Patents

Literature

140results about "Lithium hexafluorophosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of purifying lithium hexafluorosphate

InactiveUS6514474B1Phosphorus halides/oxyhalidesNon-aqueous electrolyte accumulatorsHydrogen fluoridePhosphor

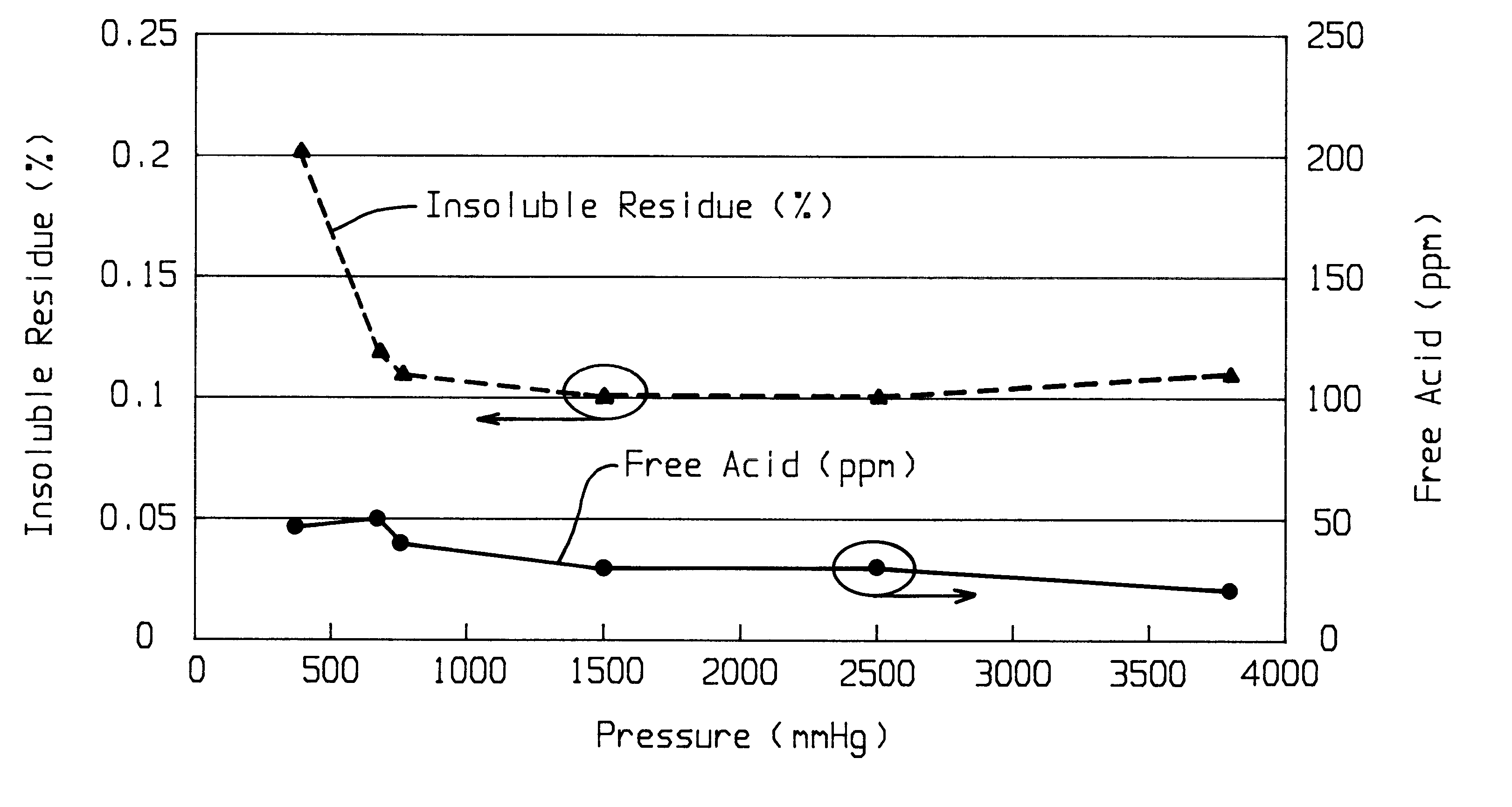

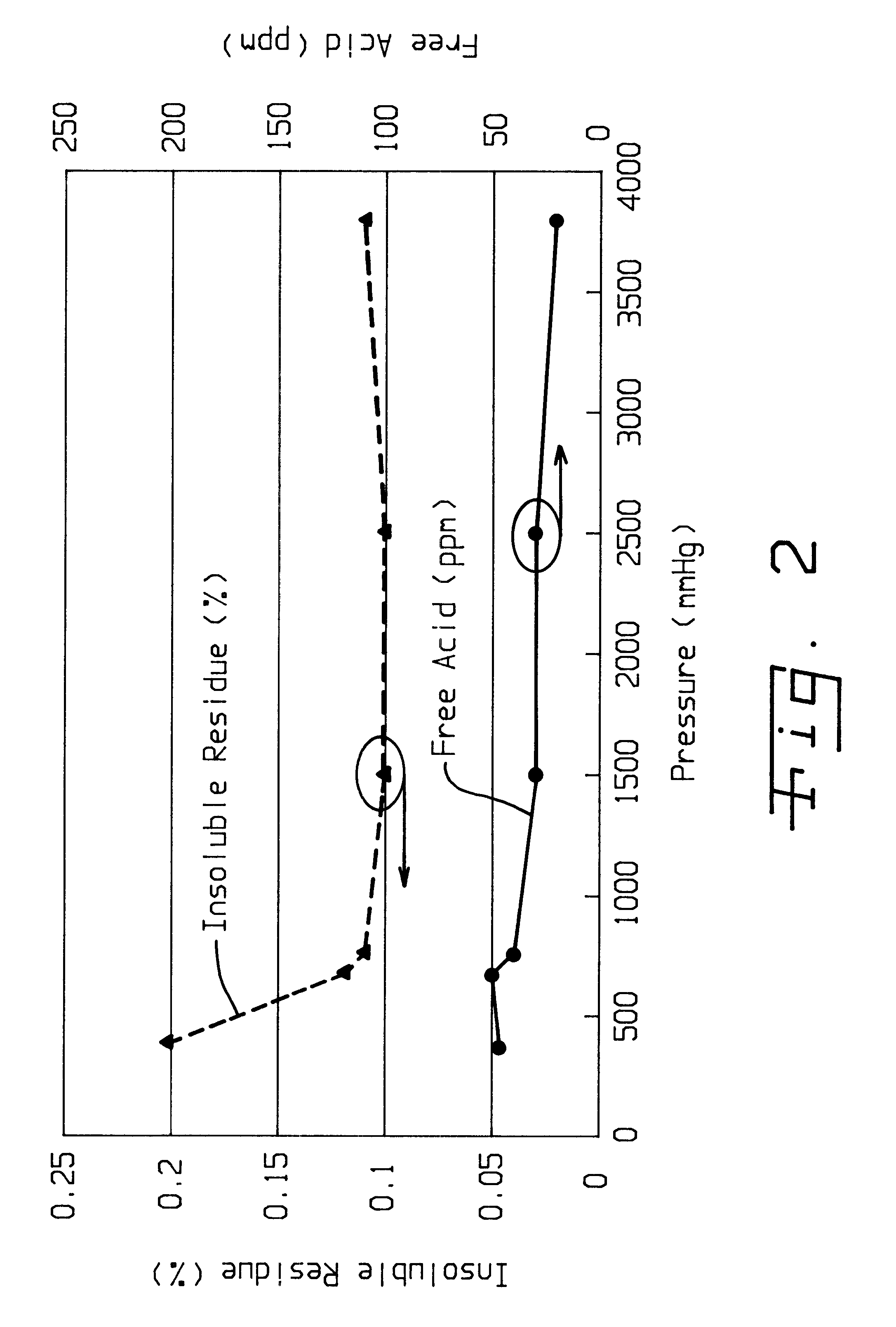

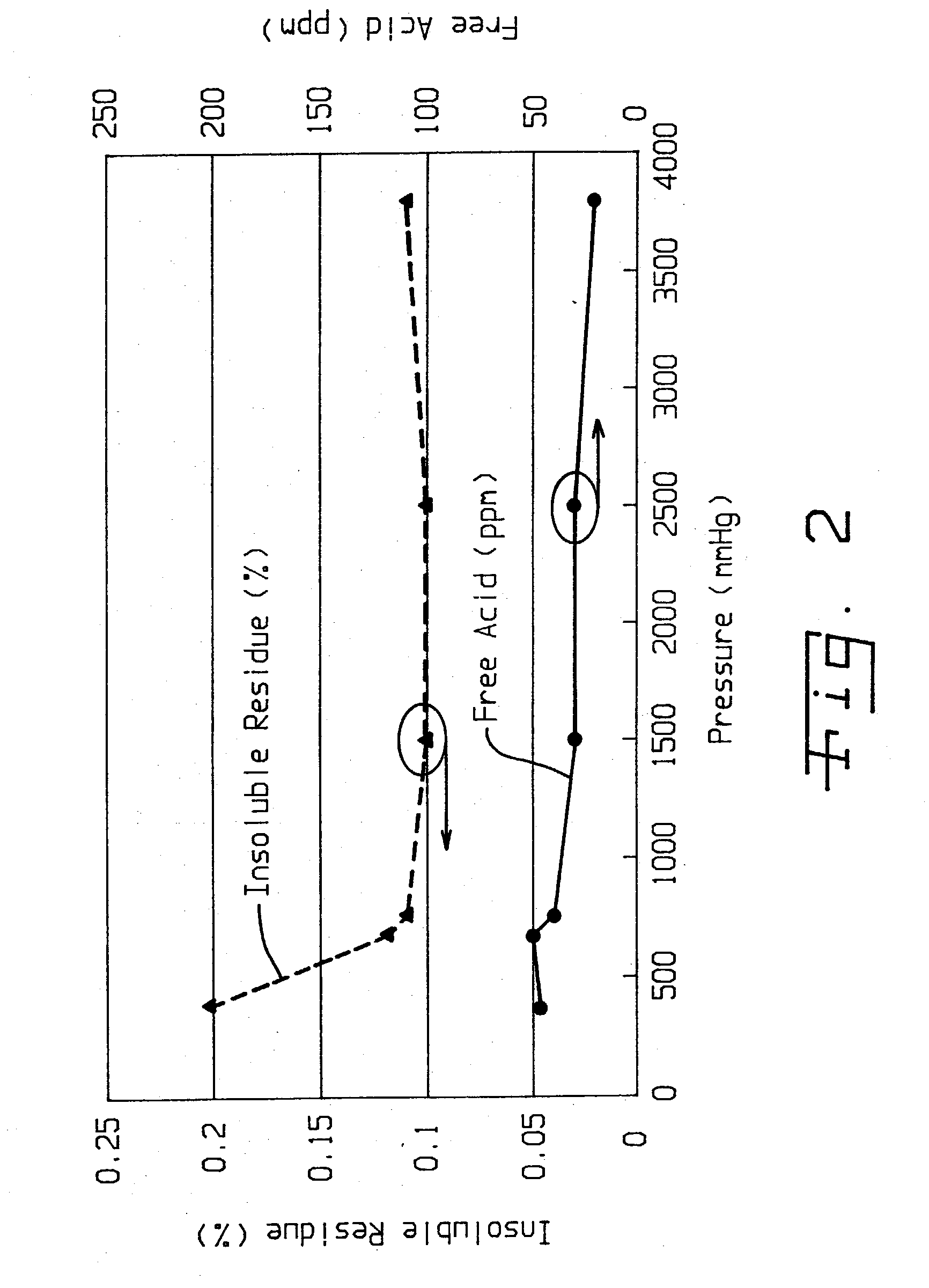

A method of purifying lithium hexafluorosphate that allows to purify lithium hexafluorophosphate, useful as lithium secondary cell electrolyte, organic synthesis medium or the like, to an extremely high purity is provided. Lithium hexafluorophosphate containing harmful impurities such as oxyfluoride, lithium fluoride is purified by adding phosphoric chloride. The purification is performed in the presence of phosphoric chloride and hydrogen fluoride of the quantity equal or superior to the equivalent amount for reacting them, and then by converting lithium fluoride to lithium hexafluorophosphate with generated phosphor pentafluoride.

Owner:STELLA CHEMIFA CORP

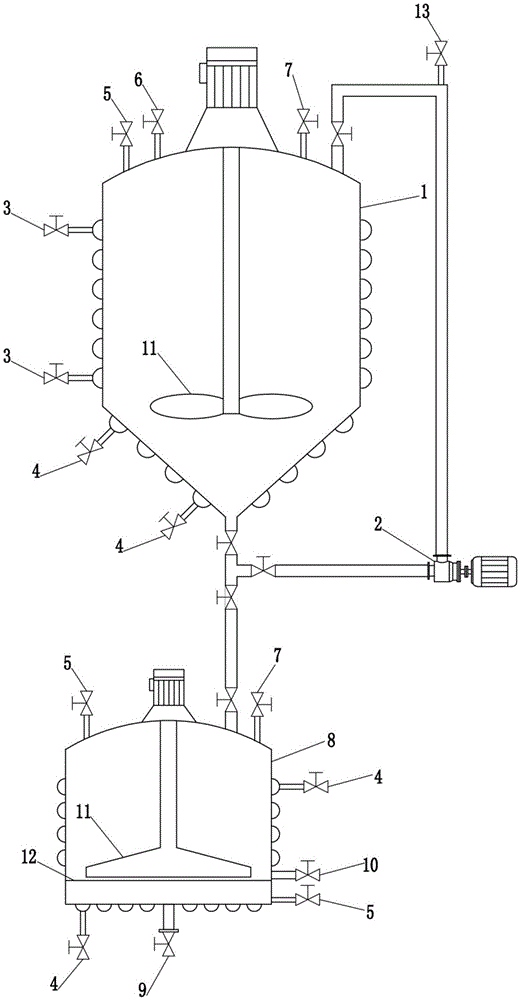

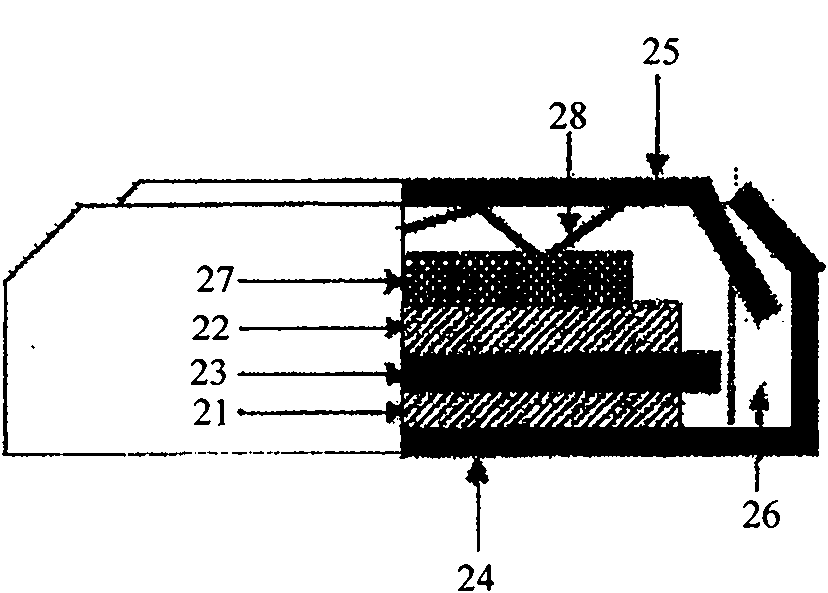

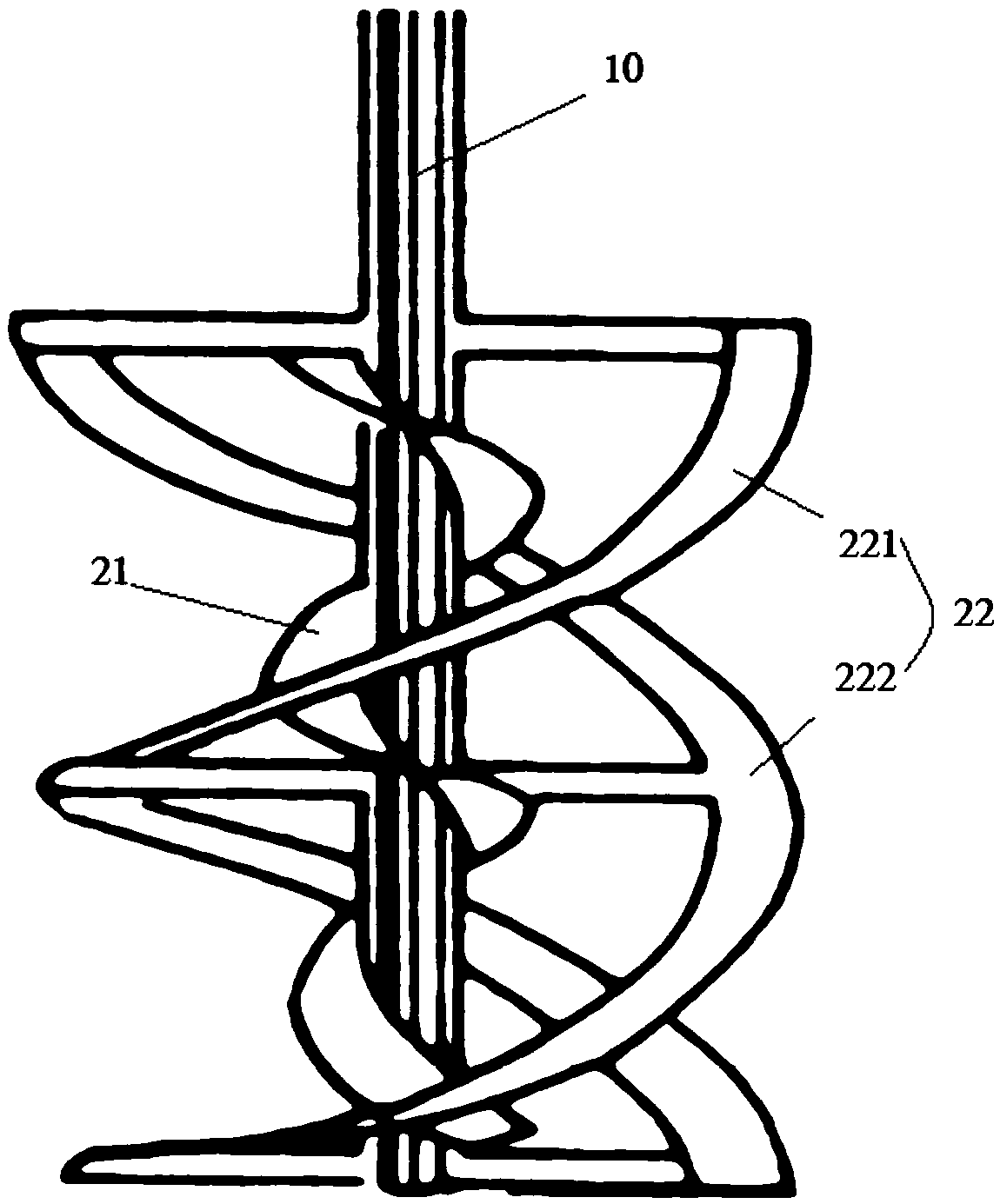

Method and device for preparing lithium hexafluorophosphate through dynamic crystallization

