, 0.2-2 parts of a lubricant and 1-2 parts of a modifier. The ternary alloy material has the excellent mechanical properties of toughness, impact strength, tensile strength and bending strength, and has the advantages of good fireproof performance, good heat resistance, low water absorption, good size stability, high crystallization efficiency, good moulding performance, good processing performance, low cost, and high usage value.

Owner:广东壹豪新材料科技股份有限公司

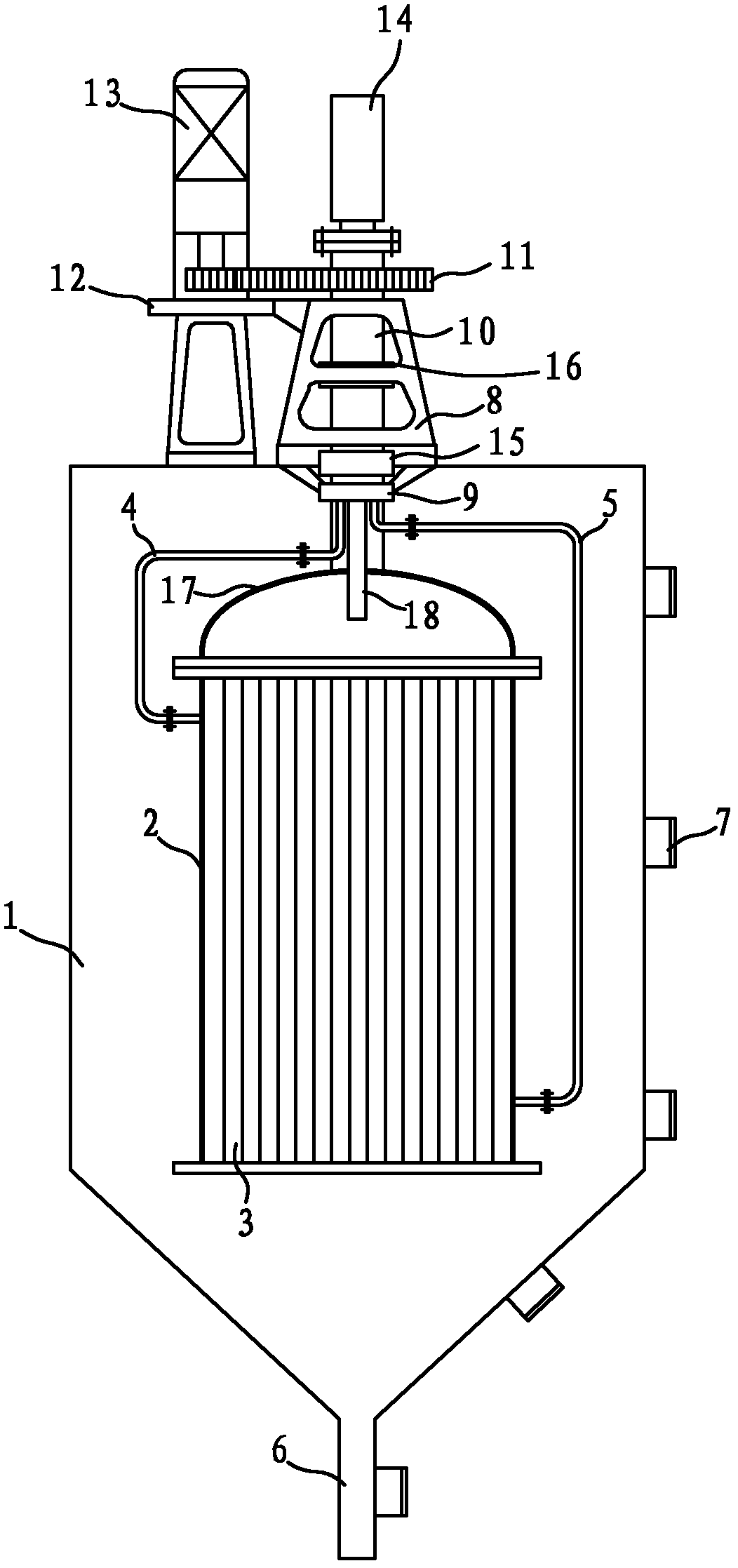

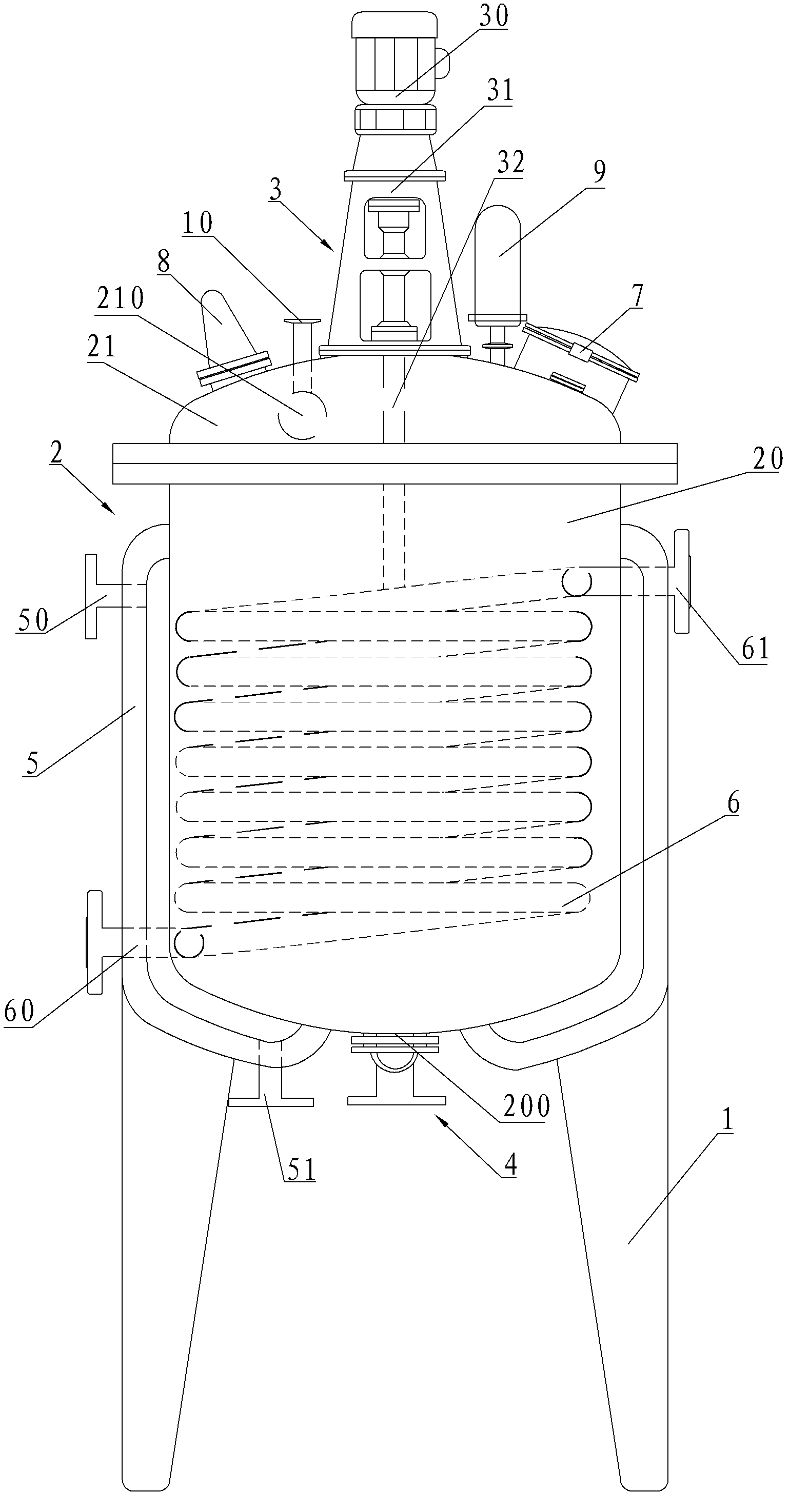

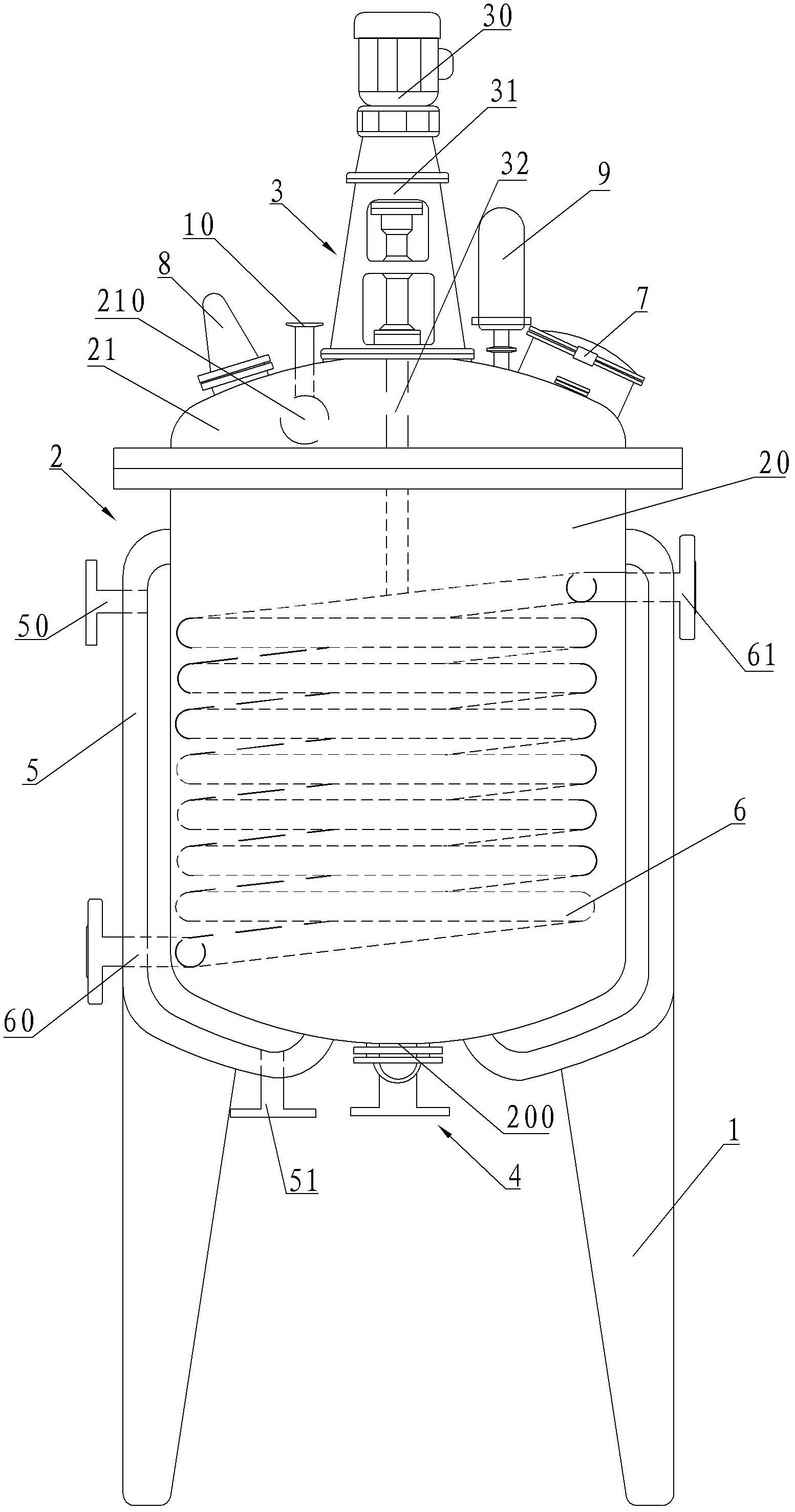

Vinpocetine special-purpose crystallization pot

InactiveCN102423543AEasy to set upEasy to operateOrganic chemistrySolution crystallizationHeat transfer efficiencyCondensed water

The invention relates to a vinpocetine special-purpose crystallization pot, which contains a pot rack, a pot and a stirring device. The pot contains a pot body and a cover. The bottom of the pot body is provided with a discharge hatch which is equipped with a discharged valve. A feed inlet is disposed on the cover. The periphery of the pot body is provided with an insulation jacket with a steam inlet and a condensed water outlet. The crystallization pot also contains a condensation coil pipe disposed inside the pot body. The condensation coil pipe is equipped with a condensate liquid inlet and a condensate liquid outlet which extend out through the pot. According to the crystallization pot, the condensation coil pipe is arranged inside the pot. As the condensation coil pipe directly contacts with a material, the heat transfer efficiency is highest, and the material can be rapidly cooled. Therefore, the vinpocetine crystallization rate can be raised and the crystallization efficiency can be improved. In addition, the invention is simple to arrange and convenient to operate.

Owner:江苏斯威森生物医药工程研究中心有限公司

Extraction method of lincomycin

ActiveCN103724380AHigh strengthExtended service lifeSugar derivativesSugar derivatives preparationChemical oxygen demandUltrafiltration

The invention provides an extraction method of lincomycin. The extraction method mainly comprises the following steps: adjusting acidity of fermentation liquor, filtering by using a ceramic ultrafiltration membrane, then adjusting alkalinity, then filtering by using a ceramic ultrafiltration membrane again, then carrying out primary sec-octyl alcohol extraction and hydrochloric acid back-extraction, adjusting alkalinity of the primary back extraction liquor and then filtering by using a ceramic ultrafiltration membrane again; carrying out secondary sec-octyl alcohol extraction and hydrochloric acid back-extraction and adding acetone to the secondary back extraction liquor to carry out evaporative crystallization. According to the extraction method provided by the invention, the yield of the lincomycin is high, the color grade of the lincomycin can be improved, and the B component content in the lincomycin is reduced. According to the extraction method of the lincomycin, the feed liquid quality of other extraction technologies can be improved by a membrane treatment process, the integral extraction efficiency is further improved, the residual volume of sec-octyl in raffinate in the extraction procedure is reduced, the product quality is improved, and meanwhile, the COD (Chemical Oxygen Demand) in produced wastewater is reduced. The extraction method has certain economic benefit and environmental benefit.

