Technology for synthesizing lithium hexafluorophosphate

A technology of lithium hexafluorophosphate and synthesis process, which is applied in the direction of phosphorus compounds, inorganic chemistry, non-metallic elements, etc., and can solve problems such as difficulty in realizing continuous production, automatic large-scale production, low utilization rate of phosphorus pentafluoride, and easy blockage of ventilation pipelines, etc. Achieve the effects of increasing travel and residence time, saving device investment costs, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

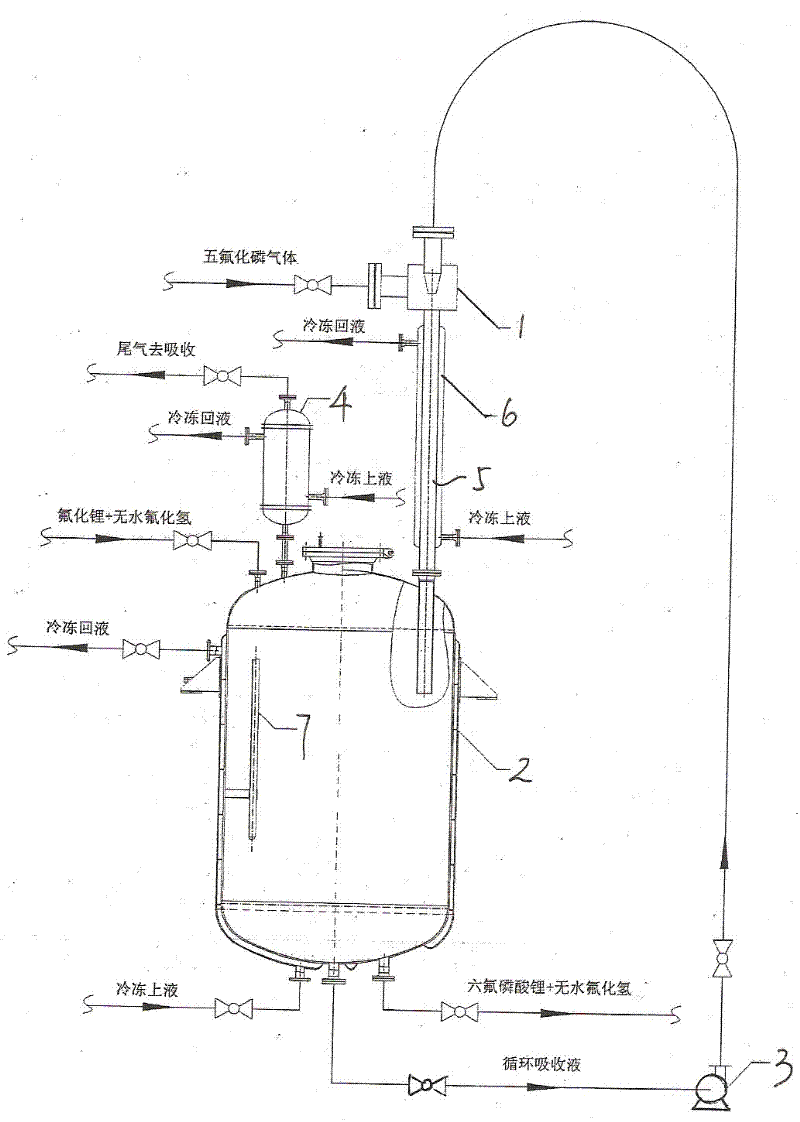

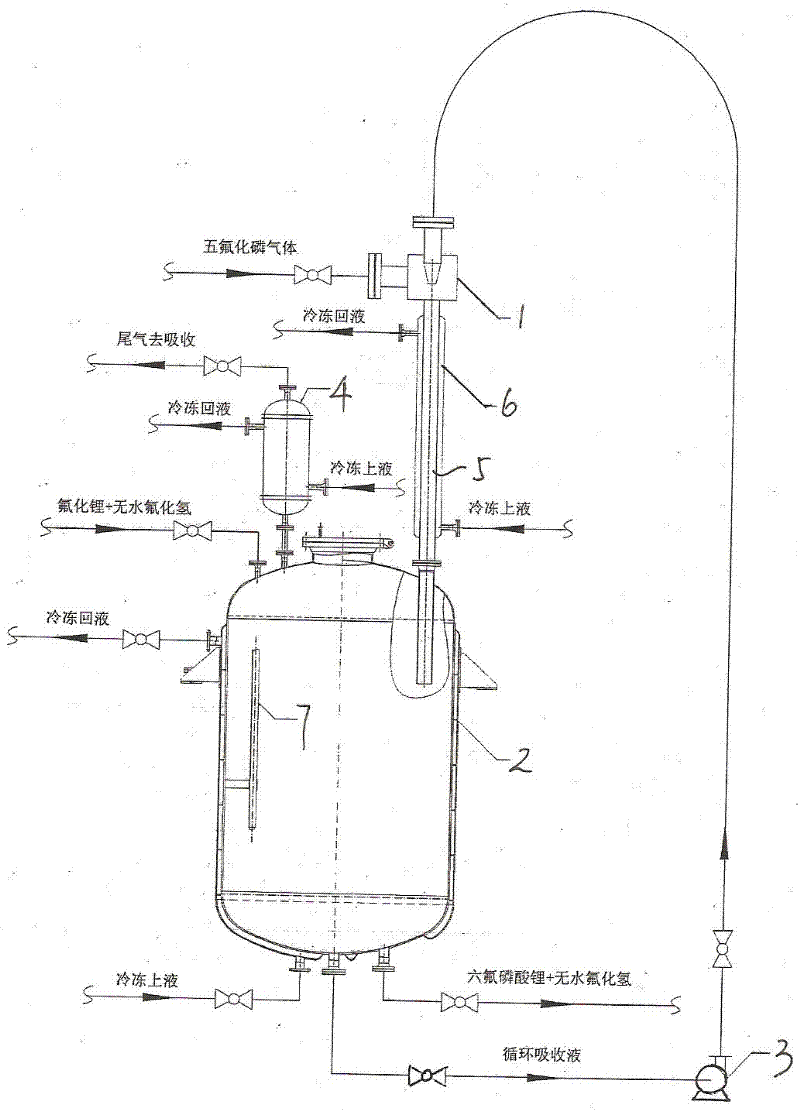

[0012] A synthesis process of lithium hexafluorophosphate. Lithium hexafluorophosphate is prepared by reacting phosphorus pentafluoride, lithium fluoride, and anhydrous hydrogen fluoride as raw materials. The purified phosphorus pentafluoride enters the mixing reactor 1 through the gas phase suction of the mixing reactor, and is mixed with The synthetic circulating liquid is pre-reacted, and the pre-reaction product and unreacted phosphorus pentafluoride are drained by the synthetic circulating liquid to the inside of the synthesis kettle 2 for further reaction with lithium fluoride and anhydrous hydrogen fluoride to synthesize lithium hexafluorophosphate; the synthetic circulating liquid is prepared by Circulation pump 3 is drawn from the synthesis kettle and pumped into the mixing reactor.

[0013] The circulation pump that draws out the synthetic circulation liquid in the synthesis tank and pumps it into the mixing reactor is installed at the bottom of the synthesis tank.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com