Patents

Literature

174 results about "Phosphorus pentafluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphorus pentafluoride, PF₅, is a phosphorus halide. It is a colourless, toxic gas that fumes in air.

Preparation method of lithium hexafluorophosphate

ActiveCN102009972ARich sourcesReduce manufacturing costPhosphorus compoundsPhosphoric acidNitrogen gas

The invention relates to a preparation method of lithium hexafluorophosphate. The preparation method comprises the following steps of: (1) distilling to obtain hydrogen fluoride liquid of which the purity is over 99.99 weight percent; (2) reacting the high-purity hydrogen fluoride liquid with phosphorus pentachloride to obtain mixed gas of the phosphorus pentafluoride and hydrogen chloride; (3) introducing the mixed gas of the phosphorus pentachloride and the hydrogen chloride into hydrogen fluoride and lithium fluoride, reacting at a certain temperature and under certain pressure to obtain solution of lithium hexafluorophosphate, exhausting hydrogen chloride gas at regular time, and absorbing by using water to prepare byproduct hydrochloric acid; and (4) crystallizing and separating, namely filtering the solution of lithium hexafluorophosphate, delivering filtrate into a crystallizing slot, separating the lithium hexafluorophosphate out at the temperature of between -70 and 80 DEG C, filtering, and performing primary drying and secondary drying to obtain a lithium hexafluorophosphate product, wherein the residual hydrogen fluoride gas is displaced by nitrogen. The preparation method has readily available raw materials and is easy to operate, the purity of the obtained lithium hexafluorophosphate product is over 99.9 percent, the moisture is lower than 10ppm, and the production requirements of lithium ion electrolytic cells are met.

Owner:MORITA NEW ENERGY MATERIALS ZHANGJIAGANG CO LTD

Methods for preparing phosphorus pentafluoride gas and preparing lithium hexafluorophosphate using the gas

ActiveCN101353161AEasily hydrolyzedStrong moisture absorptionPhosphorus halides/oxyhalidesLithiumPhysical chemistry

A preparation method of phosphorus pentafluoride gas comprises a step of causing phosphorus pentachloride to react with anhydrous hydrogen fluoride, wherein, the reaction occurs in the presence of a solvent. A preparation method of lithium hexaflourophosphate comprises a contact reaction between solid lithium fluoride and phosphorus pentafluoride gas, wherein the phosphorus pentafluoride gas is prepared by the method of the invention. Compared with the preparation method of the lithium hexaflourophosphate with the phosphorus pentafluoride gas as the raw material in the prior art, the phosphorus pentafluoride gas prepared by the preparation method of the invention has higher purity and lower cost. The yield of the lithium hexaflourophosphate prepared by the method of the invention is higher than 93%, and the purity thereof is up to 99.95%.

Owner:BYD CO LTD

Preparation of phosphorus pentafluoride

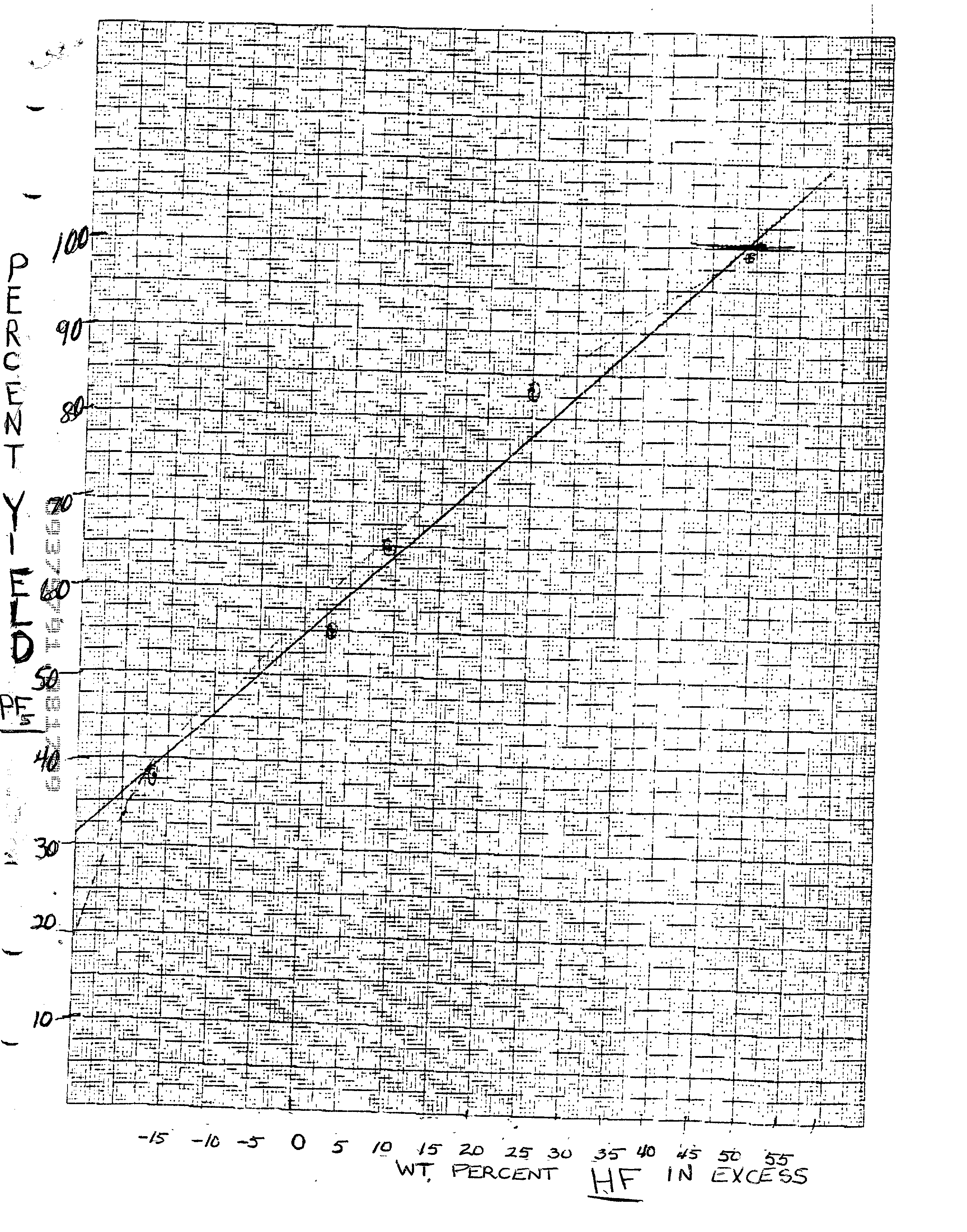

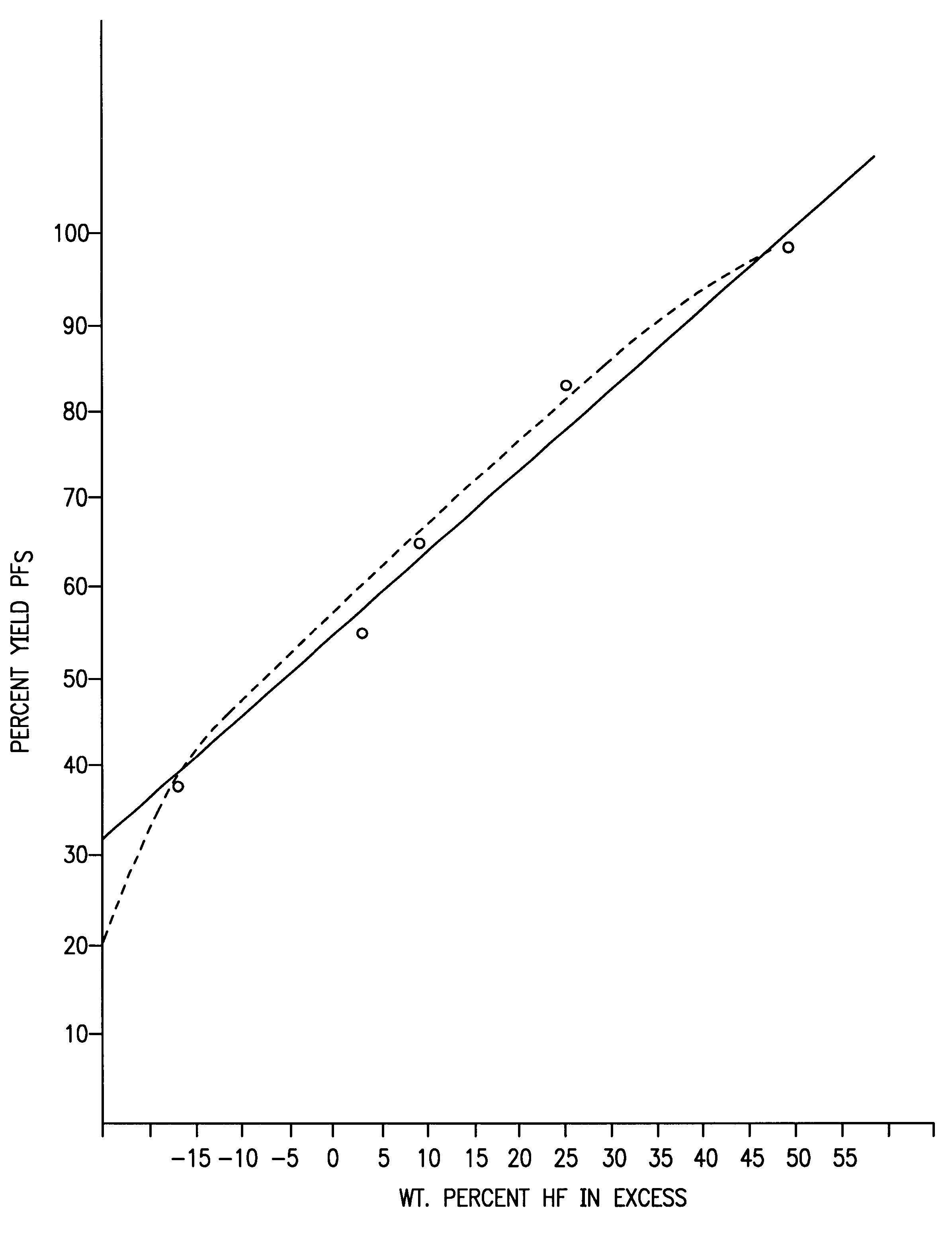

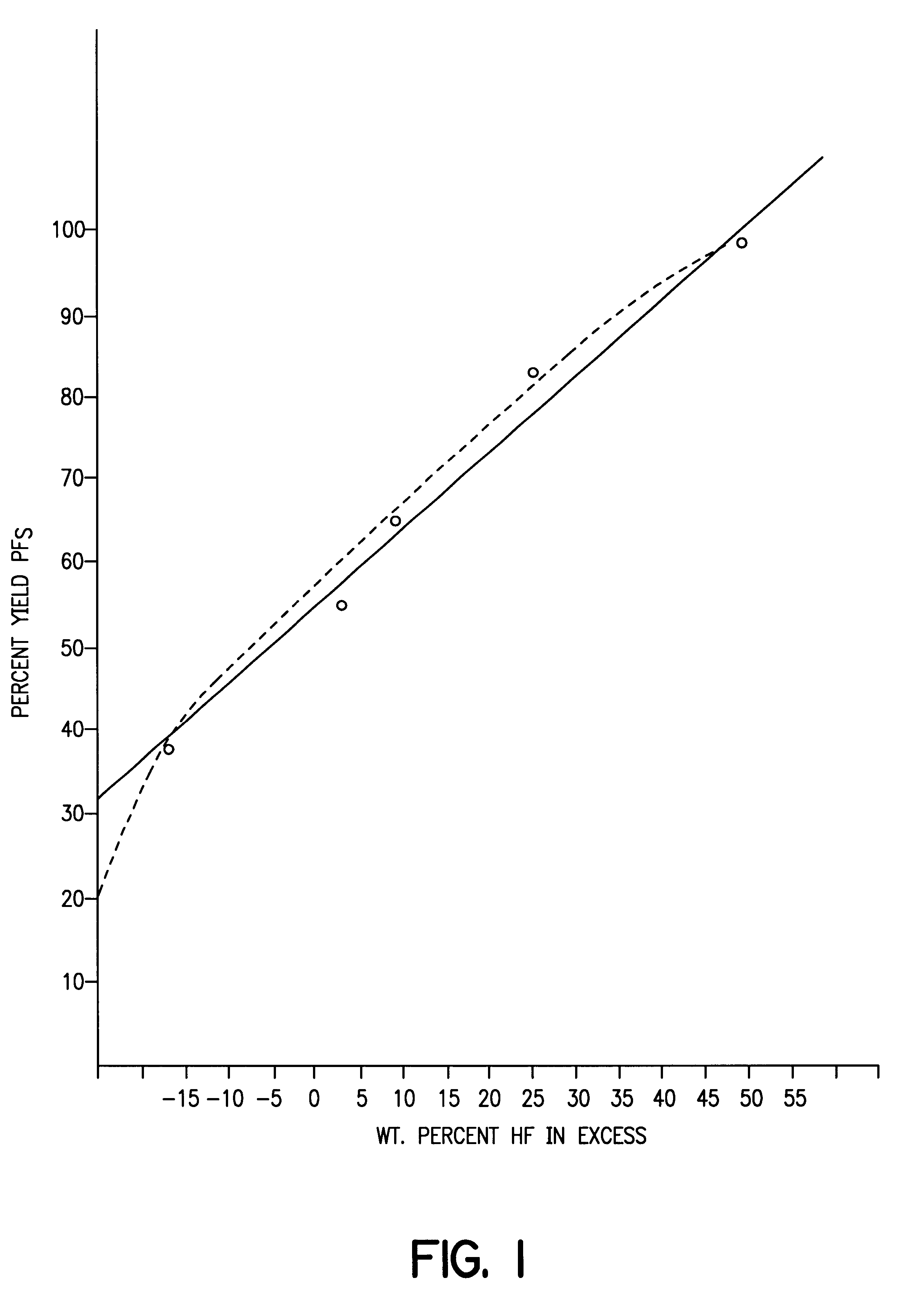

A process for the preparation of anhydrous high purity phosphorus pentafluoride in high yield. The process uses an excess of hydrogen fluoride in a reaction with a phosphoric acid to form hexafluorophosphoric acid followed by reaction with a sulfur based acid reactant in a reaction medium containing an excess of hydrogen fluoride.

