Preparation method of lithium hexafluorophosphate

A technology of lithium hexafluorophosphate and lithium fluoride, which is applied in lithium hexafluorophosphate, chemical instruments and methods, lithium compounds, etc., can solve the problems of time-consuming, labor-intensive, easy to agglomerate, time-consuming and labor-intensive, etc., to shorten the crystallization time, shorten the production cycle, Effect of improving crystallization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

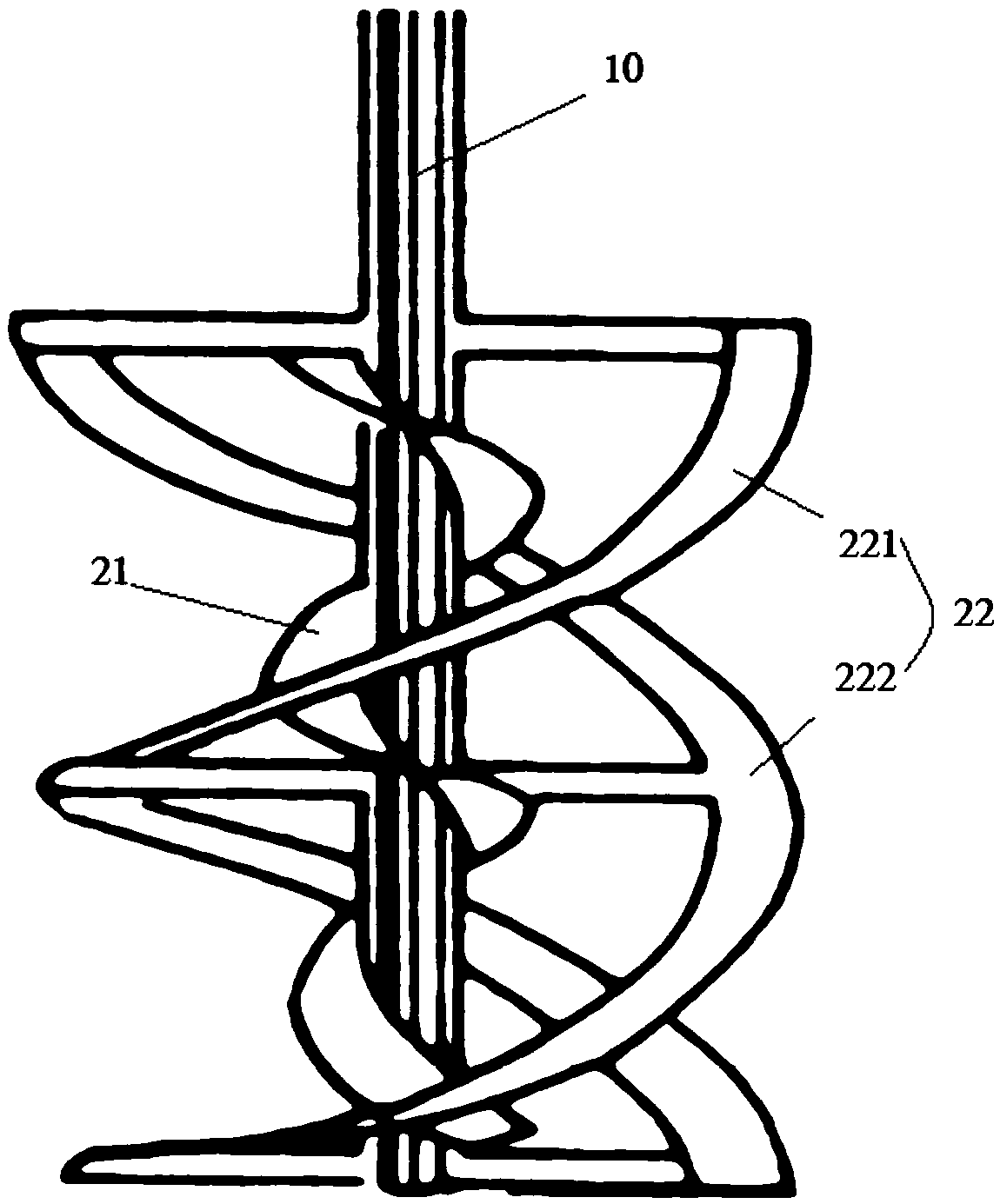

Image

Examples

preparation example Construction

[0037] (1) Preparation of high-purity raw materials: Anhydrous hydrogen fluoride is sent to a distillation tower for refining, the distillation temperature is controlled at 20-25°C, and the hydrogen fluoride gas evaporated is condensed by a condenser to produce hydrogen fluoride liquid with a purity of more than 99.99wt%. ;

[0038] (2) Preparation and purification of phosphorus pentafluoride: add hydrogen fluoride liquid into the reaction kettle that has added phosphorus pentachloride, wherein the hydrogen fluoride liquid is excessive relative to phosphorus pentachloride, and control the temperature at 178 ° C ~ Between 182°C and the pressure controlled between 0.13MPa and 0.17MPa, hydrogen fluoride reacts with phosphorus pentachloride to produce a mixed gas of phosphorus pentafluoride and hydrogen chloride. After the reaction is completed, the excess hydrogen fluoride liquid is absorbed by the condensed water of the condensing device. By-product hydrofluoric acid;

[0039] ...

Embodiment 1

[0052] A method for rapidly preparing lithium hexafluorophosphate, specifically comprising the following steps:

[0053] (1) Preparation of high-purity raw materials: Anhydrous hydrogen fluoride is sent to a distillation tower for refining, the distillation temperature is controlled at 20-25°C, and the hydrogen fluoride gas evaporated is condensed by a condenser to produce hydrogen fluoride liquid with a purity of more than 99.99wt%. ;

[0054] (2) Preparation and purification of phosphorus pentafluoride: add hydrogen fluoride liquid into the reaction kettle that has added phosphorus pentachloride, wherein the hydrogen fluoride liquid is excessive relative to phosphorus pentachloride, and control the temperature at 178 ° C ~ Between 182°C and the pressure controlled between 0.13MPa and 0.17MPa, hydrogen fluoride reacts with phosphorus pentachloride to produce a mixed gas of phosphorus pentafluoride and hydrogen chloride. After the reaction is completed, the excess hydrogen flu...

Embodiment 2

[0059] A method for preparing lithium hexafluorophosphate with special specifications, specifically comprising the following steps:

[0060] (1) Preparation of high-purity raw materials: Anhydrous hydrogen fluoride is sent to a distillation tower for refining, the distillation temperature is controlled at 20-25°C, and the hydrogen fluoride gas evaporated is condensed by a condenser to produce hydrogen fluoride liquid with a purity of more than 99.99wt%. ;

[0061] (2) Preparation and purification of phosphorus pentafluoride: add hydrogen fluoride liquid into the reaction kettle that has added phosphorus pentachloride, wherein the hydrogen fluoride liquid is excessive relative to phosphorus pentachloride, and control the temperature at 178 ° C ~ Between 182°C and the pressure controlled between 0.13MPa and 0.17MPa, hydrogen fluoride reacts with phosphorus pentachloride to produce a mixed gas of phosphorus pentafluoride and hydrogen chloride. After the reaction is completed, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com