Patents

Literature

36results about How to "The production process is safe and controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tissue engineering nerve graft prepared by biological printing technology and preparation method thereof

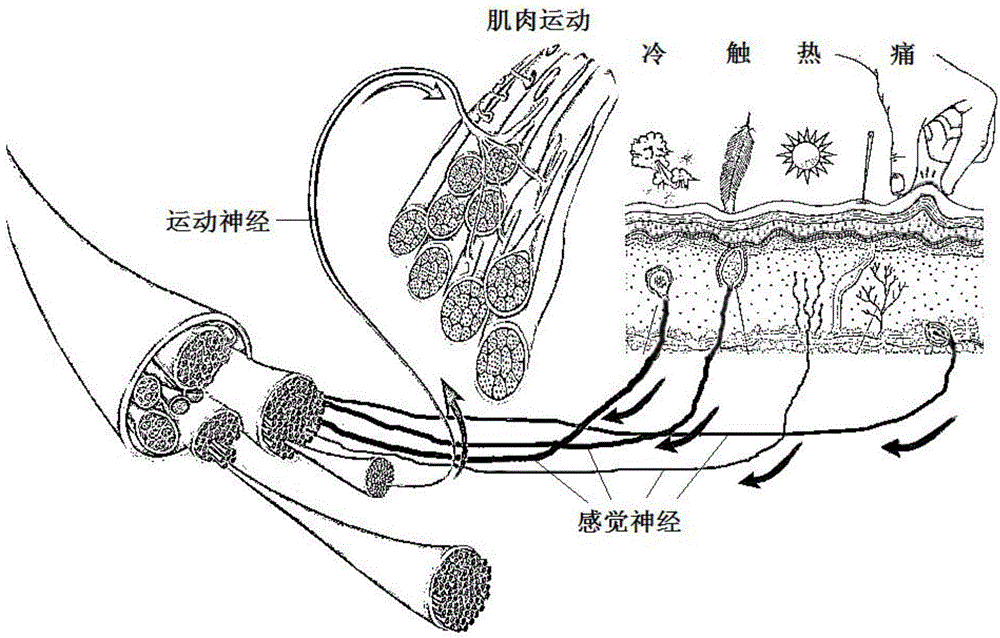

The invention provides a tissue engineering nerve graft based on a biological printing technology and a preparation method thereof. The tissue engineering nerve graft comprises an outer tube and a tube inside scaffolds, wherein trophic factors and / or cells can cover the inner surface and the outer surface. A high-fidelity printing operation is performed according to the actual nerve shape demand by utilizing the biological printing technology, a polymer solution is printed into the specified nerve graft in a three-dimensional way by using an ink-jet printer by adjusting the sizes and the quantity of the jet nozzles of the ink-jet printer, the distances from the jet nozzles to a bottom layer and the pulse frequency of a supercharger and writing a control program of specific printing, and the specified nerve graft is applied to treatment of peripheral nerve defect and spinal cord injury.

Owner:南通大学技术转移中心有限公司

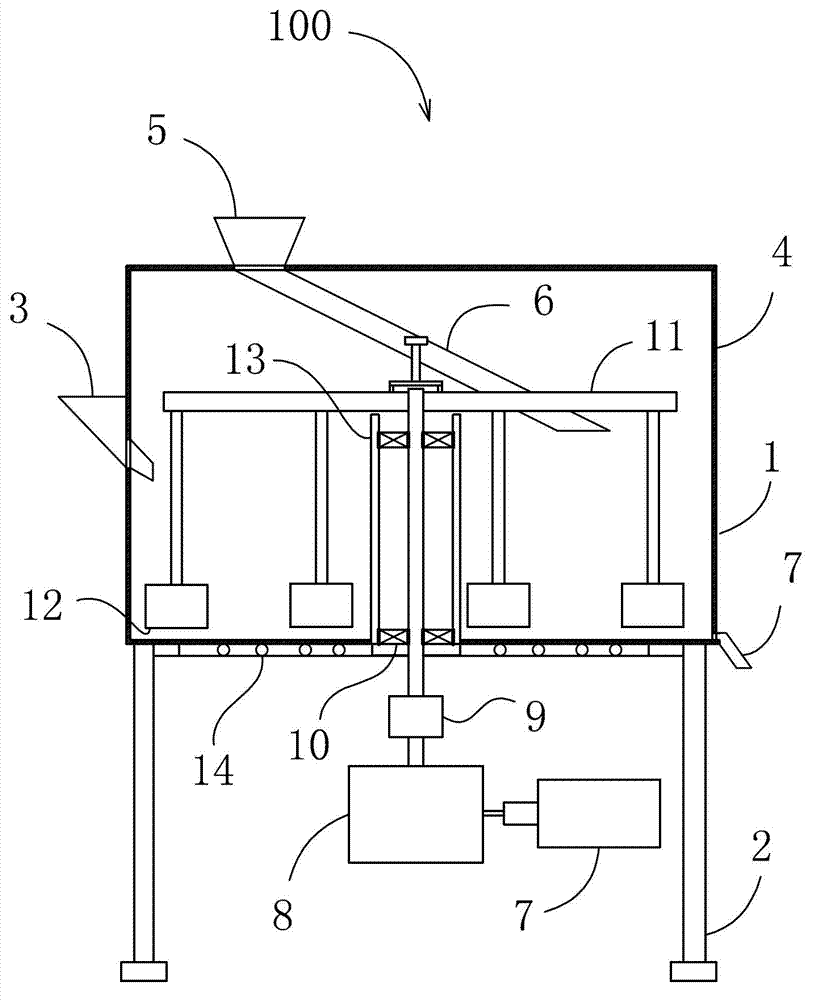

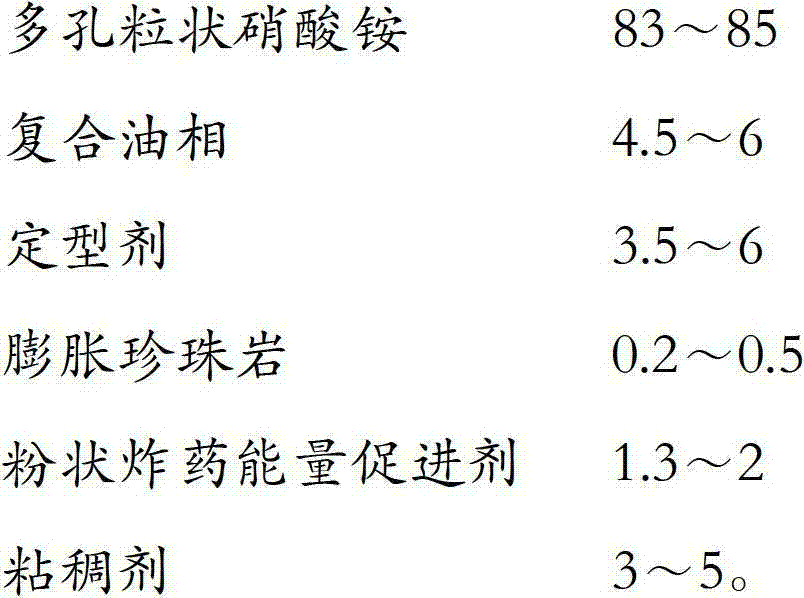

Viscous porous granulated ammonium nitrate fuel oil explosive and preparation method thereof

InactiveCN102924195AHigh detonation velocityImprove working abilityExplosivesEnvironmental resistanceFuel oil

The invention discloses viscous porous granulated ammonium nitrate fuel oil explosive and a preparation method thereof. The ammonium nitrate fuel oil explosive comprises the following constituents in weight percent: 83 to 85 percent of porous granulated ammonium nitrate, 4.5 to 6 percent of compound oil phase, 3.5 to 6 percent of tackifier, 0.2 to 0.5 percent of expanded perlite, 1.3 to 2 percent of powder type explosive energy accelerant, and 3 to 5 percent of thickener. The method comprises the following steps: a, adding the porous granulated ammonium nitrate into a viscous porous granulated ammonium nitrate fuel oil explosive mixer, then adding the compound oil phase, stirring for 2 to 4 minutes at normal temperature, mixing the porous granulated ammonium nitrate and the compound oil phase to be uniform, so as to form mixture A; b, adding the tackifier, the powder type explosive energy accelerant and the expanded perlite into the mixture A, stirring for 1 to 2 munities at normal temperature, mixing the mixture A, the tackifier, the powder type explosive energy accelerant and the expanded perlite to be uniform, so as to form mixture B; and c, adding the thickener into the mixture B, stirring for 1 to 2 munities at normal temperature, and mixing the mixture B and the thickener to be uniform, so as to form the viscous porous granulated ammonium nitrate fuel oil explosive, and then packaging the viscous porous granulated ammonium nitrate fuel oil explosive. The viscous porous granulated ammonium nitrate fuel oil explosive and the method have the advantages that preparation and storage processes are safe and controllable, the power capability is high, the storage period is long, and the explosive is efficient and environmentally friendly.

Owner:肖代军 +2

Preparation method and application thereof for cell-biological bracket compound based on biological print technology

InactiveCN103272288ABioprinting technology is simple and easyLow costSurgerySpinal cord lesionNerves regeneration

The invention provides a preparation method and the application thereof for a cell-biological bracket compound based on biological print technology. The cell-biological compound is formed by fibrous protein which is drawn out from the autoblood of a patient and processed by an ink-jet print technology. The surface and the interior of the cell-biological compound encompass one or more trophic factors and bone mesenchymal stem cells derived from self. According to the invention, the biological print technology is adopted, the appearance shape, cells and encompassing state model of the trophic factors can be designed according to requirements and practical situation, the cell-biological bracket compound is obtained through printing accurately, the fibrous protein and the bone mesenchymal stem cells are derived from self, so that the problem of immunological rejection is avoided, the trophic factors are cultivated in the bracket and are released slowly with the degradation of the bracket material, the cell-biological compound is applied to the spinal cord injured part to promote nerve regeneration and functional reconstruction on the injured part.