Owner:LITHDYNE

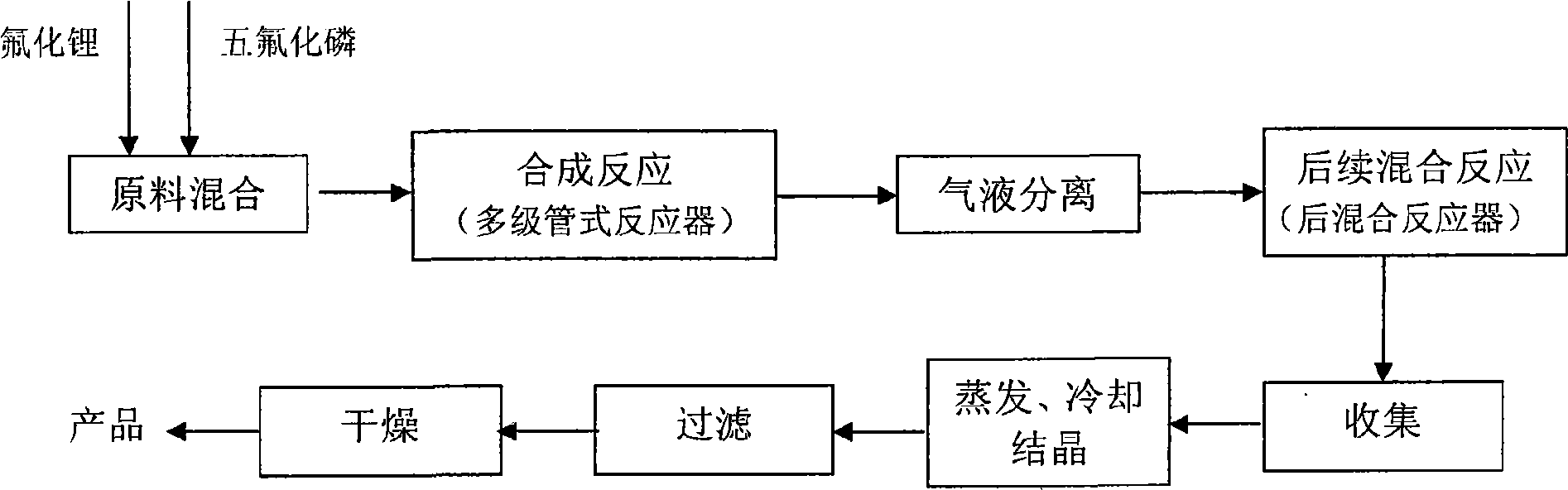

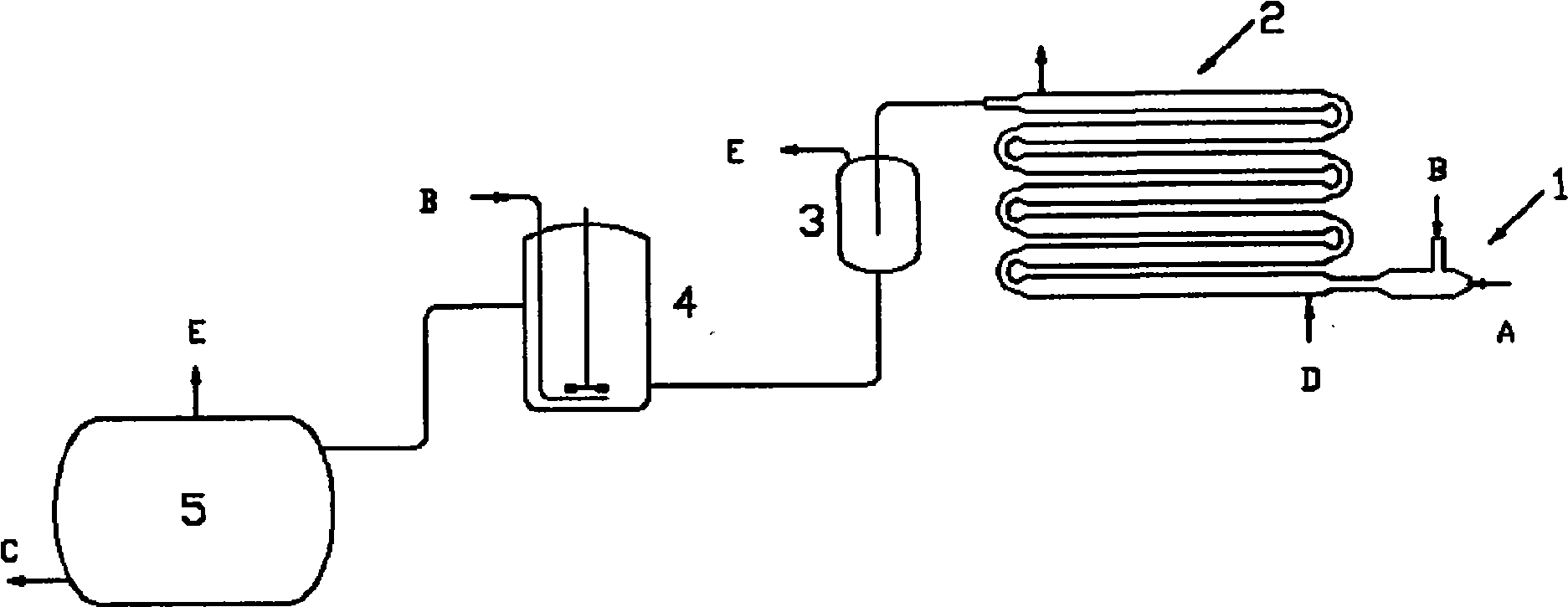

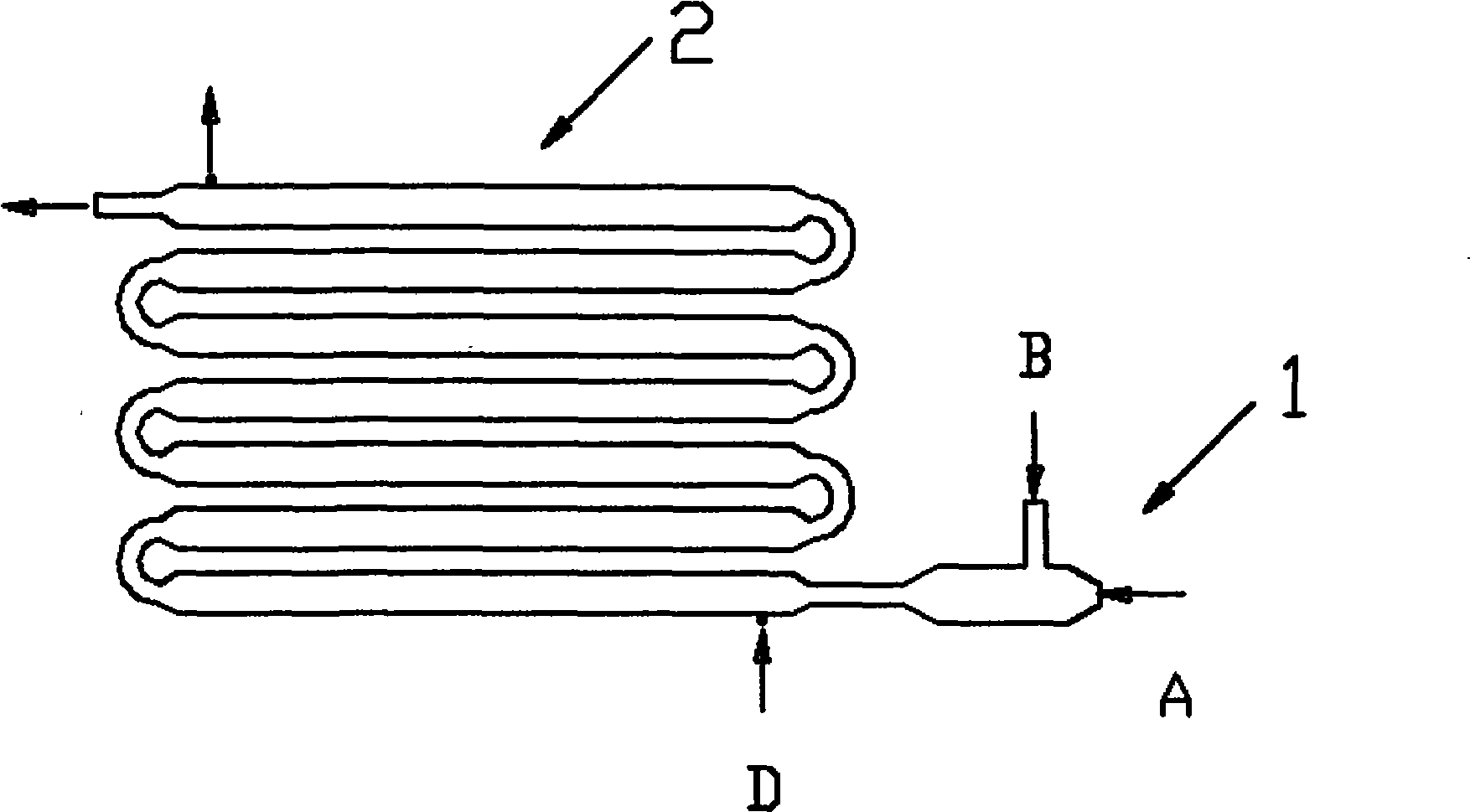

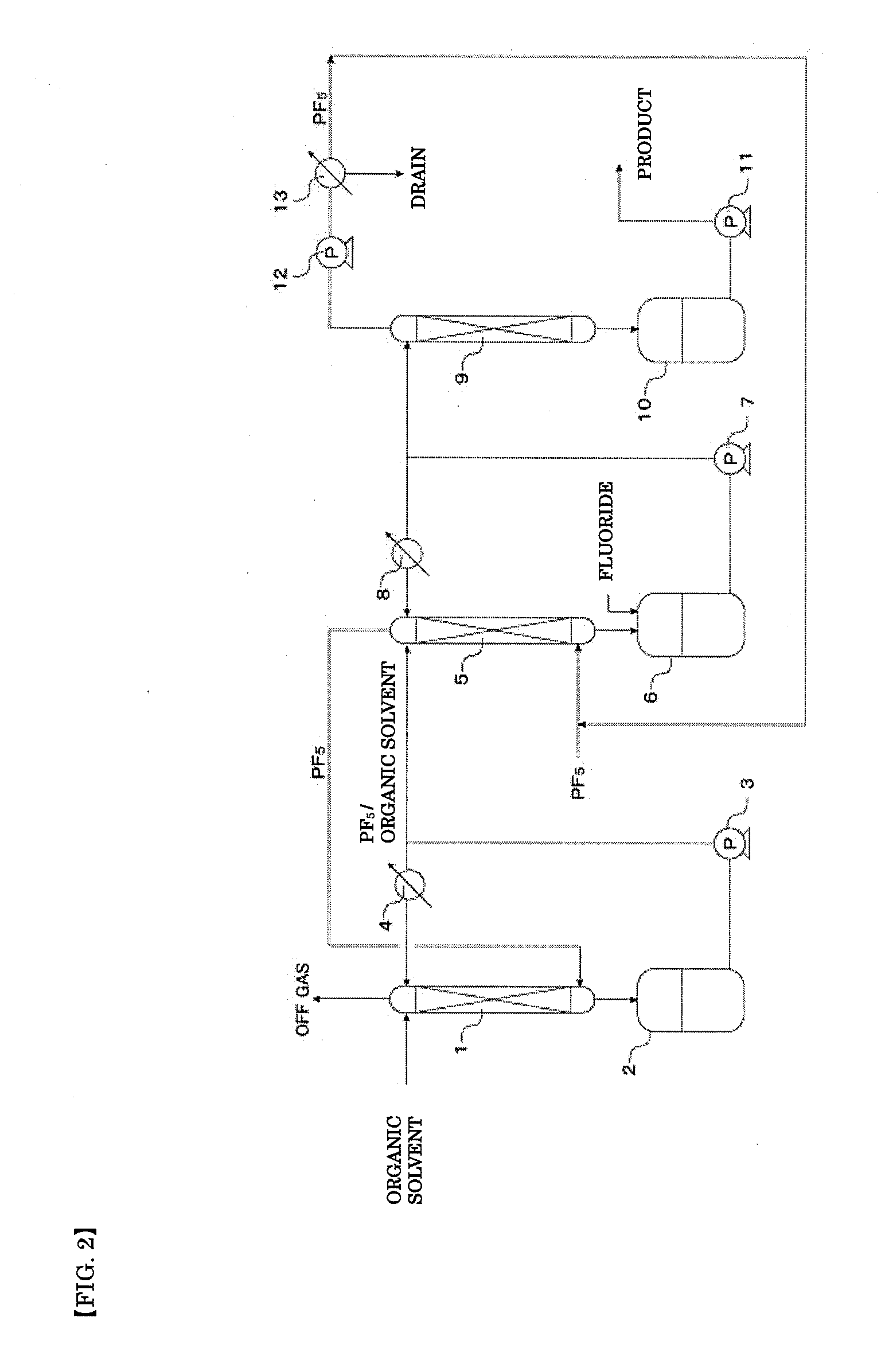

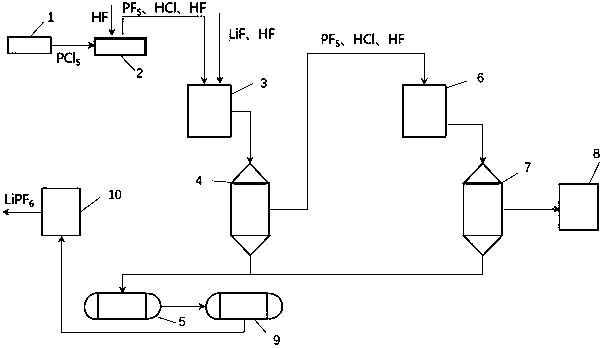

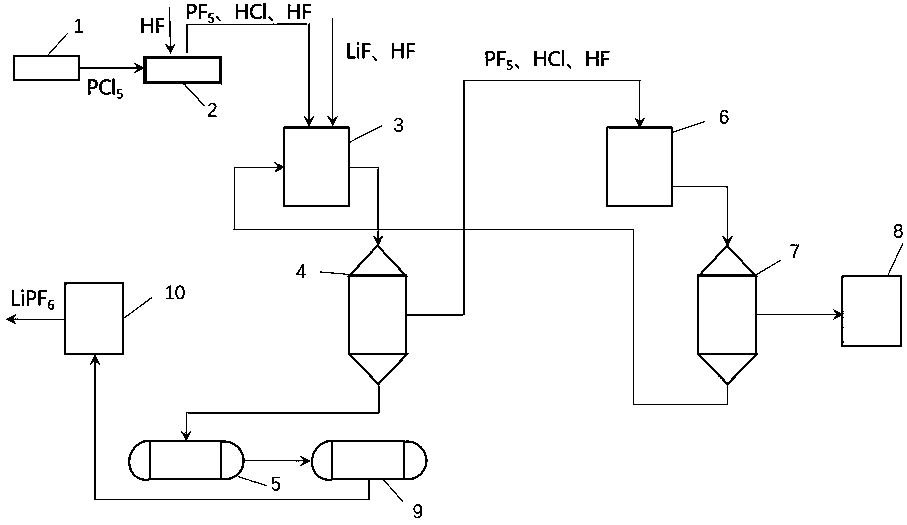

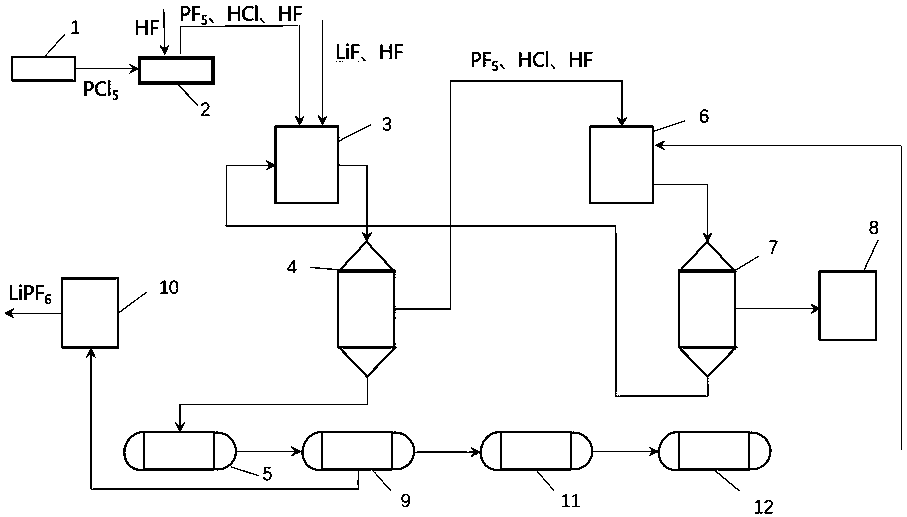

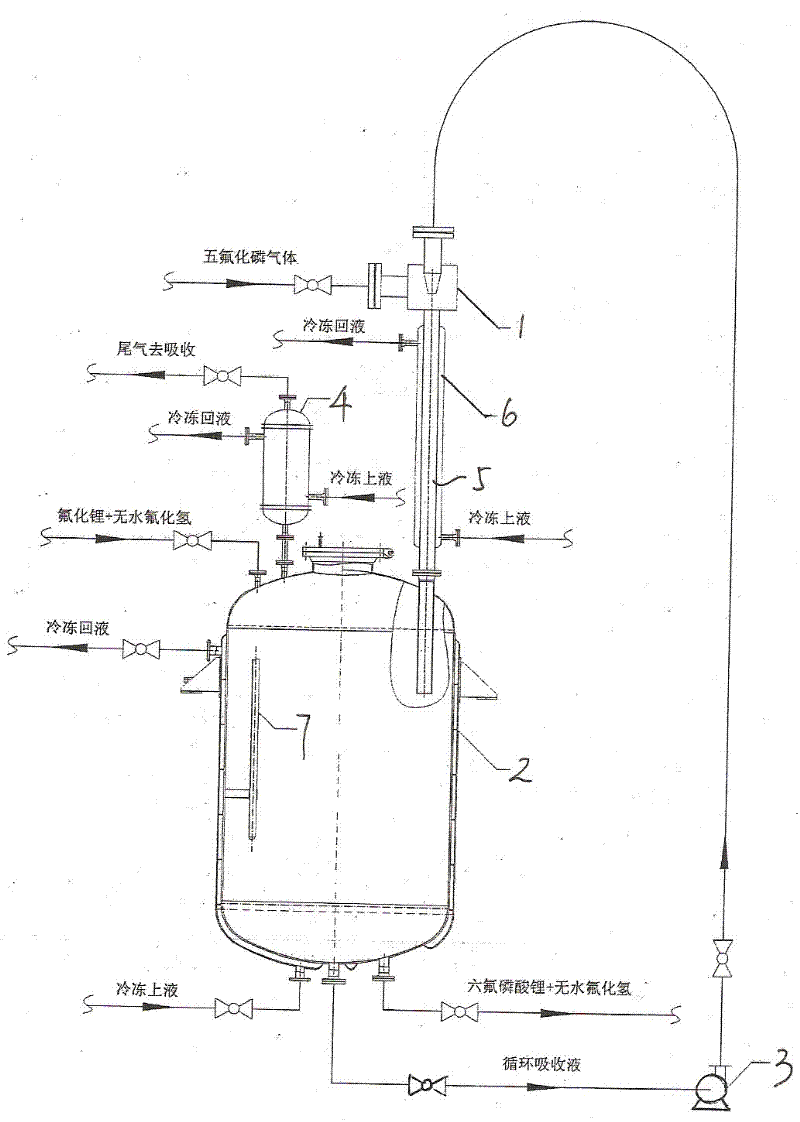

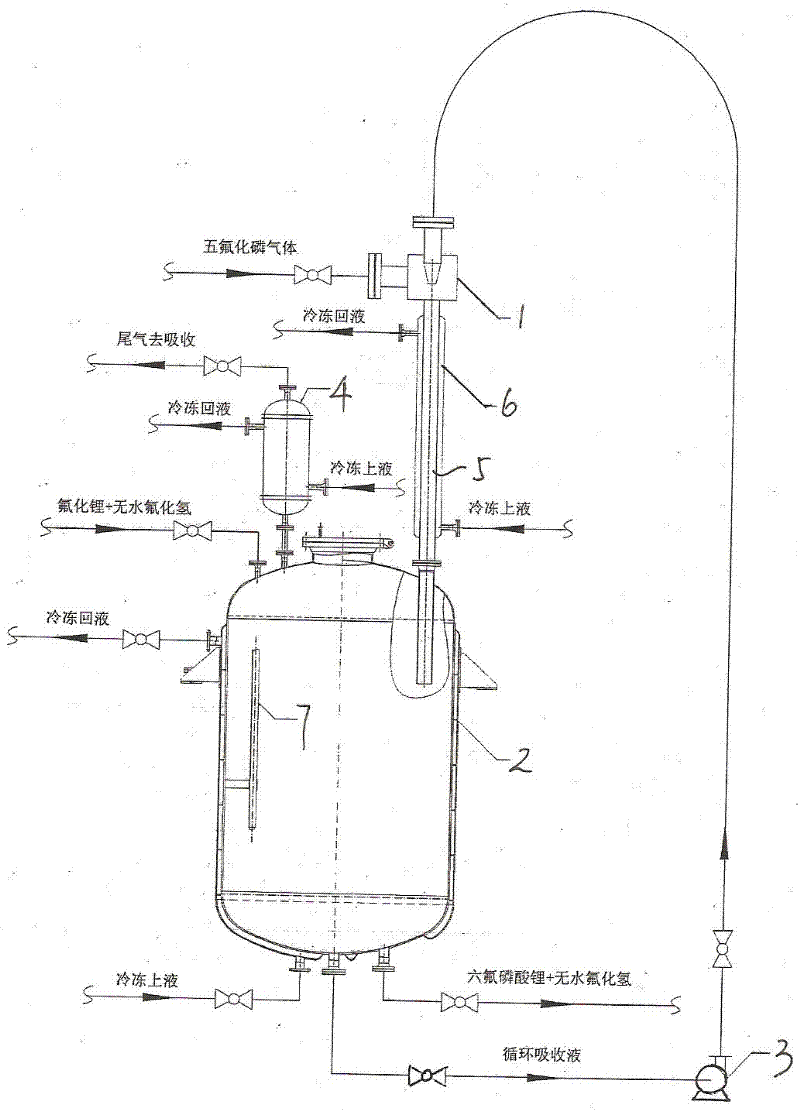

Process and device for continuous preparation of lithium hexafluorophosphate

ActiveCN101544361AAchieve conversionAchieve serializationSecondary cellsPhosphorus compoundsLiquid productFiltration

The invention discloses a process for the continuous preparation of lithium hexafluorophosphate and a device thereof. The process comprises the following steps that: a fluorine hydride solution A of lithium fluoride and phosphorus pentafluoride or a mixed gas of the phosphorus pentafluoride and other gases are subjected to raw material mixing; the raw material mixture undergoes a multistage synthetic reaction; the product of the multistage synthetic reaction enters a gas-liquid separator to remove unreacted gases; the liquid product of the multistage reaction undergoes a consequent hybrid reaction and the product of the consequent hybrid reaction is reacted with the additionally introduced phosphorus pentafluoride gas B to remove a micro amount of possibly unreacted lithium fluoride in the solution; the product of the reaction is then subjected to evaporation, cooling, crystallization, filtration and drying to form lithium hexafluorophosphate crystal with a purity of 99.9 percent; and a parent solution obtained after separation and crystallization is added with the lithium fluoride to form the raw material solution A for cycle use. The invention adopts a multistage tubular reactor which has excellent mass and heat transfer performance and can realize full gas-liquid contact, continuous material feeding and discharging and the like and consequently realize the continuous operation of a production process.

Owner:산산어드밴스드머테리얼스(취저우)컴퍼니리미티드

Method for preparing lithium hexafluorophosphate

ActiveCN101570328AImprove product qualityRich sourcesLead-acid accumulatorsPhosphorus compoundsOleumReaction rate

The invention relates to a method for preparing lithium hexafluorophosphate. The method comprises the following steps: (1), enabling anhydrous hydrogen fluoride and phosphorus pentoxide to react underthe protection of inert gas to prepare hexafluorophosphoric acid; (2), adding oleum to the hexafluorophosphoric acid under cooling stirring to prepare phosphorus pentafluoride gas; (3), dissolving high-pure lithium fluoride in an anhydrous