ActiveCN105600809AUniform growthUniform particle sizeLithium hexafluorophosphateSocial benefitsUltrasound - action

The invention discloses a method and device for preparing lithium hexafluorophosphate through dynamic crystallization. The method includes the following steps of 1, ultrasound induced nucleation, wherein a lithium hexafluorophosphate solution is cooled to minus 10-minus 15 DEG C within 2-3 hours under the action of ultrasonic waves, and a crystallization solution A is obtained; 2, stirring and crystallization, wherein the crystallization solution A is crystallized while being stirred at the cooling rate of 2-3 DEG C / h, and lithium hexafluorophosphate suspension liquid is obtained; filtering and drying are conducted, and the lithium hexafluorophosphate is obtained. According to the method, at the early stage of crystallization, ultrasound induced nucleation is adopted so that the lithium hexafluorophosphate can be subjected to homogeneous nucleation in a supersaturated interface stability zone; gradient cooling crystallization is achieved at a certain cooling rate under the stirring condition along with change of the concentration of the lithium hexafluorophosphate, so that crystal nucleus grows gradually, and a product with even particle size is obtained; the purity of the obtained product reaches 99.99%, the particle size is 40-120 meshes, the whole crystallization process only needs 6-13 hours, wall hanging does not occur easily in the crystallization process, and good economic benefits and social benefits are achieved.

Owner:DO FLUORIDE CHEM CO LTD

Preparation method of hexafluorophosphoric acid alkali metal salt

InactiveCN106745096AShort staySimple processLithium hexafluorophosphatePhosphorus compoundsChemical synthesisContinuous flow

The invention belongs to the technical field of chemical synthesis, in particular to a preparation method of a hexafluorophosphoric acid alkali metal salt. The preparation method comprises the following steps: metering and introducing phosphorus pentafluorine gas and a fluorinated alkali metal salt solution into a microchannel reactor, mixing the phosphorus pentafluorine gas and the fluorinated alkali metal salt solution, carrying out reaction on a mixture, and carrying out crystallization and drying on an obtained reaction solution to obtain the hexafluorophosphoric acid alkali metal salt. According to the preparation method, a continuous flow microchannel reaction technology is adopted to synthesize the high-purity hexafluorophosphoric acid alkali metal salt, so that the reaction time is shortened to dozens of seconds or a few minutes from a few hours, the efficiency is remarkably improved, requirement for additionally configuring a device caused in the conventional intermittent reaction and leakages caused during transferring are prevented, and the safety is improved.

Owner:JIUJIANG TINCI ADVANCED MATERIALS CO LTD

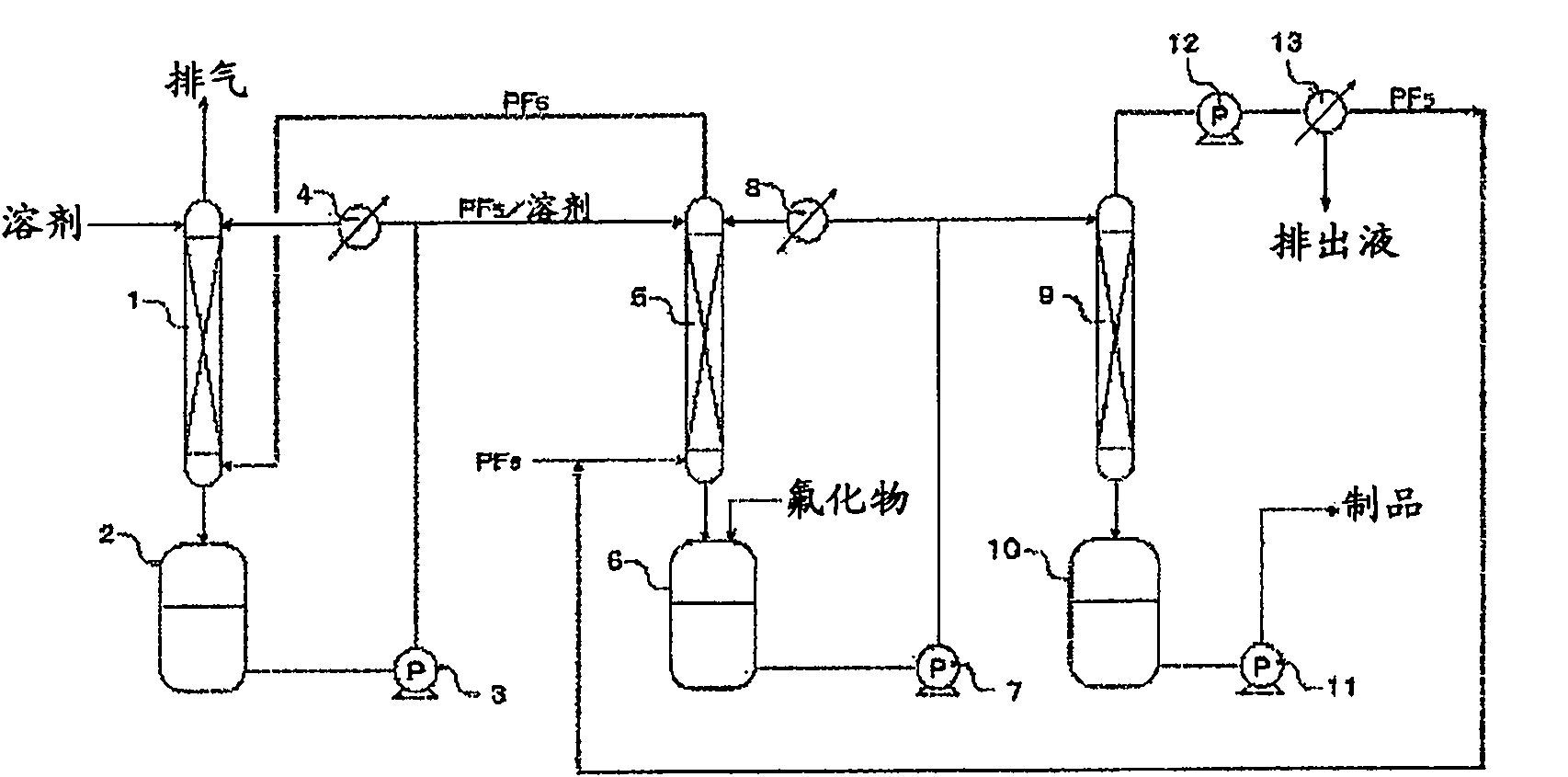

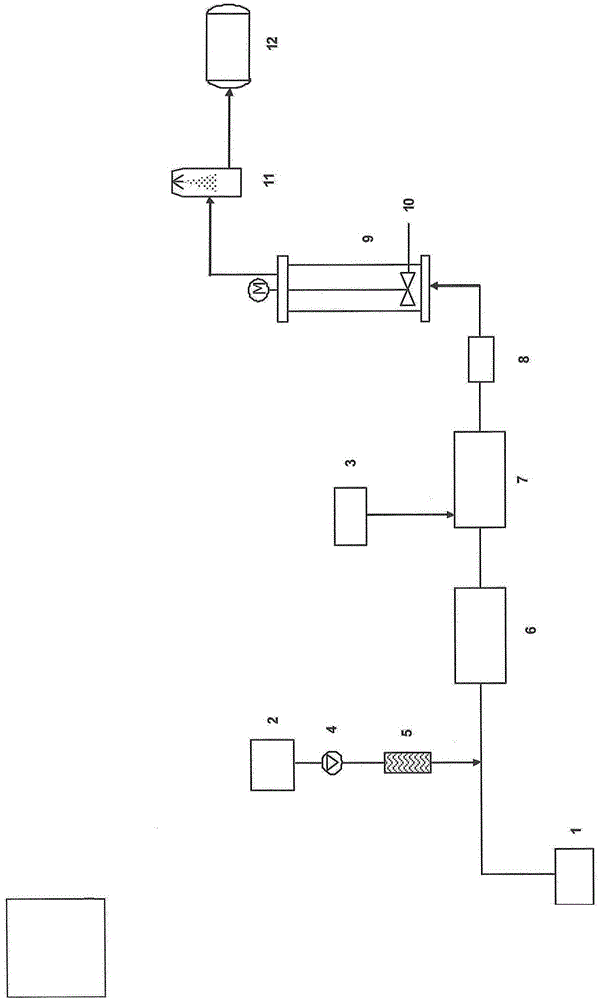

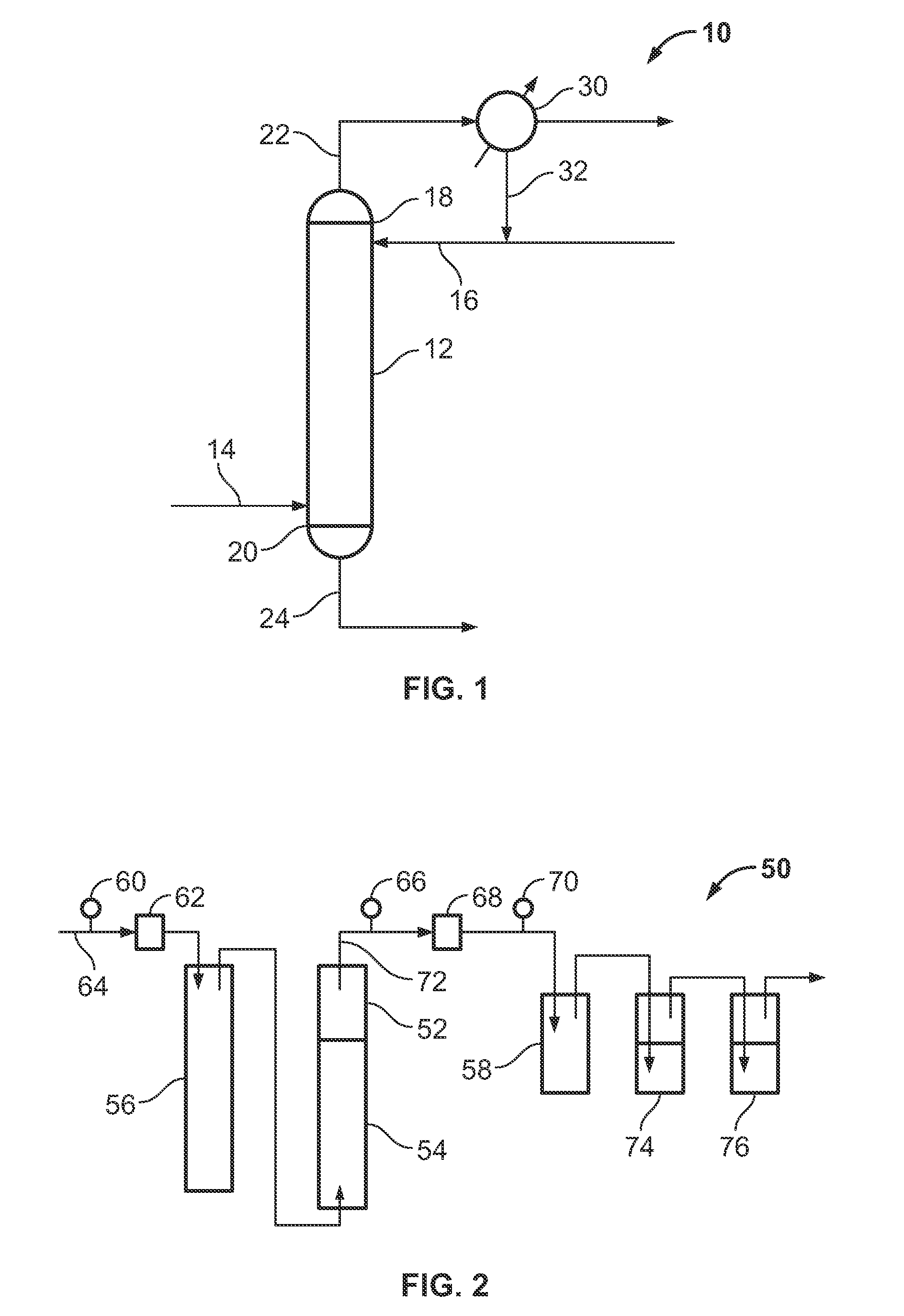

Processes for producing phosphorus pentafluoride and hexafluorophosphate

InactiveCN101605721AEasy to operateReduce synthesisPhosphorus halides/oxyhalidesDispersed particle separationPhosphatePhysical chemistry

Owner:STELLA CHEMIFA CORP

Processes for production of phosphorus pentafluoride and hexafluorophosphates

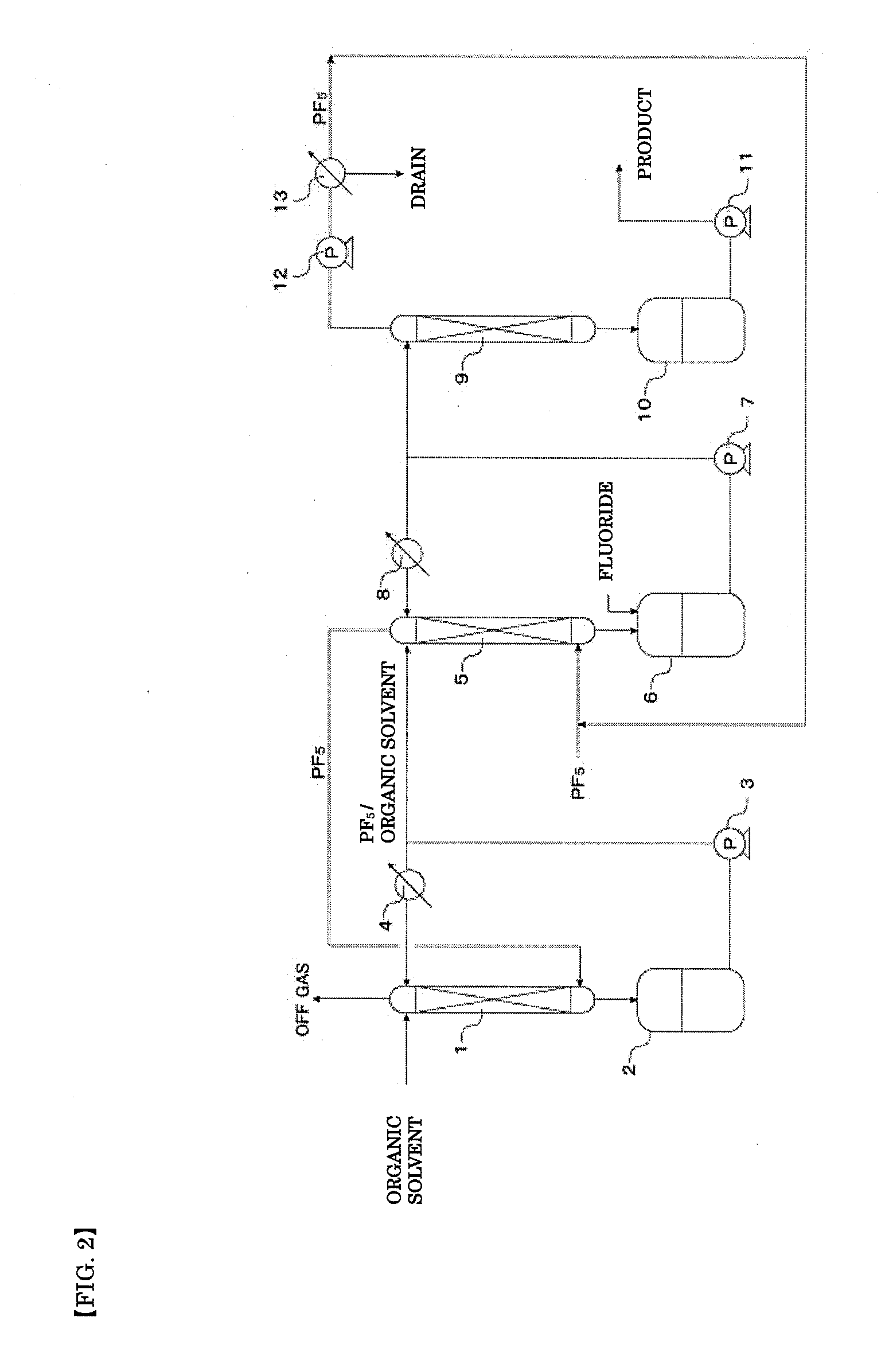

ActiveUS20110189538A1InexpensiveLow moisture concentrationPhosphorus halides/oxyhalidesLithium hexafluorophosphateChemical reactionPhysical chemistry

