Patents

Literature

126results about How to "Increase removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

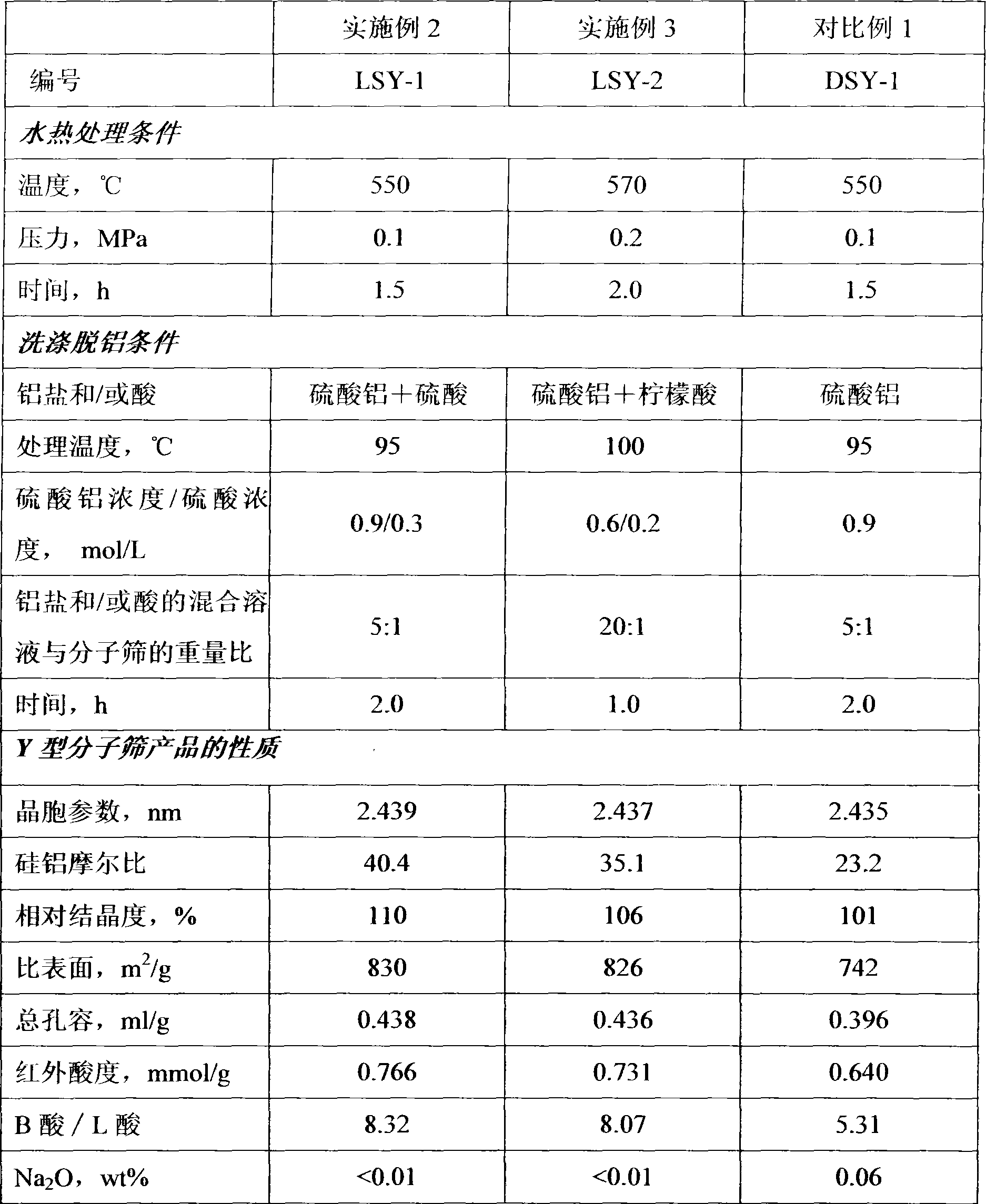

Hydrocracking catalyst containing Y molecular sieve and preparation method thereof

ActiveCN101450320AHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

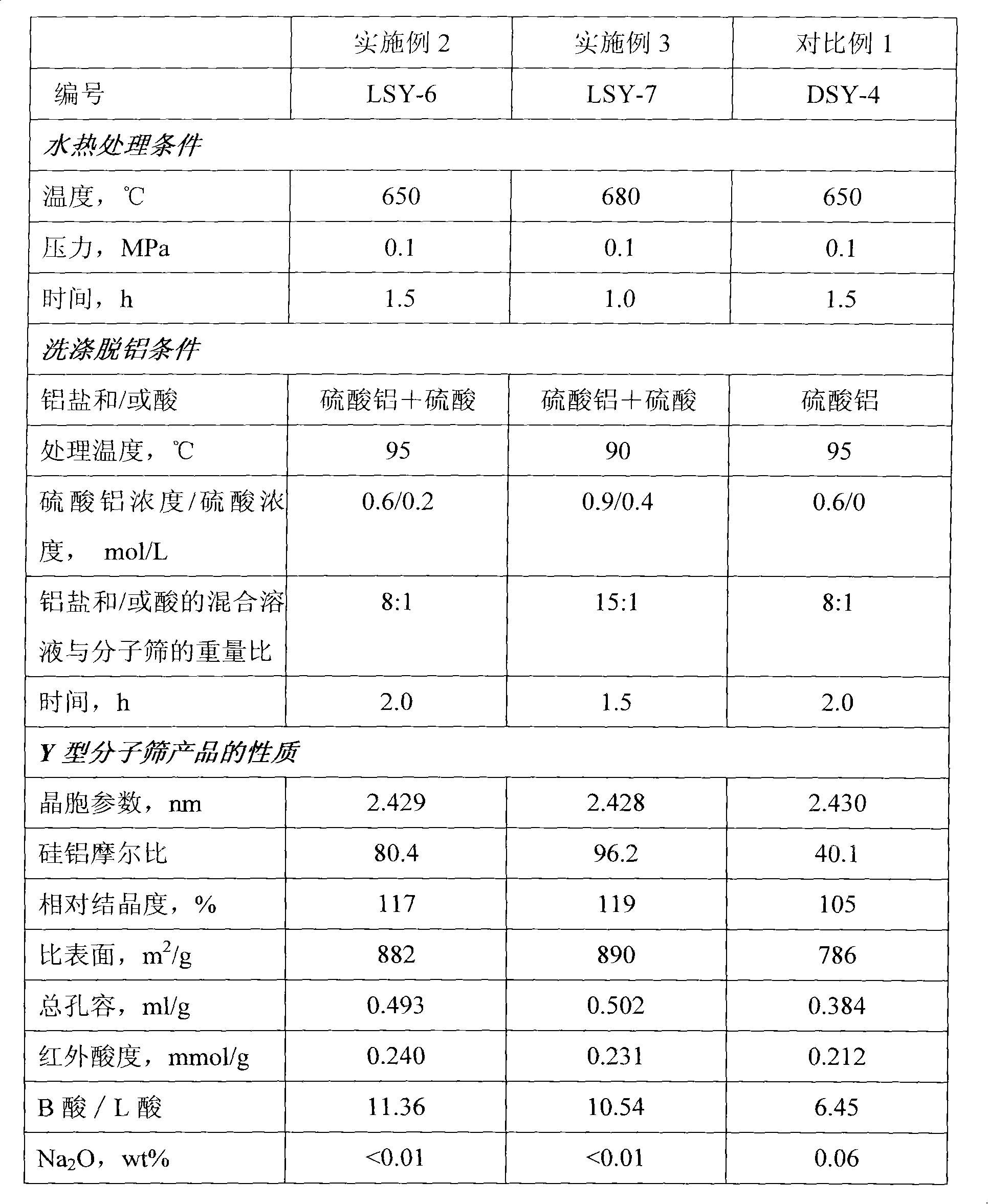

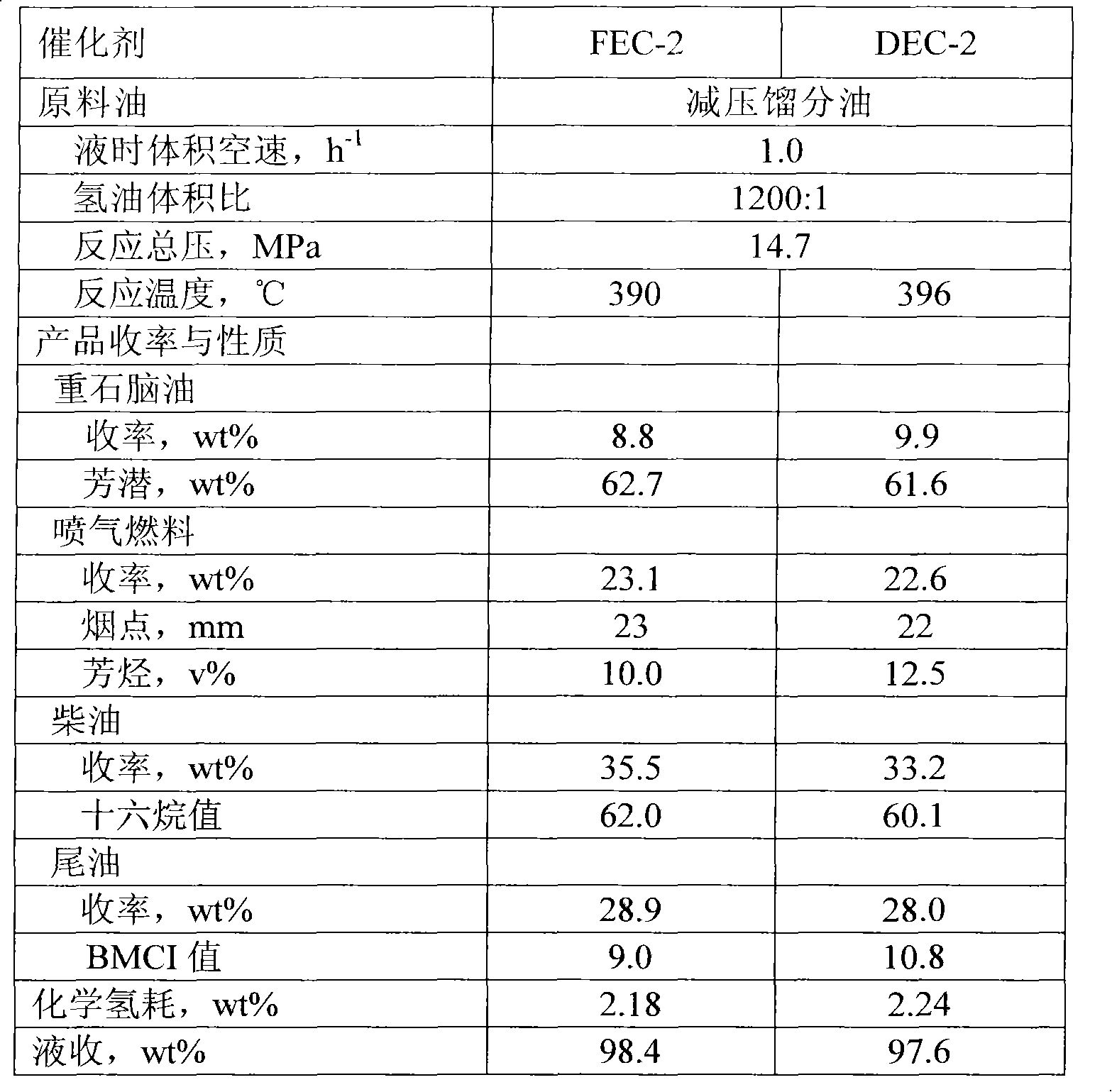

The invention discloses a hydrocracking catalyst for producing heavy naphtha in great abundance and a preparation method thereof. The catalyst contains hydrogenation active metals and a carrier which consists of modified Y molecular sieves and alumina, wherein the Y molecular sieves are obtained by using a mixed aqueous solution of aluminum salts and an acid to perform hydro-thermal treatment. The properties of the modified Y molecular sieves are as follows: the specific surface area is between 750 m<2> / g and 850 m<2> / g; the total pore volume is between 0.35 and 0.48 ml / g; the relative crystallinity is between 90 and 130 percent; the cell parameter is between 2.437 and 2.445 nanometers; the silicon-aluminum mol ratio is between 15 and 70; the infrared acid amount is between 0.5 and 1.0 mmol / g; the B acid / L acid is more than 7.0; and the content of sodium oxide is less than or equal to 0.05 weight percent. The hydrocracking catalyst has the characteristics of good catalytic activity, high heavy naphtha selectivity, high yield, high latent content of heavy naphtha arene, and so on.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN101618348AHigh activityHigh selectivityCatalyst carriersMolecular sieve catalystsMolecular sieveCrystallinity

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The catalyst carrier comprises a modified Y-type molecular sieve, amorphous silica-alumina and alumina, wherein the modified Y-type molecular sieve is Y-type molecular sieve treated by mixed aqueous solution of an aluminum salt and an acid and by hydrothermal process. In the carrier, the modified Y-type molecular sieve has a high crystallinity, high silicon to aluminum ratio and proper total acidity and acid distribution and can form an acid component with the amorphous silica-alumina. Therefore, the carrier is particularly suitable for serving as a hydrocracking catalyst carrier to improve the activity of a hydrocracking catalyst and the selectivity of middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