hydrogen fluoride solution to form an anhydrous hydrogen fluoride solution containing the lithium fluoride; (4), cooling the phosphorus pentafluoride gas at 40DEG C below zero, guiding the phosphorus pentafluoride gas to the anhydrous hydrogen fluoride solution containing the lithium fluoride, and reacting, crystallizing, separating and drying the phosphorus pentafluoride gas to obtain a pure lithium hexafluorophosphate product; and (5), continuously pumping the unreacted cooled phosphorus pentafluoride gas after a reaction to the other anhydrous hydrogen fluoride solution containing the lithium fluoride and continuously reacting to obtain a lithium hexafluorophosphate finished product. The invention has rich material resources and easily obtainable raw materials, low production cost, high reaction rate, high product quality and thorough reaction and can realize semi-continuous production by the series connection of double kettles.

Owner:DO FLUORIDE CHEM CO LTD

Method for producing lithium hexafluorophosphate

InactiveCN101570327ARich sourcesReduce manufacturing costLead-acid accumulatorsPhosphorus compoundsReaction rateMoisture

The invention relates to a method for producing lithium hexafluorophosphate. The method comprises the following steps: (1), rectifying and purifying industrial anhydrous hydrogen fluoride and removing moisture and heavy metal impurities therein; (2), enabling the rectified anhydrous hydrogen fluoride and phosphorus pentachloride to react to prepare the mixed gas of phosphorus pentafluoride and chlorine hydride; (3), dissolving high-pure lithium fluoride in an anhydrous hydrogen fluoride solution to form an anhydrous hydrogen fluoride solution containing the lithium fluoride; (4), cooling and guiding the mixed gas of the phosphorus pentafluoride and the chlorine hydride to the anhydrous hydrogen fluoride solution containing the lithium fluoride, reacting, crystallizing, separating and drying to obtain a pure lithium hexafluorophosphate product; and (5), continuously guiding the unreacted gas of the phosphorus pentafluoride and the chlorine hydride after a reaction to the other anhydrous hydrogen fluoride solution containing the lithium fluoride and continuously reacting to obtain a lithium hexafluorophosphate finished product. The invention uses the industrial anhydrous hydrogen fluoride, the phosphorus pentachloride and the high-pure lithium fluoride as raw materials to prepare the lithium hexafluorophosphate product, has rich raw material resources, low production cost, high reaction rate, high product quality and thorough reaction and can realize semi-continuous production.