Owner:JIANGSU JIUWU HITECH

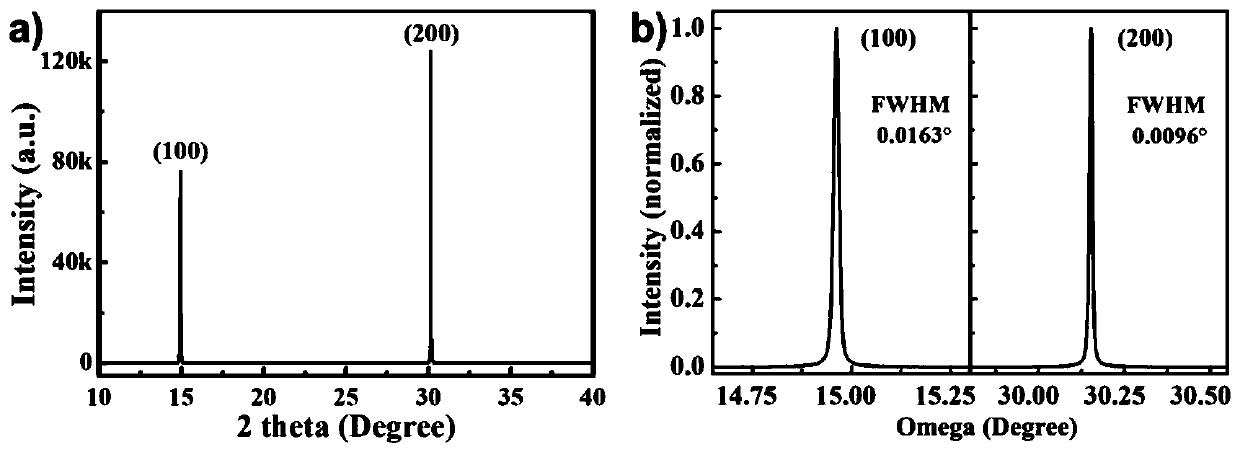

Preparation method for growing perovskite single crystal by liquid-phase diffusion separation crystallization at room temperature

InactiveCN110552061ANon-toxic and non-volatileNot volatilePolycrystalline material growthFrom normal temperature solutionsRoom temperatureSingle crystal

The invention discloses a preparation method for growing perovskite single crystals by liquid-phase diffusion separation crystallization at the room temperature. The preparation method comprises the following steps of (1) preparing a saturated perovskite precursor solution; (2) adding dimethylsilicone oil into the precursor solution, and forming a liquid seal on a perovskite solution by the dimethylsilicone oil; and (3) forming perovskite crystals by heating. The dimethylsilicone oil is insoluble with a solvent in the precursor solution; and a density relationship is that the solvent of the perovskite precursor solution is less than the dimethylsilicone oil and the dimethylsilicone oil is less than the perovskite precursor solution. According to different reactants, two-dimensional or three-dimensional perovskite single crystals can be prepared, the single crystals can be obtained at the room temperature, and the crystal quality is higher. The method is prepared in a lower-temperatureenvironment, nucleation is less, the crystal quality is higher, and defects are fewer. The perovskite single crystals have good application prospects in the photoelectric field, and the high-efficiency and simple preparation method has great potential for commercial application of the single crystals.

Owner:WUHAN UNIV

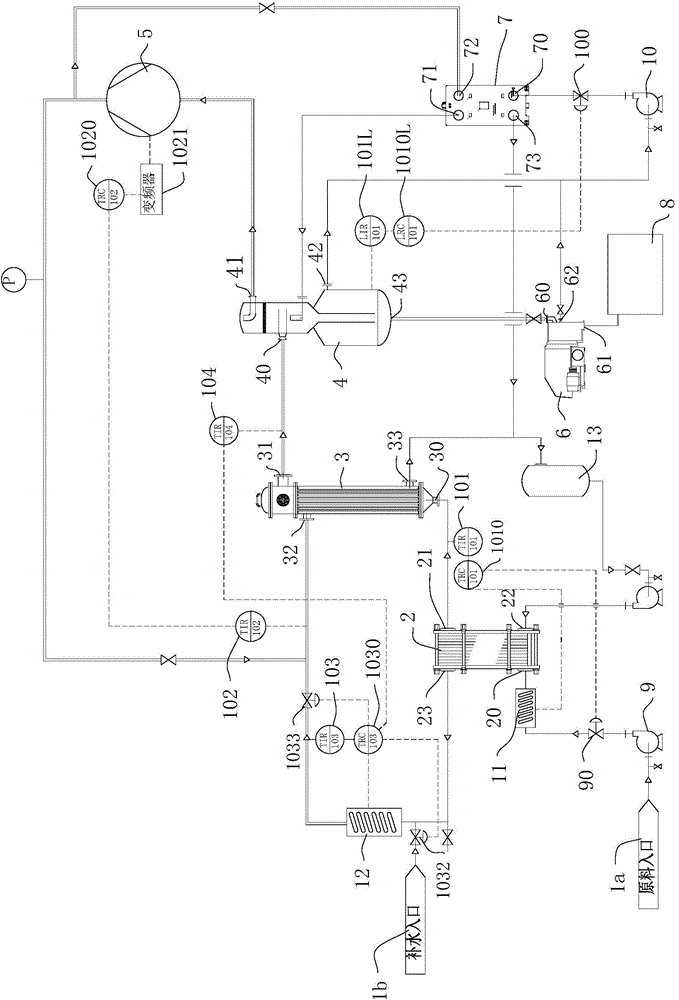

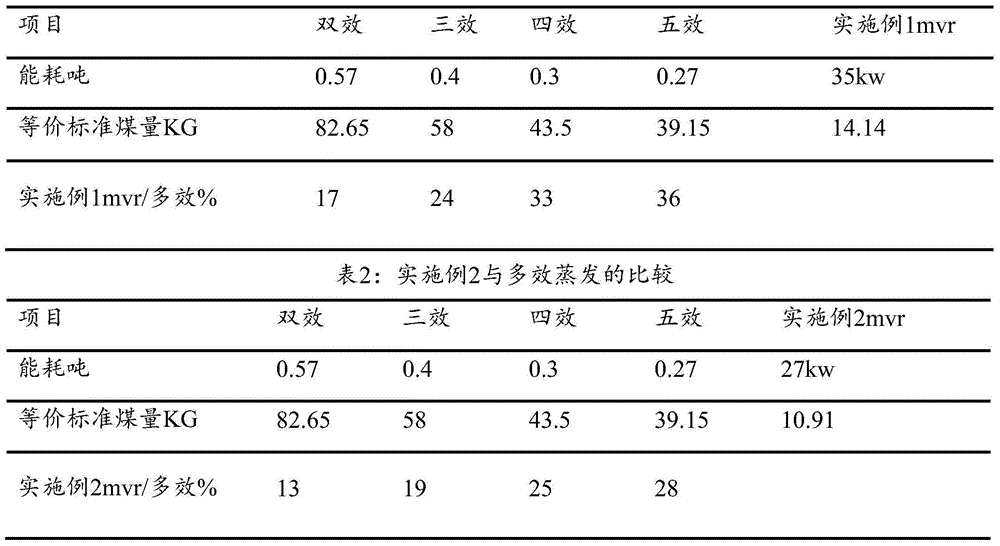

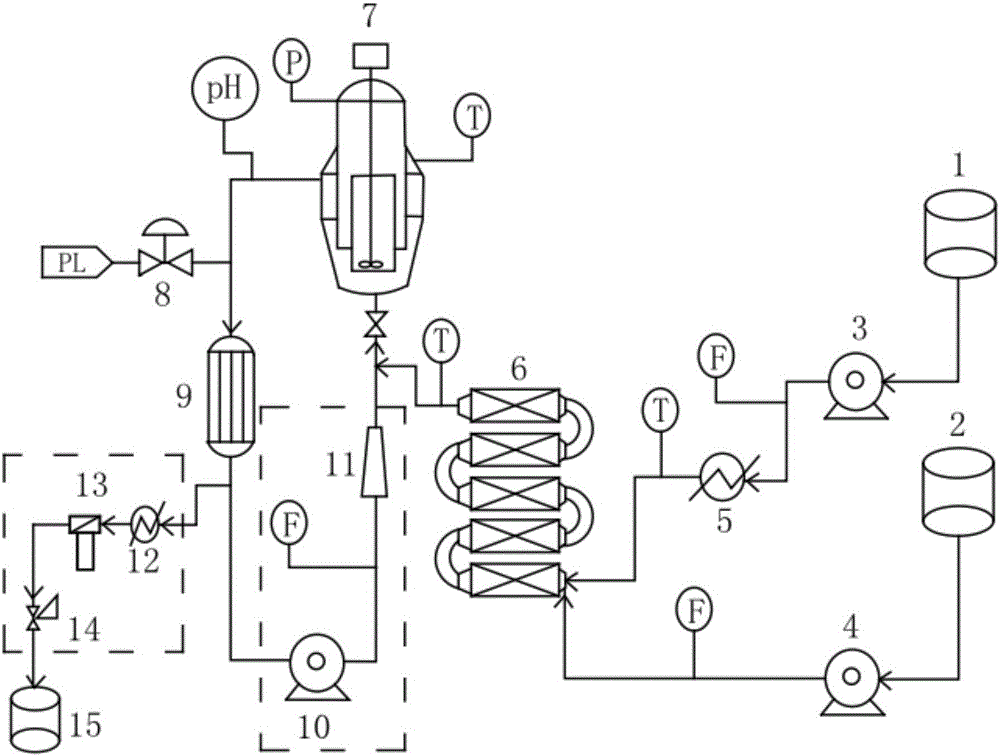

MVR (Mechanical Vapor Recompression) continuous evaporating crystallizing system

ActiveCN104524807AAchieve multi-stage recyclingImprove crystallization efficiencySolution crystallizationMultiple-effect evaporationWater savingVapor–liquid separator

The invention relates to an MVR (Mechanical Vapor Recompression) continuous evaporating crystallizing system. The system comprises a raw material inlet, a water compensating inlet, a preheater, a climbing film evaporator, an air-liquid separator, a compressor, a pipeline heater, a crystallizing separator and four control circuits; an inlet, a first outlet, a second outlet and a third outlet are formed in the air-liquid separator; the preheater is connected with the climbing film evaporator through a pipeline; the climbing film evaporator is connected with the inlet of the air-liquid separator; the compressor is connected between the air-liquid separator and the climbing film evaporator through a steam conveying pipeline; a circulating evaporator is connected between the second outlet and the inlet; cooing water subjected to heat exchange through the climbing film evaporator and cooling water subjected to heat exchange through the circulating evaporator are treated as heat sources of the preheater; the cooling water output end of the preheater and the water supplementing inlet are used for compensating water to the system together; the crystallizing separator is connected with the third outlet of the air-liquid separator; the four control circuits are arranged in the system. The system has optimal and stable parameters, achieves water saving, energy saving and raw-material saving effects and also has a good crystallizing effect.

Owner:CHINA COAL ORDOS ENERGY CHEM COP LTD

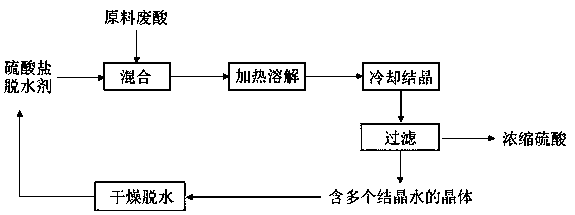

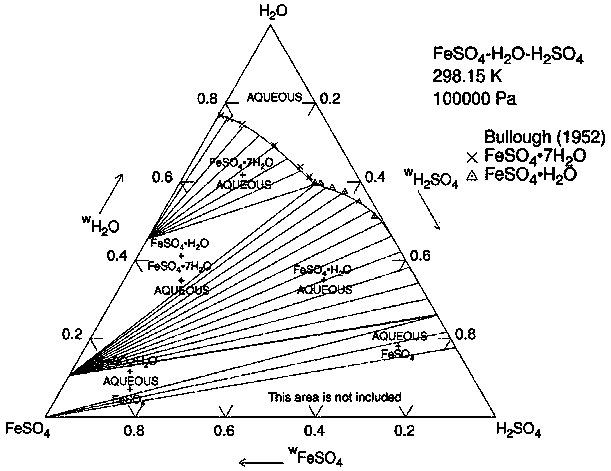

Process for concentrating titanium white waste acid through generation of crystalline hydrate by utilizing phase equilibrium principle

InactiveCN109368604AAvoid introducingAvoid it happening againSulfur-trioxide/sulfuric-acidResource utilizationCopper sulfate

The invention provides a process for concentrating titanium white waste acid through generation of crystalline hydrate by utilizing the phase equilibrium principle. According to the process, ferrous sulfate, copper sulfate or other sulfate capable of forming crystalline hydrates are added into titanium white waste acid, the phase equilibrium process is controlled by utilizing the equilibrium relationship among sulfuric acid, water and sulfate, moisture is brought out by generating sulfate hydrates containing different crystal water and crystallizing and separating the sulfate hydrate from diluted sulfuric acid, and the diluted sulfuric acid can be concentrated; and the separated ferrous sulfate and other crystalline hydrates can be recycled after being dried to remove crystal water; different concentration degrees can be realized by controlling the mode of generated crystalline hydrate and can be adjusted according to requirement, and a concentrated sulfuric acid product having an acidconcentration of higher than 60 percent can be obtained; and anhydrous ferrous sulfate and other sulfates capable of forming crystalline hydrate can be utilized as raw materials, and the raw materials have wide sources. The process is simple, has low operation temperature, small equipment investment and weak corrosion, moisture of waste acid is not needed to be directly evaporated, energy consumption is low, and resource utilization of titanium white waste acid can be realized.

