Continuous production system of lithium hexafluorophosphate

A technology of lithium hexafluorophosphate and production system, which is applied to lithium hexafluorophosphate, lithium compounds, electrochemical generators, etc., can solve the problems of difficult production technology, large reagents, large amount of by-products, etc., to reduce the possibility of contact and reaction, The effect of reducing the free acid of the product and prolonging the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

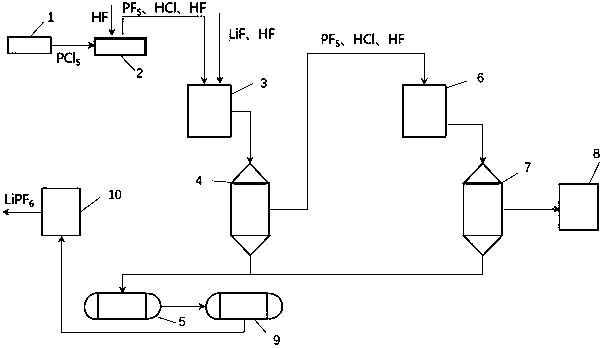

Embodiment 1

[0077] In a dissolution tank with a cooling jacket and stirring, use a pump to transport HF, and add LiF through a solid feeding device while cooling. The speed of adding LiF should be controlled so that the temperature of HF is 0°C and the concentration of LiF is 5wt. %, at the same time, the PCl 5 It is sent to the phosphorus pentafluoride generator (2) that stores HF to generate PF 5gas. Under pressure, the HF solution dissolved in LiF and PF were pumped 5 The gas is delivered to microchannel reactor A (3). Reactant PF in microchannel reactor A (3) 5 The molar ratio to LiF is 2:1, the residence time of reactants is 30 seconds, and the reaction temperature is 15°C. The reactant enters the microchannel reactor A (3) in a continuous state, and the output material is output in a continuous state, and enters the gas-liquid separator A (4) for gas-liquid separation, and the separated liquid phase product is a composition containing lithium hexafluorophosphate. points, trans...

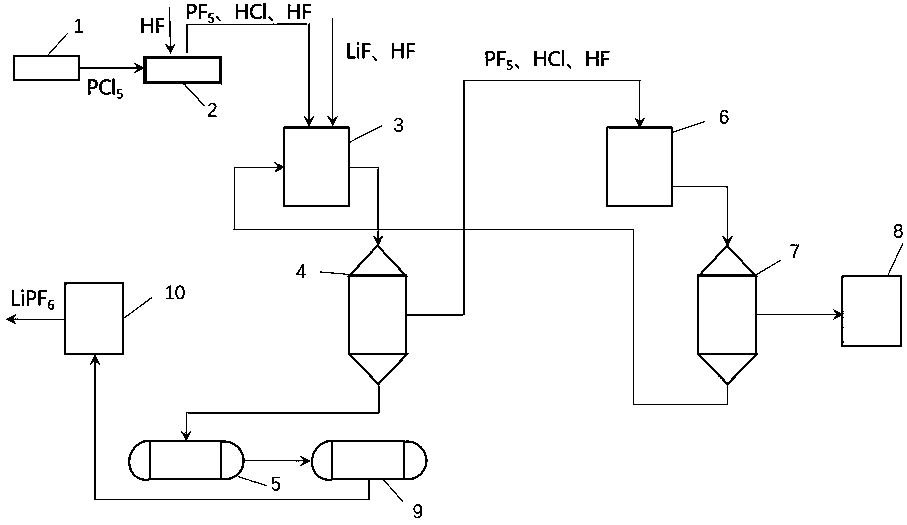

Embodiment 2

[0080] In a dissolution tank with a cooling jacket and stirring, use a pump to transport HF, and add LiF through a solid feeding device while cooling. The speed of adding LiF should be controlled so that the temperature of HF is 0°C and the concentration of LiF is 4wt. %, at the same time, the PCl 5 It is sent to the phosphorus pentafluoride generator (2) that stores HF to produce PF 5 gas. Under pressure, the HF solution dissolved in LiF and PF were pumped 5 The gas is delivered to microchannel reactor A (3). Reactant PF in microchannel reactor A (3) 5 The molar ratio to LiF is 2:1, the residence time of reactants is 30 seconds, and the reaction temperature is 15°C. The reactant enters the microchannel reactor A (3) in a continuous state, and the output material is output in a continuous state, and enters the gas-liquid separator A (4) for gas-liquid separation, and the separated liquid phase product is a composition containing lithium hexafluorophosphate. points, trans...

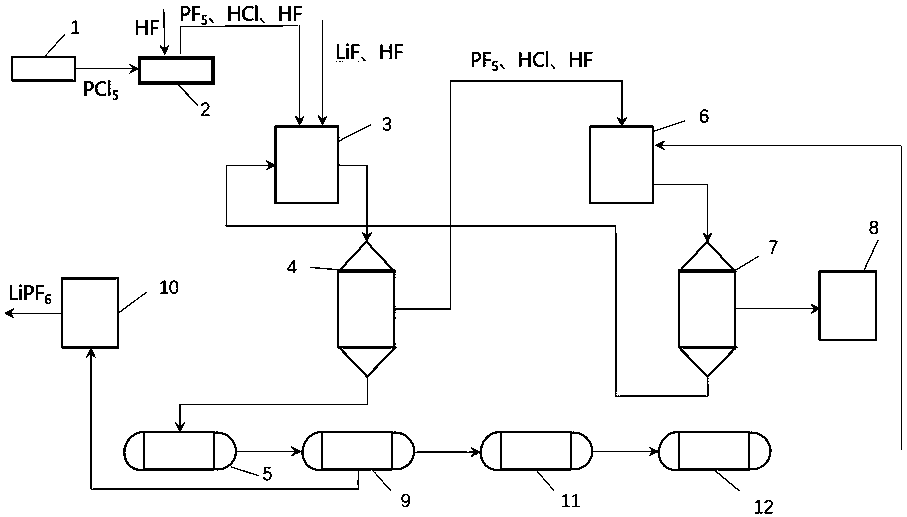

Embodiment 3

[0083] In a dissolution tank with a cooling jacket and stirring, use a pump to transport HF, and add LiF through a solid feeding device while cooling. The speed of adding LiF should be controlled so that the temperature of HF is 0°C and the concentration of LiF is 4wt. %, at the same time, the PCl 5 It is sent to the phosphorus pentafluoride generator (2) that stores HF to produce PF 5 gas. Under pressure, the HF solution dissolved in LiF and PF were pumped 5 The gas is delivered to microchannel reactor A (3). Reactant PF in microchannel reactor A (3) 5 The molar ratio to LiF is 2:1, the residence time of reactants is 30 seconds, and the reaction temperature is 15°C. The reactant enters the microchannel reactor A (3) in a continuous state, and the output material is output in a continuous state, and enters the gas-liquid separator A (4) for gas-liquid separation, and the separated liquid phase product is a composition containing lithium hexafluorophosphate. points, trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com