Automatic assembly line standard apparatus for electric energy meter calibration

A technology for the verification of electric energy meters and standard devices, which is applied in the direction of measuring devices, measuring electrical variables, instruments, etc., can solve the problems of no effective detection means for the reliability of electrical connections, damage to electric energy meters or standard devices of electric energy meters, and high labor intensity. Achieve the effect of improving verification/testing work efficiency, large contact surface and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

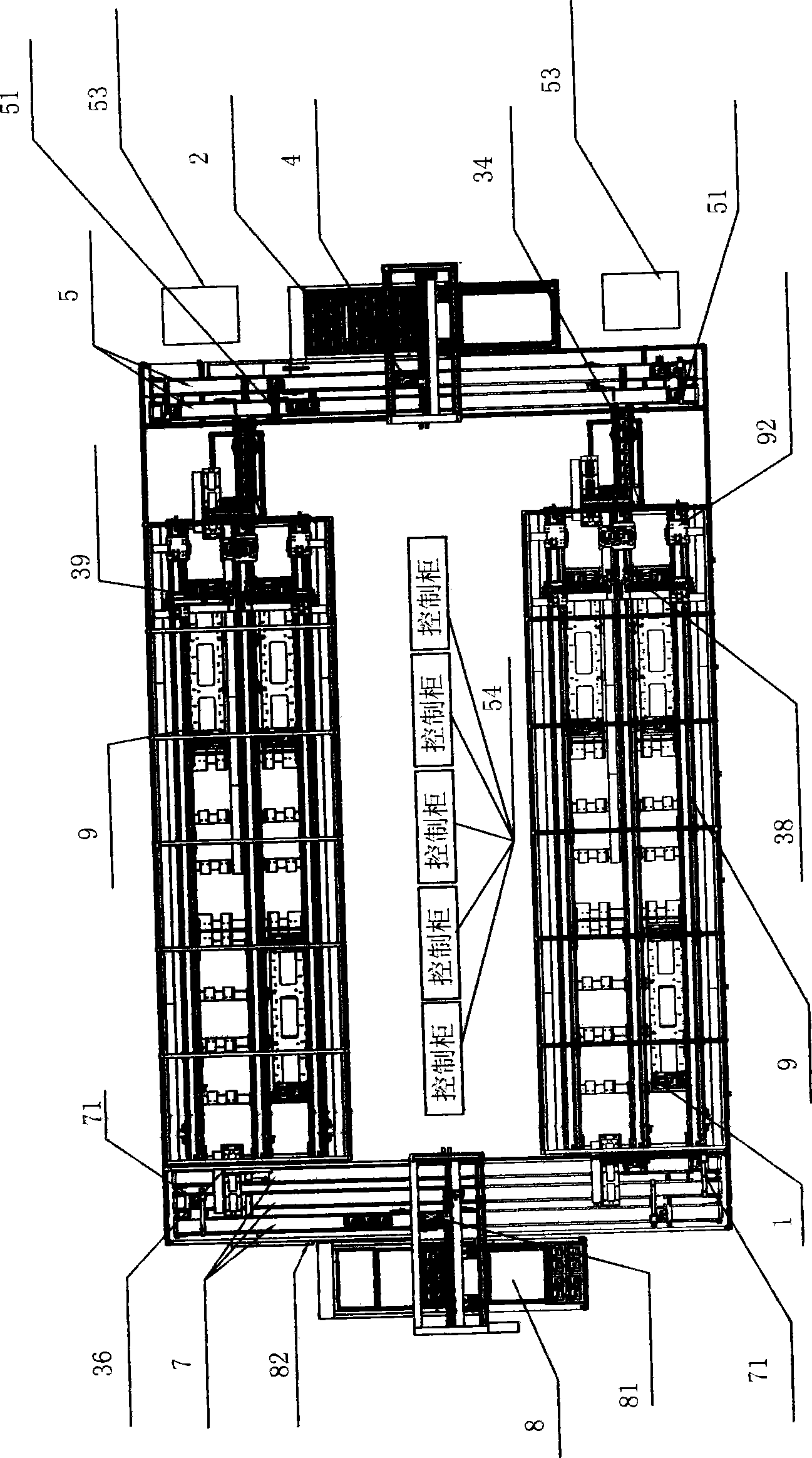

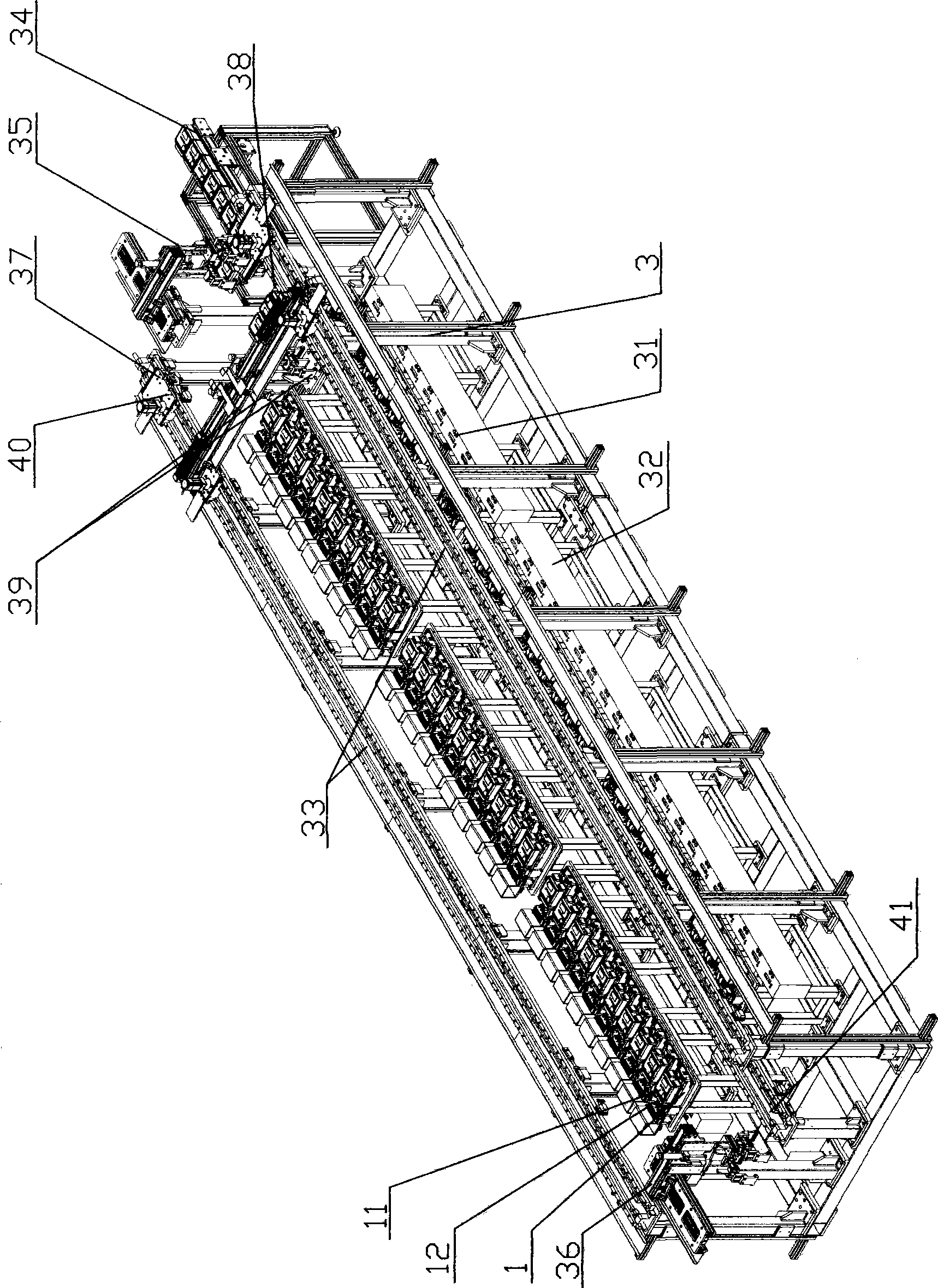

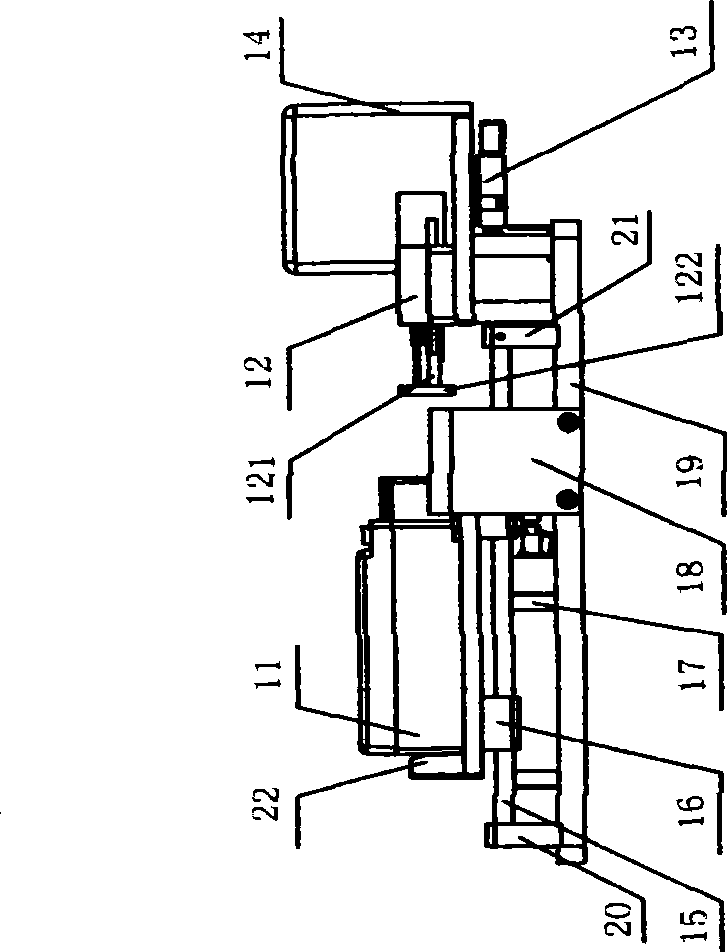

[0029] This embodiment is a standard device for automatic assembly line verification of electric energy meters, see Figures 1 to 9 As shown, it includes a loading platform 2, a feeding