Owner:SICHUAN UNIV

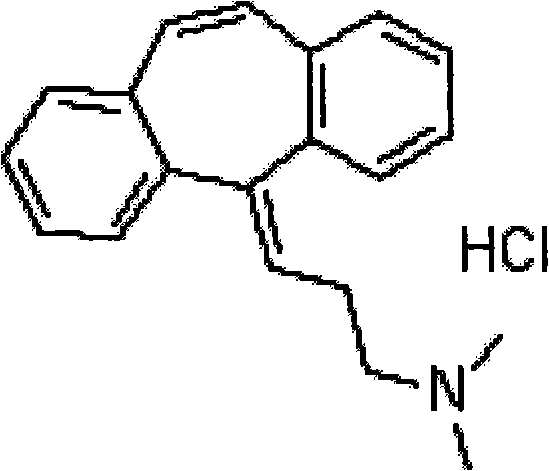

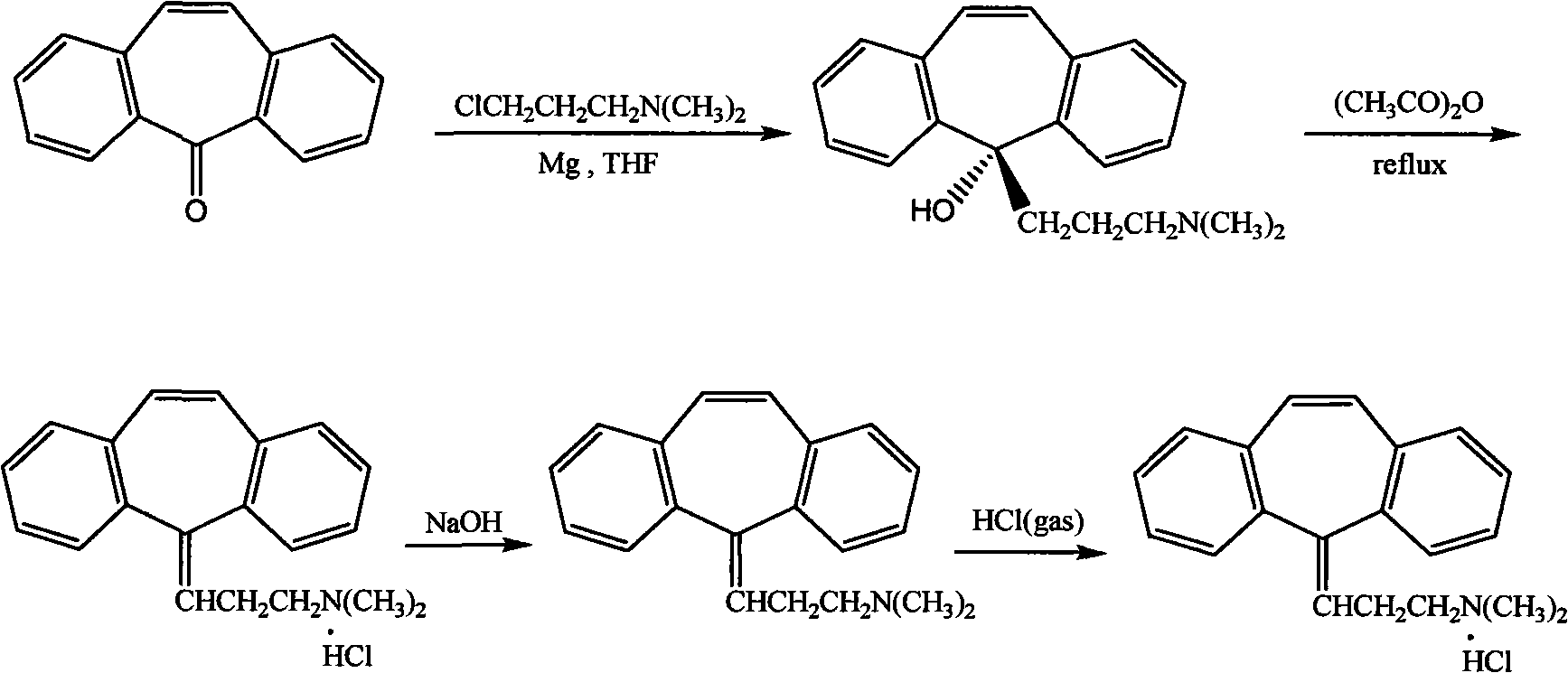

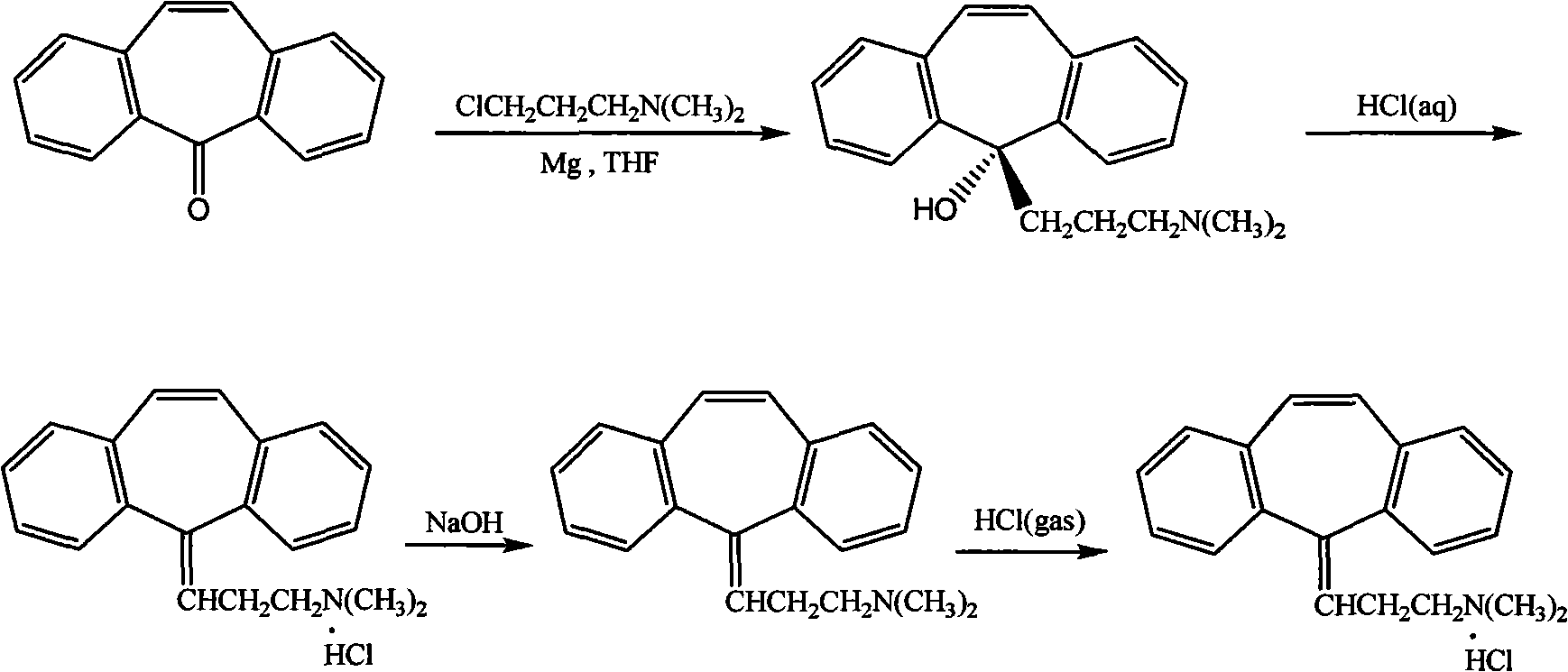

Method for refining cyclobenzaprine hydrochloride

InactiveCN101260046AHigh yieldImprove securityAmino compound purification/separationMuscular disorderOrganic layerEthyl acetate

The invention provides a refinement method for hydrochloric acid cyclobenzaprine, which is safer and more reliable, and can increase the productive efficiency. The refinement method of the hydrochloric acid cyclobenzaprine is as follows: firstly, coarse products of 5- (3- dlmethyl ammonium)- dibenzanthracene (a,d) cycloheptatriene-5-alcohol(cyclobenzaprine intermediate) are dissolved in hydrochloric acids with the concentration of between 1 and 37 percent and heated at a temperature of between 50 and 95 DEG C for 1 to 5 hours, and added in with sodium hydroxide(or other sodium salts) for neutralization so as to make a solution become basic; secondly, an aether / ethyl acetate mixed solution is used for extraction, and the organic layer is filled with dried hydrochloric acid gases for 1 to 5 hours, and coarse products of cyclobenzaprine hydrochloride are separated out; thirdly, coarse products of cyclobenzaprine hydrochloride are recrystallized by absolute isopropanol, and the use level is that each 10g of coarse products is mixed with 30 to 100ml of absolute isopropanol, and the coarse products are filtered, and filter cakes are washed to be nearly white by using acetone, aether or tetrahydrofuran, and coarse products filtered are dried to obtain finished products of cyclobenzaprine hydrochloride, and the content of hydrochloric acid cyclobenzaprine is more than 99.8 percent.

Owner:NANJING HAILING TRADITIONAL CHINESE MEDICINE RES CO LTD +1

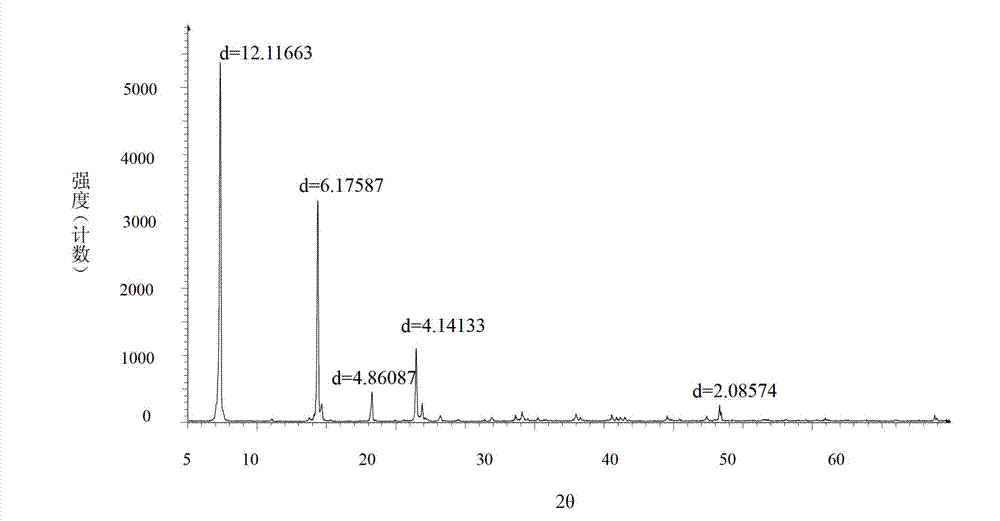

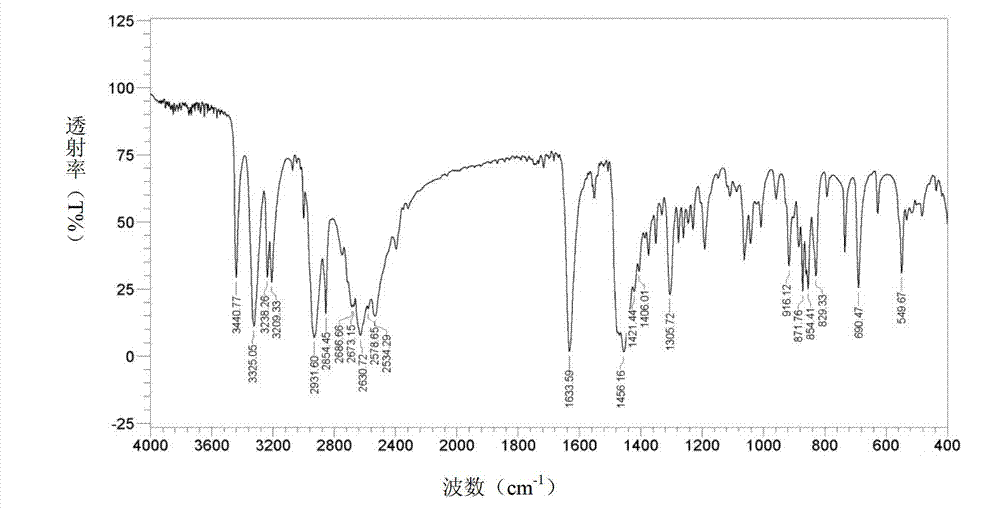

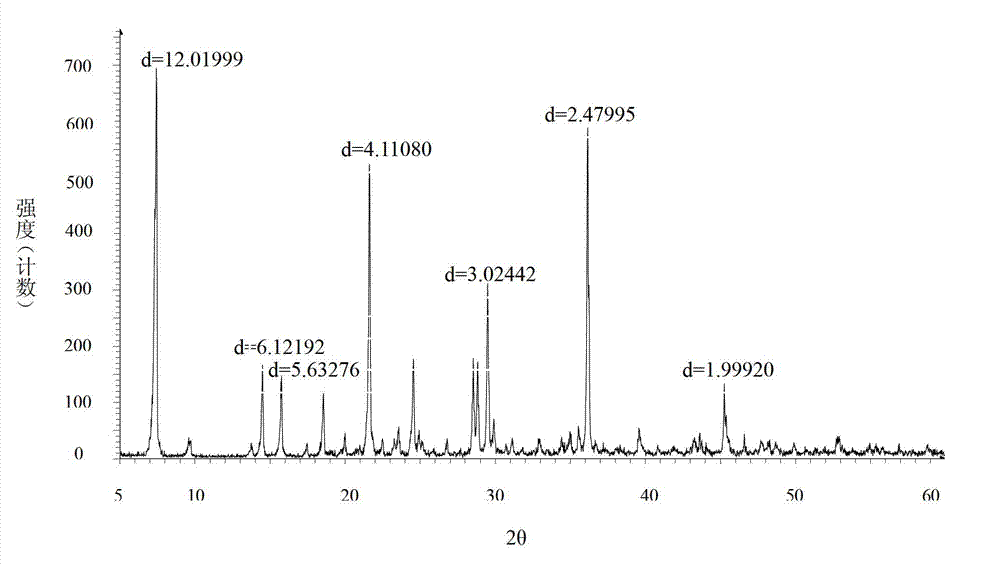

Bromhexine hydrochloride crystal as well as preparation method and application of crystal

ActiveCN102924295AHigh purityImprove quality and safetyOrganic active ingredientsAmino compound purification/separationPhysical chemistryAqueous solubility

The invention provides a bromhexine hydrochloride crystal as well as a preparation method and application of the bromhexine hydrochloride crystal. According to the crystal, an X-ray powder diffraction picture under the radiation of Cu KAlpha1 has diffraction peaks in a part with reflection angles 2 Theta of 7.29, 14.33 and 24.439. The crystal can obviously improve the water solubility of bromhexine hydrochloride, and is beneficial for the preparation of an injection; and relative materials can be further reduced, so that the safety of the preparation can be improved.