Owner:DO FLUORIDE CHEM CO LTD

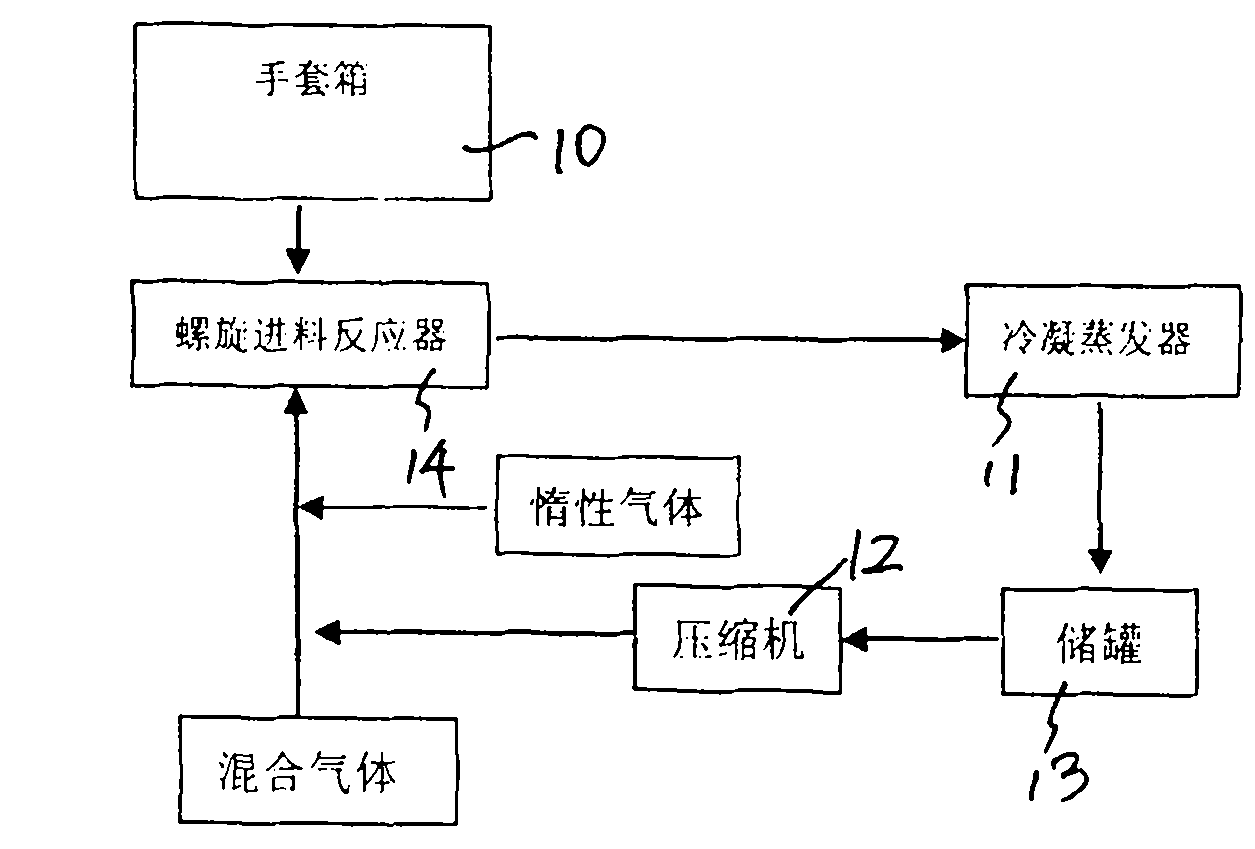

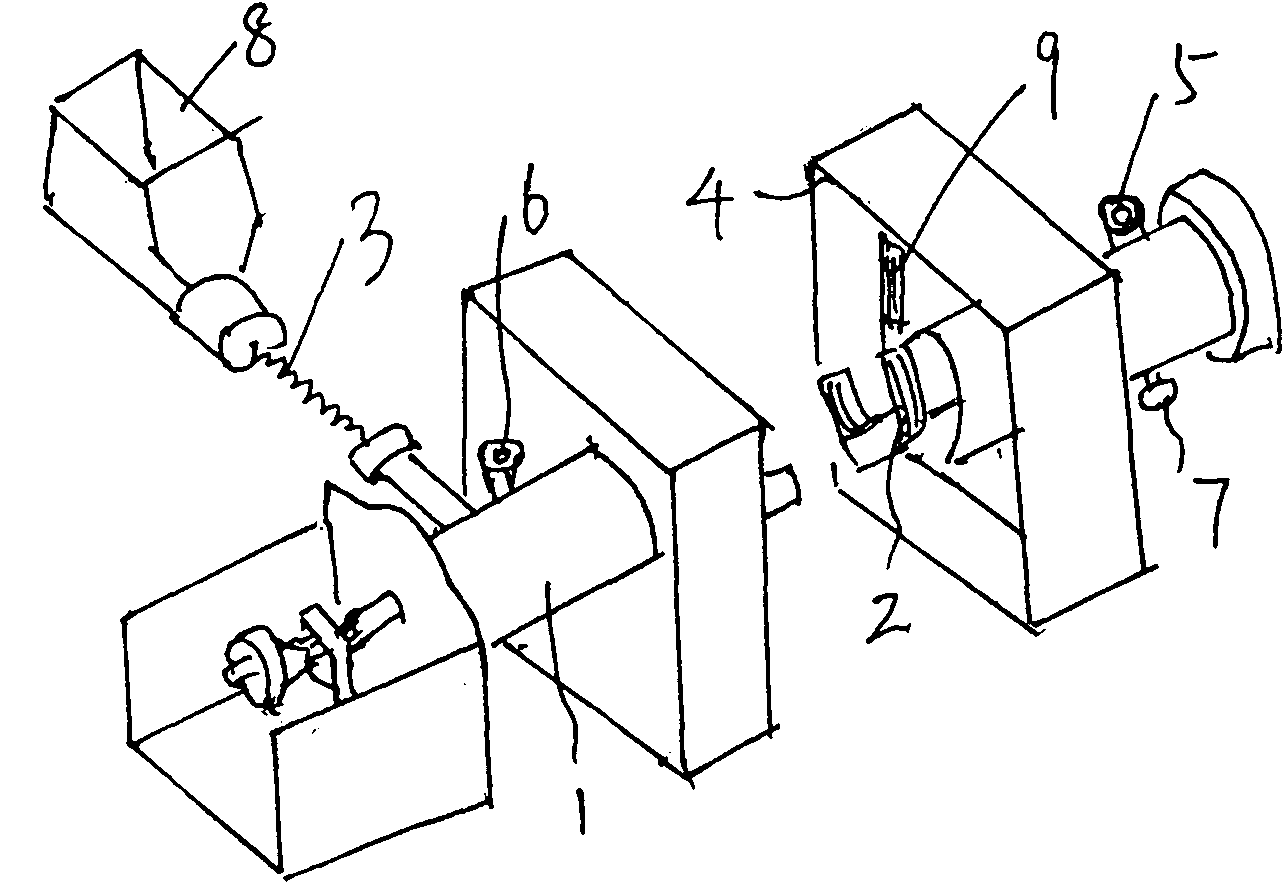

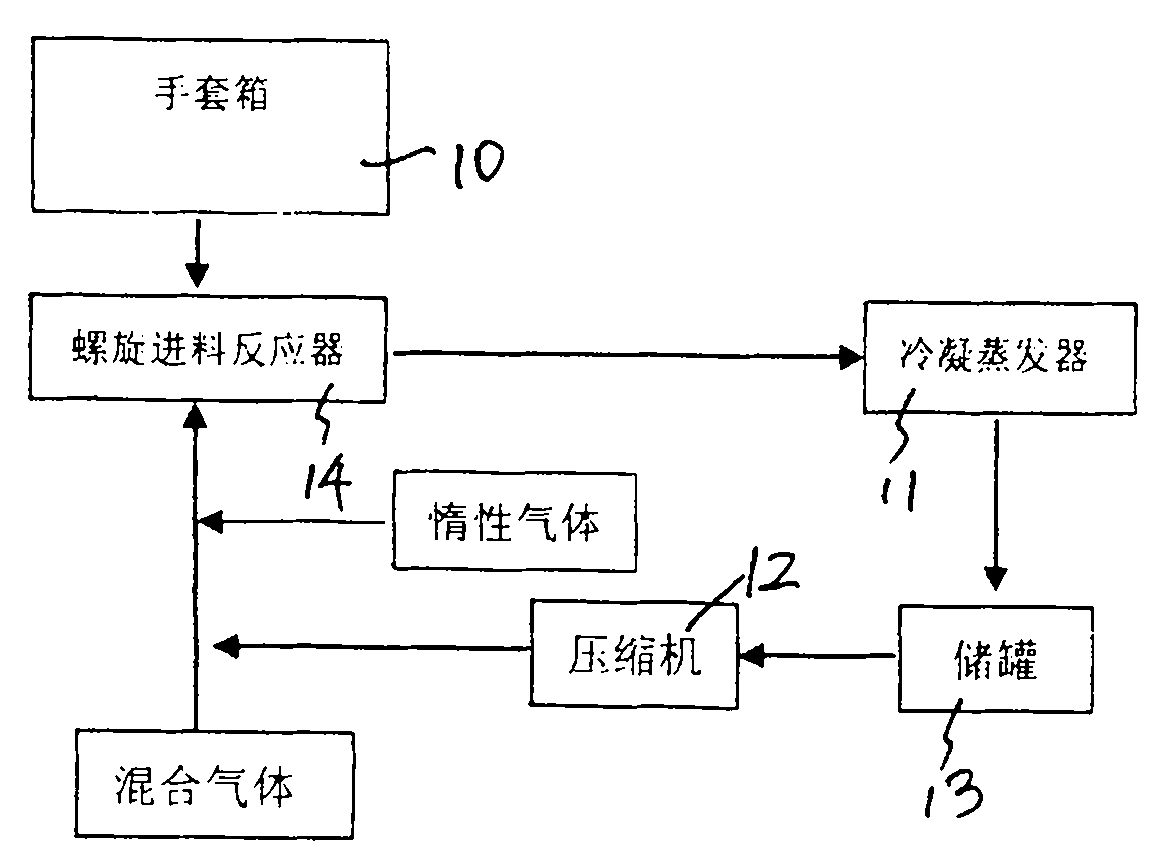

Preparation process of high-purity phosphorus pentafluoride

ActiveCN101844754AEffective control of feed rateControl feed ratePhosphorus halides/oxyhalidesPhysical chemistryHydrogen chloride

The invention discloses a preparation process of high-purity phosphorus pentafluoride, which comprises the following steps of: firstly adding phosphorous pentachloride into a feed hopper of a spiral feeder under the protection of dry gas in a glove box to assemble a gas circulation loop, and simultaneously adding inert gas into the gas circulation loop in advance; starting a spiral stirring reaction furnace, simultaneously injecting mixed gas of hydrogen fluoride and fluorine gas into the spiral stirring reaction furnace, and controlling the reaction process by controlling the rotation frequency of the phosphorous pentachloride in the spiral feeder, the temperature of gas flow at the outlet of the spiral stirring reaction furnace and the pressure of the gas circulation loop; freezing the phosphorus pentafluoride gas and the hydrogen fluoride gas generated in the reaction process and unreacted hydrogen fluoride gas by a condenser-evaporator, and collecting high-purity phosphorus pentafluoride gas after reaction. The method is simple and effective and can be operated easily.

Owner:JIANGSU JIUJIUJIU TECH

Preparation method of high purity phosphorus pentafluoride

ActiveCN104261369ALow costNo occupational health hazardPhosphorus halides/oxyhalidesPhosphoric acidSulfur trioxide

The invention provides a preparation method of high purity phosphorus pentafluoride. The preparation method comprises the following steps: step one, taking polyphosphoric acid and waterless hydrogen fluoride as the primary raw materials to prepare a hexafluorophosphoric acid water solution; step two, reacting the hexafluorophosphoric acid water solution obtained in the step one with sulfur trioxide so as to obtain a mixture of hexafluorophosphoric acid and sulfuric acid; step three, directly heating the mixture of the hexafluorophosphoric acid and sulfuric acid obtained in the step two without separation, condensing the generated phosphorus pentafluoride steam so as to obtain a coarse product of phosphorus pentafluoride; step four, refining the obtained coarse product so as to obtain high purity phosphorus pentafluoride with a purity more than 99.5%. The product prepared by the provided preparation method has a high purity and low purity content, wherein the phosphorus pentafluoride content is not less than 99.95%, the waterless hydrogen fluoride content is not more than 50 ppm, the water content is not more than 10 ppm, the metal ion content is not more than 1 ppm, and the content of other purities is not more than 5 ppm.

Owner:JIUJIANG TINCI ADVANCED MATERIALS CO LTD

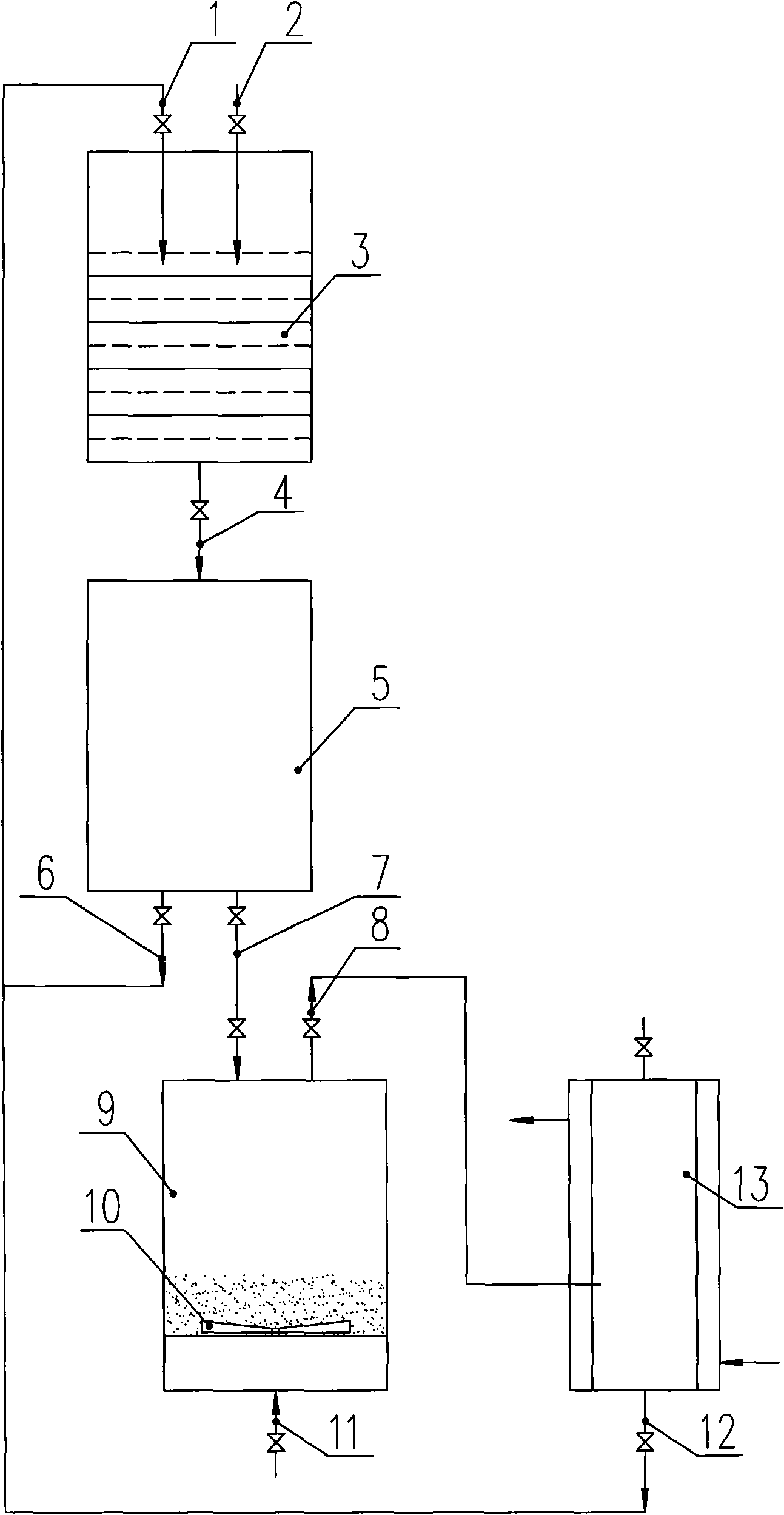

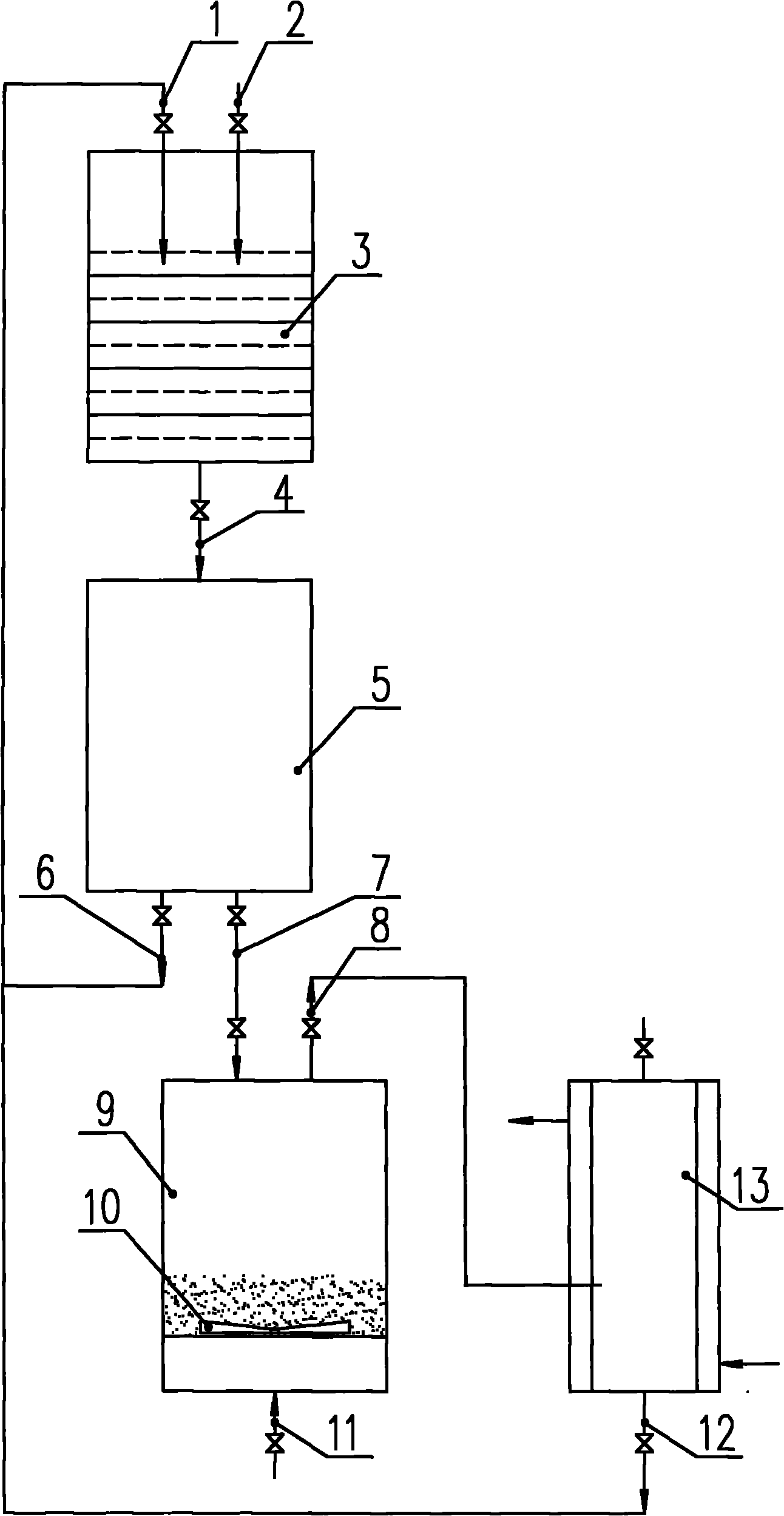

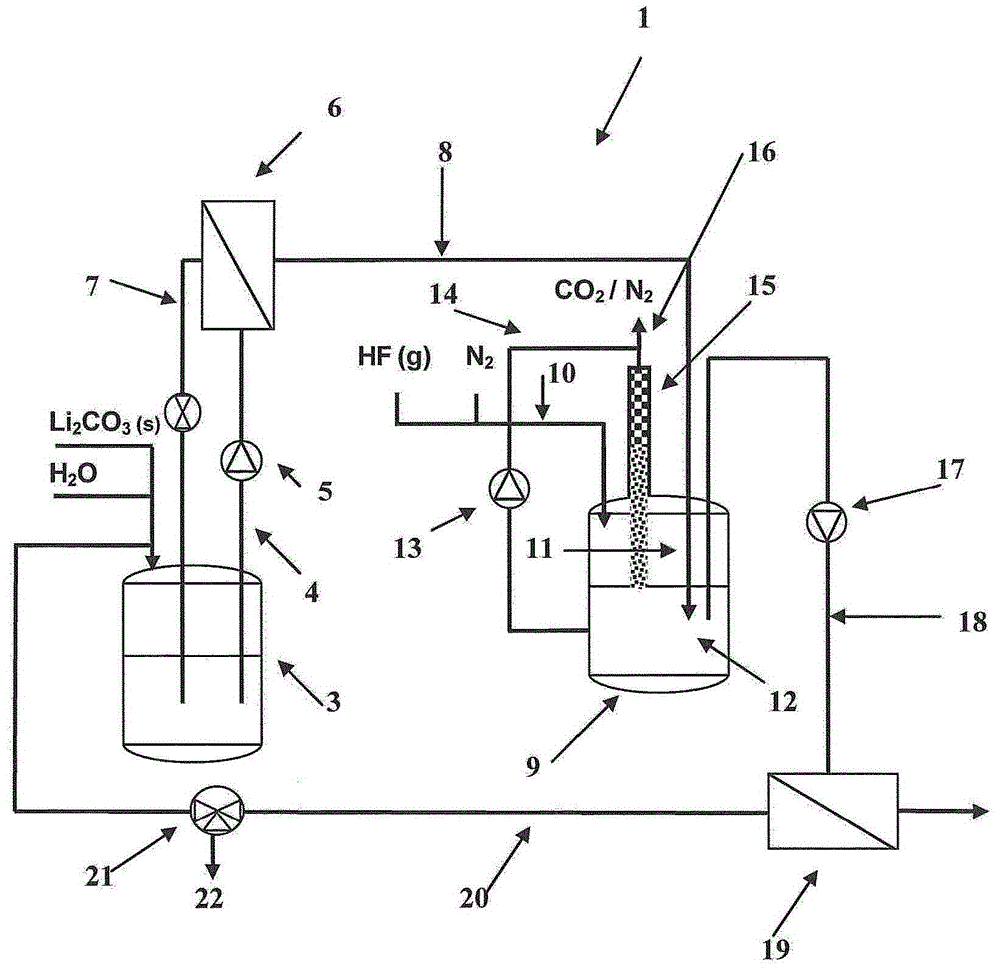

System and method for preparing high-purity phosphorus pentafluoride

ActiveCN102757027AAvoid introducingAvoid secondary pollutionPhosphorus halides/oxyhalidesPhysical chemistryPhosphorus pentafluoride

The invention relates to a system and a method for preparing high-purity phosphorus pentafluoride. The high-purity phosphorus pentafluoride is prepared from raw materials comprising PCl3, Cl2 and anhydrous HF by performing on-line purification treatment on the raw materials, performing on-line direction transformation on the intermediate product PCl5 into the PF5, performing on-line purification on the crude PF5, and the like. Preparation of the high-purity phosphorus pentafluoride is realized by the economic, high-efficiency and conveniently-operated method. The system and the method are characterized in that the high-purity phosphorus pentafluoride is prepared by performing on-line purification on the crude PF5 by two-stage condensers; and the temperatures of the two-stage condensers are respectively -50 to 19 DEG C and -85 to -76 DEG C.