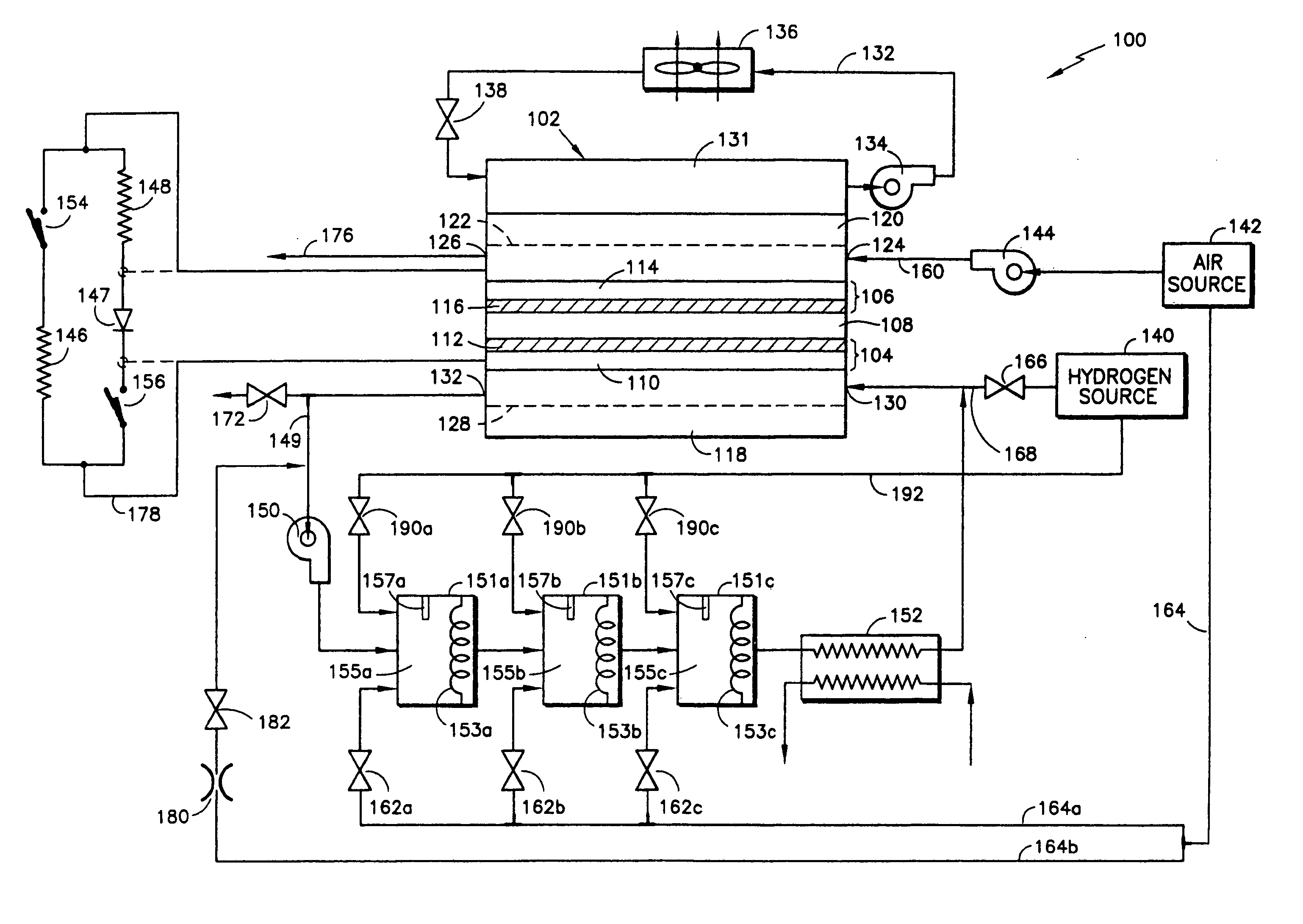

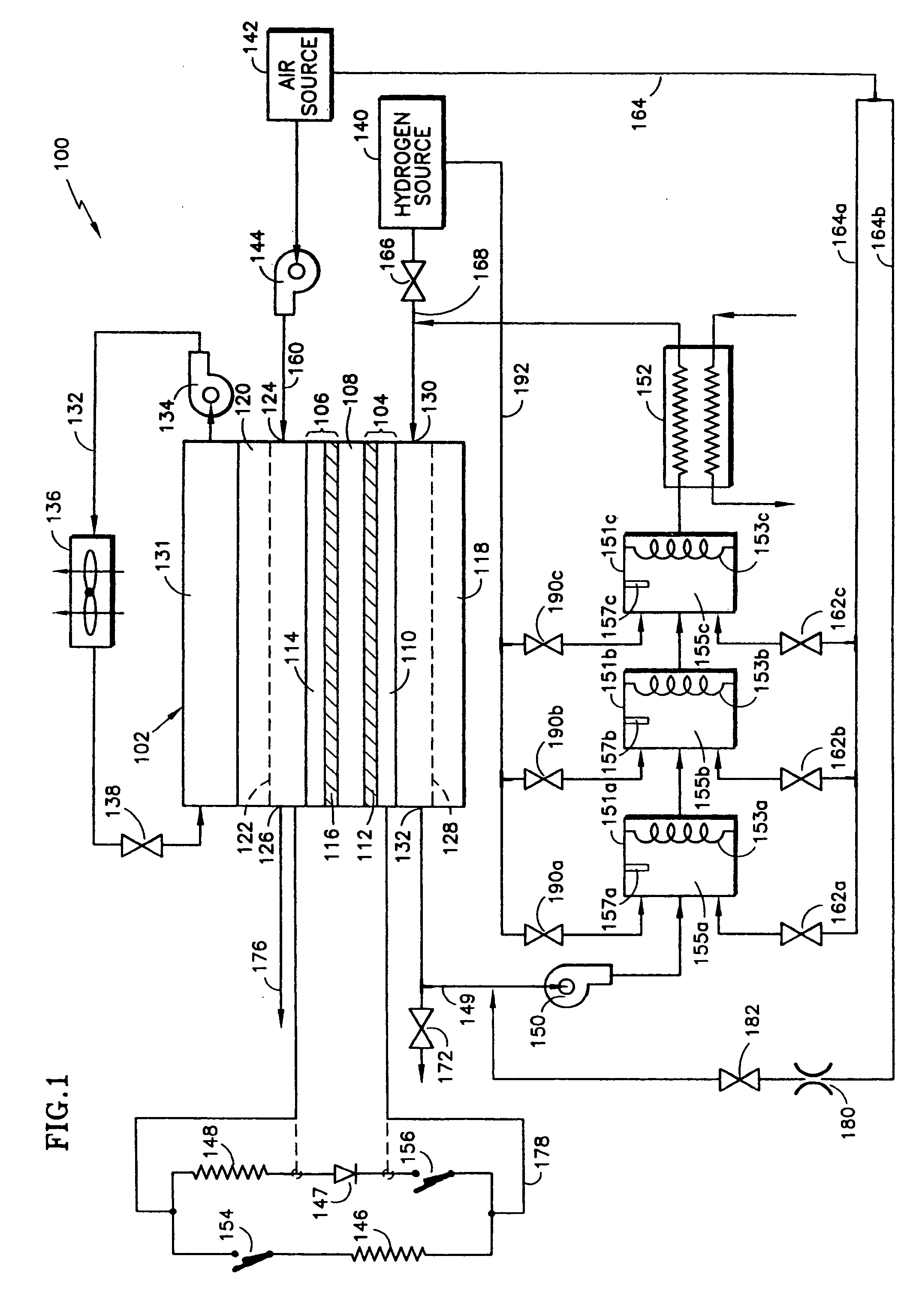

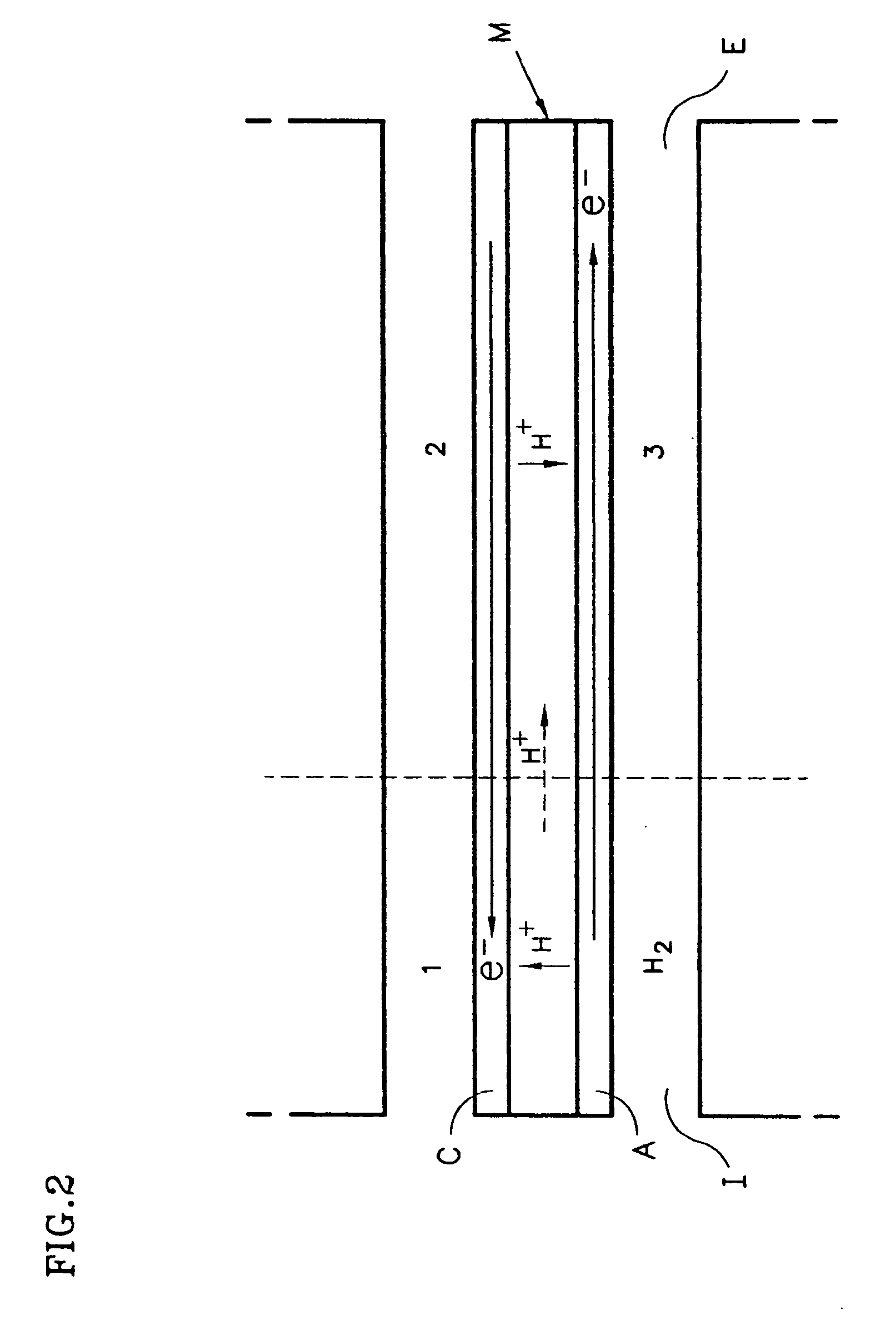

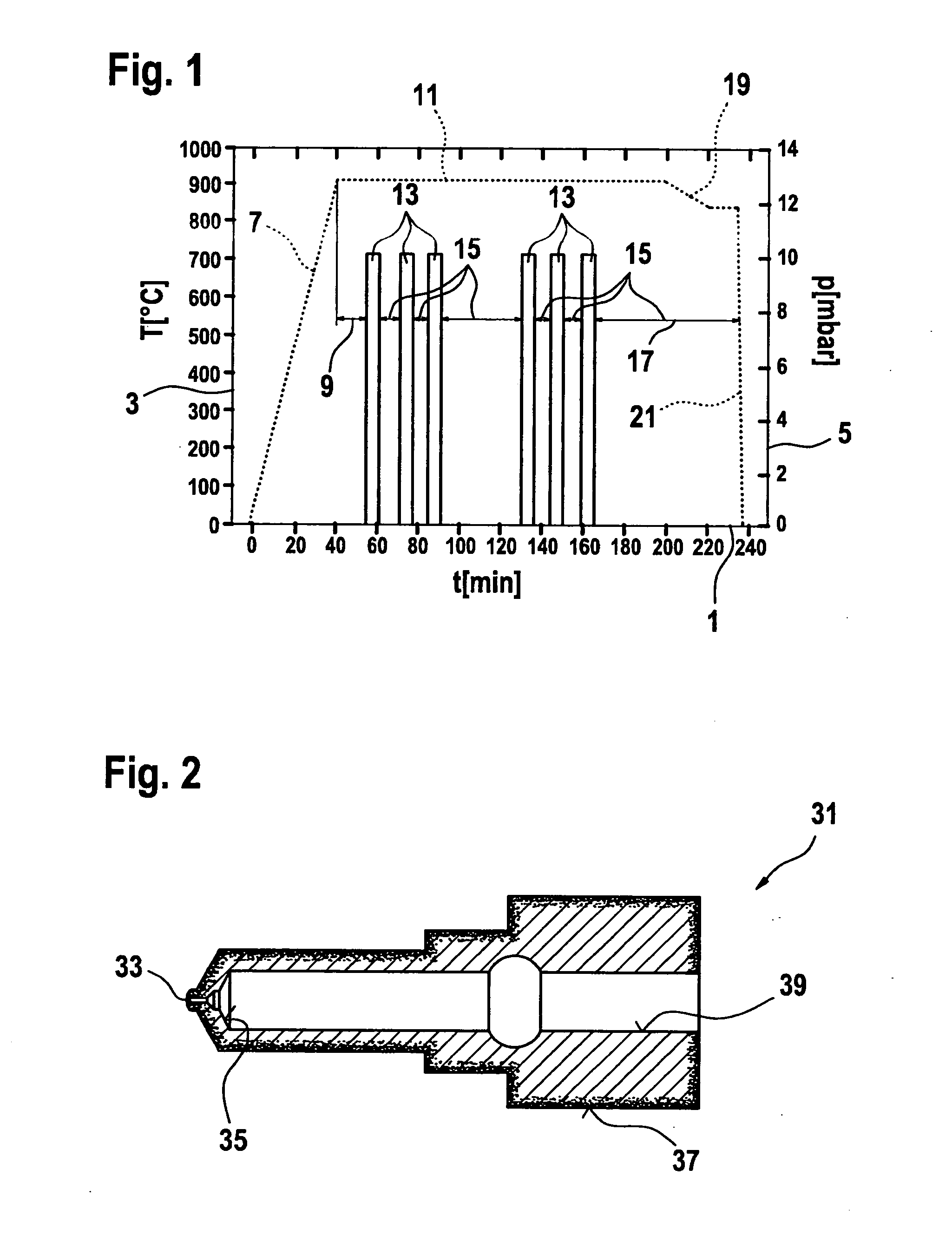

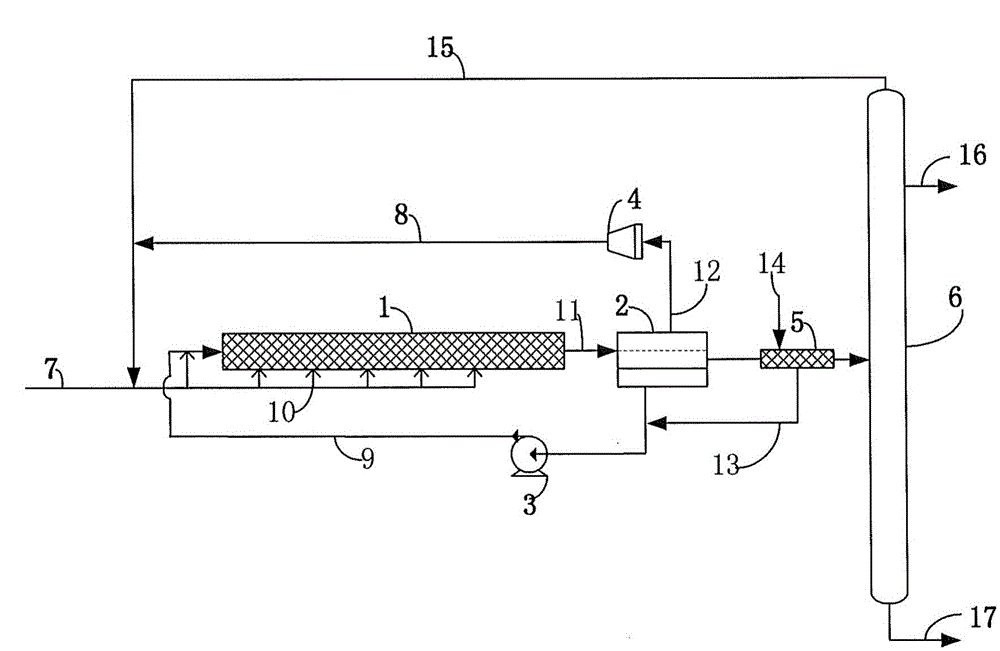

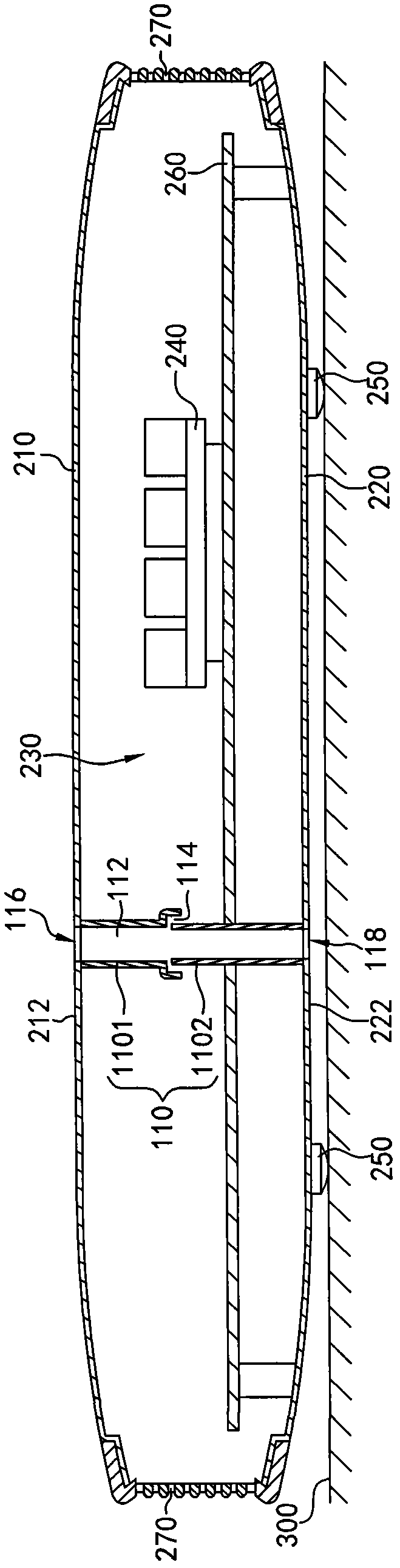

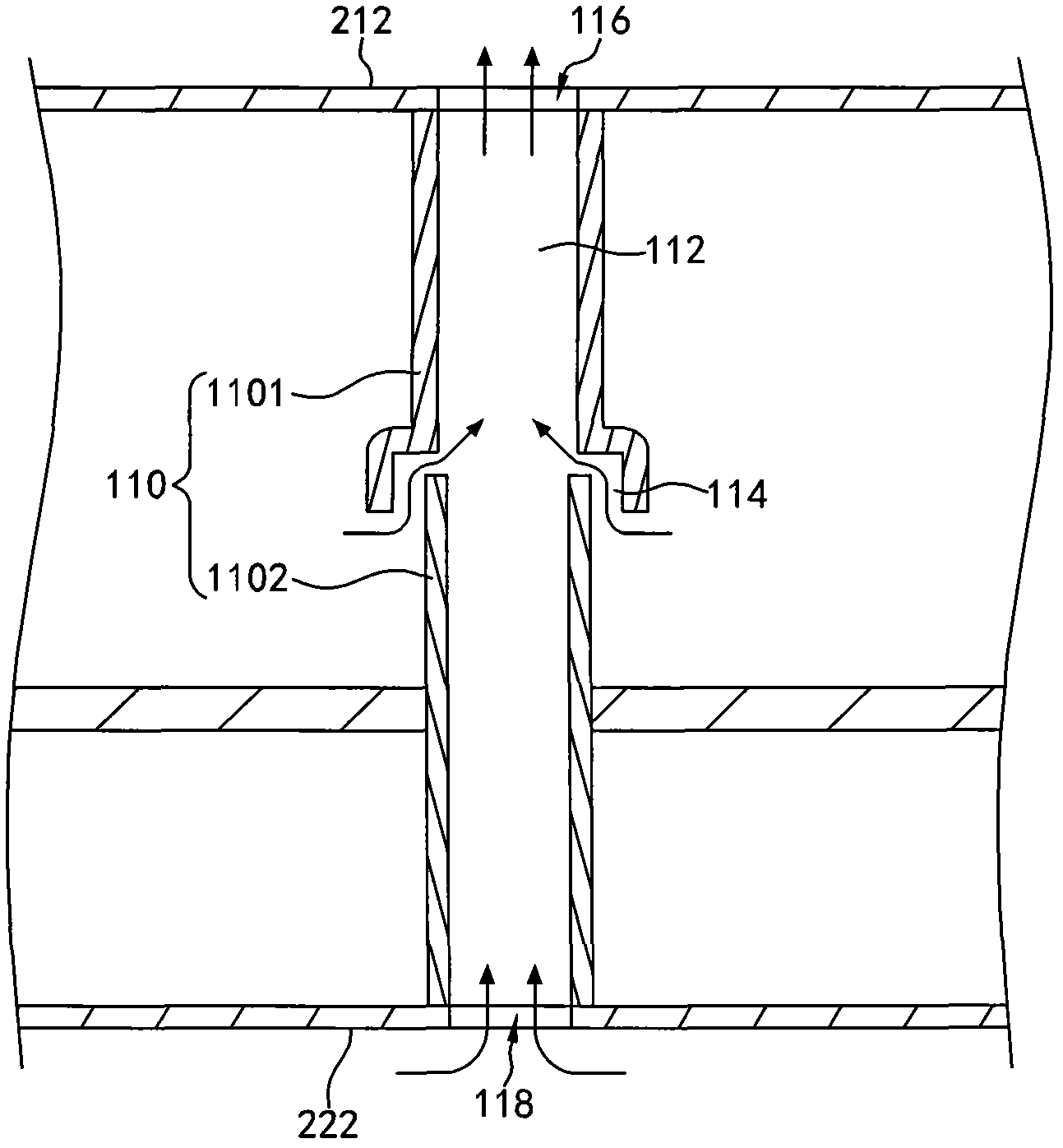

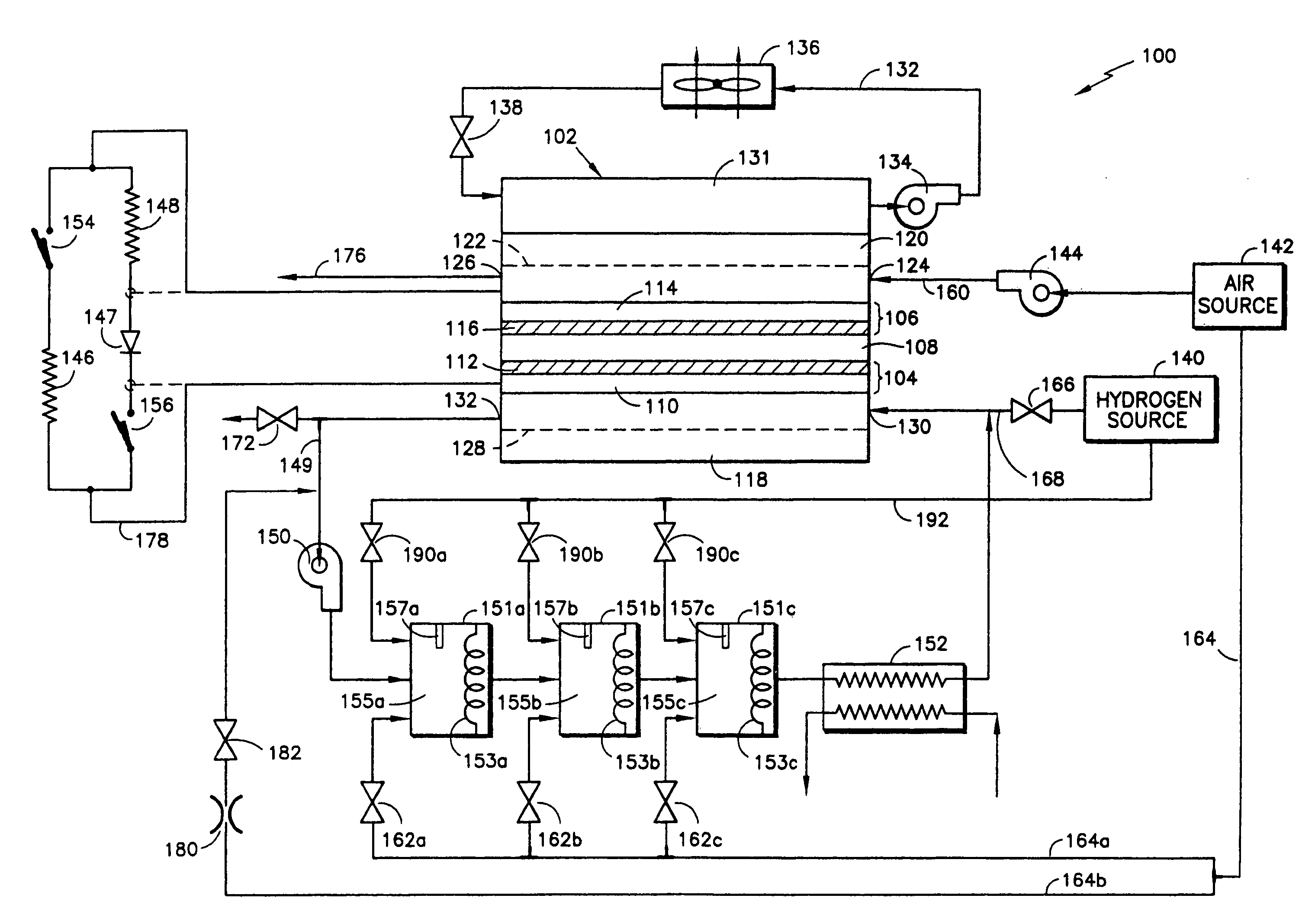

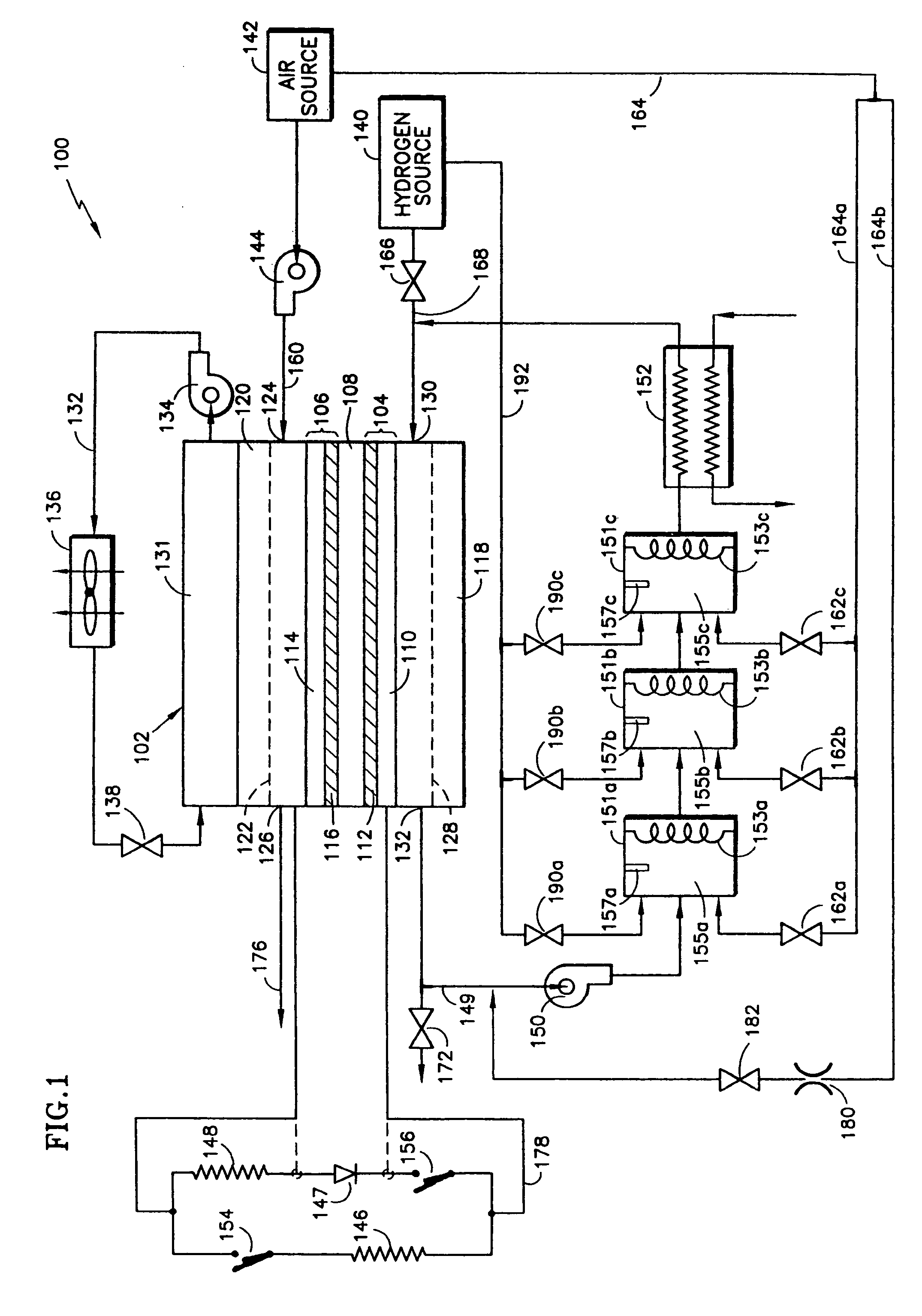

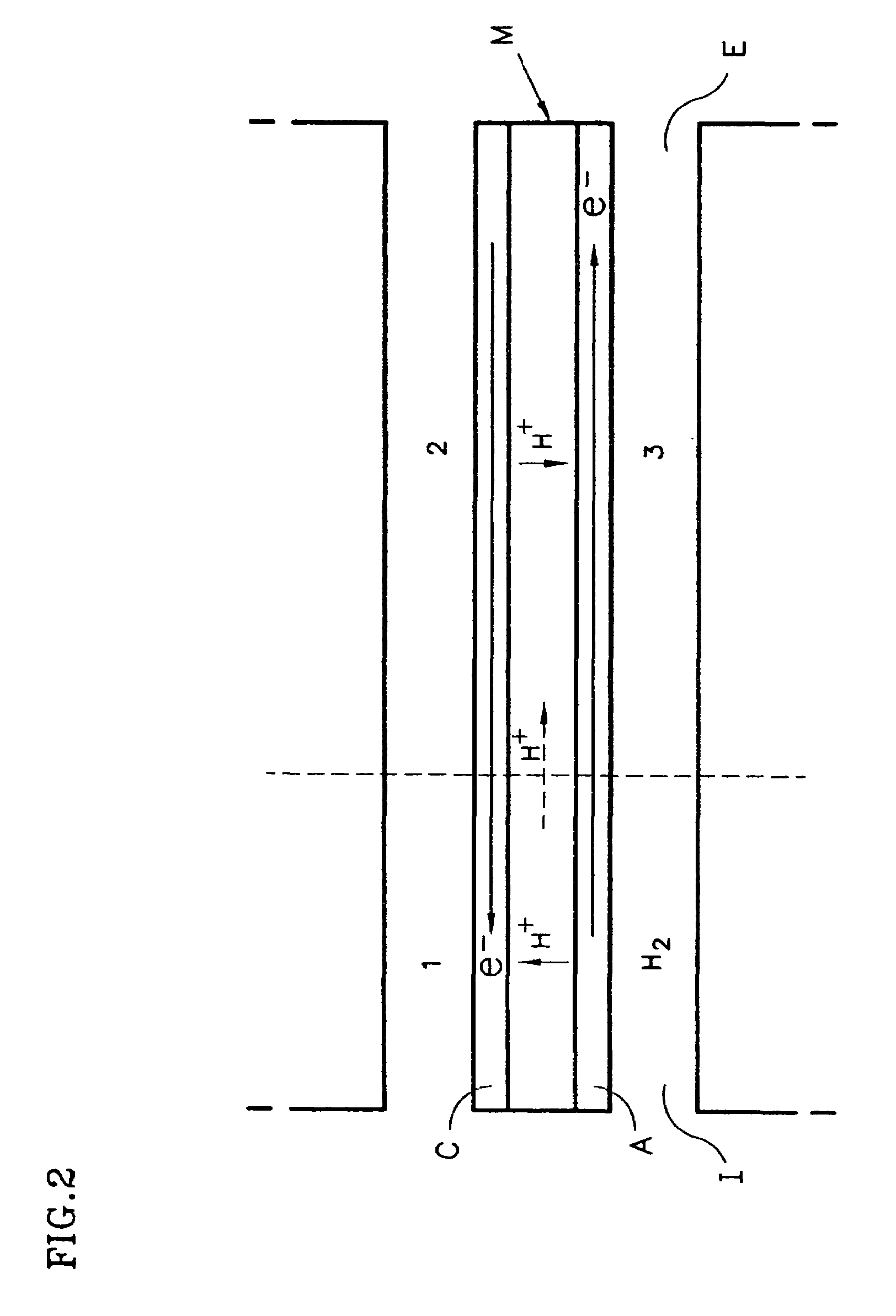

Procedure for starting up a fuel cell system having an anode exhaust recycle loop

InactiveUS20060093879A1Fuel flow rate can be increasedIncrease removalFuel cell heat exchangeSolid electrolyte fuel cellsEngineeringDissolution

A procedure for starting up a fuel cell system that is disconnected from its primary load and that has air in both its cathode and anode flow fields includes a) connecting an auxiliary resistive load across the cell to reduce the cell voltage; b) initiating a recirculation of the anode flow field exhaust through a recycle loop and providing a limited flow of hydrogen fuel into that recirculating exhaust; c) catalytically reacting the added fuel with oxygen present in the recirculating gases until substantially no oxygen remains within the recycle loop; disconnecting the auxiliary load; and then d) providing normal operating flow rates of fuel and air into respective anode and cathode flow fields and connecting the primary load across the cell. The catalytic reaction may take place on the anode or within a catalytic burner disposed within the recycle loop. The procedure allows start-up of the fuel cell system without the use of an inert gas purge while minimizing dissolution of the catalyst and corrosion of the catalyst support during the start-up process.

Owner:AUDI AG

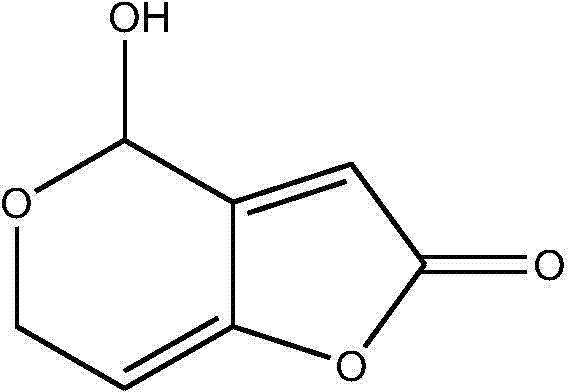

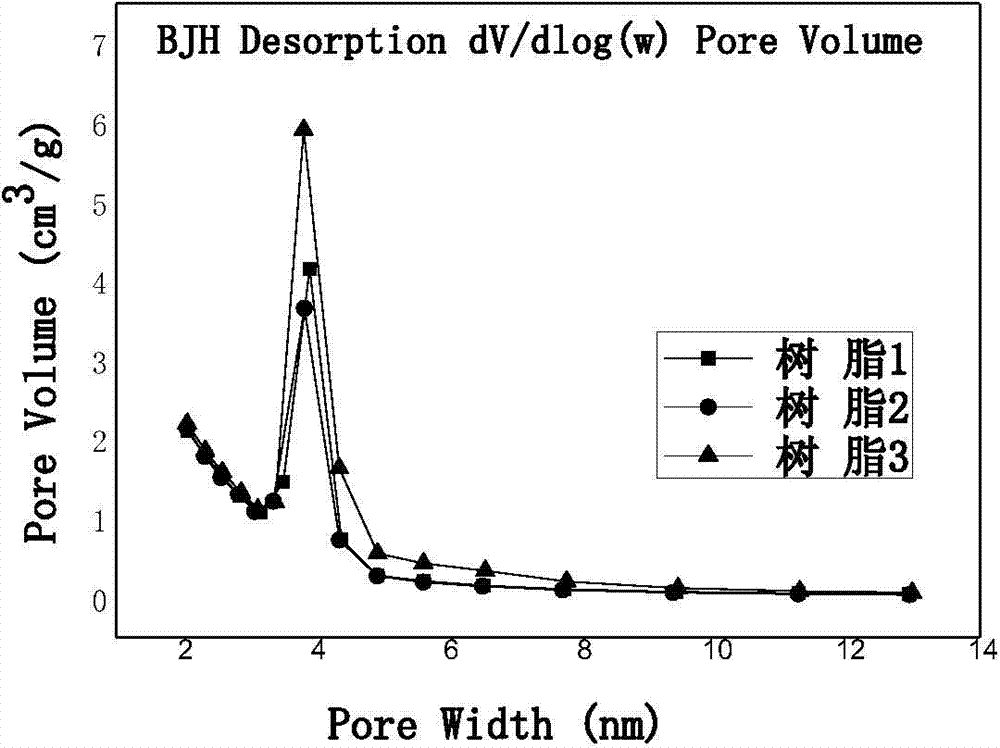

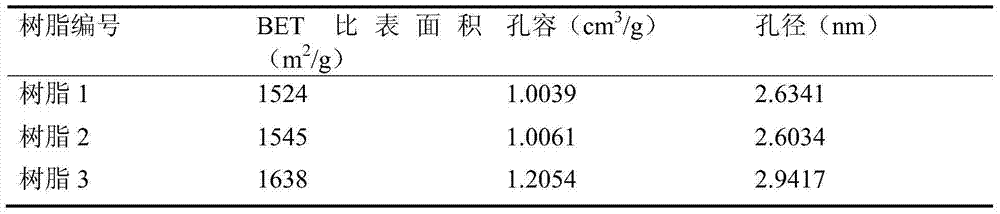

Ultrahigh cross-linked macro-porous adsorption resin applicable to removal of patulin

ActiveCN103772573ADense channelsUnique Pore Size DistributionIon-exchange process apparatusOther chemical processesCross-linkFunctional monomer

The invention provides ultrahigh cross-linked macro-porous adsorption resin which is obtained by taking a styrene monomer as a functional monomer, taking a multi-vinyl monomer as a cross-linking agent, suspending and polymerizing in the presence of a pore forming agent to obtain low-cross-linked macro-porous polystyrene white ball, reacting the obtained white ball with chloromethyl ether under the catalysis of lewis acid to obtain chloromethylation macro-porous polystyrene resin, and carrying out a Friedel-Crafts alkylation reaction on the obtained chloromethylation macro-porous polystyrene resin in the presence of a swelling agent by taking the lewis acid as a catalyst. Through adopting a novel cross-linking agent and pore forming agent system, the obtained resin has the advantages of high specific surface area and uniform pore