Owner:SHIJIAZHUANG DONGFANG PHARMA

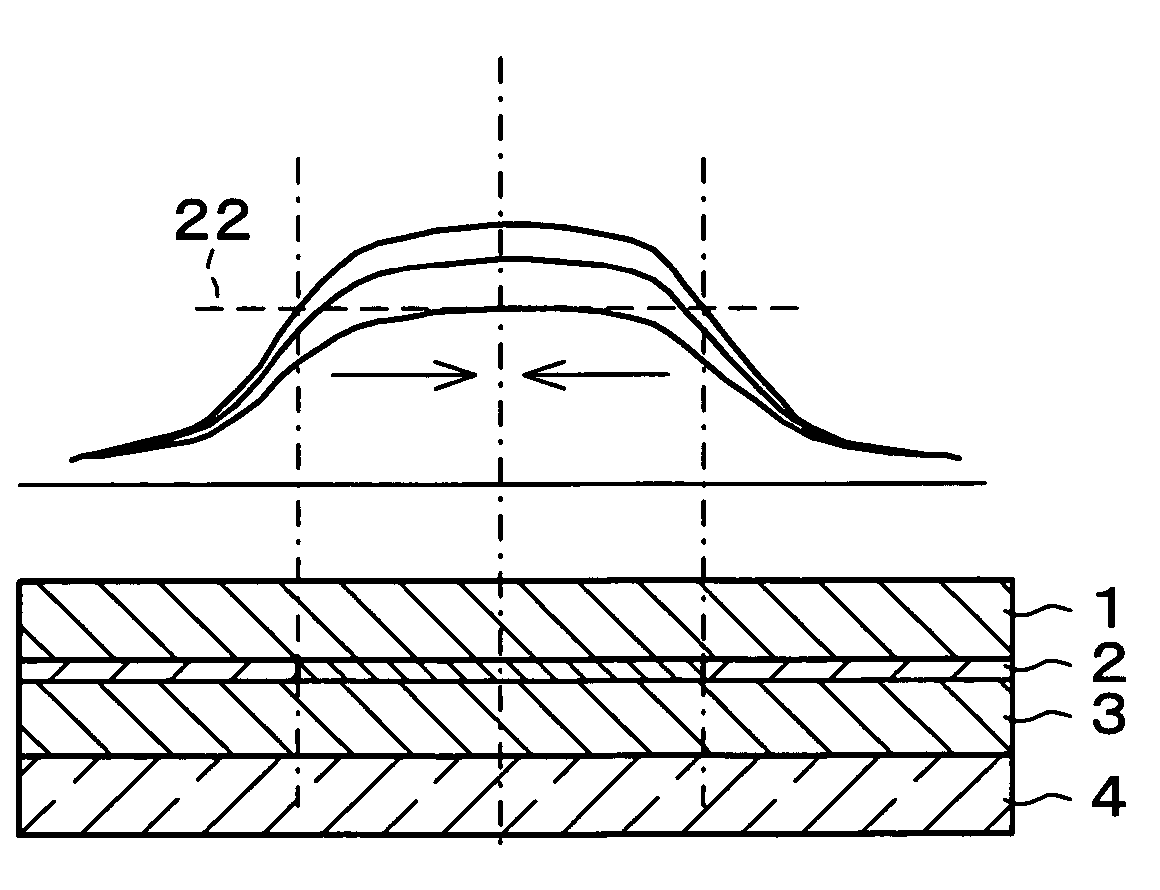

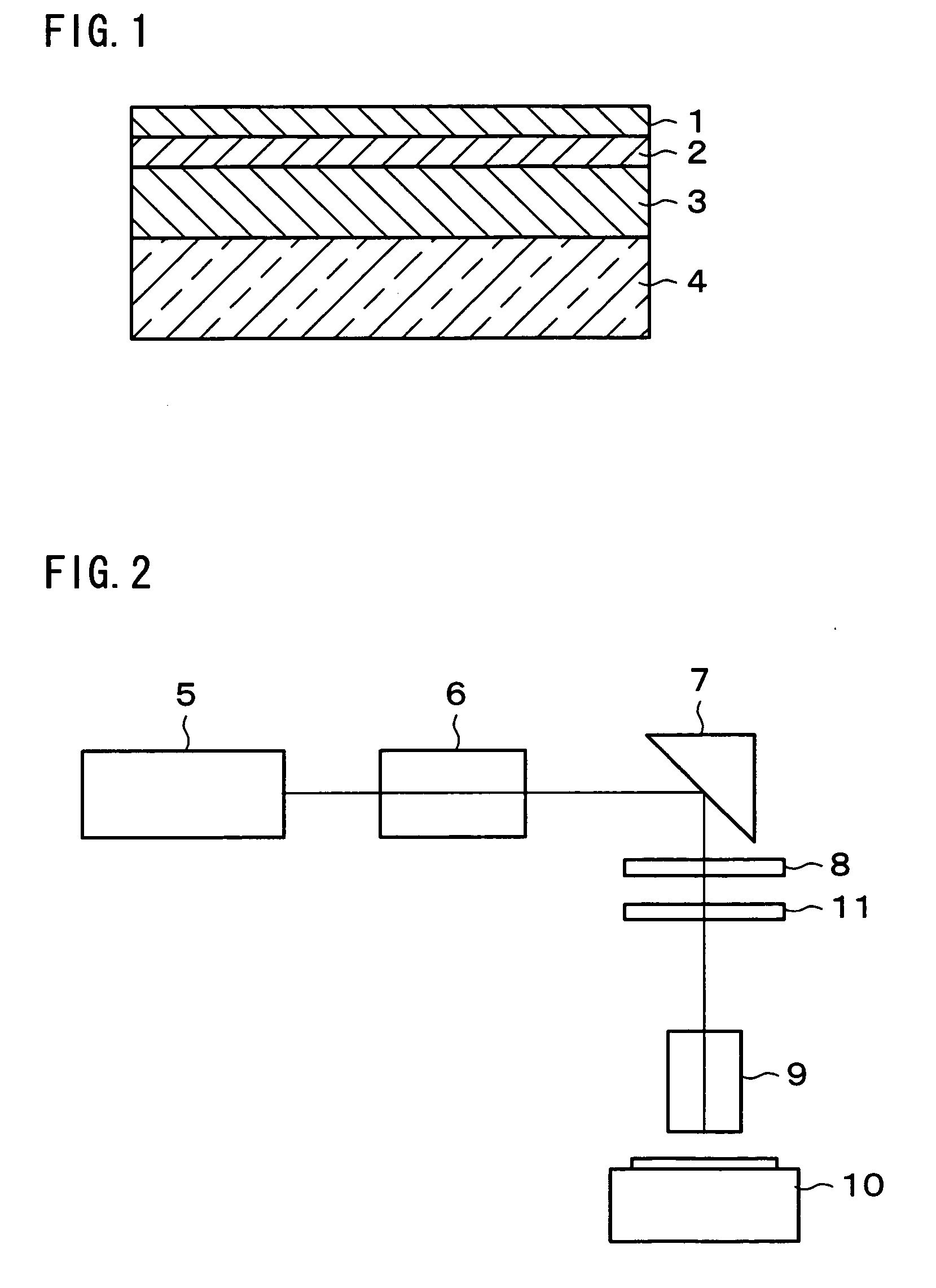

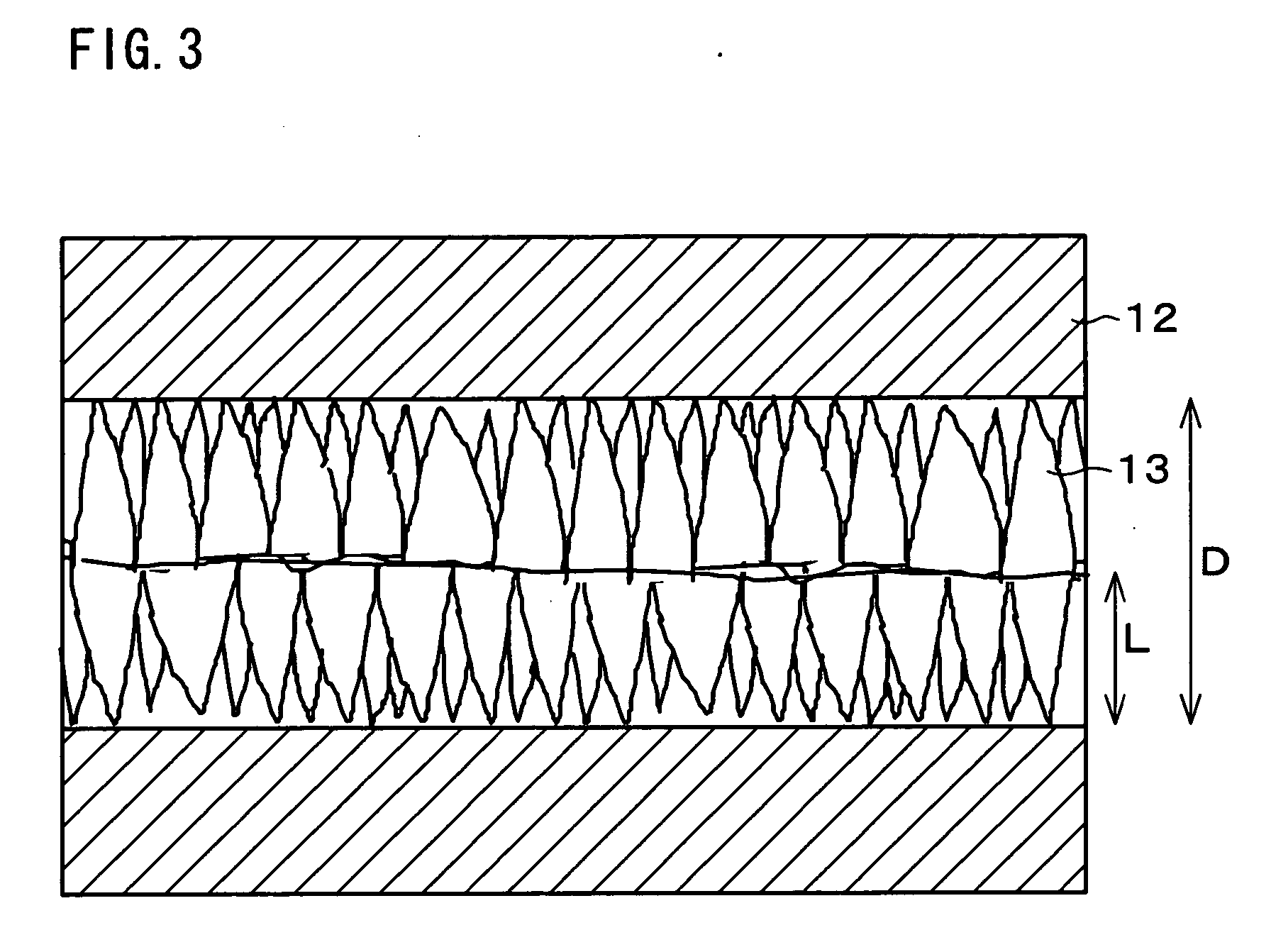

Crystallized semiconductor device, method for producing same and crystallization apparatus

InactiveUS20060183303A1Slow downReduce the temperatureTransistorSemiconductor/solid-state device manufacturingDevice materialLaser light

In a method of manufacturing a crystallized semiconductor device of the present invention, a thermal diffusion layer (1) having higher thermal conductivity than that of a substrate (4) is formed on a surface of a semiconductor layer (2), and then laser light is applied to the semiconductor layer (2) from above the thermal diffusion layer (1). As a result, it becomes possible to manufacture the crystallized semiconductor device in which a crystal is longer than that of a conventional arrangement. According to the present invention, it is possible to provide the crystallized semiconductor device having the semiconductor layer in which the size of the crystal grain is larger than that of the conventional arrangement.

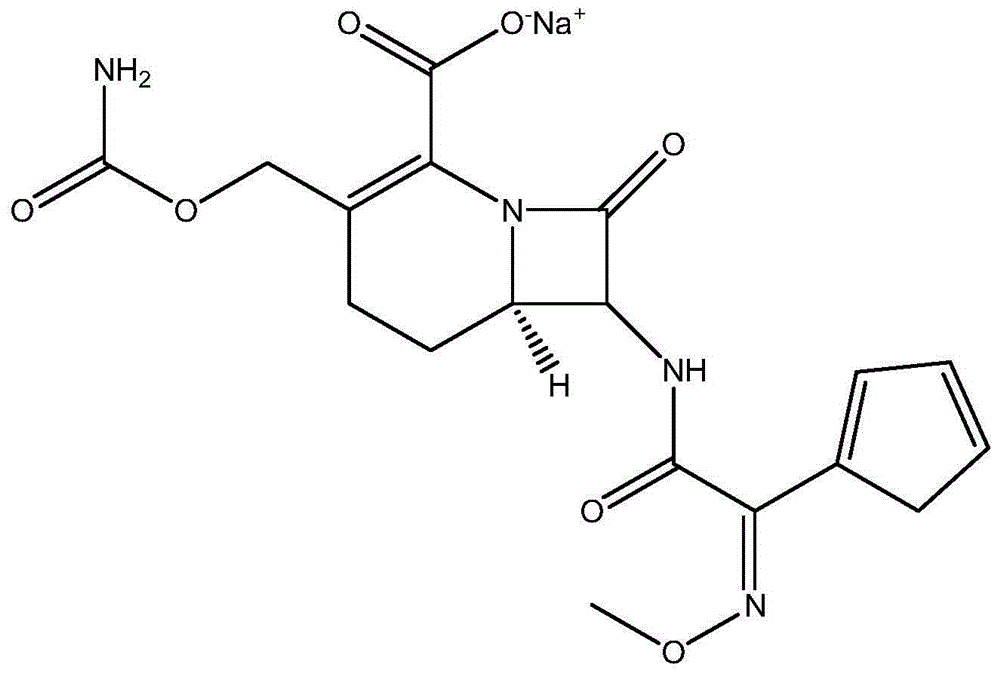

Novel industrial crystallizing technology for cefuroxime sodium

ActiveCN104961749APromote enrichmentSimple crystallization processPowder deliverySolvent extractionPhysical chemistryCefuroxime Sodium

The invention discloses novel industrial crystallizing technology for cefuroxime sodium. Recrystallizing of cefuroxime sodium is realized by adopting a mode combining supercritical fluid extraction technology with conventional crystallizing technology. In a crystallizing system, the processes of extracting, adsorbing, crystallizing and drying are completed under specific temperature and pressure conditions and under joint action of supercritical fluid, solvent, an extraction pool and a crystallization pool to realize recrystallizing of cefuroxime sodium. The novel industrial crystallizing technology is high in separation efficiency and few in impurity, and quality of cefuroxime sodium is improved greatly.

Owner:HAINAN LINGKANG PHARMA CO LTD +1

Method for producing crystal maltose alcohol

InactiveCN101486740AImprove crystallization efficiencyUniform grainSugar derivativesSugar derivatives preparationAlcoholMaltitol

The invention discloses a method for producing crystal maltol, which comprises the following contents: a maltol solution is evaporated and concentrated to be supersaturated to obtain a maltol massecuite; maltol crystal seeds are added to the massecuite and the supersaturation degree and viscosity of the solution are controlled; the maltol massecuite is continuously evaporated and crystallized, the solution maintains boiling and maltol solution is added to continuously; when the grain quantity in the massecuite reaches 50 percent to 90 percent, the massecuite is transferred into a homoiothermal reserve tank and stirred until the temperature thereof is reduced to 20 DEG C to 40 DEG C; and then centrifugal separation is conducted to obtain a finished product of crystal maltol. The method can improve the crystallization efficiency of the maltol and render the grain be even and stable.

