Crystallization reaction apparatus for recovering resources

A reaction device and crystallization technology, applied in the general layout of crystallization devices, crystallization separation, chemical instruments and methods, etc., can solve problems such as application, improve efficiency, improve purity, and increase crystallization reaction speed and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

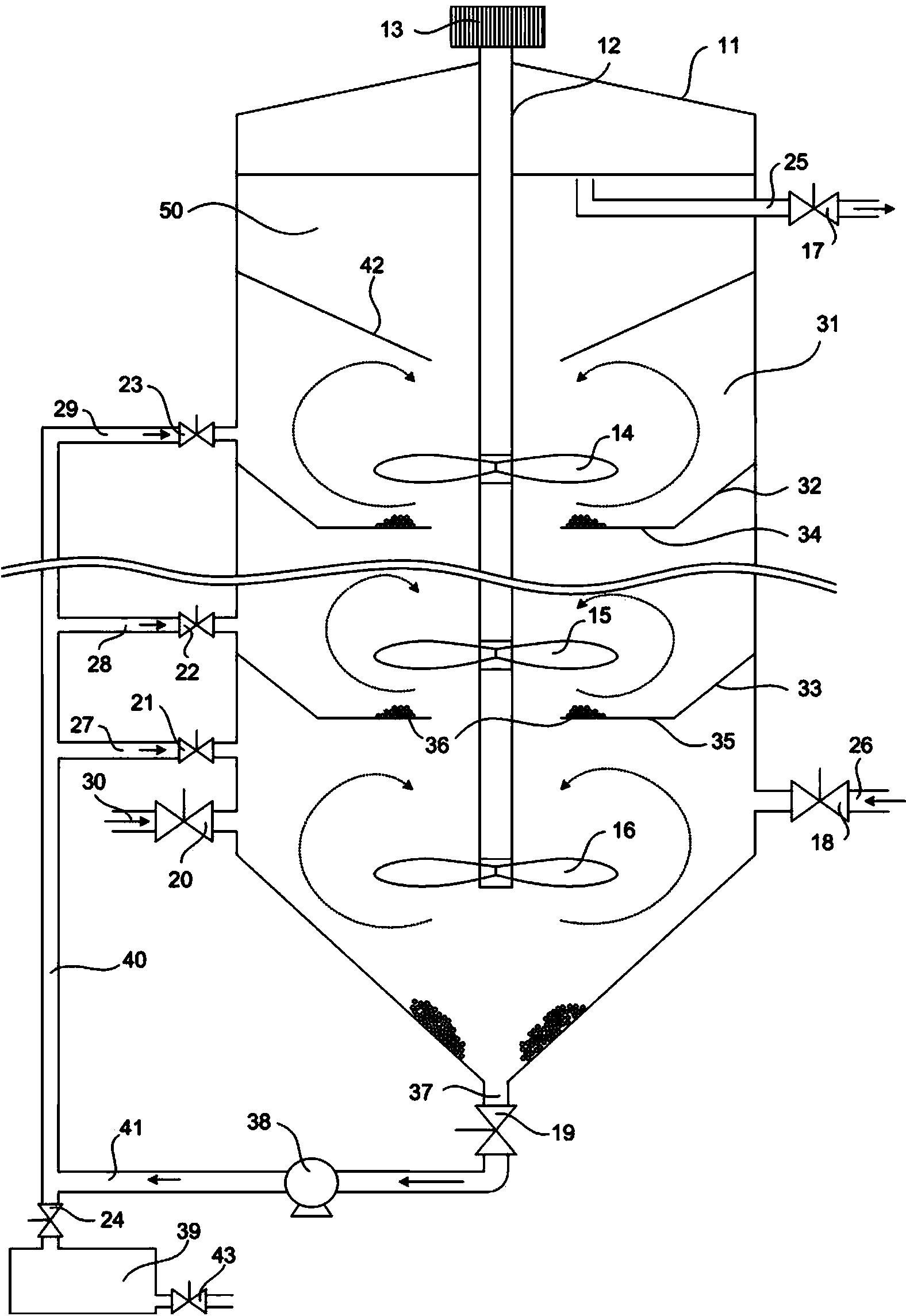

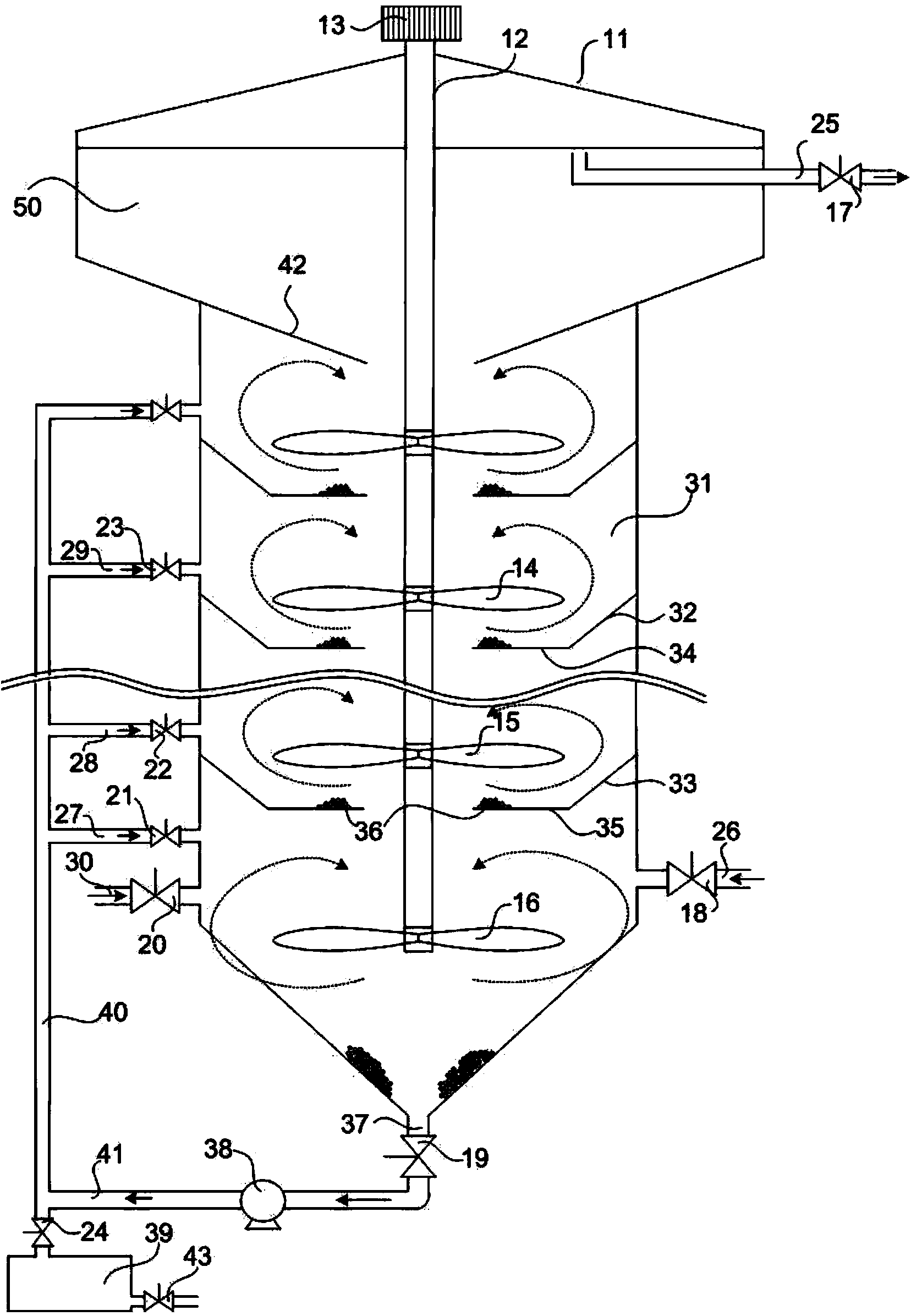

[0035] The specific embodiment 1 according to the present invention is observed based on the drawings. figure 1 The configuration of the crystallization reaction apparatus according to the present invention is shown. figure 2 Another example of the crystallization reaction apparatus according to the present invention is illustrated.

[0036] figure 1 and figure 2 The difference is that the upper space of the crystallization reaction tank is formed wider, and the sedimentation guide isolation member is further added, so that the crystal formed after the crystallization reaction can be prevented from moving upward to the maximum.

[0037] The technical composition other than the above-mentioned differences is in figure 1 and figure 2 same, therefore, based on figure 1 Observe the technical constitution of the present invention in detail.

[0038] The present invention is a crystallization reaction tank 11. The crystallization reaction tank 11 is used to remove and recyc...