diameter; the specific surface area is up to 1500-1800m<2> / g, the pore diameter distribution is uniform, a pore channel is dense and the average pore diameter is small; the pore diameter of the obtained macro-porous resin is rightly applicable to removal of patulin in juice and the removing efficiency is high; the resin can be used for pointedly removing the patulin which stably exists in the juice and the potential hazards on the human health, caused by the patulin in the juice, are solved; the ultrahigh cross-linked macro-porous adsorption resin has great social and economic benefits.

Owner:AMICOGEN CHINA BIOPHARM CO LTD

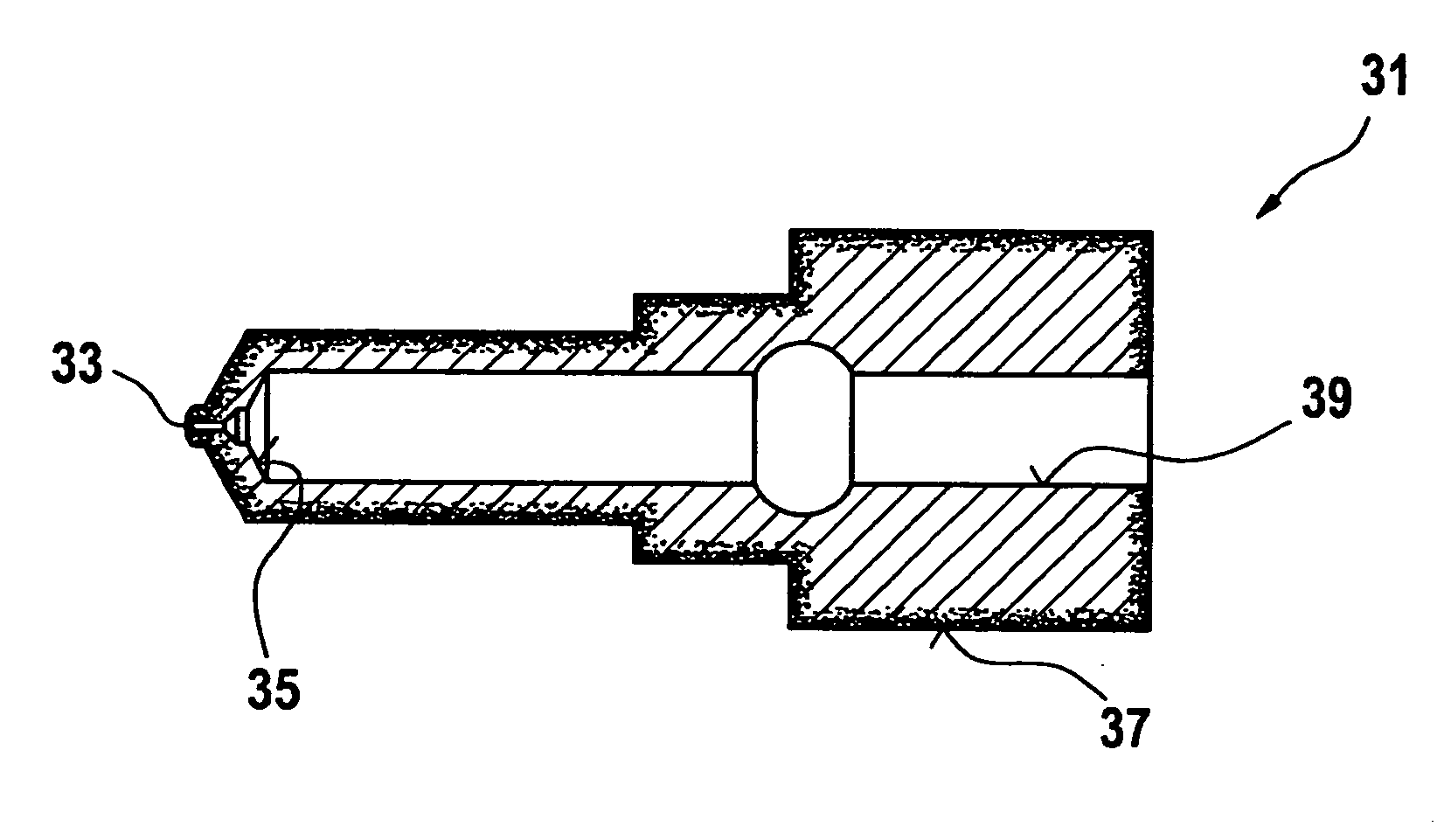

Method for carburizing workpieces and its application

InactiveUS20110277887A1Excellent surface hardnessReduce wearSolid state diffusion coatingMachines/enginesMetallurgyCarburizing

A method for carburizing workpieces made of steel, particularly workpieces having outer and inner surfaces, the workpiece being held at a temperature in the range of 850 to 1050° C. in an atmosphere containing a gaseous hydrocarbon. At least two different gaseous hydrocarbons are used and / or the workpiece is alternatingly held in the atmosphere containing the gaseous hydrocarbon during a carburizing pulse and in an atmosphere free of hydrocarbon during a diffusion phase. Also described is a use of the method.

Owner:ROBERT BOSCH GMBH

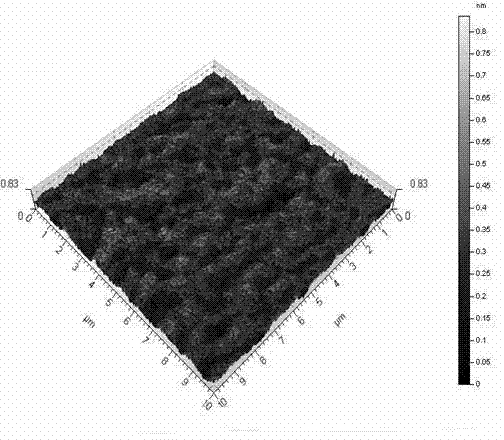

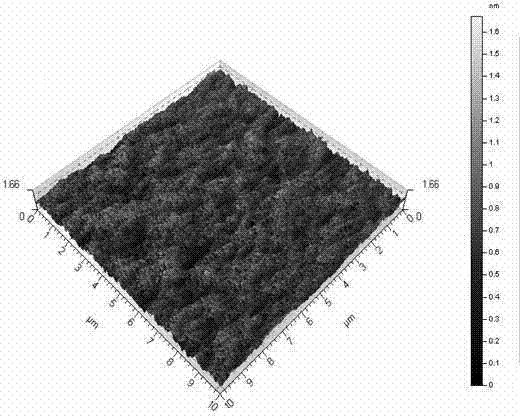

CMP (Chemical-Mechanical Polishing) polishing liquid with mixed grinding materials for alkaline sapphire substrate and preparation method thereof

ActiveCN103571333ASolve pollutionSolve many disadvantages such as easy gelPolishing compositions with abrasivesNano sio2SURFACTANT BLEND

The invention relates to a CMP (Chemical-Mechanical Polishing) polishing liquid with mixed grinding materials for an alkaline sapphire substrate and a preparation method thereof. The CMP polishing liquid consists of the following components in percentage by weight: 0.5-35% of a main grinding material, 0.015-0.09% of an auxiliary grinding material, 0.005-0.05% of a chelating agent, 0.005-0.05% of a surfactant, 0.01-0.5% of a pH adjustor, and the balance of deionized water, wherein the main grinding material is a nano SiO2 sol and the auxiliary grinding material is an Al2O3 sol. The auxiliary grinding material, the chelating agent, the surfactant and the alkaline pH adjustor are sequentially added into a nanosilicon sol suspension. In the polishing liquid, as the content of the main grinding material SiO2 sol is reduced, the phenomenon that the polishing liquid residue on the surface of the substrate after CMP is relatively severe is reduced to facilitate subsequent cleaning. A less amount of the auxiliary grinding material Al2O3 is added, so that the polishing speed is remarkably increased, and the roughness of the substrate after CMP is reduced.