Owner:陕西延长石油集团氟硅化工有限公司

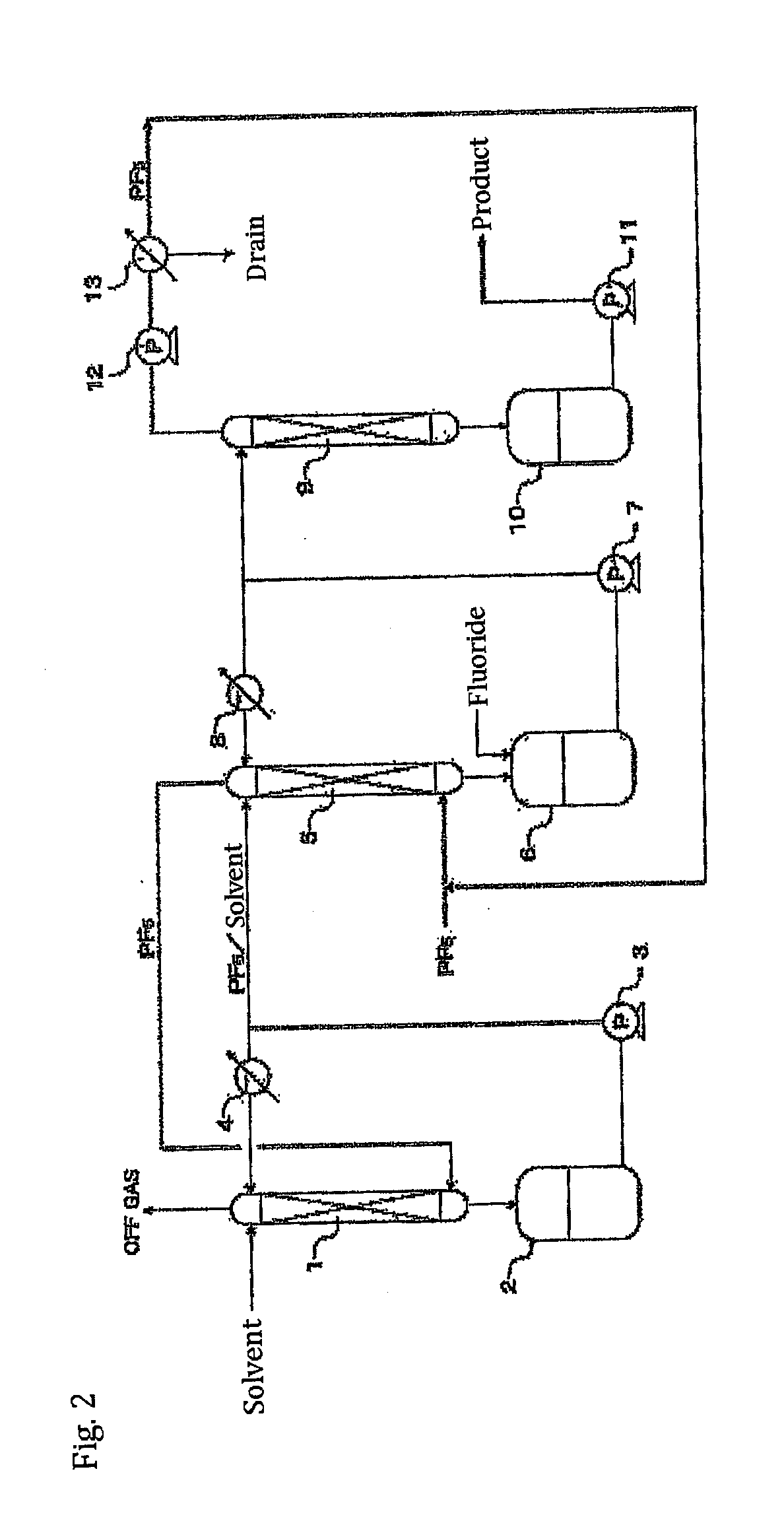

Processes for producing phosphorus pentafluoride and hexafluorophosphate

InactiveCN101605721AEasy to operateReduce synthesisPhosphorus halides/oxyhalidesDispersed particle separationPhosphatePhysical chemistry

Owner:STELLA CHEMIFA CORP

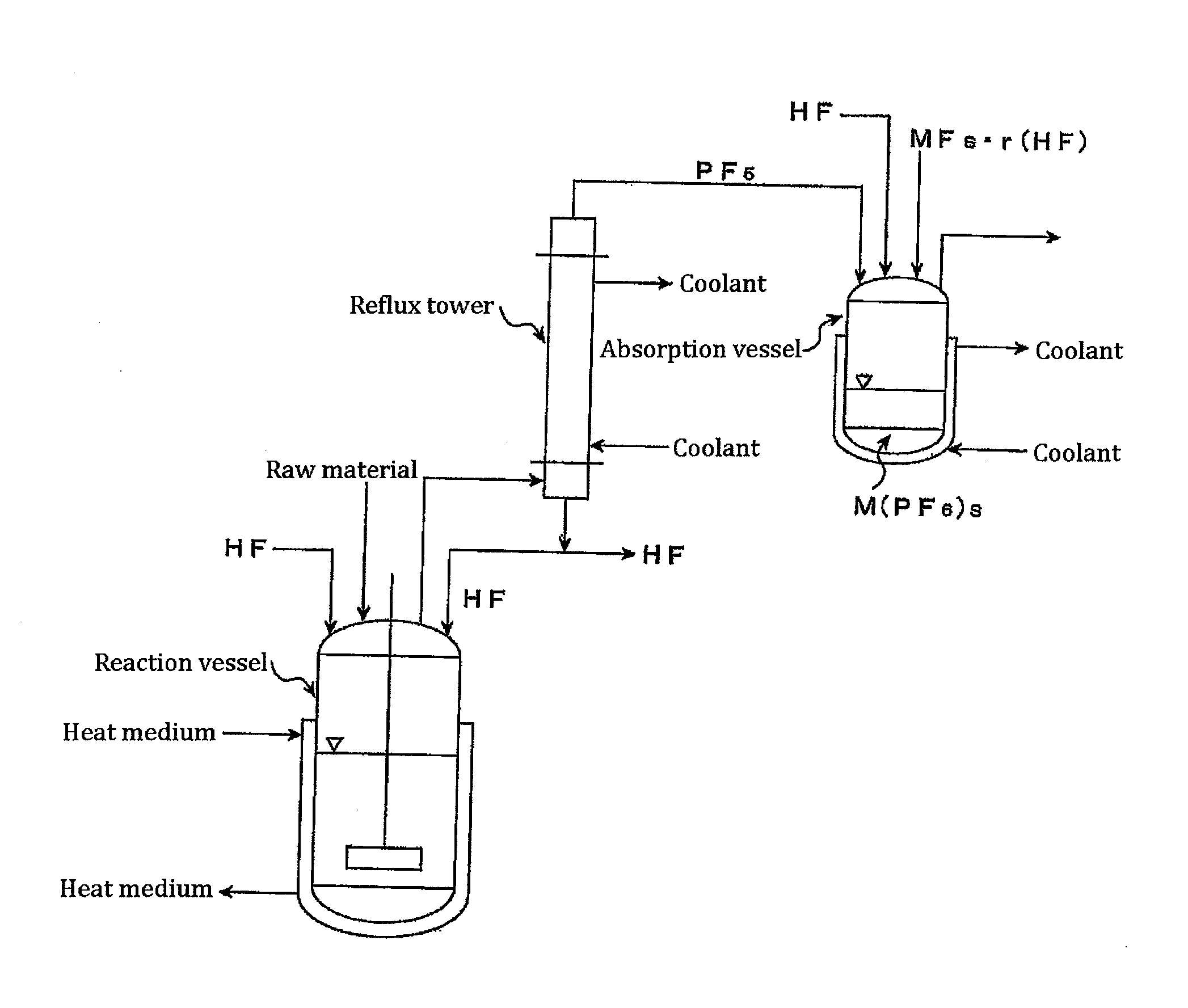

Processes for production of phosphorus pentafluoride and hexafluorophosphates

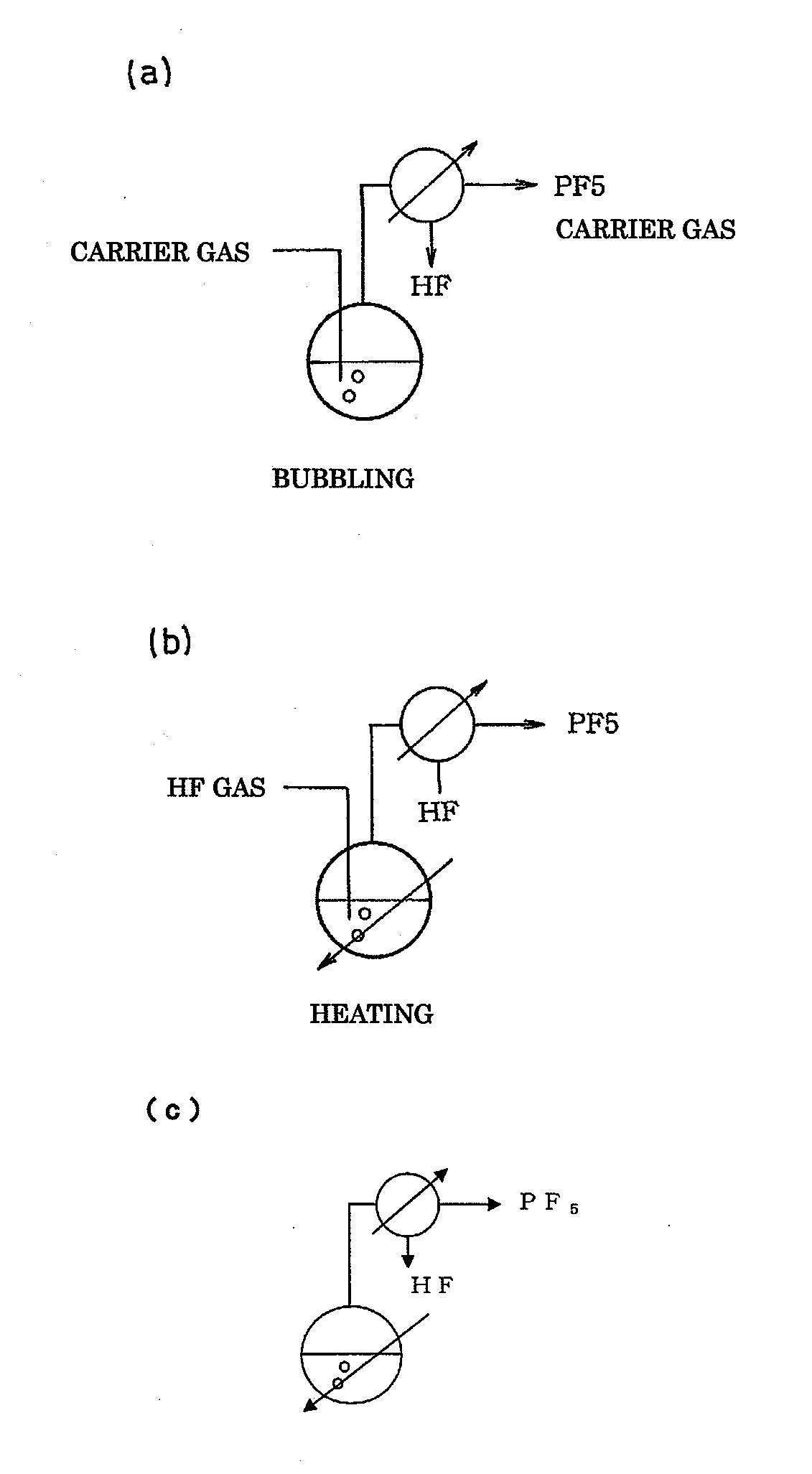

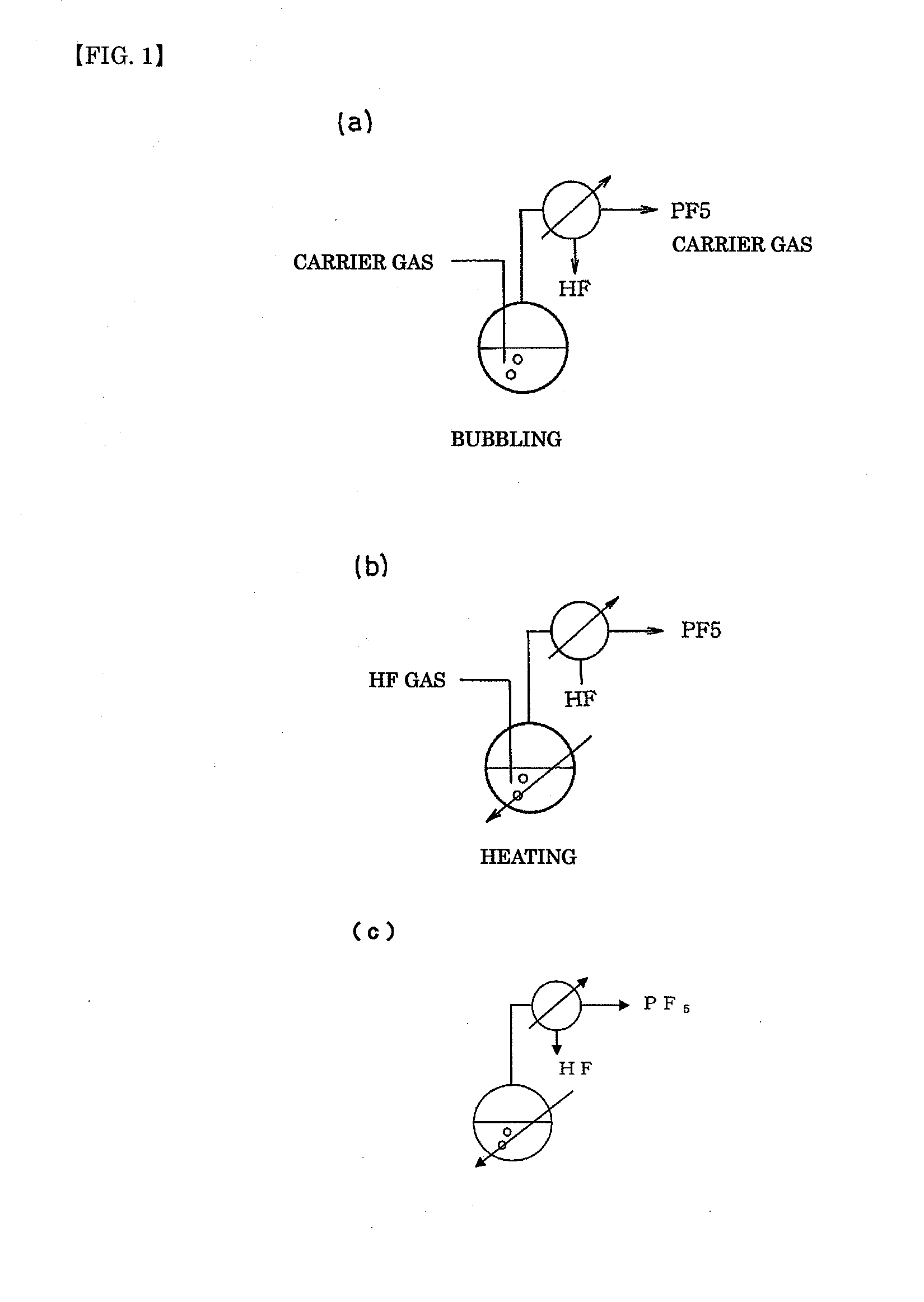

ActiveUS20110189538A1InexpensiveLow moisture concentrationPhosphorus halides/oxyhalidesLithium hexafluorophosphateChemical reactionPhysical chemistry

A method of manufacturing phosphorus pentafluoride and hexafluorophosphate can suppress the manufacturing cost and also can manufacture high-quality phosphorus pentafluoride from an inexpensive and low-quality raw material. The raw material for the method can include at least a phosphorus atom and a fluorine atom. These are brought into contact with a carrier gas, and a phosphorus pentafluoride is extracted and separated into the carrier gas. A method of manufacturing hexafluorophosphate includes reacting fluoride with the resulting phosphorus pentafluoride according to the following chemical reaction scheme: sPF5+AFs→A(PF6)s, in which s is in the range of 1≦s≦3, and A is at least one of the following: Li, Na, K, Rb, Cs, NH4, Ag, Mg, Ca, Ba, Zn, Cu, Pb, Al and Fe.

