Industrial-scale high-performance high-impact polystyrene production device and production process

A technology for polystyrene and production equipment, which is applied in the field of industrial-scale high-performance high-impact polystyrene production equipment and production technology, and can solve the problems of difficult to control styrene and poor comprehensive performance of high-impact polystyrene resin, etc. problems, to achieve the effect of improving toughness and strength, excellent impact resistance, and optimizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

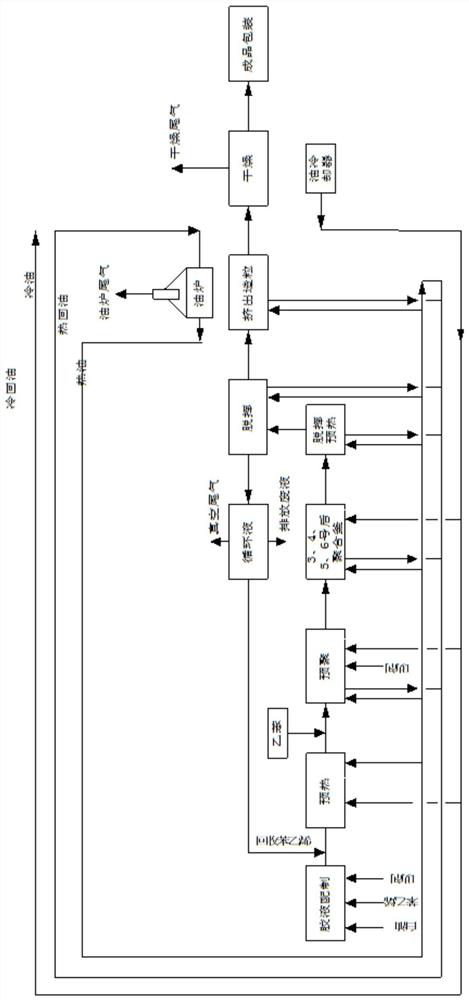

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

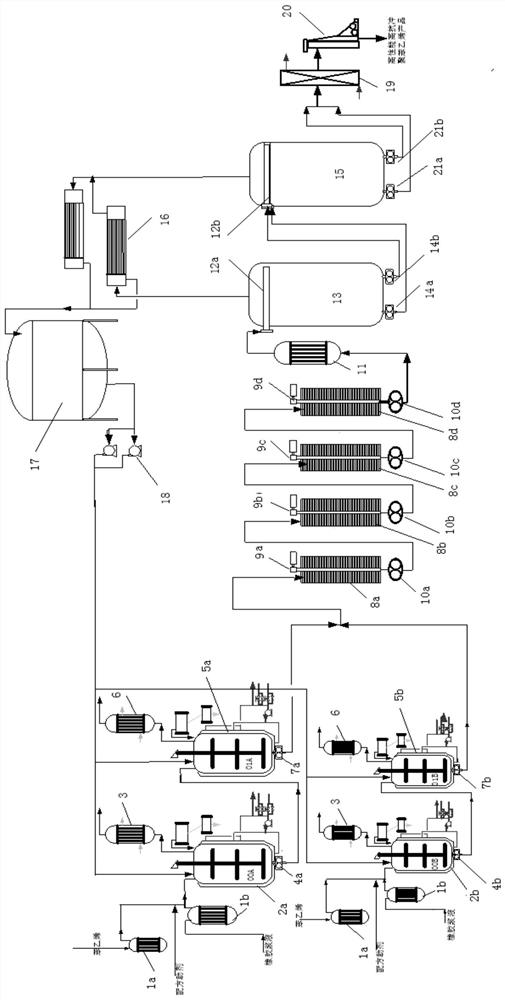

[0052] Such as figure 2 As shown, an industrial-scale high-performance high-impact polystyrene production device is invented, which includes: a glue preparation and supply device for preparing rubber-styrene glue, a styrene preheater 1a, a glue preheater 1b and glue filter, and static mixer, pre-polymerization device, post-polymerization device, polymer preheating and two-stage devolatilization device, unreacted monomer recovery device, polymer pelletizing connected in sequence through pipelines Drying device; wherein, the styrene preheater 1a is a styrene monomer preheater, and the glue preheater 1b is a preheater for a styrene-polybutadiene series rubber solution; the glue preparation and supply device is connected with the glue The liquid preheater 1b is connected; the glue preheater 1b is connected with the static mixer; the glue filter is set between the glue preheater 1b and the static mixer; the styrene preheater 1a is connected with the static mixer; The mixer is set ...