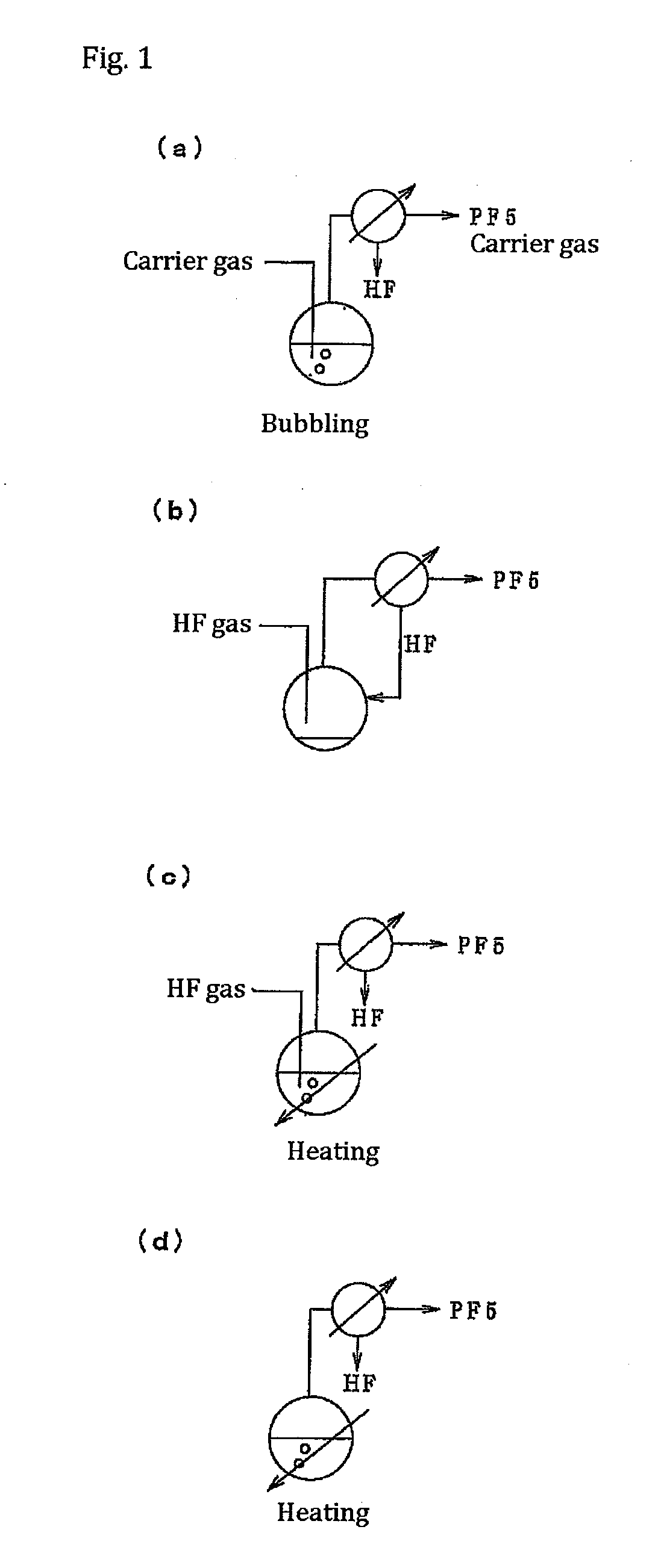

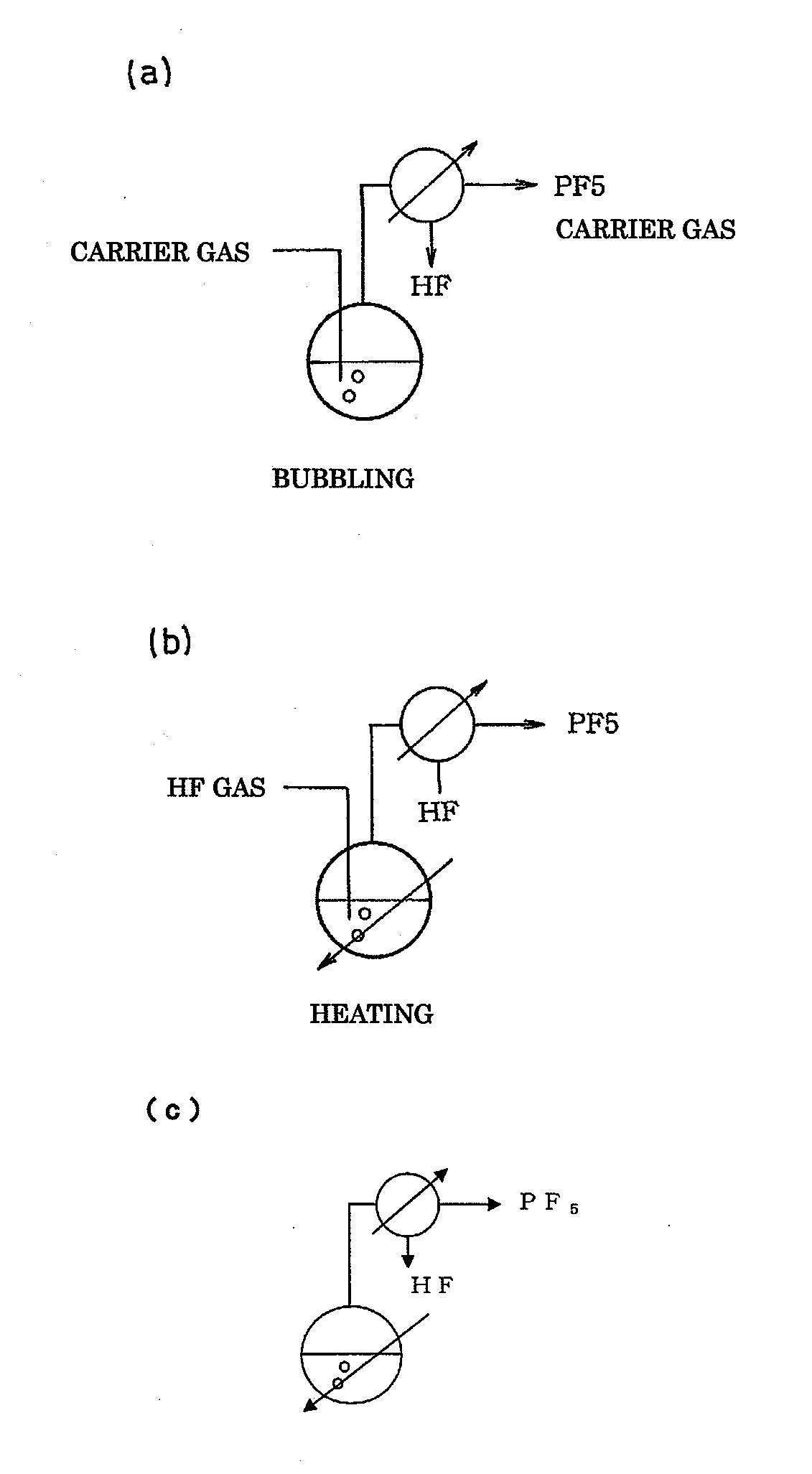

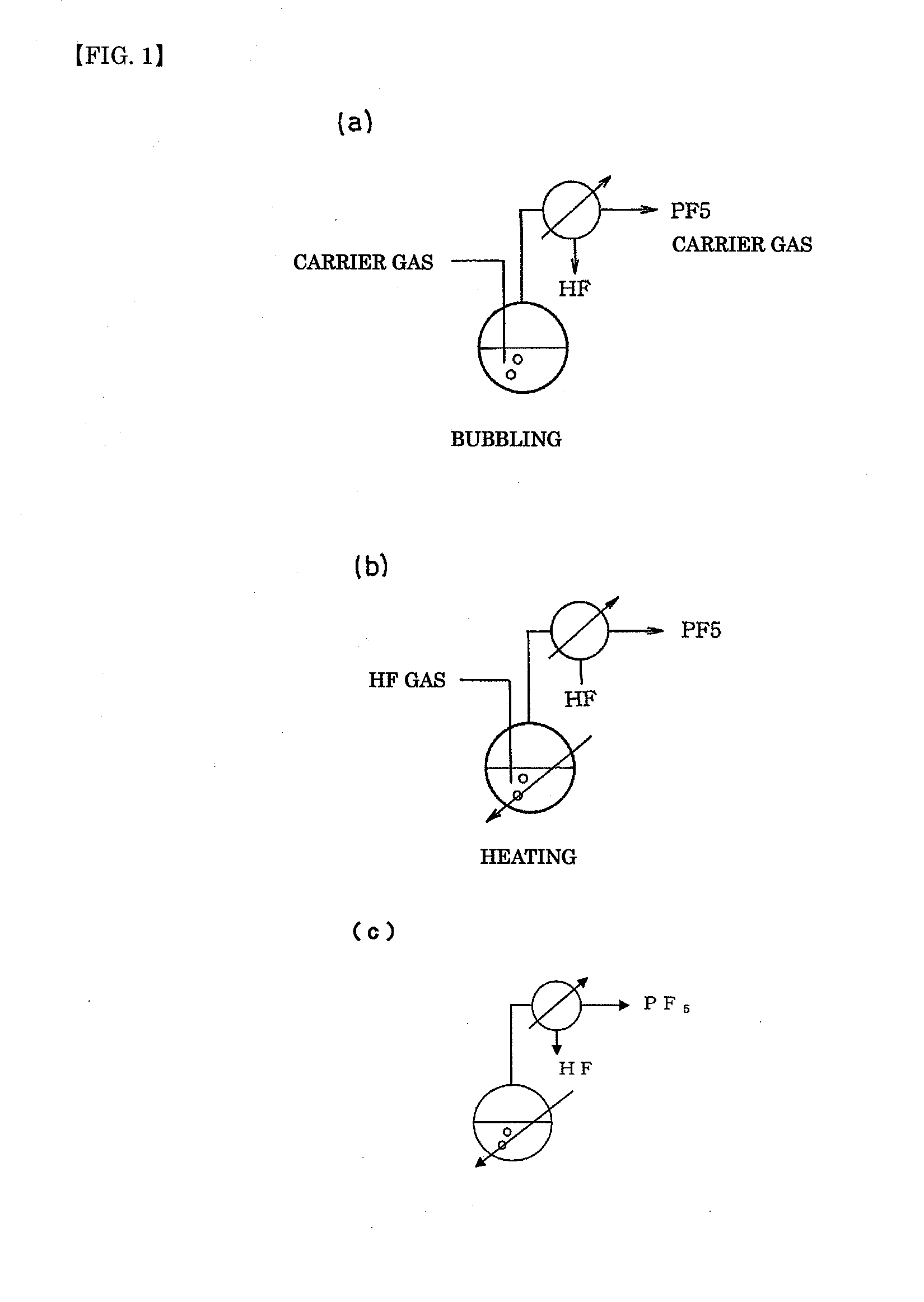

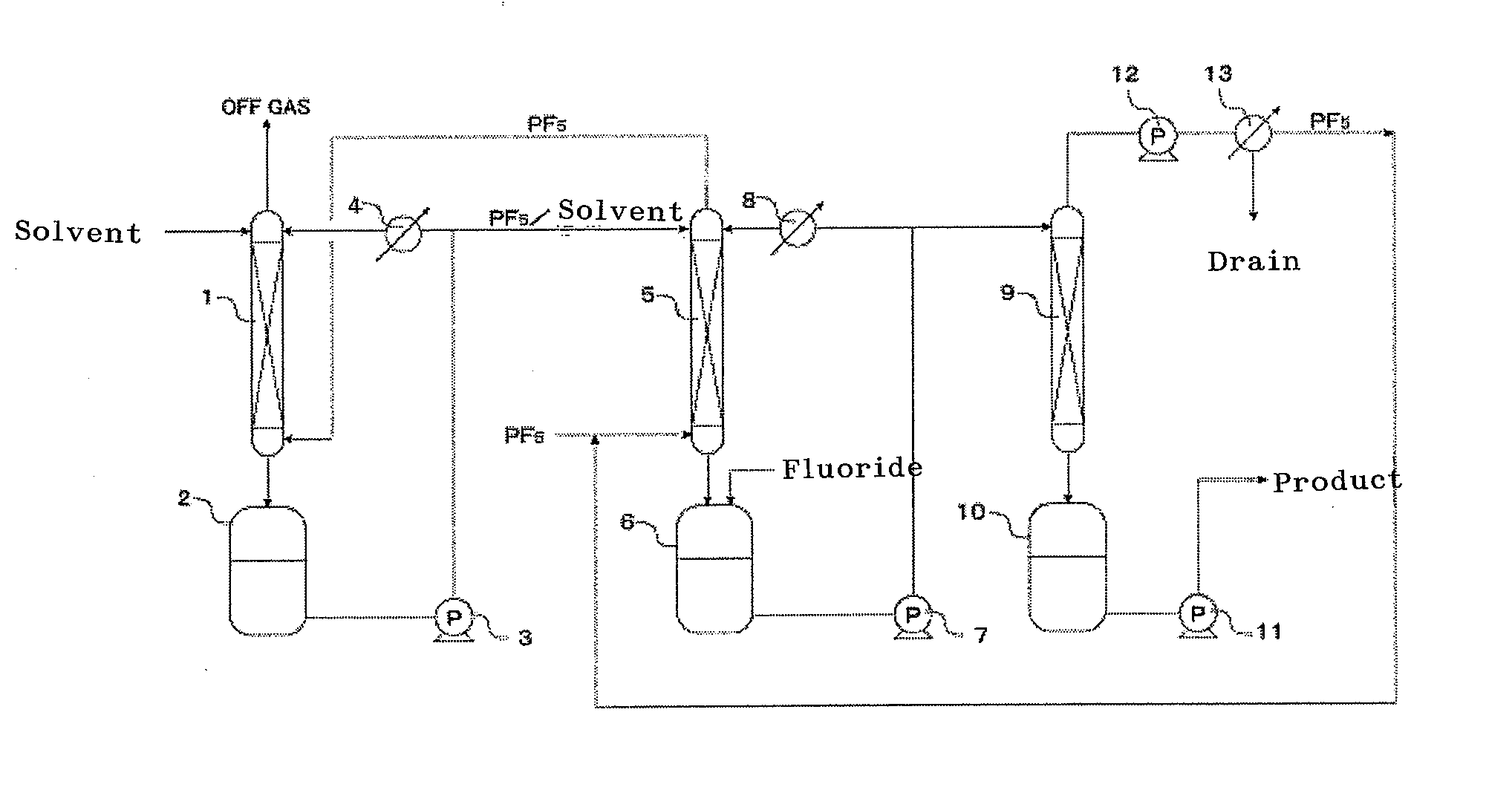

A method of manufacturing phosphorus pentafluoride and hexafluorophosphate can suppress the manufacturing cost and also can manufacture high-quality phosphorus pentafluoride from an inexpensive and low-quality raw material. The raw material for the method can include at least a phosphorus atom and a fluorine atom. These are brought into contact with a carrier gas, and a phosphorus pentafluoride is extracted and separated into the carrier gas. A method of manufacturing hexafluorophosphate includes reacting fluoride with the resulting phosphorus pentafluoride according to the following chemical reaction scheme: sPF5+AFs→A(PF6)s, in which s is in the range of 1≦s≦3, and A is at least one of the following: Li, Na, K, Rb, Cs, NH4, Ag, Mg, Ca, Ba, Zn, Cu, Pb, Al and Fe.