Owner:谢杨 +1

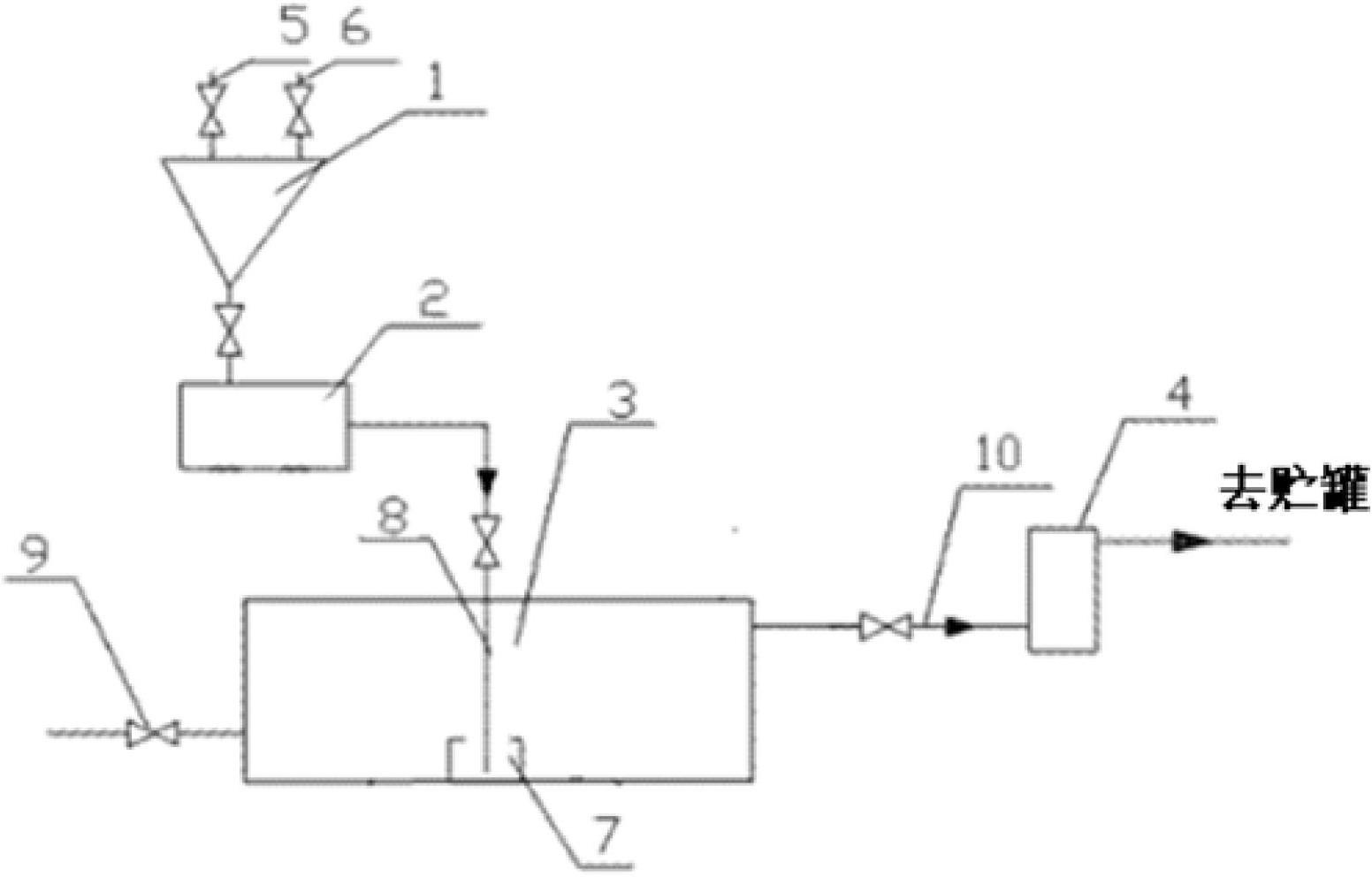

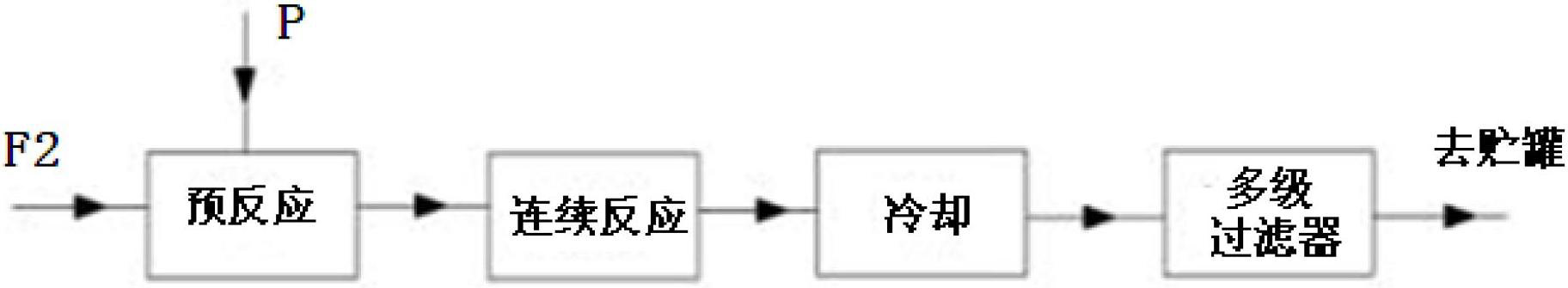

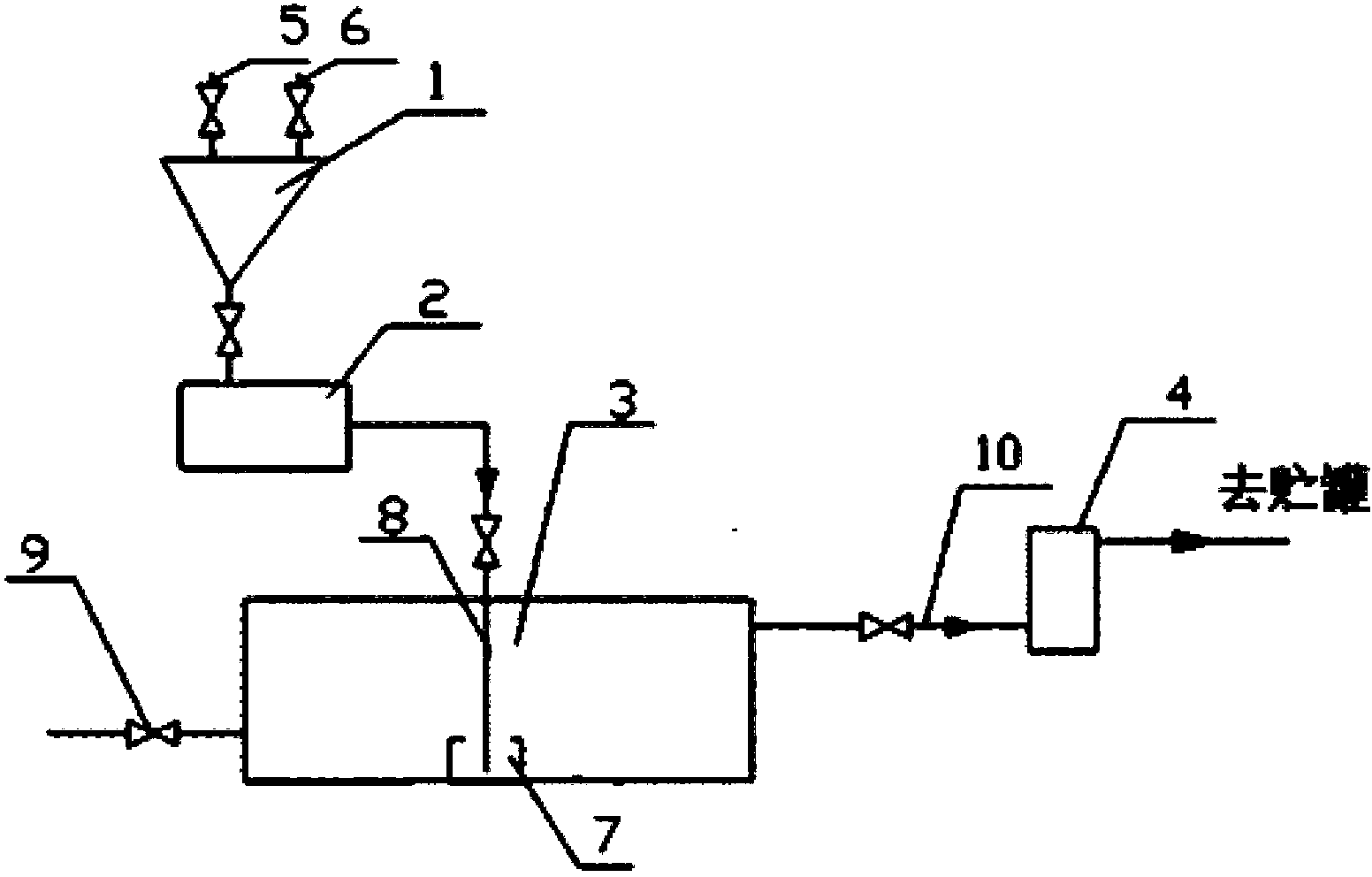

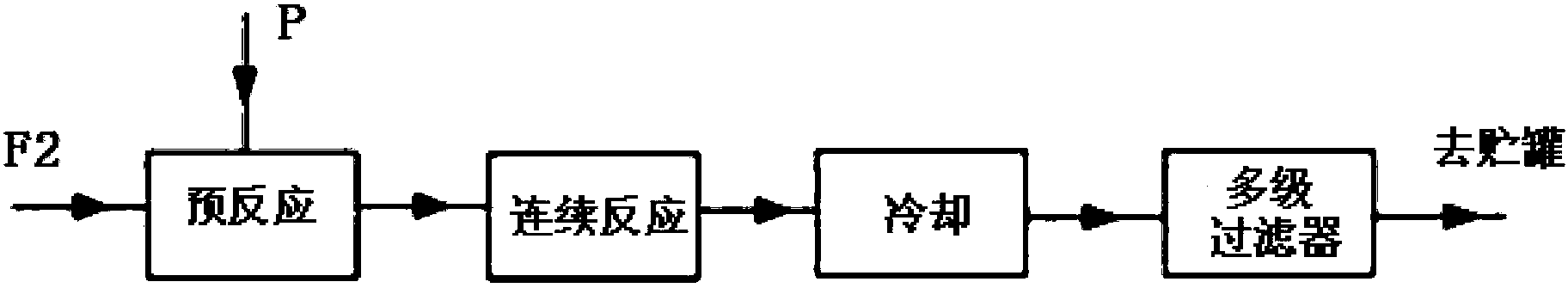

Continuous producing device and method of phosphorus pentafluoride

InactiveCN102674275AGuaranteed continuous productionThe production process is safe and controllablePhosphorus halides/oxyhalidesSingle substanceEngineering

The invention provides a continuous producing device of phosphorus pentafluoride, comprising a phosphorus single-substance closing silo, a spiral conveyer, a fluorine-phosphorus reactor, a cooling pipeline and a multi-grade filter. The continuous producing device of phosphorus pentafluoride is characterized in that the upper end of the spiral conveyer is connected to the lower end of the phosphorus single-substance closing silo, the tail end of the spiral conveyer is connected to the upper part of the fluorine-phosphorus reactor; one end of the fluorine-phosphorus reactor is connected with the cooling pipeline, and the other end of the cooling pipeline is connected with the multi-grade filter. The invention further provides a method for continuously producing phosphorus pentafluoride by using the device; the high-purity phosphorus pentafluoride gas is obtained by pre-reaction, continuous reaction, cooling and multi-grade filtering. According to the continuous producing device, the continuous production of phosphorus pentafluoride is realized; the continuous producing device has the advantages of being high in production efficiency, simple, safe and reliable in operation and good in product quality; the product purity can reach 99.8% above; therefore, the continuous producing device can be directly applied to the production of the lithium hexafluorophosphate.

Owner:ZHEJIANG KAISN FLUOROCHEM +1

Single-ingredient solvent-free type polyurethane bonding agent, and preparation method and application thereof

InactiveCN106883807ARaw materials are easy to getSimple compositionPolyureas/polyurethane adhesivesHydrogenAlcohol

The invention relates to the technical field of a polyurethane bonding agent, in particular to a single-ingredient solvent-free type polyurethane bonding agent, and a preparation method and application thereof. The single-ingredient solvent-free type polyurethane bonding agent is prepared from isocyanate terminated polyurethane prepolymers and optional additives; the isocyanate terminated polyurethane prepolymers are prepared from alcohol compounds containing reactive hydrogen and isocyanate through chain expansion reaction. The single-ingredient solvent-free type polyurethane bonding agent provided by the invention has the advantages that the raw materials can be easily obtained; the composition is simple; the production process is safe and controllable; good transparency, primary stickiness and bonding intensity are realized; the single-ingredient solvent-free type polyurethane bonding agent can be widely used in paper / plastic and paper / aluminum compounding.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

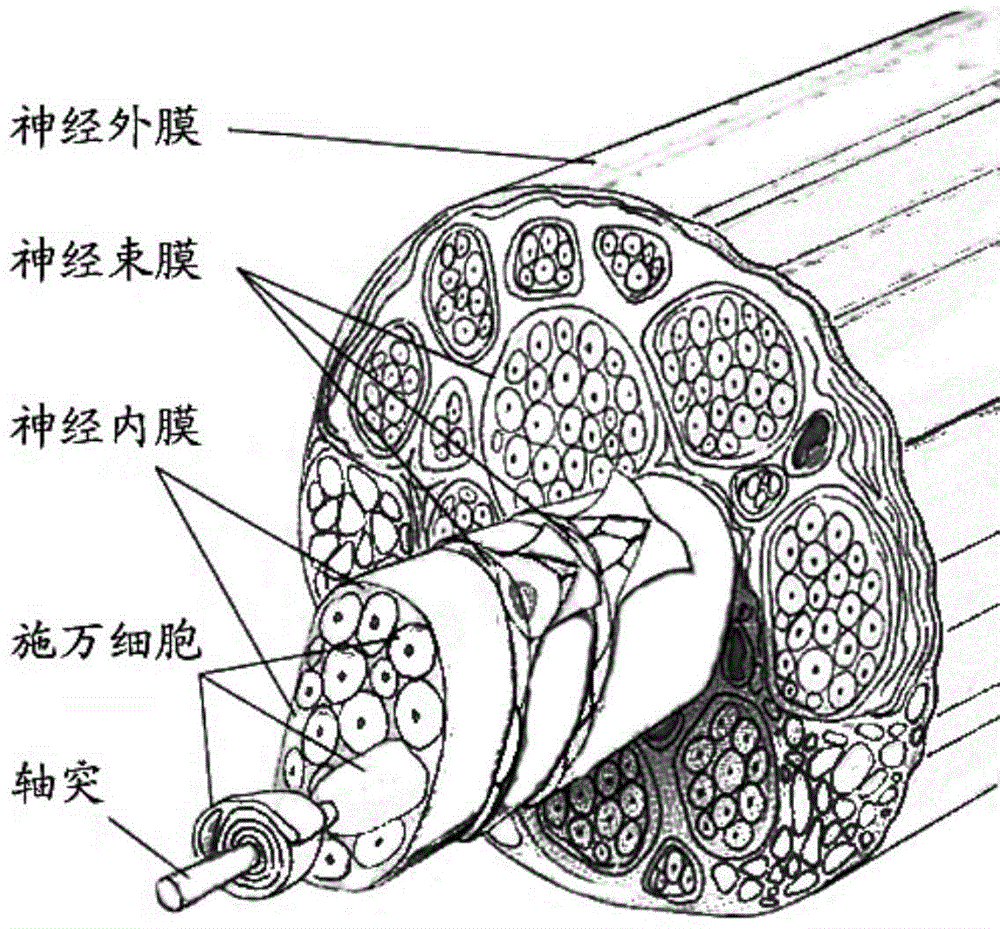

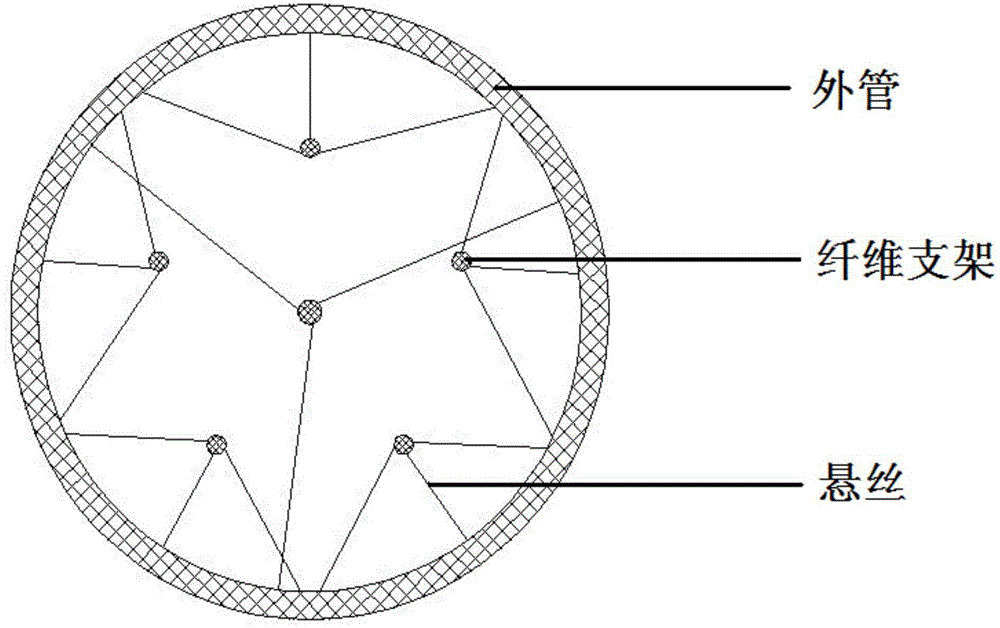

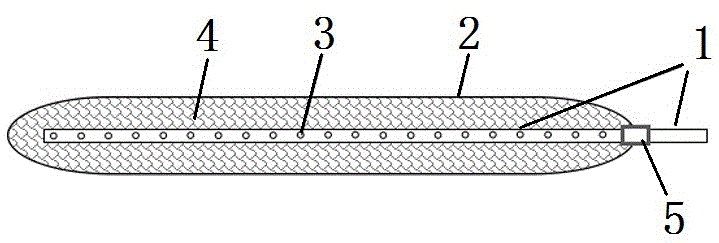

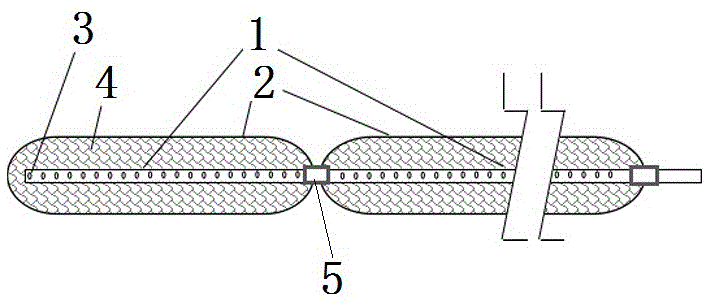

Tissue engineering nerve graft with suspension fiber scaffold and preparation method thereof

The invention discloses a tissue engineering nerve graft with a suspension fiber scaffold. The nerve graft comprises a conduit and tube fiber scaffolds. The nerve graft is characterized in that a plurality of suspensions are arranged on each fiber scaffold along the fiber length direction, and are connected with the inner wall of the conduit; and the fiber scaffolds are distributed and suspended in the conduit by virtue of the suspensions. By utilizing bio-printing technology, built-in microfilaments of a tissue engineering nerve graft can be stably and uniformly distributed in the conduit by utilizing the supporting force of the suspensions, and each fiber scaffold has an independent space to guarantee that nerve cells can directionally grow along the fiber scaffolds and cannot have error bridging, so that the success rate of operations can be greatly improved.