Owner:江西伟嘉创展企业管理有限公司

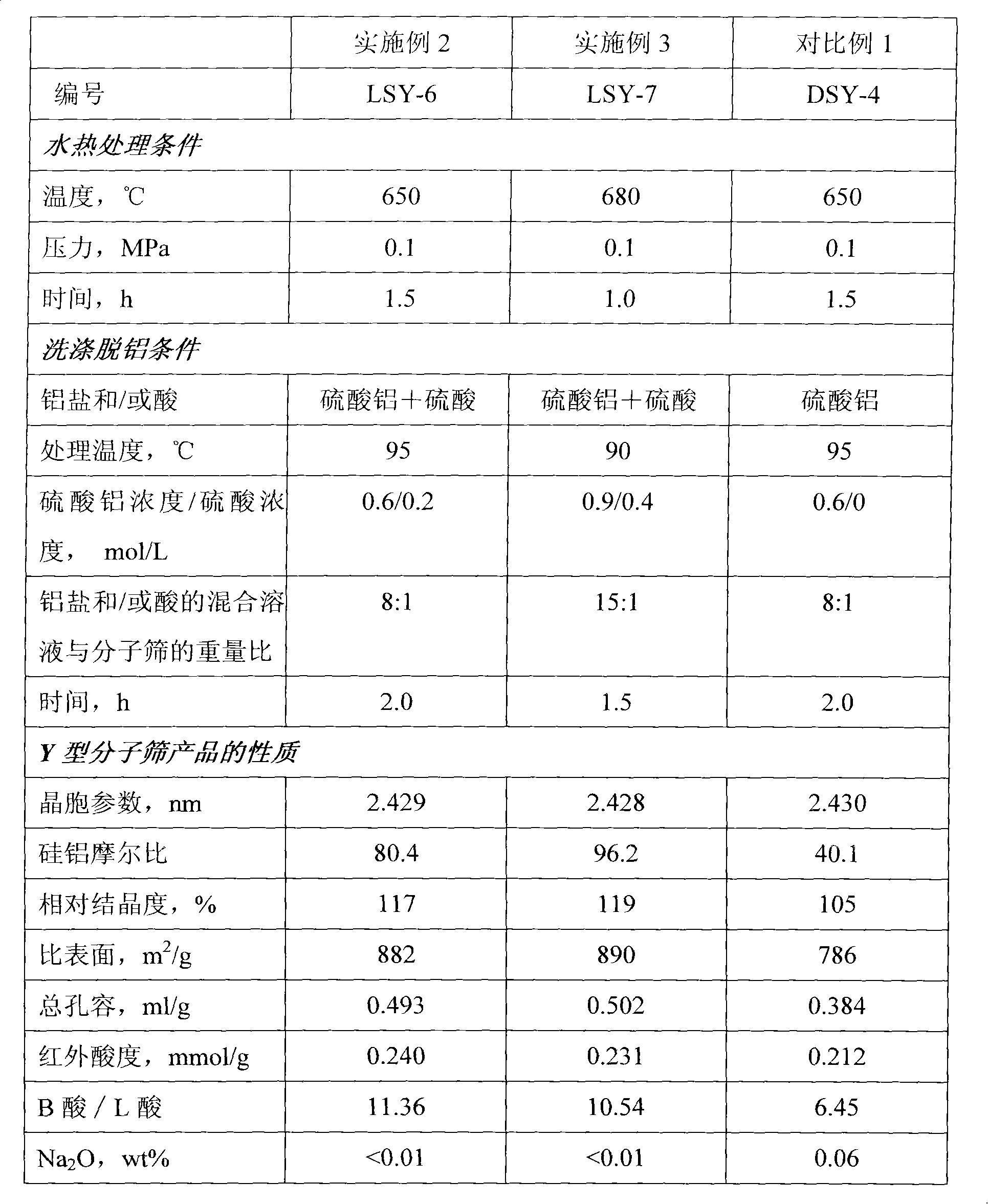

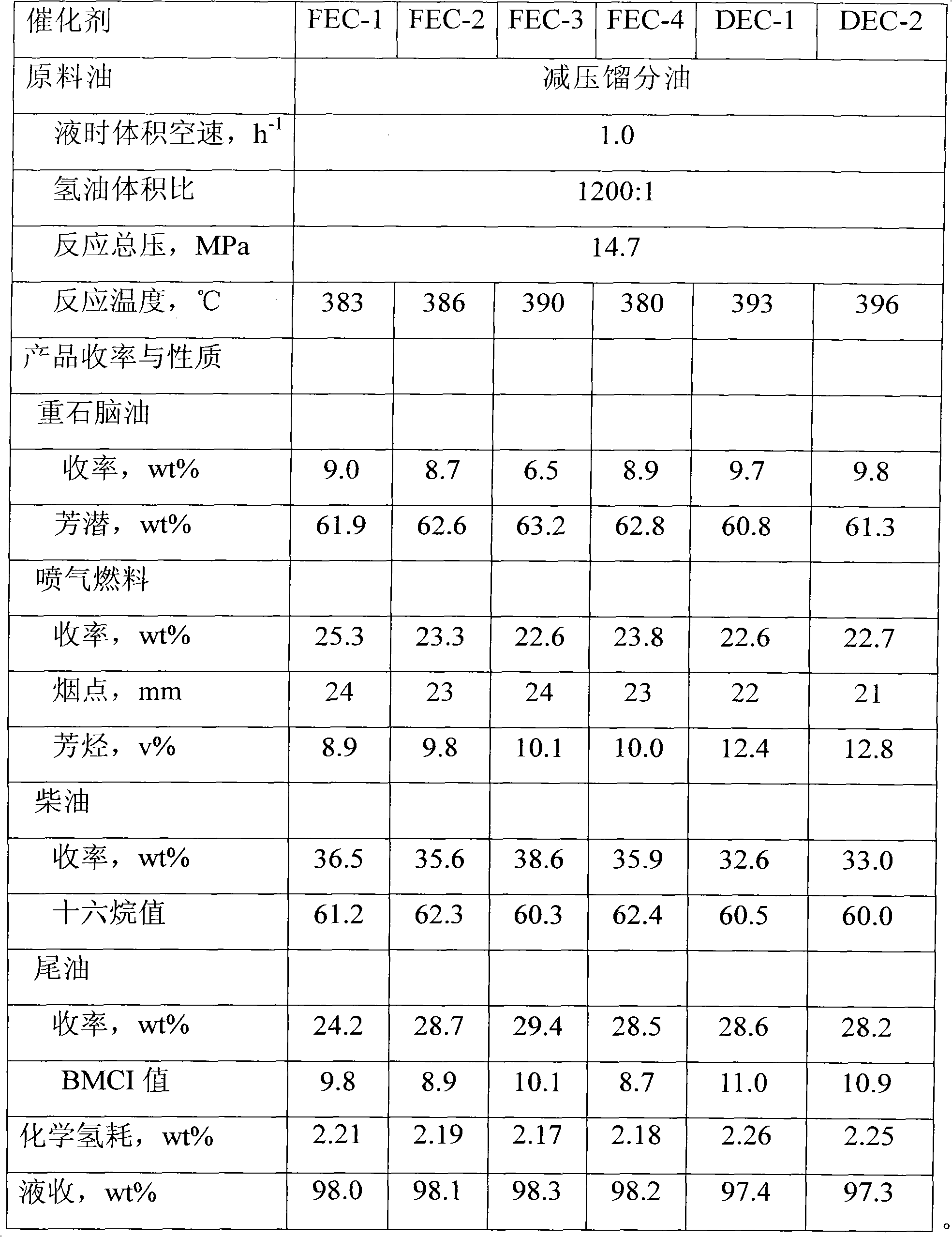

Hydro-cracking catalyst and preparation method thereof

ActiveCN102049283AIncrease removalHigh ratio of silicon to aluminumMolecular sieve catalystsCatalyst activation/preparationMolecular sieveChemistry

The invention discloses a hydro-cracking catalyst and a preparation method thereof. The catalyst comprises hydrogenated active metal ingredients and carriers containing small grain Y molecular sieves, amorphous silica-alumina and alumina, wherein the small grain Y molecular sieves are obtained by treating hydrothermally treated Y molecular sieves by using mixed aqueous solution of aluminum salt and acid. The Y molecular sieves have small grains, high crystallization degree, high silica-alumina ratio and proper total acid amount and acid distribution; the Y molecular sieves and the amorphous silica-alumina are used as acid components of the catalyst together; and the prepared catalyst can treat heavier and / or poor-quality raw materials, and has the characteristics of high catalytic activity, good selectivity of intermediate fraction oil and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

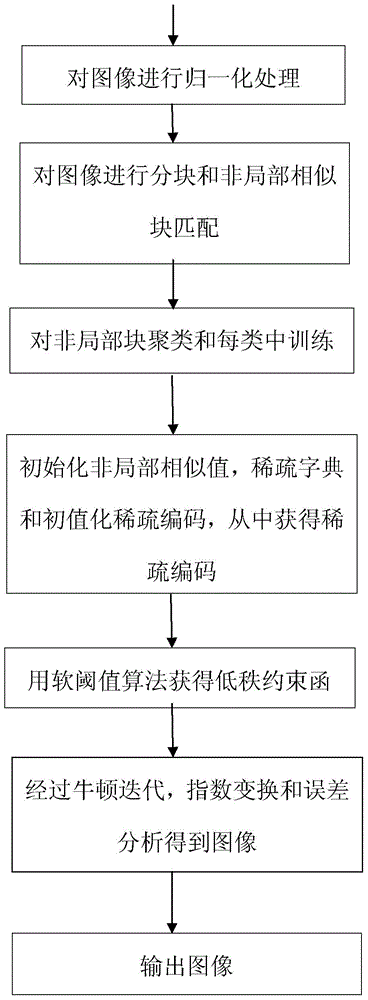

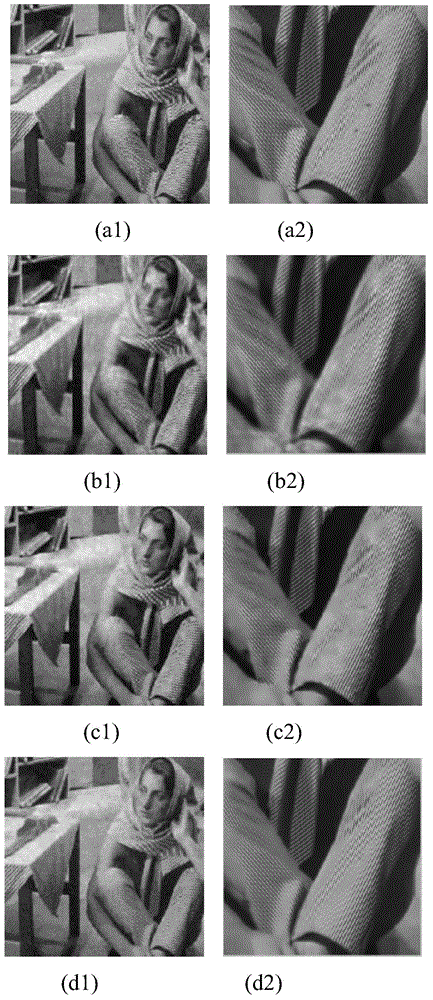

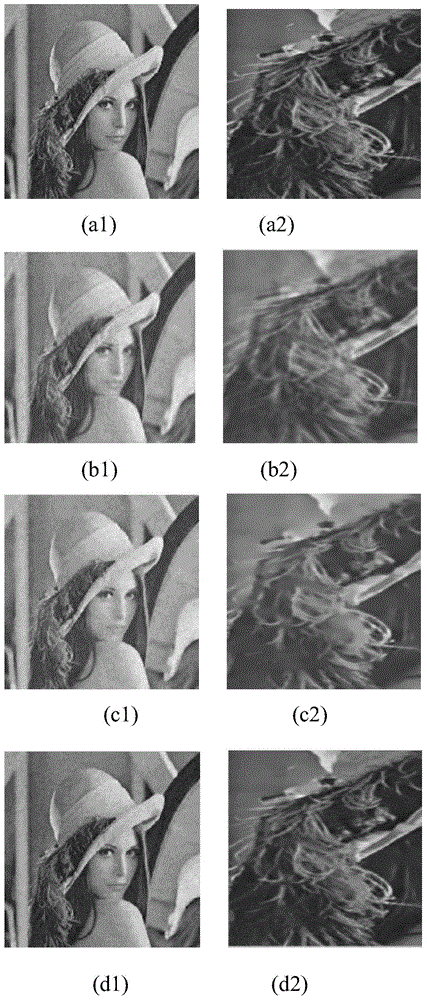

Multiplicative noise removal method for image

InactiveCN104657951AEfficient removalReduce workloadImage enhancementSignal-to-noise ratio (imaging)Noise removal

The invention discloses a multiplicative noise removal method for an image. According to the method, calculus of variations and low rank constraint condition are embedded on the basis of a non-local learned dictionary based on sparse representation, non-local similar patches are subjected to weight matching, a sparse coding is solved with an iterated function, and a soft threshold algorithm is applied to low rank solution. The multiplicative noise removal method has the advantages that very good noise removal effect and high peak signal to noise ratio are realized, edge information and textural features of the image are reserved well to be more close to an original image visually, and the similarity is improved greatly.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Hydrocracking catalyst containing Y molecular sieve and preparation method thereof

ActiveCN101450320BHigh ratio of silicon to aluminumIncrease acidityMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention discloses a hydrocracking catalyst for producing heavy naphtha in great abundance and a preparation method thereof. The catalyst contains hydrogenation active metals and a carrier which consists of modified Y molecular sieves and alumina, wherein the Y molecular sieves are obtained by using a mixed aqueous solution of aluminum salts and an acid to perform hydro-thermal treatment. The properties of the modified Y molecular sieves are as follows: the specific surface area is between 750 m<2> / g and 850 m<2> / g; the total pore volume is between 0.35 and 0.48 ml / g; the relative crystallinity is between 90 and 130 percent; the cell parameter is between 2.437 and 2.445 nanometers; the silicon-aluminum mol ratio is between 15 and 70; the infrared acid amount is between 0.5 and 1.0 mmol / g; the B acid / L acid is more than 7.0; and the content of sodium oxide is less than or equal to 0.05 weight percent. The hydrocracking catalyst has the characteristics of good catalytic activity, high heavy naphtha selectivity, high yield, high latent content of heavy naphtha arene, and so on.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

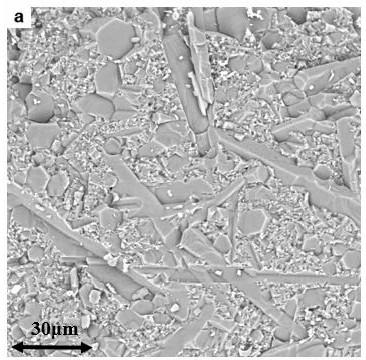

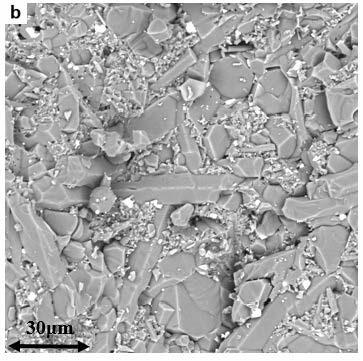

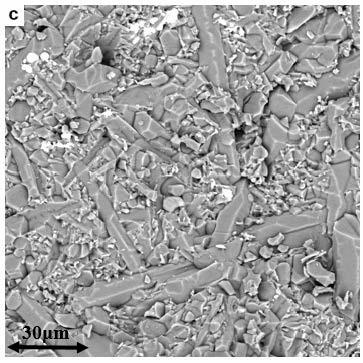

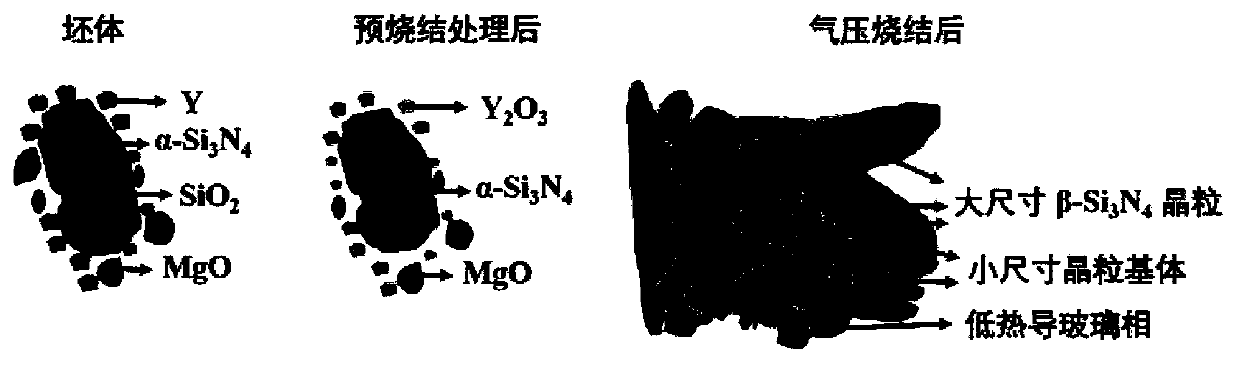

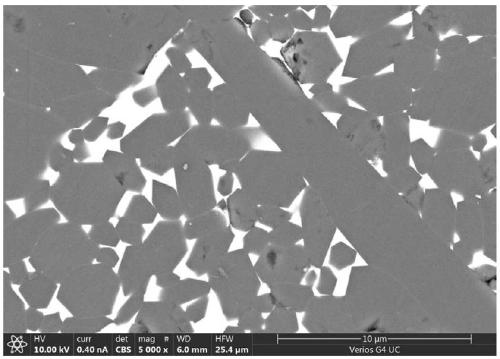

Method for preparing high-thermal-conductivity silicon nitride ceramic

ActiveCN109851369AReduce the introductionReduce glass phase contentCompression moldingGas pressure sintering

The invention relates to a method for preparing silicon nitride ceramic with high thermal conductivity, which comprises the following steps: uniformly mixing alpha-Si3N4 powder with a sintering aid, and carrying out compression molding to obtain a green body; and carrying out gas pressure sintering on the green body at the temperature of 1780-1950 DEG C in an inert atmosphere, and then cooling thesintered product to room temperature to obtain the silicon nitride ceramic; wherein the sintering aid is composed of silicide and alkaline earth metal oxide, the ratio of the alpha-Si3N4 powder to the sintering aid being (90mol%) : (10mol%) - (99mol%) : (1mol%).