Owner:STELLA CHEMIFA CORP

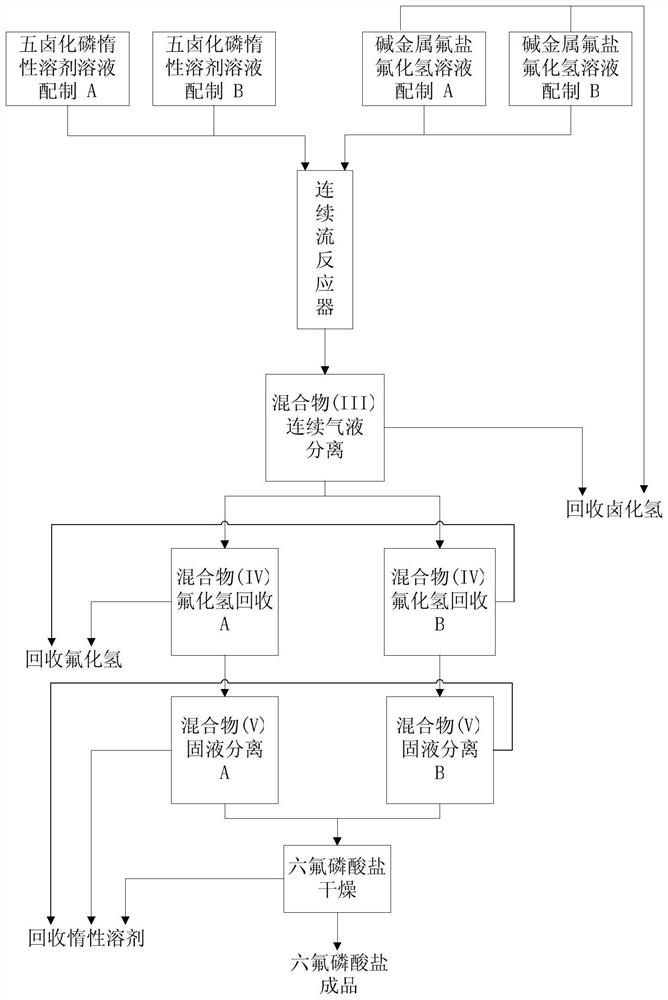

Processes for producing phosphorus tetrafluoride and phosphate hexafluoride

InactiveUS20110286905A1High purityPhosphorus halides/oxyhalidesLarge-sized flat cells/batteriesPhosphatePhotochemistry

An object the invention is to provide a phosphorus pentafluoride producing process wherein phosphorus pentafluoride is separated / extracted from a pentavalent phosphorus compound or a solution thereof, or a composition obtained by allowing the pentavalent phosphorus compound or the solution thereof to react with hydrogen fluoride, thereby producing phosphorus pentafluoride; and a phosphate hexafluoride producing process wherein the resultant phosphorus pentafluoride is used as raw material to produce a phosphate hexafluoride high in purity. The present invention relates to a process for producing phosphorus pentafluoride, wherein a carrier gas is brought into contact with either of the following one: a pentavalent phosphorus compound, a solution thereof, or a solution in which a composition obtained by allowing the pentavalent phosphorus compound or the solution thereof to react with hydrogen fluoride is dissolved, thereby a phosphorus pentafluoride is extracted into the career gas.

Owner:STELLA CHEMIFA CORP

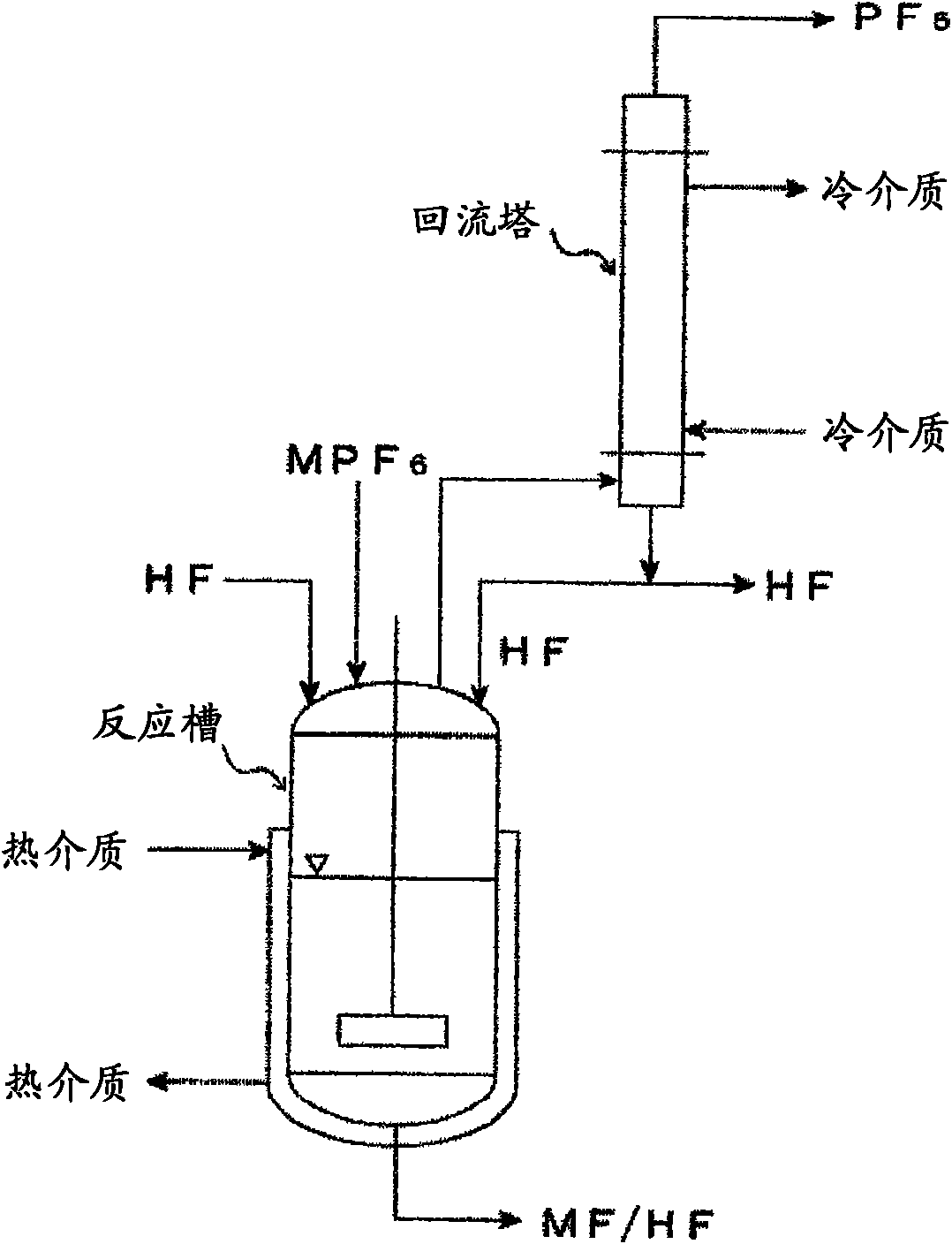

Method of manufacturing phosphorous pentafluoride and hexafluorophosphate

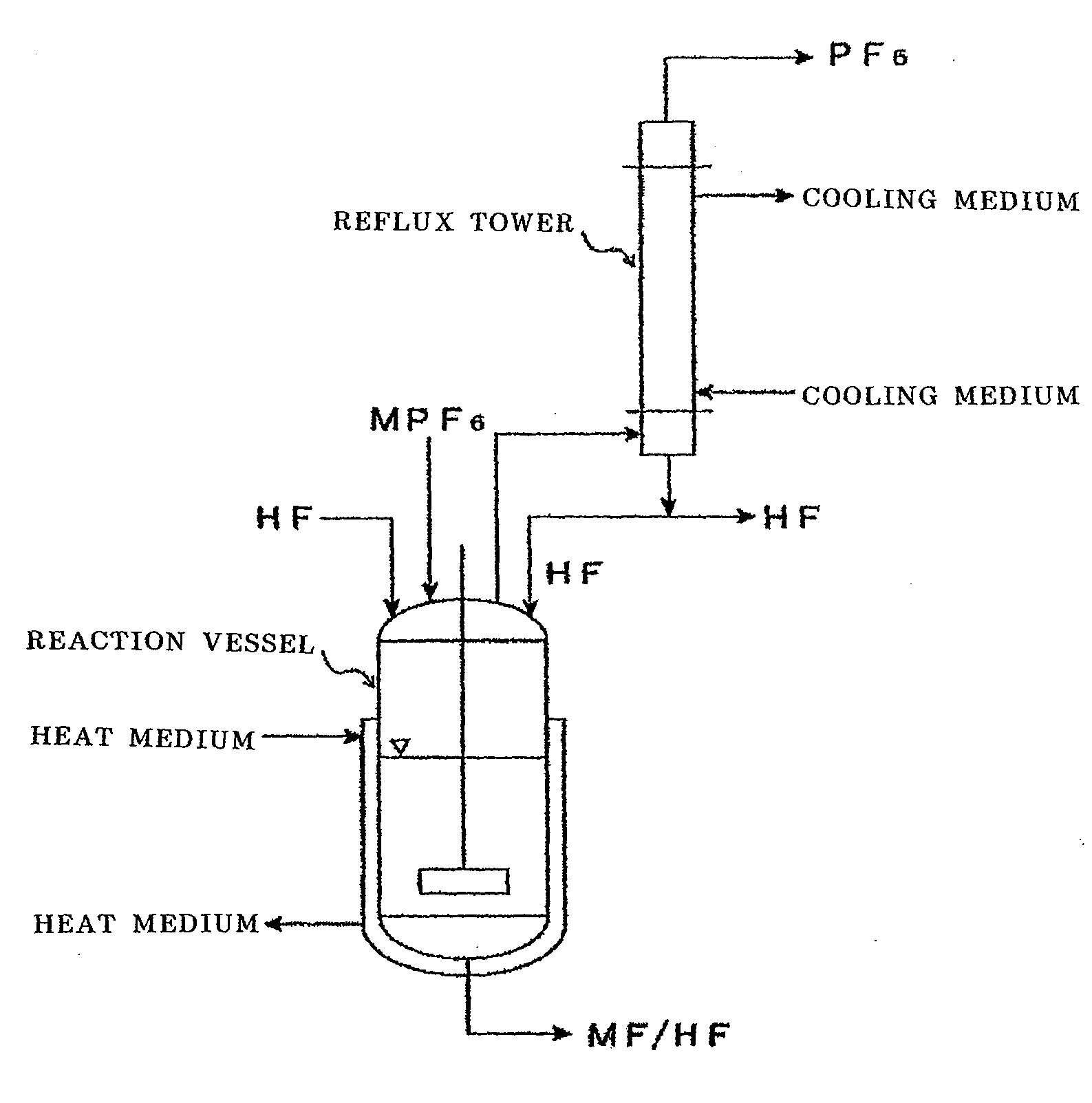

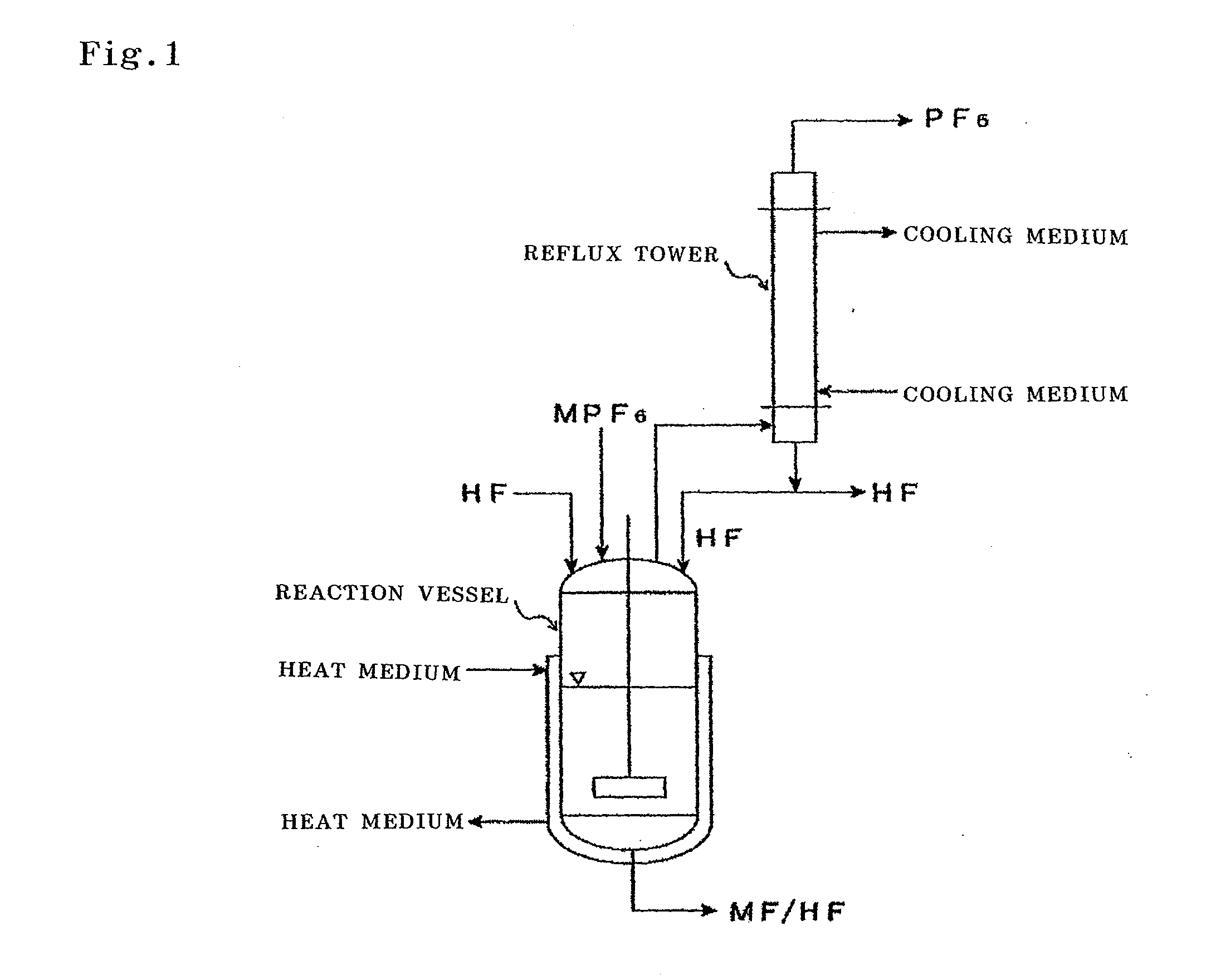

InactiveUS20100322838A1Easy to operateLow pricePhosphorus halides/oxyhalidesLithium hexafluorophosphatePentafluoridePhysical chemistry

A process for phosphorus pentafluoride production by which high-purity phosphorus pentafluoride can be produced by a simple and economical procedure without the need of a large-scale purification apparatus or high-pressure apparatus and without generating a large amount of a by-product gas requiring a special discharge-gas treatment. The process for phosphorus pentafluoride production is characterized by introducing hydrogen fluoride and a hexafluorophosphate (MPF6) into a vessel and reacting them according to the reaction shown by the scheme (1) to yield phosphorus pentafluoride. MPF6+uHF→PF5+MF r(HF) (Scheme 1) In the scheme, M is at least any one of Li, Na, K, Rb, Cs, NH4, and Ag; 0≦r≦u; and the HF is used in an amount not smaller than the stoichiometric amount.

