Method for preparing high-thermal-conductivity silicon nitride ceramic

A technology of silicon nitride ceramics and silicides, which is applied in the field of preparation of silicon nitride ceramic materials with high thermal conductivity, and can solve the problems of difficult preparation, high cost, harmful fluoride gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing silicon nitride ceramics with high thermal conductivity. The silicon nitride ceramics with high thermal conductivity are prepared by adopting a pressure sintering method and using silicides and alkaline earth metal oxides as sintering aids. The method includes: the α-Si 3 N 4 Mix the powder and sintering aids uniformly in proportion; then press molding (for example, dry pressing molding and isostatic pressing treatment in sequence) to obtain a silicon nitride ceramic green body; finally, sinter by air pressure at 1780°C-1950°C under an inert atmosphere; Cool to room temperature after sintering, for example, cool to 1000°C-1400°C (eg 1200°C) at a cooling rate of 5-15°C / min, and then cool to room temperature with the furnace. Using silicide as a sintering aid makes less oxygen introduced through the aid and adjusts the liquid phase composition, thereby reducing the lattice oxygen content and avoiding phonon scattering; and us...

Embodiment 1

[0049] With 5mol% TiSi 2 and 5mol% MgO as a sintering aid, and 90mol% α-Si 3 N 4 The powder is mixed by ball milling, dried and sieved to obtain a uniformly mixed powder of 50g; then it is dry-pressed under 20MPa pressure, and then cold isostatic pressed under 250MPa pressure; the green body obtained is put into BN Crucible, and then into the graphite crucible, at 3MPaN 2 Under the atmosphere, the temperature was raised to 1900°C at a rate of 3°C / min for 4 hours under pressure sintering; after the sintering was completed, it was cooled to 1200°C at a rate of 10°C / min, and then cooled to room temperature with the furnace.

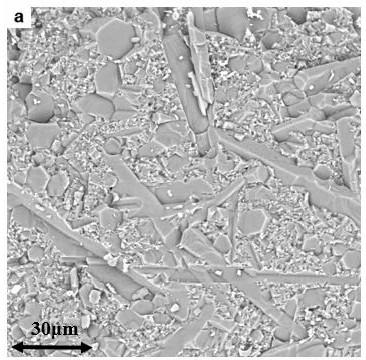

[0050] The thermal conductivity of the silicon nitride ceramics prepared in this example is 98.6W / (m·K), the three-point bending strength is 860MPa, and the fracture toughness is 6.29MPa·m 1 / 2 . The XRD pattern of the ceramic material is shown in figure 1 shown. Depend on figure 1 It can be seen that the sintered sample β-Si 3 N 4 It is the main p...

Embodiment 2

[0052] With 5mol% MoSi 2 and 5mol% MgO as a sintering aid, and 90mol% α-Si 3 N 4 The powder is mixed by ball milling, dried and sieved to obtain a uniformly mixed powder of 50g; then it is dry-pressed under 20MPa pressure, and then cold isostatic pressed under 250MPa pressure; the green body obtained is put into BN Crucible, and then into the graphite crucible, at 5MPa N 2 Under the atmosphere, sinter under pressure at 1900°C (heating rate 5°C / min) for 6 hours; after sintering, cool to 1200°C at a cooling rate of 10°C / min, and then cool to room temperature with the furnace.

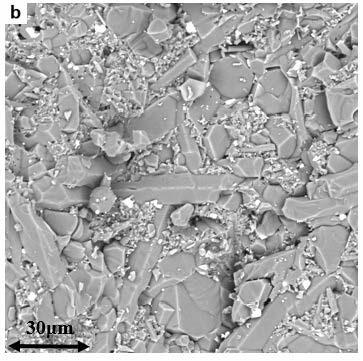

[0053] The thermal conductivity of the silicon nitride ceramics prepared in this example is 108.2W / (m·K), the three-point bending strength is 875MPa, and the fracture toughness is 6.53MPa·m 1 / 2 . The XRD pattern of the ceramic material is shown in figure 2 shown. Depend on figure 2 It can be seen that the sintered sample β-Si 3 N 4 It is the main phase, indicating that the phase transformation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com