loop belt 5 and an automatic standard device 9 for an electric energy meter; the loading platform 2 is connected to a loading loop belt 5, and a retrieving manipulator 4 and a barcode reader 51 are installed on the loading loop belt 5 The feeding ring belt 5 is connected to the automatic standard device 9 of the electric energy meter, and the automatic standard device 9 of the electric energy meter is equipped with a liquid crystal identification device 92, an input verification buffer belt 34, a loading and unloading manipulator 35, an air pressure connection disconnecting device 1, and a liquid crystal image Recognition device 37, infrared temperature measuring device 40, translation grasping manipulator 39; Electric energy meter automatic standard device 9 is connected with blanking conveying...

Embodiment 2

[0040] A kind of electric energy meter verification automatic assembly line standard device, see Figure 1 to Figure 7 , Figure 10 to Figure 12 As shown, it includes a loading platform 2, a feeding loop belt 5 and an automatic standard device 9 for an electric energy meter; the loading platform 2 is connected to a loading loop belt 5, and a retrieving manipulator 4 and a barcode reader 51 are installed on the loading loop belt 5 The feeding ring belt 5 is connected to the automatic standard device 9 of the electric energy meter, and the automatic standard device 9 of the electric energy meter is equipped with a liquid crystal identification device 92, an input verification buffer belt 34, a loading and unloading manipulator 35, an air pressure connection disconnecting device 1, and a liquid crystal image Recognition device 37, infrared temperature measuring device 40, translation grasping manipulator 39; Electric energy meter automatic standard device 9 is connected with blan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com