Owner:STELLA CHEMIFA CORP

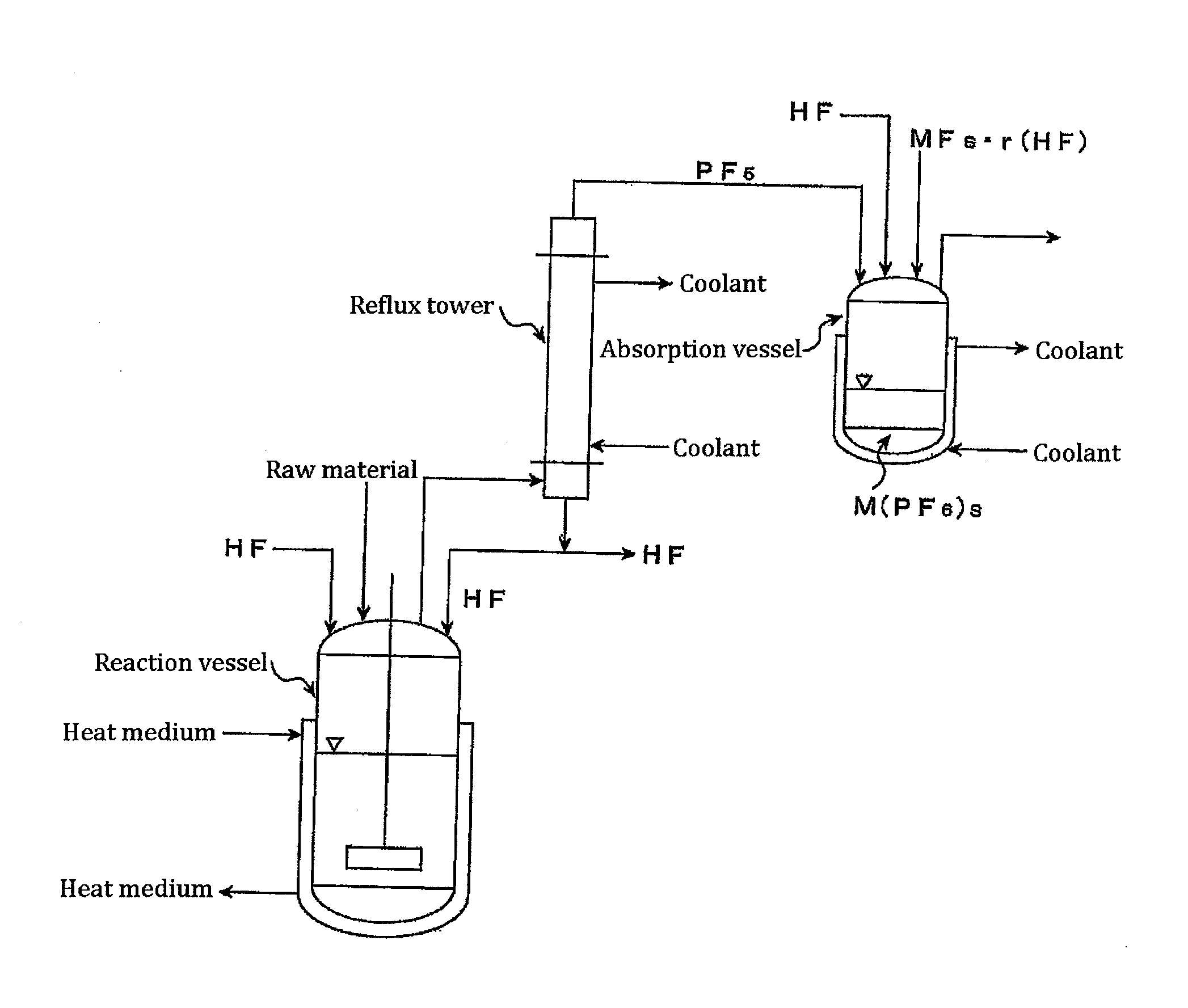

Process for production of hexafluorophosphates

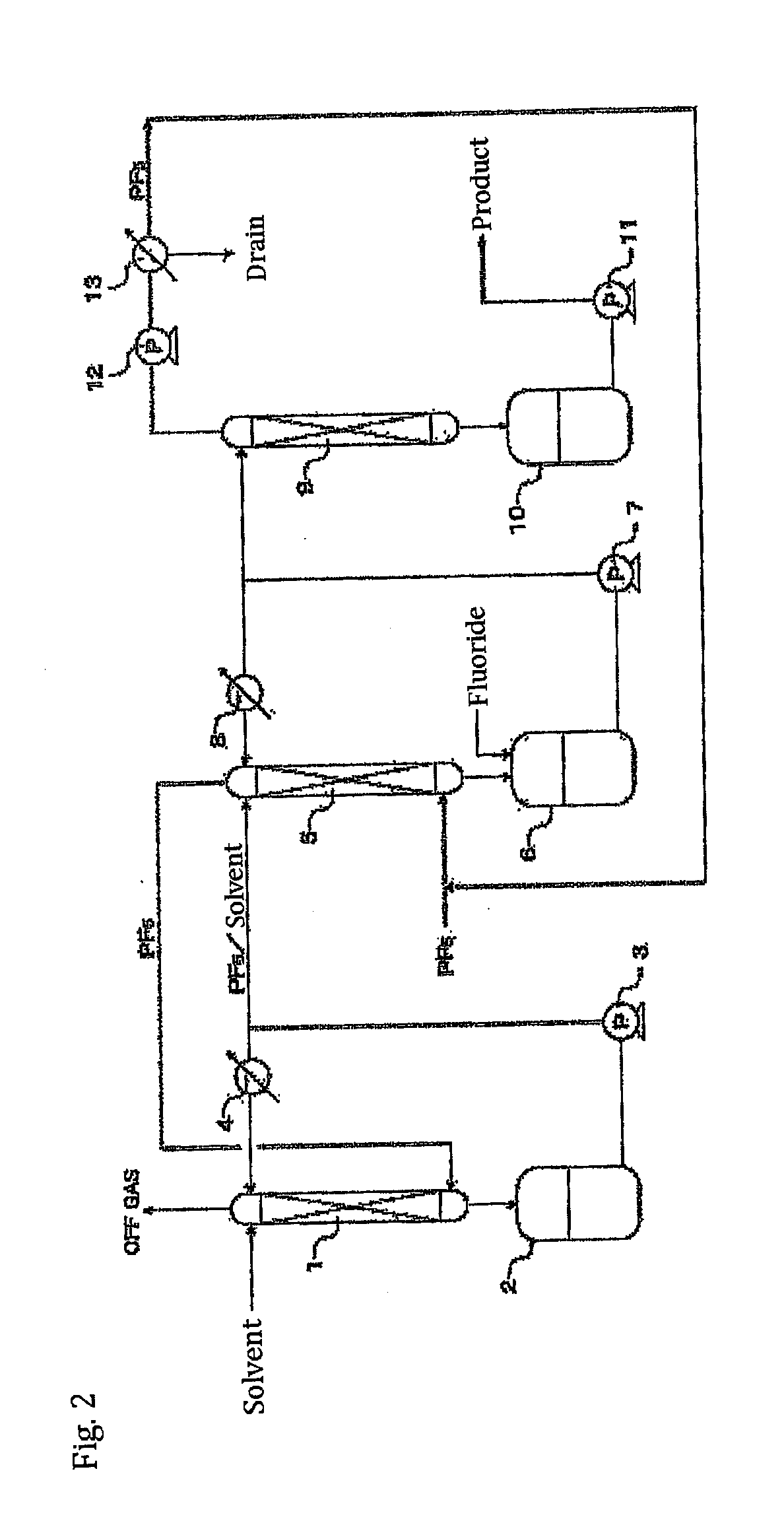

InactiveCN102105395AEasy to manufactureImprove qualitySecondary cellsLithium hexafluorophosphateElectricityFluoride

Provided are a process for production of hexafluorophosphates by which inexpensive high-quality hexafluorophosphates can be easily produced with production cost control; an electrolytic solution containing a hexafluorophosphate; and an electricity storage device equipped with the electrolytic solution. The process for production of hexafluorophosphates is characterized by reacting at least a phosphorus compound with a fluoride represented by chemical formula: MFsr(HF) [wherein 0=r=6; 1=s=3; and M is at least one selected from the group consisting of Li, Na, K, Rb, Cs, NH4, Ag, Mg, Ca, Ba, Zn, Cu, Pb, Al and Fe] to form a hexafluorophosphate represented by chemical formula: M(PF6)s.

Owner:STELLA CHEMIFA CORP

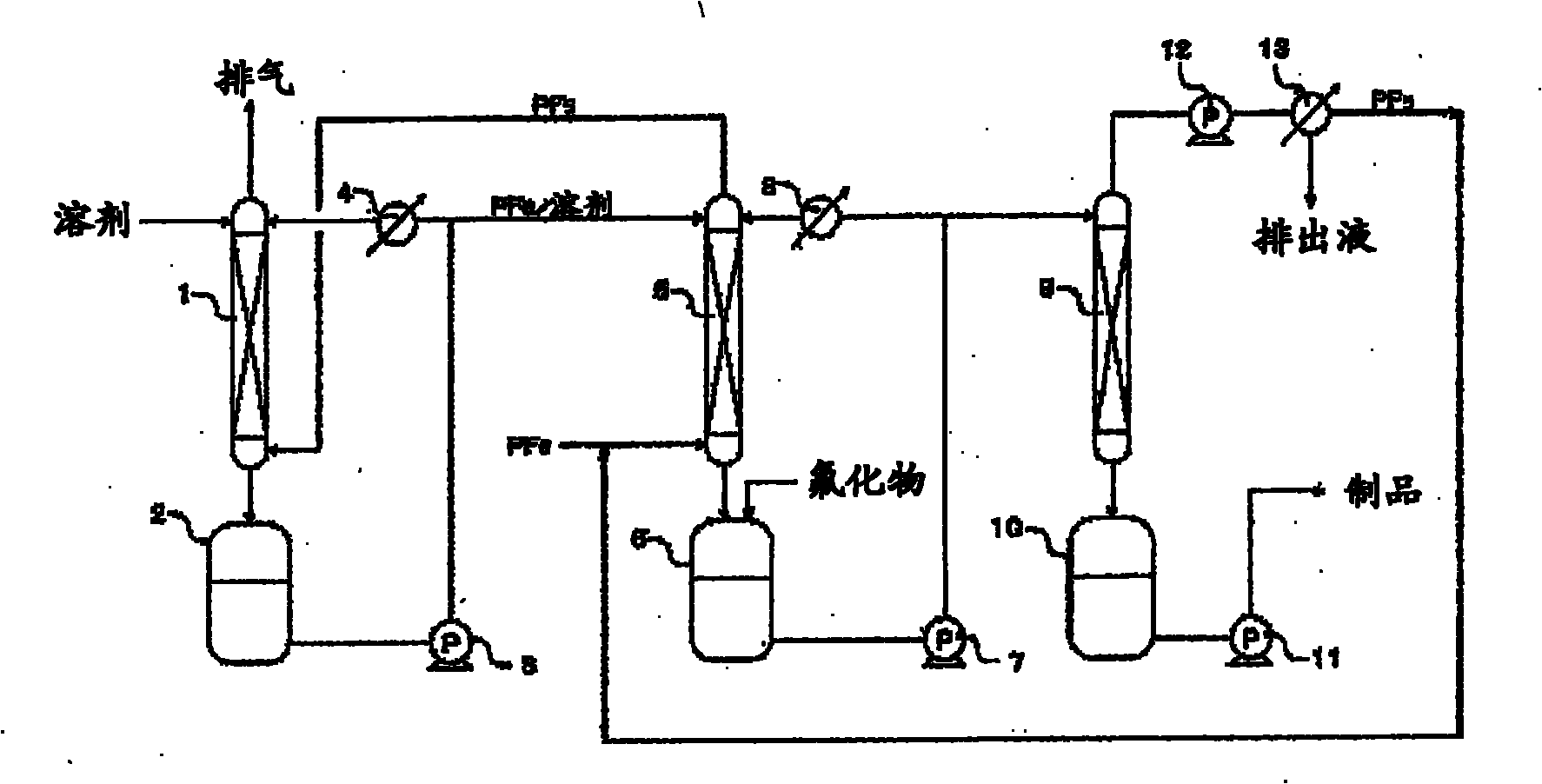

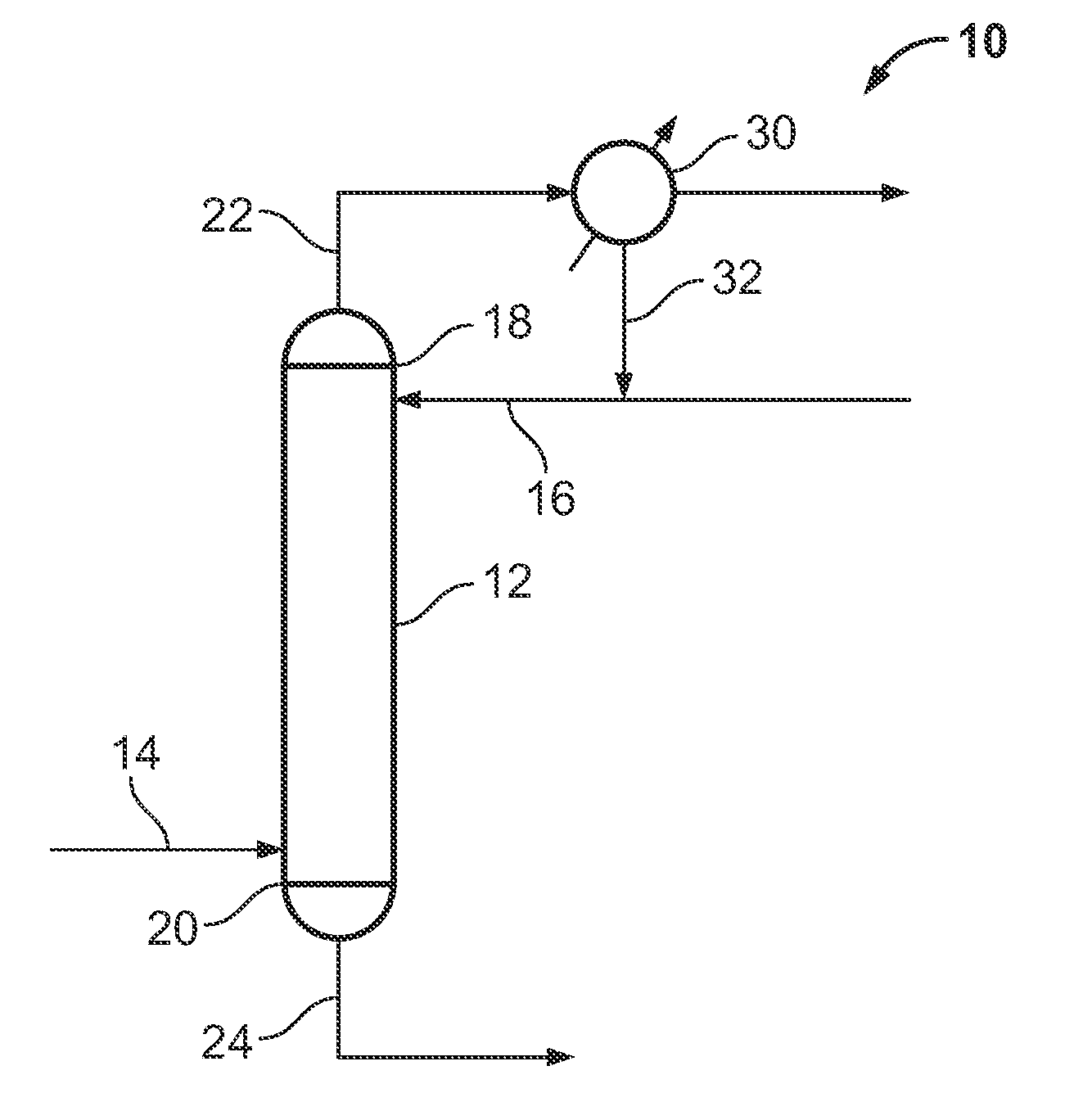

Continuous production system of lithium hexafluorophosphate

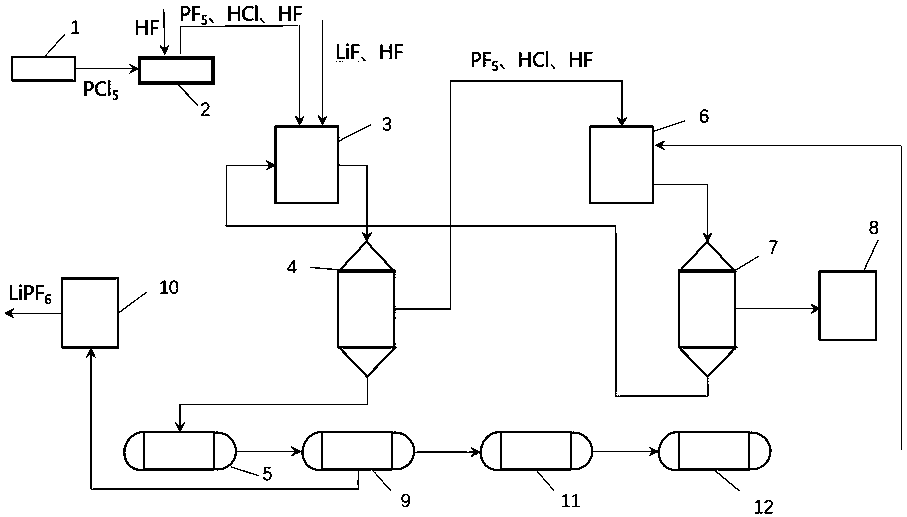

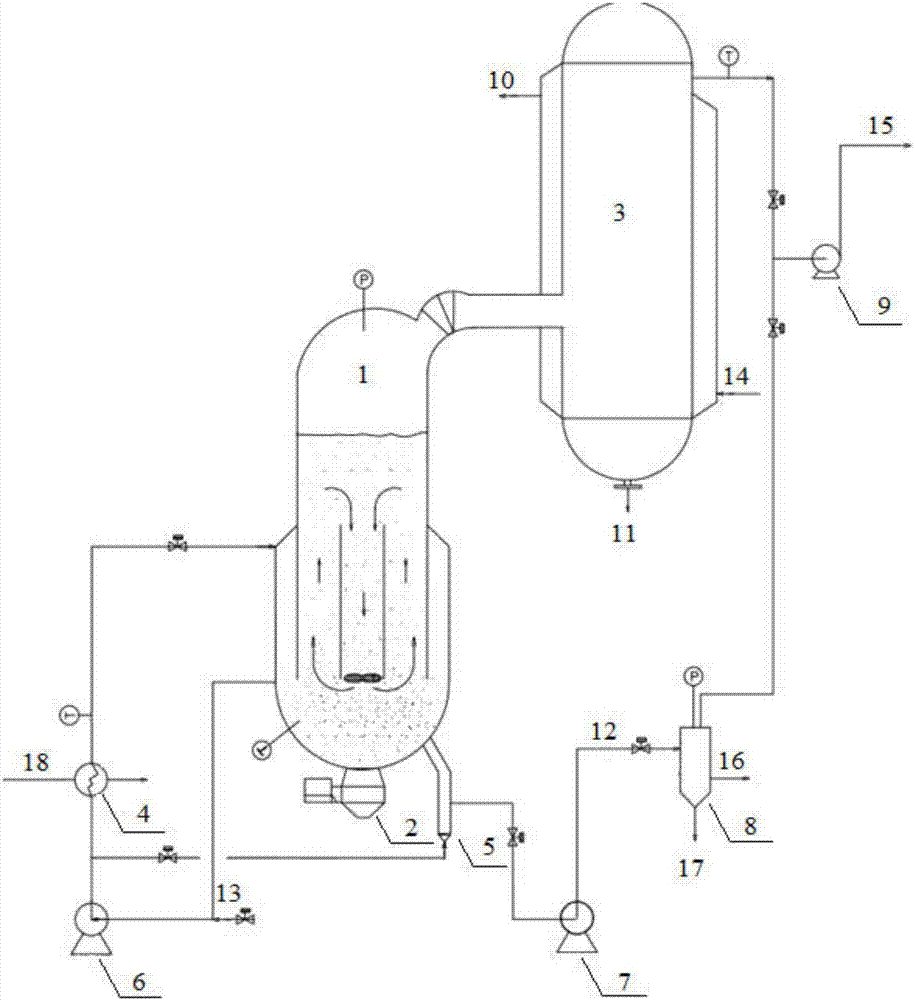

ActiveCN110683562AQuick responseShorten the timeSecondary cellsLithium hexafluorophosphateVapor–liquid separatorPhysical chemistry

The invention relates to a continuous production system of lithium hexafluorophosphate. The continuous production system comprises a phosphorus pentafluoride generator (2), a micro-channel reactor A (3), a gas-liquid separator A (4), a micro-channel reactor B (6) and a gas-liquid separator B (7), the gas generated by the phosphorus pentafluoride generator (2) is introduced into the micro-channel reactor A (3), the material output by the micro-channel reactor A (3) enters the gas-liquid separator A (4), the gas separated by the gas-liquid separator A (4) enters the micro-channel reactor B (6),and is used as a reaction raw material so as to continuously react, the material output by the micro-channel reactor B (6) enters the gas-liquid separator B (7), and a liquid component is separated out by the gas-liquid separator B (7) and is conveyed into the micro-channel reactor A (3). According to the invention, the raw materials and the by-products are recycled, so that the conversion rate and the utilization rate of the raw materials are improved, and the cost is reduced.