Owner:STELLA CHEMIFA CORP

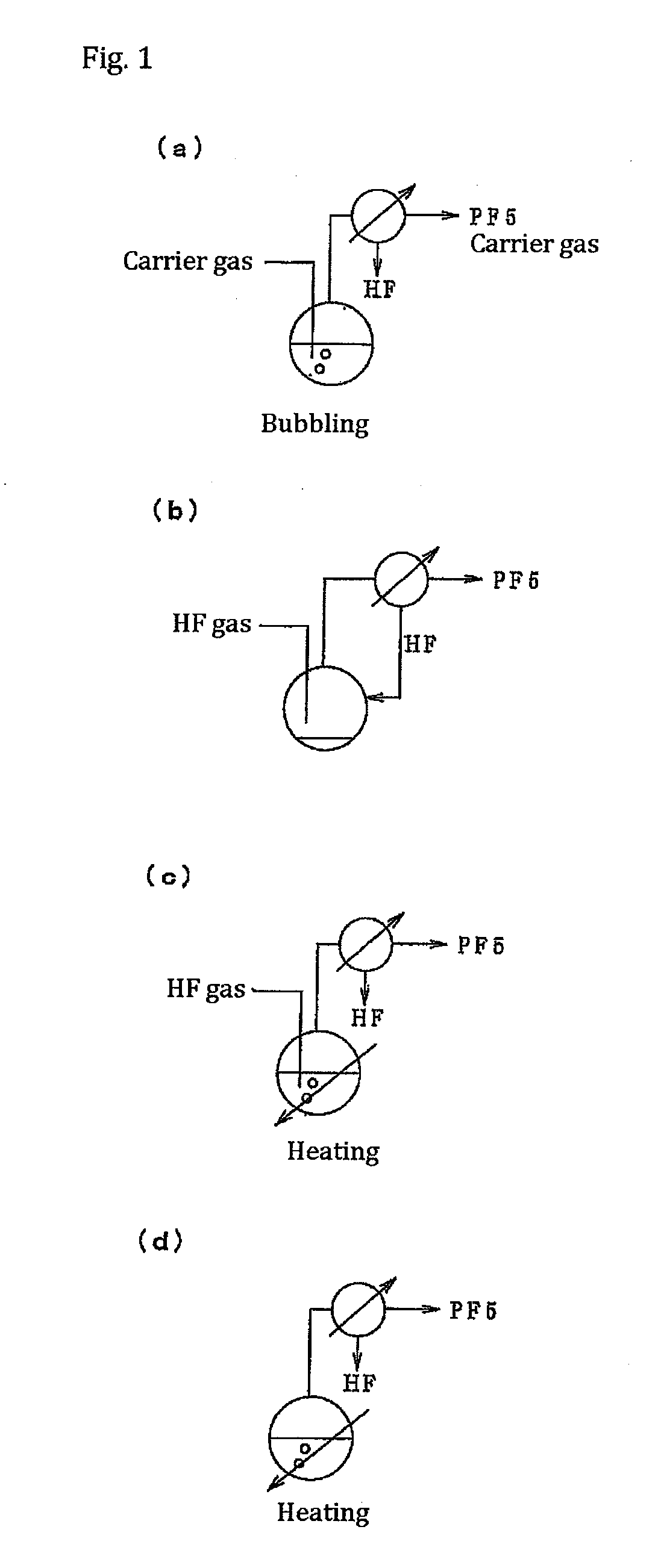

Processes for producing phosphorus tetrafluoride and phosphate hexafluoride

InactiveUS20110286905A1High purityPhosphorus halides/oxyhalidesLarge-sized flat cells/batteriesPhosphatePhotochemistry

An object the invention is to provide a phosphorus pentafluoride producing process wherein phosphorus pentafluoride is separated / extracted from a pentavalent phosphorus compound or a solution thereof, or a composition obtained by allowing the pentavalent phosphorus compound or the solution thereof to react with hydrogen fluoride, thereby producing phosphorus pentafluoride; and a phosphate hexafluoride producing process wherein the resultant phosphorus pentafluoride is used as raw material to produce a phosphate hexafluoride high in purity. The present invention relates to a process for producing phosphorus pentafluoride, wherein a carrier gas is brought into contact with either of the following one: a pentavalent phosphorus compound, a solution thereof, or a solution in which a composition obtained by allowing the pentavalent phosphorus compound or the solution thereof to react with hydrogen fluoride is dissolved, thereby a phosphorus pentafluoride is extracted into the career gas.

Owner:STELLA CHEMIFA CORP

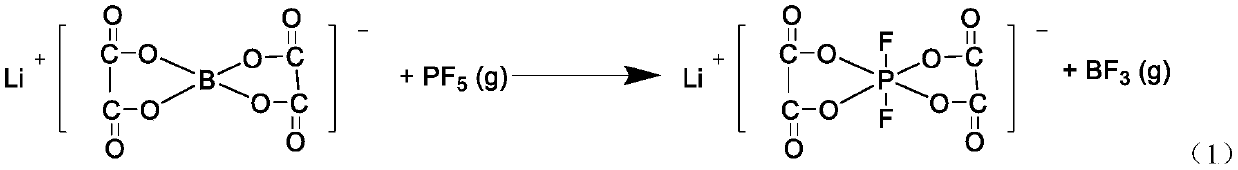

Preparation method of lithium difluoro(bisoxalate)phosphate

ActiveCN109956976AReduce usageImprove solubilityGroup 5/15 element organic compoundsSecondary cellsVacuum pumpingOxalate

The invention provides a preparation method of lithium difluoro(bisoxalate)phosphate. Lithium difluoro(bisoxalate)phosphate is prepared by a reaction between phosphorus pentafluoride and lithium oxalate. The preparation method comprises the following steps: 1) adding anhydrous lithium oxalate into a high pressure reactor with a stirrer, sealing, and vacuum-pumping; 2) slowly introducing phosphoruspentafluoride gas and high-purity carbon dioxide into the reactor at a low temperature; 3) slowly heating to 70 DEG C, adjusting pressure of the reactor to an appropriate value, and continuously stirring and reacting; and 4) carrying out separation and purification after the reaction. According to the method, raw materials are cheap and easily-available, and the reaction is carried out under mildconditions. The reaction steps are simple, and operation is convenient; the target product is only lithium difluoro(bisoxalate)phosphate; the product has high yield and high purity, and is easy to purify; the reaction is fast, postprocessing is simple, and feasibility of the industrial production is increased.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

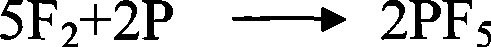

Technique for preparing phosphorus pentafluoride

InactiveCN101417791ASimple structureImprove reliabilityPhosphorus halides/oxyhalidesInternal pressureSingle substance

The invention discloses a preparation process of phosphorus pentafluoride, which has the reaction formula of 5F2 +2P -2PF5, and has the following process steps: solid single substance phosphate is pre-added in a gas solid reaction device, the internal pressure of the gas solid reaction device is controlled to be less than 0.5 MPa, fluorine gas is introduced under the condition that the reaction temperature is lower than 600 DEG C, then the crude product of the phosphorus pentafluoride is produced, and the crude product is cooled between minus 35 DEG C and minus 60 DEG C through a pre-cooler, and then introduced into a rectifying tower, the temperature of a reboiler in the rectifying tower is controlled between minus 35 DEG C and minus 40 DEG C, the temperature of a condenser in the rectifying tower is controlled between minus 60 DEG C and minus 85 DEG C, the whole reflux is kept, the reflux ratio is controlled to be 10:1 to 1:1 after the balance is reached, and the finished product of the phosphorus pentafluoride is obtained by the rectification separation The preparation process of the phosphorus pentafluoride has the advantages of simple process work and equipment structure, high reliability, simple reaction process, single product and high product purity.