Owner:江西中科上宇科技有限公司

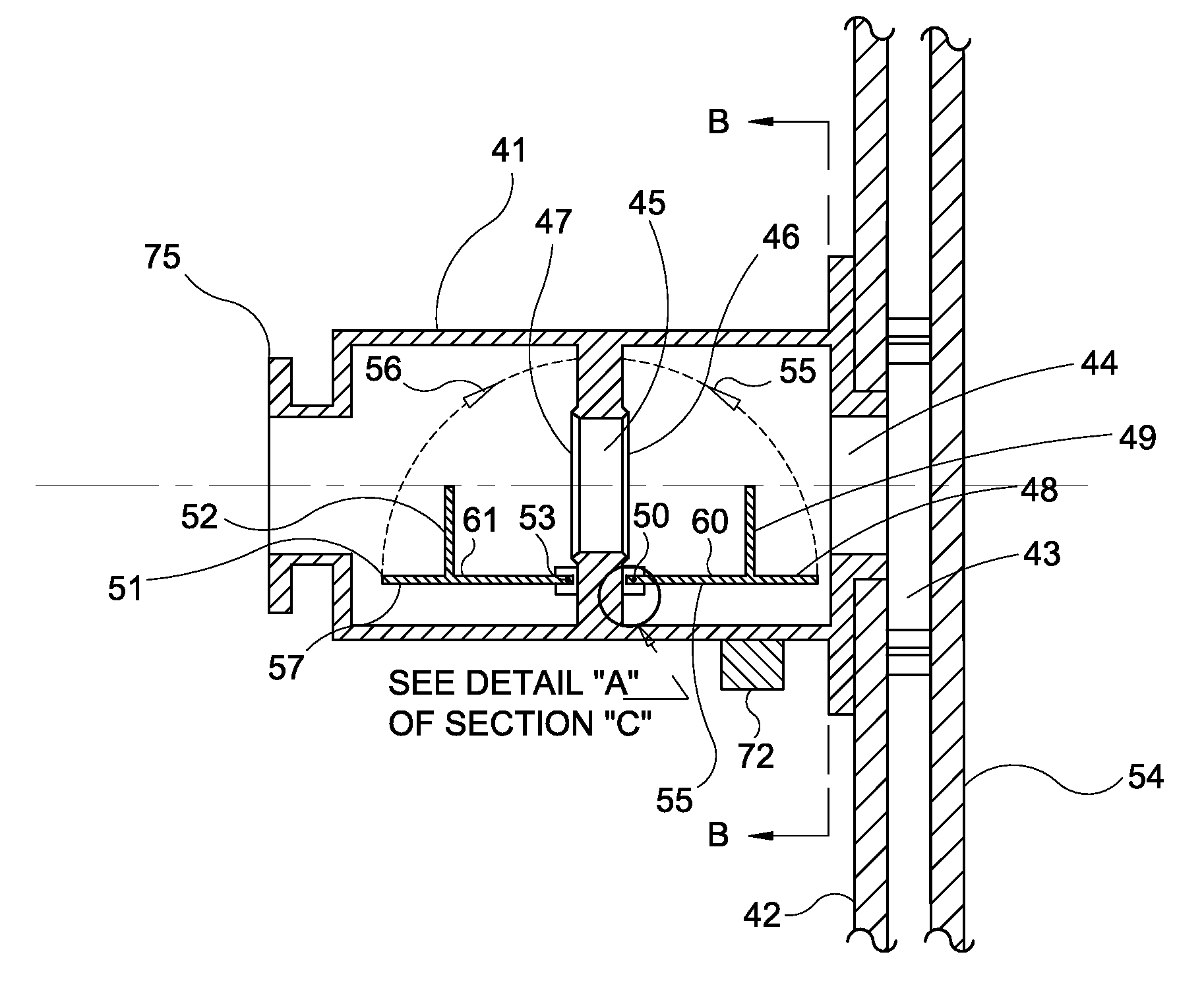

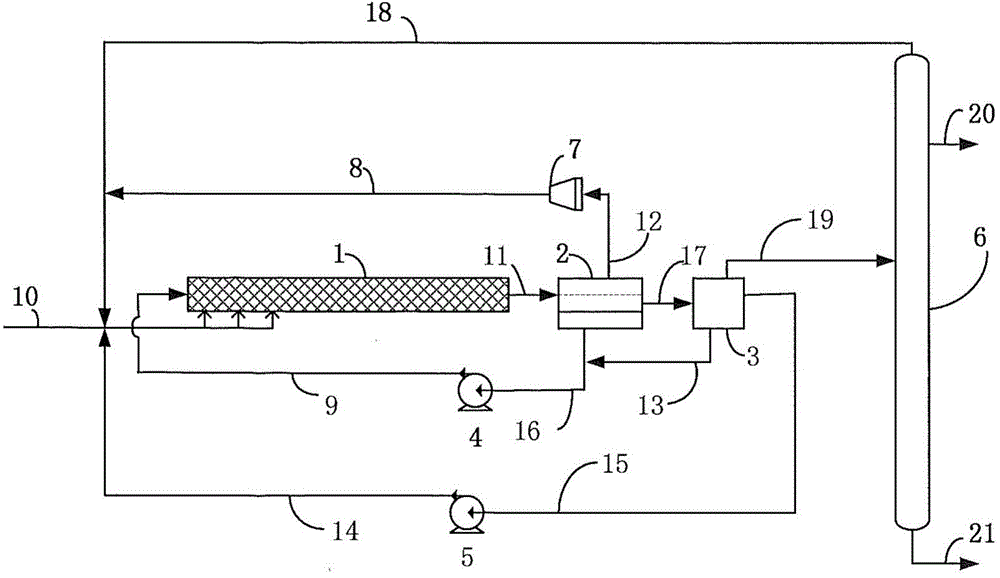

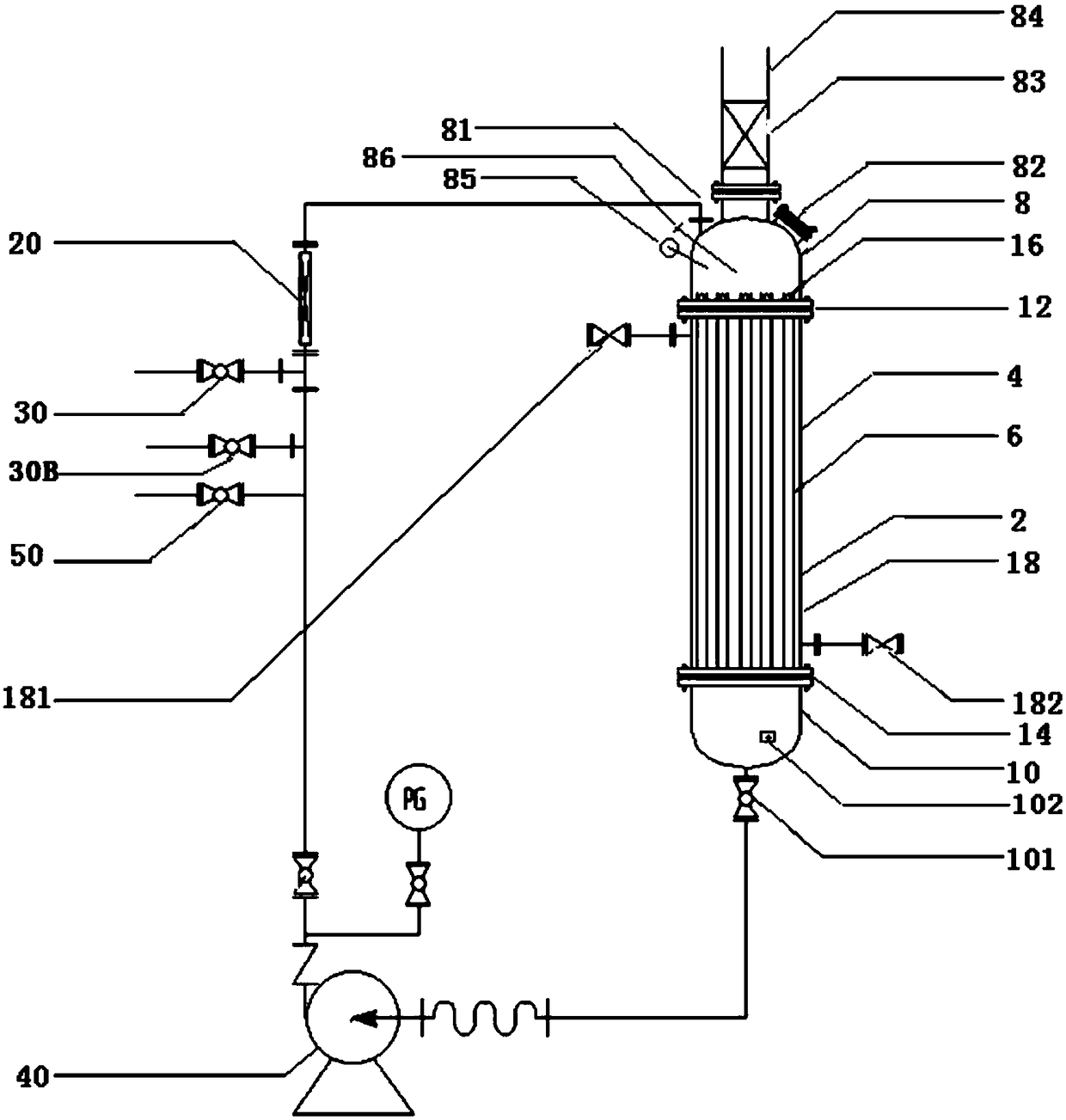

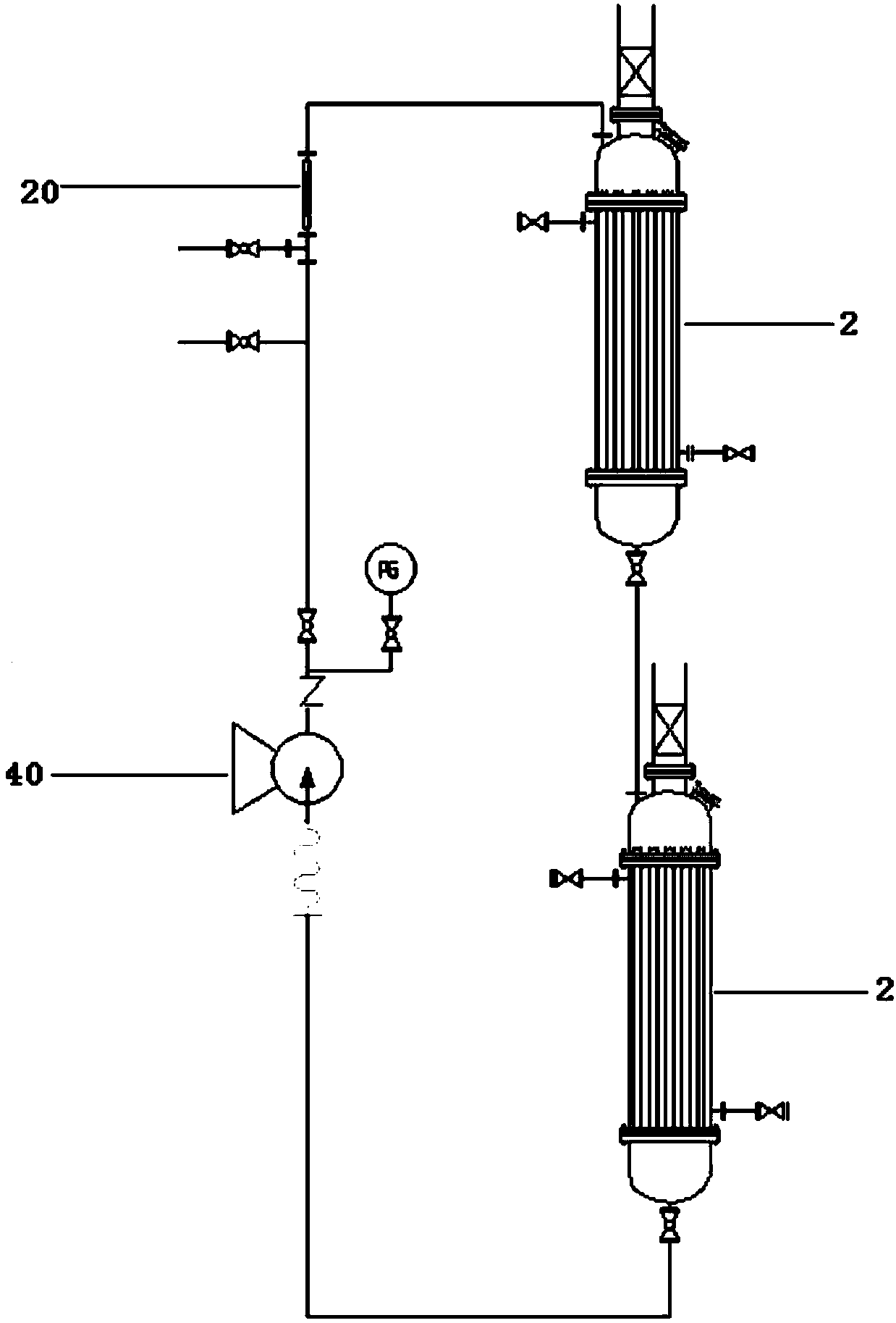

Alkylation reaction method and apparatus for isoparaffin and alkene with liquid acid for catalysis

ActiveCN106032472ADisperse fastIncrease initial micromixing levelLiquid hydrocarbon mixtures productionHydrocarbonsAlkyl transferEmulsion

A liquid acid-catalyzed method for the alkylation of isoparaffins and olefins, characterized in that the raw materials for the alkylation reaction are divided into multiple feeds from the side of a static mixer, and are mixed with the acid hydrocarbons in the main channel of the static mixer. After the emulsion is mixed and contacted for 0.2-15min, it enters the separator under reduced pressure. The pressure of the separator is controlled to be 0.005-0.18MPa to vaporize the carbon tetraalkane and take away the reaction heat. Most of the acid hydrocarbon emulsion in the lower part of the separator is pressurized and circulated. Return to the main channel of the static mixer; the gas phase components separated from the upper part of the separator enter the compressor system, and are compressed and condensed by the compressor to cool the raw materials of the alkylation reaction, and a small part of the hydrocarbon phase is produced in the middle of the separator and enters the coalescer , the acid phase obtained by coalescence returns to the static mixer, the hydrocarbon phase enters the deisobutanizer, the isobutane obtained from the top of the deisobutanizer is recycled back to the static mixer, and the tower still obtains the alkylation product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Vacuum system comprising vacuum insulated glass units

InactiveUS20140116516A1Process can be speededReduce stressDoors/windowsPressure pumpsVacuum pumpElectrical and Electronics engineering

Owner:JONES ROBERT S

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN101618348BHigh ratio of silicon to aluminumLarger than surfaceCatalyst carriersMolecular sieve catalystsMolecular sieveCrystallinity

Owner:CHINA PETROLEUM & CHEM CORP +1

Alkylation reaction method for isoparaffin and alkene with liquid acid for catalysis

InactiveCN106032349ADisperse fastIncrease initial micromixing levelHydrocarbonsHydrocarbon preparationGas phasePressure reduction

The invention provides an alkylation reaction method for isoparaffin and alkene with liquid acid for catalysis. The method is characterized in that the method comprises the following steps: alkylation reaction raw materials are fed from a side surface of a static mixer in one stream or several streams, the raw materials and an acid hydrocarbon emulsion which is in a main runner of the static mixer are mixed and contacted, after the mixture is reacted and contacted for 0.2-15 minutes, pressure reduction is carried out for the mixture, the mixture enters a separator, the pressure of the separator is controlled at 0.005-0.18MPa, butane is vaporized in order to take away reaction heat, the acid phase below the separator is supercharged by an acid circulation pump and recycled to the main runner of the static mixer; gas phase components which are separated from an upper part of the separator enter a compressor system, and the components are compressed and condensed by a compressor in order to cool the alkylation reaction raw materials; a hydrocarbon phase which is partially separated from the separator enters a coalescer, most of the hydrocarbon phase which is separated from the coalesce is supercharged by a hydrocarbon circulation pump and mixed with the raw materials, and the mixture enters the side surface of the static mixer for feeding; an acid phase which is separated from the lower part of the coalesce returns an inlet of the circulation pump; a small part of a hydrocarbon phase which is extracted from the upper part of the coalescer enters a deisobutanizer, isobutane which is obtained from the top of the deisobutanizer is circulated and returns to the static mixer, and alkylation products are obtained from the bottom of the deisobutanizer.

Owner:CHINA PETROLEUM & CHEM CORP +1

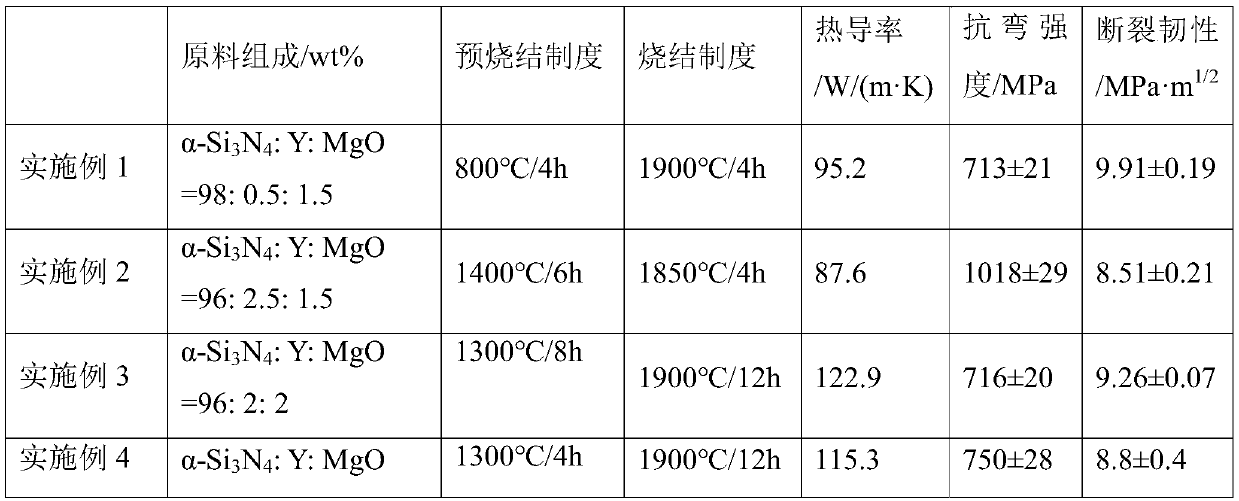

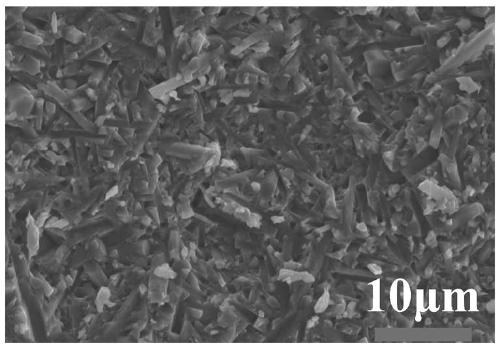

High-strength, high-toughness and high-thermal-conductivity silicon nitride ceramic material and preparation method thereof

The invention relates to a high-strength, high-toughness and high-thermal-conductivity silicon nitride ceramic material and a preparation method thereof. The silicon nitride ceramic material is prepared from the following raw materials: alpha-Si3N4 and a sintering aid, wherein the sintering aid is a rare earth metal simple substance and an alkaline earth metal oxide, and the total content of the sintering aid is 2-12wt%; the rare earth metal simple substance is Y; and the alkaline earth metal oxide is preferably at least one of MgO, CaO and BaO.

Owner:江西中科上宇科技有限公司

A composition for wet wipes which is gentle to the skin

InactiveCN1816320AImprove the lubrication effectReduce frictionCosmetic preparationsToilet preparationsWet wipeSURFACTANT BLEND

