MVR (Mechanical Vapor Recompression) continuous evaporating crystallizing system

An evaporative crystallization and rising film evaporator technology, applied in the field of MVR continuous evaporative crystallization system, can solve the problems of high energy consumption of compressors, small crystallite size, waste of water resources, etc. The effect of less process disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

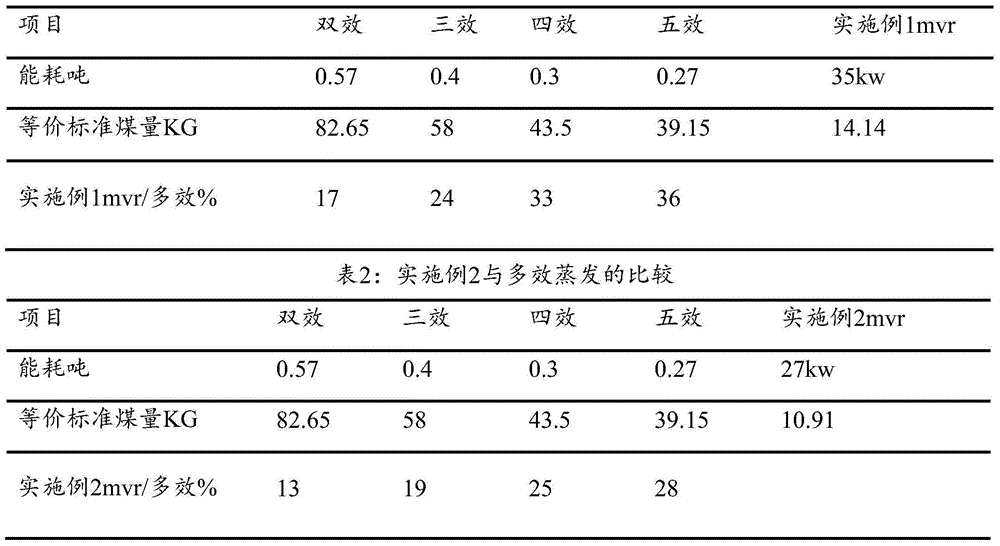

Embodiment 1

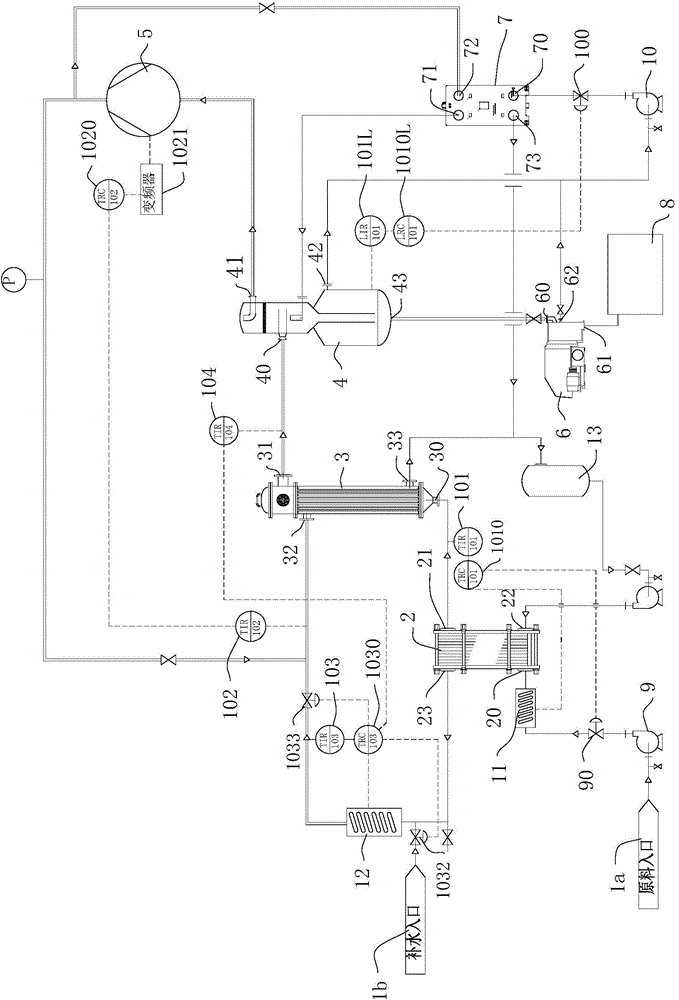

[0050] Such as figure 1A MVR continuous evaporation and crystallization system is shown, which is mainly composed of raw material inlet 1a, water supply inlet 1b, preheater 2, rising film evaporator 3, gas-liquid separator 4, a mechanical vapor recompressor 5, forced circulation Evaporator 7, pipe heater 12, crystal separator 6, buffer tank 13, forced circulation pump 10, cooling water delivery pump and four automatic control loops on the system. The four automatic control loops are the feed temperature control loop, the compressed steam control loop, the added steam control loop and the gas-liquid separator liquid level control loop

[0051] The above-mentioned preheater 2, rising film evaporator 3 and forced circulation evaporator 7 mainly heat the materials flowing into them through heat exchange. Therefore, their structures are heat exchange units, which all have material input for material inflow There are four ports in total, the heat source input end and the cooling wa...

Embodiment 2

[0081] The difference between Embodiment 2 and Embodiment 1 is that the mechanical vapor compressor 5 of this embodiment is a centrifugal compressor, and the rest of Embodiment 1 is repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com