Owner:NANTONG UNIVERSITY

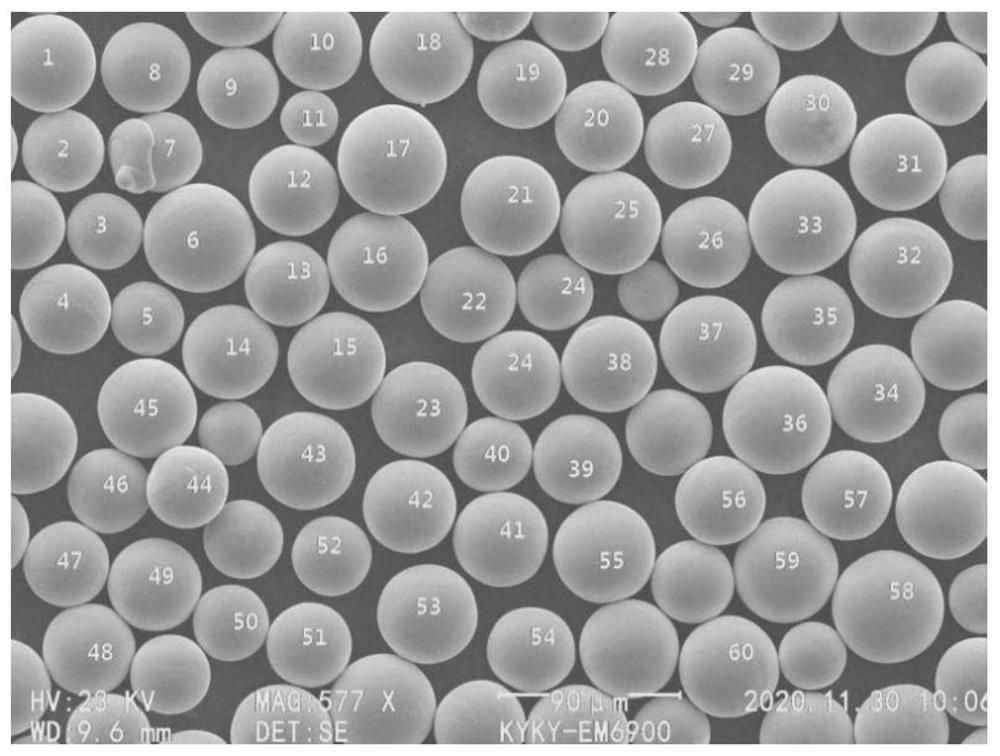

High-purity nickel-based high-temperature alloy and preparation method of spherical powder of high-purity nickel-based high-temperature alloy

PendingCN113817935AHigh purityHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyIngotSuperalloy

The invention discloses a high-purity nickel-based high-temperature alloy and a preparation method of spherical powder of the high-purity nickel-based high-temperature alloy. The alloy comprises the following steps of selecting high-purity metal ingredients, smelting in a vacuum induction suspension smelting furnace, realizing pure smelting by controlling parameters such as smelting vacuum degree, refining temperature, time and the like, then pouring to obtain a steel ingot, and preparing the steel ingot into a bar; carrying out smelting, atomizing and powdering on the bar through EIGA and PREP technologies to obtain spherical metal powder; adopting vibrating screening and airflow classification, and classifying spherical powder under the protection of inert gas. According to the method, the content of nonmetal impurities is effectively controlled through raw material smelting control, atomization process control and post-treatment control, so that chemical elements of the powder have extremely high purity, and the high-purity high-temperature alloy spherical powder is not prone to generating cracks and other defects in the subsequent laser additive printing and laser cladding process and is good in binding force, high in strength, good in toughness and good in mechanical property, and the powder can be used for repairing high-end parts.

Owner:盘星新型合金材料(常州)有限公司

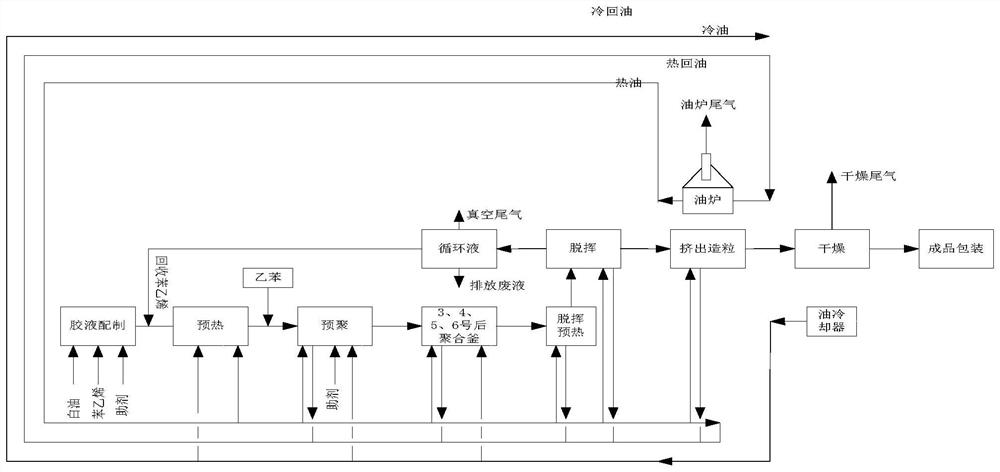

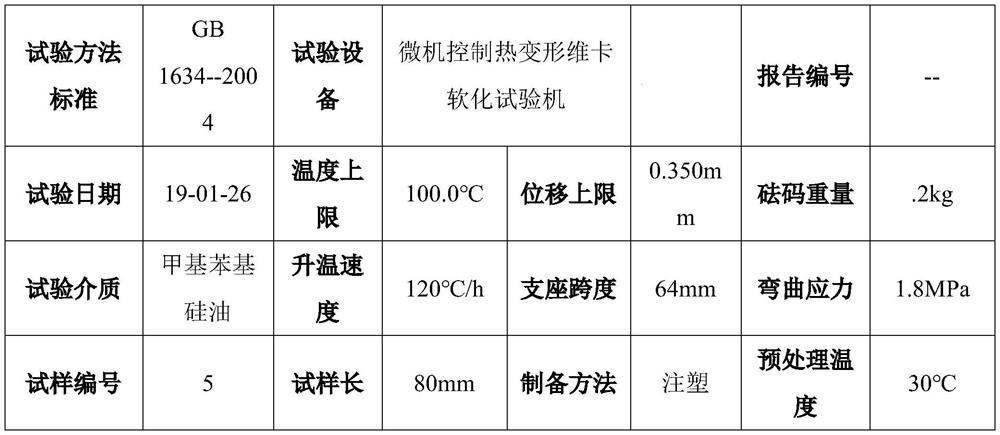

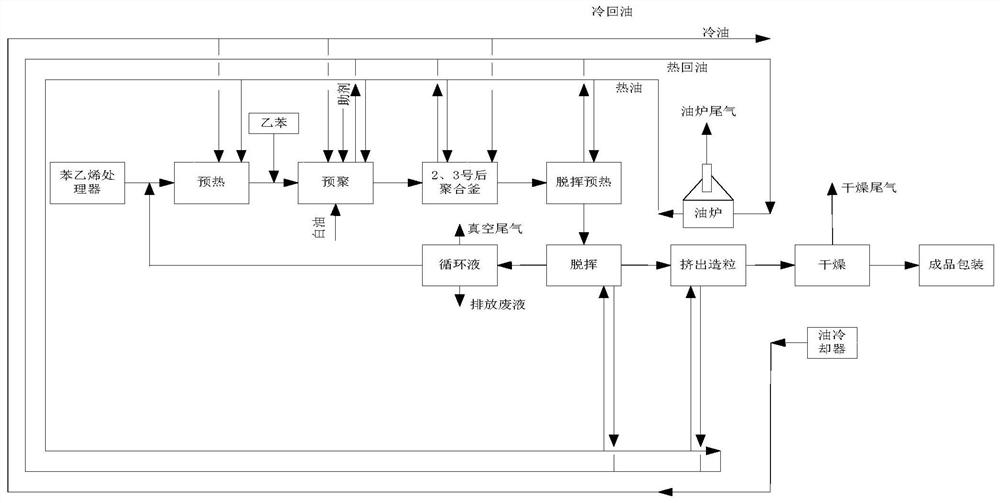

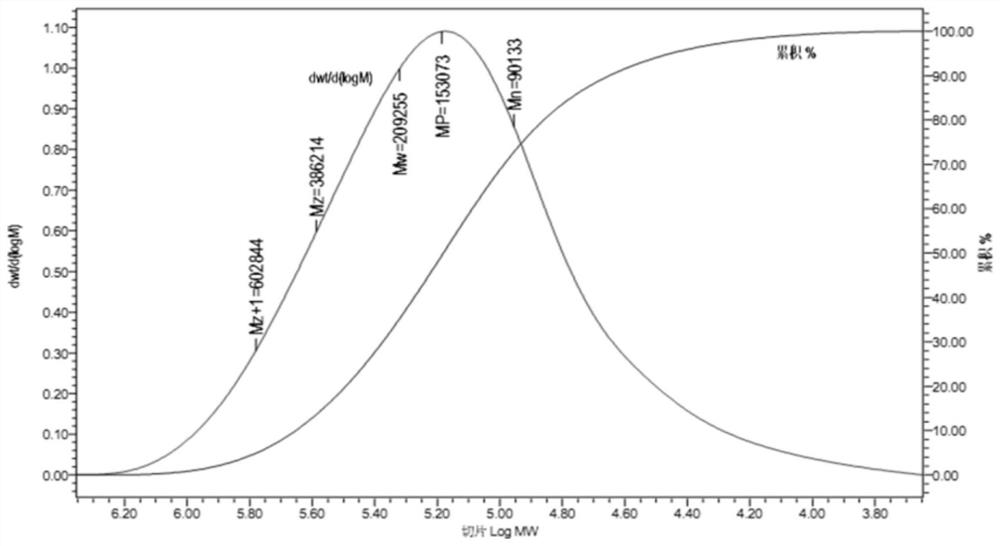

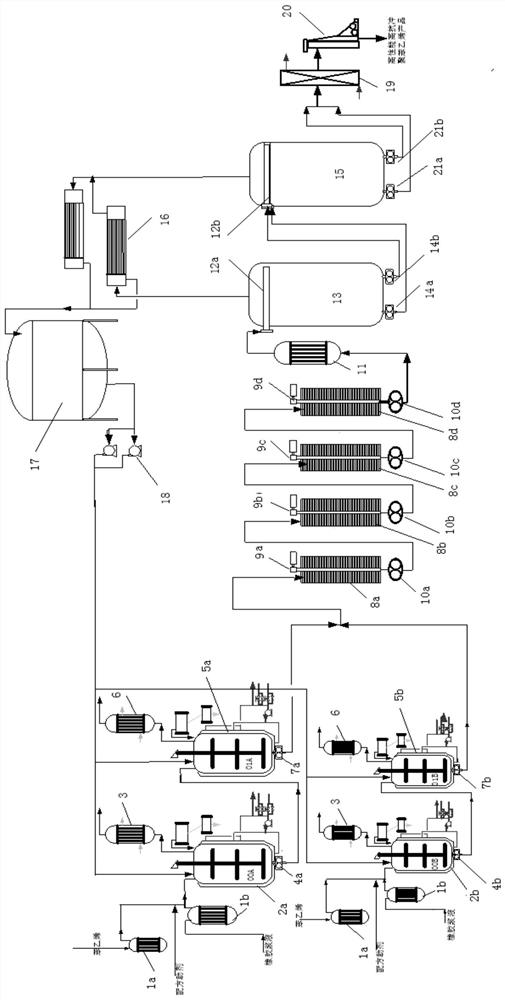

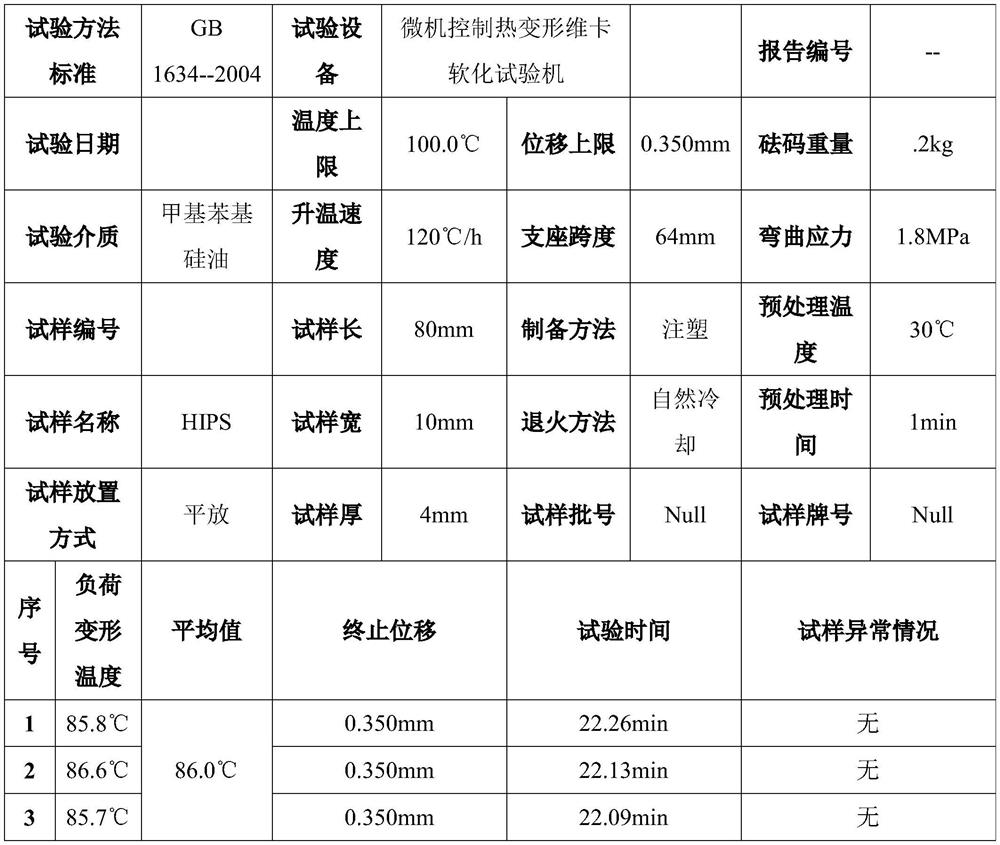

Impact polystyrene with capacity scale of 50,000 tons or above as well as equipment and production process of impact polystyrene

PendingCN112661910AImprove impact resistanceHigh tensile strengthChemical industryChemical/physical/physico-chemical stationary reactorsPolystyreneStearic acid

The invention discloses impact polystyrene with the capacity scale of 50,000 tons or above as well as equipment and a production process of the impact polystyrene. More than 90% of the components of the rubber modified polystyrene product are represented by the formula, n is the polymerization degree, the range of n is 600-7000, and n is different along with different types of products; in addition to the main components, the rubber composition also contains 3-10% of butadiene rubber for modification, 0-7% of white oil, 0-1% of an additive of stearate, and a small amount of an organic residue such as a monomer (the total amount is 800 ppm or less). The modified polystyrene has good impact strength, the vicat softening point is 92-106 DEG C, the tensile strength of the modified polystyrene is 22-45 MPa at normal temperature, and the modified polystyrene is a thermoplastic material with good toughness. No process waste water is generated in the production process, all the raw materials are recycled, a small amount of generated process waste gas reaches the standard and is discharged after being subjected to condensation and adsorption treatment of special equipment, and the good environment-friendly, energy-saving and consumption-reducing effects can be achieved.