Owner:PROCTER & GAMBLE CO

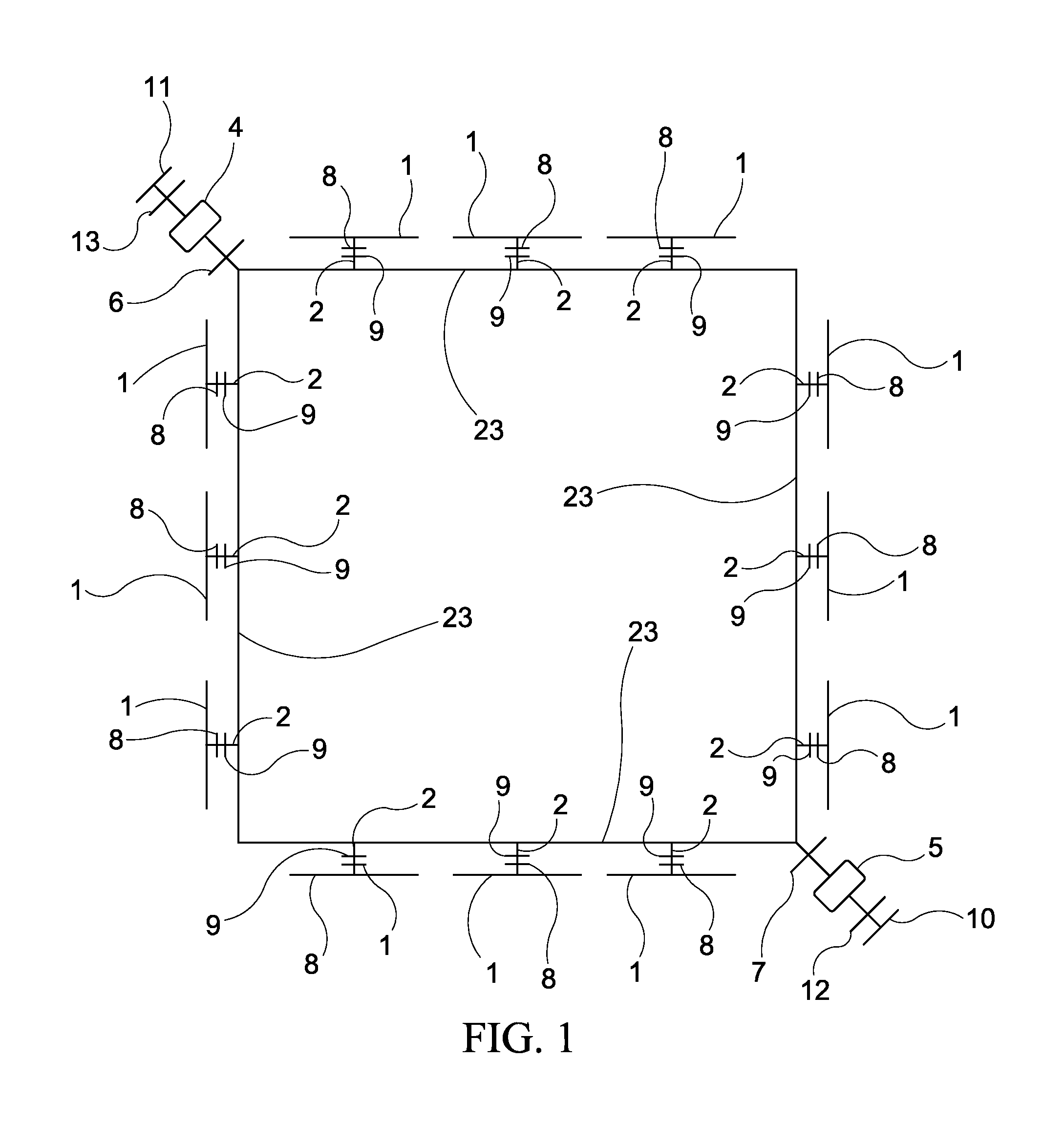

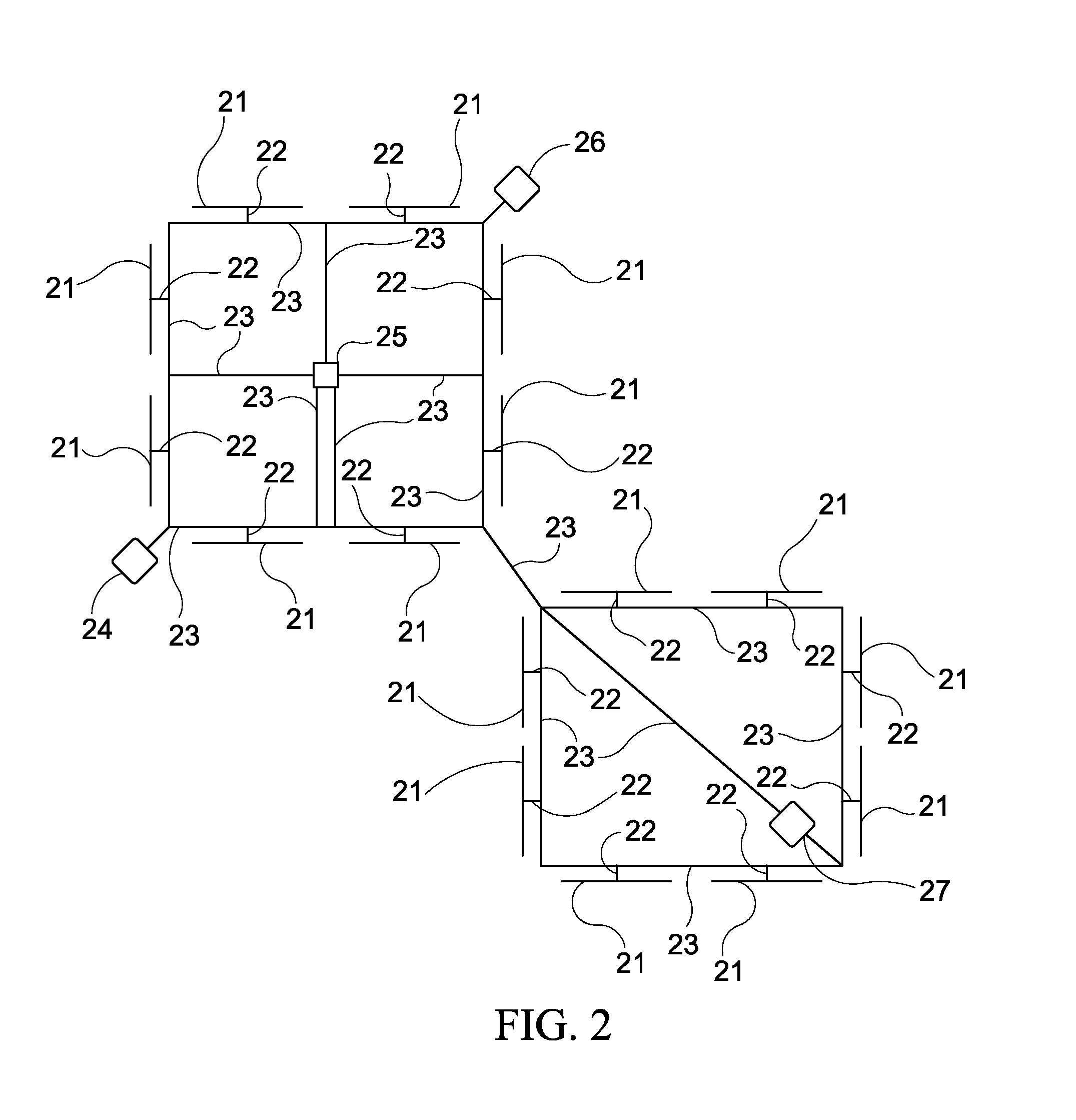

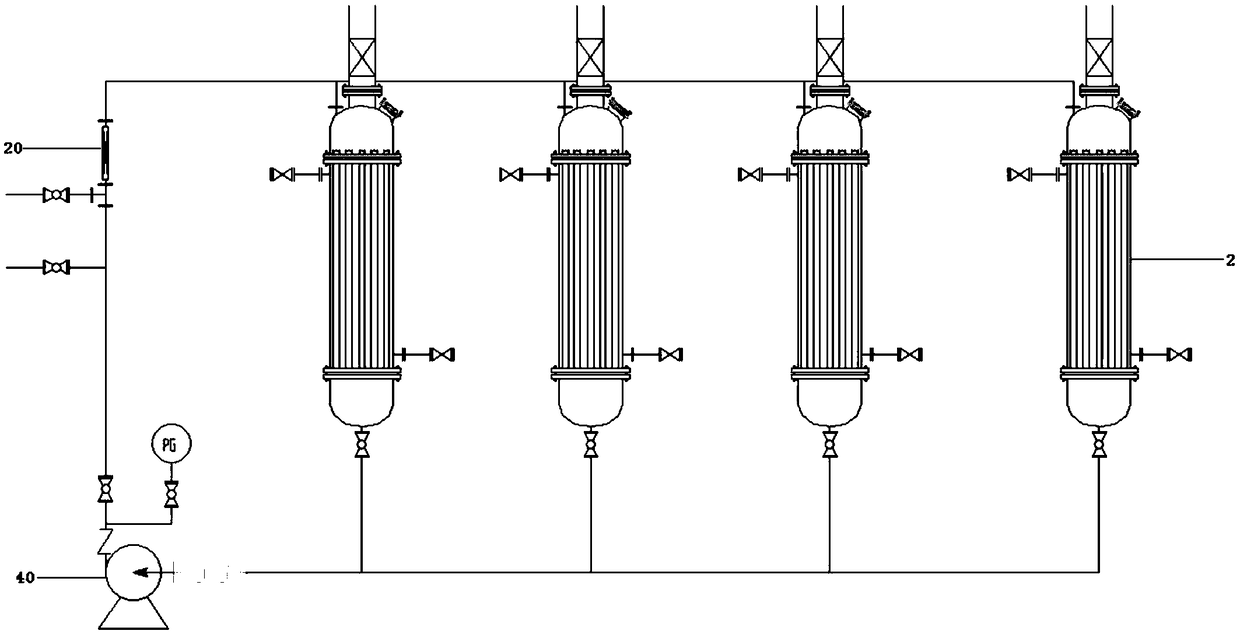

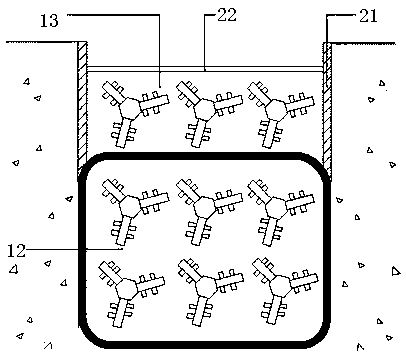

Self circulation array pipe reaction device with efficient mixer and reaction method using same

PendingCN109225114ALarge specific surface areaFast heat transferFlow mixersTransportation and packagingEngineeringCirculating pump

The invention relates to a self circulation array pipe reaction device with an efficient mixer and a reaction method using the same. The material mixing problem is solved through the arrangement of anefficient mixer and a circulation pump. The heat transfer problem and the reaction flux problem can be effectively solved in time through installing an array pipe reactor and controlling the circulation quantity. The reaction device provided by the invention has the advantages that the heat transfer effect is good; the material mixing is uniform; the continuous and automatic reaction can be realized. The reaction method using the reaction device provided by the invention has the advantages that the operation is simple; the reaction efficiency is high; the heat transfer effect is good; side reactions are few; the reaction flux is great.

Owner:葛沁怡

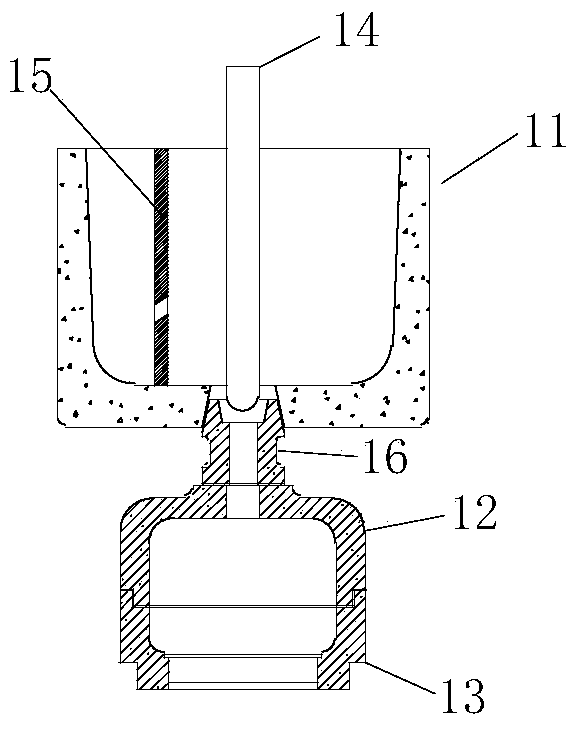

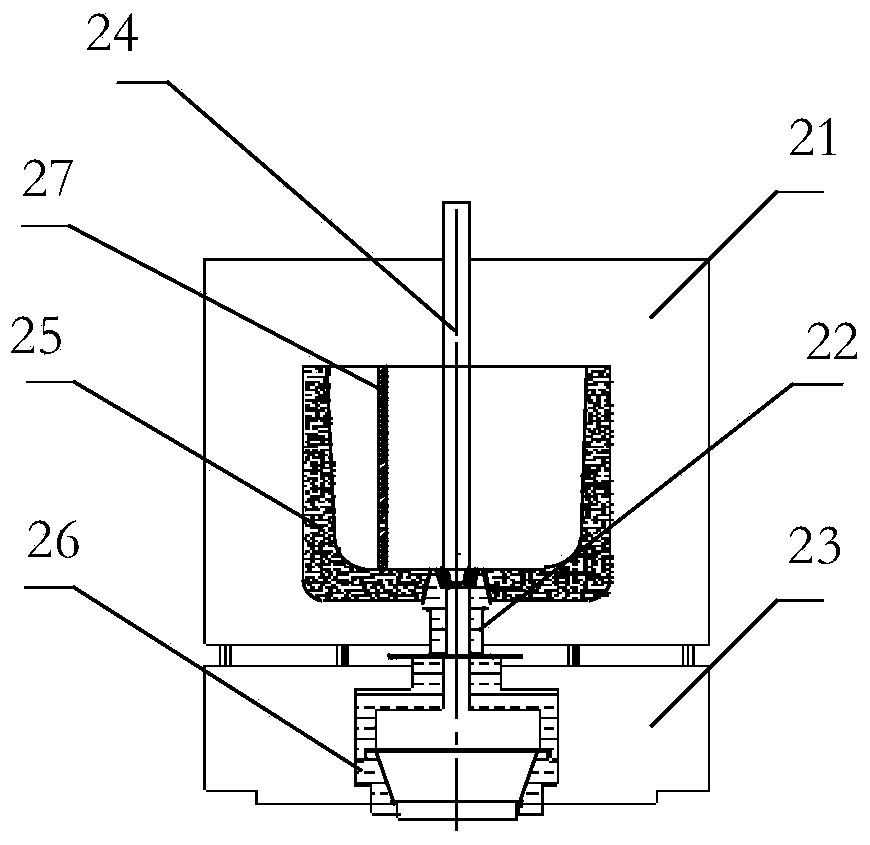

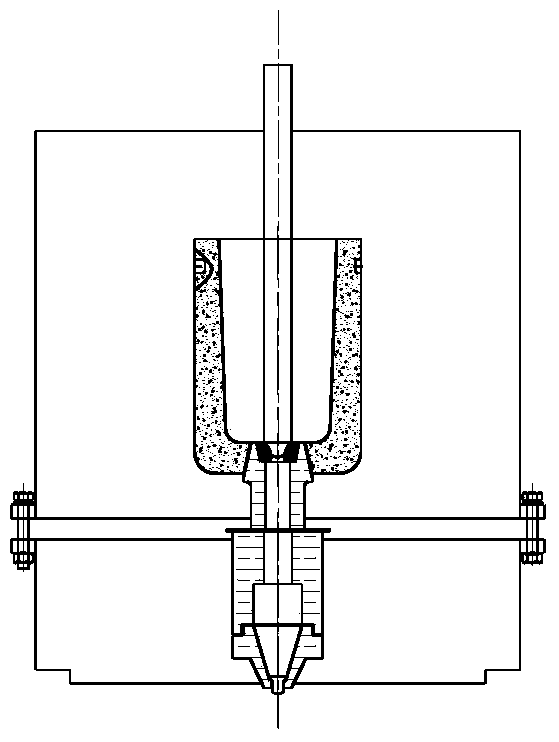

Quick-changing type spraying package

The invention relates to a quick-changing type spraying package. The quick-changing type spraying package comprises a crucible, a stopper rod and a spraying cup. The crucible is accommodated in an upper package shell, amorphous ribbon molten metal liquid is poured in the crucible, and a water gap is formed in the bottom of the crucible. The bottom of the stopper rod is plugged in the water gap, the spraying cup is accommodated in a lower package shell, and the lower package shell is fixedly linked in the upper package shell through bolts. A through hole is formed in the top of the spraying cup, and a spraying hole is formed in the bottom of the spraying cup. The water gap is communicated with the through hole. When the stopper rod is removed from the water gap, the amorphous ribbon molten metal liquid in the crucible flows into the spraying cup through the water gap and the through hole and then sprayed out through the spraying hole, and then amorphous ribbons are formed. The spraying cup in the spraying package is a detachable device.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