Owner:山东福田科技集团有限公司

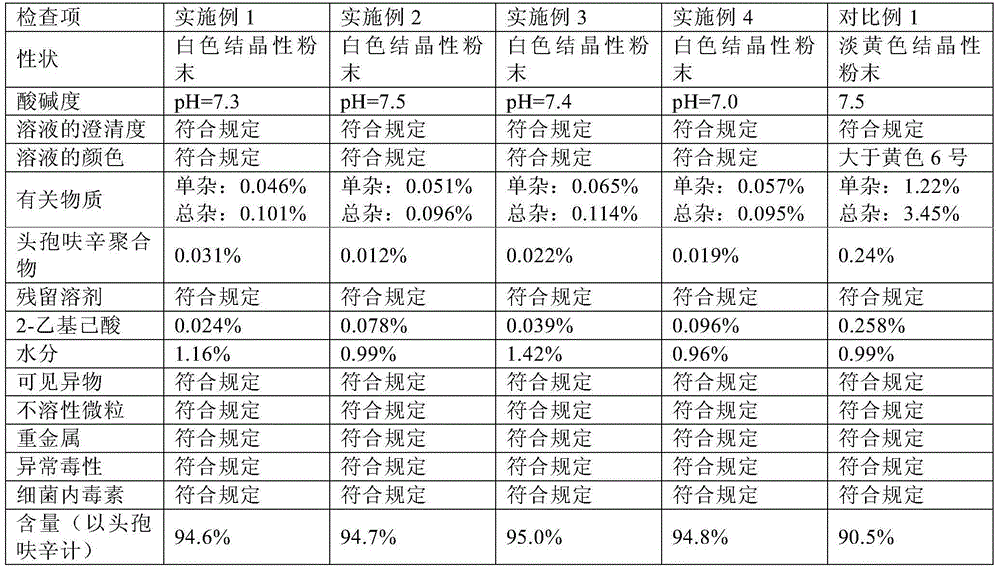

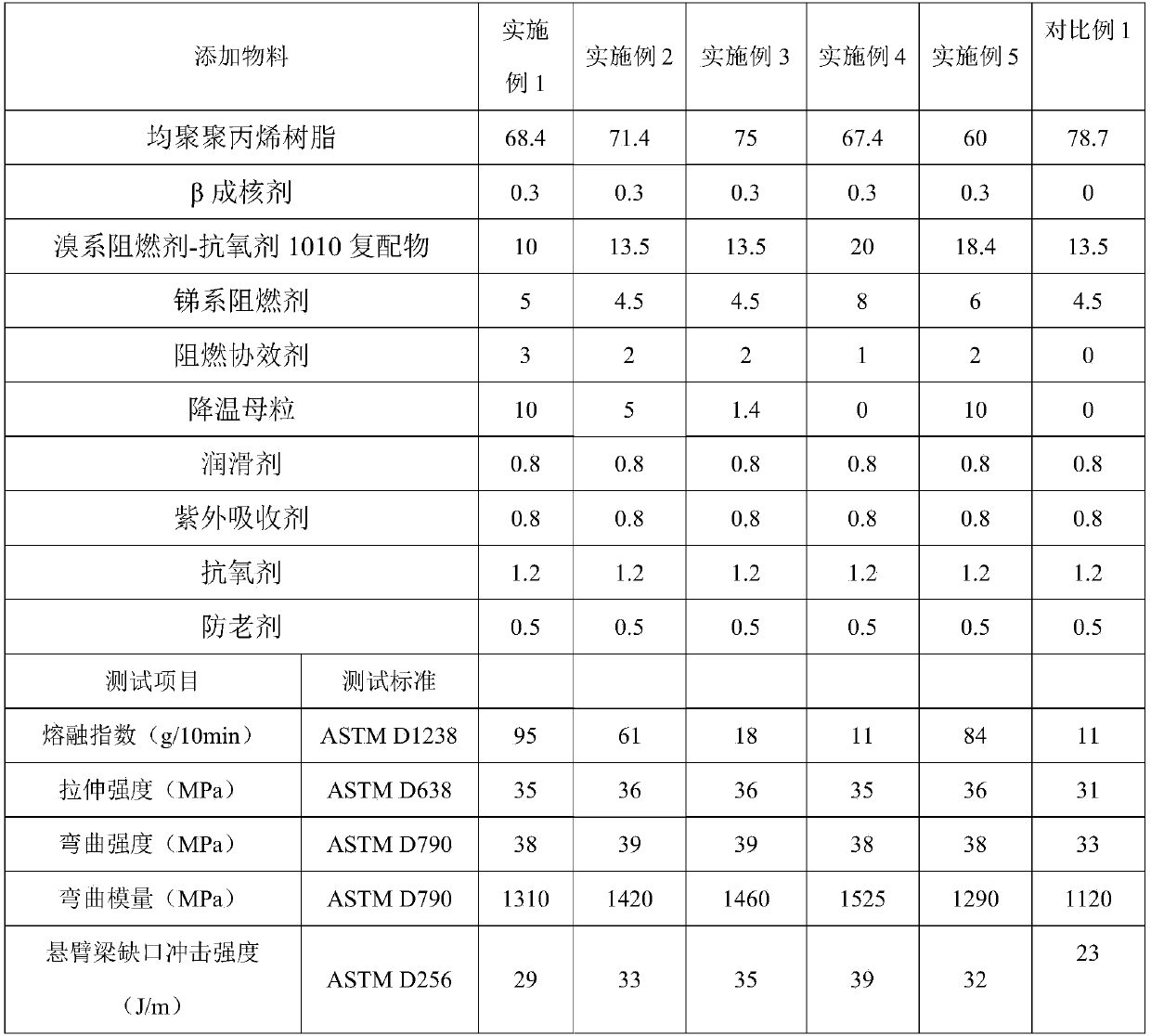

Highly flame retardant polypropylene material and preparation method and applications thereof

The invention discloses a highly flame retardant polypropylene material and a preparation method and applications thereof. The polypropylene material is composed of following raw materials: homo-polymerized polypropylene resin, a beta nucleating agent, a complex composed of a bromine fire retardant and an antioxidant 1010, an antimony fire retardant, a flame retardant synergist, a UV absorbent, anantioxidant, a lubricant, and functional additives. The polypropylene material is characterized in that for each 100 parts by weight of the polypropylene material, the polypropylene material comprises 0.8 to 1.5 parts by weight of antioxidant, and 0.6 to 1.0 part of UV absorbent, the antioxidant is a mixture composed of an antioxidant 168, an antioxidant 3114, and an antioxidant DLTDP; and the UVabsorbent is prepared by compounding hindered amines with benzotriazole. The flame retardant grade of prepared material can reach UL1694 SC-0, the outdoor UV grade is F1, the polypropylene material has the advantages of good insulation performance, good heatproof property, good size stability, and excellent processing and flowing performance, the preparation method is simple and efficient, and the polypropylene material can be used to prepare embedded metal parts, which should be highly flame retardant.

Owner:GUANGDONG JUSHI CHEM CO LTD

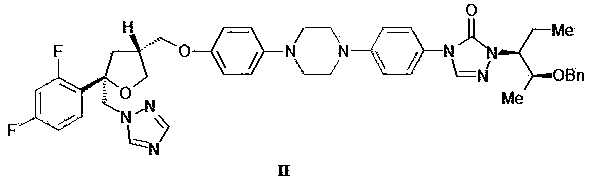

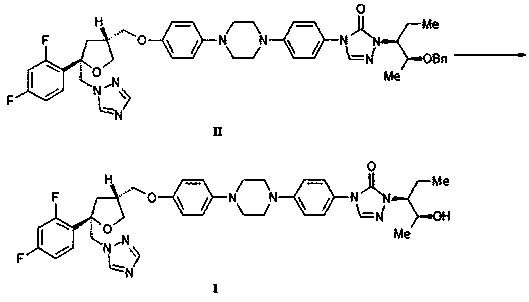

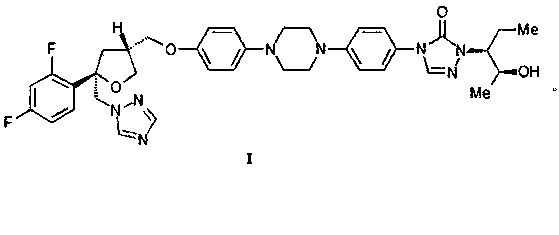

Preparation method of novel triazole antifungal drug

The invention relates to a preparation method of a novel triazole antifungal drug and concretely relates to a posaconazole preparation method. The preparation method comprises that a compound II undergoes a debenzylation reaction without a Pd catalyst under normal pressure to produce posaconazole, and after the reaction, posaconazole is extracted through a water-insoluble organic solvent under acidic conditions so that genotoxic impurity benzyl chloride is substantially removed. The preparation method has the advantages of operation simpleness and convenience, high safety, controllable final product quality and high purity and yield.

Owner:BRIGHTGENE BIO MEDICAL TECH (SUZHOU) CO LTD +1

Dehumidifying colorless PET (polyethylene Terephthalate) color master batch

InactiveCN103172985AReduce manufacturing costReduce dosagePolyethylene terephthalate glycolPolyethylene terephthalate

The invention discloses a dehumidifying colorless PET (polyethylene Terephthalate) color master batch which is prepared from the components in percentage by weight as follows: 40-60% of carrier, 1-3% of coloring agent, 1-3% of dispersant, 5-15% of dehumidifying additive and 15-25% of nucleating agent. The invention further discloses a preparation method of the dehumidifying colorless PET color master batch. According to the dehumidifying colorless PET color master batch provided by the invention compared with color master batches marketed with similar functions, the price is more economical, and the production cost of a plastic process is reduced. With the adoption of an integral production mode, the production process is reduced and the energy resources are saved. According to the invention, the structure of PET grains is further changed, so that the crystallizing efficiency is improved, the mechanical performance is increased, the forming period is shortened and the economic benefit of enterprises is improved. According to the invention, novel components are adopted, and the use level of harmful substances is reduced, so that the harmful substances are substantially not volatilized without affecting the health of a human body. The color master batch is suitable for application and use in the manufacturing industry.

Owner:胡君

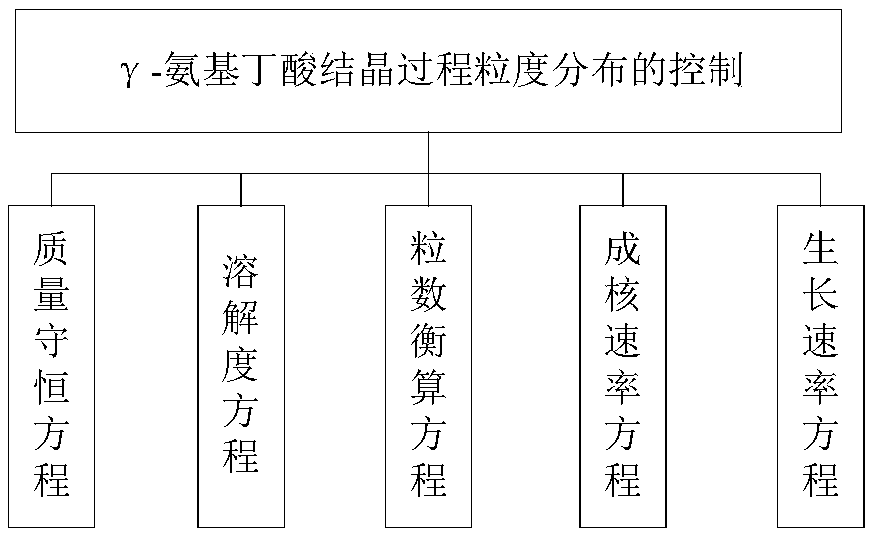

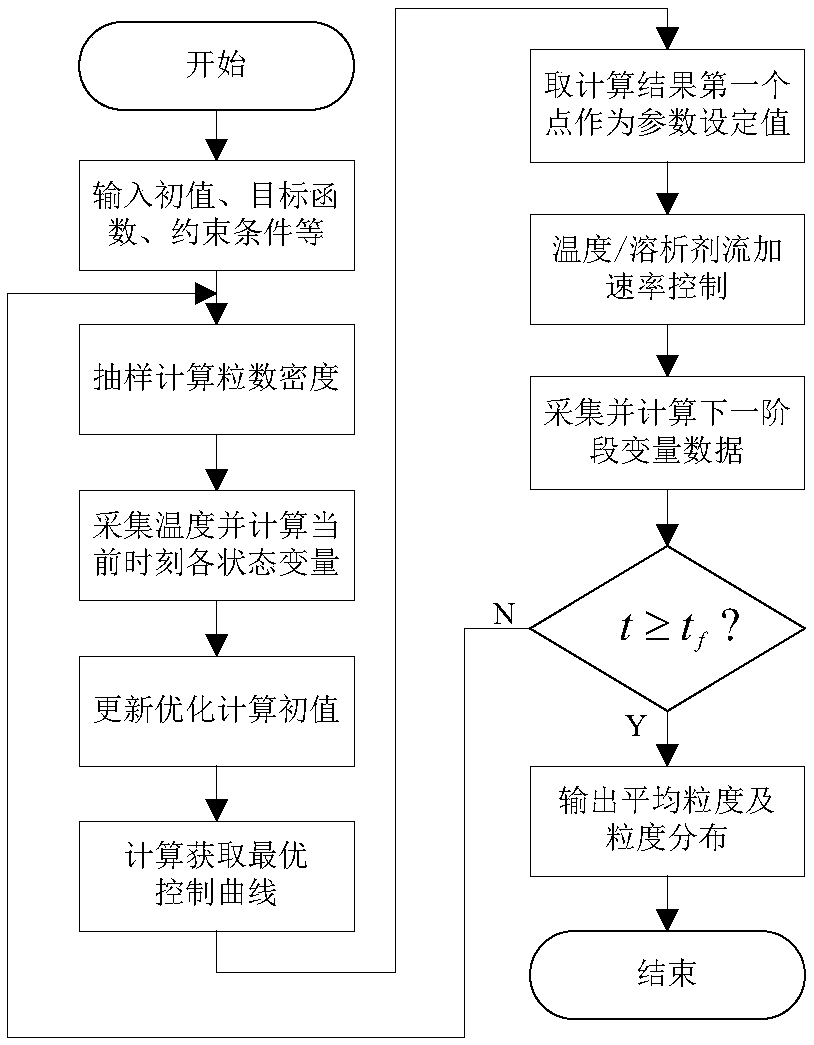

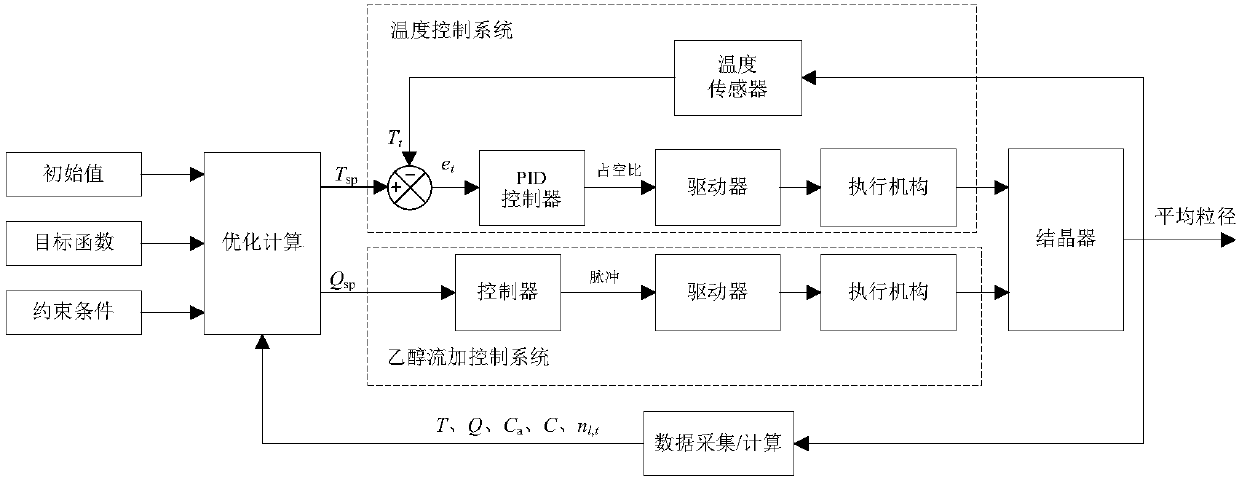

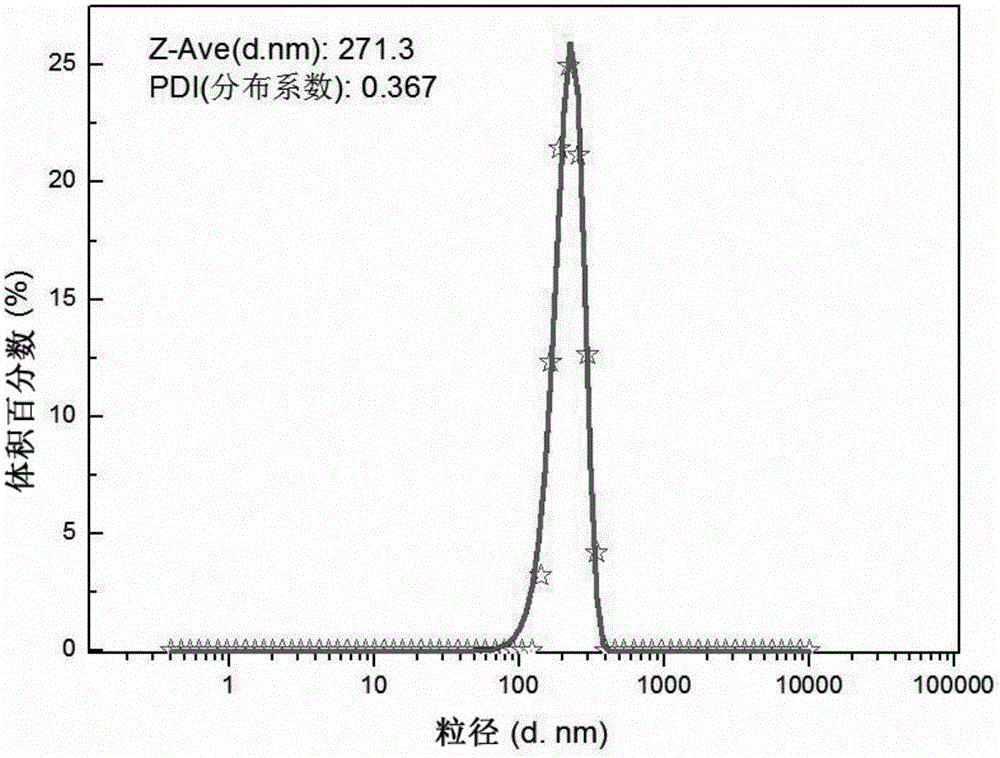

Particle size distribution modeling and control method in crystallization process