Owner:SINOCHEM LANTIAN +2

Production of high-purity lithium difluorophosphate

InactiveCN104684845AHigh purityPhosphorus halides/oxyhalidesSecondary cellsDifluorophosphateOrganic solvent

Producing lithium fluorophosphate, comprises contacting the solid lithium fluoride having a water content of more than 1500 ppm, preferably 5000-15000 ppm with gas containing phosphorus pentafluoride. An independent claim is included for lithium difluorophosphate having a purity of 99.9-99.9995 wt.%, preferably 99.97-99.9995 based on anhydrous product.

Owner:LANXESS DEUTDCHLAND GMBH

Method for producing hexafluorophosphate salt

InactiveCN101605723AEasy to operateLithium hexafluorophosphateSodium/potassium compoundsPhosphateAqueous solution

Disclosed is a method for producing a hexafluorophosphate salt (MPF6: M = Li, Na, K, Rb, Cs, NH4, Ag), which uses at least an aqueous HxPOyFz solution, an aqueous hydrofluoric acid solution and MF r(HF) as raw materials (provided that r >= 0, 0 <= x <= 3, 0 <= y <= 4 and 0 <= z <= 6). This method enables to produce a hexafluorophosphate salt (MPF6: M = Li, Na, K, Rb, Cs, NH4, Ag) having excellent workability at low cost from easily available raw materials, and the reaction can be controlled in this method.

Owner:STELLA CHEMIFA CORP

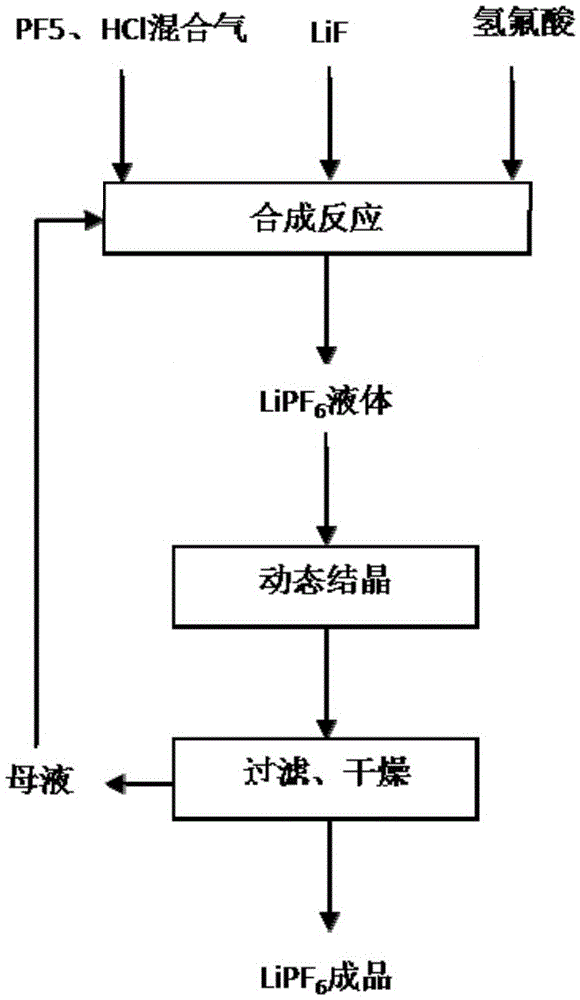

Preparation and purification method of lithium hexafluorophosphate

ActiveCN106882819AEfficient purificationEfficient removalCell electrodesSecondary cellsHydrogen fluoridePurification methods

The invention discloses a preparation and purification method of lithium hexafluorophosphate. The method comprises the following steps of (1) preparing a lithium hexafluorophosphate solution by using PF5, LiF and hydrogen fluoride; (2) removing a trace amount of insoluble impurities from the lithium hexafluorophosphate solution obtained in the step (1), transferring the solution o an evaporation crystallizer, and heating and evaporating one part of hydrogen fluoride; and (3) stopping evaporating until the liquid level is 1 / 3 to 2 / 3 of initial liquid level, cooling to -20 DEG C to -40 DEG C according to a temperature gradient and filtering to obtain a crude product of lithium hexafluorophosphate and purifying to obtain a target product lithium hexafluorophosphate. The preparation method is simple in process and low in cost, and the obtained product is high in purity.

Owner:东营石大胜华新能源有限公司

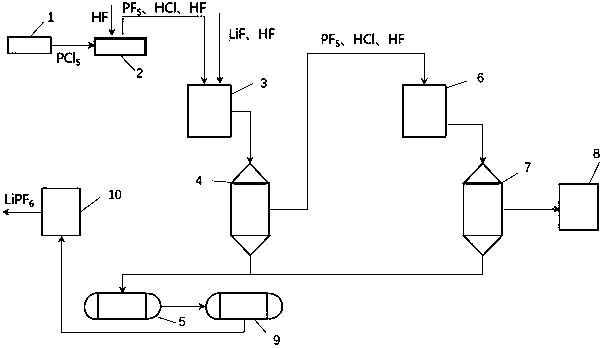

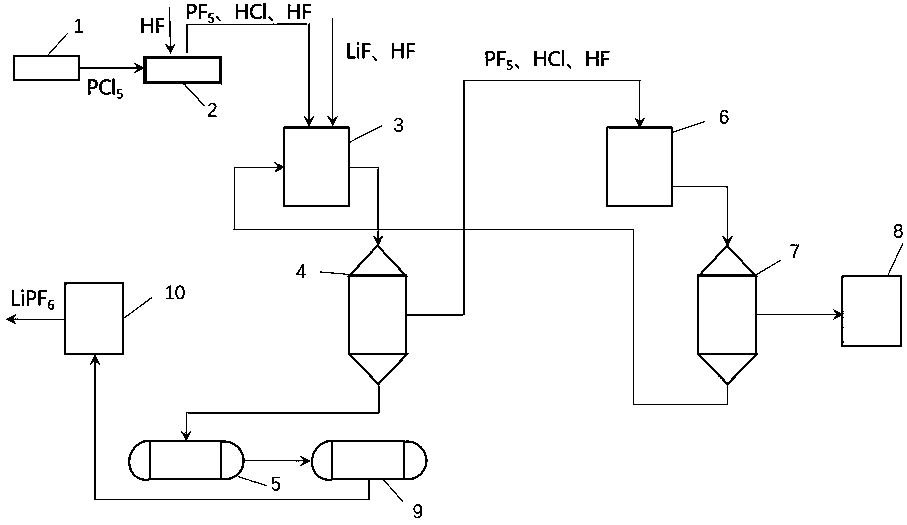

Preparation method of lithium hexafluorophosphate

InactiveCN1108985CHigh purity preventionHigh purity assuranceNon-aqueous electrolyte accumulatorsRubidium/caesium/francium compoundsHydrofluoric acidHydrogen fluoride

A method of preparing lithium hexafluoro phosphate (LiPF6) using phosphorous pentachloride (PCl5), lithium chloride (LiCl), and hydrogen fluoride (HF) as raw materials. The method includes the steps of: (a) reacting the phosphorous pentafluoride with the hydrogen fluoride to prepare phosphorous pentafluoride (PF5), and (b) reacting the phosphorous pentafluoride with the lithium chloride in a hydrogen fluoride to prepare the lithium hexafluoro phosphate. Anhydrous hydrogen fluoride, from which moisture was removed by treating with F2 gas, is used in the steps (a) and (b), and the step (b) further comprises contacting the reaction system of the step (b) with F2 gas. Accordingly, as the method adopts relatively cheap raw materials, it enables lithium hexafluoro phosphate (LiPF6) to be prepared at a high yield and purity.

Owner:FOOSUNG

Method of purifying lithium hexafluorosphate

InactiveUS20030143145A1Improve developmentIncrease contentPhosphorus halides/oxyhalidesLithium hexafluorophosphateHydrogen fluorideOrganic synthesis

A method of purifying lithium hexafluorophosphate that allows to purify lithium hexafluorophosphate, useful as lithium secondary cell electrolyte, organic synthesis medium or the like, to an extremely high purity is provided. Lithium hexafluorophosphate containing harmful impurities such as oxyfluoride, lithium fluoride is purified by adding phosphoric chloride. The purification is performed in the presence of phosphoric chloride and hydrogen fluoride of the quantity equal or superior to the equivalent amount for reacting them, and then by converting lithium fluoride lithium hexafluorophosphate with generated phosphor pentafluoride.

Owner:STELLA CHEMIFA CORP

Process for production hexafluorophosphates

InactiveUS20110097626A1InexpensiveImprove securityPhosphorus halides/oxyhalidesLithium hexafluorophosphateFluoridePhosphorus

An object is to provide a method of manufacturing a hexafluorophosphate, that can simply and easily manufacture an inexpensive and high-quality hexafluorophosphate while suppressing the manufacturing cost, an electrolytic solution containing a hexafluorophosphate, and an electricity storage device including the electrolytic solution. The present invention relates to a method of manufacturing a hexafluorophosphate, which comprises reacting at least a phosphorus compound with a fluoride represented by MFs.r(HF) (wherein 0≦r≦6, 1≦s≦3, and M is at least one kind selected from the group consisting of Li, Na, K, Rb, Cs, NH4, Ag, Mg, Ca, Ba, Zn, Cu, Pb, Al and Fe) to produce a hexafluorophosphate represented by the chemical formula M(PF6)s.

Owner:STELLA CHEMIFA CORP

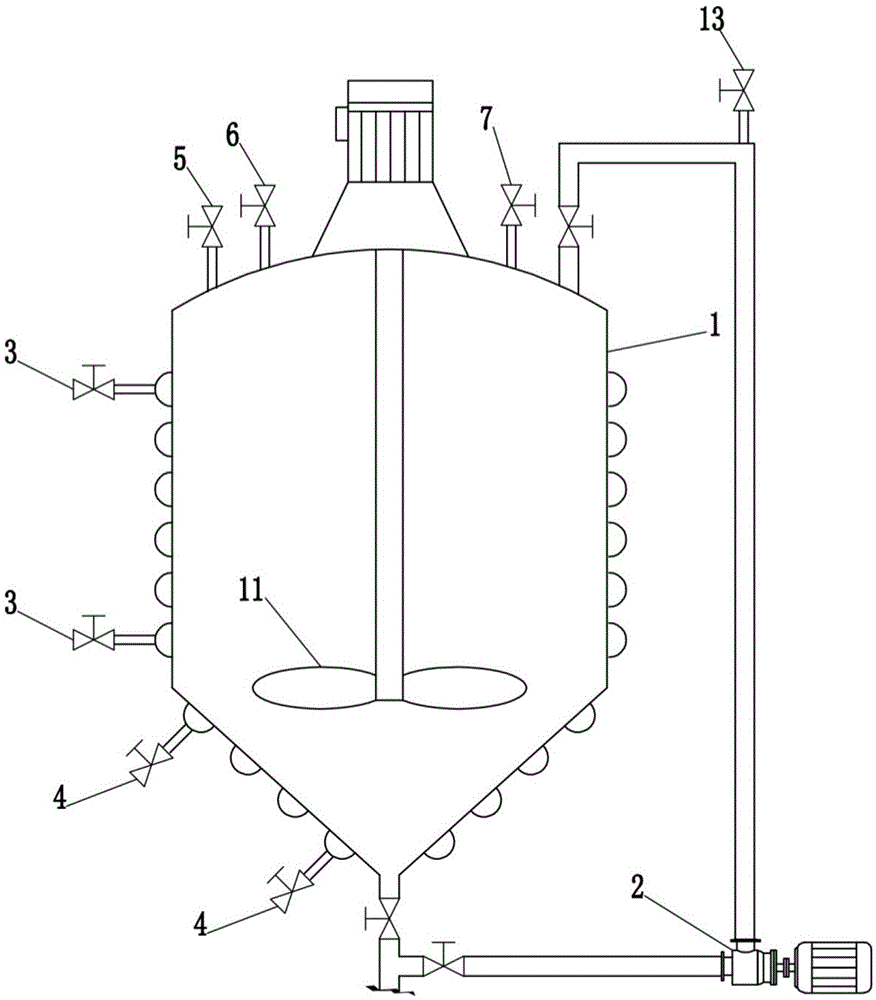

Method and device for continuous preparation of lithium hexafluorophosphate

ActiveCN107244681AEfficient productionEfficient evaporation crystallization method and advanced DBT type continuous productionCell electrodesSecondary cellsEvaporationCirculating pump

The invention relates to a device and method for continuous preparation of lithium hexafluorophosphate. The device comprises a continuous evaporation crystallizer, a condensation recoverer, a heater, an ex-situ circulation pump, a product crystal delivery pump and a separation apparatus. Specifically, the continuous evaporation crystallizer is internally equipped with a stirrer, and the lower part of the continuous evaporation crystallizer is equipped with an elutriating leg; the ex-situ circulation pump, the heater, and the continuous evaporation crystallizer are connected in order; the elutriating leg is connected to the product crystal delivery pump; the product crystal delivery pump is connected to the separation apparatus; and the condensation recoverer is connected to the upper part of the continuous evaporation crystallizer. The invention employs an effective evaporative crystallization method and the advanced DBT type continuous efficient evaporation crystallizer to make the crystalline particles of lithium hexafluorophosphate more uniform, and effectively lowers the product investment cost and energy consumption per ton, thus realizing continuous, efficient and large-scale production of lithium hexafluorophosphate.

Owner:东营石大胜华新能源有限公司

Method for Producing Electrolyte Solution for Lithium Ion Battery and Battery Using Same

ActiveUS20090081559A1Easy to produceElectrolytic capacitorsOrganic electrolyte cellsHydrogen fluorideLithium chloride

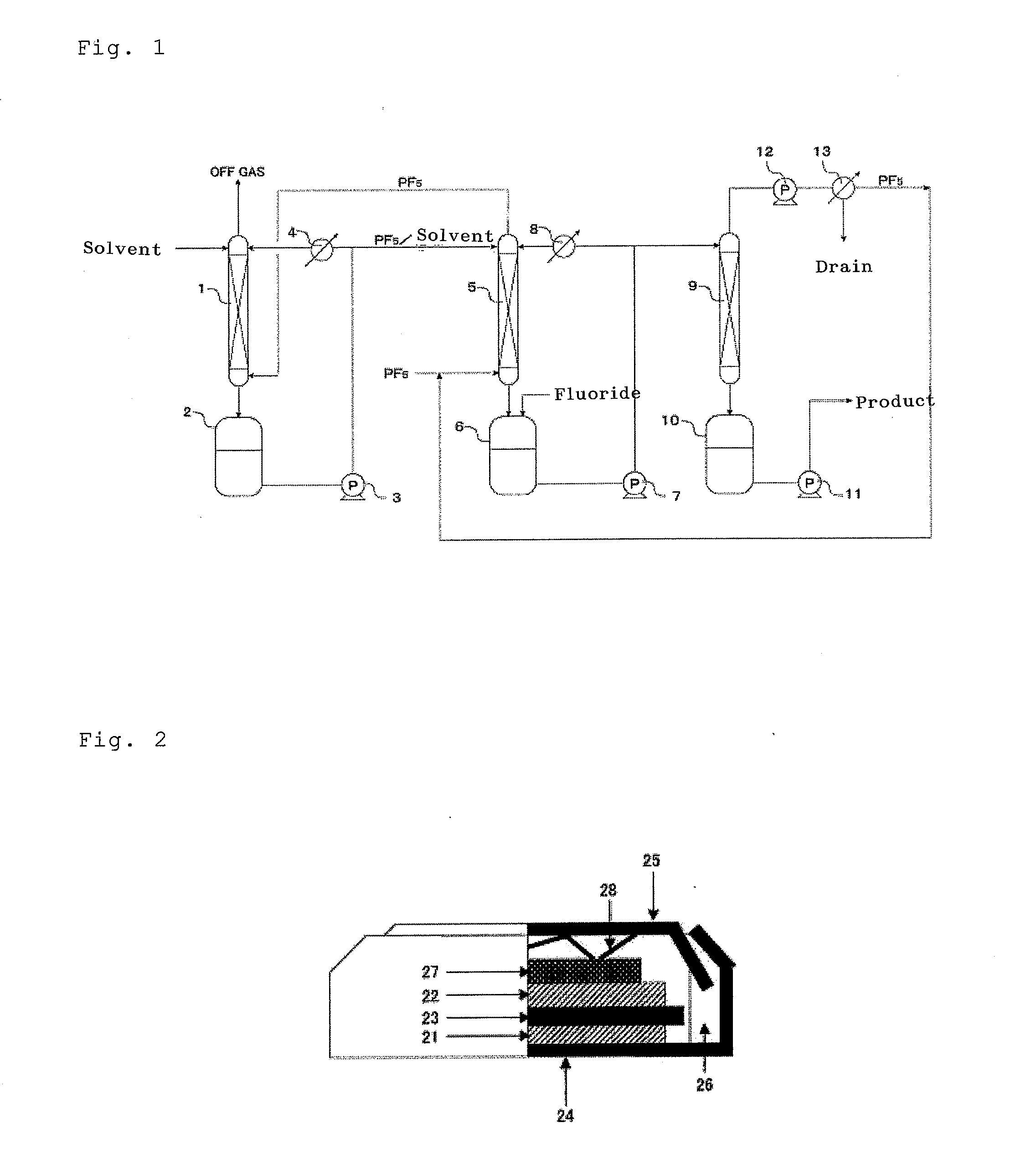

There is provided a method for producing an electrolyte solution for lithium ion battery, which is characterized in that lithium fluoride, lithium chloride, lithium bromide, lithium iodide or a mixture of any of these is reacted with phosphorus pentachloride and hydrogen fluoride in a nonaqueous organic solvent, when an electrolyte solution for lithium ion battery, which contains lithium hexafluorophosphate as an electrolyte, is produced.