Owner:袁翔云

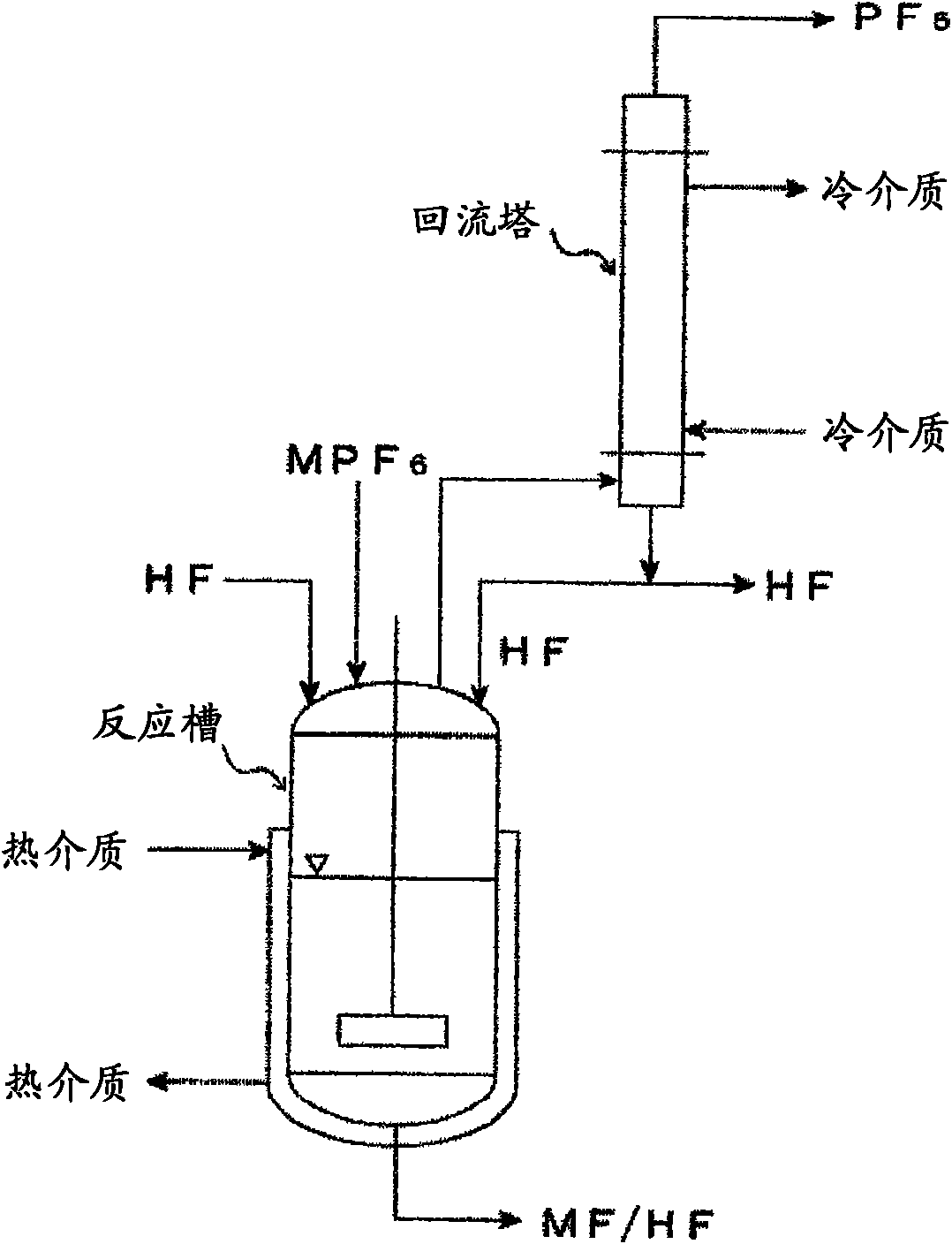

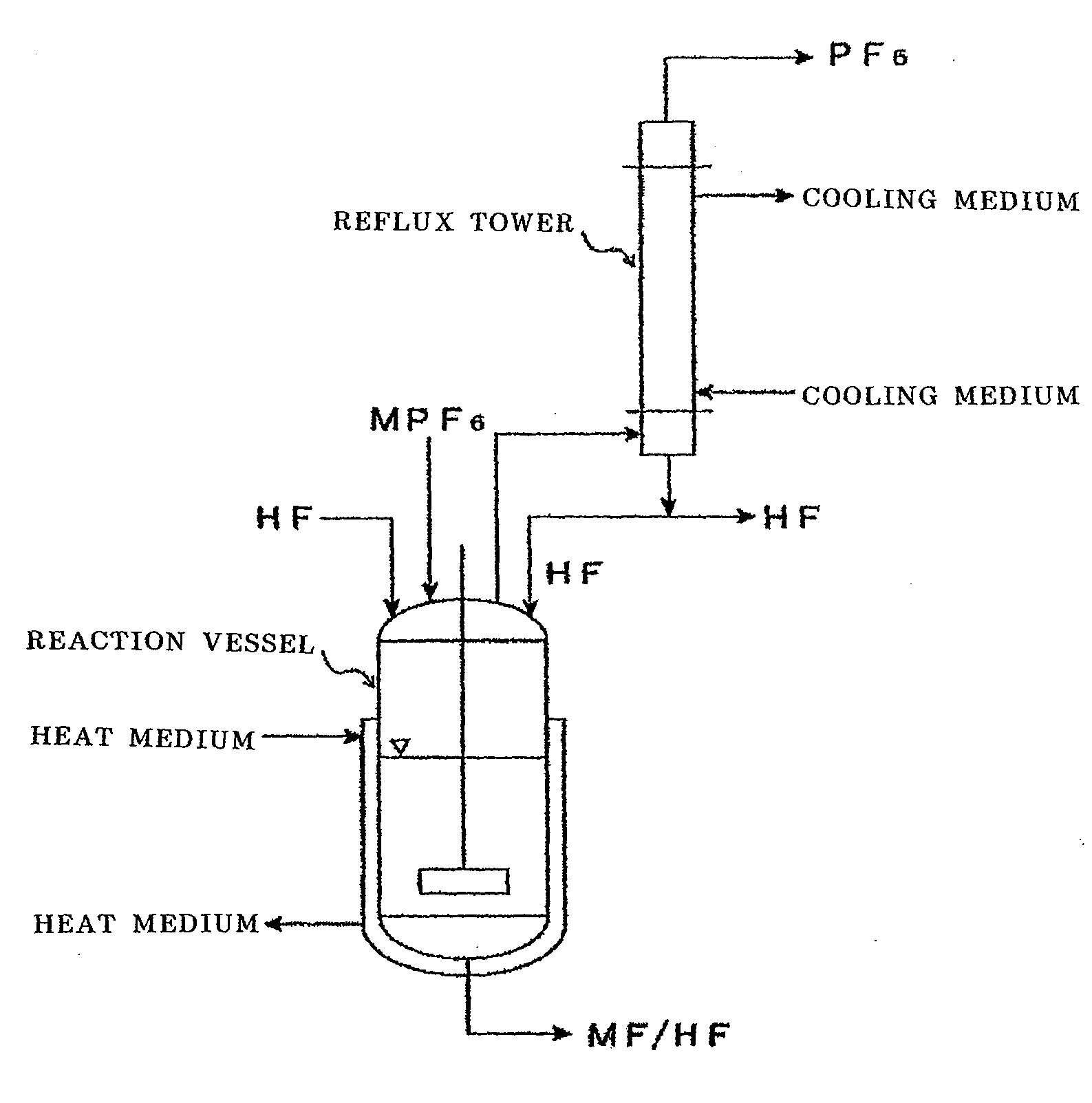

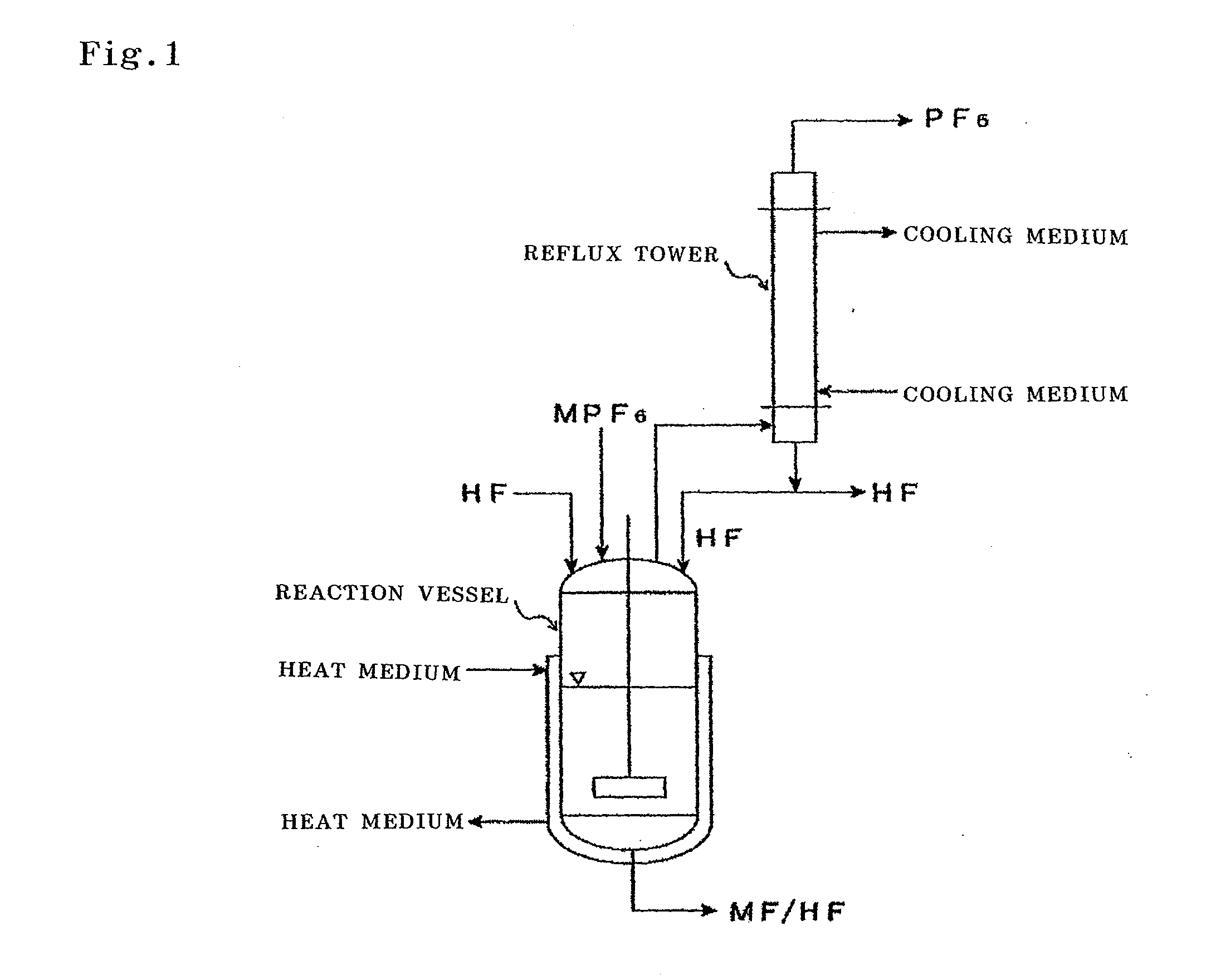

Method of manufacturing phosphorous pentafluoride and hexafluorophosphate

InactiveUS20100322838A1Easy to operateLow pricePhosphorus halides/oxyhalidesLithium hexafluorophosphatePentafluoridePhysical chemistry

A process for phosphorus pentafluoride production by which high-purity phosphorus pentafluoride can be produced by a simple and economical procedure without the need of a large-scale purification apparatus or high-pressure apparatus and without generating a large amount of a by-product gas requiring a special discharge-gas treatment. The process for phosphorus pentafluoride production is characterized by introducing hydrogen fluoride and a hexafluorophosphate (MPF6) into a vessel and reacting them according to the reaction shown by the scheme (1) to yield phosphorus pentafluoride. MPF6+uHF→PF5+MF r(HF) (Scheme 1) In the scheme, M is at least any one of Li, Na, K, Rb, Cs, NH4, and Ag; 0≦r≦u; and the HF is used in an amount not smaller than the stoichiometric amount.

Owner:STELLA CHEMIFA CORP

Synthesis method of a lithium hexafluorophosphate non-aqueous solvent method

InactiveCN102153064AAvoid decompositionLess impuritiesPhosphorus compoundsChemical reactionSynthesis methods

The invention discloses a synthesis method of a lithium hexafluorophosphate non-aqueous solvent method, which includes the steps of allowing gaseous phosphorus pentafluoride to react with anhydrous hydrogen fluoride solution of lithium fluoride to generate reaction product containing lithium hexafluorophosphate; freezing and crystallizing the reaction product after the reaction is finished; then separating the reaction product containing the lithium hexafluorophosphate by a solid product sedimentation device; and transferring the obtained solid product to a drying device for drying treatment. The drying treatment method includes the steps of heating the mixed gas of inert gas and fluorine or phosphorus pentafluoride gas which presents chemical reaction inertness with the lithium hexafluorophosphate, the hydrogen fluoride and the phosphorus pentafluoride, then introducing the mixed gas into the drying device to contact with the solid product so as to carry out the hydrogen fluoride remaining on the surface of the solid product, and finally obtaining a solid product, namely lithium hexafluorophosphate solid. The synthesis method has the advantages of effectively reducing impurities or restricting the generation of the impurities and being beneficial to the improvement of the product quality when the product carrying out drying.

Owner:张家港市亚源高新技术材料有限公司

Method for preparing lithium hexafluorophosphate quickly

InactiveCN104555959AAdjust feed weight ratioEasy to operatePhosphorus halides/oxyhalidesDistillationMixed gas

The invention discloses a method for preparing lithium hexafluorophosphate quickly. The method comprises steps as follows: (1) performing distillation to obtain a hydrogen fluoride liquid with the purity higher than 99.99wt%; (2) reacting the hydrogen fluoride liquid with phosphorous pentachloride to obtain a mixed gas of phosphorus pentafluoride and hydrogen chloride; (3) feeding the mixed gas of the phosphorus pentafluoride and the hydrogen chloride into hydrogen fluoride and lithium fluoride to obtain a lithium hexafluorophosphate solution; (4) filtering the lithium hexafluorophosphate solution obtained in Step (3) to remove insoluble impurities, performing stirring crystallization on a filtrate at the stirring speed of 50-100 rpm, and performing rotary drying at the temperature of 120 DEG C-130 DEG C after stirring crystallization to directly obtain the lithium hexafluorophosphate product with the radius ranging from 100 meshes to 400 meshes. According to the method, the operation is convenient, the lithium hexafluorophosphate obtained through stirring crystallization is in uniform granule shape directly, repeated drying and crushing steps are omitted, and the crystallization time is shortened.

Owner:MORITA NEW ENERGY MATERIALS ZHANGJIAGANG CO LTD

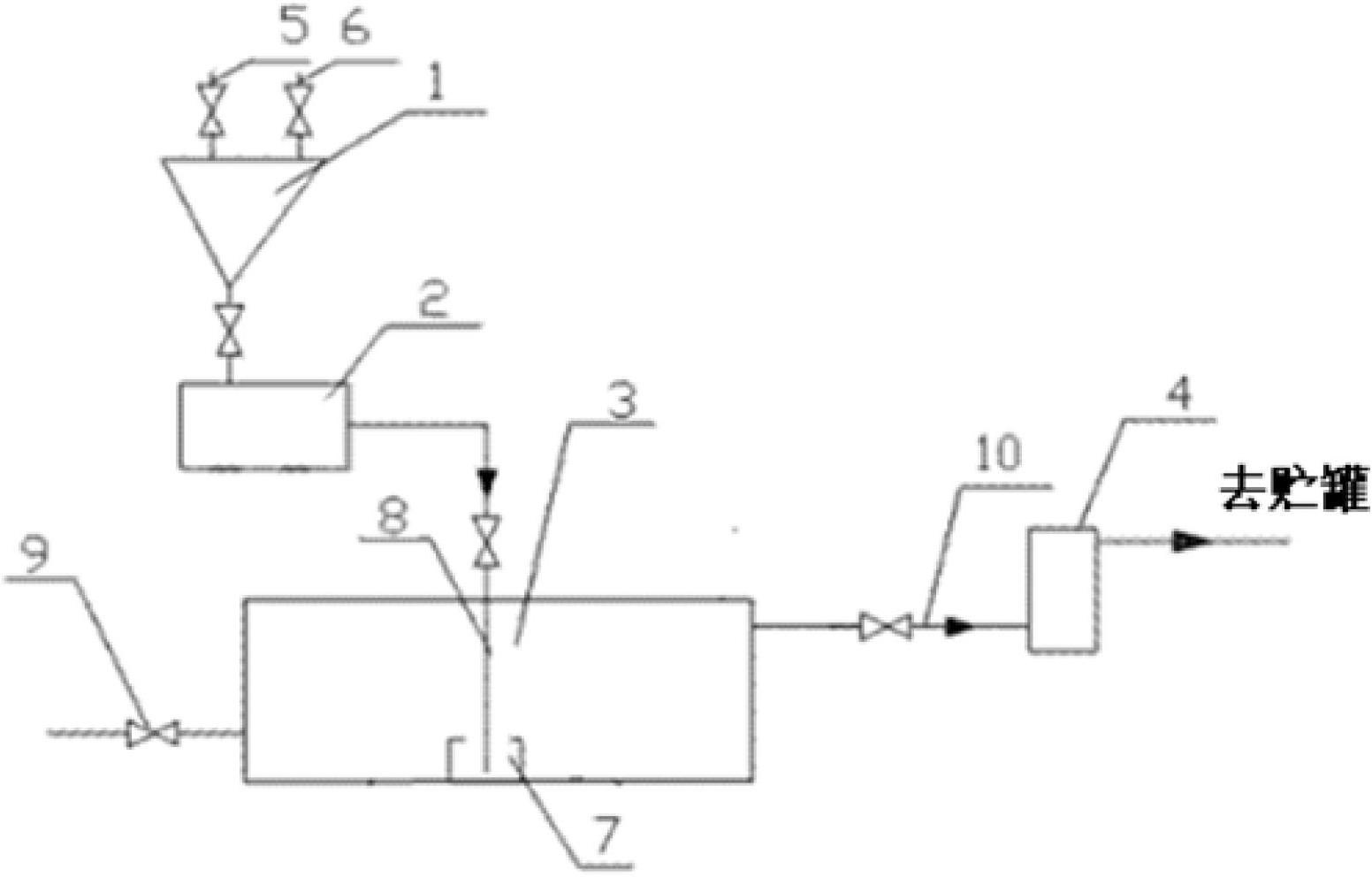

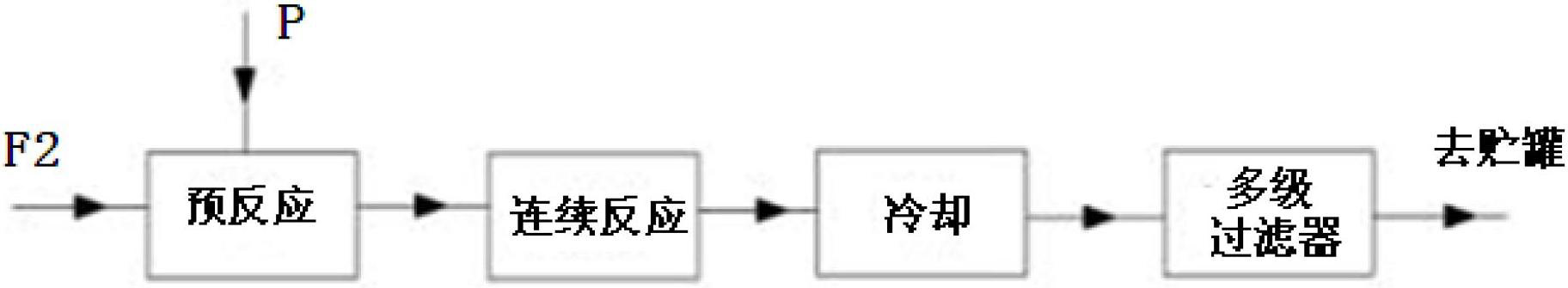

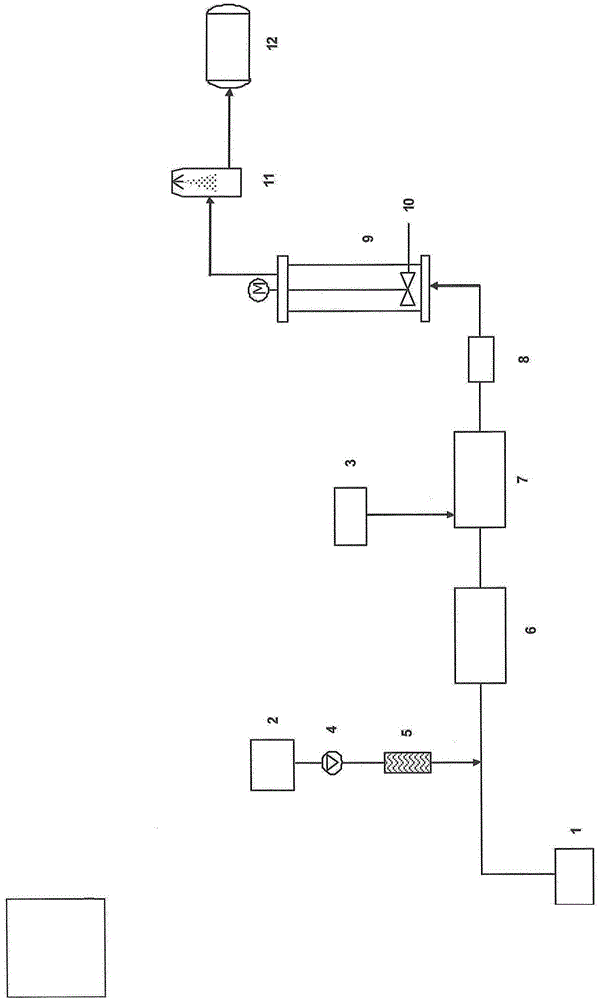

Continuous producing device and method of phosphorus pentafluoride

InactiveCN102674275AGuaranteed continuous productionThe production process is safe and controllablePhosphorus halides/oxyhalidesSingle substanceEngineering

The invention provides a continuous producing device of phosphorus pentafluoride, comprising a phosphorus single-substance closing silo, a spiral conveyer, a fluorine-phosphorus reactor, a cooling pipeline and a multi-grade filter. The continuous producing device of phosphorus pentafluoride is characterized in that the upper end of the spiral conveyer is connected to the lower end of the phosphorus single-substance closing silo, the tail end of the spiral conveyer is connected to the upper part of the fluorine-phosphorus reactor; one end of the fluorine-phosphorus reactor is connected with the cooling pipeline, and the other end of the cooling pipeline is connected with the multi-grade filter. The invention further provides a method for continuously producing phosphorus pentafluoride by using the device; the high-purity phosphorus pentafluoride gas is obtained by pre-reaction, continuous reaction, cooling and multi-grade filtering. According to the continuous producing device, the continuous production of phosphorus pentafluoride is realized; the continuous producing device has the advantages of being high in production efficiency, simple, safe and reliable in operation and good in product quality; the product purity can reach 99.8% above; therefore, the continuous producing device can be directly applied to the production of the lithium hexafluorophosphate.