ActiveCN108490793AImprove crystallization yieldImprove particle size distributionAdaptive controlControl vectorChemical physics

The invention discloses a particle size distribution modeling and control method in a crystallization process. The particle size control method in the crystallization process comprises the following steps: establishing an optimal control module of particle size distribution in the crystallization process by taking the average crystal particle size as index for measuring the crystal particle size distribution and combining with crystallization process constraint conditions on the basis of a particle size distribution model in the crystallization process; performing discretization and parameterization processing on particle size control vectors in the crystallization process, to solve the optimal control model of the particle size distribution in the crystallization process, so as to obtainan optimal control curve in the crystallization process, and realize maximization of average particle size of crystals. According to the method, an acquiring method of a control curve in the crystallization process can be improved, and the crystallization efficiency and average crystal particle size can be improved.

Owner:SHANDONG UNIV

Preparation method of lithium hexafluorophosphate

InactiveCN108640129AReduce acidityReduce moistureLithium hexafluorophosphateLithium hexafluorophosphateLithium fluoride

The invention discloses a preparation method of lithium hexafluorophosphate. The preparation method comprises the following steps: (1) introducing phosphorus pentafluoride gas into a reaction kettle filled with lithium fluoride and hydrogen fluoride liquid and carrying out reaction for 1 to 2 hours to obtain a lithium hexafluorophosphate solution; (2) realizing partial crystallisation under a stirring condition; (3) carrying out drying. The preparation method of lithium hexafluorophosphate disclosed by the invention has the advantages that the operation is convenient, the lithium hexafluorophosphate which is obtained by carrying out partial crystallisation is directly formed into uniform particles, so that the steps of multiple drying and pulverization are eliminated, and the partial crystallisation time is shortened.

Owner:MORITA NEW ENERGY MATERIALS ZHANGJIAGANG CO LTD

Cooling crystallization device

InactiveCN107519660ASmall footprintLow costSolution crystallizationHeat exchange cooling cystallizationCooling towerSmall footprint

Cooling and crystallization equipment, which includes a cooling tower, a crystallization tank and a circulating pump. The cooling tower also includes a cylinder, a spray device, a material sieve plate and a fan. There is an air inlet at the bottom of the cylinder and an air outlet at the top. At the air outlet of the body, the spray device includes a feed pipe, an elbow and a nozzle. The feed pipe penetrates into the cylinder from the outside of the cylinder. One end of the elbow is connected to the feed pipe and the other end is connected to the nozzle. The nozzle is located in the cylinder. The material screen The plate is set under the nozzle, the material sieve plate is provided with sieve holes, and the crystallization tank is provided with a feed port and a discharge port. The feed port of the crystallization tank is connected with the cooling tower, and the discharge port is connected with one end of the circulation pump. One end is connected to the sprinkler of the cooling tower. Compared with the cooling and crystallization equipment in the prior art, the present invention not only occupies a small area, is low in cost, and is convenient for maintenance, but also has low operating costs, is not easy to block parts, and has high cooling and crystallization efficiency.

Owner:LEIYANG JINYUE SCI & TECH DEV

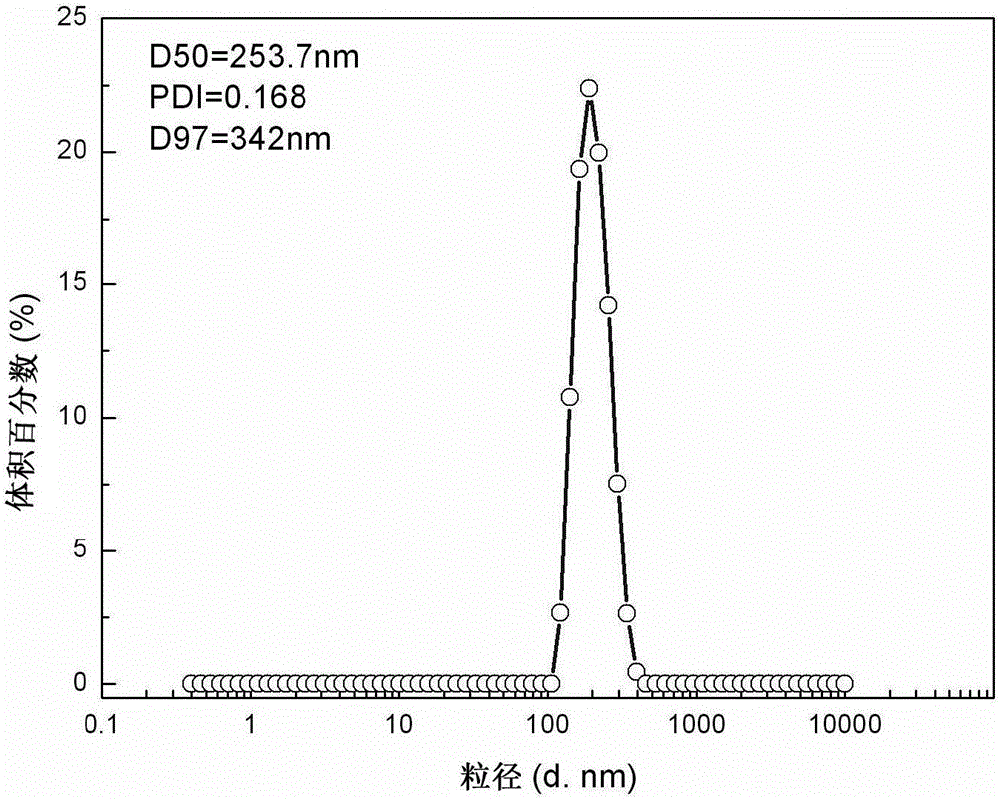

Device system and preparation technology for preparing submicron material through continuous hydrothermal method

ActiveCN104986796AAchieve growthHigh crystallinitySolution crystallizationTitanium dioxideProcess engineeringSlurry

The invention provides a device system and preparation technology for preparing a submicron material through a continuous hydrothermal method. The device system comprises burdening kettles, a preheater, a first crystallizer and a second crystallizer. The first burdening kettle is communicated with the first crystallizer through a first feeding pump and the preheater, and the second burdening kettle is communicated with the first crystallizer through a second feeding pump. The first crystallizer is communicated with the second crystallizer, a discharging opening of the second crystallizer is communicated with an inlet of a heat exchanger, one outlet of the heat exchanger is communicated with an outer circulating unit and then communicated with an inlet of the second crystallizer, and the other outlet of the heat exchanger is communicated with an aftertreatment unit and a slurry collector. The first crystallizer is a tubular reaction crystallizer, and the second crystallizer is a continuous crystallizer. The device system is adopted in the preparation technology. According to the device system and preparation technology, the device cost is low, meanwhile, the submicron material with even particle size distribution and the high degree of crystallinity can be prepared continuously, and the device system and preparation technology are suitable for industrial production.

Owner:ZHANGJIAGANG HEZHI NANO TECH CO LTD

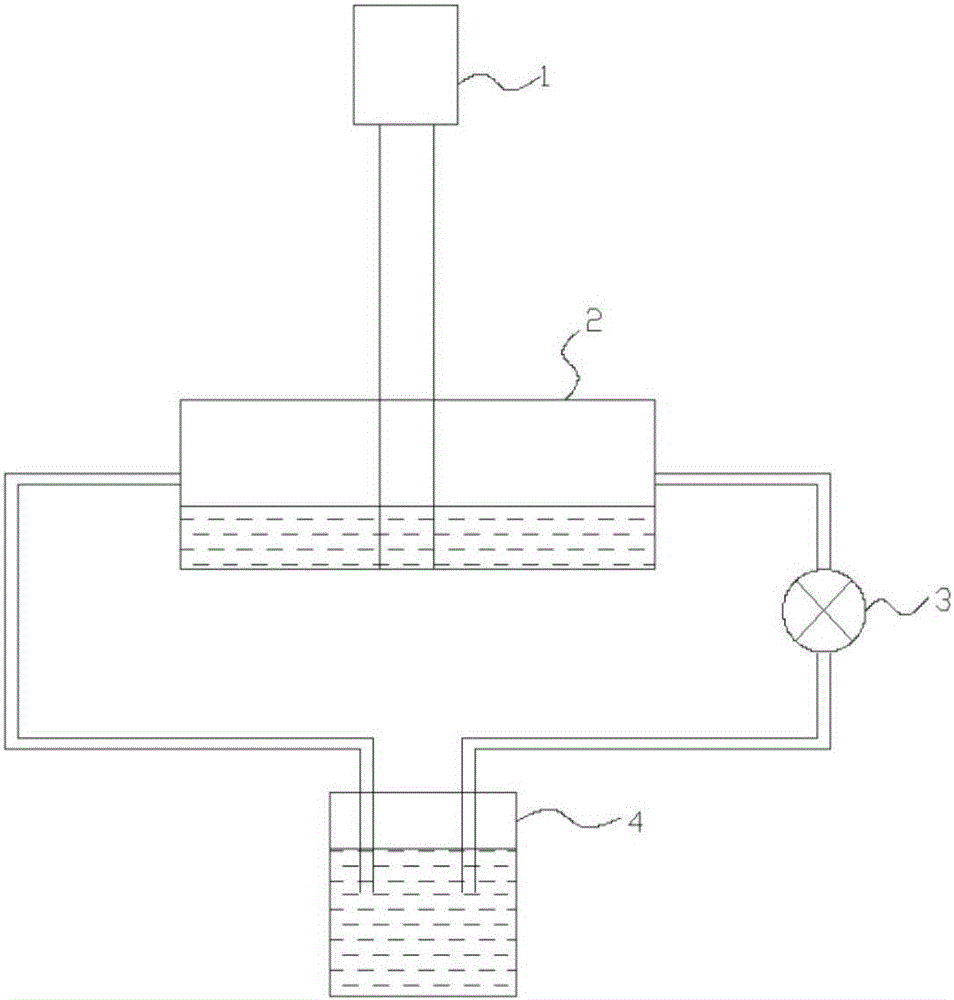

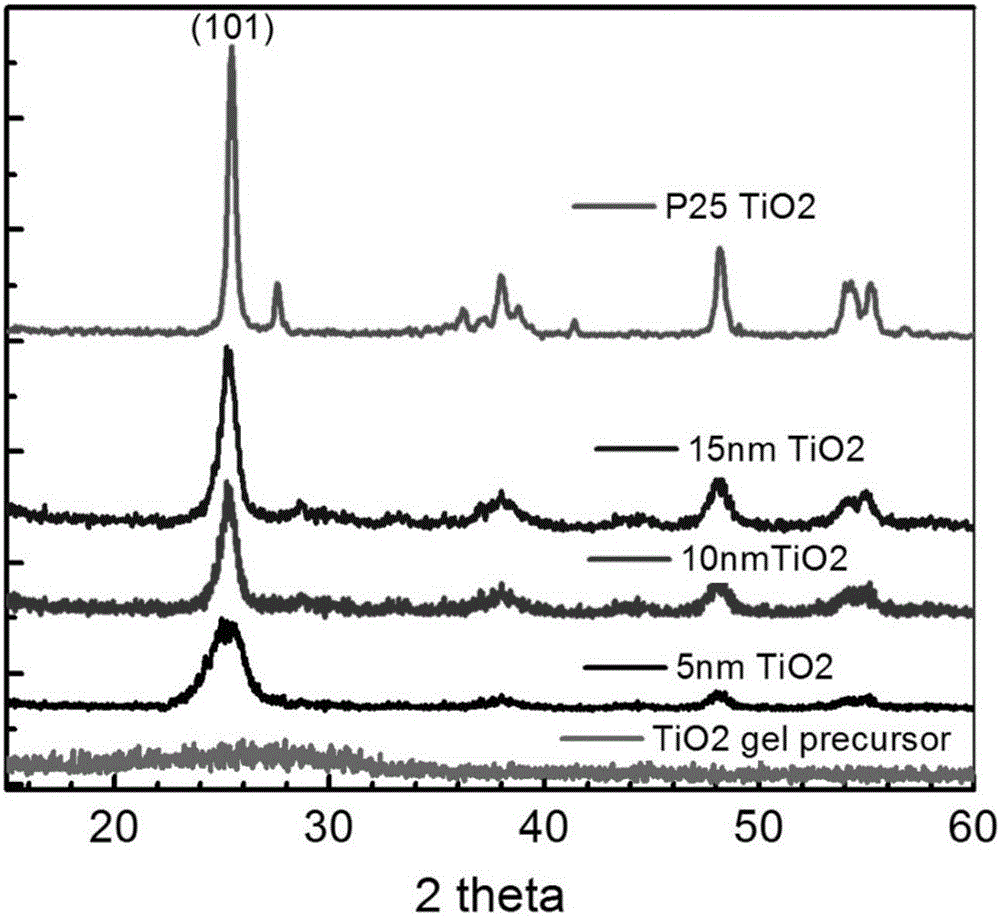

Homogeneous crystallized TiO2 nano-scale solution, preparation method thereof and crystallization equipment

ActiveCN106006727AImprove stabilityAvoid reunionMaterial nanotechnologyTitanium dioxideRoom temperatureIon doping

The invention relates to a high-stability TiO2 nano-scale solution and a preparation method thereof, and further relates to special crystallization equipment for the preparation method. The preparation method comprises steps as follows: titanate is taken as a titanium source and hydrolyzed under the acidic condition, a TiO2 sol precursor solution is formed, and the TiO2 sol precursor solution is irradiated with ultrafast laser under the condition that the TiO2 sol precursor solution keeps a flowing state. The preparation method can realize crystallization of particles in the solution at the room temperature, and has the advantages of being simple, low in preparation cost and high in crystallization efficiency; besides, with the adoption of the preparation method, the homogeneous crystallized TiO2 nano-scale solution with the particle size of 5-20 nm can be obtained, and have a good photocatalytic effect; meanwhile, by means of the preparation method, ion doping can be performed better, particle aggregation caused by heating in a doping process is avoided, and accordingly, the photoresponse range of the catalyst is extended into a visible light region.