Owner:江苏可立特工程设计研究有限公司

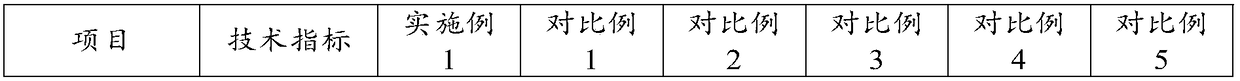

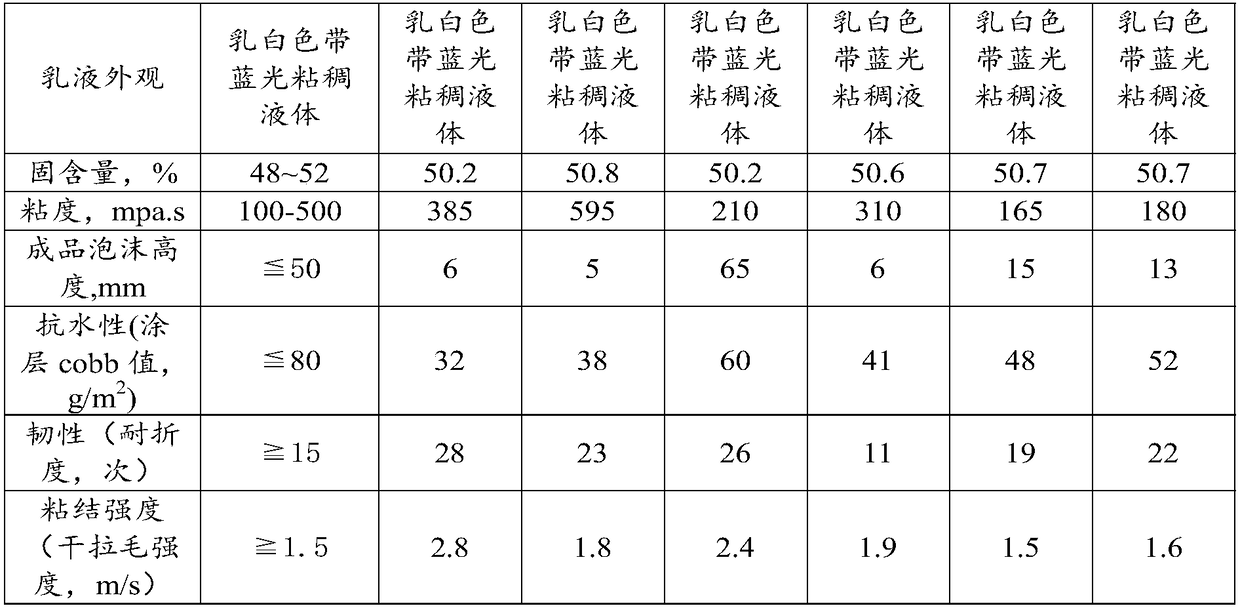

Starch-base styrene-acrylic emulsion and preparation method thereof

The invention relates to the field of styrene-acrylic emulsions and provides a starch-base styrene-acrylic emulsion and a preparation method thereof. The starch-base styrene-acrylic emulsion containsthe following components in percentage by mass: 10%-30% of anionic starch and a derivative of the anionic starch, 0.5%-1.5% of vegetable gum, 10%-30% of a monomer mixture, 0.2%-1.0% of an initiator, 0.5%-3% of an inner cross-linking agent, 0.1%-3% of an outer cross-linking agent, and 40%-70% of water. The preparation method comprises the following steps: mixing the anionic starch and the vegetablegum, heating for decoction, cooling, dropwise adding the monomer mixture, the initiator and the inner cross-linking agent, maintaining the temperature, and adjusting the pH value to 6-8; and coolingto the temperature below 60 DEG C, adding the outer cross-linking agent for generate cross-linking reaction, cooling, and filtering. According to the preparation method, the tenacity of the starch-base styrene-acrylic emulsion is improved, little bubble is produced in the preparation process, the production process is safe and controllable, and the prepared starch-base styrene-acrylic emulsion ishigh in bonding strength, good in tenacity, elasticity and water tolerance and low in cost.

Owner:浙江莱科新材料科技有限公司

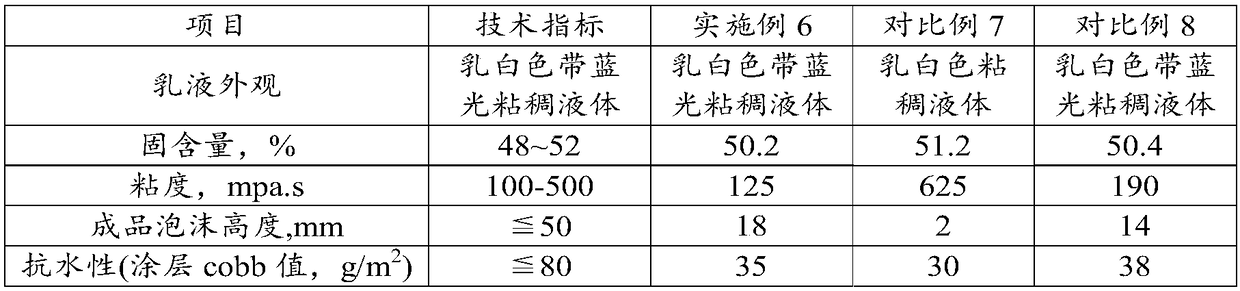

Light heat-insulation noise-reduction SiO2 aerogel material and preparation method thereof

InactiveCN110255567ALow costThe production process is safe and controllableSilicon compoundsAlkoxy groupLow density

The invention discloses a light heat-insulation noise-reduction SiO2 aerogel material and a preparation method thereof, and belongs to the technical field of high-performance porous materials. The preparation method comprises the following steps: carrying out an acid-base two-step method and standing replacement on a trifunctional silicon source and a cationic surfactant in a water solvent to obtain an aerogel material; wherein the molecule of the trifunctional silicon source comprises a non-polar group which does not participate in hydrolytic condensation and three alkoxy groups which participate in the hydrolytic condensation. In the preparation method designed by the invention, water is used as a solvent, a surfactant is added to reduce the surface tension of the solvent, and an ordered assembly is formed in an aqueous solution to provide a micro-reaction container for a hydrophobic trifunctional silicon source; therefore, the prepared SiO2 aerogel material has the advantages of low density, low heat conductivity coefficient, high transparency and the like.

Owner:NAVAL UNIV OF ENG PLA

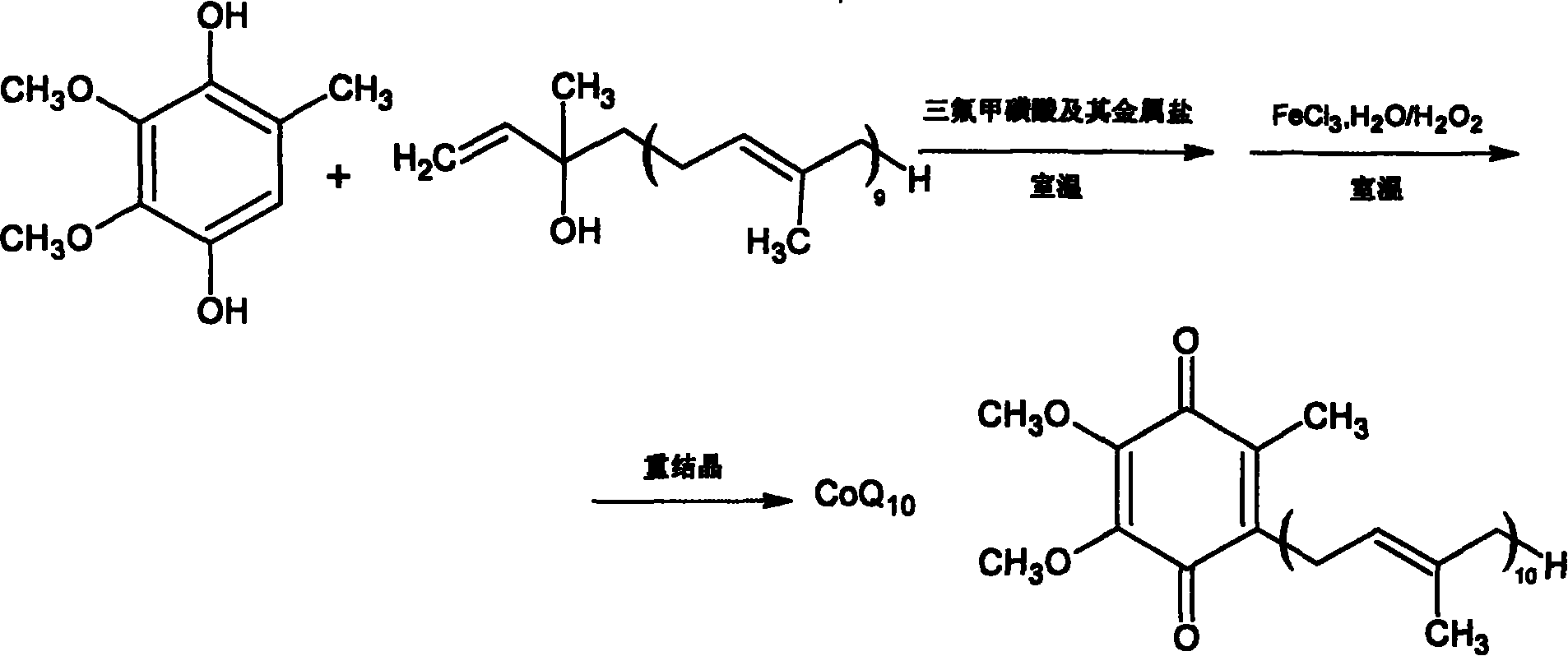

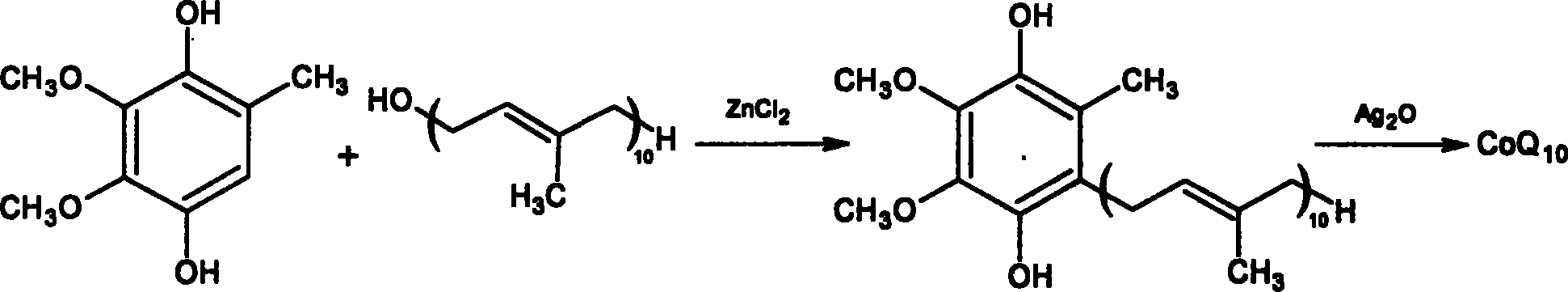

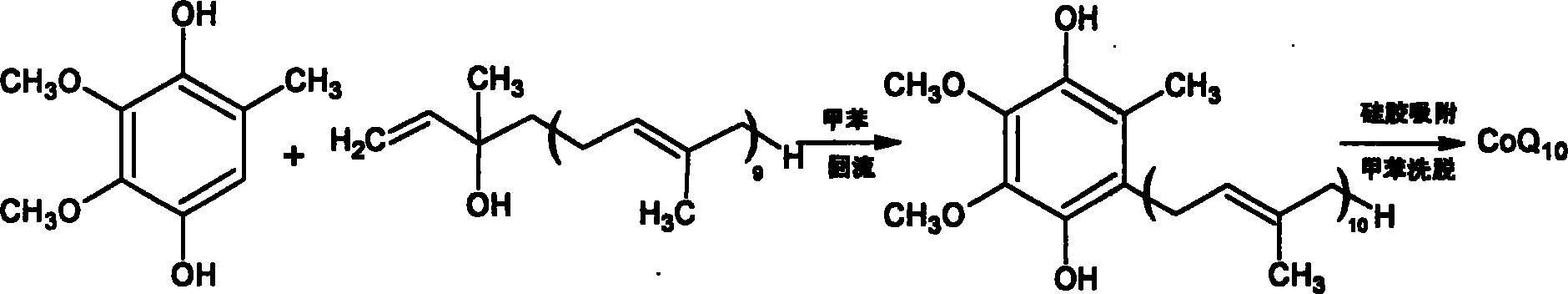

Coenzyme Q10 synthesizing process

InactiveCN1931818ASimple and fast operationEasy to purifyQuinone preparation by oxidationTriflic acidOxygen

The coenzyme Q10 synthesizing process with coenzyme Q0 hydroquinone and isodecyl alcohol deca-isopentyl alcohol of purity not lower than 95 % as material includes dewatering and condensation reaction at room temperature under the catalysis of trifluoro methane sulfonic acid in no oxygen environment to obtain coenzyme Q10 hydroquinone, the oxidation of the reacted product without passing through any treatment with hydrogen peroxide and water solution of ferric trichloride to obtain crude coenzyme Q10 product, and crystallization of the crude coenzyme Q10 product in acetone to obtain yellow coenzyme Q10 product powder in content over 99 % and yield over 65 %. The present invention has simple operation, easy purification of the product, high yield, mild reaction condition, safe and controllable production process and industrial production value.

Owner:KUNMING TONGFA IND

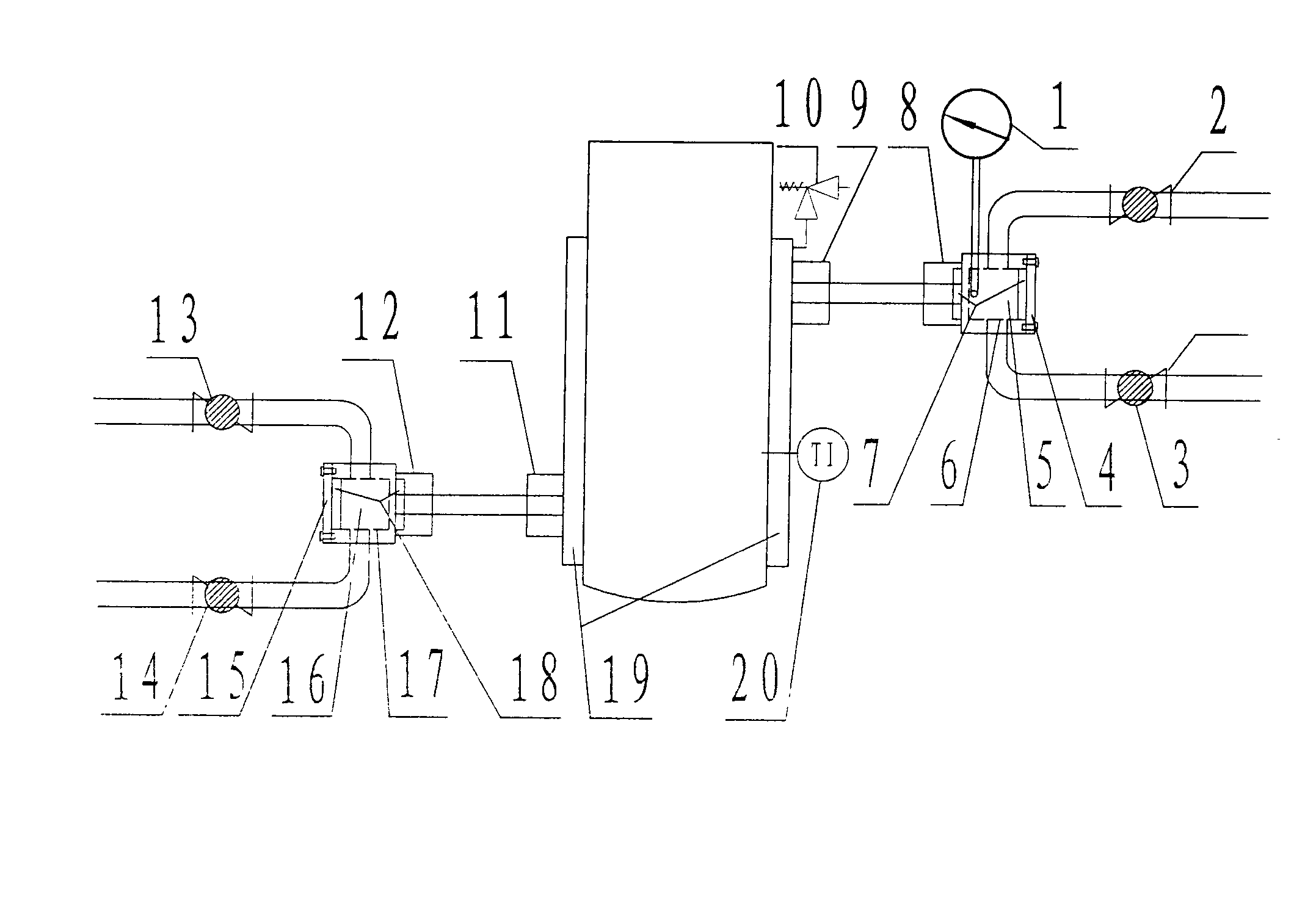

Cool/hot double-pipeline visible safety device for biological fermentation tank

InactiveCN103103105AThe production process is safe and controllableBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringSilica gel

The invention relates to a cool / hot double-pipeline visible safety device for a biological fermentation tank, belonging to the technical field of beer fermentation equipment. The technical scheme is as follows: the cool / hot double-pipeline visible safety device comprises a pressure meter, a hot water pipeline valve A, a cooling medium pipeline valve A, a sight glass sheet A, a sight glass A, a filter screen A, a silica gel sealing gasket A, a movable joint A, a movable joint B, a safety valve, a movable joint C, a movable joint D, a hot water pipeline valve B, a cooling medium pipeline valve B, a sight glass sheet B, a sight glass B, a filter screen B, a silica gel sealing gasket B, a fermentation tank jacket and a temperature indicating meter. In order to heat or cool the fermentation tank, the cooling medium or hot water pipeline valve is closed, and the hot water or cooling medium pipeline valve is opened; and the hot water or cooling medium heats or cools the fermentation tank through the hot water or cooling medium pipeline valve, sight glass and fermentation tank jacket. In the heating or cooling process, the flow state of the hot water or cooling medium can be observed through the sight glass, the pressure meter displays the pressure of the pipelines and jacket, and the pressure can be automatically relieved under the condition of overpressure, thereby ensuring the safe and controllable production process.