Embodiment 2

[0059] Such as figure 1 , figure 2 As shown, a production process of industrial-scale high-performance high-impact polystyrene utilizing the production device of industrial-scale high-performance high-impact polystyrene in Example 1 of the present invention is described in detail as follows:

[0060] Step 1. Glue configuration and processing:

[0061] Styrene and chopped rubber are dissolved in the sol tank (rubber configuration tank) by blending and stirring, and are prepared into a rubber styrene solution (rubber slurry, referred to as glue) with a corresponding concentration; temperature control facilities are installed in the sol tank to control The glue preparation temperature is in a suitable temperature range; the prepared glue is stored in the glue storage tank, and is used after circulating and dissolving in the glue storage tank for 24 hours; whether it is glue distribution, circulation or glue transportation, all need The gear pump is used to transport the glue. ...

Embodiment 3

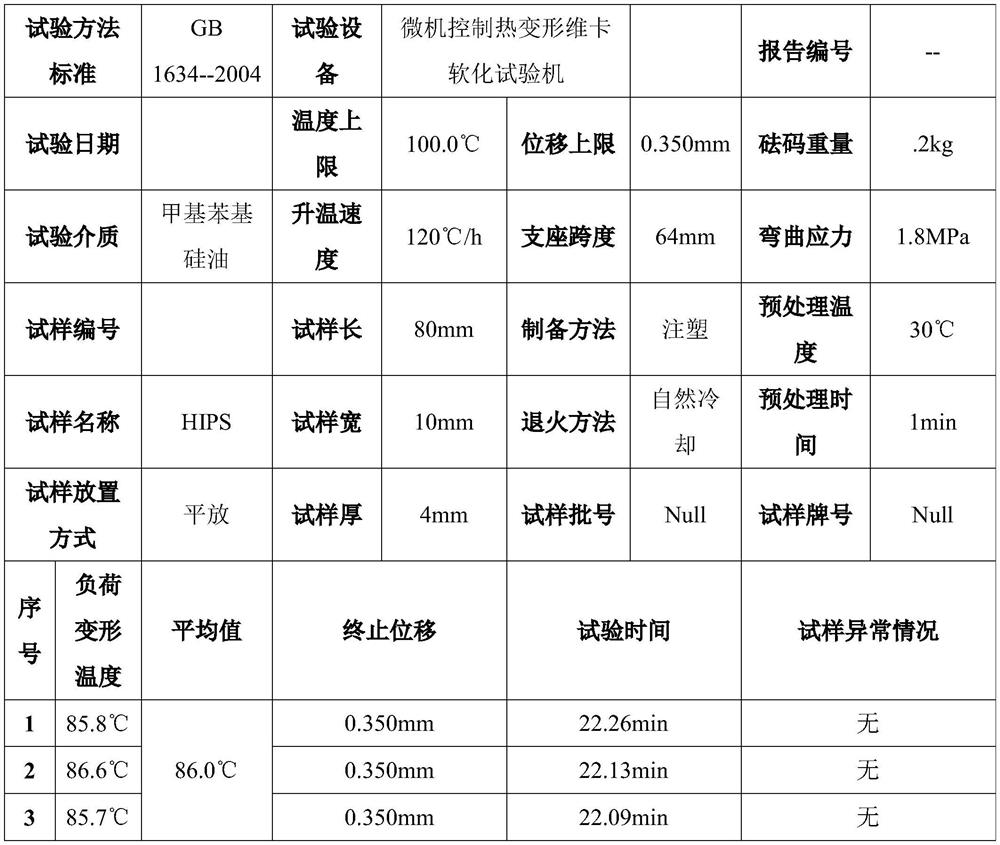

[0086] The formula used by a specific product of the present embodiment is as follows:

[0087] A. Styrene: purity greater than 99.8%, colorless transparent liquid, dosage 0.910 parts.

[0088] B. Industrial white oil: a colorless transparent liquid with a flash point greater than 240°C, the dosage is 0.020 parts.

[0089] C. Internal and external lubricants: zinc stearate, stearic acid amide, 2 kinds of white granules or powders with a purity greater than 99.8%. These 2 kinds are used in combination according to the needs in production according to the ratio of 6:1. The total dosage is 0.005 parts.

[0090] D. Antioxidant: BHT, Irganox1076, according to the needs of production, use these two kinds in combination with a ratio of 2:1, and the dosage is 0.005 parts.

[0091] E. Polybutadiene rubber: the dosage is 0.072 parts.

[0092] F. Ultraviolet absorber and light stabilizer: Tinuvin328, Tinuvin622, these two kinds are used in combination according to the needs in product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com