Owner:SUZHOU SHENGFENGYUAN NEW MATERIAL TECH CO LTD

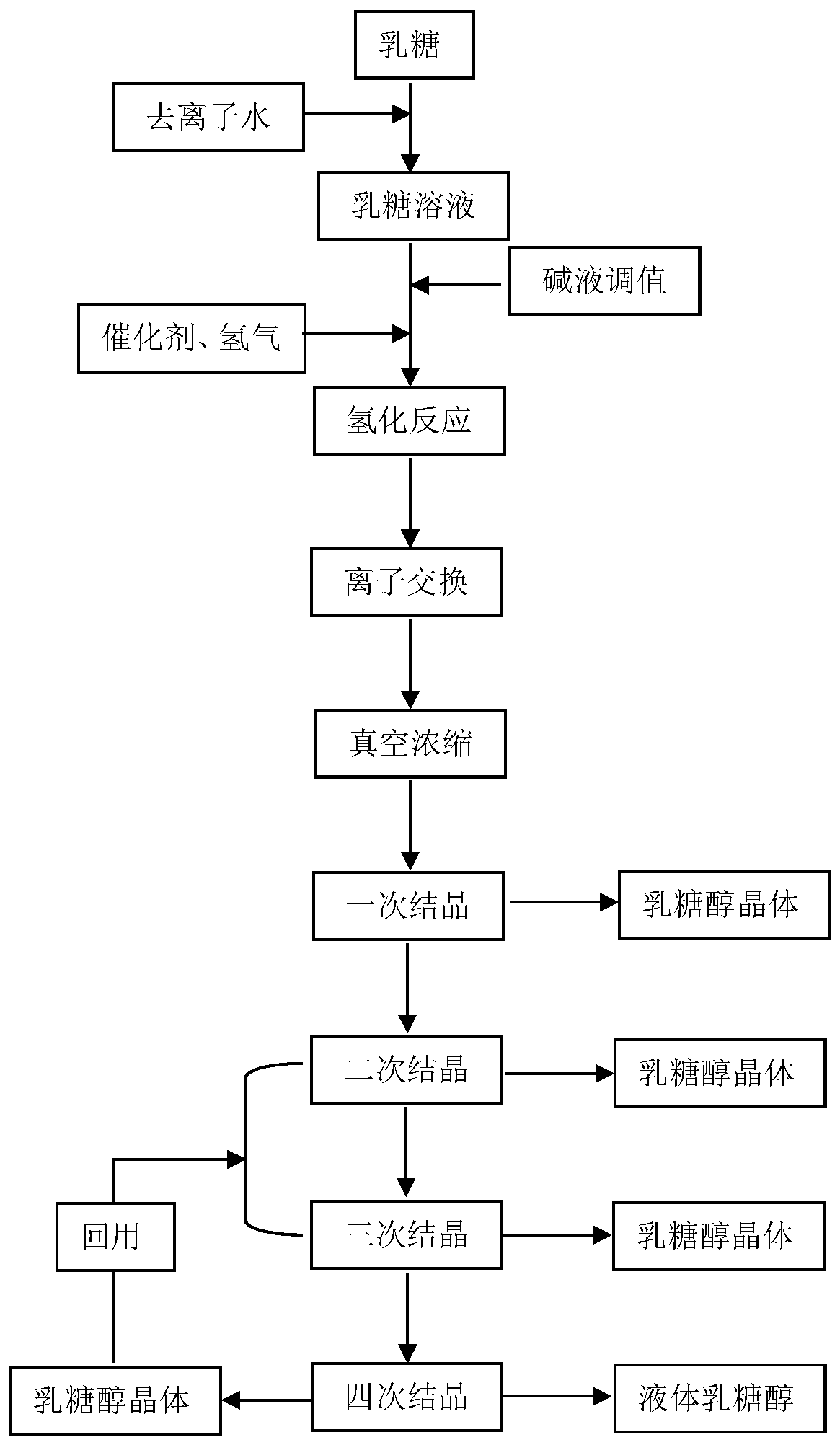

Production technology of lactitol

ActiveCN110818752AConvenient amountHigh activitySugar derivativesSugar derivatives preparationPtru catalystHydrogenation reaction

The present invention discloses a production technology of lactitol. Lactose is added into deionized water to prepare a lactose solution, pH is adjusted, a certain amount of a catalyst is added, a hydrogenation reaction is conducted under high temperature and high pressure to obtain a lactose hydrogenation solution, after the catalyst is removed, a lactitol solution is obtained, the lactitol solution is then purified, and concentration, crystallization and drying are conducted to obtain lactitol crystals. A primary crystallization yield of the lactitol relative to the lactose raw material reaches 55.0%-68.0% and a total yield of the lactitol relative to the lactose raw material reaches 92.2%-96.5%. At the same time, the technology is simplified in processes, liable for production and operation and also relatively low in production cost.

Owner:FUTASTE PHARM CO LTD

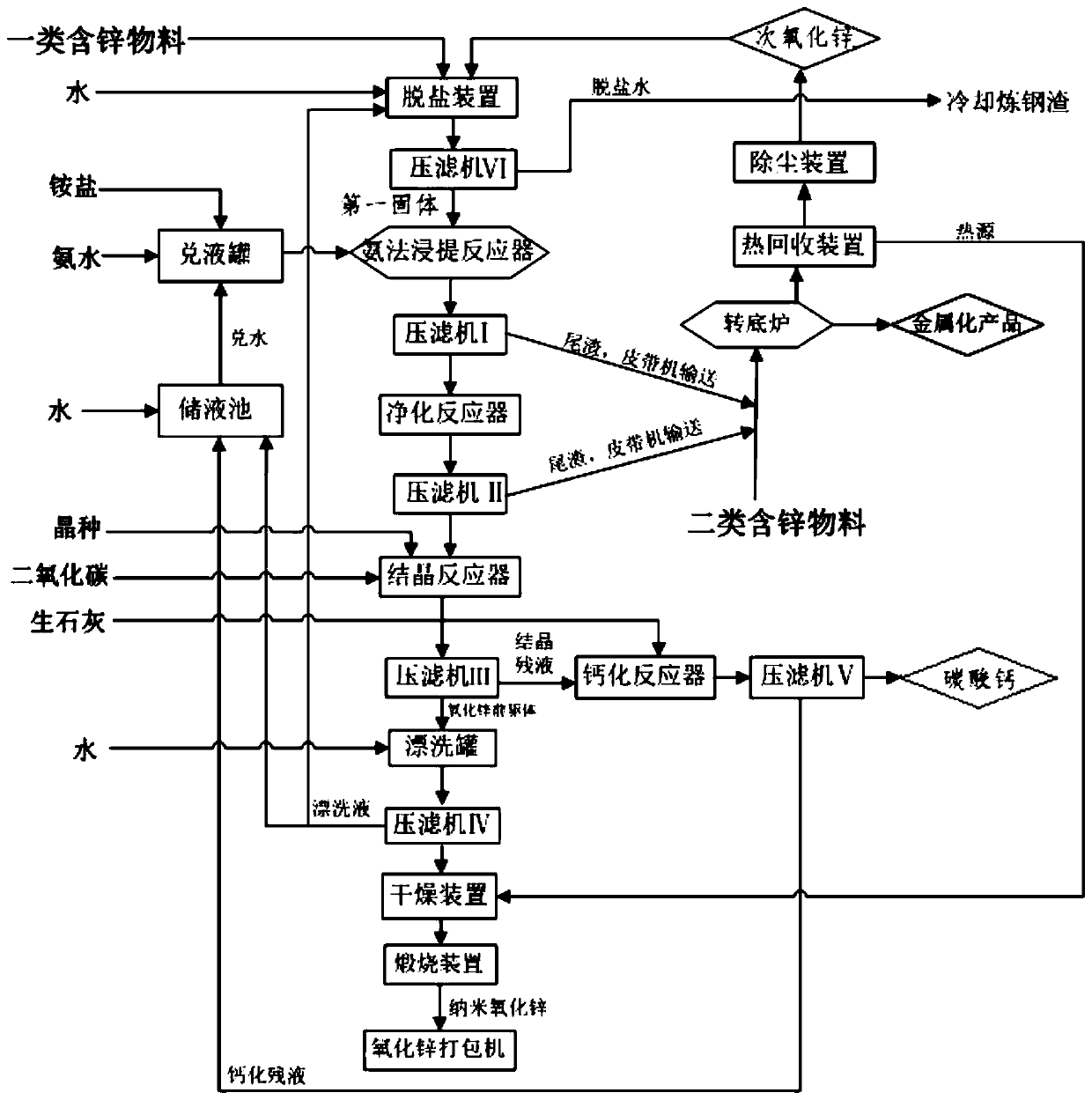

System and method for industrially recycling zinc to produce nanometer zinc oxide

PendingCN110775998AImprove economic efficiencyImprove crystallization efficiencyCalcium/strontium/barium carbonatesMaterial nanotechnologyChemistryDeep level

The invention discloses a system and method for industrially recycling zinc to produce nanometer zinc oxide, and belongs to the technical field of chemical metallurgy. According to the production sequence of zinc recycling, the system comprises a rotary hearth furnace, a desalination device, an ammonia process digestion reactor, a purification reactor, a crystallization reactor, a calcification reactor, a rinsing tank, a drying device and a calcination device. The method comprises the steps that a second-class of zinc-containing material is fed into the rotary hearth furnace for the first timeof zinc recycling refining to produce secondary zinc oxide; ammonia process digestion is carried out on the secondary zinc oxide produced with the rotary hearth furnace and a first-class of zinc-containing material for the second time of zinc recycling refining so as to produce zinc and ammonia complex liquid; then the zinc and ammonia complex liquid is subjected to purification and carbonizationcrystallization to produce zinc oxide precursors; and the zinc oxide precursors are subjected to rinsing, drying and calcination to form a nanometer zinc oxide product. According to the system and method for industrially recycling zinc to produce nanometer zinc oxide, by combining an ammonia process and a rotary hearth furnace technology, the zinc in the zinc-containing materials is deeply recycled in a crossing combination manner, the zinc in the zinc-containing materials is completely recycled, and the grade of the produced zinc-containing product is 95% or more.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD

Cooling crystallization device

InactiveCN107174836ARapid coolingCool evenlySolution crystallizationHeat exchange cooling cystallizationLiquid storage tankWater circulation

The invention relates to a cooling crystallization device. The cooling crystallization device comprises a liquid storage tank, a draught fan, a base, a motor, a bracket and a tank body, wherein the motor is mounted in the base, the bracket is located on the base, and the tank body is mounted on the bracket; an output shaft of the motor stretches out of the base and is fixed with the bracket, and a feeding hole and a discharging hole are formed in the top end and bottom end of the tank body, respectively; and a refrigerator is connected to the liquid storage tank through a first branched pipe, an atomizer is connected to the refrigerator through a second branched pipe, and an atomizing nozzle of the atomizer and an air outlet of the draught fan are aligned with the tank body. According to the cooling crystallization device, water in the liquid storage tank can be cooled through the refrigerator, and the output shaft can drive the bracket to rotate so as to drive the tank body to rotate, so that the whole peripheral surface of the tank body can be cooled; meanwhile, the draught fan can be used for blowing, and atomized water can be rapidly evaporated so as to absorb a large number of heat emitted by crystallization liquid in the tank body, so that the crystallization efficiency is high; atomized water is liquidized into water drops by a cooling cover to fall into the liquid storage tank, so that the circulation use of water is realized; and the cooling is carried out outside the tank body, so that no impurity is produced in the tank body.

