High-strength, high-toughness and high-thermal-conductivity silicon nitride ceramic material and preparation method thereof

A technology for silicon nitride ceramics and raw materials, which is applied in the fields of high thermal conductivity silicon nitride ceramic materials and their preparation, high strength and high toughness, and can solve the problems of limited large-scale application, low thermal conductivity of ceramics, poor mechanical properties, etc. , to achieve the effect of reducing the volume fraction of glass phase, high thermal conductivity, and reducing glass phase content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

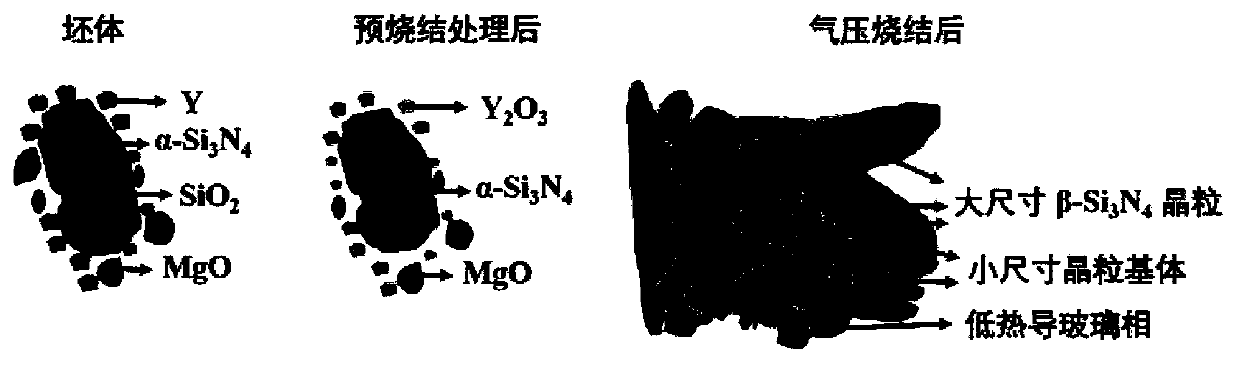

Method used

Image

Examples

preparation example Construction

[0034] As an example of the preparation of a mixed powder, including: α-Si 3 N 4 The powder is mixed with the sintering aid, and the uniformly mixed powder is obtained through the processes of ball milling, drying and sieving. The ball milling can adopt vacuum ball milling tank wet ball milling, and the atmosphere in the ball milling tank can be vacuum or filled with Ar and N 2 , wet ball milling uses alcohol as a solvent, the ratio of material: solvent can be (1:1) ~ (3:1), the ratio of material: ball can be (1:1) ~ (5:1), and the number of rotations of the ball mill is 200 ~500rpm, ball milling time is 4~20h. Drying can be carried out by rotary evaporation drying or vacuum drying, and the whole drying process can be carried out under vacuum, Ar, N 2 etc. in a protective atmosphere. Wherein, the drying temperature may be 50°C-100°C, and the drying time may be 8-24 hours. The mesh number of the sieve can be 60-300 mesh.

[0035] The mixed powder is pressed into shape to ...

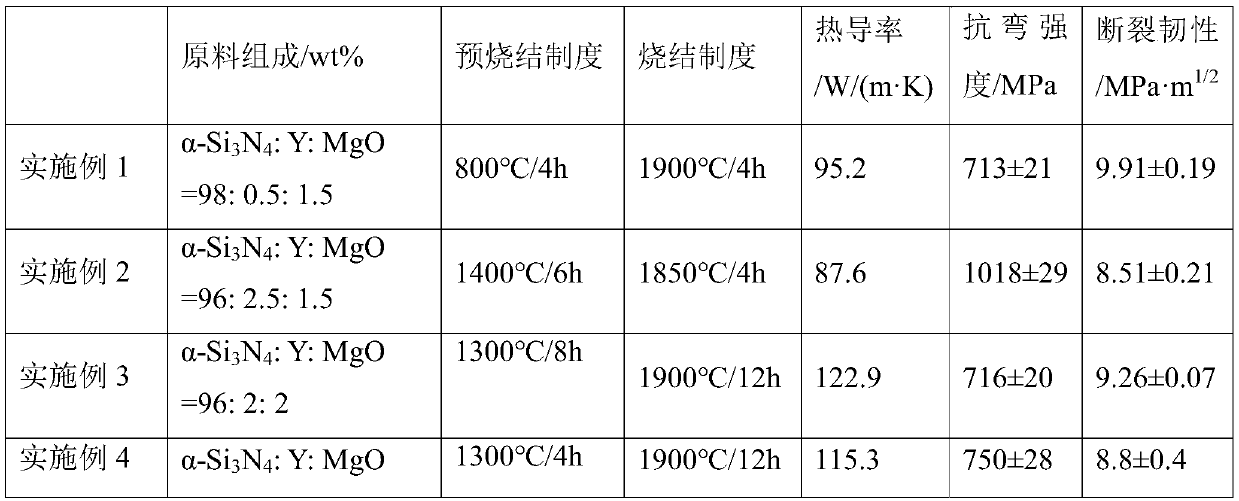

Embodiment 1

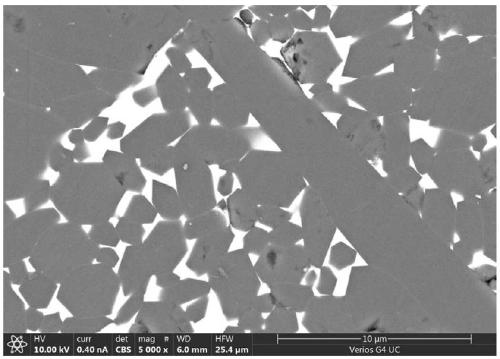

[0046] With 0.5wt% Y and 1.5wt% MgO as sintering aids, and 98wt% α-Si 3 N 4 The powder is mixed by ball milling, dried and sieved to obtain a uniformly mixed powder; then it is dry-pressed under a pressure of 20MPa, and then subjected to cold isostatic pressing under a pressure of 250MPa; the green body obtained is put into a BN crucible , pre-sintered at 800°C for 4h in an Ar atmosphere; then the pre-sintered green body was sintered at 1900°C under pressure, with a heating rate of 10°C / min, N 2 The pressure is 1MPa, and the holding time is 4h; after sintering, cool to 1200°C at a cooling rate of 10°C / min, and then cool to room temperature with the furnace.

[0047] The thermal conductivity of the silicon nitride ceramic material prepared in Example 1 is 95.2W / (m·K), the three-point bending strength is 713±21MPa, and the fracture toughness is 9.91±0.19MPa·m 1 / 2 .

Embodiment 2

[0049] With 2.5wt% Y and 1.5wt% MgO as sintering aids, and 96wt% α-Si 3 N 4 The powder is mixed by ball milling, dried and sieved to obtain a uniformly mixed powder; then it is dry-pressed under a pressure of 30MPa, and then subjected to cold isostatic pressing under a pressure of 300MPa; the green body obtained is put into a BN crucible , pre-sintered at 1400°C for 6h in an Ar atmosphere; then the pre-sintered green body was sintered at 1850°C under pressure, with a heating rate of 5°C / min, N 2 The pressure is 1MPa, and the holding time is 4h; after sintering, cool to 1000°C at a cooling rate of 10°C / min, and then cool to room temperature with the furnace.

[0050] The thermal conductivity of the silicon nitride ceramic material prepared in Example 2 is 87.6W / (m K), the three-point bending strength is 1018±29MPa, and the fracture toughness is 8.51±0.21MPa·m 1 / 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com