Embodiment 2

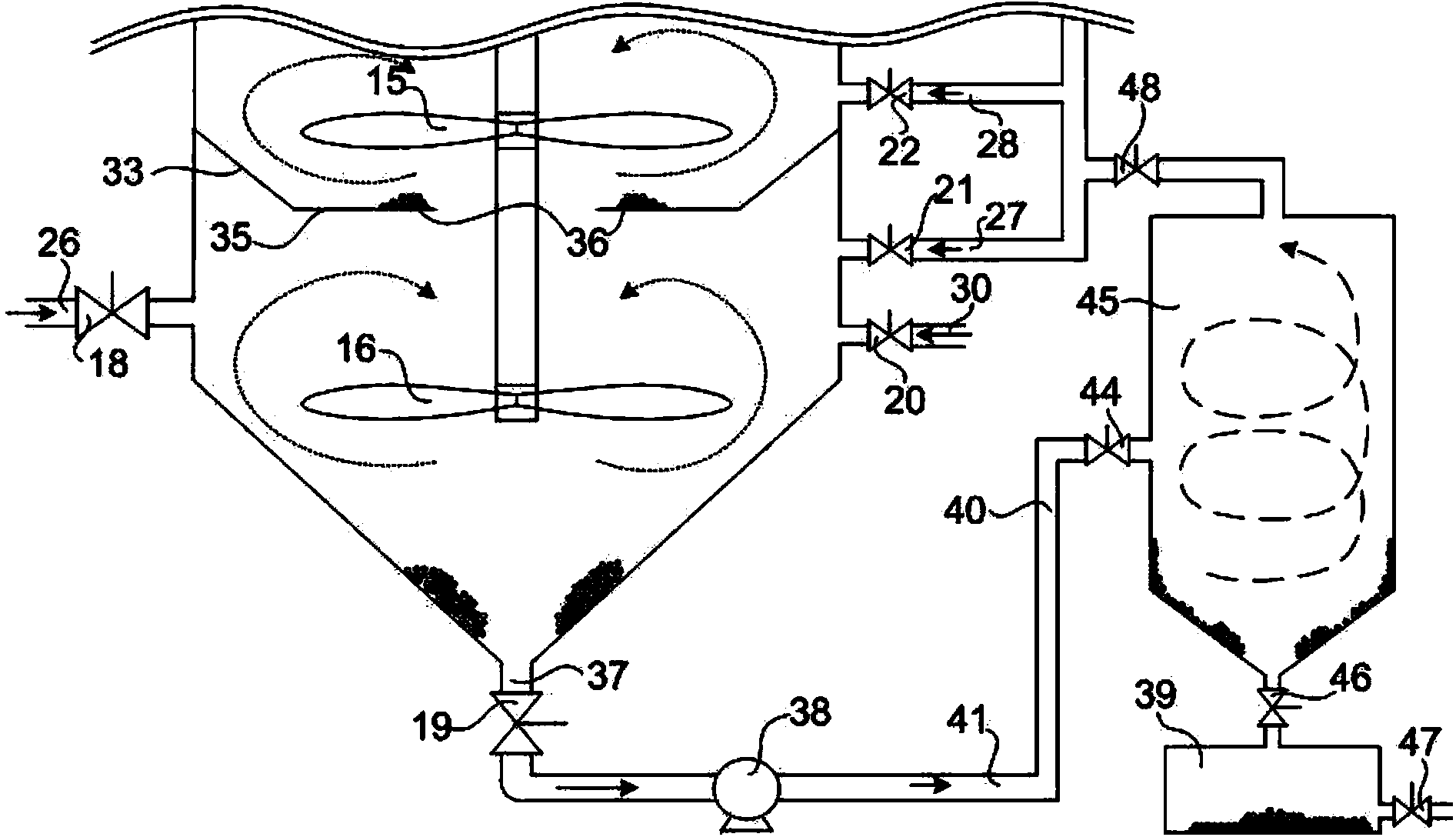

[0072] Example 2 is as image 3 In that way, the composition of the cyclone separator is additionally provided so as to more effectively collect the figure 1 and figure 2 The crystallized substance after the crystallization reaction can be collected by centrifugation.

[0073] Just according to Example 2 image 3 In terms of, as in Example 1 figure 1 and figure 2 In the illustrated drawing, when injecting into the crystal storage tank 39, since crystals and sludge coexist, there exists a problem that the purity of crystals will fall greatly.

[0074] Usually, the specific gravity of the crystals generated by the crystallization reaction is about 1.7, and the specific gravity of the sludge is about 1.05 to 1.17. Therefore, when passing through the cyclone, the sludge and the crystals can be effectively separated.

[0075] And it is constituted that the liquid (crystal+sludge) that has completed the crystallization reaction is injected into the cyclone separator 45, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com