Owner:SHANDONG ZHONGDE EQUIP

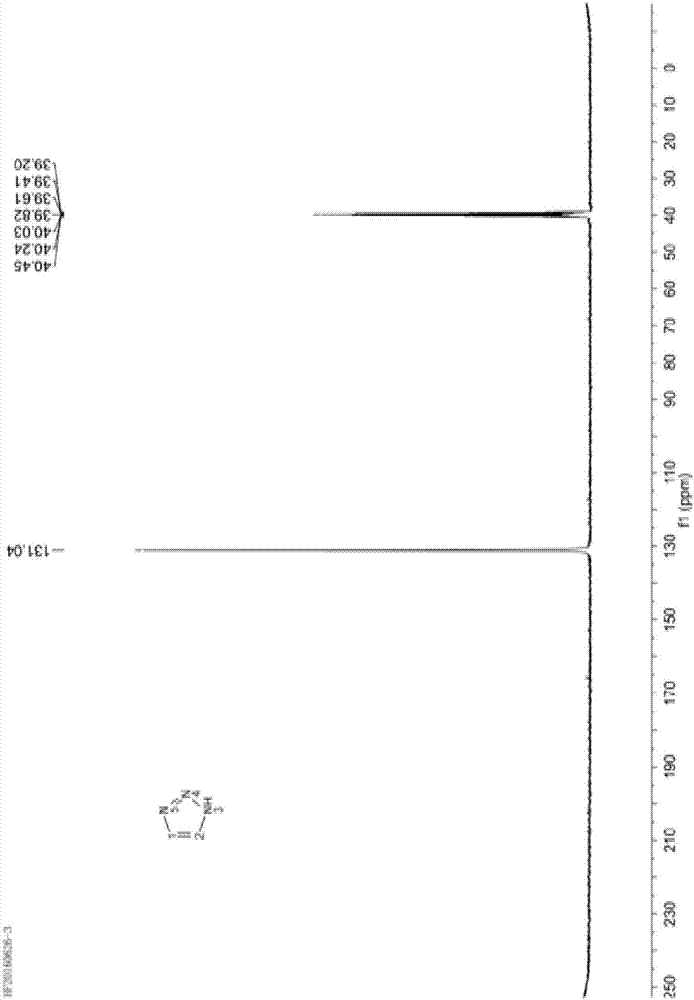

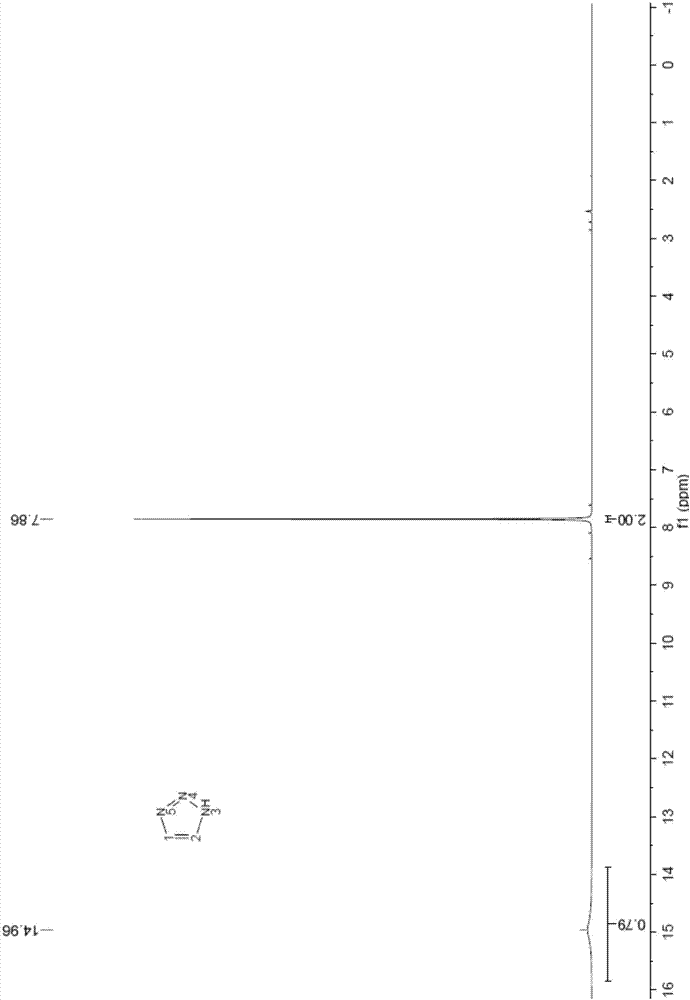

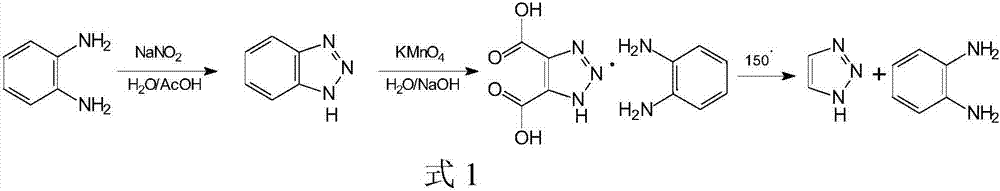

Preparation method of 1H-1, 2, 3-triazole

ActiveCN107382885AAchieve recyclingSuitable for industrialized mass productionOrganic chemistryCompound aProduction line

The invention discloses a preparation method of 1H-1, 2, 3-triazole. The preparation method comprises the following step: performing a reaction on a compound A and sodium nitrite in a solvent I, wherein the compound A is 1,2-diamido-ethylene, 1,2-diamido-ethylene salt or a mixture of 1,2-diamido-ethylene and 1,2-diamido-ethylene salt. Compared with the prior art, the preparation method has the beneficial effects that (1) a production line is short, the conversion rate of a target product is high, the utilization ratio of atoms is high, and the atom economy is high; (2) the molar yield is high, and the total molar yield is above 90%; (3) the solvent can be recycled and reused, and the discharge amount of waste water is very small; and (4) a production process is safe and controllable.

Owner:潍坊奥通药业有限公司

Continuous producing device and method of phosphorus pentafluoride

InactiveCN102674275BAchieve serializationAvoid intermittent operationPhosphorus halides/oxyhalidesSingle substanceEngineering

The invention provides a continuous producing device of phosphorus pentafluoride, comprising a phosphorus single-substance closing silo, a spiral conveyer, a fluorine-phosphorus reactor, a cooling pipeline and a multi-grade filter. The continuous producing device of phosphorus pentafluoride is characterized in that the upper end of the spiral conveyer is connected to the lower end of the phosphorus single-substance closing silo, the tail end of the spiral conveyer is connected to the upper part of the fluorine-phosphorus reactor; one end of the fluorine-phosphorus reactor is connected with the cooling pipeline, and the other end of the cooling pipeline is connected with the multi-grade filter. The invention further provides a method for continuously producing phosphorus pentafluoride by using the device; the high-purity phosphorus pentafluoride gas is obtained by pre-reaction, continuous reaction, cooling and multi-grade filtering. According to the continuous producing device, the continuous production of phosphorus pentafluoride is realized; the continuous producing device has the advantages of being high in production efficiency, simple, safe and reliable in operation and good in product quality; the product purity can reach 99.8% above; therefore, the continuous producing device can be directly applied to the production of the lithium hexafluorophosphate.

Owner:ZHEJIANG KAISN FLUOROCHEM +1

Transparent polystyrene with capacity scale of 50,000 tons or above as well as production equipment and process of transparent polystyrene

PendingCN112724296AMolecular weight easyEasy distributed controlPolystyreneStructural Macromolecules

The invention discloses transparent polystyrene with the capacity scale of 50,000 tons or above as well as production equipment and process of the transparent polystyrene. The main component of the obtained transparent polystyrene product is as follows: n is the degree of polymerization, and the range of the n is 600-7000, and the n is different along with different types of products. The transparent polystyrene has good transparency, the Vicat softening point is 85-106 DEG C, the tensile strength of the transparent polystyrene is 40-55 Mpa at normal temperature, and the transparent polystyrene is a thermoplastic material. The molecular structure contains a small amount of macromolecules with a special structure, and a considerable amount of hydrocarbon micromolecules are contained in gaps of the macromolecules, so that certain slippage can be generated among the macromolecules, and the material has good transparency and mechanical properties compared with products obtained by other process production methods. The process waste water is basically not generated in the production process, all the raw materials are recycled, a small amount of generated process waste gas reaches the standard and is discharged after being condensed and adsorbed by special equipment, and good environment-friendly, energy-saving and consumption-reducing effects can be achieved.

Owner:江苏可立特工程设计研究有限公司

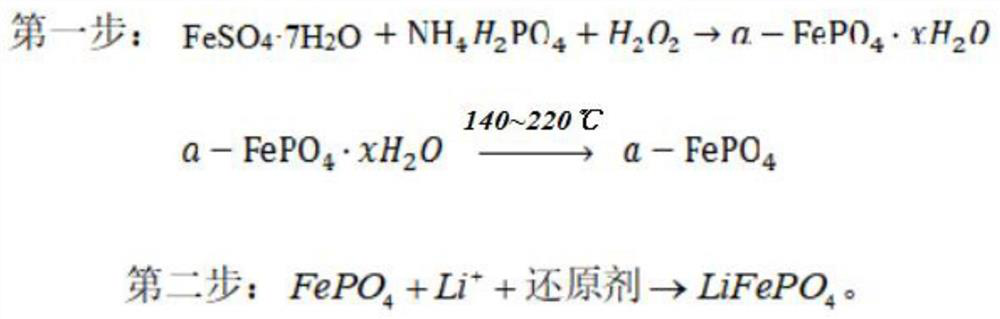

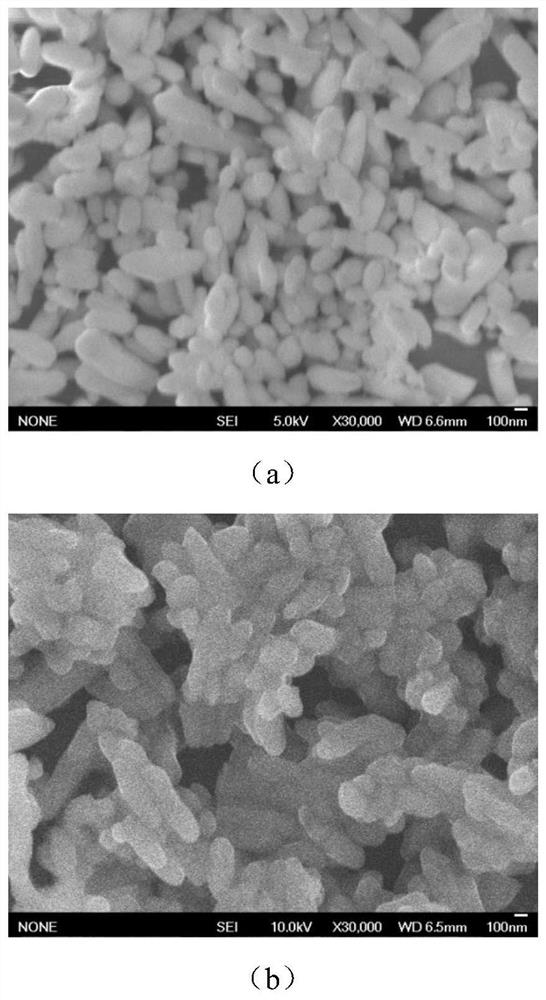

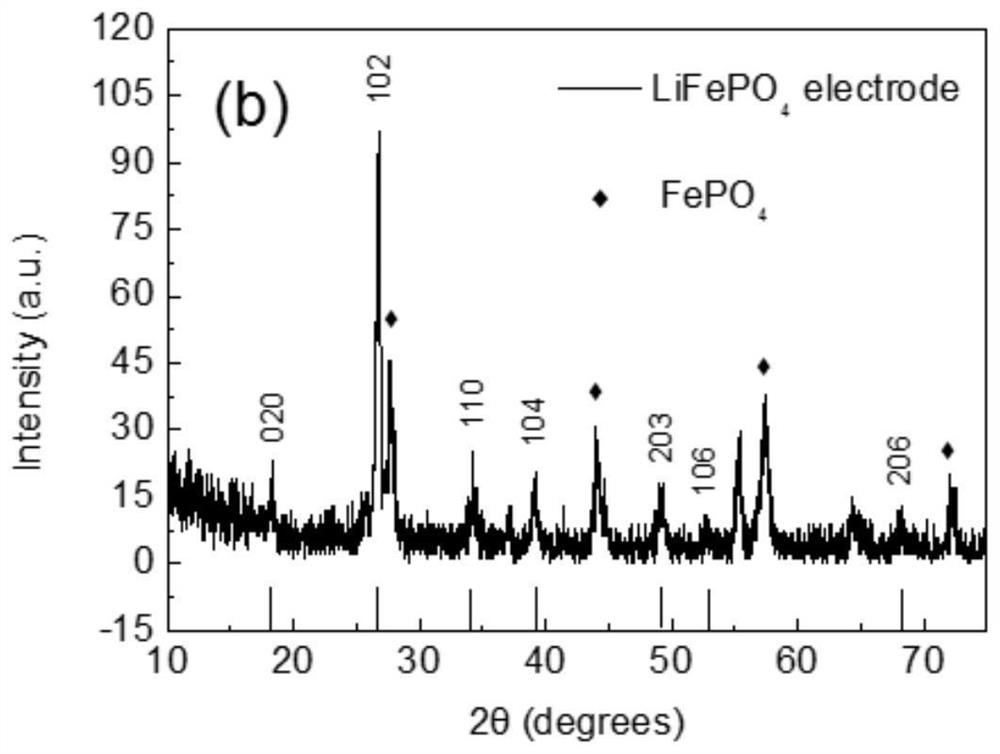

A method and application of low-cost preparation of lithium iron phosphate cathode material

ActiveCN110600735BReduce manufacturing costOperational securityPhosphatesCell electrodesLithium iron phosphateSpray dried

The invention relates to a method for preparing a lithium iron phosphate cathode material at low cost and an application of the lithium iron phosphate cathode material in a lithium ion battery. The preparation method comprises the following steps: firstly, introducing aqueous solutions of a lithium source and a phosphorus source into a spray drying cavity at a certain flow rate by an industrial spray drying method, and enabling the two substances to quickly react at relatively high surface energy at 140-220 DEG C, so as to prepare an iron phosphate material; then respectively preparing a lithium source solution, a reducing agent solution and an iron phosphate turbid liquid; under the conditions of normal temperature and constant-speed stirring, respectively injecting the lithium source solution and the reducing agent solution into a reaction kettle filled with iron phosphate turbid liquid, performing stirring for 2-3 hours at a constant speed, and centrifuging, washing and drying a product after the reaction is finished to obtain the lithium iron phosphate material. The synthesis process is carried out at 220 DEG C or below, and inert gas shielding is not needed; the whole processis operated in air, so the operation is safe, easy and convenient, the repeatability is good, the preparation cost of the target product is low, and the method has important significance in practicalapplication.