Owner:CENT GLASS CO LTD

Lithium hexafluorophosphate purification method

InactiveCN107055574AEfficient removalImprove qualityLithium hexafluorophosphatePurification methodsMetal impurities

The invention relates to a lithium hexafluorophosphate purification method, and belongs to the technical field of a lithium ion battery. The lithium hexafluorophosphate purification method comprises the following steps that (1) under the protection atmosphere, an organic solvent is added into lithium hexafluorophosphate to be purified for dissolution; filtering is performed to obtain filter liquid; (2) silazane is added into the filter liquid for performing deacidification reaction; crystallization is performed to obtain crystals; drying is performed; the finished product is obtained. The purification method disclosed by the invention has the advantages that an ether solvent, a carbonic ester type solvent or acetonitrile is used as the organic solvent for purifying the lithium hexafluorophosphate crude products; insoluble substances in the lithium hexafluorophosphate are removed; then, the silazane is added to act with HF acid remained in the lithium hexafluorophosphate crude products for removing free acid; metal impurities are removed through the recrystallization process. The lithium hexafluorophosphate purification method has the advantages that the lithium hexafluorophosphate with poor quality is treated; acid and metal impurities attached at the surface or blended inside the lithium hexafluorophosphate crystals can be effectively removed; the insoluble substance content is reduced; the quality of the lithium hexafluorophosphate product is improved.

Owner:DO FLUORIDE CHEM CO LTD

Lithium ion battery

ActiveCN112310483AGive full play to the advantages of high temperatureGive full play to the advantages of high conductivityNitrosyl chlorideFinal product manufactureElectrolytic agentFloating charge

The invention relates to the field of electrochemistry, and particularly relates to a lithium ion battery. One aspect of the invention provides a lithium ion battery. The lithium ion battery comprisesa positive pole piece, a negative pole piece, an isolation membrane and an electrolyte, and is characterized in that the negative pole piece comprises a negative active material layer containing a negative active material, the electrolyte comprises an electrolyte lithium salt, the electrolyte lithium salt comprises a first lithium salt, the first lithium salt is selected from fluorine-containingsulfimide lithium salt, and the first lithium salt and the negative pole piece meet a relational expression (1). According to the invention, the fluorine-containing sulfimide lithium salt is used as the electrolyte of the first lithium salt, so that too fast impedance increase or too large concentration polarization of the battery can be effectively inhibited, the high-temperature advantage and the high-conductivity advantage of the fluorine-containing sulfimide lithium salt can be fully exerted, the formed battery is relatively low in floating charge physical resistance increase rate, the safety problems such as lithium precipitation in the middle and later periods of circulation are avoided, and finally the excellent properties of high safety performance, long cycle life and good high-temperature storage are achieved.

Owner:CONTEMPORARY AMPEREX TECH CO

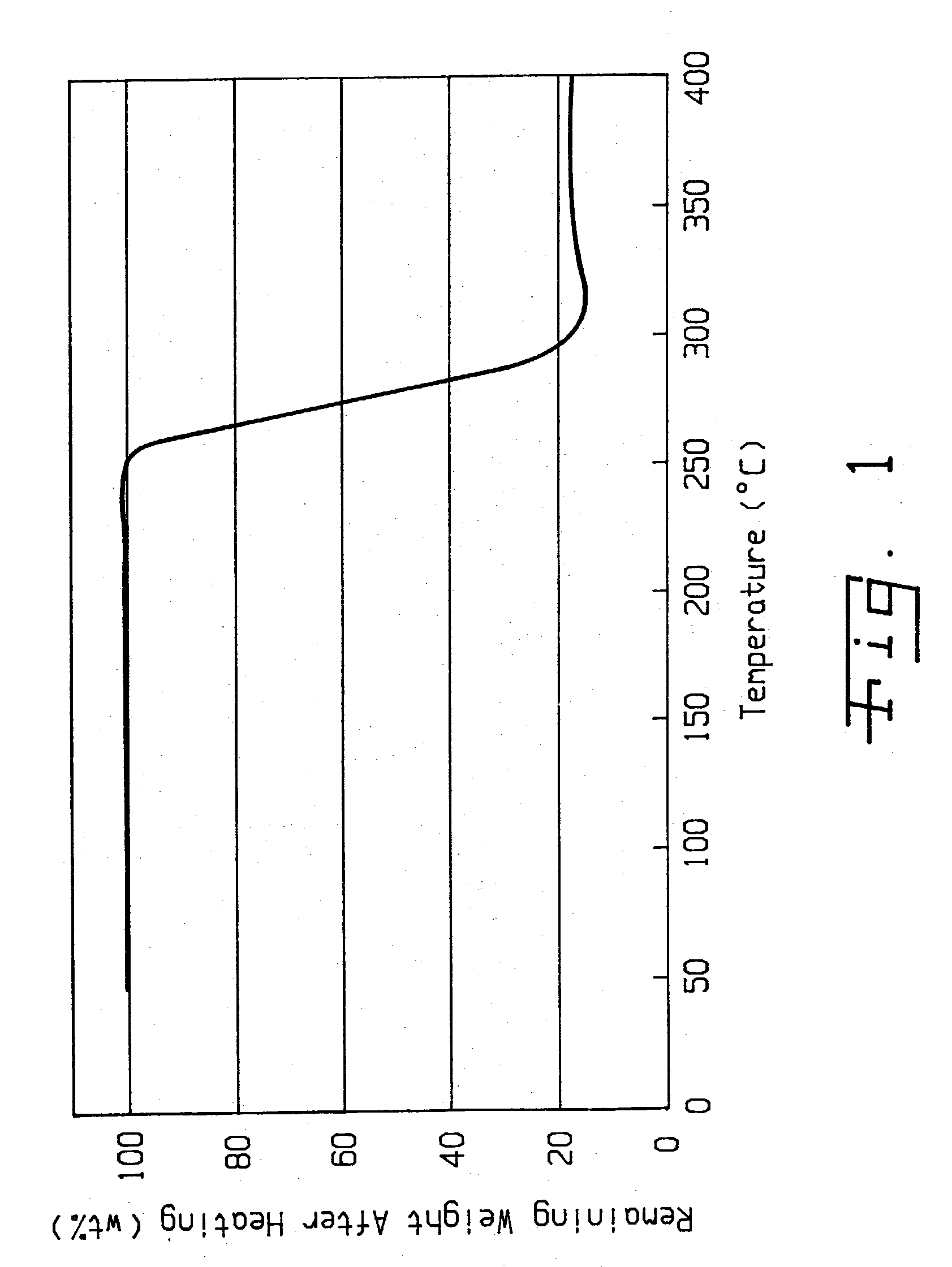

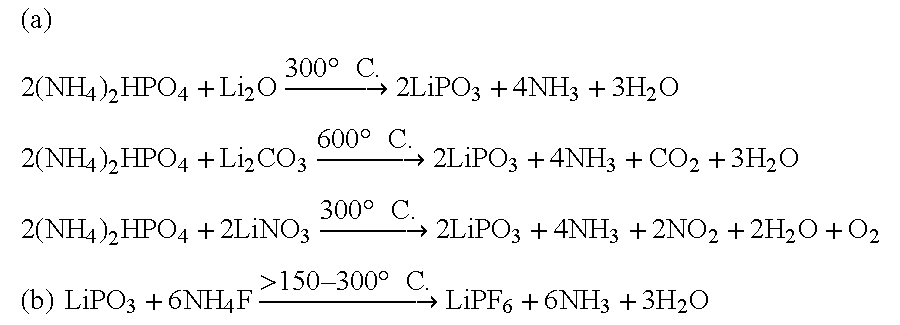

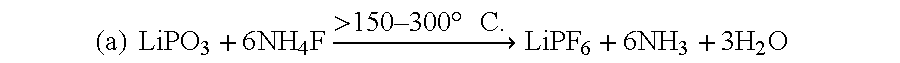

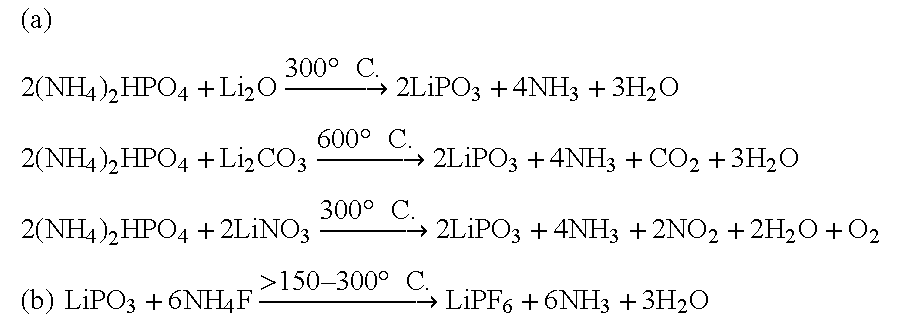

Solid state thermal method for the synthesis of lithium hexafluoro phosphate (LiPF)6 as battery electrolyte

InactiveUS6824754B2Improve efficiencyPhosphatesPhosphorus halides/oxyhalidesHydrogen phosphatePhosphate

Owner:COUNCIL OF SCI & IND RES

Method of manufacturing electrolyte solution for lithium ion battery and lithium ion battery using it

ActiveCN101310407ANon-aqueous electrolyte accumulatorsLithium hexafluorophosphateLithium chlorideElectrical battery

Disclosed is a method for producing an electrolyte solution for lithium ion batteries which uses lithium hexafluorophosphate as the electrolyte. This method does not use an anhydrous hydrogen fluoride solvent which is hard to handle, or require expensive equipment or complicated operations. In addition, this method enables to produce an electrolyte solution using lithium hexafluorophosphate as the electrolyte at low cost without performing a crystallization process. Also disclosed is a lithium ion battery using an electrolyte solution obtained by such a method. Specifically disclosed is a method for producing an electrolyte solution for lithium ion batteries using lithium hexafluorophosphate as the electrolyte, which comprises a step wherein phosphorus trichloride, chlorine and lithium chloride are reacted in a nonaqueous organic solvent, and another step wherein the reaction product produced in the solvent is reacted with hydrogen fluoride.

Owner:CENT GLASS CO LTD

Methods and apparatuses for purifying phosphorus pentafluoride

InactiveUS20130004402A1Reduce the presence of impuritiesPhosphorus halides/oxyhalidesLithium hexafluorophosphatePhysical chemistryImpurity

Embodiments of methods and apparatuses for purifying phosphorus pentafluoride are provided. The method comprises the step of contacting a feed stream comprising phosphorus pentafluoride and impurities with anhydrous hydrogen fluoride. The anhydrous hydrogen fluoride reduces the impurities from the feed stream to form an impurity-depleted phosphorus pentafluoride effluent.

Owner:HONEYWELL INT INC

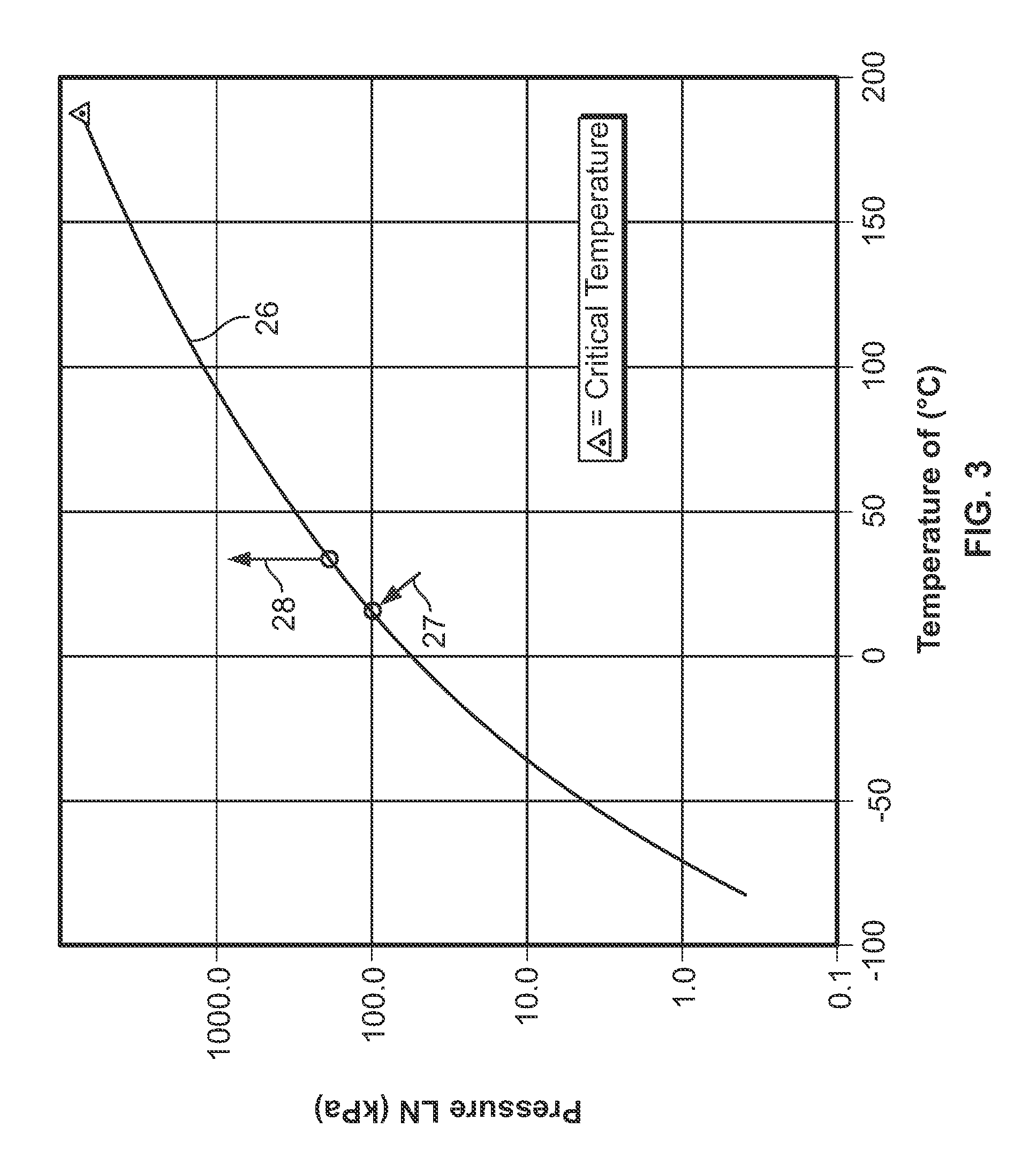

Synthetic method of hexafluorophosphate

ActiveCN114132912APrecise control of feed rateAccurate control precisionLithium hexafluorophosphatePhosphorus compoundsHydrogen fluorideHydrogen halide

The invention discloses a synthesis method of hexafluorophosphate, which belongs to the technical field of chemical synthesis, and is characterized by comprising the following steps: dissolving phosphorus pentahalide in an inert solvent to obtain a phosphorus pentahalide inert solvent solution, dissolving alkali metal halide salt in anhydrous hydrogen fluoride to obtain an alkali metal villiaumite hydrogen fluoride solution, the method comprises the following steps: inputting hexafluorophosphate, hydrogen fluoride, an inert solvent and hydrogen halide into a reactor in proportion for reaction to obtain a mixture consisting of the hexafluorophosphate, the hydrogen fluoride, the inert solvent and the hydrogen halide, firstly removing hydrogen halide gas through gas-liquid separation, then recovering the hydrogen fluoride through heating evaporation, finally recovering the inert solvent through solid-liquid separation, and drying a solid to obtain the hexafluorophosphate, the synthesis method disclosed by the invention has the advantages of simplicity in operation, good safety, high reaction yield, excellent product quality, capability of realizing continuous production and the like.