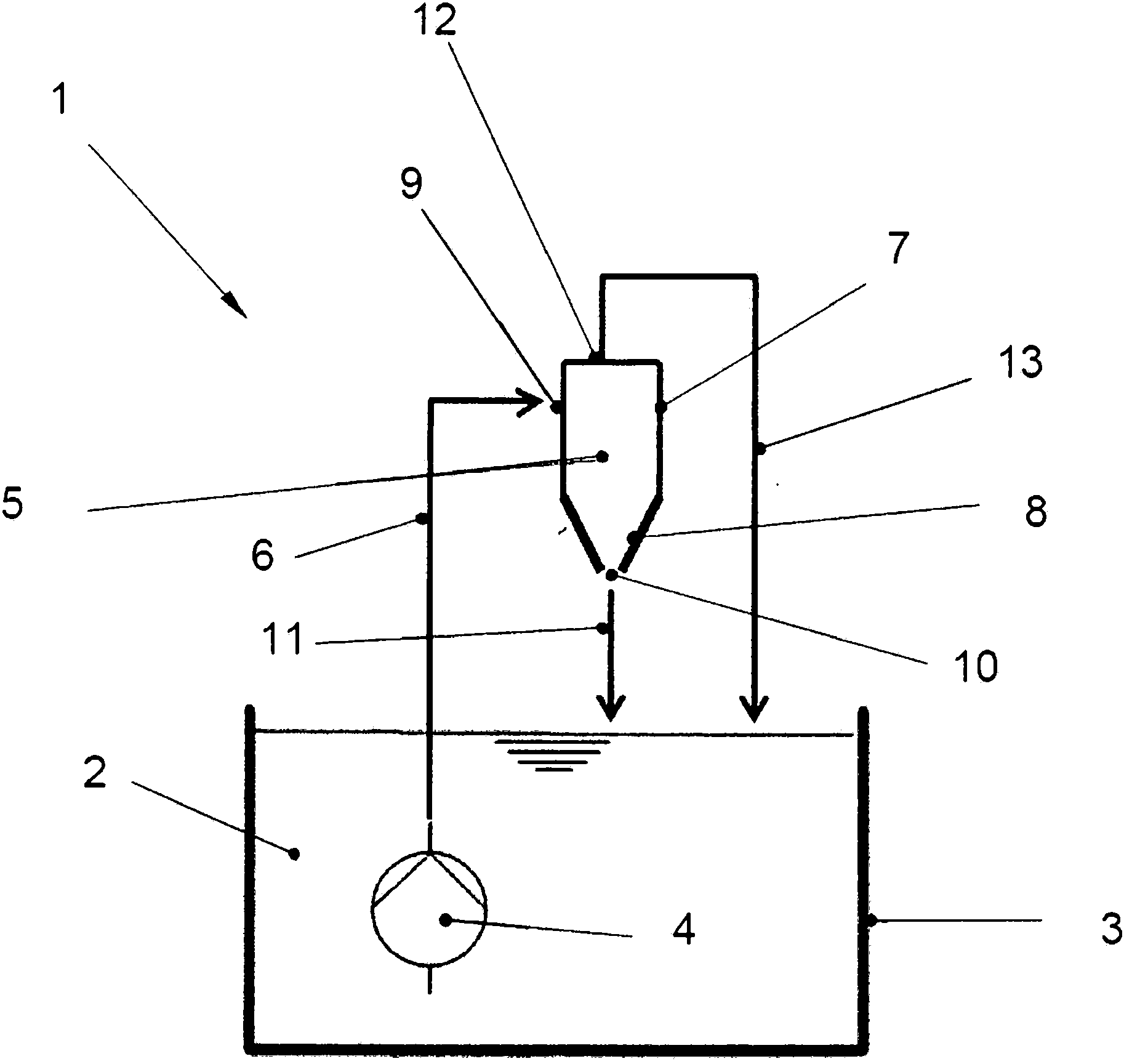

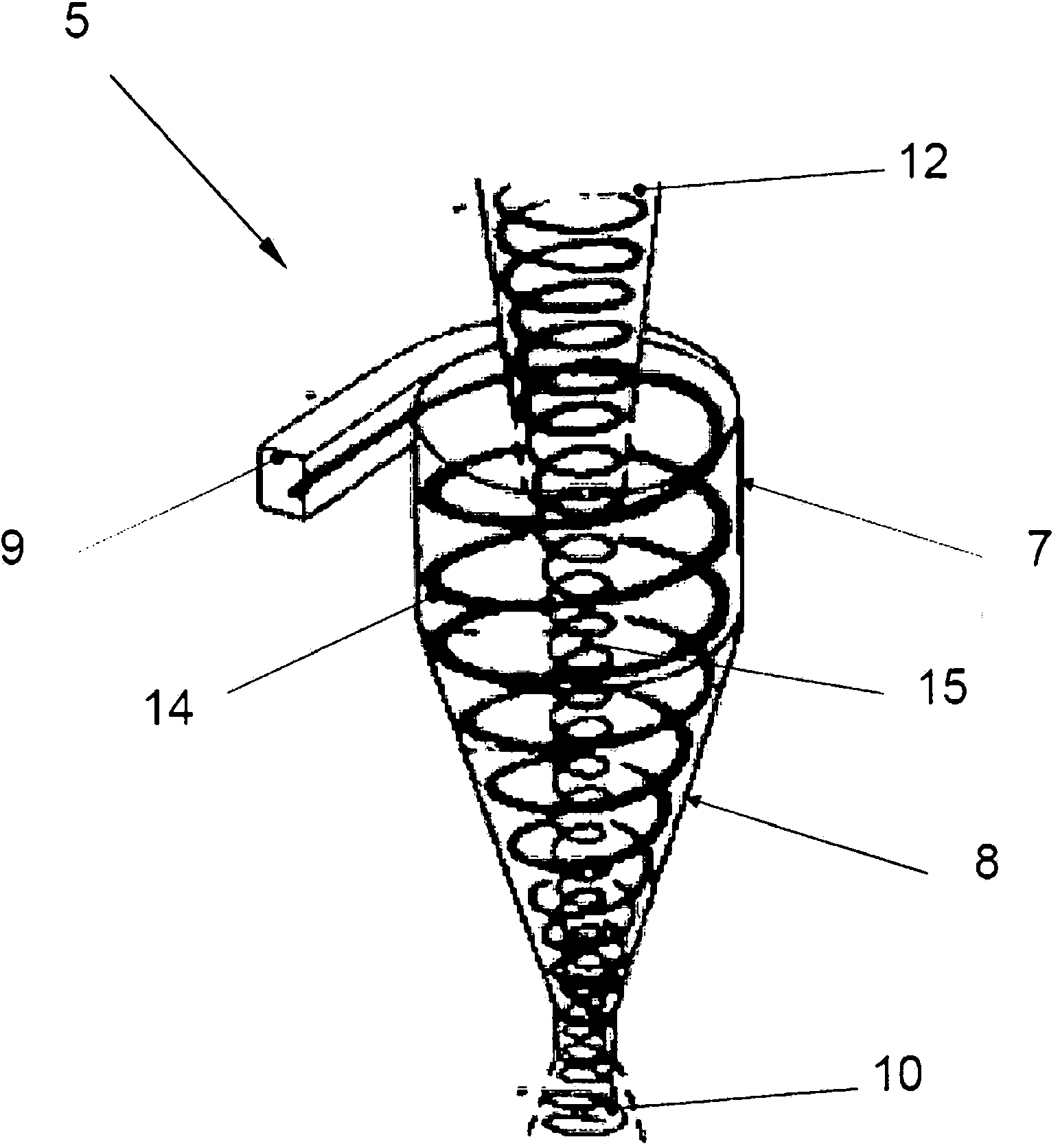

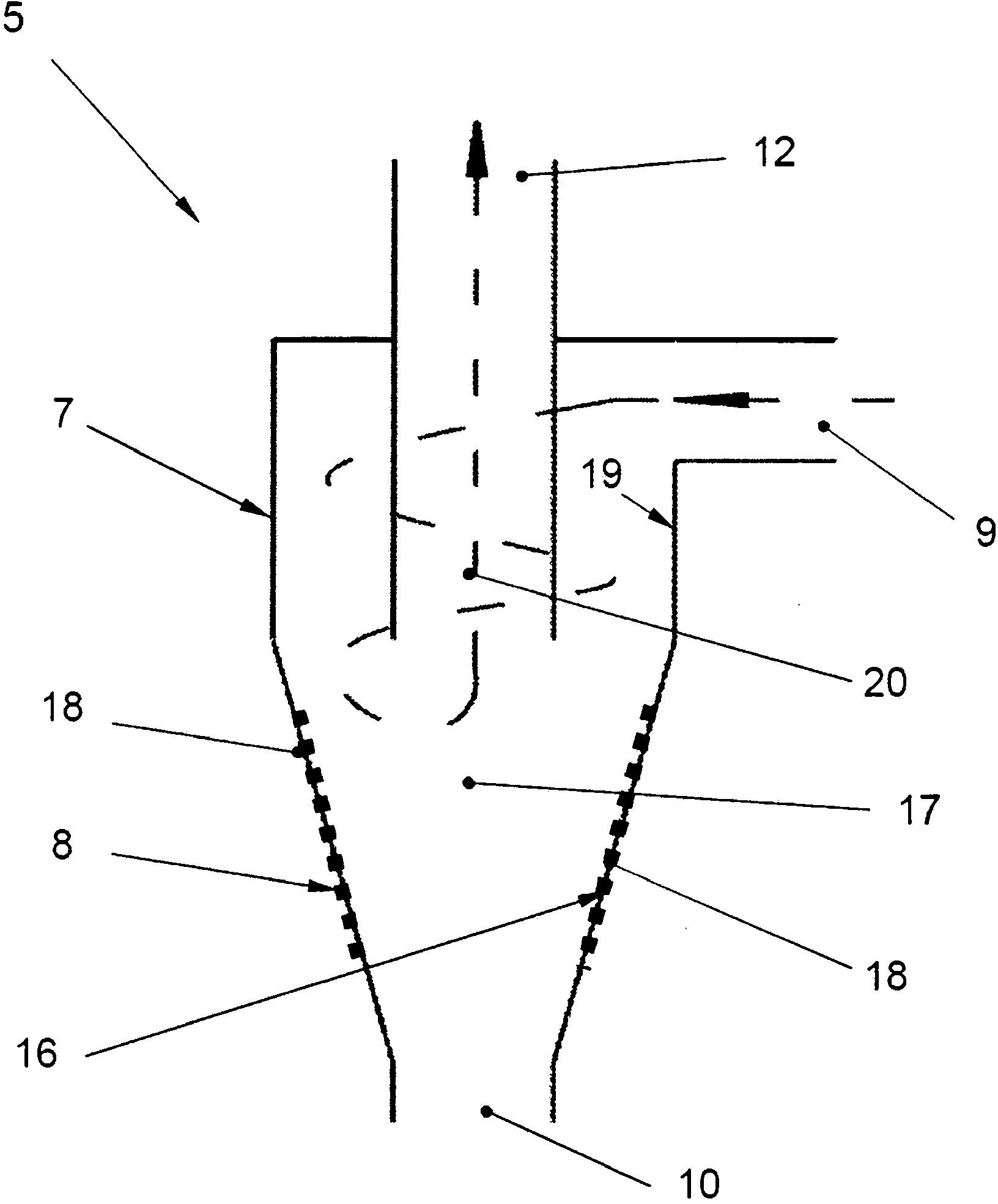

Method and installation for treating wastewater containing ammonia

ActiveCN104108788AIncrease removalEfficient removalWater contaminantsTreatment with anaerobic digestion processesActivated sludgeAmmonia-oxidizing bacteria

A method and installation for treating wastewater containing ammonia includes feeding activated sludge from an aeration tank into a hydrocyclone. The sludge is separated into a specifically heavy fraction containing mostly anaerobic ammonia-oxidizing bacteria (anammox) and a specifically light fraction containing mostly aerobic oxidizing bacteria (AOB), which are returned to the aeration tank. The hydrocyclone includes a roughened inner wall surface for at least partially removing an organic or inorganic cover layer disposed on the anaerobic ammonium-oxidizing bacteria (anammox).

Owner:CYKLAR STULZ ABWASSERTECHN

Heat dissipation structure

InactiveCN102467196AIncrease removalImprove cooling effectDigital data processing detailsCold airEngineering

Owner:INVENTEC CORP

Procedure for starting up a fuel cell system having an anode exhaust recycle loop

InactiveUS7250229B2Increase removalReduce voltageFuel cell heat exchangeSolid electrolyte fuel cellsDissolutionEngineering

A procedure for starting up a fuel cell system that is disconnected from its primary load and that has air in both its cathode and anode flow fields includes a) connecting an auxiliary resistive load across the cell to reduce the cell voltage; b) initiating a recirculation of the anode flow field exhaust through a recycle loop and providing a limited flow of hydrogen fuel into that recirculating exhaust; c) catalytically reacting the added fuel with oxygen present in the recirculating gases until substantially no oxygen remains within the recycle loop; disconnecting the auxiliary load; and then d) providing normal operating flow rates of fuel and air into respective anode and cathode flow fields and connecting the primary load across the cell. The catalytic reaction may take place on the anode or within a catalytic burner disposed within the recycle loop. The procedure allows start-up of the fuel cell system without the use of an inert gas purge while minimizing dissolution of the catalyst and corrosion of the catalyst support during the start-up process.

Owner:AUDI AG

Cloth coiling block transfer trolley

The invention discloses a cloth coiling block transfer trolley comprising a bottom tank and a trolley wheel assembly fixed to a bottom board of the bottom tank, wherein an adjusting assembly is arranged inside the bottom tank and comprises a worm gear, a worm, a lead screw and a shell body; the two ends of the worm are hinged to a left side board and a right side board of the bottom tank; one end of the worm extends out of the left side board or the right side board; a crank is fixed to the worm; one side of the worm gear extends out of a notch and is meshed with the worm; the upper portion and the lower portion of the lead screw are connected to an upper top board and the bottom board of the bottom tank in a screwed mode; the middle of the lead screw is inserted into and sleeved with the shell body and two annular sliding blocks and is connected into a center screw hole of the worm gear in a screwed mode; the top end of the lead screw extends out of the upper top board and is fixed to the bottom face of a bracket; the bottom end of the lead screw extends out of the bottom board. By means of the cloth coiling block transfer trolley, the bracket can be adjusted in a fine mode to meet the heights of take-up rollers of different take-up devices, a cloth coiling block removing device can be placed on the bracket to be conveyed conveniently, and meanwhile the cloth coiling block transfer trolley has the buffering function so as to lower the noise generated when the take-up rollers are thrown onto a coiling block placement block and reduce damage.

Owner:苏州欧得凯纺织科技有限公司

Repairing method of cadmium polluted farmlands and applications thereof

PendingCN109967521AImprove securityImprove repair efficiencyContaminated soil reclamationAgricultureAgronomy

The invention provides a repairing method of cadmium polluted farmlands and applications thereof, and relates to the technical field of agricultural plantation. According to the repairing method, cornand amaranth are intercropped in a cadmium polluted farmland; and the intercropping mode is as follows: (1) corn plants are planted in wide rows and narrow rows, between two neighbored wide corn rows, one to two rows of amaranth plants are planted; (2) corn plants are planted in rows with equal spacing, and between two neighbored corn rows, one to two rows of amaranth plants are planted; and (3)four rows of corn plants and four rows of amaranth plants are planted at intervals alternatively. The provided repairing method can obviously improve the efficiency of repairing cadmium polluted farmlands; the cadmium removal rate is increased to 363.1 to 873.4 mg / mu; the corn output is barely influenced; and the output is increased by 10.5%.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Method for processing dietary fiber duck dried meat floss

ActiveCN103689640ARemove fishy smellImprove qualityFood ingredient functionsFood preparationDietary fiberSaccharum

The invention relates to a method for processing dietary fiber duck dried meat floss. The adopted raw material is fresh lean duck, and the adopted additives comprise sucrose, soy sauce, millet wine, galangal, fennel, table salt, pectin and yeast. The specific processing operation steps are as follows: 1) cutting the lean duck to lumps; 2) soaking the lumpish duck in a yeast solution for fermenting to remove the fishy smell; 3) cooking the additives in water for 20 minutes through slow fire, putting the lumpish lean duck into the solution, and cooking for 120 minutes at a boiling state; 4) frying the cooked lumpish duck, and adding the pectin in the frying process; 5) rubbing and roasting dried meat floss: removing the coked duck, and rubbing the duck into dried meat floss in a dried meat floss rubbing machine, and roasting the dried meat floss to remove excessive moisture to obtain the duck dried meat floss. According to the method provided by the invention, the duck is soaked in the yeast solution to effectively remove the fishy smell of the duck; the pectin is added in the frying process to effectively perfect the shape, color, luster and taste of the duck dried meat floss.

Owner:HEFEI UNIV OF TECH

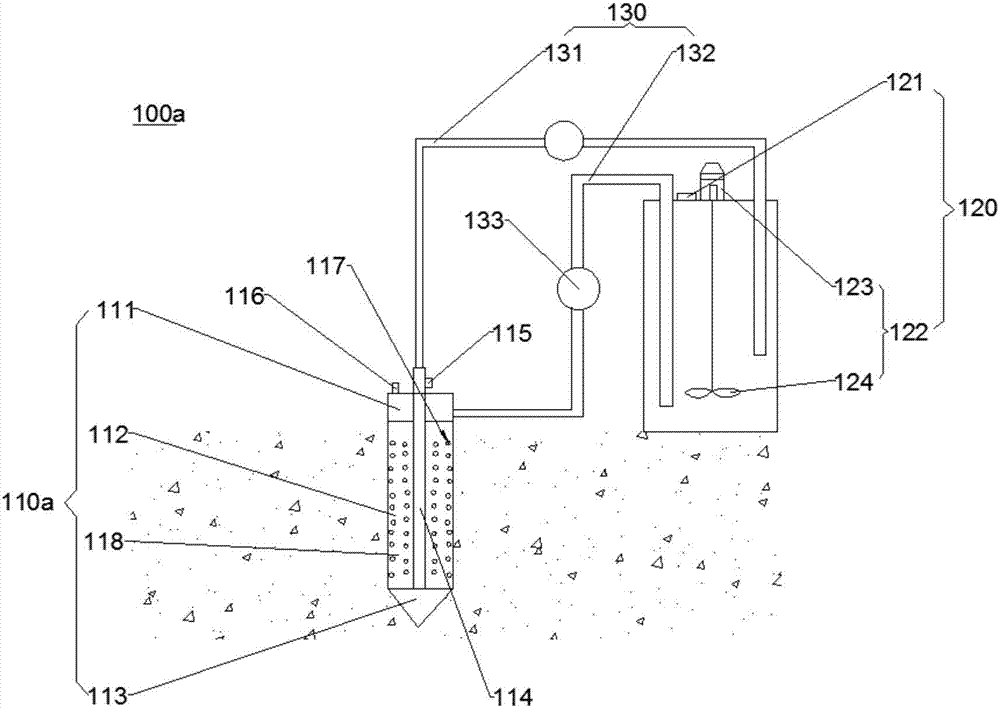

Comprehensive pipe rack shallow burying project integrated construction device

PendingCN108018882ASave time and costSave construction costArtificial islandsUnderwater structuresSupporting systemArchitectural engineering

The invention discloses a comprehensive pipe rack shallow burying project integrated construction device. The comprehensive pipe rack shallow burying project integrated construction device comprises atelescopic cutter head which is arranged on a steel plate at the upper portion of a tunneling face, is capable of moving up and down along the upper portion of the tunneling face and is used for cutting a soil body. A steel plate at the lower portion of the tunneling face is provided with a fixed cutter head for cutting the soil body. A soil cabin is arranged behind the fixed cutter head. One endof a spiral conveyor is arranged in the soil cabin, and the other end of the spiral conveyor is arranged above one end of a muck conveying belt. The other end of the muck conveying belt stretches outof a pipe rack. According to the comprehensive pipe rack shallow burying project integrated construction device, an excavation system and a support system are integrated, additional support structurebuilding time and construction cost are saved, and the construction efficiency is greatly improved.

Owner:CENT SOUTH UNIV +1

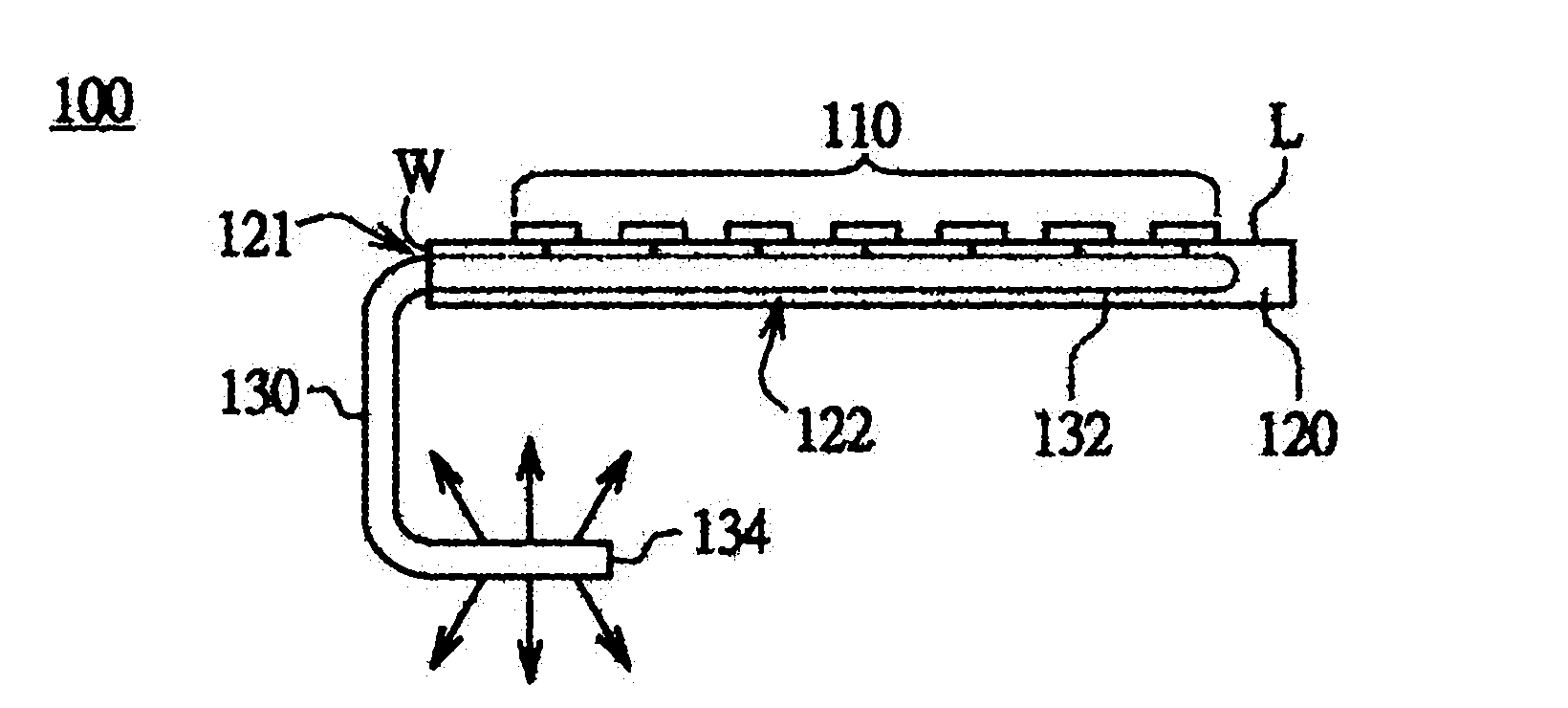

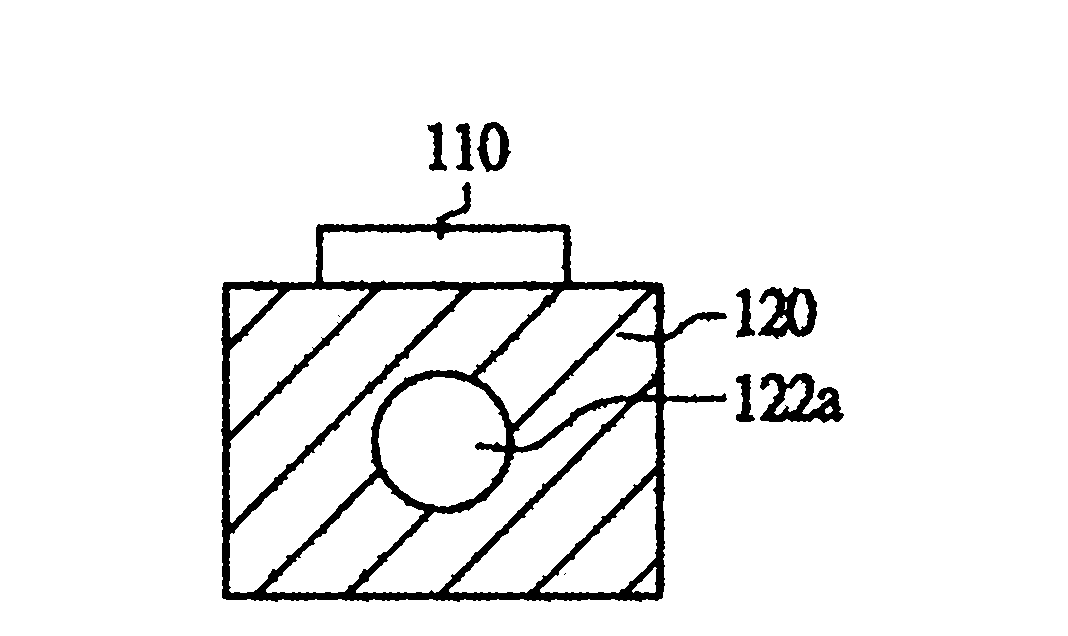

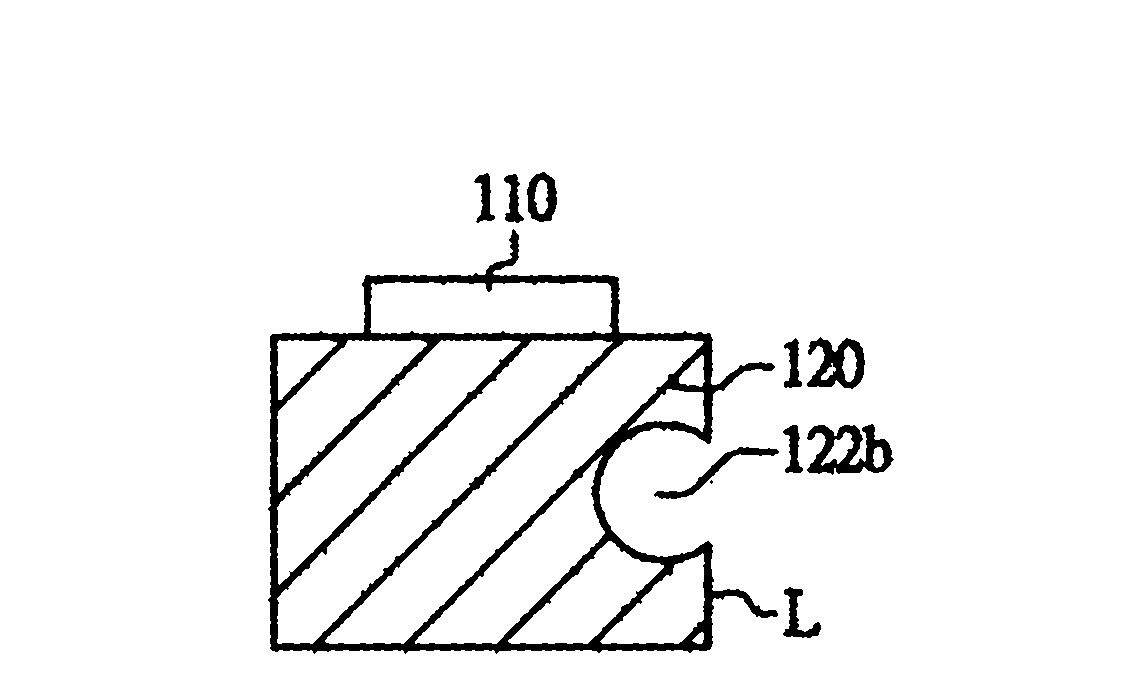

Light source module and area light source module using the same

InactiveCN102606902AIncrease removalImprove cooling effectMechanical apparatusPoint-like light sourceHeat conductingComputer module

The invention discloses a light source module and an area light source module using the same, wherein the light source module includes a light-emitting element, a heat radiating sheet and a heat conducting pipe. The heat radiating sheet is arranged at the bottom of the light-emitting element. The heat radiating sheet is provided with a groove. The heat conducting pipe is connected with one side surface of the heat radiating sheet. The heat conducting pipe is provided with a heat absorbing end and a heat releasing end. The heat absorbing end of the heat conducting pipe is inserted into the groove and the heat is conducted to the outside through the heat releasing end.