Owner:DONGGUAN UNIV OF TECH

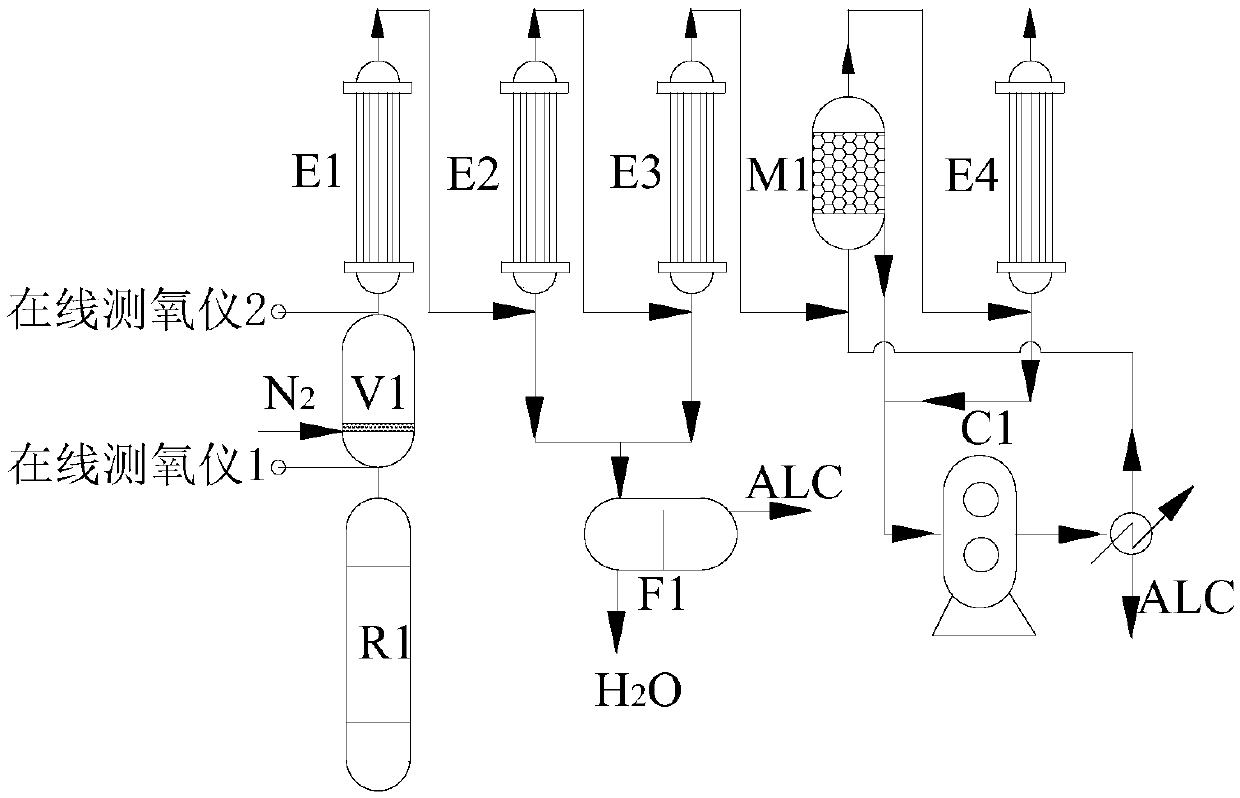

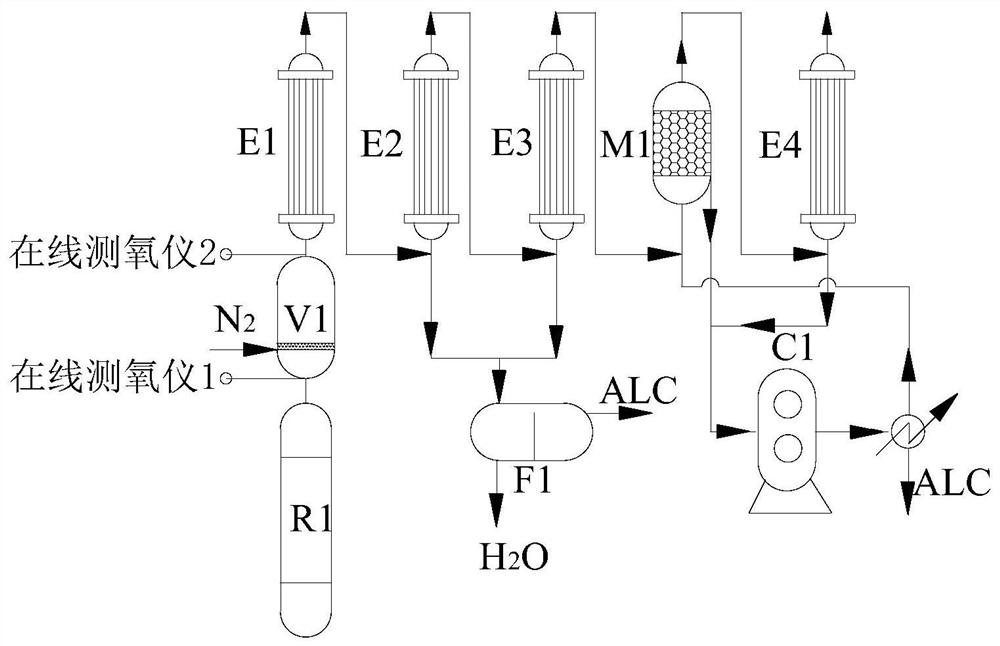

Treatment method for waste gas generated in process of producing epoxy chloropropane through chloropropene epoxidation

ActiveCN111233622AThe production process is safe and controllableHalogenated hydrocarbon separation/purificationPtru catalystExhaust fumes

The invention discloses a treatment method for waste gas generated in the process of producing epoxy chloropropane through chloropropene epoxidation. The method comprises the following steps: treatingwaste gas generated in the process of preparing epoxy chloropropane through epoxidation reaction of a reaction control phase transfer catalyst, hydrogen peroxide and chloropropene, wherein the wastegas contains nitrogen, oxygen, chloropropene and water vapor; the nitrogen is added into a gas-phase buffer tank (V1)at the top of a reactor (R1)to dilute tail gas, the diluted tail gas passes througha first-stage condenser (E1), a second-stage condenser (E2)and a third-stage condenser (E3)to recover condensed chloropropene and condensate water and then enters a membrane filter (M1)to filter a chloropropene-containing gas, and the chloropropene-containing gas is compressed to recover the chloropropene; an inorganic matter-containing gas filtered by the membrane filter (M1)is condensed by a four-stage condenser (E4)to recover trace chloropropene in the inorganic matter-containing gas so as to reach the emission standard.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Industrialized cultivation method of volvariella volvacea

ActiveCN102696400BImprove physical and chemical propertiesImprove protectionBio-organic fraction processingEnergy inputPathogenic bacteriaBiology

The invention discloses an industrialized cultivation method of volvariella volvacea, comprising the following steps: 1) building workshops for volvariella volvacea; 2) preparing cultivation material; and, 3) cultivating. According to the method, 70-80% of waste cotton is replaced by needle mushroom residues, the physicochemical property of the cultivation material is improved so as to make the cultivation material suitable for the mechanical blending, and the traditional dipping trampling manner is replaced. Therefore, the method is beneficial to the environmental protection and also reduces the production cost. The different pathogenic bacteria carried by the cultivation material are reduced by using a fermenting decomposing process. Meanwhile, as the nutrients are absorbed more easily by the volvariella volvacea, the output benefit is increased. The prepared cultivation material is carried into the workshops for volvariella volvacea by the cultivation baskets. The method realizes the management manner of the industrialized production and enables the production process to be safe and controllable by controlling environmental parameters through the networking system with the ground source heat pumps, humidifiers and ventilators and so on.

Owner:江苏江南生物科技有限公司 +1

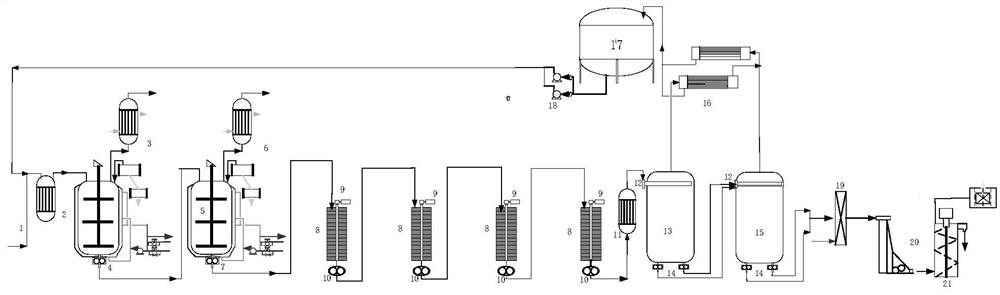

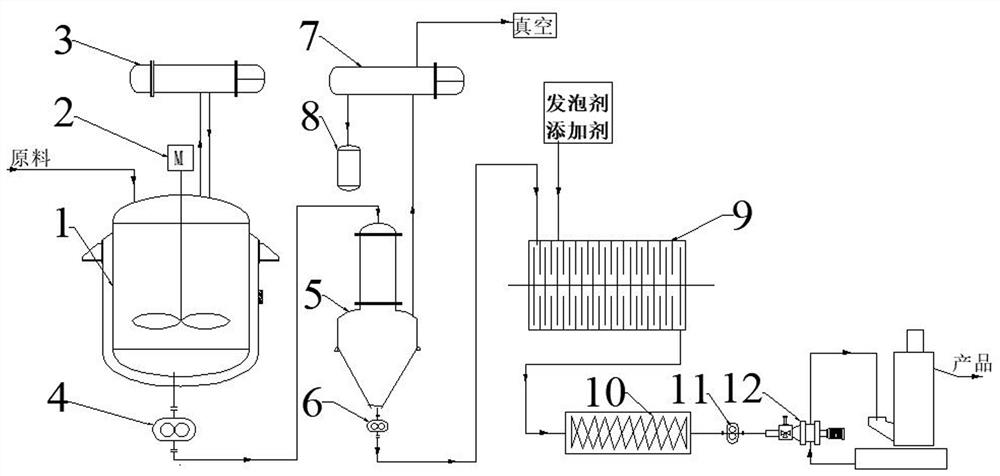

Device for producing expandable polystyrene by bulk method

PendingCN114749126AGood impact resistance and tensile strengthGood foam processing performanceTransportation and packagingMixersResidual monomerPolymer chemistry

A device for producing expandable polystyrene by a bulk method comprises a polymerization reaction unit which is connected with a heating devolatilization device through a discharge pump; the upper end of the heating devolatilization device is connected with a condenser and a vacuum liquid collection tank; and the lower part of the heating devolatilization device is connected with a mixer, a melt heat exchanger, a pump and a high-pressure underwater pelletizing system through a pump. The device can be used for producing flame-retardant expandable polystyrene (EPS) and can also be used for producing graphite expandable polystyrene (EPS). The materials in the polymerization reaction unit comprise the following components in parts by weight: 80-95 kg of styrene, 2-10 kg of a solvent and 0.5-8 kg of an auxiliary agent. The particle size of the obtained expandable polystyrene EPS ranges from 0.7 mm to 1.0 mm, residual monomers are low, waste water is little, and the environment-friendly effect is good.

Owner:粟中民

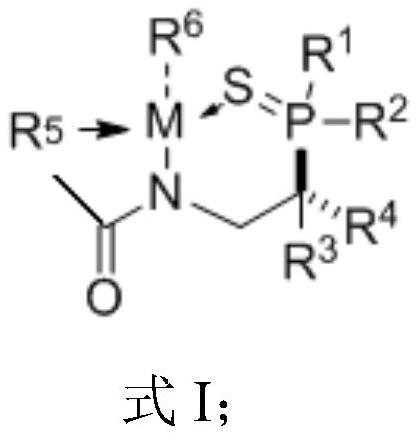

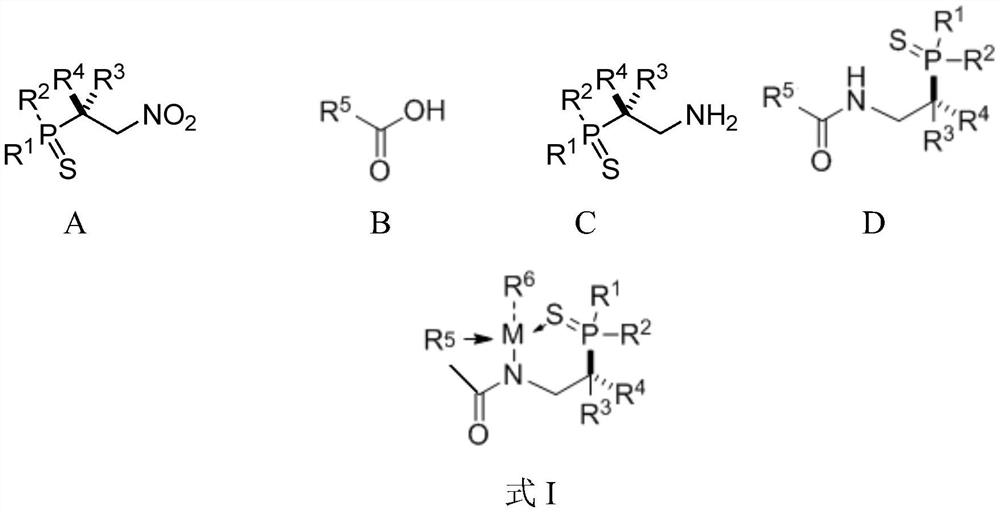

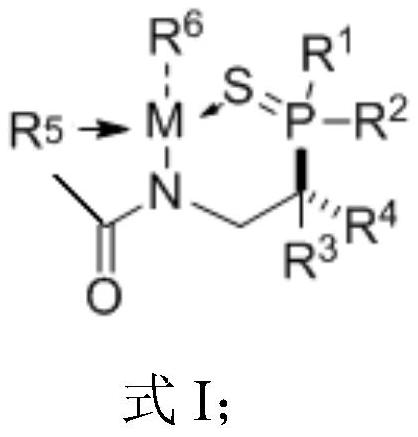

Metal complex and preparation method thereof

PendingCN112430249AReduce manufacturing costReduce pollution pressureGroup 8/9/10/18 element organic compoundsOrganic synthesisSulphur compound

The invention belongs to the technical field of organic synthetic chemistry, and particularly relates to a metal complex and a preparation method thereof. The general molecular structural formula of the metal complex is shown as formula I in the specification. The metal complex is a complex formed by complexing a chiral phosphorus-sulfur compound and metal, has a typical high-functionalization structure, such as a chiral quaternary carbon atom containing an electron withdrawing group and an amino group, not only has a classical organic metal complex structure, but also widens the coordinationof the phosphorus-sulfur compound, can expand organic asymmetric catalytic reaction, and has good application in synthesis of drug intermediates and preparation of functional materials.