Owner:ZHEJIANG ZHONGXIN FLUORIDE MATERIALS CO LTD +1

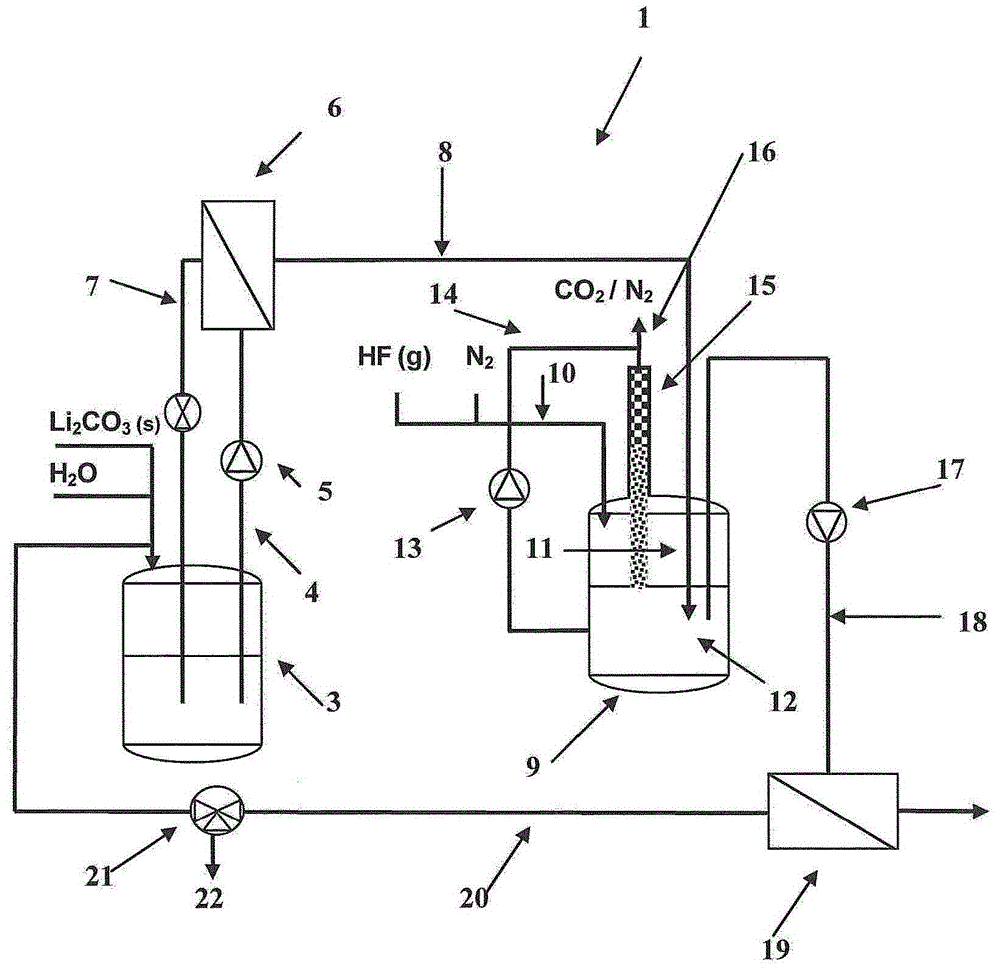

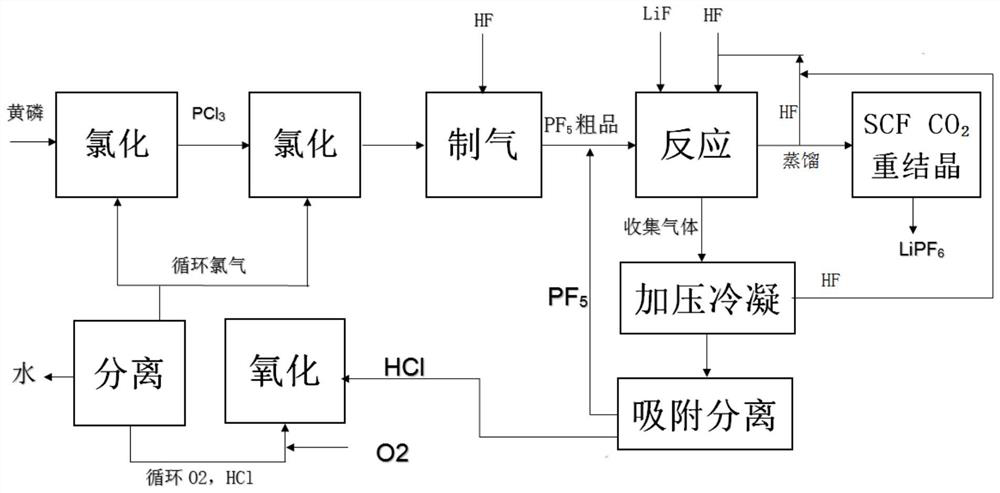

Preparation method of high-purity lithium hexafluorophosphate

PendingCN114538406ALow costPromote safe productionLithium hexafluorophosphatePhosphorus compoundsPhosphoric acidPhysical chemistry

The invention relates to the technical field of lithium ion batteries, and discloses a preparation method of high-purity lithium hexafluorophosphate, which comprises the following steps: 1) reacting phosphorus pentachloride with anhydrous hydrofluoric acid or hydrogen fluoride gas to prepare phosphorus pentafluoride; 2) dissolving LiF in an anhydrous HF solvent, introducing the obtained phosphorus pentafluoride into the anhydrous HF solvent, and reacting to obtain an anhydrous HF solution of lithium hexafluorophosphate; 3) distilling the obtained anhydrous HF solution of lithium hexafluorophosphate to remove hydrofluoric acid to obtain solid lithium hexafluorophosphate; and 4) recrystallizing the lithium hexafluorophosphate solid by adopting supercritical carbon dioxide or liquid carbon dioxide as a solvent to obtain purified lithium hexafluorophosphate. Carbon dioxide is adopted for recrystallization, so that the method is green, environment-friendly, low in cost, safe in production process and good in purification effect; the reaction gas in the step 2) is collected, separated and reused, the whole-process clean production process of the lithium hexafluorophosphate is formed, the whole production process is green and environmentally friendly, and waste emission is little.

Owner:江西吉翔医药化工有限公司

Preparation method of lithium hexafluorophosphate

InactiveCN108640129AReduce acidityReduce moistureLithium hexafluorophosphateLithium hexafluorophosphateLithium fluoride

The invention discloses a preparation method of lithium hexafluorophosphate. The preparation method comprises the following steps: (1) introducing phosphorus pentafluoride gas into a reaction kettle filled with lithium fluoride and hydrogen fluoride liquid and carrying out reaction for 1 to 2 hours to obtain a lithium hexafluorophosphate solution; (2) realizing partial crystallisation under a stirring condition; (3) carrying out drying. The preparation method of lithium hexafluorophosphate disclosed by the invention has the advantages that the operation is convenient, the lithium hexafluorophosphate which is obtained by carrying out partial crystallisation is directly formed into uniform particles, so that the steps of multiple drying and pulverization are eliminated, and the partial crystallisation time is shortened.

Owner:MORITA NEW ENERGY MATERIALS ZHANGJIAGANG CO LTD

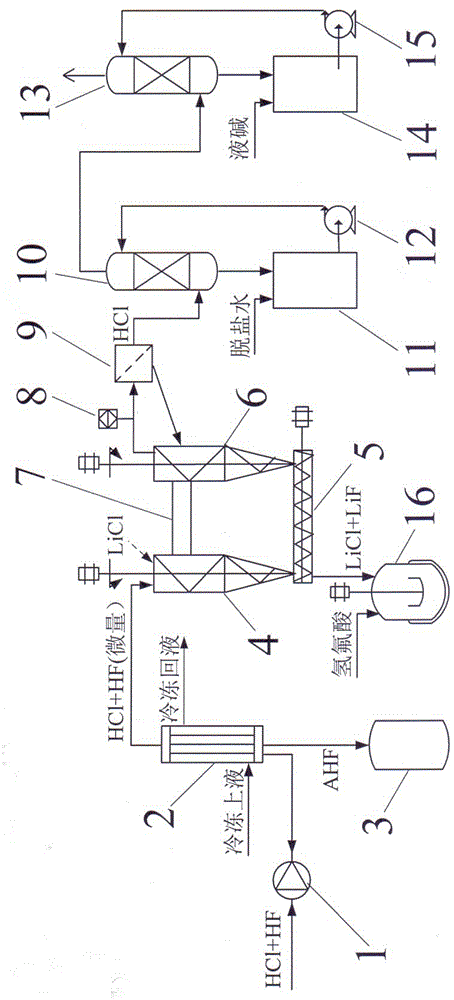

Method and dedicated device for lithium hexafluorophosphate synthesis tail gas treatment

ActiveCN105460893AEfficient removalImprove qualityChlorine/hydrogen-chlorideHydrogen fluorideHydrogen fluorideMaterial balance

The invention discloses a method and dedicated device for lithium hexafluorophosphate synthesis tail gas treatment. Tail gas is pressurized through a booster fan and then sent to a condenser, condensate is recycled to an anhydrous hydrogen fluoride reception tank, mixed gas discharged from the condenser passes through an airtight first-stage agitation reactor, a horizontal auger delivery reactor and a second-stage agitation reactor in sequence in the material stirring and guiding direction, a trace of HF in the mixed gas reacts with LiCl powder added into an agitation reaction combined device in advance, and LiCl powder in the second-stage agitation reactor returns into the first-stage agitation reactor through a material balance pipe to be forced to be stirred and circulated inside an agitation reaction system; tail gas discharged from the second-stage agitation reactor enters a water scrubber to generate hydrochloric acid after passing through a dust remover for gas trapping so that a small amount of powder can be taken away, and gas discharged from the water scrubber passes through an alkaline tower for alkaline washing and then is discharged. By the adoption of the method and dedicated device, HF in the mixed tail gas can be effectively removed, the quality of by-product hydrochloric acid is improved, and the application field is broadened.

Owner:JIANGSU JIUJIUJIU TECH

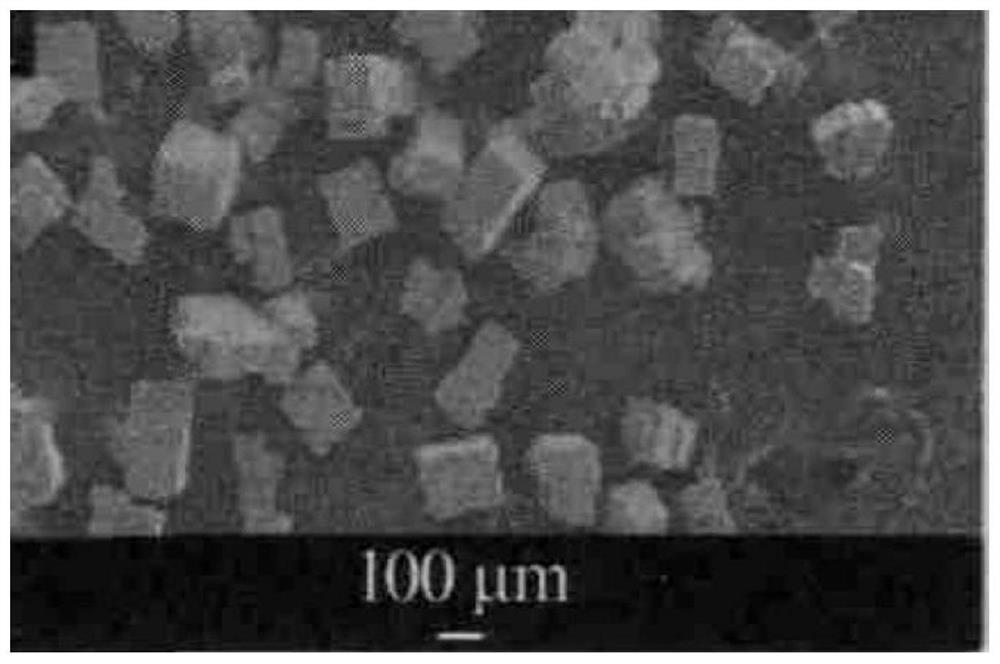

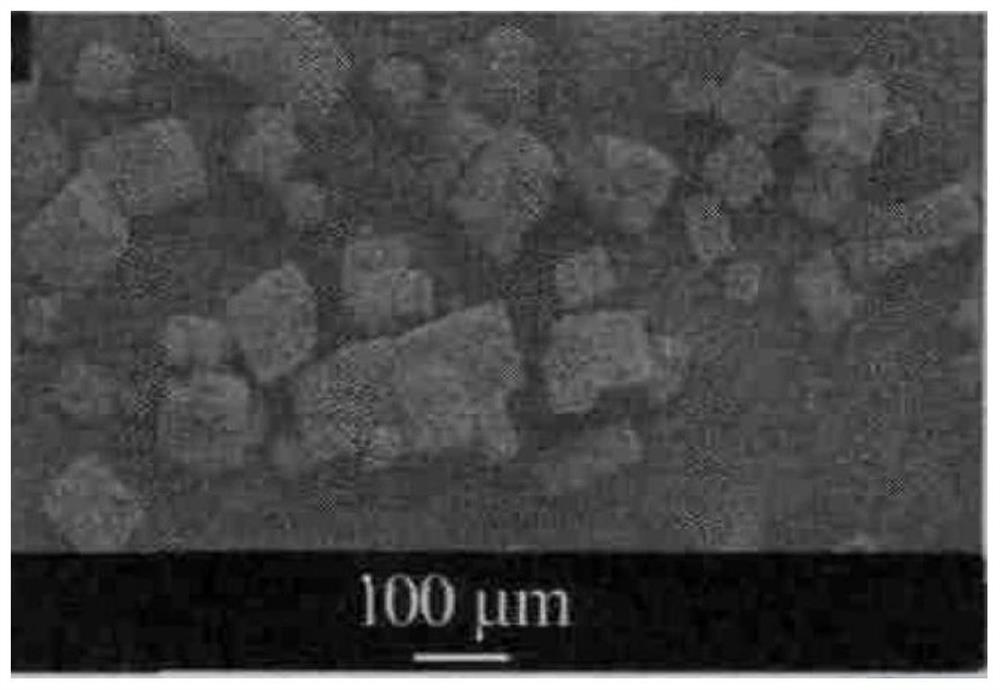

Lithium hexafluorophosphate, crystal and preparation method thereof, lithium ion battery electrolyte and lithium ion battery

PendingCN112340754ANo wall stickingHigh puritySecondary cellsSolution crystallizationPhysical chemistryElectric Capacitance

The invention relates to the field of lithium hexafluorophosphate, and discloses lithium hexafluorophosphate, a crystal and a preparation method thereof, a lithium ion battery electrolyte and a lithium ion battery. The crystallization method comprises the following steps: (1) dropwise adding mother liquor containing lithium hexafluorophosphate into a crystallization tank under a first stirring condition; and (2) under a second stirring condition, cooling and crystallizing the mother liquor in the crystallization tank to obtain lithium hexafluorophosphate. According to the method, dynamic crystallization is provided, high-purity lithium hexafluorophosphate crystals can be obtained, the crystallization induction period can be effectively shortened, and the crystallization speed is increased.And the formed lithium ion battery is large in capacitance and high in cycle efficiency.

Owner:HUIZHOU BYD BATTERY

Method for producing phosphorus pentafluoride

InactiveCN103153847AImprove cooling effectEliminate problems such as cloggingPhosphorus halides/oxyhalidesCell electrodesHalogenGas phase

The present invention provides a method for producing phosphorus pentafluoride, which is characterized by having a phosphorus trihalide represented by general formula PX3 (wherein X represents F, Cl or Br) react with a molecular halogen or hydrogen fluoride that is in a gaseous state. This method is a method for efficiently producing phosphorus pentafluoride at low cost, which is applicable to the production on an industrial scale.

Owner:DAIKIN IND LTD

Method for producing electrolyte solution for lithium ion battery and lithium ion battery using same

ActiveUS20090311610A1Low priceEasy to handleNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsHydrogen fluorideLithium chloride

There is provided a method for producing an electrolyte solution for lithium ion batteries, in which lithium hexafluorophosphate is used as an electrolyte, comprising the steps of (a) reacting phosphorus trichloride, chlorine and lithium chloride in a nonaqueous organic solvent; and (b) reacting a reaction product of the step (a) formed in the solvent, with hydrogen fluoride.

Owner:CENT GLASS CO LTD

Manufacturing method of hexafluorophosphate

InactiveUS20100317511A1Low costInexpensivePhysical/chemical process catalystsPhosphorus halides/oxyhalidesHydrofluoric acidAqueous solution

In the manufacturing method of hexafluorophosphate (MPF6: M=Li, Na, K, Rb, Cs, NH4, and Ag) of the present invention, at least a HxPOyFz aqueous solution, a hydrofluoric acid aqueous solution, and MF.r (HF) are used as raw materials (wherein, r≧0, 0≦x≦3, 0≦y≦4, and 0≦z≦6). According to the above description, a manufacturing method of hexafluorophosphate can be provided which is capable of manufacturing hexafluorophosphate (GPF6: G=Li, Na, K, Rb, Cs, NH4, and Ag) at a low cost in which the raw materials can be easily obtained, the control of the reaction is possible, and the workability is excellent.

Owner:STELLA CHEMIFA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com