Owner:ZHEJIANG KAISN FLUOROCHEM +1

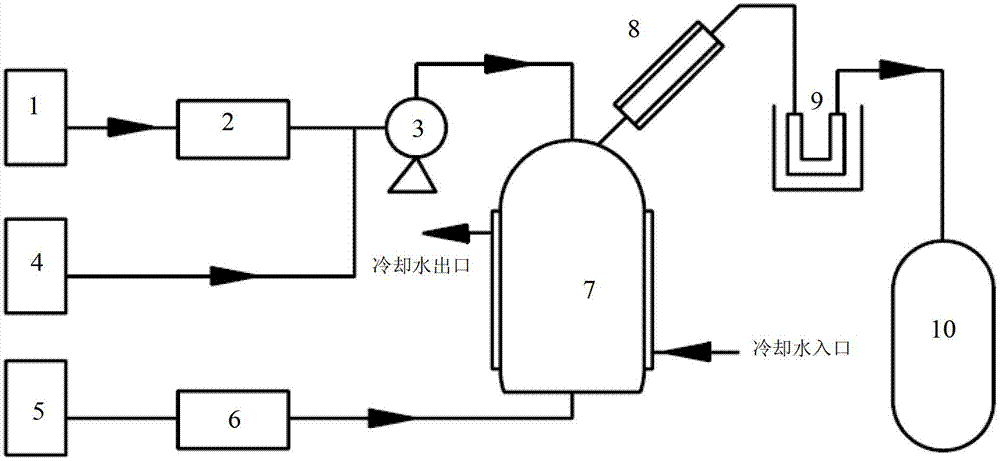

Continuous production system of lithium hexafluorophosphate

ActiveCN110683562AQuick responseShorten the timeSecondary cellsLithium hexafluorophosphateVapor–liquid separatorPhysical chemistry

The invention relates to a continuous production system of lithium hexafluorophosphate. The continuous production system comprises a phosphorus pentafluoride generator (2), a micro-channel reactor A (3), a gas-liquid separator A (4), a micro-channel reactor B (6) and a gas-liquid separator B (7), the gas generated by the phosphorus pentafluoride generator (2) is introduced into the micro-channel reactor A (3), the material output by the micro-channel reactor A (3) enters the gas-liquid separator A (4), the gas separated by the gas-liquid separator A (4) enters the micro-channel reactor B (6),and is used as a reaction raw material so as to continuously react, the material output by the micro-channel reactor B (6) enters the gas-liquid separator B (7), and a liquid component is separated out by the gas-liquid separator B (7) and is conveyed into the micro-channel reactor A (3). According to the invention, the raw materials and the by-products are recycled, so that the conversion rate and the utilization rate of the raw materials are improved, and the cost is reduced.

Owner:SINOCHEM LANTIAN +2

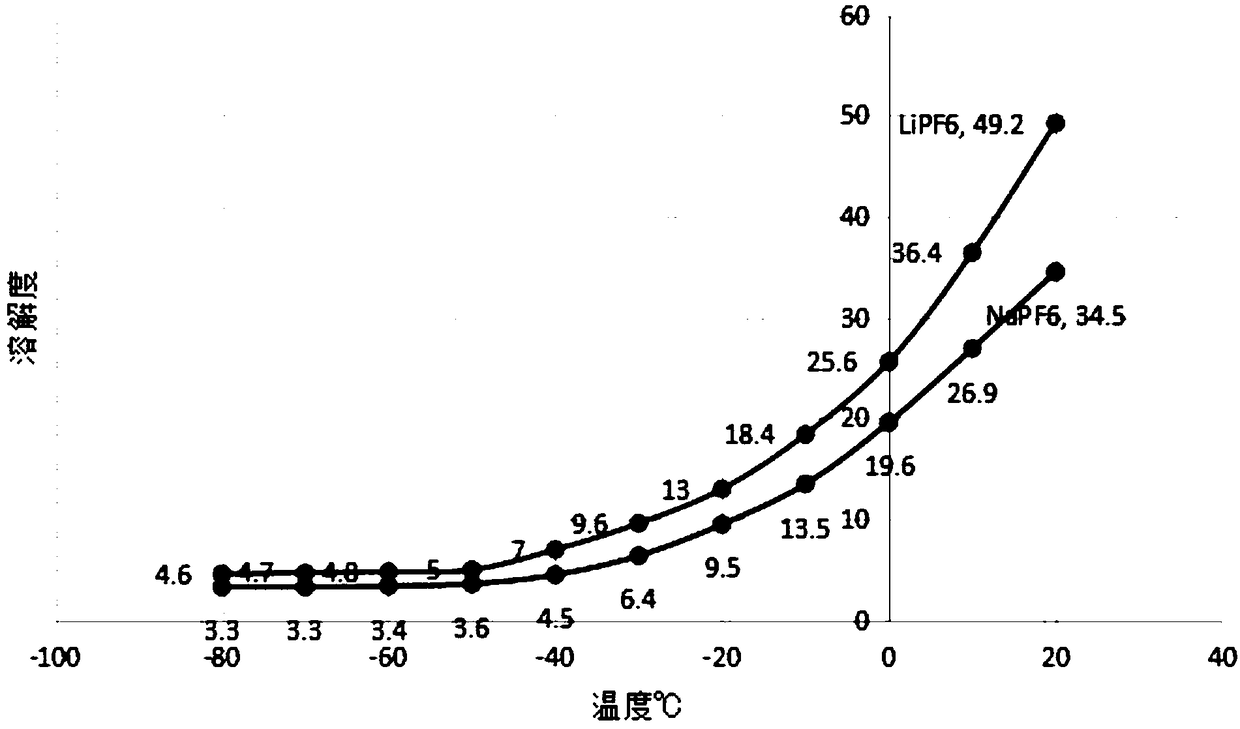

Preparation method of sodium hexafluorophosphate

InactiveCN108946769AHigh purityIncrease productionSodium/potassium compoundsProcess equipmentSodium-ion battery

The invention discloses a preparation method of sodium hexafluorophosphate. The preparation method comprises the following steps: (1) introducing phosphorus pentafluoride gas into a reaction kettle containing lithium fluoride and hydrogen fluoride liquid for reaction, so as to obtain a sodium hexafluorophosphate solution; (2) carrying out crystallization under a stirring condition; and (3) drying.The preparation method has the advantages that the reaction conditions are mild, the yield is high, the process equipment is simple, and a high-purity sodium hexafluorophosphate target product can beprepared. Sodium hexafluorophosphate can be used as sodium salt for sodium-ion battery electrolyte.

Owner:MORITA NEW ENERGY MATERIALS ZHANGJIAGANG CO LTD

Production of high-purity lithium difluorophosphate

InactiveCN104684845AHigh purityPhosphorus halides/oxyhalidesSecondary cellsDifluorophosphateOrganic solvent

Producing lithium fluorophosphate, comprises contacting the solid lithium fluoride having a water content of more than 1500 ppm, preferably 5000-15000 ppm with gas containing phosphorus pentafluoride. An independent claim is included for lithium difluorophosphate having a purity of 99.9-99.9995 wt.%, preferably 99.97-99.9995 based on anhydrous product.

Owner:LANXESS DEUTDCHLAND GMBH

Synthetic process of lithium hexafluorophosphate

InactiveCN101423207AImprove mixing efficiencyQuick responsePhosphorus compoundsMicro bubbleGas phase

The invention discloses a synthesis process of a lithium hexafluorophosphate non-aqueous solvent method. The gas-phase phosphorus pentafluoride is arranged in a super-micro bubble generation device to generate micro-bubbles with the diameter of 0.1-2000 microns; subsequently, the phosphorus pentafluoride reacts with lithium fluoride which is dissolved in anhydrous hydrogen fluoride in advance in a reaction unit to generate a lithium hexafluorophosphate crude product which is frozen and then separated by a solid liquid separation device; the solid gained by separation is transferred to a drying device and dried, thus gaining the lithium hexafluorophosphate solid. The process has the advantages that the interface mixing efficiency is high, the reaction speed is high, the jamming phenomenon of solid outcome is not generated, the continuous production is easy to achieve, and the generated solid has uniform granularity and high purity.

Owner:张家港市亚源高新技术材料有限公司

Preparation of phosphorus pentafluoride

A process for the preparation of anhydrous high purity phosphorus pentafluoride in high yield. The process uses an excess of hydrogen fluoride in a reaction with a phosphoric acid to form hexafluorophosphoric acid followed by reaction with a sulfur based acid reactant in a reaction medium containing an excess of hydrogen fluoride.

Owner:LITHDYNE

Method for preparing high purity phosphorus pentafluoride gas

InactiveCN101391760AReduce moisture contentLow impurity contentPhosphorus halides/oxyhalidesOleumProcess equipment

The invention discloses a preparation method of high-pure phosphorus pentafluoride gas, which comprises: phosphorus pentoxide is put into a reaction container lined with PTFE and is introduced with anhydrous hydrogen fluoride, and the temperature is preserved to be minus 20 to 0 DEG C; according to the chemical reaction counting, the anhydrous hydrogen fluoride is overdosed by 50 to 60 percent; the reaction is carried out for 3 to 5 hours. After the reaction is completed, 60 percent of oleum is added in an intermittent way with stirring and the dosage of the oleum is 35 to 40 percent more than a theoretic value. The intermediate outcome of the reaction is heated for decomposing under the temperature of 120 to 150 DEG C so as to generate the phosphorus pentafluoride; the product is guided into a condenser for cooling the impurity and then the high-pure phosphorus pentafluoride is obtained. The content of PF<5> obtained by the method is greater than 99.9 percent, the content of impurity is low, the water content is less than 10ppm, HF content is less than 50ppm; moreover, the process equipment is comparatively simple, thus being beneficial to the industrial manufacturing.

Owner:CENT SOUTH UNIV

Lithium difluorobisoxalate phosphate preparation method, non-aqueous electrolyte and battery

ActiveCN109824726AImprove discharge rateLower requirementGroup 5/15 element organic compoundsLi-accumulatorsPhosphateDistillation

The invention relates to the technical field of energy storage batteries, and provides a lithium difluorobisoxalate phosphate preparation method which includes the steps: dissolving lithium difluoroborate by non-aqueous solvents to obtain first solution; heating the first solution to reach the temperature of 50-130 DEG C, leading phosphorus pentafluoride gas into the first solution and performingreaction to obtain lithium difluorobisoxalate phosphate solution; performing reduced pressure distillation on the lithium difluorobisoxalate phosphate solution and adding inert solvent crystals to obtain lithium difluorobisoxalate phosphate. Raw materials needed by the preparation method are low in cost and easy to obtain, and a reaction product is the lithium difluorobisoxalate phosphate, so thatthe prepared product is high in purify and yield. The technological process of the method is simple, requirements for equipment and environments are low, and the method is suitable for industrial production and application. The invention further provides non-aqueous electrolyte and a battery comprising the same. The non-aqueous electrolyte comprises the lithium difluorobisoxalate phosphate prepared by the method. The non-aqueous electrolyte is good in conductivity and electrochemically stable.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Method for preparing high purity lithium hexafluorophosphate

InactiveCN101391762ANo pollution in the processHigh purityPhosphorus compoundsAcetonitrileHeating furnace

The invention discloses a lithium hexafluorophosphate preparation method, which comprises the following steps: anhydrous acetonitrile is put into a sealed pressure heating furnace, simultaneously solid high-pure nano lithium fluoride is added into the furnace, and after dried inert gas is adopted to drive air out from the furnace a suspension is formed under sealed stirring condition; compressed phosphorus pentafluoride gas is introduced in and the lithium hexafluorophosphate is synthesized continually under the sealed stirring condition. The product prepared by the method has high purification, the content of LiPF<6> is greater than 99.9 percent, the water content is less than 10ppm, the content of HF is less than 50ppm and the content of total impurity metal is less than 50ppm; moreover, the technique is simple, the preparation process is environment-friendly, thus having extremely high industrial popularization value.

Owner:CENT SOUTH UNIV

Method for producing high-purity lithium hexafluorophosphate

InactiveCN102515132ASimple processImprove performancePhosphorus compoundsPhysical chemistryHydrogen chloride

The invention discloses a method for producing high-purity lithium hexafluorophosphate, comprising the following steps: 1) reacting hydrogen fluoride with phosphorus pentachloride to prepare a mixed gas of phosphorus pentafluoride and hydrogen chloride, removing impurities by letting the mixed gas pass through a washing device; 2) dissolving lithium fluoride in hydrogen fluoride to form a hydrogen fluoride solution of lithium fluoride; and 3) reacting lithium fluoride solution with phosphorus pentafluoride in an absorption reactor to form a lithium hexafluorophosphate solution, carrying out crystallization, separating and drying to obtain a high-purity lithium hexafluorophosphate solid.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Preparation method of lithium hexafluorophosphate

InactiveCN102381695AHigh purityReduce moisture contentPhosphorus compoundsOrganic solventMetal impurities

The invention discloses a preparation method of lithium hexafluorophosphate, comprising the following steps of: (1) dissolving a phosphorus pentoxide solid and dispersing in an organic solvent to prepare a mixed solution with the phosphorus pentoxide content of 1-100wt%, adding a fluorine compound with fluorine and phosphorus in the mass ratio of (4.0-6.0):1, controlling the reaction temperature between 30 DEG C below zero and 240 DEG C to prepare a phosphorus pentafluoride gas and drying; (2) suspending a lithium fluoride solid in the organic solvent to prepare a lithium fluoride suspension with fluorine and phosphorus in the mass ratio of 1: (0.5-2); (3) sufficiently reacting and enriching the prepared phosphorus pentafluoride gas and the lithium fluoride suspension; (4) concentrating and separating to obtain a solid and drying; (5) saturating and dissolving the dried solid in the organic solvent to obtain a clear solution; and (6) repeating the step (4) to obtain the lithium hexafluorophosphate. The lithium hexafluorophosphate prepared by using the method provided by the invention has high purification, small water content and low content of free acid and metal impurities.

Owner:四川省黄铭锂能源新材料有限公司

Technology for synthesizing lithium hexafluorophosphate

InactiveCN102502566AEnsure reliabilityIncrease profitPhosphorus compoundsGas phasePhysical chemistry

The invention discloses a technology for synthesizing lithium hexafluorophosphate, which uses phosphorus pentafluoride, lithium fluoride and anhydrous hydrogen fluoride as raw material. The method comprises: sucking purified phosphorus pentafluoride into a mixing reactor by the gas phase suction of the mixing reactor, pre-reacting the purified phosphorus pentafluoride with a synthesis circulation solution, leading pre-reacted products and unreacted phosphorus pentafluoride into a synthesis kettle by the synthesis circulation solution, and obtaining lithium hexafluorophosphate by further reacted with lithium fluoride and anhydrous hydrogen fluoride. The synthesis circulation solution is led out from the synthesis kettle by a circulating pump and is pumped into the mixing reactor. The synthesized lithium hexafluorophosphate has good performance, and the technology is suitable for large-scale production.

Owner:YANAN BICON PHARMACEUTICAL LISTED COMPANY

Preparation method of lithium hexafluorophate

The invention discloses a preparation method of lithium hexafluorophate. The preparation method includes preparing gas mixture of phosphorus pentafluoride and hydrogen chloride; preparing anhydrous hydrogen fluoride mixed liquor containing lithium fluoride; realizing combination reaction of the gas mixture and the mixed liquor; realizing quick cooling crystallization of lithium hexafluorophate liquor; separating solid from liquid; realizing rotary vacuum drying; and finally obtaining lithium hexafluorophate crystal. The preparation method is a high-efficiency gas, solid and liquid three-phasereaction method, purity of the quality of products is guaranteed, simultaneously, yield further can be increased, the yield of the products can reach 90% at least, moisture and metal impurities in the products are effectively reduced, zero emission of the phosphorus element can be realized in aftertreatment, requirements of current national environmental protection policy are met, byproducts of hydrochloric acid and hydrofluoric acid can be sold to bring certain income, production cost is further lowered, the quality of the products is further improved by means of adopting high-specification equipment and materials, requirements of high-end electrolyte products can be met, and the preparation method has excellent practicality and can produce good economic benefit and social benefit.

Owner:JIANGSU XINTAI MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com