Owner:SHENZHEN BAY LAB PINGSHAN TRANSLATIONAL MEDICINE CENT

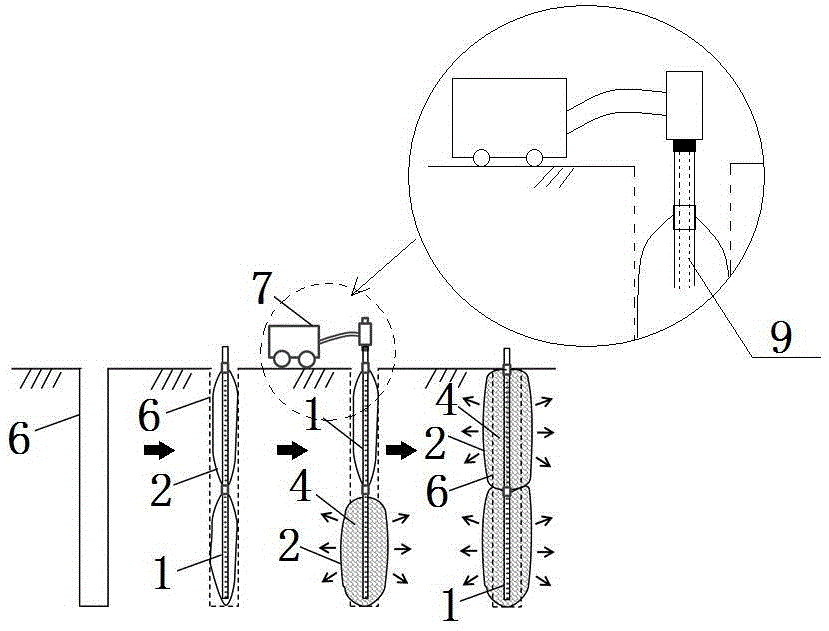

Polyurethane grouting micro-pile with pile bag and its construction method and application method

ActiveCN103741678BSimple and fast constructionNo maintenance time requiredBulkheads/piles% diameter reductionGrout

The invention discloses a polyurethane grouting micropile with a pile bag as well as a construction method and an application method of the polyurethane grouting micropile. The polyurethane grouting micropile is characterized by comprising an outer grouting pipe, the flexible pile bag arranged on the outer grouting pipe in a sleeving manner, and polyurethane foams filled in the outer grouting pipe and the flexible pile bag, wherein a bag opening of the flexible pile bag is hermetically connected with the outer wall at one end of the outer grouting pipe. The micropile has the advantages of high single pile bearing capacity, good foundation embedding and fixing capability, simplicity and quickness for construction, controllable pile shape and diameter, low grout consumption, short working period and no quality accidents of diameter reduction and pile breakage.

Owner:SHANGHAI SHEN YUAN GEOTECHN +1

A method for the production of r22 and r21 by pipeline polygeneration by liquid phase method

ActiveCN110776393BEasy accessThorough explanationPreparation by halogen replacementHydrogen fluoridePtru catalyst

The invention discloses a method for producing R22 and R21 through pipelined polygeneration using a liquid phase method. The method includes the following steps: (1) Pumping raw materials from the inlet of the pipelined reactor, so that in the presence of a fluorination catalyst, Trichloromethane and hydrogen fluoride are contacted in the pipelined reactor to perform a fluorination reaction to obtain a reaction liquid stream containing R22 and R21; (2) sequentially separate parts of the reaction liquid stream from step (1) of R21, and the remaining reaction liquid stream continues to perform a fluorination reaction in the pipeline reactor to obtain a reaction liquid stream containing R22; (3) separate R22 from the reaction liquid stream containing R22 in step (2), The remaining reaction liquid stream is recycled to step (1). By providing a method for the polygeneration of R21 and R22, the present invention enables the production of R22 and R21 to have the characteristics of small online reaction volume, small safety hazards, easy reaction control, continuous production, and low production cost.

Owner:ZHEJIANG UNIV +1

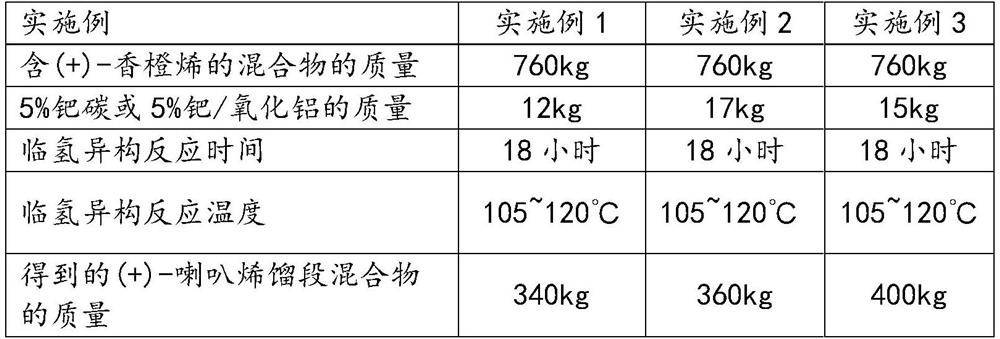

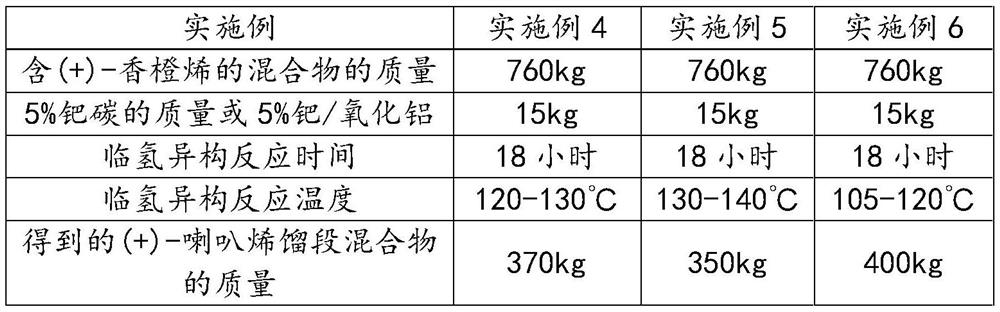

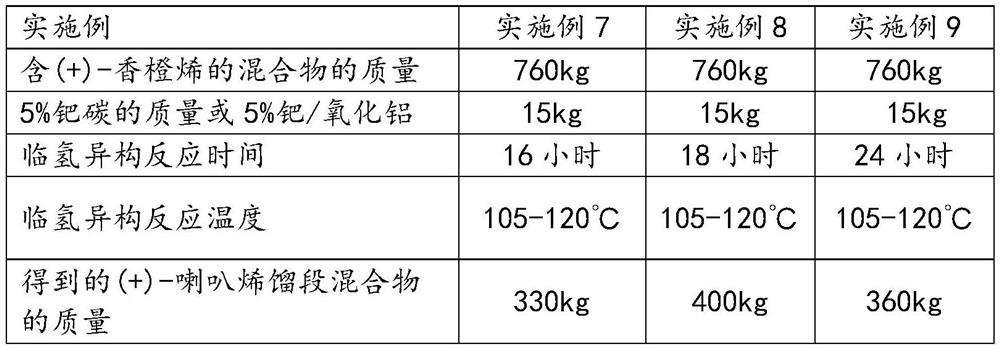

Process for the catalytic isomerization of (+)-hornene from mixtures containing (+)-omanrene

ActiveCN112028729BIncrease productionImprove use valueHydrocarbon by isomerisationOrganic chemistry methodsPtru catalystIsomerization

The invention discloses a method for catalyzing the isomerization of (+)-hornene from a mixture containing (+)-omanrene. Reactor mixing, under the environment of 60-150°C and hydrogen pressure of 0.5-2.5kg, undergo hydroisomerization reaction for 16-24h, and fractionate the obtained product to obtain a higher content (+)-hornene mixture. The method of the present invention not only improves the output of (+)-hornene, satisfies the market demand for (+)-hornene, but also expands the utilization value of the mixture containing (+)-arrene in industrial production, while reducing The discharge of three industrial wastes from the production of trumpetene has been reduced.

Owner:昆山铭达百晟贸易有限公司

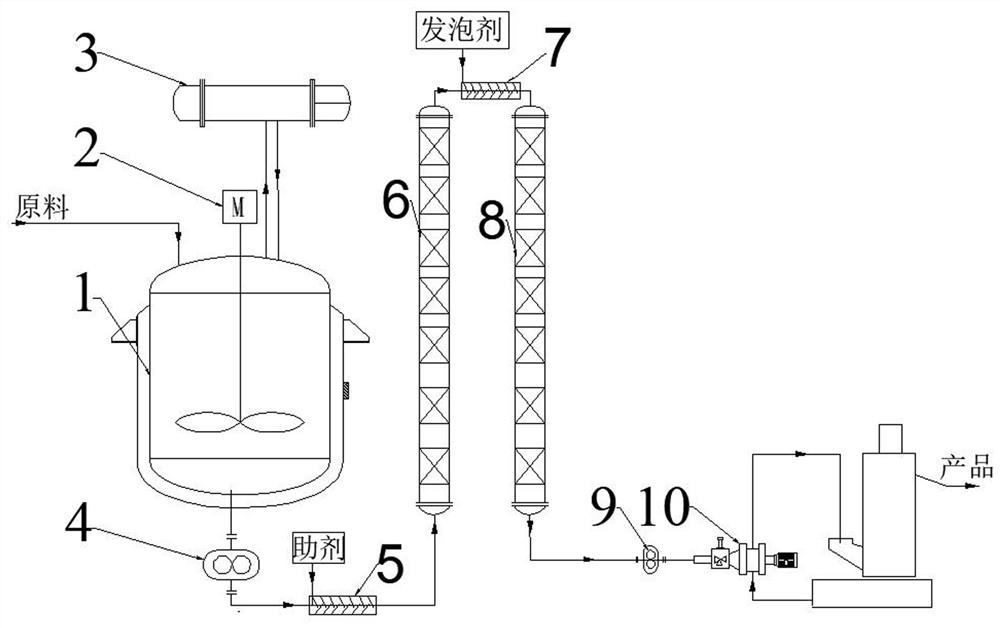

Low-energy-consumption device for producing expanded polystyrene by bulk process

PendingCN114749127AGood foam processing performanceGood lookingChemical/physical/physico-chemical stationary reactorsPhysical chemistryPolystyrene

A low-energy-consumption device for producing expanded polystyrene through a bulk method comprises a polymerization reactor (1), the lower end of the polymerization reactor (1) is connected with a mixer (5) through a discharging pump (4), and then the polymerization reactor (1) is sequentially connected with a plug flow reactor (6), a static mixer (7), a plug flow reactor (8), a pump (9) and a high-pressure underwater pelletizing system (10) through pipelines. When the front end of the mixer (5) is provided with an interface for adding a molten flame retardant master batch, flame-retardant expandable polystyrene (EPS) can be produced; when the front end of the mixer (5) is provided with an interface for adding molten graphite master batches, graphite expandable polystyrene (EPS) can be produced. The size of the obtained expanded polystyrene particles can be strictly controlled between 0.7 mm and 1.0 mm, the expanded polystyrene particles have good impact resistance and tensile strength, and the unit energy consumption is reduced to one third.

Owner:粟中民

A method for preparing para-aramid fiber by spray method

ActiveCN113045750BIncrease removalSafe and efficient preparationPolyamide coatingsPolymer sciencePyrrolidinones

The invention discloses a method for preparing para-aramid fibers by spraying method. By using p-phenylenediamine and terephthaloyl chloride as monomers and nitrogen methyl pyrrolidone as solvents, the monomers are dissolved in an inert gas environment. The dispersed phase is formed through spray gun atomization, and the mist clusters collide to quickly undergo polycondensation reaction, and the product is directly sprayed on the material panel, and after high-temperature drying, an aramid coating is formed in one step. During the reaction process, the atomization state is used to increase the contact specific surface area of the reactants, so as to realize the rapid removal of reaction heat and improve the process safety. The invention realizes rapid removal of reaction heat in the aramid fiber polymerization process, the production process is safe and controllable, and the thermal insulation coating material can be manufactured more efficiently.

Owner:NANJING TECH UNIV

A method for treating waste gas produced in the process of producing epichlorohydrin by epoxidation of propylene chloride

ActiveCN111233622BThe production process is safe and controllableHalogenated hydrocarbon separation/purificationPtru catalystEmission standard

A method for treating waste gas produced in the process of producing epichlorohydrin by epoxidation of propylene chloride, the method is to treat the waste gas produced in the process of preparing epichlorohydrin by reaction control phase transfer catalyst, hydrogen peroxide, and epoxidation of propylene chloride. The exhaust gas contains nitrogen, oxygen, chloropropene and water vapor. Add nitrogen to the gas phase buffer tank (V1) at the top of the reactor (R1) to dilute the exhaust gas. After dilution, the exhaust gas passes through the primary condenser (E1) and the secondary condenser (E2) 1. The three-stage condenser (E3) reclaims condensed chloropropene and condensed water and then enters the membrane filter (M1) to filter the chloropropene gas, and compresses the chlorpropene gas to recycle the chloropropene; to the membrane filter (M1) filtered out The gas containing inorganic substances is condensed and recovered by the fourth-stage condenser (E4) to recover the trace amount of chloropropene to reach the emission standard.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

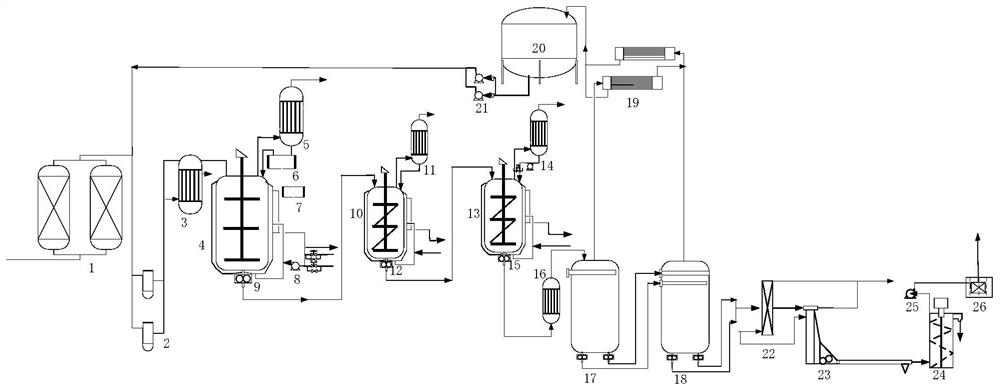

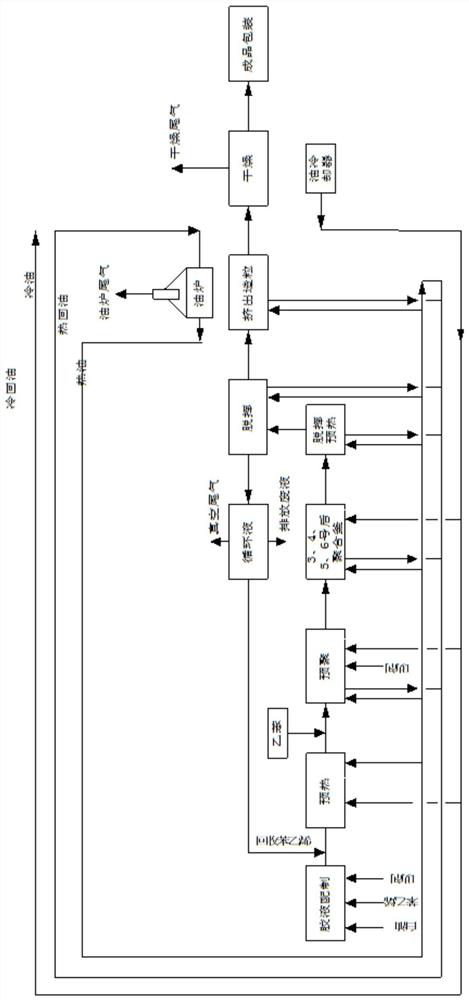

Industrial-scale high-performance high-impact polystyrene production device and production process

The invention discloses an industrial-scale high-performance high-impact polystyrene production device and a production process. A pre-polymerization reaction device in the production device is a pre-polymerization reaction kettle group which is formed by combining four full mixing flow reaction kettles with stirring in a specific series-parallel connection manner; the prepolymerization reaction kettle group comprises two groups of parallel two-stage prepolymerization kettles, and each group of two-stage prepolymerization kettles consists of a first-stage prepolymerization kettle and a second-stage prepolymerization kettle which are connected in series. The production process is a styrene and rubber mixed solution graft copolymerization reaction process formed by combining four prepolymerization kettles; in the prepolymerization reaction, two groups of parallel two-stage prepolymerization kettles are adopted for feeding at the same time; by controlling different process conditions of each group of kettles, the reaction of each group of two-stage prepolymerization kettles reaches the styrene reaction conversion rate and the rubber grafting rate which meet specific requirements; and mixing the two groups of materials in a plug flow reactor, and further polymerizing to obtain the dispersed phase particle modified high-performance high-impact polystyrene with a submicrostructure with specific particle size and particle size distribution.

