Quick-changing type spraying package

A quick-change, cladding technology, used in casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of non-reusable generation of spray cups, low generation efficiency, interruptions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

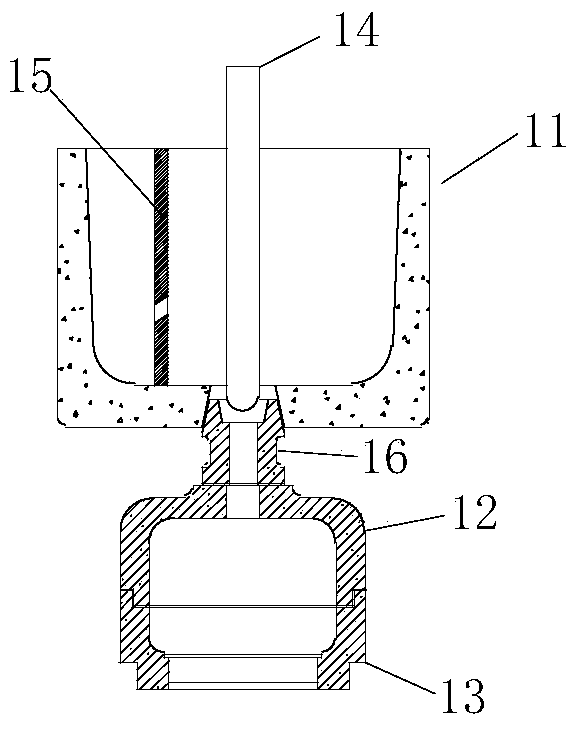

[0017] Because the crucible and the spray cup in the existing spray package are bonded with glue, which is an integral spray package, the spray cup is difficult to replace. Therefore, the present invention connects the crucible and the spray cup with screws, so that the spray cup can be replaced in time.

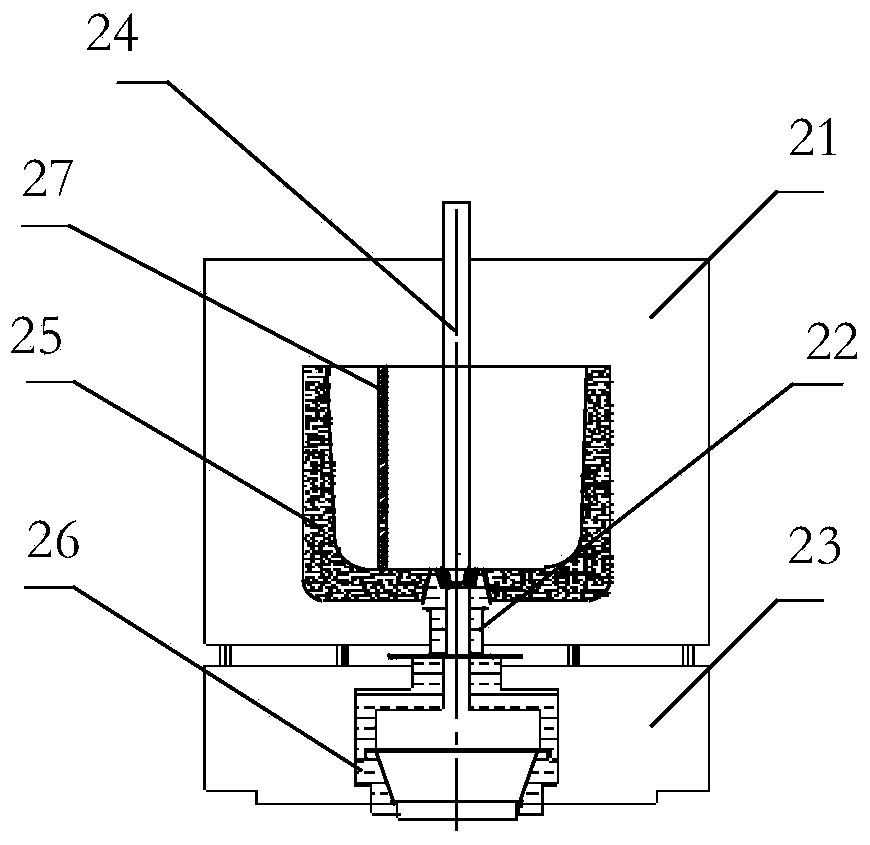

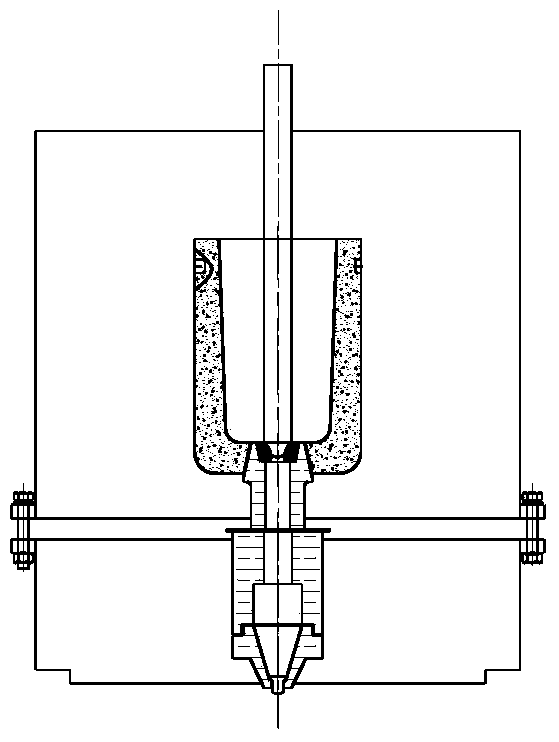

[0018] Figure 2A -B is a front sectional view and a side sectional view of the quick-change spray bag for amorphous broadband tape manufacturing equipment in the embodiment of the present invention. As shown in the figure, the quick-change spray package includes an upper cladding 21 , a nozzle 22 , a lower cladding 23 , a stopper 24 , a crucible 25 , a spray cup 26 , and a slag retaining plate 27 .

[0019] The crucible in the present invention is accommodated in the upper cladding 21, with a nozzle 22 at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com