Owner:LEXTAR ELECTRONICS CORP

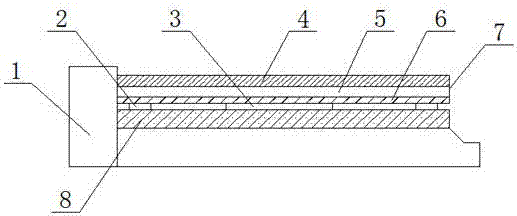

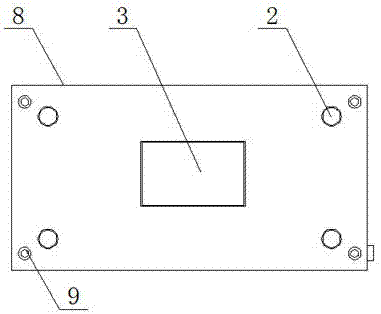

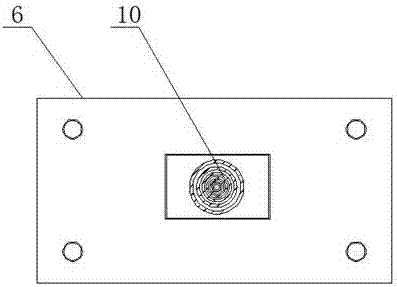

Novel heating bottom plate of 3D (three-dimensional) printing machine

InactiveCN107097425AGuaranteed continuitySolve the plugging problemManufacturing heating elementsRadio reception3d printer

The invention discloses a novel heating bottom plate of a 3D (three-dimensional) printing machine. The novel heating bottom plate comprises a base. An aluminum oxide ceramic substrate is fixedly arranged on the upper side of the base, electromagnets are arranged at four corners of the aluminum oxide ceramic substrate, a radio transmission plate is embedded and mounted in the center of the aluminum oxide ceramic substrate, a heating bottom plate is arranged above the aluminum oxide ceramic substrate and comprises a high-temperature glass layer, a ceramic heating plate and a support plate from top to bottom, and a radio receiving ring which corresponds to the radio transmission plate is arranged in the center of the support plate. The novel heating bottom plate has the advantages that the heating bottom plate can be conveniently integrally taken down to be replaced by a new heating bottom plate on the base after 3D printing forming is carried out, accordingly, the continuity of 3D printing working procedures can be kept, and the printing efficiency can be improved; the problems in the aspect of circuit plugging due to frequent disassembling can be solved by the aid of radio connection modes, a body of the heating bottom plate is made of ceramic materials, accordingly, heat can be uniformly conducted, and edge warping can be prevented.

Owner:芜湖智享三维打印服务有限公司

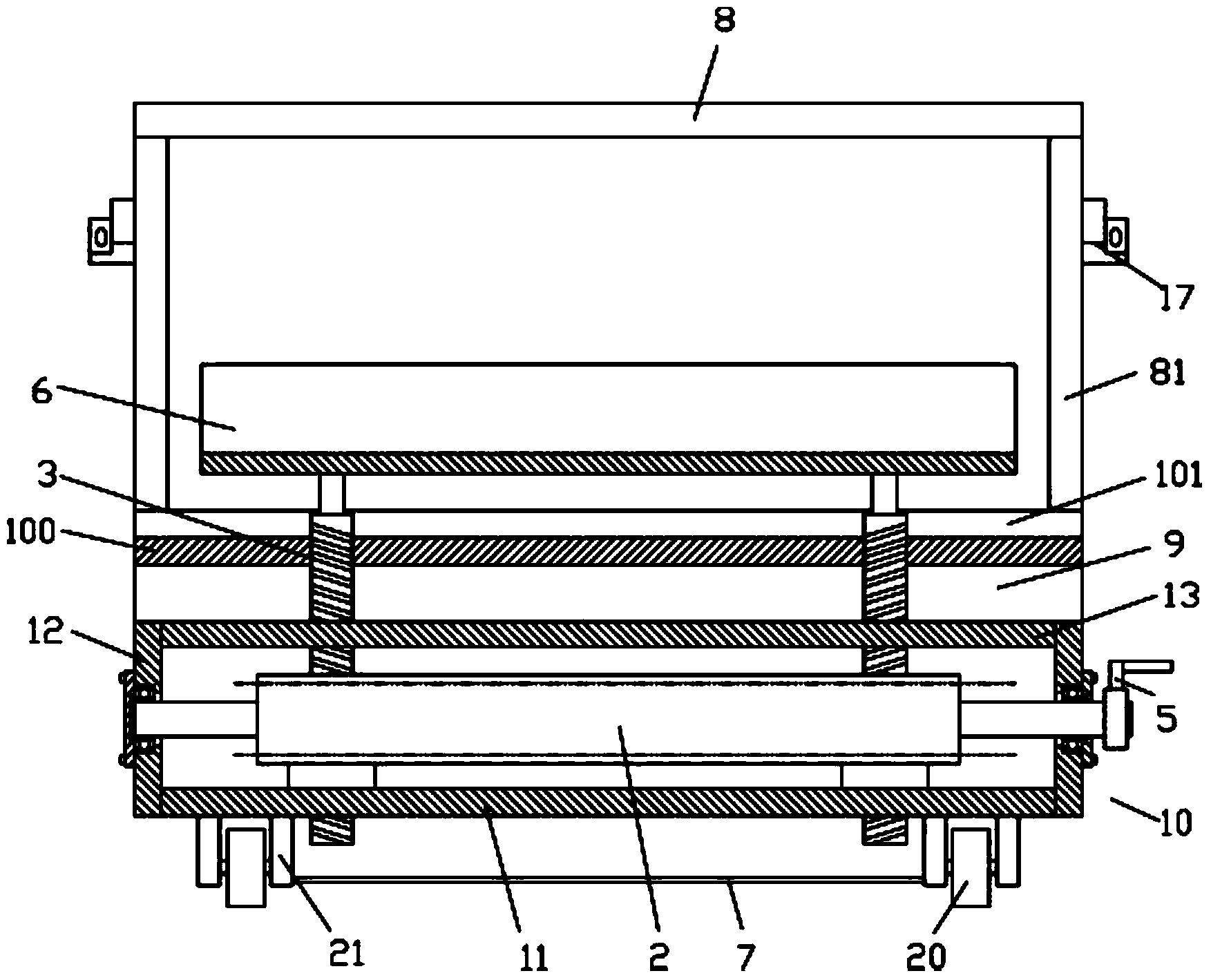

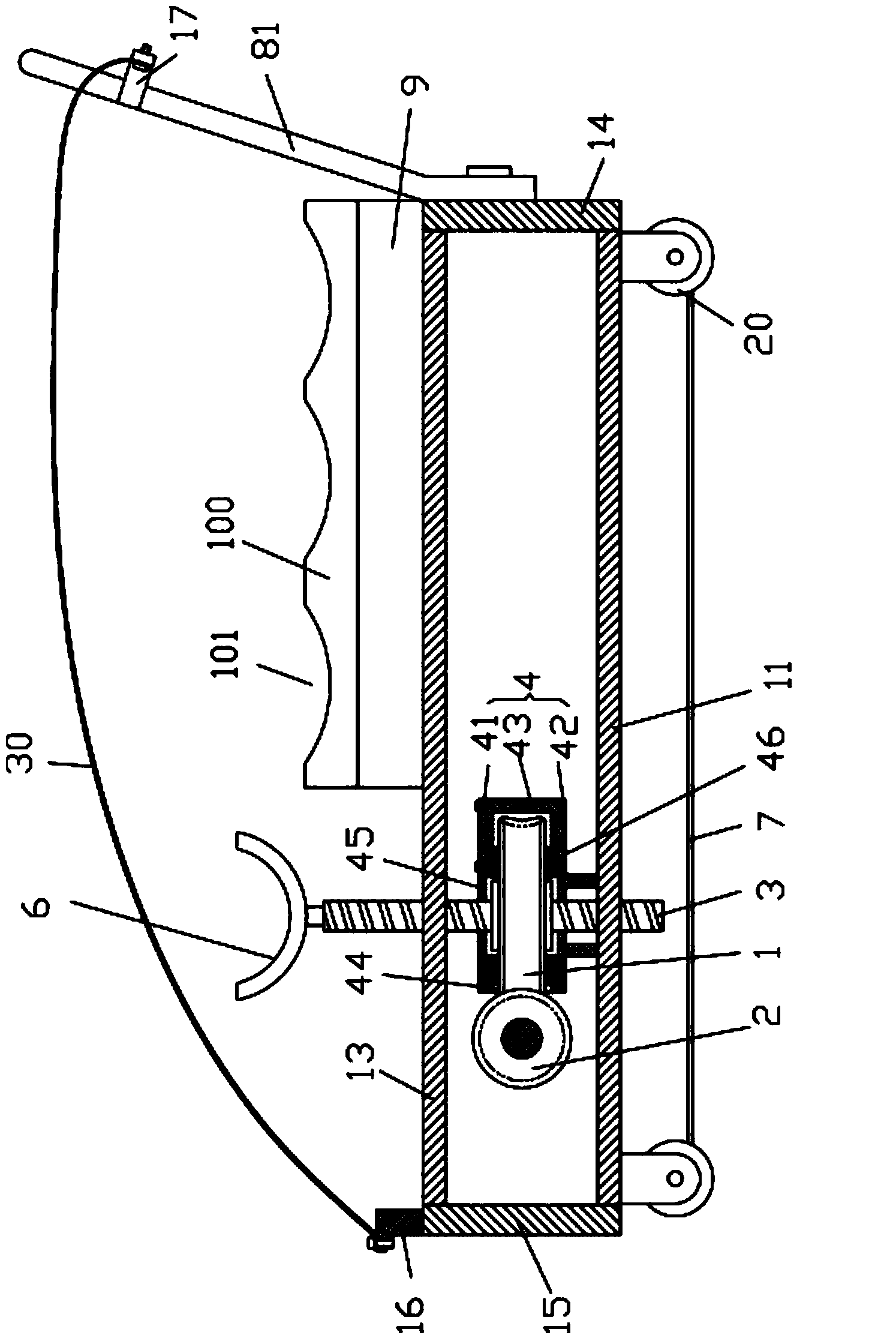

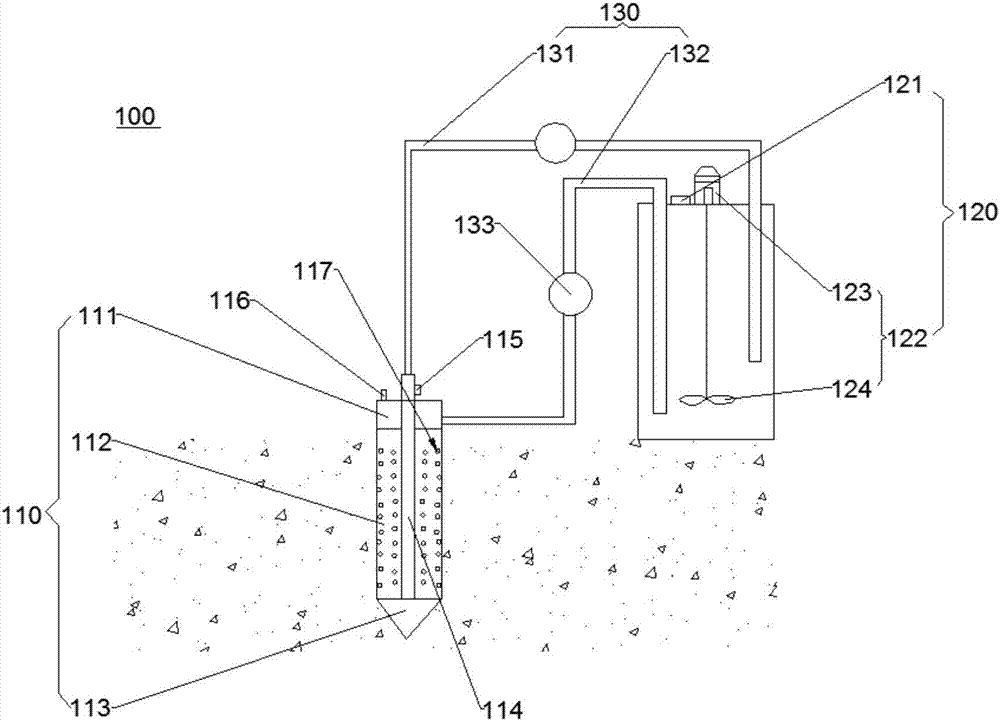

Electrolyte for soil remediation, electrolysis system for soil remediation and soil remediation method of electrolysis system for soil remediation

InactiveCN106881346APromote degradationIncrease removalContaminated soil reclamationOrganic fertilisersElectrolysisSoil science

The invention relates to the technical field of environmental protection, in particular to a technology for remedying organic polluted soil and compound polluted soil and specifically relates to an electrolyte for soil remediation, an electrolysis system for soil remediation and a soil remediation method of the electrolysis system for soil remediation. According to the soil remediation method, remediation is conducted through the electrolysis system for soil remediation. The soil remediation method specifically comprises the following steps that a remediation section of an electrode chamber is inserted into a soil area to be remedied through a fixing section, the remediation section is connected with an electrolyte storage chamber through a first pipeline and a second pipeline, electrolyte is poured into the metal electrode chamber and the electrolyte storage chamber, and the electrolyte enters the soil to be remedied under the action of electroosmosis flow and the like. By the adoption of the soil remediation method, under the combined action of the electrolysis system and the electrolyte, the risk of secondary soil pollution is lowered during soil remediation, and the soil remediation cost is reduced because of circulation of the electrolyte.

Owner:上海乾堉环境科技有限公司

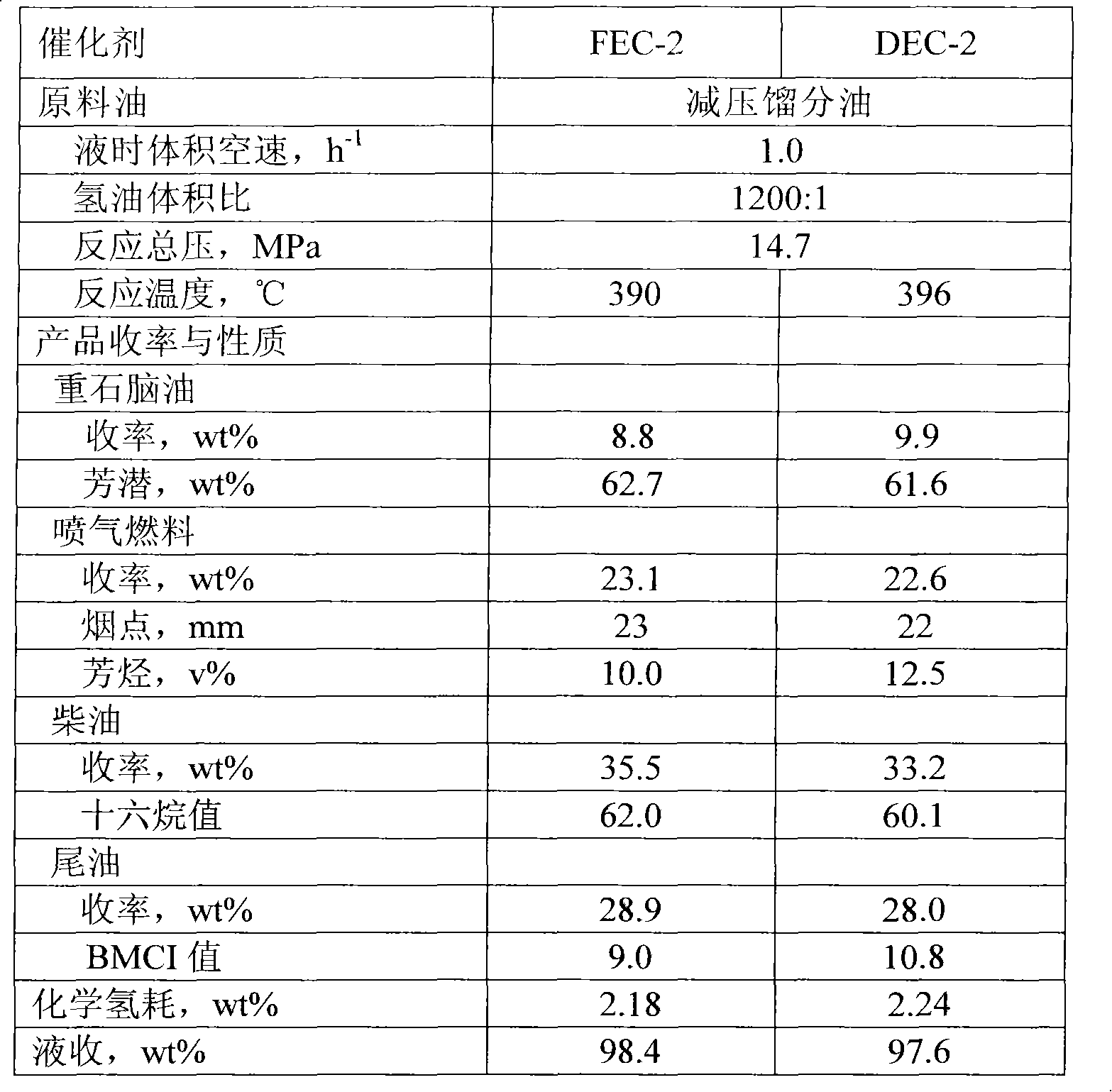

Hydrocracking catalyst and preparation method thereof

ActiveCN101380589BHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The present invention discloses a hydrocracking catalyst and a preparation method thereof. The catalyst comprises hydrogenation active metals and a carrier containing modified Y molecular sieve, alumina and amorphous aluminium silicon, wherein, the Y molecular sieve is prepared by the following method: the Y molecular sieve undergone hydro-thermal treatment by mixed water solution of aluminium salt and acid is adopted; the performance of the Y molecular sieve is as follows: specific surface is 800m<2> / g-900m<2> / g, total aperture volume is 0.40ml / g-0.50ml / g, relative crystallinity is 90%-130%, cell parameter is 2.434-2.440nm, aluminium silicon mol ratio is 20-100, infrared acid volume is 0.3-0.8mmol / g, the mol ratio of acid B and acid L is above 7.0, sodium oxide content is less than or equal to 0.05wt%. The catalyst prepared by the invention has the advantages of high catalytic activity, good target product selectivity and can produce heavy naphtha, aviation fuel and diesel fuel, and the like, with high yield and good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

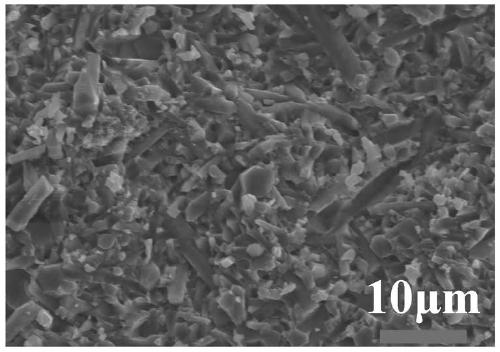

High-thermal-conductivity silicon nitride ceramic material and preparation method thereof

ActiveCN111196727APromote densificationHigh thermal conductivityMetallic hydrogenAlkaline earth oxides

The invention relates to a high-thermal-conductivity silicon nitride ceramic material and a preparation method thereof. The silicon nitride ceramic material is prepared from the following raw materials: alpha-Si3N4 and a sintering aid, wherein the sintering aid is metal hydride and alkaline earth metal oxide, and the total content of the sintering aid is 5-20wt%; the metal hydride is TiH2; and thealkaline earth metal oxide is preferably MgO.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com