Owner:上海希尔吾新材料科技发展有限公司

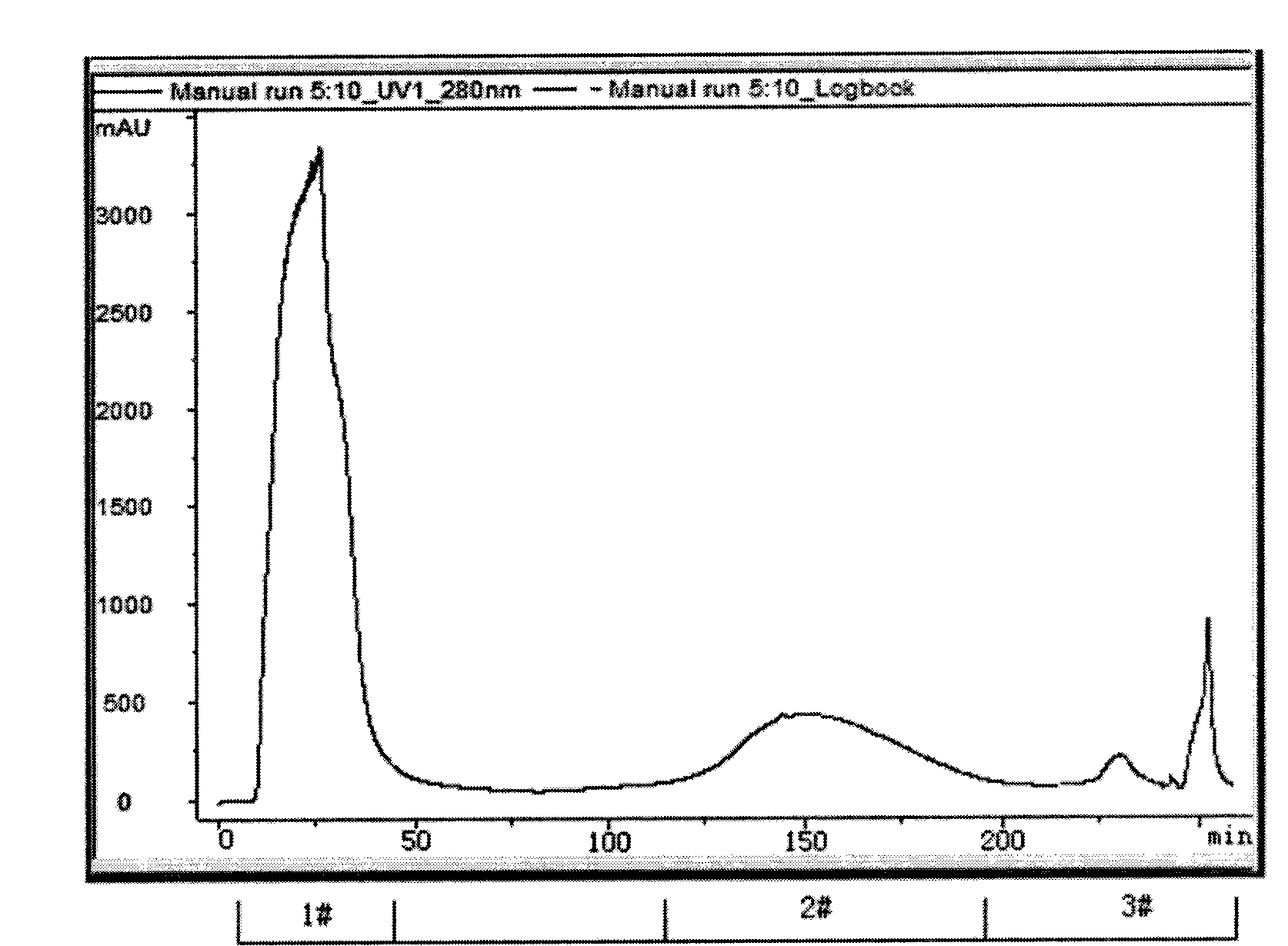

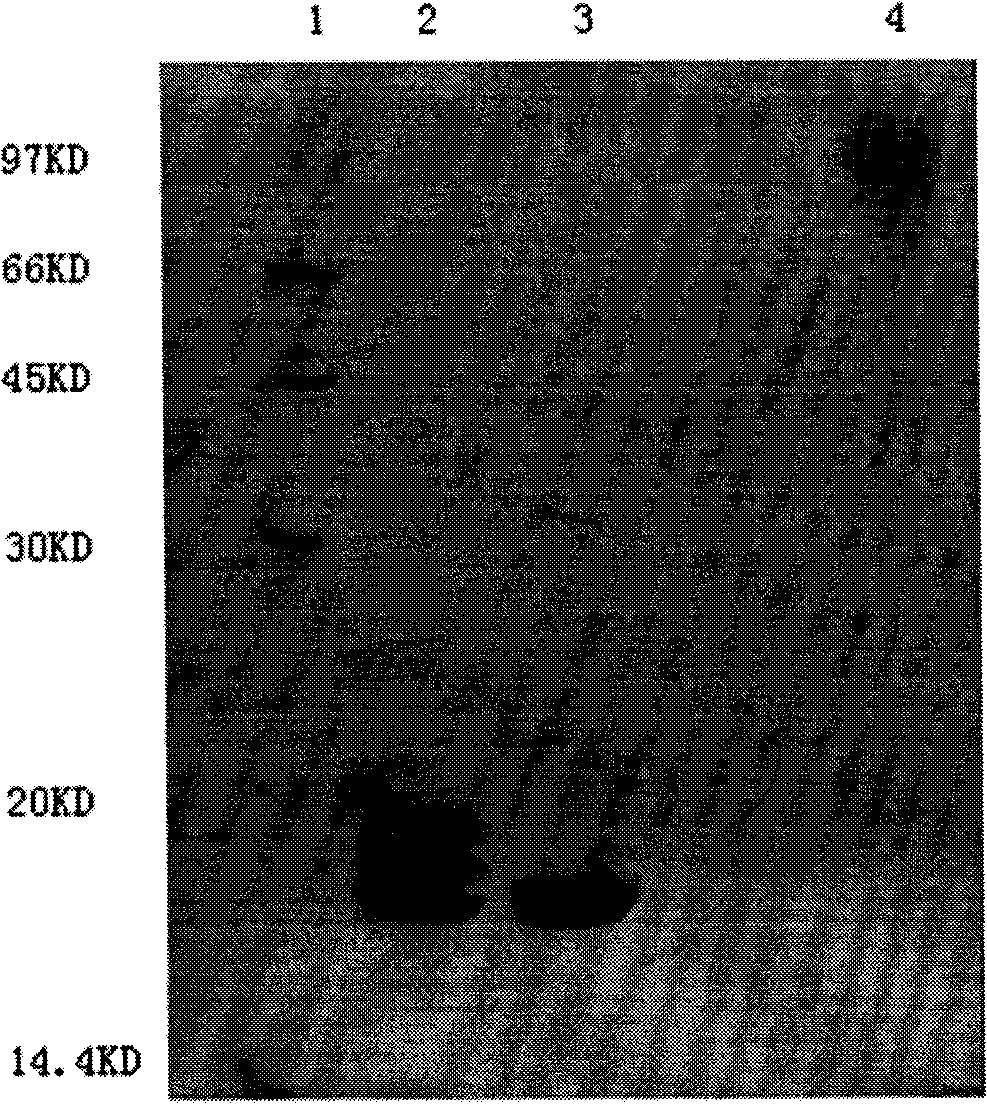

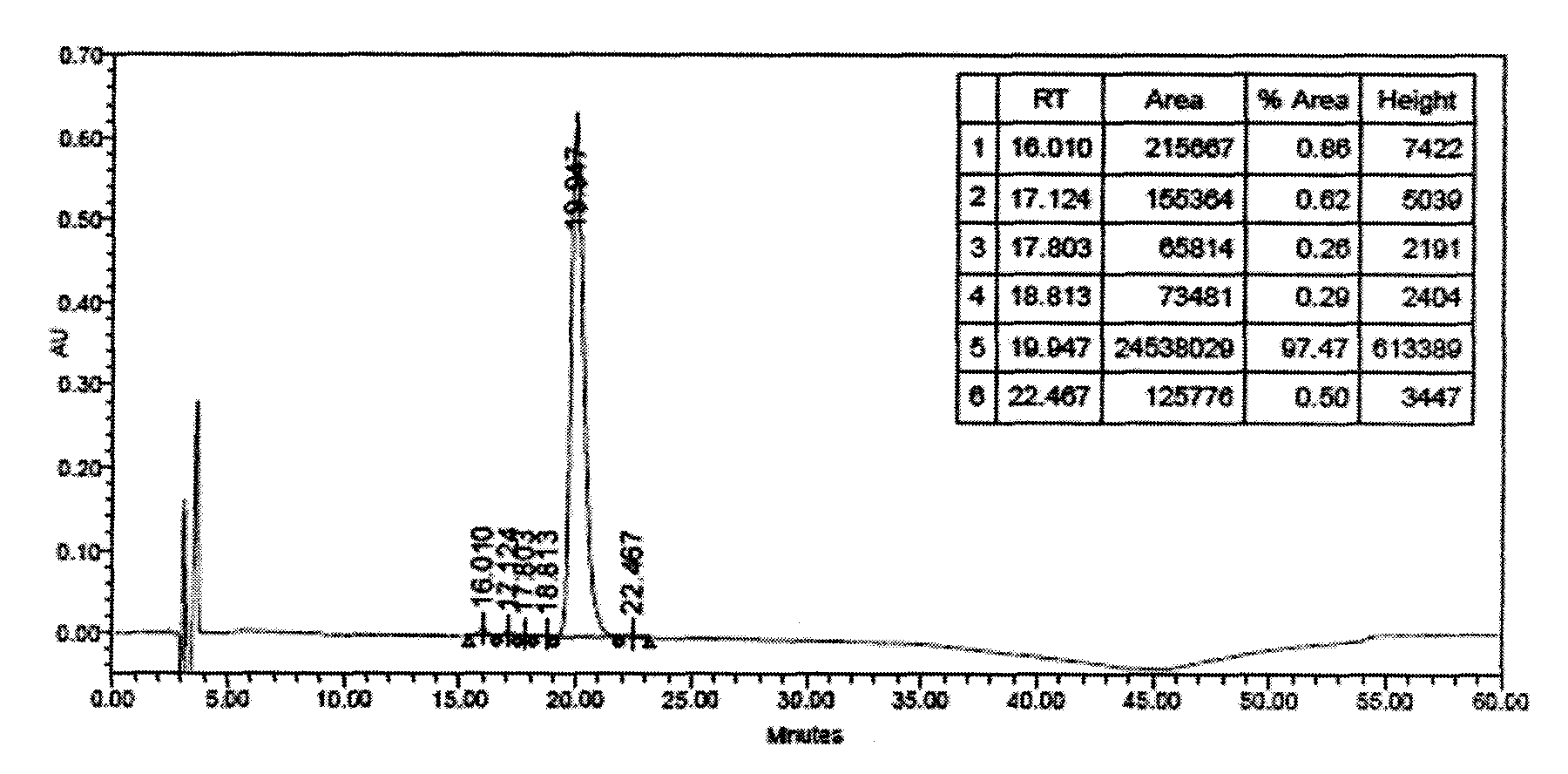

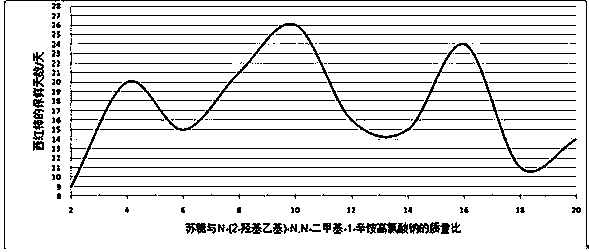

Fermentation post-treatment process for recombinant human interferon alpha2b

ActiveCN101974084BPrevent oxidationInhibit aggregationPeptide preparation methodsInterferonsProtein targetEconomic benefits

Owner:XIAMEN AMOYTOP BIOTECH

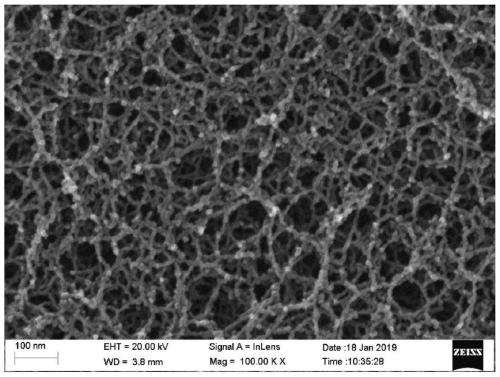

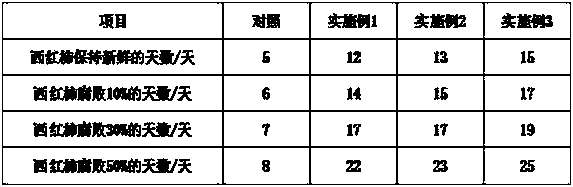

Preparation and application of a composite nanofiber fresh-keeping film

The invention discloses a composite nano fiber fresh-keeping film preparation and application thereof. The composite nano fiber fresh-keeping film preparation includes: microwave synthesis of modifiedchitosan, preparation of a spinning solution, composite spinning, and application. The method uses glutaraldehyde to modify chitosan, prepares the modified chitosan, polyoxyethylene, polylactic acid,and a cross-linking agent into the spinning solution, and adopts an electrostatic spinning technology to prepare the composite nano fiber fresh-keeping film. The beneficial effects of the fresh-keeping film are that antibacterial ingredients of the fresh-keeping film can break plasma membranes of harmful microorganisms contacting the antibacterial ingredients, can kill the microorganisms, and achieve an antibacterial fresh-keeping function; the composite nano fiber fresh-keeping film is large in specific surface area, is high in porosity, is excellent in fiber uniformity, and is excellent inmechanical property; the composite nano fiber fresh-keeping film has good water and air permeability, can protect fruits and vegetables from decay due to high temperature, has an excellent mechanicalproperty, is safe, non-toxic, and biodegradable, and is a safe, high-efficiency, and environment-friendly composite nano fiber fresh-keeping film.

Owner:ZHEJIANG OCEAN UNIV

Preparation method and application thereof for cell-biological bracket compound based on biological print technology

InactiveCN103272288BBioprinting technology is simple and easyLow costSurgeryBiologic scaffoldSpinal cord lesion

Owner:谢杨 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com