Owner:SUZHOU JINXIANG TITANIUM EQUIP

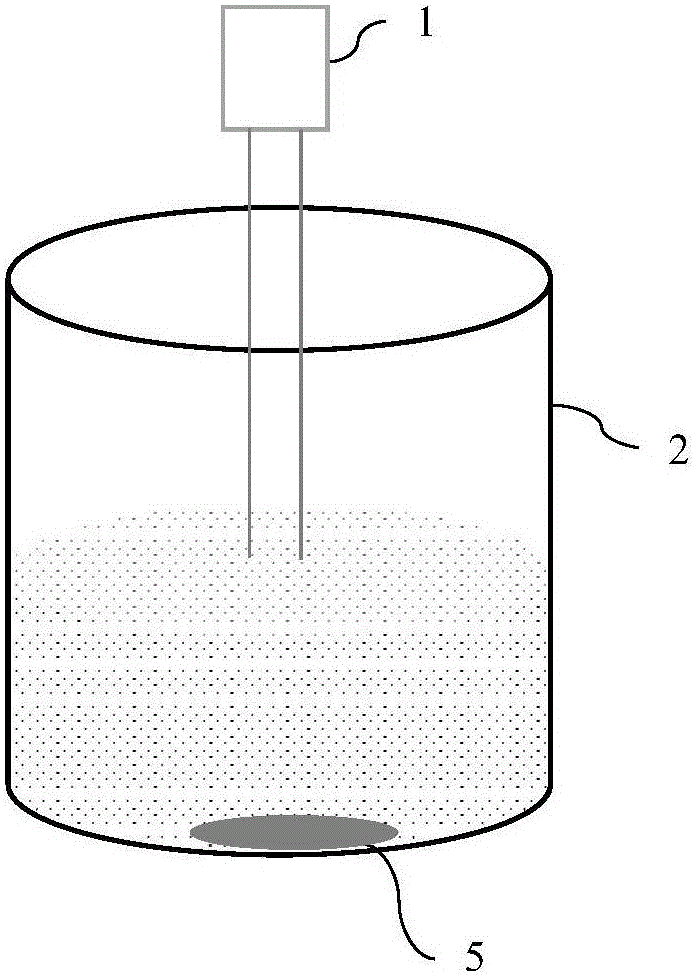

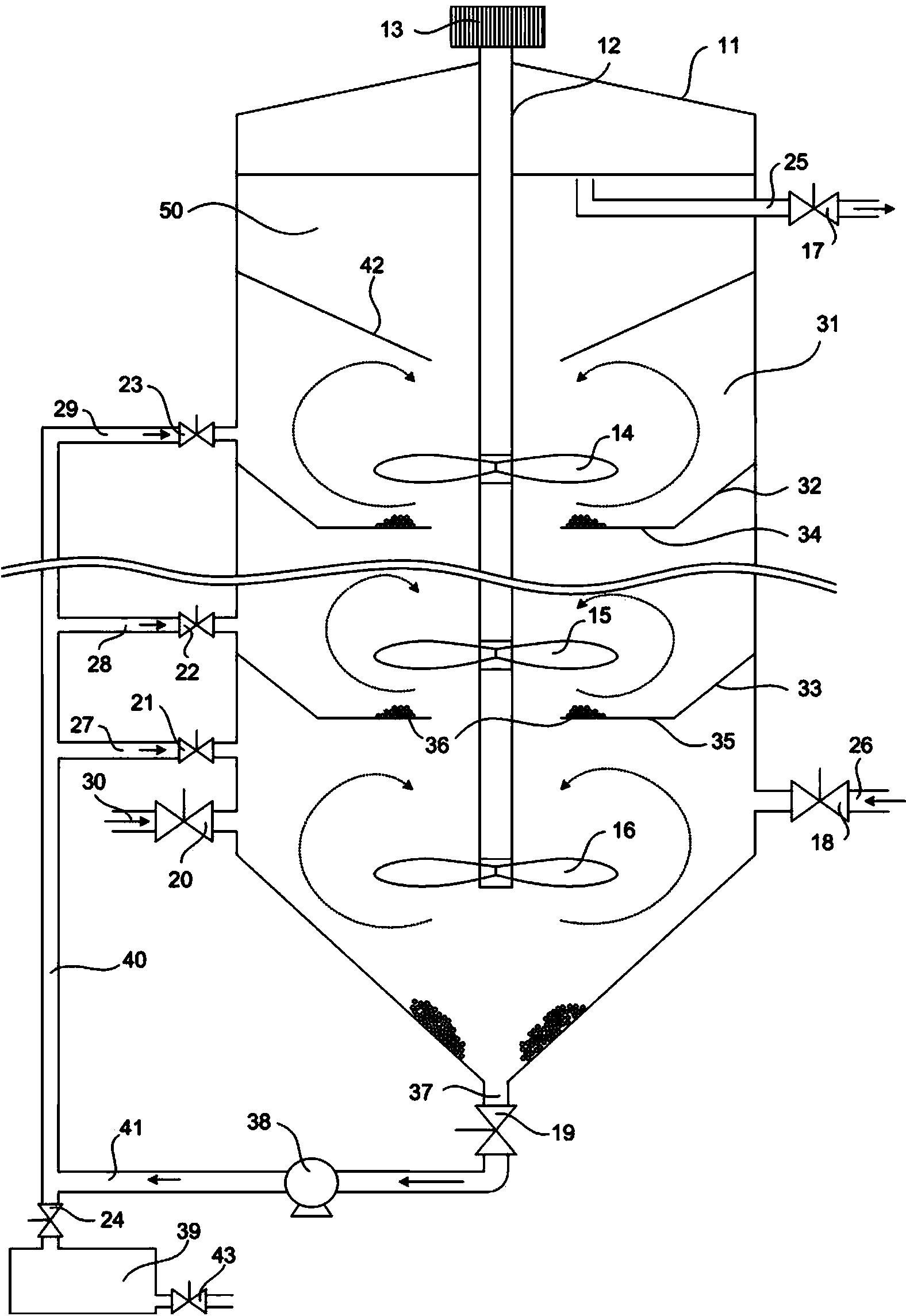

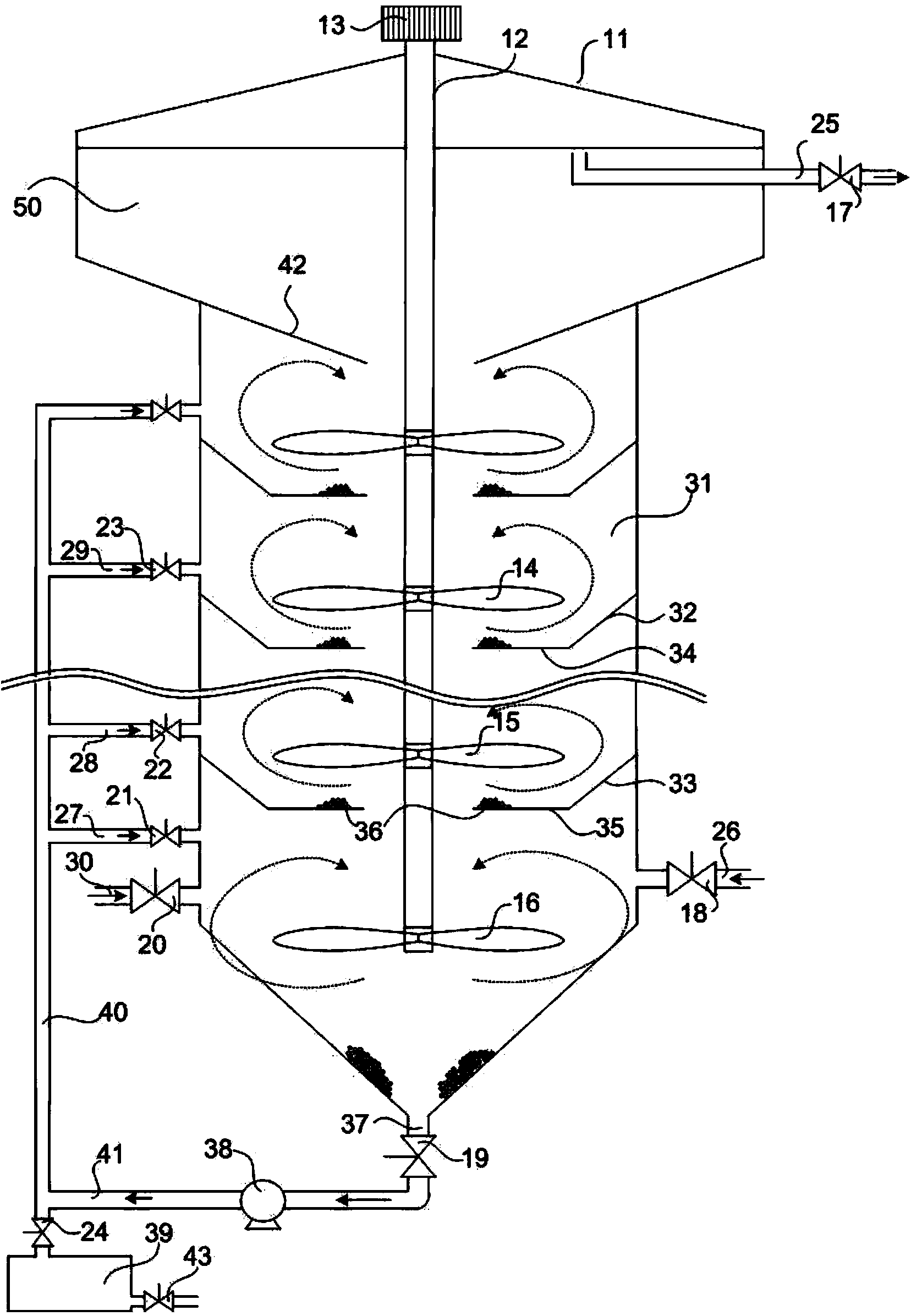

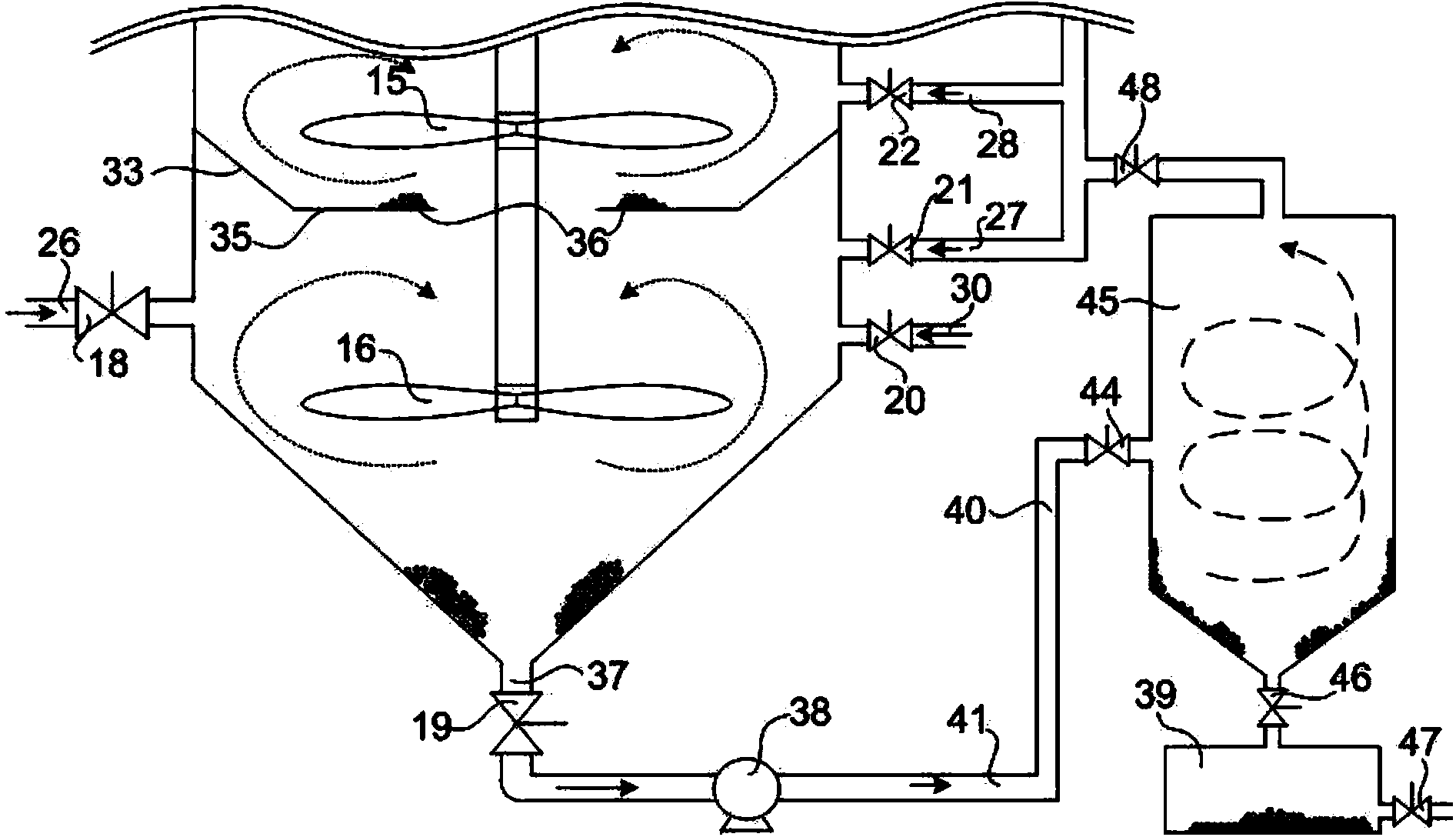

Crystallization reaction apparatus for recovering resources

InactiveCN104114499AEfficient removalExtended reaction timeWater/sewage treatment by centrifugal separationSludge treatment by de-watering/drying/thickeningEutrophicationSludge

The present invention relates to a crystallization reaction apparatus, which is provided with one or more agitating wings therein and comprises a seed inlet for increasing crystallization efficiency, for: removing a nutrient salt causing eutrophication such as phosphorus, nitrogen, and the like present in sewage / wastewater-treated water, and a nutrient salt causing eutrophication such as phosphorus, nitrogen, and the like present in an effluent generated in a step of dehydrating the sludge obtained through a digestion tank during a process for treating sludge wastes such as sewage / wastewater sludge, food waste, domestic animal excrement, and the like; and forming plug flow with one or more isolation layers.

Owner:姜锡雄

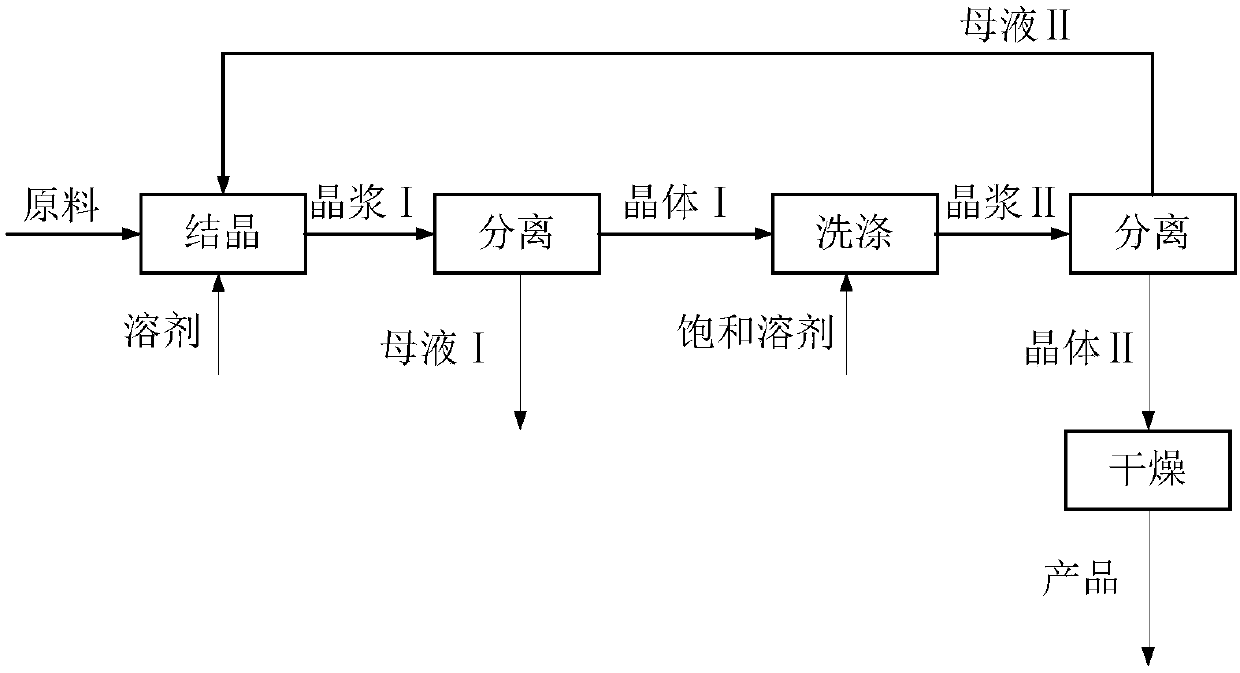

Dicumyl peroxide production method

ActiveCN109694342AImprove product qualityReduce production energy consumptionOrganic compound preparationPeroxy compound preparationSolventHigh energy

The invention relates to a dicumyl peroxide production method, which comprises: co-feeding a dicumyl peroxide raw material and a crystallization solvent into a crystallizer, carrying out cooling crystallization, and carrying out solid-liquid separation on the obtained crystal slurry to obtain a dicumyl peroxide crystal I and a crystallization mother liquor I; discharging the crystallization motherliquor I out of the crystallization device, and carrying out solvent recovery; feeding the dicumyl peroxide crystal I into a beating washing tank, and carrying out beating washing on the dicumyl peroxide crystal I by using a washing liquid; carrying out solid-liquid separation on the obtained crystal slurry to obtain a dicumyl peroxide crystal II and a crystallization mother liquor II; drying thedicumyl peroxide crystal II, and discharging as the product; and returning the crystallization mother liquor II to the crystallizer, and continuously crystallizing. According to the present invention, the dicumyl peroxide production method can solve the problems of poor product quality, irregular crystal shape, poor transparency, serious crystal occlusion and coalescence, non-uniform size and non-uniform distribution of crystal particles, low yield of large particle crystals and high energy consumption in the prior art, and can be used in the production of dicumyl peroxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com