Comprehensive pipe rack shallow burying project integrated construction device

A technology of comprehensive pipe gallery and construction device, which is applied in water conservancy projects, infrastructure engineering, artificial islands, etc., can solve the problems of not being able to use it in a timely and reasonable manner, restrict the speed of comprehensive pipe gallery, increase construction costs, etc., and avoid the demolition process , flexible support methods, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

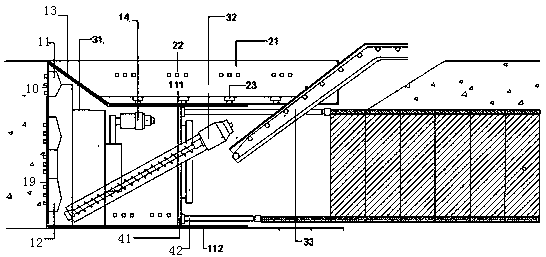

[0021] like figure 1 , figure 2 As shown, an embodiment of the present invention includes an excavation system 1 for rapid excavation and timely removal of muck to form a working space for constructing a pipe gallery; a support system 2 for providing temporary support, which is the main structure of the pipe gallery The construction provides a safe working environment; the backfill system 3 realizes the on-site utilization of muck and backfills the main structure of the completed pipe gallery to quickly restore road traffic or the surface; the jacking system 4 provides power for the advancement of the excavation system .

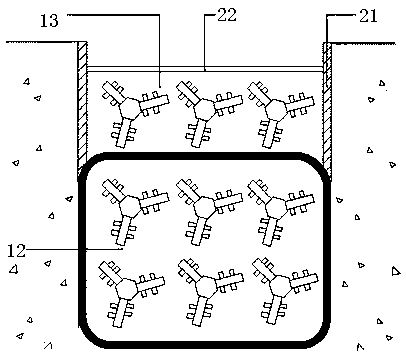

[0022] like figure 2 , image 3 , Figure 4 As shown, the excavation system is composed of a telescopic cutterhead 11, a fixed cutterhead 12, a telescopic brace 13, a cutter engine 14, a cutterhead jack 15, and the like. The telescopic cutter head 11 is hinged with the telescopic support plate 13, and the cutter head is lifted and lowered by the cutte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com